EN

Operating instructions. . . . . . . . . . . .pages 1 to 20

Original

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

1

1. About this document

1.1 Function

This operating instructions manual provides all the information you

need for the mounting, set-up and commissioning to ensure the safe

operation and disassembly of the safety switchgear. The operating

instructions must be available in a legible condition and a complete

version in the vicinity of the device.

1.2 Target group: authorised qualified personnel

All operations described in this operating instructions manual must

be carried out by trained specialist personnel, authorised by the plant

operator only.

Please make sure that you have read and understood these operating

instructions and that you know all applicable legislations regarding

occupational safety and accident prevention prior to installation and

putting the component into operation.

The machine builder must carefully select the harmonised standards

to be complied with as well as other technical specifications for the

selection, mounting and integration of the components.

Content

1 About this document

1.1 Function.............................................1

1.2 Target group: authorised qualied personnel ................1

1.3 Explanation of the symbols used..........................2

1.4 Appropriate use.......................................2

1.5 General safety instructions ..............................2

1.6 Warning about misuse..................................2

1.7 Exclusion of liability ....................................2

2 Product description

2.1 Ordering code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1.1 Safety light curtain (Standard)............................2

2.1.2 Safety light grid (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1.3 Safety light curtain (IP69K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1.4 Safety light grid (IP69K) ................................2

2.2 Special versions ......................................3

2.3 Included in delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3.1 Included in delivery of SLC/SLG 420 Standard...............3

2.3.2 Included in delivery of SLC/SLG 420 IP69K . . . . . . . . . . . . . . . . . 3

2.4 Destination and use....................................3

2.5 Technical data ........................................3

2.5.1 Technical data IP69K (additions)..........................3

2.6 Response time (reaction time) ...........................4

2.7 Effective resolution ....................................4

2.8 Safety classication....................................5

2.9 Functions............................................5

2.9.1 Protective mode ......................................5

2.9.2 Restart interlock (manual reset) ..........................5

2.9.3 Fixed blanking SLC 420 ................................5

2.9.4 Floating blanking SLC 420 ..............................6

2.9.5 Floating blanking SLG 420 ..............................6

2.9.6 Contactor control (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.9.7 Start interlock ........................................7

2.10 Self-test .............................................7

2.11 Beam coding A .......................................7

3 Mounting

3.1 General conditions ....................................7

3.2 Protection eld and approach . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Alignment ...........................................8

3.4 Setting mode .........................................8

3.5 Safety distance .......................................8

3.5.1 Minimum distance to reecting surfaces ...................11

3.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.6.1 Dimensions transmitter and receiver SLC 420 (Standard) .....12

3.6.2 Dimensions transmitter and receiver SLG 420 (Standard) . . . . . 12

3.6.3 Dimensions transmitter and receiver SLC 420 IP69K .........13

3.6.4 Dimensions transmitter and receiver SLG 420 IP69K.........13

3.7 Scope of delivery and accessories .......................14

3.7.1 Included in delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7.2 Optional accessories ..................................14

4 Electrical connection

4.1 Wiring example default................................15

4.2 Activation of the contactor control (EDM) without PC software..16

4.3 Connector conguration Receiver, Transmitter & Cable .......16

5 Set-up and maintenance

5.1 Check before start-up .................................17

5.2 Maintenance ........................................17

5.3 Regular check .......................................17

5.4 Half-yearly inspection .................................17

5.5 Cleaning ...........................................17

6 Diagnostic

6.1 LED status information ................................18

6.2 Fault diagnostic ......................................19

6.3 Extended diagnostic ..................................19

7 Disassembly and disposal

7.1 Disassembly ........................................19

7.2 Disposal............................................19

8 Appendix

8.1 Contact ............................................19

9 EU Declaration of conformity

x.000 / 09.2016 / v.A. - 103010741-EN / B / 2016-09-21 / AE-Nr. 6553

Version 2.0

2

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

1.3 Explanation of the symbols used

Information, hint, note:

This symbol is used for identifying useful additional information.

Caution: Failure to comply with this warning notice could

lead to failures or malfunctions.

Warning: Failure to comply with this warning notice could

lead to physical injury and/or damage to the machine.

1.4 Appropriate use

The products described in these operating instructions are developed to

execute safety-related functions as part of an entire plant or machine. It

is the responsibility of the manufacturer of a machine or plant to ensure

the correct functionality of the entire machine or plant.

The safety switchgear must be exclusively used in accordance with

the versions listed below or for the applications authorised by the

manufacturer. Detailed information regarding the range of applications

can be found in the chapter "Product description".

1.5 General safety instructions

The user must observe the safety instructions in this operating

instructions manual, the country-specific installation standards as well

as all prevailing safety regulations and accident prevention rules.

Further technical information can be found in the Schmersal

catalogues or in the online catalogue on the Internet:

www.schmersal.net.

The information contained in this operating instructions manual is

provided without liability and is subject to technical modifications.

The entire concept of the control system, in which the

safety component is integrated, must be validated to

EN ISO 13849-2.

There are no residual risks, provided that the safety instructions as well

as the instructions regarding mounting, commissioning, operation and

maintenance are observed.

Additional measures could be required to ensure that the electrosensitive device does not present a dangerous breakdown, when other

forms of light beams are available in a special application (e.g. use

of wireless control devices on cranes, radiation of welding sparks or

effects of stroboscopic lights).

1.6 Warning about misuse

In case of improper use or manipulation of the safety

switchgear, personal hazards or damages to machinery or

plant components cannot be excluded when safety switchgear is used. The relevant requirements of the standard

EN ISO 13855 must be observed.

Only if the information described in this operating instructions

manual are realised correctly, the safety function and therefore

the compliance with the Machinery Directive is maintained.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

2.1.1 Safety light curtain (Standard)

SLC420-E/R➀-➁-RFB-

➂

No. Option Description

➀

xxxx Protection field heights in mm available lengths:

0170, 0250, 0330, 0410, 0490, 0570, 0650, 0730,

0810, 0890, 0970, 1050, 1130, 1210, 1290, 1370,

1450, 1530*, 1610*, 1690*, 1770*

➁

14 Resolution 14 mm

30 Resolution 30 mm

50 Resolution 50 mm

➂

Range 0,3 m ... 7 m

only for resolution 14 mm

Range 0,3 m ... 10 m

only for resolution 30 and 50 mm

H Range 0,3 m ... 18 m, High range

only for resolution 30 mm

Note

* Protection field heights from 1530 to 1770 mm

only with resolution of 30 and 50 mm

2.1.2 Safety light grid (Standard)

SLG420-E/R➀-RF-

➁

No. Option Description

➀

Distance between outermost beams:

0500-02 500 mm, 2-beam

0800-03 800 mm, 3-beam

0900-04 900 mm, 4-beam

➁

Range 0,3 m ... 18 m

H Range 8 m ... 50 m, High range

2.1.3 Safety light curtain (IP69K)

SLC420-E/R➀-➁-69-RFB

No. Option Description

➀

xxxx Protection field heights in mm available

lengths: 0170, 0250, 0330, 0410, 0490,

0570, 0650, 0730, 0810, 0890, 0970, 1050,

1130, 1210, 1290, 1370, 1450

➁

14 Resolution 14 mm

with a range of 0.3 m … 7 m

30 Resolution 30 mm

with a range of 0.3 m … 10 m

2.1.4 Safety light grid (IP69K)

SLG420-E/R➀-69-RF

No. Option Description

➀

Distance between outermost beams:

0500-02 500 mm, 2-beam

0800-03 800 mm, 3-beam

0900-04 900 mm, 4-beam

Range 0,3 m ... 18 m

3

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Included in delivery

2.3.1 Included in delivery of SLC/SLG 420 Standard

- Sensors E, R

- Mounting kit MS-1030

- Test rod

- Operating instructions DE/EN

2.3.2 Included in delivery of SLC/SLG 420 IP69K

- Sensors E, R

- Mounting kit MS-1038

- 5 m long connection cable,

permanently integrated on the transmitter and receiver

- Test rod

- Operating instructions DE/EN

2.4 Destination and use

The SLC 420 is a non-contact, self-testing safety guard, which is used

for the protection of hazardous points, hazardous areas and machine

accesses. If one or more light beams are interrupted, the hazardous

movement must be stopped.

The user must evaluate and design the safety chain in

accordance with the relevant standards and the required

safety level.

