schmersal SLG 425I Series,SLG425I-ER-0500-02-RF,SLG425I-ER-0900-04-RF,SLG425I-ER-0800-03-RF Operating Instructions Manual

Operating instructions

Safety light grid

Operating instructions. . . . . . . . . . . .pages 1 to 18

EN

Translation of the original operating instructions

Vous trouverez la version

FR

actuelle du mode d’emploi dans

votre langue nationale officielle

sur l’Internet,

www.schmersal.net.

U vindt de huidige versie van de

NL

gebruikshandleiding in uw

officiële landstaal op het Internet, www.schmersal.net.

EU公用語で書かれた最新の取扱

JP

説明書は,インターネッ

(www.schmersal.net) からダウ

ンロードできます。

Encontrará el manual de

ES

instrucciones actual en su

idioma oficial de la UE en

nuestra página de Internet

www.schmersal.net.

Il manuale d‘istruzioni aggior-

IT

nato nella vostra lingua (lingua

ufficiale UE) è scaricabile in

Internet all‘indirizzo

www.schmersal.net.

SLG 425I

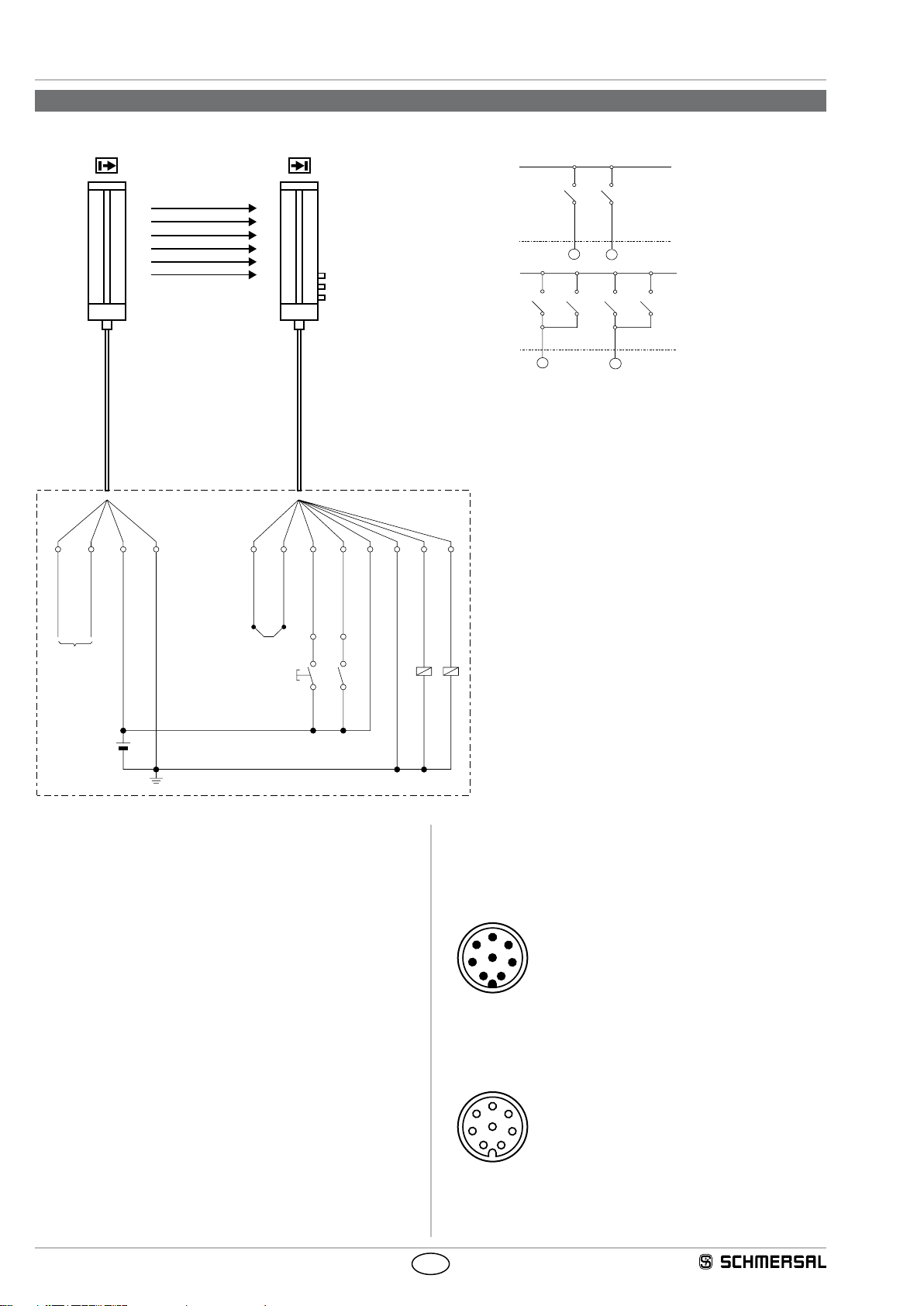

4 Electrical connection

4.1 Wiring example Muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Connector conguration Receiver, Emitter & Cable. . . . . . . . . .14

5 Set-up and maintenance

5.1 Check before start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.3 Regular check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Half-yearly inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.5 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Diagnostic

6.1 LED status information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.2 Fault diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Extended diagnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7 Disassembly and disposal

7.1 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8 Appendix

8.1 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.2 EC Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Content

1 About this document

1.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Target group: authorised qualied personnel. . . . . . . . . . . . . . . . 1

1.3 Explanation of the symbols used . . . . . . . . . . . . . . . . . . . . . . . . .1

1.4 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.5 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1. About this document

1.1 Function

This operating instructions manual provides all the information you

need for the mounting, set-up and commissioning to ensure the safe

operation and disassembly of the safety switchgear. The operating

instructions must be available in a legible condition and a complete version in the vicinity of the device.

1.6 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.7 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Target group: authorised qualified personnel

All operations described in this operating instructions manual must

2 Product description

2.1 Destination and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

be carried out by trained specialist personnel, authorised by the plant

operator only.

2.2 Ordering code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.3 Special versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Scope of delivery and accessories . . . . . . . . . . . . . . . . . . . . . . .2

2.4.1 Accessories included in delivery . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4.2 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Please make sure that you have read and understood these operating instructions and that you know all applicable legislations regarding

occupational safety and accident prevention prior to installation and

putting the component into operation.

2.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.6 Response time (reaction time). . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.7 Safety classication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.8 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

The machine builder must carefully select the harmonised standards to

be complied with as well as other technical specifications for the selection, mounting and integration of the components.

2.8.1 Factory setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.8.2 Restart interlock (manual reset). . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Explanation of the symbols used

2.8.3 Start interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.8.4 Beam coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.8.5 Fixed blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.8.6 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Information, hint, note:

This symbol is used for identifying useful additional information.

2.9 Operating mode muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.9.1 Adequate and appropriate application . . . . . . . . . . . . . . . . . . . . .4

2.9.2 Muting sensors MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.9.3 Muting lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.9.4 Signal sequence muting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.9.5 Conguration of the muting function . . . . . . . . . . . . . . . . . . . . . .6

Caution: Failure to comply with this warning notice could

lead to failures or malfunctions.

Warning: Failure to comply with this warning notice could

lead to physical injury and/or damage to the machine.

2.9.6 Saving the data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9.7 Muting applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4 Appropriate use

The products described in these operating instructions are developed to

3 Mounting

3.1 General conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Protection eld and approach . . . . . . . . . . . . . . . . . . . . . . . . . .10

execute safety-related functions as part of an entire plant or machine. It

is the responsibility of the manufacturer of a machine or plant to ensure

the correct functionality of the entire machinery or plant.

3.3 Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Safety distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.4.1 Minimum distance to reecting surfaces . . . . . . . . . . . . . . . . . . 11

3.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

x.000 / Juli 2012 / v.A. - 1012 14175-EN / C / 20 12-07-06 / AE -Nr. 164 8

EN

1

Operating instructions

Safety light grid

SLG 425I

The safety switchgear must be exclusively used in accordance with the

versions listed below or for the applications authorised by the manufacturer. Detailed information regarding the range of applications can be

found in the chapter "Product description".

1.5 General safety instructions

The user must observe the safety instructions in this operating instructions manual, the country-specific installation standards as well as all

prevailing safety regulations and accident prevention rules.

Further technical information can be found in the Schmersal

catalogues or in the online catalogue on the Internet: www.

schmersal.net.

The information contained in this operating instructions manual is provided without liability and is subject to technical modifications

The entire concept of the control system, in which the safety

component is integrated, must be validated to EN ISO 13849-2.

There are no residual risks, provided that the safety instructions as well

as the instructions regarding mounting, commissioning, operation and

maintenance are observed.

Additional measures could be required to ensure that the electro-sensitive device does not present a dangerous breakdown, when other forms

of light beams are available in a special application (e.g. use of wireless

control devices on cranes, radiation of welding sparks or effects of

stroboscopic lights).

1.6 Warning about misuse

In case of inadequate or improper use or manipulations of the

safety switchgear, personal hazards or damage to machinery or plant components cannot be excluded. The relevant

requirements of the standards EN ISO 13855 (successor of

EN 999) and EN ISO 13857 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary repairs, conversions and modifications to the device are strictly forbidden;

the manufacturer shall accept no liability for damages resulting from

such invasive work, arbitrary repairs, conversions and/or modifications

to the device.

2. Product description

2.1 Destination and use

The SLC 425I is a non-contact, self-testing safety guard, which is used

for the protection of hazardous points, hazardous areas and machine

accesses. If one or more light beams are interrupted, the hazardous

movement must be stopped.

The user must evaluate and design the safety chain in accordance with the relevant standards and the required safety

level.

2.2 Ordering code

This operating instructions manual applies to the following types:

SLG425I-ER-➀-RF

No. Option Description

➀

0500-02 500 mm, 2-beam

0800-03 800 mm, 3-beam

0900-04 900 mm, 4-beam

Only if the information described in this operating instructions manual are realised correctly, the safety function and

therefore the compliance with the Machinery Directive is

maintained.

2.3 Special versions

For special versions, which are not listed in the order code, these

specifications apply accordingly, provided that they correspond to the

standard version.

2.4 Scope of delivery and accessories

2.4.1 Accessories included in delivery

Mounting kit MS-1030

The kit comprises 4 rotating mounting angles and 16 mounting screws

for fixing to the end caps.

2.4.2 Optional accessories

Centre fixing MS-1051

Consisting of 2 steel angles, 4 fixing screws and 4 T-slot nuts

Connecting cable for transmitter

Item number Designation Description Length

101207741 KA-0804 Female connector M12, 4-pole 5 m

101207742 KA-0805 Female connector M12, 4-pole 10 m

101207743 KA-0808 Female connector M12, 4-pole 20 m

Connecting cable for receiver

Item number Designation Description Length

101207728 KA-0904 Female connector M12, 8-pole 5 m

101207729 KA-0905 Female connector M12, 8-pole 10 m

101207730 KA-0908 Female connector M12, 8-pole 20 m

BUS converter NSR-0801

Converter for parametrization and diagnostics. Detailled information can

be found in the operating instructions manual of the NSR-0801.

Included in delivery: integrated connecting cable, PC-software USB

2.0 connection (L x W x H, 122 x 60 x 35 mm), indications of measurements without cable

MSD4 Vibration damper

Kit consisting of: 8 vibration dampers 15 x 20 mm, 8 M5 cylinder head

screws with hexagon socket, 8 spring washers

The MSD4 vibration damper kit must be used for damping vibrations

and oscillations on the SLG 425I. For applications with higher mechanical stresses, e.g. presses, punching machines, we recommend the

MSD4 kit. In this way, the availability of the SLG 425I is increased.

2.5 Technical data

Standards: EN 61496-1; CLC/TS 61496-2;

Material of the enclosure: Aluminium

Number of beams: 2, 3, 4 beams

Protection field heights: 500 mm, 800 mm, 900 mm

Detection ability for test bodies:

Distance between outermost beams:

EN ISO 13849; EN 62061

2 beams with resolution 500 mm *3

3 beams with resolution 400 mm *3

4 beams with resolution 300 mm *3

2

EN

Operating instructions

Safety light grid

SLG 425I

Response time: 2 - 4 beams:

15 ms (Standard)

2 - 4 beams: 20 ms

(beam coding A)

Range of the protection field: 0,3 m - 18 m

Rated operating voltage:24 VDC ±10% (PELV) supply unit to EN 60204

(power drop > 20 ms)

Operating current: 400 mA max. + 0.5 A

(OSSD load + output signal quality load)

Wave length of the sensor: 860 nm

Safety outputs (OSSD1, OSSD2): 2 x PNP-type semi-conductor,

short-circuit proof

Switching voltage HIGH¹: 15 … 28,8 V

Switching voltage LOW¹: 0 … 2 V

Switching current: 0 … 500 mA

Leakage current²: 1 mA

Load capacity: 2 µF

Load inductance: 2 H

Admissible conduction resistance between OSSD and load: 2.5 Ω

Supply cable: 1 Ω

Input restart interlock (manual reset)

Input voltage HIGH (active): 17 … 29 V

Input voltage LOW (inactive): 0 … 2.5 V

Input current HIGH: 3 … 10 mA

Input current LOW: 0 … 3 mA

Function: Start and restart interlock (manual reset),

fixed beam blanking and muting

Voltage: 24 VDC

Current: 500 mA

Signal times

Restart interlock (manual reset): 50 ms … 1.0 s signal transmission in

case of trailing edge

Start interlock: 250 … 1500 ms, adjustable

LED indications transmitter: Transmitting, status

LED indications receiver: OSSD ON, OSSD OFF, restart, signal

reception, blanking, multifunction

Connection: M12 Connector plug with metal thread,

receiver 8-pole, transmitter, 4-pole (male),

Muting sensors 2 pc. M8 3-pole,

Muting lamp M8 3 pole

Ambient temperature: −10° C … +50° C

Storage temperature: −25° C … +70° C

Interface: Diagnostics and function setting

Protection class: IP67 (IEC 60529)

Resistance to vibrations: 10 - 55 Hz to IEC 60068-2-6

Resistance to shock: 10 g; 16 ms; to IEC 60068-2-29

Year of construction: as of 2010 version 1.0

¹) To IEC 61131-2

²) In case of failure, the leakage current at the most flows to the OSSD

cable. The downstream control element must recognise this state as

LOW. A safety PLC must detect this state.

3

) resolution = beam distance + beam diameter 10 mm

2.8 Functions

The system consists of a receiver and a transmitter. For the described

functions, no further switching elements are required. For the diagnostics and function selection, a user-friendly PC-software is offered as

accessory. For the connection to a PC, the NSR-0801 BUS converter is

required (not included in delivery).