2.5 Technical data

Standards: EN 61496-1; EN 61496-2;

EN ISO 13849; EN 62061

Material of the enclosure: Aluminium

Number of beams: 2 … 144 beams

Protection field heights:

- SLC 420 with resolution 14 mm: 170 mm … 1450 mm,

- SLC 420 with resolution 30 mm: 170 mm … 1770 mm,

- SLC 420 with resolution 50 mm: 170 mm … 1770 mm,

- SLG 420: 500 mm, 800 mm, 900 mm

Detection ability for test rod:

- SLC 420: 14 mm, 30 mm, 50 mm

- SLG 420: 2 beams with resolution 500 mm 1)

3 beams with resolution 400 mm 1)

4 beams with resolution 300 mm

1)

Range of the protection field:

- SLC 420 with resolution 14 mm: 0.3 … 7.0 m

- SLC 420 with resolution 30 und 50 mm: 0.3 … 10.0 m

- SLC 420 with resolution 30 mm (High range): 0.3 … 18.0 m

- SLG 420: 0.3 … 18.0 m

- SLG 420 (High range): 8.0 … 50.0 m

Response time:

- Beam coding (normal): 1 - 48 beams = 10 ms

49 - 144 beams = 20 ms

- Beam coding A: 1 - 48 beams = 15 ms

49 - 144 beams = 27 ms

Rated operating voltage: 24 VDC ±10% (PELV) supply unit

to EN 60204 (power drop > 20 ms)

Rated operating current: 250 mA max. + 2 x 250 mA each OSSD

Wave length of the sensor: 870 nm

Safety outputs:

Test cycle time: 750 ms

Test impulse length: 200 µs

Safety outputs: 2 x PNP-type semi-conductor,

short-circuit proof

Switching voltage HIGH 2): 15 … 26.4 V

Switching voltage LOW 2): 0 … 2 V

Switching current: 0 ... 250 mA

Leakage current 3): 1 mA

Load capacity: 200 nF

Load capacity 4): 2 H

Admissible conduction resistance between OSSD and load: 2.5 Ω

Supply cable: 1 Ω

Contactor control (EDM):

Input voltage HIGH (inactive): 17 … 26.4 V

Input voltage LOW (active): 0 … 2 V

Input current HIGH: 3 … 10 mA

Input current LOW: 0 … 2 mA

Input restart interlock

Input voltage HIGH (active): 17 … 26.4 V

Input voltage LOW (inactive): 0 … 2 V

Input current HIGH: 3 … 10 mA

Input current LOW: 0 … 3 mA

Functions: contactor control,

beam blanking fixed and floating,

setting mode

Operating modes: protective mode,

start and restart interlock

Signal times:

- Contactor control: 50 … 500 ms, adjustable

- Authorized operation restart interlock: 100 ms to 1500 ms,

Signal acquisition with falling edge

- Start interlock: 250 … 1500 ms, adjustable

LED indications:

- Transmitter: Transmitting, status

- Receiver: OSSD ON, OSSD OFF, restart,

signal reception, blanking, multifunction

Connection: M12 connector plug with metal thread,

receiver 8-pole, transmitter 4-pole

Ambient temperature: −25° C … + 50° C

at −25° C: Reduction of range by −10%

Storage temperature: −25° C … + 70° C

Interface: Diagnostics and function setting

Protection class: IP67 (IEC 60529)

Resistance to vibration: 10 … 55 Hz to IEC 60068-2-6

Resistance to shock: 10 g, 16 ms, to IEC 60028-2-29

Year of construction: as of 2015 version 2.0

1)

Resolution = beam distance + beam diameter 10 mm

2)

To EN 61131-2

3)

In case of failure, the leakage current flows to the OSSD cable.

The downstream control element must recognise this state as LOW.

A safety PLC must detect this state.

4)

The load induction generates an induced voltage during the

switch-off, which compromises the downstream components

(spark quenching element).

2.5.1 Technical data IP69K (additions)

For the IP69K versions, the same technical data is valid as described in

point 2.5, with the exception of the following details:

Material of the enclosure: Aluminium

- Protective tube: PMMA plastic tubes

- End plugs: PA 6

- Membrane: V4A, Gore Tex membrane M12 x 1.5

Protection field heights:

- SLC 420 IP69K with resolution 14 mm: 170 mm … 1450 mm

- SLC 420 IP69K with resolution 30 mm: 170 mm … 1450 mm

- SLG 420 IP69K: 500 mm, 800 mm, 900 mm

Range of the protection field:

- SLC 420 IP69K with resolution 14 mm: 0.3 … 7 m

- SLC 420 IP69K with resolution 30 mm: 0.3 … 10 m

- SLG 420 IP69K: 0.3 … 18 m

Connection: screwed cable gland M16 x 1.5

cable connector M12 x 1; 4-pole fixed to transmitter,

M12 x 1; 8-pole fixed to receiver integrated

Ambient temperature: −10° C … +50° C

Protection class: IP69K

4

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

2.6 Response time (reaction time)

The response time depends on the hight of the protection field, the

resolution, the number of light beams and the beam coding.

SLC 420 Resolution 14 mm

Pro-

tection

field

height

[mm]

Beams

[Number]

Res-

ponse

time

[ms]

Response

time with

beam coding

A

[ms]

Weight

Standard

[kg]

Weight

IP69K

[kg]

170 16 10 15 0.9 1.6

250 24 10 15 1.2 1.9

330 32 10 15 1.5 2.3

410 40 10 15 1.8 2.6

490 48 10 15 2.0 3.0

570 56 20 27 2.3 3.3

650 64 20 27 2.5 3.7

730 72 20 27 2.8 4.1

810 80 20 27 3.1 4.5

890 88 20 27 3.4 4.8

970 96 20 27 3.6 5.2

1050 104 20 27 3.9 5.6

1130 112 20 27 4.2 6.0

1210 120 20 27 4.5 6.4

1290 128 20 27 4.7 6.8

1370 136 20 27 5.0 7.2

1450 144 20 27 5.2 7.6

SLC 420 Resolution 30 mm

Pro-

tection

field

height

[mm]

Beams

[Number]

Res-

ponse

time

[ms]

Response

time with

beam coding

A

[ms]

Weight

Standard

[kg]

Weight

IP69K

[kg]

170 8 10 15 0.9 1.6

250 12 10 15 1.2 1.9

330 16 10 15 1.5 2.3

410 20 10 15 1.8 2.6

490 24 10 15 2.0 3.0

570 28 10 15 2.3 3.3

650 32 10 15 2.5 3.7

730 36 10 15 2.8 4.1

810 40 10 15 3.1 4.5

890 44 10 15 3.4 4.8

970 48 10 15 3.6 5.2

1050 52 20 27 3.9 5.6

1130 56 20 27 4.2 6.0

1210 60 20 27 4.5 6.4

1290 64 20 27 4.7 6.8

1370 68 20 27 5.0 7.2

1450 72 20 27 5.2 7.6

1530 76 20 27 5.5 ---

1610 80 20 27 5.8 ---

1690 84 20 27 6.1 ---

1770 88 20 27 6.3 ---

SLC 420 Resolution 50 mm

Protection

field height

[mm]

Beams

[Number]

Response

time

[ms]

Response time with

Beam coding A

[ms]

Weight

[kg]

170 4 10 15 0.9

250 6 10 15 1.2

330 8 10 15 1.5

410 10 10 15 1.8

490 12 10 15 2.0

570 14 10 15 2.3

650 16 10 15 2.5

730 18 10 15 2.8

810 20 10 15 3.1

890 22 10 15 3.4

970 24 10 15 3.6

1050 26 10 15 3.9

1130 28 10 15 4.2

1210 30 10 15 4.5

1290 32 10 15 4.7

1370 34 10 15 5.0

1450 36 10 15 5.2

1530 38 10 15 5.5

1610 40 10 15 5.8

1690 42 10 15 6.1

1770 44 10 15 6.3

SLG 420

Beams

[Number]

Beam

dis-

tance

[mm]

Res-

ponse

time

[ms]

Response time

with beam

coding A

[ms]

Weight

Standard

[kg]

Weight

IP69K

[kg]

2 500 10 15 2.5 3.7

3 400 10 15 3.5 5.1

4 300 10 15 3.6 5.2

2.7 Effective resolution

The effective resolution in case of activated blanking of floating beams

can be found in the following table:

Blanked beams Physical resolution Effective resolution

1 14 24

2 14 34

3 14 44

4 14 54

Blanked beams Physical resolution Effective resolution

1 30 48

2 30 68

3 30 88

4 30 108

Blanked beams Physical resolution Effective resolution

1 50 88

2 50 128

3 50 168

4 50 208

5

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

2.8 Safety classification

Standards: EN ISO 13849-1, EN 62061

PL: up to e

Control category: up to 4

PFH value: 6.19 x 10-9 / h

SIL: up to 3

Service life: 20 years

2.9 Functions

The system consists of a receiver and a transmitter. For the described

functions, no further switching elements are required. For the

diagnostics and function selection, a PC-software is offered as an

accessory.