The system has the following features:

• Start interlock

• Restart interlock (manual reset)

• Beam coding

• Blanking of fixed protection field areas

• Muting

2.8.1 Factory setting

The system features many functions without needing any additional

devices. The following table gives an overview of the possible functions

and the factory settings configuration.

Function Factory setting Configuration

Restart interlock

(manual reset)

Fixed blanking not active With BUS converter NSR-0801

Muting active With BUS converter NSR-0801

Start interlock not active With BUS converter NSR-0801

Beam coding not active With BUS converter NSR-0801

2.8.2 Restart interlock (manual reset)

The restart interlock (manual reset) prevents an automatic enabling of

the outputs (OSSD's ON state) after switch-on of the operating voltage

or an interruption of the protection field.

The system switches the outputs only to ON state, when an external

command device (restart button) generates an enabling signal at the

restart input (receiver).

The command devices (enabling button) must be installed

outside of the hazardous area. The operator must have a

clear view on the hazardous area when actuating the enabling button.

In supply condition, the restart interlock (manual reset) is

not active. You must select an operating mode in order for

the outputs OSSD's to be enabled. If no type of protection is

selected, you will obtain the following signalisation through

the LED status indication in the receiver:

LED OSSD OFF (red) + LED restart (yellow) flashing

not active External wiring

and PC-software

and PC-software

and PC-software

and PC-software

2.6 Response time (reaction time)

The response time depends on the hight of the protected field, the

resolution, the number of light beams and the beam coding.

Beam

distance

[mm]

500 2 15 20 2.6

400 3 15 20 3.6

300 4 15 20 3.7

2.7 Safety classification

Standards: EN ISO 13849-1, EN 62061

PL: up to e

Control category: up to 4

PFH value: 7.42 x 10-9 / h

SIL: up to 3

Service life: 20 years

Beams

[Number]

Response

time

[ms]

Response time with

beam coding A

[ms]

Weight

[kg]

2.8.3 Start interlock

The start interlock prevents an automatic start of the machine when the

supply voltage is switched on. After enabling of the start interlock - by

the one-time interruption of the protection field -, this protective function

is deactivated until the next power reset.

The start interlock is not activated upon delivery. This function

is activated by means of the NSR-0801 BUS converter and a

PC or laptop.

EN

3

Operating instructions

E ER R

E RR E

Safety light grid

SLG 425I

2.8.4 Beam coding

The beam coding of the safety light grid must be adjusted, when

systems operating in each other's vicinity and a set-up as shown in the

image below (no interference) is impossible. When supplied, the beam

coding is not active. With beam coding A, a receiver can distinguish the

beams of the transmitter with the same beam coding A, which are destined to this particular receiver, from foreign beams. The beam coding A

must be set for each sensor (receiver and transmitter) individually. The

function is activated by means of the NSR-0801 BUS converter and a

PC or laptop.

If adjacent systems are operated without beam coding, the user is at risk.

no interference

Interference: beam coding required!

• The beam coding increases the safety and avoids mutual interference

of adjacent systems.

• The beam coding increases the immunity against optical interference

(e.g. sun light, welding sparks).

• The beam coding A is permanently shown by the transmitter and the

receiver by means of flashing LED's (refer to LED status information).

On adjacent systems, the beam coding A must be used.

The response time of the system is increased when beam

coding A is used. To this end, the safety distance must be

adjusted to the hazardous movement. Refer to chapter

Response time.

• The blanking of beams is not authorised for an SLG 425I

with 2 beams!

• The blanking of one beam at the most in the SLG 425I

3-beam version or the SLG 425I 4-beam version is authorised, provided that the protective function is taken into

account.

• The blanking of multiple beams is not authorised.

• The remaining lateral areas must be protected against intrusion by means of mechanical covers.

• The lateral covers must be fixed with the object. Partial covers are not authorised.

• The restart interlock (manual reset) function of the safety

light grid or the machine must be activated.

The function is activated by means of the NSR-0801 BUS

converter and a PC or laptop. The activation of the function

is signaled by the blanking LED ashing in the diagnostic

window of the receiver.

2.8.6 Testing

The system performs a complete self-test and safety test within 2 seconds after the operating voltage has been switched on. If the protection

field is not interrupted, the system switches to the ON condition.

In case of an error, the outputs at the receiver do not switch to the ON

state. The LED OSSD OFF starts flashing, thus emitting an error message. Further indications can be found in the chapter Fault diagnostic.

During operation, the system continuously executes a self-test. Safetyrelevant faults are detected within the cycle time and cause the outputs

to be switched off.

2.9 Operating mode muting

2.9.1 Adequate and appropriate application

The objective of the by-pass function is the safe distinction between

material and the presence of a person in front of the hazardous area. To

this effect, (2 or 4) additional sensors must be connected to provide for

a safe distinction between persons and the material to be transported.

To activate and parameterise the muting function, the

NSR-0801 BUS converter and the SLC4 PC software is

required.

2.8.5 Fixed blanking

The SLC 425I can blank stationary parts in the protection field.

The fixed blanking range is authorised for individual beams in case of

obstacles, taking the protective function into account.

4

Fixed blanking area

3

2

1

R1E1

Access to lateral areas must be prevented by means of

mechanical covers!

The first beam line, which realises the optical synchronisation and is

located immediately behind the diagnostic window, cannot be blanked.

The area of the fixed blanking must not be modified after the teach-in

process. Any change of the area or removal of the part from the protection field will be detected by the system. As a result, the outputs are

disabled (locked). This locking can be neutralised by executing a new

teach-in process in accordance with the actual beam interruptions.

Special mounting instructions for muting

All components must only be connected, wired and fitted by a specialist, who has sufficient electrical professional training and knowledge of

the harmonised safety regulations.

Testing and start-up by a qualified person, who has professional knowledge as well as in particular knowledge of the harmonised legal and

governmental regulations.

Instruction and training of the operators by an expert on the application.

4

EN

Operating instructions

+ 24VDC

MS 1

MS 2

MS 1

MS 2

+ 24VDC

Safety light grid

SLG 425I

After connection and fitting by an expert, the following instructions must

be respected and observed:

• Set-up of the sensors to the operating instructions SLG 425I. The muting function must not be started by a person unintentionally accessing

the hazardous area. The sensors must be set up so that a normal

approach by a body part, e.g. foot, leg, hand, arm movement does not

activate the muting mode.

• The selection of the operating parameters, e.g. simultaneity, muting

time, operating mode, special functions, etc. must be adjusted to the

application, e.g. termination of the muting cycle after passing through

the protection field.

• The muting cycle must be started automatically after the command device is enabled and be controlled by at least two independent signals

(sensors).

• The command device for the enabling and override function must be

set up so that the operator has a clear view on the entire hazardous

area. The mounting position must be selected so that the device cannot be actuated at the hazardous point.

• The muting state can be signalled through a muting lamp.

The muting function must only be used for automatic material

transport to protect the accesses to the hazardous area. In

this way, the material passes through the accesses and the

protection field of the SLG 425I without disabling the outputs.

This function is only authorised for the above-described application. For other applications, no warranty claims shall be

accepted.

This document includes information for the adequate and

proper by-passing of the protection field of an ESD and is

reserved to persons, who have the necessary expertise and

technical know-how. The users of this document must be able

to adequately and correctly evaluate the risks involved in this

operating mode.

A new muting process can only be started when the previous is terminated (all sensors not actuated). A safety distance of at least 50 mm

(belt speed V < 2.0 m/s) must be observed with regard to the protection

field, in order to ensure a safe signal evaluation by the control system.

Installation of the muting sensors

If 4 muting sensors are used, the switching outputs of the muting

sensors MS 1 and MS 3 as well as MS 2 and MS 4 must be wired in

parallel. MS 1 and MS 3 are connected to the MS1/MC female connector on the sensor connection plate. MS 2 and MS 4 to the MS 2 female

connector.

Sensor connection:

with 2

muting sensors

with 4

muting sensors

MS 1

SLG 425I sensor connection

MS 1

MS 3 MS 2

MS 2

MS 4

This document does not provide all technical know-how,

which is required in conjunction with this operating mode.

To this effect, the harmonised governmental and legal provisions regarding the technical know-how must be obeserved.

Definitions:

Muting: specific intended brief by-passing of the outputs of an

ESD in case of automatic material transport

Muting sensor:

Muting lamp: the muting lamp signals the muting state

Override: the function enables the material transport after an

Belt speed: the muting running time is stopped as long as the

2.9.2 Muting sensors MS

The MS muting sensor can be a mechanical, capacitive, inductive or

optoelectronic sensor. They have no particular requirements as failsafety is regarded. The set-up must be executed tamper-proof. When

reflexion light barriers are used, the sensors and reflectors must be

arranged alternately to avoid mutual interference. When optoelectronic

sensors are used, the switching outputs must be set to dark operation

(sensor actuated = 24 VDC).

The sensors must be arranged so that the transported material part is

detected without any interruption over the entire length. The sensors

must detect the material, not the carrier.

The distance of the sensors must not be too large, so that all activated muting sensors are actuated by the travelling material during a

cycle. The simultaneity (max. 3 sec.) of the switching outputs must be

observed.

sensor for the uniform recognition of material

exceptional stop of the muting cycle.

"belt stop" signal is active

SLG 425I sensor connection

The muting sensors must be arranged so that any unintentional access or penetration of a person into the hazardous

area is prevented. When positioning the muting sensors,

the distance and the height must be choses so that a clear

distinction is made between material and a person!

2.9.3 Muting lamp

The operating mode "muting" can be signalled through an external muting lamp. This lamp must be connected to the sensor connection plate

(ML) through a connection with a 3-pole connector socket. The muting

lamp is not monitored! I.e. the electrical connection and the included

illuminant are not checked by the control system of the SLG 425I.

The muting lamp signals the following operating modes:

Muting lamp Signal Note

ON Continuous signal Muting cycle active

OFF Muting cycle not active

Flashing 2 Hz Muting cycle error or over-

ride mode

If the muting lamps are flashing, the following failures can be present:

• Muting cycle time exceeded

• Belt stopping time exceeded

• Sequence or simultaneity of the signal conditions of the muting sensors not observed

EN

5

Operating instructions

t<3st<3s

MS1

MS2

Safety light grid

SLG 425I

Illuminant

For the muting lamp, a LED block with a lifetime of approx. 50 000

operating hours must be used as admissible illuminant. The utilisation

of MK2 type muting lamps is recommended.

2.9.4 Signal sequence muting

*1

MS 1

*2

*1

MS 2

*2

*1

ML

*2

*1

Muting

*2

t

*1: active

*2: inactive

MS1

Sensor group 1 Sensor group 2

Parameter setting: muting mode with 2 sensor groupes (4 muting sensors), direction detection 1, premature termination not active

MS3 MS2

MS4

Operating mode set-up for muting mode:

After the correct connection of the muting sensors and the NSR-0801,

the following parameters must be set by means of the PC software in

the "muting function" menu field in accordance with your application.

Operating mode and transport direction

First choose the operating mode and the transport direction (set-up and

number of the muting sensors).

Muting with 2 sensors, diagonal arrangement

• Muting variante with 2 crosswise arranged muting sensors

• Transport direction: material transport in both directions (factory setting)

• Selectable options: belt stop, reduced muting cycle, override, protection field area

The muting function is activated after first MS 1 (first sensor group) and

subsequently MS 2 (second sensor group) is actuated by the material

(direction detection 1). The material first actuates the proteciton field

of the SLG 425I, after that MS 3 (first sensor group) and finally the MS

4 (second sensor group). The muting cycle is cancelled, when MS 3

(second sensor group) is no longer actuated.

2.9.5 Configuration of the muting function

The parameters for the muting mode are set by means of the PC software: SLC 4 Kunde.exe

To this effect, the NSR-0801 BUS converter must be connected to the

SLG 425I and a PC or laptop. Please use the NSR-0801 BUS converter

manual for the connection.

6

EN

Operating instructions

Safety light grid

SLG 425I

Muting with 2 sensors, parallel arrangement

• Muting variante with 2 muting sensors

• Transport direction: out of the hazardous area, reduced muting cycle

(factory setting)

• Selectable options: belt stop, override, protection field area

The use of 2 parallel arranged sensors is only authorised for

outward material transport, i.e. the transport of material out

of the hazardous area. The muting sensors must be installed

inside the hazardous area.

Muting with 4 sensors, parallel arrangement

• Muting with each time 2 symmetrically arranged sensors before and

after the protection field of the SLG 425I.

• Transport direction: material transport in both directions selectable

• Selectable options: belt stop, reduced muting cycle, override, protection field area

Muting cycle time

The muting cycle time is the time expiring between the moment of

activation of the muting until the inward or outward material transport in

the hazardous area is completely terminated.

The muting cycle time depends on the length of the material, the belt

speed and the sensor arrangement.

The time must be defined so that the material can travel by all sensors

within the muting cycle time (enabling of all muting sensors). Before a

new muting cycle can be initiated, all sensors must be clear (no actuation).

The muting cycle time can be set from a few seconds up to multiple

hours. Longer muting cycle times can result in hazardous operating

conditions. The muting cycle time must take variations in the belt speed

as well as position and length tolerances of the material into consideration.

Reduced muting cycle

A normal muting cycle is terminated by a muting sensor in the following

way:

• Muting with 2 sensors, diagonal arrangement after enabling of muting

sensor MS 2

• Muting with 4 sensors, parallel arrangement after enabling of muting

sensor MS 3

For very long muting cycle times, this results in a time window with

bridged protection field, as long as the material is located between the

protection field and the muting sensor MS 2/MS 3.

By activating the function "reduced muting time", the muting cycle is

shortened/reduced. The muting cycle is terminated, when the material

has travelled by the protection field of the SLG 425I (protection field

clear).

This field is always activated when applied with 2 parallel arranged

muting sensors. For applications with 2 diagonally arranged MS or 4

parallel arranged MS, the function can be activated by means of the

software.

A new muting cycle can only be started, when all muting sensors are no

longer actuated.

Simultaneity of the sensors

The timeframe between the first and the second muting sensor is

monitored. In this way, a uniformly-shaped transport good can be distinguished from other switching times (passing by of a person) in case of

an adequate arrangement of the muting sensors.

The simultaneity setting must take variations in the belt speed, as well

as the position and length tolerances of the material into consideration.

The simultaneity of the sensors can be set between 1 to 3 seconds.

Setting the special functions is recommended. In this way, the

protective function and the availability of the muting application is

increased.

Restart interlock (manual reset)

The restart interlock (manual reset) prevents an automatic belt start

after voltage interruption or material jamming.

The restart interlock (manual reset) must be wired as shown in the wiring diagram (chapter 4). The function is active upon delivery.

The command device must be installed outside of the hazardous area,

so that the operator has a clear view on the area.