For the diagnostics or the setting of parameters with a PC, the BUS

converter NSR-0801 is required (not included in scope of delivery).

The system has the following features:

• Protective mode (automatic start after release of the protection field)

• Start interlock

• Restart Interlock (manual reset)

• Contactor control (EDM)

• Beam coding

• Blanking of fixed protection field areas

• Blanking of movable protection field areas

Factory setting

The system features many functions without needing any additional

devices. The following table gives an overview of the possible functions

and the factory settings configuration.

Function Factory

setting

Configuration

Protective mode not active External wiring

Restart interlock

(manual reset)

not active External wiring

Blanking

fixed/floating

not active With BUS converter

NSR-0801 and PC-software

Contactor control

(EDM)

not active With BUS converter

NSR-0801 and PC-software

Start interlock not active With BUS converter

NSR-0801 and PC-software

Beam coding A not active With BUS converter

NSR-0801 and PC-software

2.9.1 Protective mode

The protective mode switches the OSSD outputs to ON state

(protection field not interrupted), without external release of a switching

device. The protected operation is activated with an electrical

connection between pin 1 and pin 6 of the receiver

This type of protection generates an automatic restart of the machine if

the protection field is not interrupted.

This operating mode may only be chosen in conjunction

with the restart interlock (manual reset) of the machine.

This operating mode must not be chosen, when persons

can step behind the protection field.

With a new start of the system a 24 VDC H signal on the

input of pin 1 causes the operating mode to change to the

setting mode.

2.9.2 Restart interlock (manual reset)

The restart interlock (manual reset) prevents an automatic enabling of

the outputs (OSSD's ON state) after switch-on of the operating voltage

or an interruption of the protection field. The system switches the

outputs only to ON state, when an external command device (restart

button) generates an enabling signal at the restart input (receiver).

The operating mode restart interlock is activated with an electrical

connection between pin 5 and pin 6 on the receiver.

The command devices (enabling button) must be installed

outside of the hazardous area. The hazardous area must be

easily visible to the user.

By default neither the restart interlock (manual reset) nor

the protective mode is active. You must choose one of

both operating modes to enable the OSSD outputs. If no

type of protection is selected, you will obtain the following

signalisation through the LED status indication in the

receiver:

LED OSSD OFF (red) + LED restart (yellow) flashing

2.9.3 Fixed blanking SLC 420

The SLC 420 can blank stationary parts in the protection field.

Multiple protection field areas can be blanked. If small changes

are made within the fixed blanking area, each time 1 beam can be

additionally blanked to increase the tolerance. Refer to the chapter

"Floating blanking".

Fixed blanking area

E1 R1

The range of the fixed blanking can be arbitrarily chosen in the

protection field.

The first beam line, which realises the optical synchronisation and is

located immediately behind the diagnostic window, cannot be blanked.

The area of the fixed blanking must not be modified after the teachin process. Any change of the area or removal of the part from the

protection field will be detected by the system. As a result, the outputs

are disabled (locked). This locking can be neutralised by executing a

new teach-in process in accordance with the actual beam interruptions.

The function is activated by means of the NSR-0801 BUS

converter and a PC or laptop. If the function is activated, the

LED blanking in the diagnostic window of the receiver starts

flashing.

• The remaining lateral areas must be protected against

intrusion by means of mechanical covers.

• The lateral covers must be fixed with the object.

• Partial covers are not authorised.

• After the fixed blanking, the protection field must be tested

by means of the test rod.

• The restart interlock function of the safety light curtain or

the machine must be activated.

6

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

2.9.4 Floating blanking SLC 420

The SLC 420 can blank movable parts in the protection field.

Cylinder for material ejection

The function enables an arbitrary floating blanking of partial areas in the

protection field. The first beam, which is located immediately behind

the diagnostic window, cannot be blanked.

The SLC 420 can blank one or more beams in the protection field. A

combination of fixed and floating blanking is possible.

This function allows for an interruption of the protection height without

the outputs being disabled in case of material movement in the

protection field, e.g. material ejection or process-controlled material

movement. In this way, the physical resolution changes into an effective

resolution. This effective resolution must be used to calculate the

safety distance. Use formula (1) to calculate the safety distance with

the effective resolution if a maximum of 2 light beams are blanked; use

formula (3) indicated in the "Safety distance" chapter if more than 2 light

beams are blanked.

The number of beams to be blanked is limited by the software, see

Table Effective resolution.

In a system with a physical resolution of 14 mm, the effective resolution

changes to a value of 34 mm with floating blanking of two beams. The

effective resolution must be permanently known and well visible on the

information label of the receiver.

The muting is configured using the BUS converter

NSR-0801 and a PC / Laptop. If the function is activated,

the LED blanking in the diagnostic window of the receiver

starts flashing.

Perform a new calculation of the safety distance with the

effective resolution. Adjust the safety distance in accordance

with your calculation.

The Standard IEC/TS 62046 describes the measures that

may be necessary to protect persons from hazards due to

protected areas that are blanked.

2.9.5 Floating blanking SLG 420

The SLG 420 can blank movable objects in the protection eld.

4

3

2

1

R1E1

The function of floating blanking is allowed for only one beam taking

into consideration the protective function. This function can be used for

temporary beam suppression due to environmental conditions.

The first beam line, which realises the optical synchronisation and is

located immediately behind the diagnostic window, cannot be blanked.

The function is activated by means of the NSR-0801 BUS

converter and a PC or laptop. If the function is activated,

the LED blanking in the diagnostic window of the receiver

starts flashing.

• The blanking of beams is not available for an SLG 420

with 2 beams!

• The blanking of one beam at the most in the SLG 420

3-beam version or the SLG 420 4-beam version is available,

provided that the protective function is taken into account.

• The restart interlock (manual reset) function of the safety

light grid or the machine must be activated.

• The standard IEC/TS 62046 includes information, which

describes possibly required additional measures to prevent

a person from reaching a hazard through the blanking areas

of a protection field.

• After configuration, the protection field must be checked by

a responsible person by means of a test rod; in addition to

that, this person must compare the size of the blanked area

to the object size and if necessary provide for additional

covers or a larger distance of the safety guard with regard

to the hazardous point.

2.9.6 Contactor control (EDM)

The contactor control monitors the controlled switching elements

(auxiliary contacts of the contactors) of both outputs. This monitoring

is realised after each interruption of the protection field and prior to the

restart (enabling) of the outputs. In this way, malfunctions of the relays

are detected, e.g. contact welding or contact spring breakage. If the

light curtain detects a malfunctioning of the switching elements, the

outputs are locked, i.e. after elimination of the failure, a Power Reset is

required. The auxiliary contacts must only be connected, when the

function is activated!

After the solving of a fault, a system start must be

performed (voltage reset)

The contactor control is not activated upon delivery. This

function is activated by means of the NSR-0801 BUS

converter and a PC or laptop.

Activation of the contactor control (EDM) without software

The contactor control can be activated without PC software as of

firmware version 1.23, by means of cable bridges (refer to chapter

Parameterisation of the Contactor Control without PC software).

7

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

2.9.7 Start interlock

The start interlock prevents an automatic start of the machine when the

supply voltage is switched on. After enabling the start interlock - by the

one-time interruption of the protection field -, this protective function is

deactivated until the next power reset.

The start interlock is not activated upon delivery. This

function is activated by means of the NSR-0801 BUS

converter and a PC or laptop.

2.10 Self-test

The system performs a complete self-test within 2 seconds after the

operating voltage has been switched on. If the protection field is not

interrupted, the system switches to the ON condition. In case of an

error, the outputs at the receiver do not switch to the ON state. The LED

OSSD OFF starts flashing, thus emitting an error message. For more

information, refer to chapter Fault diagnosis.

During operation, the system continuously executes a self-test. Safetyrelevant faults are detected within the cycle time and cause the outputs

to be switched off.