The command device must be actuated after any interruption of the

voltage or the protection field or fault of the muting cycle. Enabling is

only possible, when all muting sensors are not actuated. The signalling

for the actuation of the command device is realised by a status LED on

the receiver.

The function can be deactivated by removing the check mark in the

software. By doing this the following operating condition is created:

the outputs OSSD's are released, when all light beams and the muting

sensors are not interrupted (light path clear). The same applies after an

interruption of the voltage supply. A release through the command device is only required after a malfunction (muting cycle fault). The owner

then must secure this function through the application.

The deactivation of the "restart interlock (manual reset)" function can trigger an automatic muting cycle. In this way, persons can access/penetrate into the hazardous area. Persons

within the hazardous area are exposed to severe injuries.

Belt stop

The function can extend the muting cycle time in case of a belt stop or

material jamming, thus preventing a premature shutdown. In this way,

the muting function can be extended until the failure/belt stop is rectified. After that, the normal muting cycle can be completed.

The machine control makes the belt stop input available as signal. The

function is activated by switching on 24 VDC at pin 8 of the receiver. A

status change of the muting sensors (switching output) when the function is active, causes the muting function to be switched off.

The function is deactivated upon delivery. The belt stop time can be set

from 1 to 30 minutes.

Override

This function enables bridging the outputs of the SLG 425I in case of

failure (voltage interruption, material jamming). The function is limited in

time and exclusively reserved to the elimination of the material jamming

(muting sensor or protection field actuated).

The function is activated by means of the command device (restart

interlock enabling). The command device must be actuated in the sequence ON-OFF-ON. The time-related sequence for the start (ON-OFFON) with a minimum duration of 100 ms up to the maximum duration of

1.5 sec. must be observed. If the material jamming is eliminated (protection field and muting sensors no longer actuated), the outputs of the

SLG 425I are locked. To start a new muting cycle, the command device

(enabling of the restart interlock) must be actuated one time (ON-OFF).

The muting lamp starts flashing (2 Hz) to signal the interruption of the

muting cycle. The function is not activated upon delivery.

EN

7

Operating instructions

MS1

MS2 MS3 MS4

Safety light grid

Multiple interruption of the protection field during the muting cycle

This function increases the availability of the system in case of different

material qualities on one pallet.

Without the function "multiple interruption of the protection field", the

protection field is monitored during the active muting cycle and any nonactuation (no beam interrupted) immediately cancels the muting cycle.

This error function is triggered when all active beams of the protection field are not actuated for a period of time of over 20 ms e.g. due

to an irregular loading of the material on the carrier. If the function is

activated, no shutdown is triggered if the beams are not actuated during

the muting cycle. The correct termination is realised by the configuration or the muting sensors. The combination with the parameter setting

"reduced muting cycle" is not possible. These restrictions are marked in

the software and must be observed.

Activating the protection field

During a muting cycle, the entire protection field height of the SLG 425I

is bridged. This causes the risk that persons located on or beside the

material can get into the hazardous area.

The risk can be avoided by activating the remainder of the protection

field, if the conveyed material has a throughout identical height. In this

way, the presence of persons within the active protection field height is

detected!

Procedure:

Position the material onto the carrier so that the protection field of

the SLG 425I is actuated. If the material height is slightly varying, the

carrier can be slightly increased during the teaching process to avoid

false triggering. Now activate the teach sample field in the software.

The menu automatically switches to the beam view. The beams interrupted by the material are represented in red. The teaching process is

terminated with a mouse click on the "teach" field. You will return to the

main menu "muting".

Changing the protection field area

If the protection field height parameterised by means of the teach

process needs to be changed, the saved value must be deleted and

reparameterised.

Procedure:

Activating the entire protection field (the previous value is deleted)

Activating the teach sample (change to beam view)

Saving the new value (teach process) with teach

Mounting:

The first light beam (near the diagnostic window) must not be

interrupted! I.e. observe the downward cable connection.

SLG 425I

This saving procedure is recommended so that configuration changes

can be reproduced at a later moment. Click the (yes) button with your

mouse to confirm.

You now can save the configuration setting onto your PC or laptop.

2.9.7 Muting applications

Arrangement of the muting sensors

Muting lamp

MS1

Material

Belt

Reector

Reflektor

Muting sensor

Muting Sensor

SLG 425I-E/R

SLC 425I-E/R

Carrier

MS2

MS3

MS4

S

Belt

Material

S3

E

S2 S1 S1 S2

2.9.6 Saving the data

After the reconfiguration, the data to be saved are prepared by selecting the button "Save settings". To avoid any unintentional saving of

data, every intentional saving process must be confirmed within 10

seconds by clicking on the button "Confirm with this button within 10

seconds".

If it is not confirmed within this timeframe, the settings that were saved

before the change was made will be maintained without any change.

After the data transmission, the following confirmation is displayed. You

are simultaneously asked to save the configuration data in the form of

a text file.

8

SF = Protection field

S1 = distance of the inner MS to SF

S2 = distance between two MS

S3 = material length

MS 1 = Muting sensor 1

MS 2 = Muting sensor 2

MS 3 = Muting sensor 3

MS 4 = Muting sensor 4

S = Transmitter

E = Receiver

Minimum distances muting sensors

For the evaluation of the signals (MS) in the control system, a minimum

distance is required for the muting sensors.

The minimum signal length between the sensors, which are fitted

closest to the SLG 425I, must be at least 50 ms. This corresponds to a

minimum distance of 100 mm at a belt speed of 2.0 m/s.

The minimum signal length of the outer sensors must exceed 50 ms.

The signal running time between the muting sensors must be 3 seconds at the most (depending on the chosen setting).

EN

Operating instructions

Safety light grid

SLG 425I

The mounting distance of the inner sensors to the protection field of the

SLG 425I must be chosen as small as possible.

The sensors (transmitter/receiver) of the SLG 425I must be fixed as

close as possible to the conveyed material to avoid the creation of

gaps. Otherwise, there is a risk that persons can slip between the material and the MS arrangement into the hazardous area during the muting

cycle.

In case of different material widths, the gap between the sensors (transmitter/receiver) of the SLG 425I and the material must be protected with

an additional cover.

Muting with 2 sensors, parallel arrangement

The arrangement shows the muting application with two parallel arranged muting sensors. This arrangement enables the material to be

transported in only one direction, out of the hazardous area.

Schematic representation

Additional safety guard

Carrier

Belt

Material

S3

Hazardous point

MS2

MS1

S

E

Muting with 2 sensors, diagonal arrangement

The arrangement shows the muting application with two diagonally

(crosswise) arranged muting sensors. This arrangement enables the

material to be transported in both directions.

Schematic representation

Carrier

Additional safety guard

Hazardous point

S

Belt

Material

S3

S1 = distance MS 1 to SF

S2 = distance MS 2 to SF

S3 = material length

MS 1 = Muting sensor 1

MS 2 = Muting sensor 2

S = Transmitter

E = Receiver

VB = belt speed (m/s)

SF = Protection field

E

S2S1

MS1MS2

S2 S1

S1 = distance MS 1 to SF

S2 = distance MS 1 to MS 2

S3 = material length

MS 1 = Muting sensor 1

MS 2 = Muting sensor 2

S = Transmitter

E = Receiver

VB = belt speed (m/s)

SF = Protection field

S3 > S1+S2

S1 = belt speed VB (m/s) x 0,05 s

The muting cycle is as follows: MS2 - MS1 - SF - end

Selectable options: belt stop, override, protection field area

Factory setting: reduced muting cycle, i.e. the muting cycle is terminated

when the protection field is released.

This arrangement is only authorised when the muting sensors

are installed inside the hazardous area.

The intersection of the muting sensors must always be within

the hazardous area!

S3 > S1 + S2

S1 = belt speed VB (m/s) x 0,05 s

In the schematic diagram, the arrangement of the muting sensors is

represented with a larger distance to enable a uniform identification of

the sensor sequence. Please observe the smallest possible distance

of the MS to the transported material. The distance of MS 1 and MS

2 to the protection field of the SLG 425I must be chosen as small as

possible as well.

The muting cycle is as follows: MS1 - MS2 - SF - MS2 - end

Selectable options: belt stop, reduced muting cycle, override, protection

field area

Factory setting: material transport in both directions

The muting sensors must be arranged so that a uniform sequence of

the muting sensors is ensured.

EN

9

Operating instructions

MS1

MS2 MS3 MS4

Safety light grid

SLG 425I

Muting with 4 sensors, parallel arrangement

The arrangement shows the muting application with four parallel arranged muting sensors. This arrangement enables the material to be

transported in both directions.

Carrier

S

Belt

Material

S3

E

S2 S1 S1 S2

S1 = distance of the inner MS to SF

S2 = distance between two MS

S3 = material length

MS 1 = Muting sensor 1

MS 2 = Muting sensor 2

MS 3 = Muting sensor 3

MS 4 = Muting sensor 4

S = Transmitter

E = Receiver

VB = belt speed (m/s)

SF = Protection field

S3 > 2(S1 + S2)

S1 = belt speed VB (m/s) x 0,05 s

The muting cycle is as follows: MS1 - MS2 - SF - MS3 end

MS4 - MS3 - SF - MS2 end

Selectable options: belt stop, reduced muting cycle, override, protection

field area

Factory setting: material transport in both directions

The muting figure with each time 2 muting sensors shows a symmetrical arrangement before and after the protection field of the SLG 425I.

3. Mounting

3.1 General conditions

The following guidelines are provided as preventive warning notices

to ensure a safe and appropriate handling. These guidelines are an

essential part of the safety instructions and therefore must always be

observed and respected.

• The SLG must not be used on machines, which can be

stopped electrically in case of emergency.

• The safety distance between the SLG and a hazardous machine movement must always be observed and respected.

• Additional mechanical safety guards must be installed so that

the operator has to pass by the protection field to reach the

hazardous machine parts.

• The SLG must be installed so that the personnel always

must be within the detection zone when operating the machine. An incorrect installation can lead to serious injuries.

• Never connect the outputs to +24VDC. If the outputs are

wired to +24VDC, they are in ON state, as a result of which

they are unable to stop a hazardous situation occuring on the

application/machine.

• The safety inspections must be conducted regularly.

• The SLG must not be exposed to inflammable or explosive

gasses.

• The connecting cables must be connected in accordance

with the installation instructions.

• The fixing screws of the end caps and the mounting angle

must be firmly tightened.

• Additional measures could be required to ensure that the

electro-sensitive device does not present a dangerous

breakdown, when other forms of light beams are available in

a special application (e.g. use of wireless control devices on

cranes, radiation of welding sparks or effects of stroboscopic

lights).

3.2 Protection field and approach

The protection field consists only of the available individual beams with

a distance of 300, 400 or 500 mm. Additional protective devices must

ensure that hazardous machine movements can only be reached after

passing through the protection field.

The SLG must be installed to so that the hazardous area is completely

protected, if necessary by means of additional safety guards.

The safety distance before the hazardous point to the SLG safety

guard must be imperatively respected. The safety distance enables the

presence of persons within the hazardous area. Therefore, it must be

ensured that the hazardous movement can only take place, when no

persons are inside the hazardous area anymore. The legal and governmental provisions must be observed for the operation and use. These

provisions are usually region- and country-dependent.

The command devices (enabling button) must be installed

outside of the hazardous area sot hat any operation from

within the hazardous area is prevented. The operator must

have a clear view on the hazardous area, when actuating the

command device (enabling button).

3.3 Alignment

Procedure:

1. The transmitter and the receiver must be fitted parallel to each other

and at the same height.

2. Turn the transmitter and monitor the diagnostic window of the receiver. Fix the light grid, when the LED OSSD ON (green) is on and

the LED signal reception (orange) is off.

3. Determine the max. rotating angle to the left and to the right, at which

the LED OSSD ON (green) is on and tighten the mounting screws in

central position. Make sure that the LED signal reception (orange) is

not on or flashing.

10

EN

Operating instructions

8° 8°

a= 262 mm

D [m]

0 3 5 10

15 20

Safety light grid

SLG 425I

3.4 Safety distance

The safety distance is the minimum distance between the SLG 425I

and the hazardous point, which must be observed in order to ensure

that the hazardous point can only be reached after the hazardous

movement has come to standstill.

The protection using individual beams must be chosen so

that bodies or body parts larger than the selected resolution

(beam distance + beam diameter 10 mm) of the SLG 425I are

detected.

Calculation of the safety distance to EN ISO 13855 and

EN ISO 13857

The safety distance depends on the following elements:

• Run-on time of the machine (calculation by run-on time measurement)

• Response time of the machine and the safety light grid and the downstream relay (entire safety guard)

• Approach speed

• Resolution of the safety light grid

Calculation of the safety distance for the safety light grid:

S = (K 1600 mm/s x T ) + C

S = Safety distance [mm]

T = Run-on time of the machine + reaction time of the safety light grid

K = Approach speed 1600 mm/s

C = Safety supplement 850 mm

To calculate the minimum distances of the safety guards with

regard to the hazardous point, the EN ISO 13855 and EN

ISO 13857 must be observed.

If an overlap of the protection field is possible, take care to

the calculation of the safety distanca refering to additional

CRO according to the table A1 as per norm EN ISO 13855.

3.4.1 Minimum distance to reflecting surfaces

During the installation, the effects of reflecting surfaces must be taken

into account. In case of an incorrect installation, interruptions of the

protection field could possibly not be detected, which could lead to

serious injuries. The hereafter-specified minimum distances with regard

to reflecting surfaces (metal walls, floors, ceilings or parts) must be

imperatively observed.

Access direction

Transmitter

5° 5°

Limit of the hazardous point

optical axis

Obstacle

a=130mm

reecting body

(e.g. Material container)

Receiver

Example:

Reaction time of the SLG 425I = 10 ms

Run-on time of the machine T = 170 ms

S = 1600 mm/s * (170 ms + 10 ms) + 850 mm

S = 1138 mm

The following mounting heights must be observed:

Number of beams Mounting height above reference floor in

2 400, 900

3 300, 700, 1100

4 300, 600, 900, 1200

The safety distance between the safety light grid and the

hazardous point must always be respected and observed. If

a person reaches the hazardous point before the hazardous

movement has come to standstill, he/she is exposed to serious injuries.

Safety distance to the hazardous area

Transmitter

Direction from which the

hazardous area is accessed

mm

S

Hazardous

point

Table: Safety distance to reflecting surfaces a depending on the aperture angle

a [mm]

1000

900

800

700

600

500

400

300

200

100

Calculate the minimum distance to reflecting surfaces as a function of

the distance with an aperture angles of ± 2.5° degrees or use the value

from the table below:

Distance [m] between

transmitter and receiver

0.2 … 3.0 130

4 175

5 220

7 310

10 440

15 660

Formula: a = tan 2.5° x L [mm]

a = Minimum distance to reflecting surfaces

L = Distance between transmitter and receiver

Minimum distance a

[mm]

Receiver

Command device

Authorised operation

Mechanical protection

The formulae and calculation examples are related to the vertical set-up

(refer to drawing) of the safety light grid with regard to the hazardous

point. Please observe the applicable harmonised EN standards and

possible applicable national regulations.