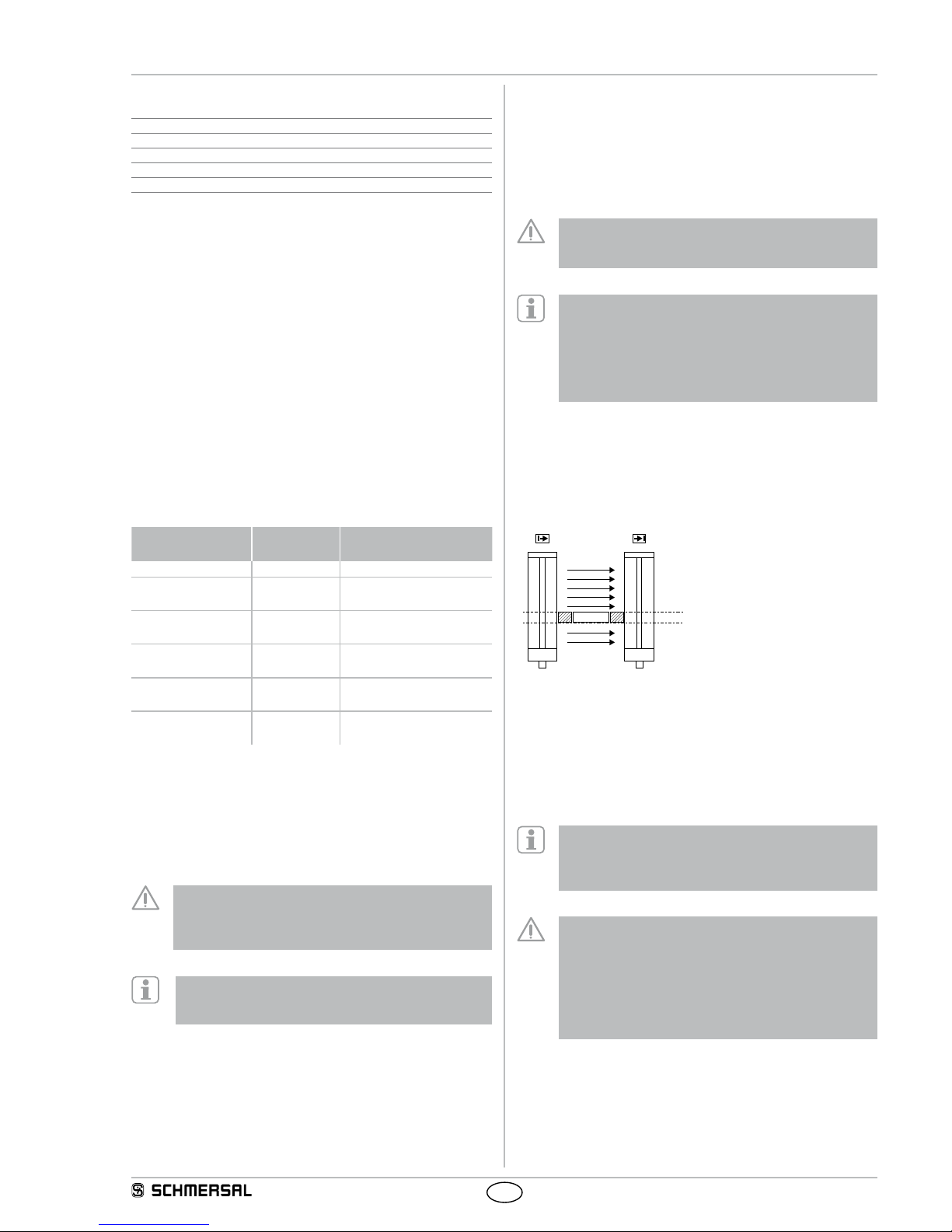

2.11 Beam coding A

The beam coding of the safety light curtain must be adjusted, when

systems operating in each other's vicinity and a set-up as shown in

the image below (no interference) is impossible. With beam coding

A, a receiver can distinguish the beams of the transmitter with the

same beam coding A, which are destined to this particular receiver,

from foreign beams. The beam coding A must be set for each sensor

(receiver and transmitter) individually. The function is activated by

means of the NSR-0801 BUS converter and a PC or laptop.

If adjacent systems are operated without beam coding A,

the user is at risk.

EERR

No interference

ERRE

Interference:

beam coding A required!

• The beam coding A avoids mutual interference of adjacent systems.

• The beam coding A is permanently shown by the transmitter and the

receiver by means of flashing LED's (refer to LED status information).

The response time of the system is increased when beam

coding A is used. To this end, the safety distance must be

adjusted to the hazardous movement. Refer to chapter

Response time.

3. Mounting

3.1 General conditions

The following guidelines are provided as a preventative warning notice

to ensure safe and appropriate handling. These guidelines are an

essential part of the safety instructions and therefore must always be

observed and respected.

• The SLC must not be used on machines, which can be

stopped electrically in case of emergency.

• The safety distance between the SLC and a hazardous

machine movement must always be observed and respected.

• Additional mechanical safety guards must be installed so that

the operator has to pass by the protection field to reach the

hazardous machine parts.

• The SLC must be installed so that the personnel always must

be within the detection zone when operating the machine. An

incorrect installation can lead to serious injuries.

• Never connect the outputs to +24VDC. If the outputs are

wired to +24VDC, they are in ON state, as a result of which

they are unable to stop a hazardous situation occurring on the

application/machine.

• The safety inspections must be conducted regularly.

• The SLC must not be exposed to inflammable or explosive

gasses.

• The connecting cables must be connected in accordance with

the installation instructions.

• The fixing screws of the end caps and the mounting angle

must be firmly tightened.

3.2 Protection field and approach

The protection field of the SLC consists of the entire range located

between the protection field markings of transmitter and receiver.

Additional protective devices must ensure that the operator has to pass

by the protection field to reach the hazardous machine parts.

The SLC must be installed so that personnel are always located within

the detection zone of the safety device when operating the hazardous

machine parts to be secure.