EN

11

Operating instructions

C

C

Safety light grid

SLG 425I

3.5 Dimensions

All measurements in mm.

SLG425I-ER-0500-02-RF (2-beam version)

A B C L2 L1

Trans-

mitter

500 648 712 684 748 303 239 349

Re-

ceiver

Trans-

mitter

Re-

ceiver

Trans-

mitter

Re-

ceiver

L2

Receiver 161 / Transmitter 97

80

Receiver 150 / Transmitter 86

6.05

48.749.6

B

SLG425I-ER-0800-03-RF (3-beam version)

A B C L2 L1

Trans-

mitter

400 948 1012 948 1048 203 139 249

Re-

ceiver

Trans-

mitter

Re-

ceiver

Trans-

mitter

Re-

ceiver

L2

97

Receiver 161 / Transmitter 97

80

86

Receiver 150 / Transmitter 86

6.05

48.749.6

AA

B

A

51

31.5

42

L1

Legend

A = Beam distance

B = Mounting dimension

C = Total length

L1 = Mounting distance (mm) between floor and slotted hole centre

(short end cap)

L2 = Mounting distance (mm) between floor and slotted hole centre

(diagnostic window)

*All measurements ± 1 mm

51

31.5

42

L1

Legend

A = Beam distance

B = Mounting dimension

C = Total length

L1 = Mounting distance (mm) between floor and slotted hole centre

(short end cap)

L2 = Mounting distance (mm) between floor and slotted hole centre

(diagnostic window)

*All measurements ± 1 mm

12

EN

Operating instructions

C

20

Safety light grid

SLG 425I

SLG425I-ER-0900-04-RF (4-beam version)

A B C L2 L1

Trans-

mitter

300 1088 1152 1124 1188 203 139 209

B

97

Receiver 161 / Transmitter 97

AAA

ceiver

86

Receiver 150 / Transmitter 86

Re-

Trans-

mitter

Re-

ceiver

L2

80

Transmitter

6.05

Re-

ceiver

48.749.6

Accessories

Fixing kit MS-1030

The fixing kit consists of 4 steel angles and 16 fixing screws.

18,9

6,5

42

14,5

40

32

52

Centre fixing MS-1051 (optional accessory)

Mounting kit consists of 2 steel angles, 4 screws and 4 T-slot nuts for

central fixing

40

20

42

14,5 18,9

32

38

20

51

31.5

Legend

A = Beam distance

B = Mounting dimension

C = Total length

L1 = Mounting distance (mm) between floor and slotted hole centre

(short end cap)

L2 = Mounting distance (mm) between floor and slotted hole centre

(diagnostic window)

*All measurements ± 1 mm

42

L1

EN

13

Operating instructions

+ 24VDC

MS 1

MS 2

MS 1

MS 2

+ 24VDC

5

8

5

8

Safety light grid

4. Electrical connection

4.1 Wiring example Muting

MS 1

MS 2

MS 1

MS 3 MS 2

SLG 425I

Sensor connection:

with 2 muting sensors

with 4 muting sensors

MS 4

5

1 342

DIAG IN (WH)

DIAG OUT (BK)

DIAG IN (WH)

DIAG OUT (BK)

Nur für Diagnose

Only for diagnostic

Bridge 1: Restart interlock (manual reset) active (bridge between DIAG

OUT and DIAG IN)

Legend

K1, K2: Relay for processing the switching outputs OSSD 1,OSSD 2

MK: Machine contact belt stop (optional)

S1: Command device button for enabling restart/override

E1: Power supply 24 VDC ± 10%

0 VDC (BU)

+24 VDC (BN)

+24 VDC (BN)

0 VDC (BU)

E 1

Erdung

Earth connection

6

DIAG IN (GY)

DIAG OUT (PK)

DIAG OUT (PK)

DIAG IN (GY)

Brücke 1

Bridge 1

1

Freigabe/Override (WH)

Release/Override (WH)

S 1

8

2

Bandstopp (RD)

+24 VDC (BN)

Belt stop (RD)

+24 VDC (BN)

MK

7

0 VDC (BU)

0 VDC (BU)

3

4

OSSD 1 (GN)

OSSD 2 (YE)

OSSD 2 (YE)

OSSD 1 (GN)

K 1 K 2

4.2 Connector configuration Receiver, Emitter & Cable

RECEIVER

SLG: connector

M12 / 8 pole male

6

7

1

Cable: Connector

M12 / 8 pole female

4

3

2

Signal

Designation Description

1 WH Release/Override Input

2 BN 24 VDC Power supply

3 GN OSSD 1 Safety output 1

4 YE OSSD 2 Safety output 2

5 GY Diagnostic IN Input diagnostic data

6 PK Diagnostic OUT Output diagnostic data

7 BU 0 VDC Power supply

8 RD Belt stop Input

14

4

3

2

EN

6

7

1

Operating instructions

Safety light grid

SLG 425I

TRANSMITTER

SLG: connector

M12 / 4 pole male

4

1

Cable: Connector

M12 / 4 pole female

3

2

Sensor connection field

3

2

4

1

The colour codes are only valid for the cable types mentioned

below "optional accessories".

Signal

Designation Description

1 BN 24 VDC Power supply

2 WH Diagnostic IN Input diagnostic data

3 BU 0 VDC Power supply

4 BK Diagnostic OUT Output diagnostic data

MS1 / MC MS2 ML

4. The double insulation between the light grid output and an external

potential is guaranteed.

5. The outputs OSSD1 and OSSD2 are not connected to +24 VDC.

6. The connected switching elements (load) are not connected to +24

VDC.

7. If two or more SLG are used within close range compared to each

other, an alternating arrangement must be observed. Any mutual

interference of the systems must be prevented.

Switch the SLG on and check the operation in the following way:

The component performs a system test during approx. 2 seconds after

the operating voltage has been switched on. After that, the outputs are

enabled (if the protection field is not interrupted). The LED "OSSD ON"

of the receiver is on.

In case of incorrect functioning, please follow the instructions

listed in the chapter Fault diagnostic.

5.2 Maintenance

Do not use the SLG before the next inspection is terminated.

An incorrect inspection can lead to serious and mortal injuries.

Conditions

For safety reasons, all inspection results must be archived. The operating principle of the SLG and the machine must be known in order to

be able conducting an inspection. If the fitter, the planning technician

and the operator are different persons, please make sure that the user

has the necessary information at his disposal to be able conducting the

maintenance.

MS1/MC = Muting sensor 1/machine contact MC

MS 2 = muting sensor 2

ML = Muting lamp

Muting sensors PIN No. Signal Description

4

3

Muting lamp PIN No. Signal Description

4

3

5. Set-up and maintenance

5.1 Check before start-up

Prior to start-up, the following items must be checked by the responsible person.

Wiring check prior to start-up

1. The voltage supply is a 24V direct current power supply, which meets

the CE Directives, Low Voltage Directives. A power downtime of 20

ms must be bridged.

2. Presence of a voltage supply with correct polarity at the SLG.

3. The connecting cable of the transmitter is correctly connected to the

transmitter and the connecting cable of the receiver correctly to the

receiver.