8

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

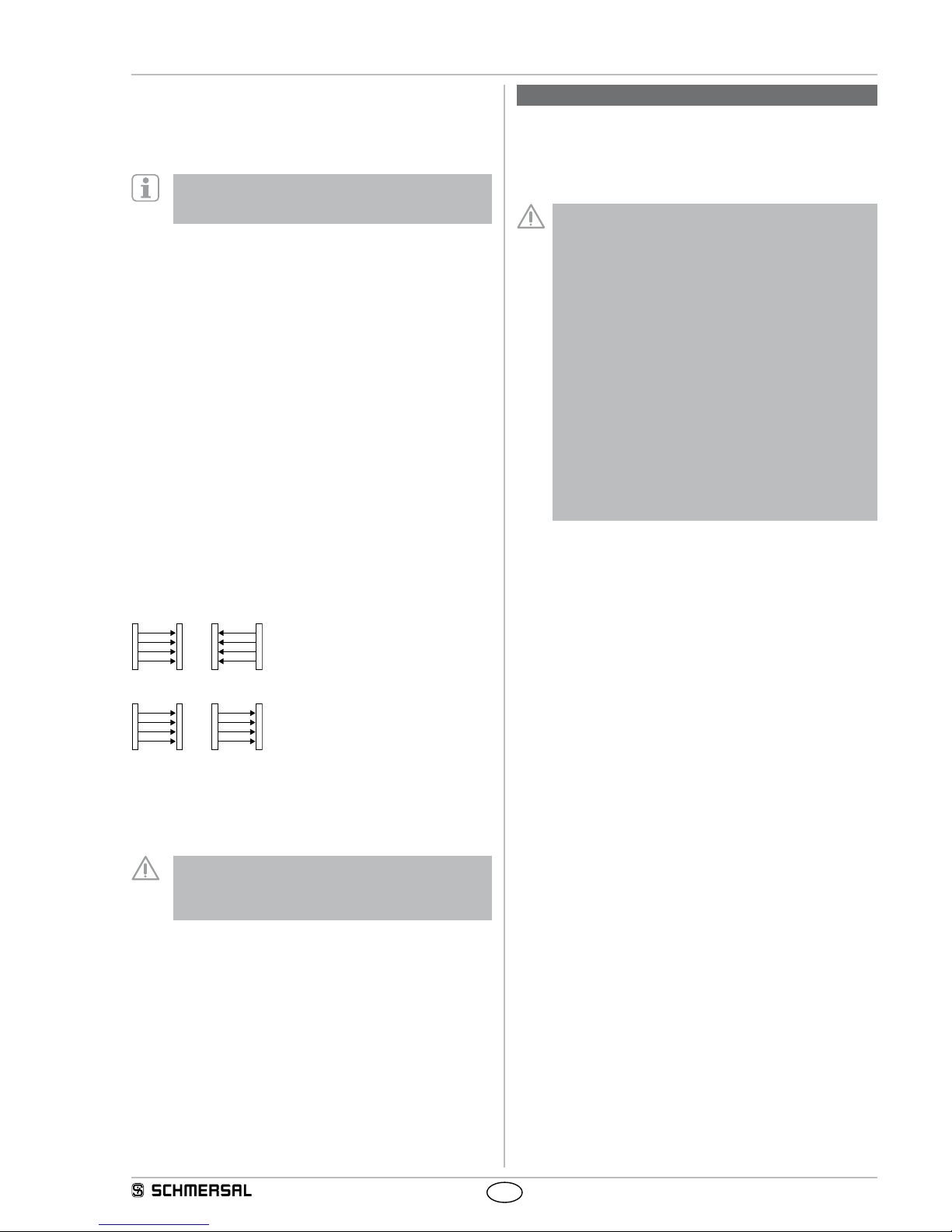

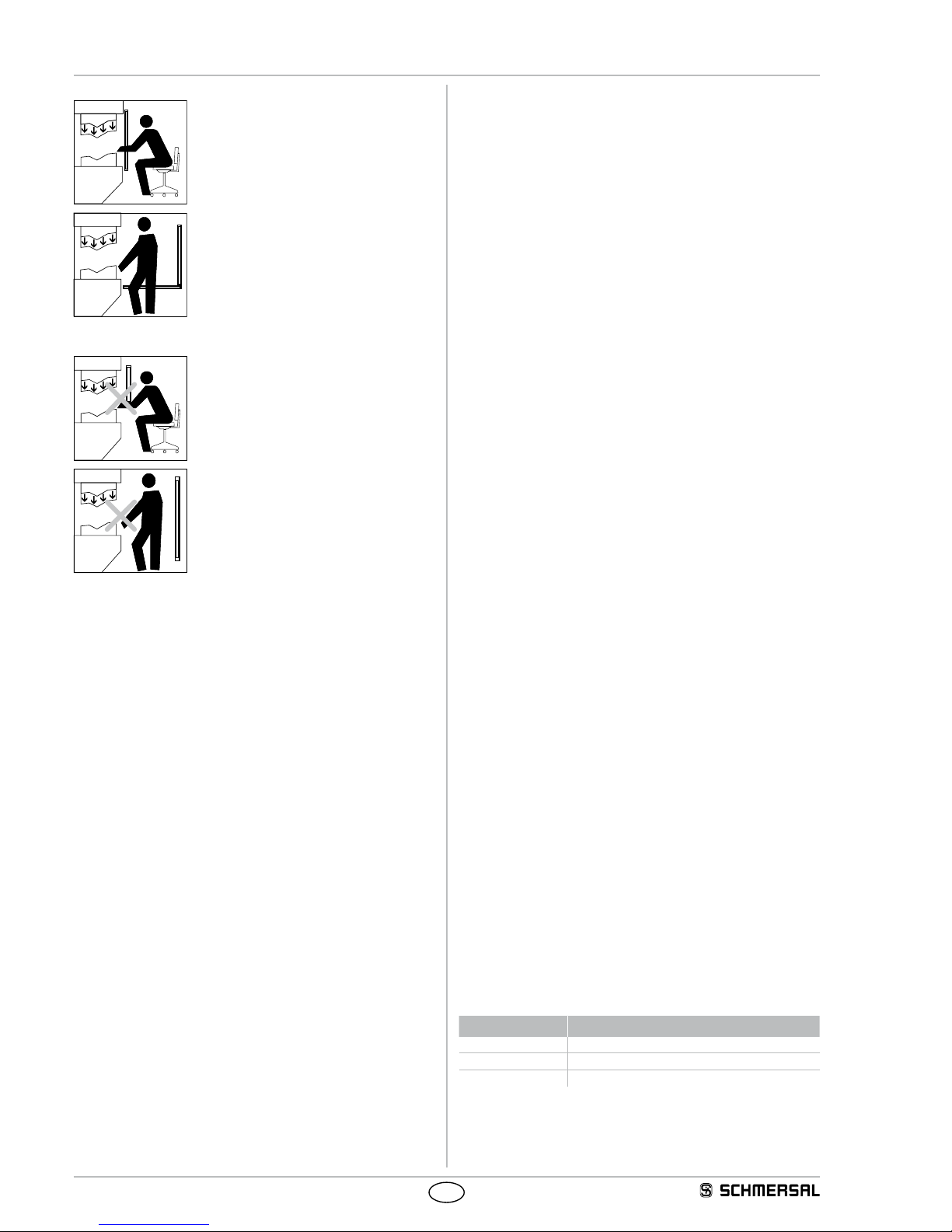

Correct installation

Hazardous machine parts can only be reached

after passing through the protection field.

Persons between the protection field and

hazardous machine parts must be prevented

(protection against stepping over).

Unauthorised installation

Hazardous machine parts can be reached

without passing through the protection field.

Persons between the protection field and

hazardous machine parts is enabled.

3.3 Alignment

Procedure in automatic operating mode:

1. The transmitter and the receiver must be fitted parallel to each other

and at the same height.

2. Turn the transmitter and monitor the diagnostic window of the

receiver. Fix the light curtain, when the LED OSSD ON (green) is on

and the LED signal reception (orange) is off.

3. Determine the max. rotating angle to the left and to the right, at which

the LED OSSD ON (green) is on and tighten the mounting screws in

central position. Make sure that the LED signal reception (orange) is

not on or flashing.

3.4 Setting mode

The alignment of the sensors is carried out using the setting mode.

Activating setting mode

If +24 V is on the input (pin 1, receiver) "Release restart interlock" at

system start for at least two seconds (by pressing the button restart),

the system changes over to the setting mode of operation.

The signal strength at the receiver is indicated with the signal strength

LED (colour orange) through light pulses. The better the alignment, the

higher the frequency of the light pulses. The alignment is optimal when

the light pulses switch over to continuous light.

If there is no optical synchronisation between the transmitter and the

receiver, a light pulse is emitted every 3 seconds. The setting mode is

ended by a system start ( +UB OFF/ON).

Additional signalling with the SLG 420 by the status light

In this mode the signal strength of the beam is signalled to the status

indicator with the lowest value through light pulses (colour yellow).

The better the alignment, the higher the frequency of the light

pulses. The alignment is correct when the light pulses switch over to

continuous light.

3.5 Safety distance

The safety distance is the minimum distance between the protection

field of the safety light curtain and the hazardous area. The safety

distance must be observed to ensure that the hazardous area cannot

be reached before the hazardous movement has come to standstill.

Calculation of the safety distance to EN ISO 13855

The safety distance depends on the following elements:

• Stopping time of the machine (calculation by run-on time

measurement)

• Response time of the machine and the safety light curtain and the

downstream relay (entire safety guard)

• Approach speed

• Resolution of the safety light curtain

• Vertical or horizontal installation

Safety light curtain SLC 420

The safety distance for resolutions 14 mm up to 40 mm (vertical

installation) is calculated by means of the following formula:

(1) S = K x T + C [mm]

S = Safety distance [mm]

K = Approach speed 2000 mm/s

T = Total reaction time (machine run-on time, reaction time of the safety

guard, relays, etc.)

d = Resolution of the safety light curtain

C = additional distance depending on the resolution,

C = 8 (d - 14) [mm]

If value S <= 500 mm after the calculation of the safety distance, then

use this value.

If the value S >= 500 mm then redetermine the distance S using an

approach speed K of 1600 mm/s:

(2) S = 1600 mm/s * T + 8 (d - 14) [mm]

If the new value S > 500 mm, use this value as safety distance.

If the new value S < 500 mm, use a minimum distance of S = 500 mm.

Example:

Reaction time of the safety light curtain = 10 ms

Resolution of the safety light curtain = 14 mm

Stopping time of the machine = 330 ms

S = 2000 mm/s * (330 ms + 10 ms) + 8(14 mm - 14 mm)

S = 680 mm

S = > 500 mm, therefore new calculation with K = 1600 mm/s

S = 544 mm

Calculation of the safety distance for SLG 420 and SLC 420 with a

resolution d > 40 mm

(3) S = ( 1600 mm/s * T ) + 850 mm

S = Safety distance [mm]

T = Stopping time of the machine + reaction time of the

safety light curtain

K = Approach speed 1600 mm/s

C = Additional distance 850 mm

The following mounting heights must be observed:

Number of beams Mounting height above reference level in mm

2 400, 900

3 300, 700, 1100

4 300, 600, 900.1200

9

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

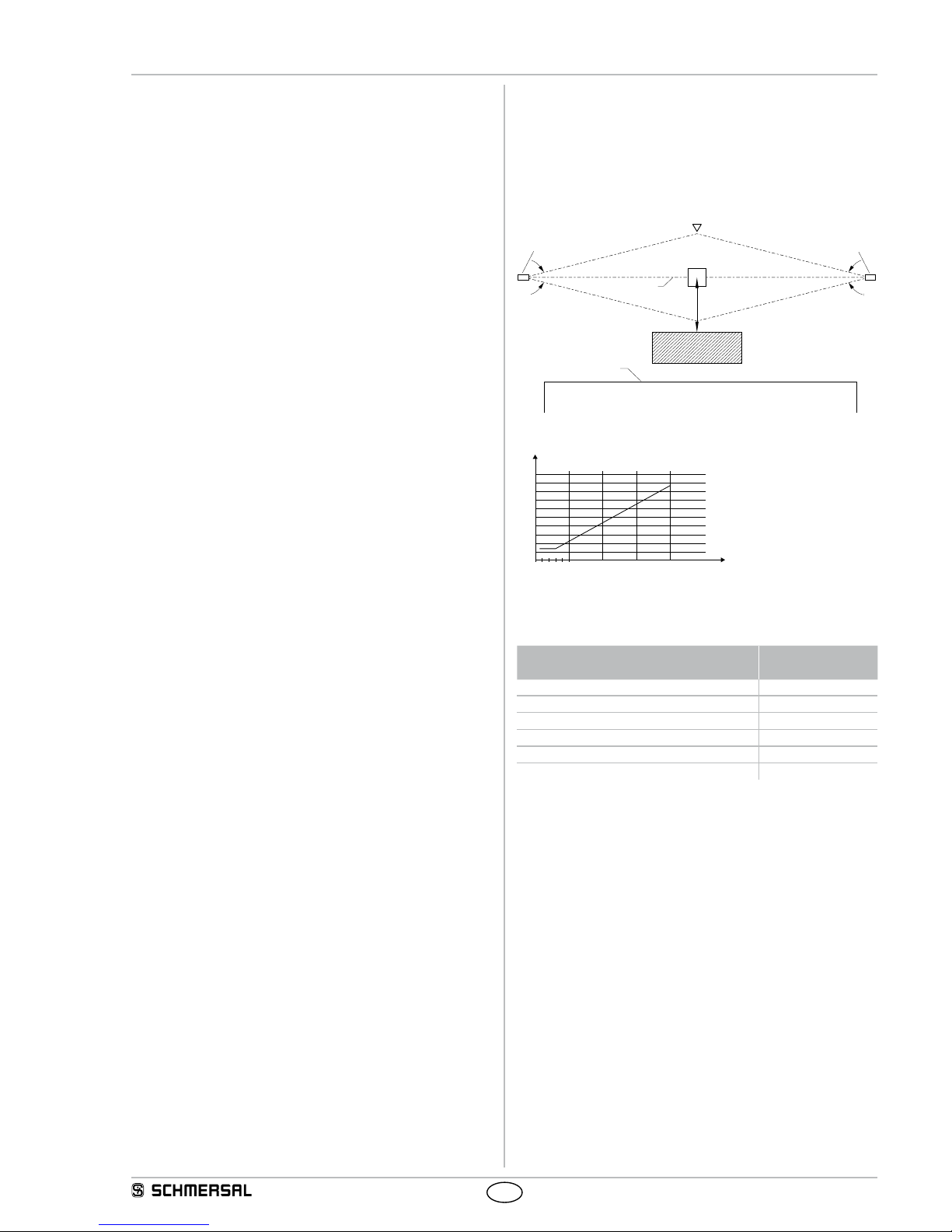

Safety distance to the hazardous area

S

Hazardous

point

Transmitter

Receiver

Command device

Authorised operation

Mechanical protection

Direction from which

the hazardous area

is accessed

The safety distance between the safety light curtain and the

hazardous point must always be respected and observed. If

a person reaches the hazardous point before the hazardous

movement has come to a standstill, he or she is exposed to

serious injuries.

Safety distance to the hazardous area

Limit of the hazardous point

Safety distance (S)

Protection field

marking

Tool - upper part

Signal to stop the

hazardous movement

Standstill of the

hazardous movement

t

n

= tB - t

A

Tool - lower part

t

A

S

t

B

≤ 75 mm = max. distance for protection against stepping over

To prevent persons from stepping over the protection field this dimension must be

imperatively respected and observed.

The formulae and calculation examples are related to the vertical set-up

(refer to drawing) of the light curtain with regard to the hazardous point.

Please observe the applicable harmonised EN standards and possible

applicable national regulations.

To calculate the minimum distances of the safety guards with

regards to the hazardous point, the EN ISO 13855 must be

observed.

If reaching through the protection field is possible, take care

with the calculation of the safety distance and add an amount

as per norm EN ISO 13855.

The norm EN ISO 13855 defines two types of safety distances,

- Access through the protection area with an additional distance C,

according to the resolving power

- Access over the protection area with an additional distance CRO

according to table 1

If it is possible to reach through the hazardous area (vertical alignment)

then both values C and C

RO

have to be determined. The larger of the

two values is to be used for calculating the safety distance. Calculating

the safety distance with CRO:

S

CRO

= K x T + C

RO

K = Approach speed

T = Total reaction time (machine run-on time, reaction time of the safety

guard, relays, etc.)

CRO = Additional distance due to reaching through the hazardous area

with parts of body, see table 1 for value

1

2

3

KxT

S

RO

C

RO

a

b

1 Safety sensor

2 Hazardous point

3 Floor

a Height of the hazardous point

b Height of the topmost beam of the safety sensor

10

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

Reaching through the protective area of a non-contact functioning guard system (extract EN ISO 13855)

Height of the

hazardous point

a [mm]

Height b of the upper edge of the protection area of the non-contact functioning guard system

900 1000 1100 1200 1300 1400 1600 1800 2000 2200 2400 2600

Additional distance CRO to the hazardous area [mm]

2600 0 0 0 0 0 0 0 0 0 0 0 0

2500 400 400 350 300 300 300 300 300 250 150 100 0

2400 550 550 550 500 450 450 400 400 300 250 100 0

2200 800 750 750 700 650 650 600 550 400 250 0 0

2000 950 950 850 850 800 750 700 550 400 0 0 0

1800 1100 1100 950 950 850 800 750 550 0 0 0 0

1600 1150 1150 1100 1000 900 850 750 450 0 0 0 0

1400 1200 1200 1100 1000 900 850 650 0 0 0 0 0

1200 1200 1200 1100 1000 850 800 0 0 0 0 0 0

1000 1200 1150 1050 950 750 700 0 0 0 0 0 0

800 1150 1050 950 800 500 450 0 0 0 0 0 0

600 1050 950 750 550 0 0 0 0 0 0 0 0

400 900 700 0 0 0 0 0 0 0 0 0 0

200 600 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0

Schedule 1

a = Height of the hazard spot [mm]

b = Height of the upper edge of the protection area of the AOPD

CRO = Additional distance to the hazardous area [mm]

Determination of the additional distance CRO from the table:

1) Locate the height of the upper edge of the hazardous area a (left table column)

2) Locate the height of the protection area b (upper table row)

3) CRO is to be taken from the crossing point of both exes

If the known value for a and b is between the table values, the next higher value is to be used.

11

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

Example: Calculation of the safety distance, vertical installation

Total response time T = 220 ms, resolving capability d = 30 mm, height

of the hazardous area 1400 mm, height of the protection area above

the floor 1600 mm

S = K * T + C = 2000 mm/s * 220 ms + 8 (30 -14) = 568 mm

(S > 500 mm, following K = 1600 mm/s)

S = K * T + C = 1600 mm/s * 220 ms + 8 (30 -14) = 480 mm

(S < 500 mm, following S = 500 mm) S = 500 mm

Safety distance C

RO

S

CRO

= K x T + CRO = 1600 mm/s x 220 ms + 650 mm = 1002 mm

S

CRO

> S i.e.

Safety distance S = 1002 mm

If the safety distance of 1002 mm is too large for the application, the

protection field height can be increased from 1600 mm to 1800 mm, this

makes the value CRO = 0 mm (table 1).

Result: By adjusting the protection field height to the value

1800 mm above the floor results in a safety distance: S = 500 mm

3.5.1 Minimum distance to reflecting surfaces

During the installation, the effects of reflecting surfaces must be taken

into account. In case of an incorrect installation, interruptions of the

protection field could possibly not be detected, which could lead to

serious injuries. The hereafter-specified minimum distances with regard

to reflecting surfaces (metal walls, floors, ceilings or parts) must be

imperatively observed.

8° 8°

a= 262 mm

Access direction

Receiver

Obstacle

Optical axis

Transmitter

Reflecting body

(e.g. Material container)

Limit of the

hazardous point

a=130mm

5° 5°

Safety distance a

a [mm]

D [m]

03510

100

200

300

400

500

600

700

800

900

1000

15 20

Calculate the minimum distance to reflecting surfaces as a function of

the distance with an aperture angles of ± 2.5° degrees or use the value

from the table below:

Distance between transmitter and receiver

[m]

Minimum distance a

[mm]

0.2 … 3.0 130

4 175

5 220

7 310

10 440

15 660

Formula: a = tan 2.5° x L [mm]

a = Minimum distance to reflecting surfaces

L = Distance between transmitter and receiver

12

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

3.6 Dimensions

3.6.1 Dimensions transmitter and receiver SLC 420 (Standard)

All measurements in mm.