1 +24 VDC Power supply

1

3 0 V Power supply

4 +24 VDC Switching output sensor

3 0 V Power supply

4 +24 VDC Switching output muting

lamp

5.3 Regular check

A regular visual inspection and functional test, including the following

steps, is recommended:

1. The component does not have any visible damages.

2. The optics cover is not scratched or soiled.

3. Hazardous machinery parts can only be accessed by passing

through the protection field of the SLG.

4. The staff remains within the detection area, when works are con-

ducted on hazardous machinery parts.

5. The safety distance of the application exceed the mathematically

calculated one.

Operate the machine and check whether the hazardous movement

stops under the hereafter-mentioned circumstances.

6. Hazardous machine parts do not move when the protection field is

interrupted.

7. The hazardous machine movement is immediately stopped, when

the protection field is interrupted with the test rod immediately before

the transmitter, immediately before the receiver and in the middle

between the transmitter and the receiver.

8. No hazardous machine movement when the test rod is within the

protection field.

9 The hazardous machine movement comes to standstill, when the volt-

age supply of the SLG 425I is switched off.

5.4 Half-yearly inspection

The following items must be checked every six months or when a machine setting is changed.

1. Machine stops or does not inhibit any safety function.

2. No machine modification or connection change, which affects the

safety system, has taken place.

3. The outputs of the SLG are correctly connected to the machine.

4. The total response time of the machine does not exceed the response time calculated during the first putting into operation.

5. The cables, the connectors, the caps and the mounting angles are in

perfect condition.

EN

15

Operating instructions

Safety light grid

5.5 Cleaning

If the optics cover of the sensors is extremely soiled, the OSSD outputs

can be disabled. Clean with a soft cloth without exercising pressure.

The use of agressive, abrasive or scratching cleaning agents, which

could attack the surface, is prohibited.

6. Diagnostic

6.1 LED status information

Receiver Function LED colour Description

Multifunction

Blanking

Signal reception

Protection field

Restart

OSSD OFF

OSSD ON

Transmitter Function LED colour Description

Transmitting Status

Multifunction green Function display, beam coding

Blanking blue Protection field(s) inactive (blanking)

Signal reception orange Evaluation of the signal reception

Restart yellow Input for command device

OSSD OFF red Safety outputs signal condition OFF

OSSD ON green Safety outputs signal condition ON

Transmitting orange Transmitter active

Status green Function display, beam coding

SLG 425I

Protection field

Receiver

LED Status LED Description

OSSD ON ON Protection field clear

Flashing Diagnostic mode active

OSSD OFF ON Protection field interrupted, system or configuration error

Flashing Diagnostic mode active, error output refer to Fault diagnostic table

Restart ON Start or restart interlock (manual reset) active, signal expected at output WA

Signal reception ON/flashing Signal reception too low, check alignment and installation height between

transmitter and receiver

Cleaning the black profile cover

OFF Alignment between transmitter and receiver OK

Blanking 1 flashes Fixed blanking of the protection field(s)

Multifunction 1 flashes Muting (complete protection field)

2 flashes Muting (only teached protection field)

3 flashes Muting through BUS control

4 flashes reserved

5 flashes Beam coding A is active

Transmitter

LED Status LED Description

Transmitting ON Standard operation, transmitter active

Flashing Configuration error

Status Flashing Beam coding A is active

16

EN

Operating instructions

Safety light grid

6.2 Fault diagnostic

The light grid performs an internal self-test after the operating voltage is switched on and the protection field is enabled. When a fault is detected, a

corresponding flashing pattern is emitted at the receiver through the LED OSSD OFF (red). Every fault emission is followed by a one-second pause.

LED OSSD OFF Fault feature Action

OSSD OFF and LED restart

continuous flashing

1 flashes Error at sensor receiver Replace receiver

2 flashes Error contactor control OFF Check connections at contactor control input, refer to

3 flashes Error contactor control ON Check wiring at contactor control input, short-circuit at +UB and

4 flashes Errors at the OSSD outputs Check the wiring of the outputs, OSSD for short-circuit at +UB and

5 flashes Error configuration data Check the configuration settings by means of the NSR-0801 BUS

6 flashes Error blanking The receiver has detected blanked beams as beams without inter-

Wiring error for function selection

(Restart interlock (manual reset), automatic

mode)

Check connection at the receiver, bridge 1 or

bridge 2 must be wired (refer to Wiring)

Wiring, check wiring of the auxiliary contacts

mass. Power reset after fault rectification.

mass

converter

ruption, i.e. locking. Check the configuration settings by means of the

NSR-0801 BUS converter, repeat the teach process with blanking.

SLG 425I

6.3 Extended diagnostic

By means of the optional configuration software and the NSR-0801

BUS converter, an extended diagnostic can be executed. The software

provides the status information of the component and can represent the

individual light lines. This feature enables an optimal adjustment of the

light grid. The diagnostic mode is signalled by the OSSD ON and OSSD

OFF LED‘s at the receiver. In diagnostic mode, protective mode is

disabled, the ODDS outputs being locked. The change from diagnostic

mode to protective mode is automatically realised after Power Reset,

when the BUS converter is no longer integrated and the connecting

cable of the sensor is reconnected.

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised condition only.

7.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.

8. Appendix

8.1 Contact

Consultancy / Sales:

K.A. Schmersal GmbH

Industrielle Sicherheitsschaltsysteme

Möddinghofe 30

D-42279 Wuppertal

Tel:+49 (0) 202 64 74 -0

Fax:+49 (0) 202 64 74- 100

You will also find detailed information regarding our product variety on

our website: www. schmersal.com

Repair handling / shipping:

Safety Control GmbH

Am Industriepark 11

D-84453 Mühldorf / Inn

Tel.: +49 (0) 8631-18796-0

Fax: +49 (0) 8631-18796-1

EN

17

Operating instructions

Safety light grid

Appendix

8.2 EC Declaration of conformity

EC Declaration of conformity

SLG 425I

Translation

of the original declaration of conformity

We hereby certify that the hereafter described safety components both in its basic design and construction conform to the applicable European Directives.

Name of the safety component / type:

Description of the safety component: Safety light grid

Harmonised EC-Directives: 2006/42/EC - EC-Machinery Directive

Applied standards: EN 61496-1:2004 + A1 2008

Person authorized for the compilation

of the technical documentation:

Notied body for the prototype test: TÜV Nord Cert GmbH

EC- test certicate: n° 44 205 10 555867 005

Safety Control GmbH

Am Industriepark 33

84453 Mühldorf / Inn

Germany

Internet: www.schmersal.com

SLG 425I

2004/108/EC - EMC-Directive

CLC/TS 61496-2:2006

EN ISO 13849-1:2008; PL e

EN 62061:2005; SIL 3

Ulrich Loss

Möddinghofe 30

42279 Wuppertal

Langemarckstr.20

45141 Essen

ID n°: 0044

Place and date of issue: Mühldorf, February 1, 2010

Authorised signature

Christian Spranger

Managing Director

SLG 425I-B-EN

The currently valid declaration of conformity can be downloaded from the internet at www.schmersal.net.

Safety Control GmbH

Am Industriepark 33

D-84453 Mühldorf / Inn

Telefon +49 - (0)86 31 - 187 - 9 60

Telefax +49 - (0)86 31 - 187 - 9 61

E-Mail: info@safetycontrol.com

Authorised signature

Klaus Schuster

Managing Director

18

EN

Loading...

Loading...