49,6

48,7

42

31,5

6

80

86

A

B

C

Type A

Protected

height

B

Mounting

dimension

C

Total

lenght

SLC420-E/R0170-XX-RFB 170 288 324

SLC420-E/R0250-XX-RFB 250 368 404

SLC420-E/R0330-XX-RFB 330 448 484

SLC420-E/R0410-XX-RFB 410 528 564

SLC420-E/R0490-XX-RFB 490 608 644

SLC420-E/R0570-XX-RFB 570 688 724

SLC420-E/R0650-XX-RFB 650 768 804

SLC420-E/R0730-XX-RFB 730 848 884

SLC420-E/R0810-XX-RFB 810 928 964

SLC420-E/R0890-XX-RFB 890 1008 1044

SLC420-E/R0970-XX-RFB 970 1088 1124

SLC420-E/R1050-XX-RFB 1050 1168 1204

SLC420-E/R1130-XX-RFB 1130 1248 1284

SLC420-E/R1210-XX-RFB 1210 1328 1364

SLC420-E/R1290-XX-RFB 1290 1408 1444

SLC420-E/R1370-XX-RFB 1370 1488 1524

SLC420-E/R1450-XX-RFB 1450 1568 1604

SLC420-E/R1530-XX-RFB 1530 1648 1684

SLC420-E/R1610-XX-RFB 1610 1728 1764

SLC420-E/R1690-XX-RFB 1690 1808 1844

SLC420-E/R1770-XX-RFB 1770 1888 1924

3.6.2 Dimensions transmitter and receiver SLG 420 (Standard)

All measurements in mm.

L2

42

L1

51

B

C

31;5

A

97

86

49,6

48,7

6

80

Type A

Beam

distance

B

Mounting

dimension

C

Total

lenght

L1 L2

SLG420-E/R0500-02-RF 500 648 684 349 303

SLG420-E/R0800-03-RF 400 948 984 249 203

SLG420-E/R0900-04-RF 300 1088 1124 209 203

L1 = Mounting distance (mm) between floor and slotted hole centre

(short end cap)

L2 = Mounting distance (mm) between floor and slotted hole centre

(diagnostic window)

13

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

3.6.3 Dimensions transmitter and receiver SLC 420 IP69K

All measurements in mm.

60

B

80

A

C

D

42

91

54

Type A

Protec-

ted

height

B

Sensor

length

C

Mounting

dimension

D

Total

length

SLC420-E/R0170-xx-69-RFB 170 267 315 351

SLC420-E/R0250-xx-69-RFB 250 347 395 431

SLC420-E/R0330-xx-69-RFB 330 427 475 511

SLC420-E/R0410-xx-69-RFB 410 507 555 591

SLC420-E/R0490-xx-69-RFB 490 587 635 671

SLC420-E/R0570-xx-69-RFB 570 667 715 751

SLC420-E/R0650-xx-69-RFB 650 747 795 831

SLC420-E/R0730-xx-69-RFB 730 827 875 911

SLC420-E/R0810-xx-69-RFB 810 907 955 991

SLC420-E/R0890-xx-69-RFB 890 987 1035 1071

SLC420-E/R0970-xx-69-RFB 970 1067 1115 1151

SLC420-E/R1050-xx-69-RFB 1050 1147 1195 1231

SLC420-E/R1130-xx-69-RFB 1130 1227 1275 1311

SLC420-E/R1210-xx-69-RFB 1210 1307 1355 1391

SLC420-E/R1290-xx-69-RFB 1290 1387 1435 1471

SLC420-E/R1370-xx-69-RFB 1370 1467 1515 1551

SLC420-E/R1450-xx-69-RFB 1450 1547 1595 1631

3.6.4 Dimensions transmitter and receiver SLG 420 IP69K

All measurements in mm.

80

104

A

C

D

B

60

42

A1

Type A

Beam

dis-

tance

A1

Beam

posi-

tion

B

Sen-

sor

length

C

Mounting

dimensi-

on

D

Total

length

SLG420-E/R0500-02-69-RF 500 71 627 675 711

SLG420-E/R0800-03-69-RF 400 71 927 975 1011

SLG420-E/R0900-04-69-RF 300 111 1067 1115 1151

14

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

3.7 Scope of delivery and accessories

3.7.1 Included in delivery

Test rod PLS

The test rod, according to the resolution is used for testing the

protection field.

Mounting kit MS-1030 (SLC/SLG 420 Standard)

The mounting kit consists of 4 steel angles and 16 fixing screws.

14,5

42

18,9

20

6,5

40

32

52

Mounting kit MS-1038 (SLC/SLG 420 IP69K)

The mounting kit consists of 4 pcs V4A stainless steel brackets

and 16 pcs V4A fastening screws

14,5

42

18,9

20

6,5

40

32

52

21

¤5,5

Integrated status indication (only SLG 420)

The status indication at the receiver indicates the switching condition of

the outputs OSSD1 and OSSD2.

Green = Outputs in ON state (H-signal 24V)

Red = Outputs in OFF state (L-signal 0V)

Yellow = Restart Interlock released / Setting mode

18

30

¤

20

3.7.2 Optional accessories

Centre fixing MS-1051

Mounting kit consists of 2 steel angles, 4 screws and 4 T-slot nuts for

central fixing

40

42

20

14,5 18,9

32

20

38

Connecting cable for transmitter

Item Number Designation Description Length

1207741 KA-0804 Female connector M12,

4-pole

5 m

1207742 KA-0805 Female connector M12,

4-pole

10 m

1207743 KA-0808 Female connector M12,

4-pole

20 m

Connecting cable for Receiver

Item Number Designation Description Length

1207728 KA-0904 Female connector M12,

8-pole

5 m

1207729 KA-0905 Female connector M12,

8-pole

10 m

1207730 KA-0908 Female connector M12,

8-pole

20 m

BUS converter NSR-0801

Converter for parameterisation and diagnostics. Detailled information

can be found in the operating instructions manual of the NSR-0801.

Included in delivery: integrated connecting cable, PC-software USB 2.0

connection (L x W x H, 122 x 60 x 35 mm), dimensions exclude cable.

MSD4 Vibration damper

Kit consisting of: 8 vibration dampers 15 x 20 mm, 8 cylinder head

screws M5 with hexagon socket, 8 spring washers

The MSD4 vibration damper kit is recommend to be used for damping

vibrations and oscillations (such as presses and stamps) on the

SLC/SLG. In this way, the availability of the SLC/SLG is increased.

15

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

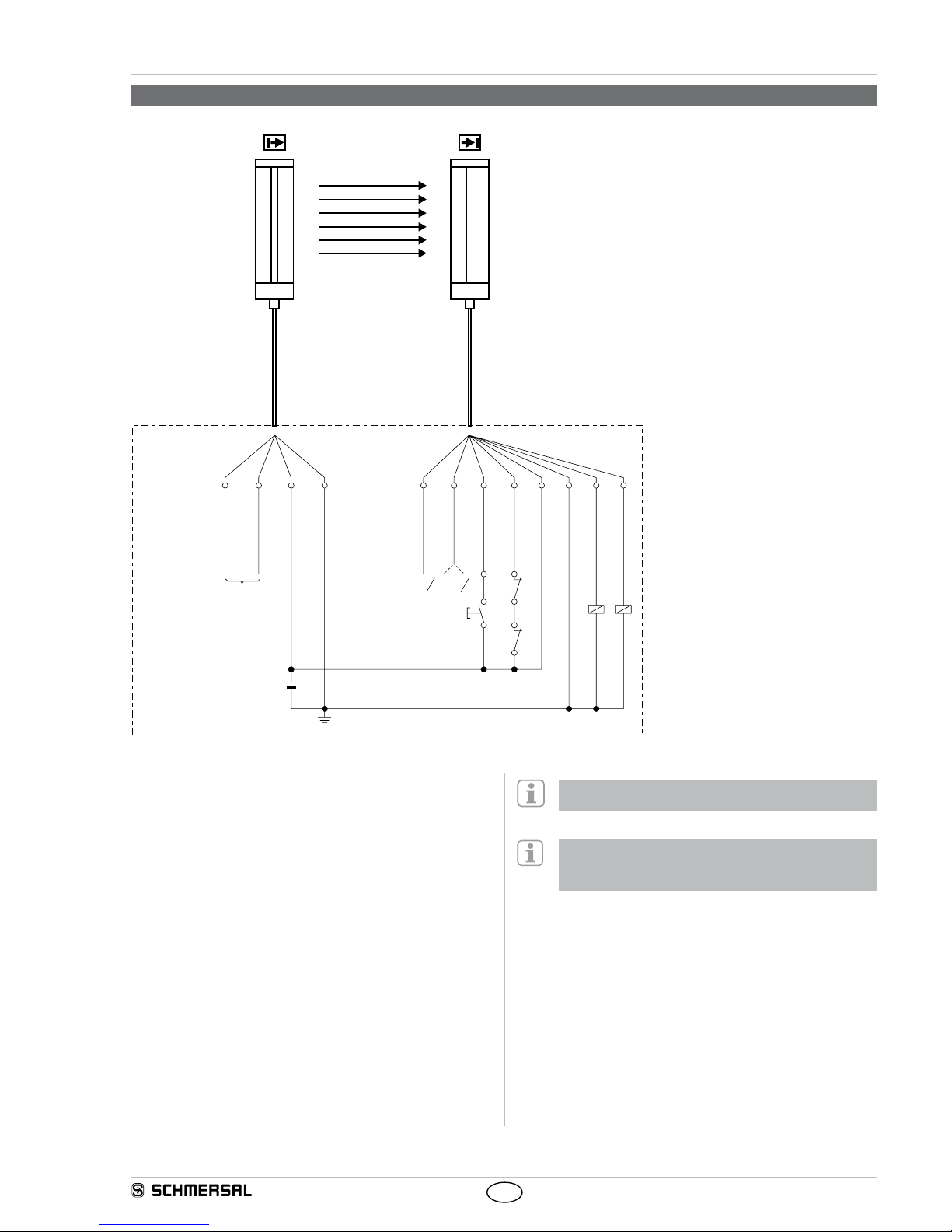

4. Electrical connection

4.1 Wiring example default

5

Kn 1

Kn 2

S 1

K1 K2

6

1

8

2

7

3

4

Schützkontrolle/EDM(RD)

DIAG IN (WH)

DIAG IN (GY)

DIAG OUT (PK)

Freigabe WA (WH)

DIAG OUT (BK)

0 V DC (BU)

0 V DC (BU)

OSSD 1 (GN)

OSSD 2 (YE)

+24 V DC (BN)

+24 V DC (BN)

Brücke 1

Brücke 2

Erdung

E1

Nur für Diagnose

1

2

3

4

DIAG IN (WH)

DIAG OUT (BK)

Only for Diagnostic

DIAG IN (GY)

Bridge 1

DIAG OUT (PK)

+24 VDC (BN)

0 VDC (BU)

Release/restart

interlock (WH)

Bridge 2

+24 VDC (BN)

Contactor control/EDM (RD)

OSSD 2 (YE)

OSSD 1 (GN)

0 VDC (BU)

Earth connection

Restart interlock (manual reset) (bridge 1)

By bridging DIAG IN (pin 5) and DIAG OUT (pin 6), the restart interlock

(manual reset) is activated.

Protective mode (bridge 2)

By bridging DIAG OUT (pin 6) and enable (pin 1), the automatic

protective mode is activated. Do not connect S1.

K1, K2: Relay for processing the switching outputs

OSSD 1,OSSD 2

Kn1, Kn2: Auxiliary contacts of the last switching relay (optional)

signals at input EDM (pin 8): only to be connected when

the function is activated

S1: Command device for restart (optional)

E1: Power supply 24 VDC +/-10%

For proper functioning, the operating mode restart interlock

or operating mode automatic is to be wired.

Upon delivery, the "contactor control" function is deactivated.

The function is activated by means of the NSR0801 BUS

converter and the PC software.

16

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

4.2 Activation of the contactor control (EDM) without PC software

The contactor control can be activated without PC software as of

firmware version 2.0 in diagnostic mode by means of cable bridges.

To activate the EDM function without PC software, proceed in the

following way:

Establish the connections in accordance with the wiring diagram,

see below.

Both outputs OSSD1 and OSSD2 of the light curtain must be

separated from the machine control.

S1

E1

24VDC

27

13

4

The parameter configuration EDM is activated for at least 2 seconds

when the system starts if there is a wire link between OSSD 1 ➔ OSSD2

and a +24V level on the input restart interlock.

The active operating mode parameterisation is signalled by the cyclical

changing of the red, yellow and green LEDs until the restart interlock

button is no longer being pressed.

The parameterisation can now be made by pressing the button.

• If the red and greed LEDs flash at the same time, this indicates that

the EDM function is active, if only the red LED flashes then the EDM

function is not active.

• Holding down the button from 2.5 to 6 seconds changes the state of

the EDM function between active and not active and saves the current

selection.

After the parameterisation, the link OSSD1 ➔ OSSD2 is to be removed

and a system start is to be carried out (+ 24V, OFF/ON). If the EDM

function is parameterised with the wire link, the max. value of 500 ms is

set for the signal delay. This value can be adjusted using the PC software

/ NSR-0801.

If the parameterisation is missing the process can be repeated.

4.3 Connector configuration Receiver, Transmitter & Cable

RECEIVER

SLC: Connector

male M12 / 8 pol.

Signal

Designation Description

5

8

4

3

2

1

7

6

1 WH Restart Input

2 BN 24 VDC Power supply

3 GN OSSD 1 Safety output 1

4 YE OSSD 2 Safety output 2

5 GY Diagnostic IN Input diagnostic data

6 PK Diagnostic OUT Output Diagnostic data

7 BU 0 VDC Power supply

8 RD Contactor

control EDM

Input

Cable: Connector

female M12 / 8 pole

5

8

4

3

2

1

7

6

TRANSMITTER

SLC: Connector

male M12 / 4 pol.

Signal

Designation Description

3

2

1

4

1 BN 24 VDC Power supply

2 WH Diagnostic IN Input diagnostic data

3 BU 0 VDC Power supply

4 BK Diagnostic OUT Output Diagnostic data

Cable: Connector

female M12 / 4 pole

3

2

1

4

The colour codes are only valid for the cable types

mentioned below "optional accessories".

17

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

5. Set-up and maintenance

5.1 Check before start-up

Prior to start-up, the following items must be checked by the

responsible person.

Wiring check prior to start-up

1. If a power supply is used then it must comply with IEC 60449 PELV

and should be able to bridge a loss of power for at least 20 ms as

per EN 60204.

2. Presence of a voltage supply with correct polarity at the SLC.

3. The connecting cable of the transmitter is correctly connected to the

transmitter and the connecting cable of the receiver correctly to the

receiver.

4. The double insulation between the light curtain output and an

external potential is guaranteed.

5. The outputs OSSD1 and OSSD2 are not connected to +24 VDC.

6. The connected switching elements are not connected to the +24

VDC and do not exceed the allowable load on the safety output.

There are no short circuits between the safety switching outputs.

7. If two or more SLC are used within close range compared to each

other, an alternating arrangement must be observed. Any mutual

interference of the systems must be prevented.

Switch the SLC on and check the operation in the following way:

The component performs a system test during approx. 2 seconds after

the operating voltage has been switched on. After that, the outputs are

enabled if the protection field is not interrupted. The LED "OSSD ON"

at the receiver is on.

In case of incorrect functionality, please follow the instructions

listed in the chapter Fault diagnostic.

5.2 Maintenance

Do not use the SLC before the next inspection is

terminated. An incorrect inspection can lead to serious

and mortal injuries.

Conditions

For safety reasons, all inspection results must be archived. The

operating principle of the SLC and the machine must be known in order

to be able to conduct an inspection. If the fitter, the planning technician

and the operator are different persons, please make sure that the user

has the necessary information at his disposal to be able conduct the

maintenance.

5.3 Regular check

A regular visual inspection and functional test, including the following

steps, is recommended:

1. The component does not have any visible damages.

2. The optics cover is not scratched or soiled.

3. Hazardous machinery parts can only be accessed by passing

through the protection field of the SLC.

4. The staff remains within the detection area, when works are

conducted on hazardous machinery parts.

5. The safety distance of the application exceeds the mathematically

calculated one.

Operate the machine and check whether the hazardous movement

stops under the hereafter-mentioned circumstances.

6. Hazardous machine parts do not move when the protection field is

interrupted.

7. The hazardous machine movement is immediately stopped, when

the protection field is interrupted with the test rod immediately before

the transmitter, immediately before the receiver and in the middle

between the transmitter and the receiver.

8. No hazardous machine movement when the test rod is within the

protection field.

9. The hazardous machine movement comes to standstill, when the

voltage supply of the SLC is switched off.

5.4 Half-yearly inspection

The following items must be checked every six months or when a

machine setting is changed.

1. Machine stops or does not inhibit any safety function.

2. No machine modification or connection change, which affects the

safety system, has taken place.

3. The outputs of the SLC are correctly connected to the machine.

4. The total response time of the machine does not exceed the

response time calculated during the first putting into operation.

5. The cables, the connectors, the caps and the mounting angles are in

perfect condition.

5.5 Cleaning

If the optics cover of the sensors is extremely soiled, the OSSD outputs

can be disabled. Clean with a clean, soft cloth with low pressure.

The use of agressive, abrasive or scratching cleaning agents, which

could attack the surface, is prohibited.

18

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

6. Diagnostic

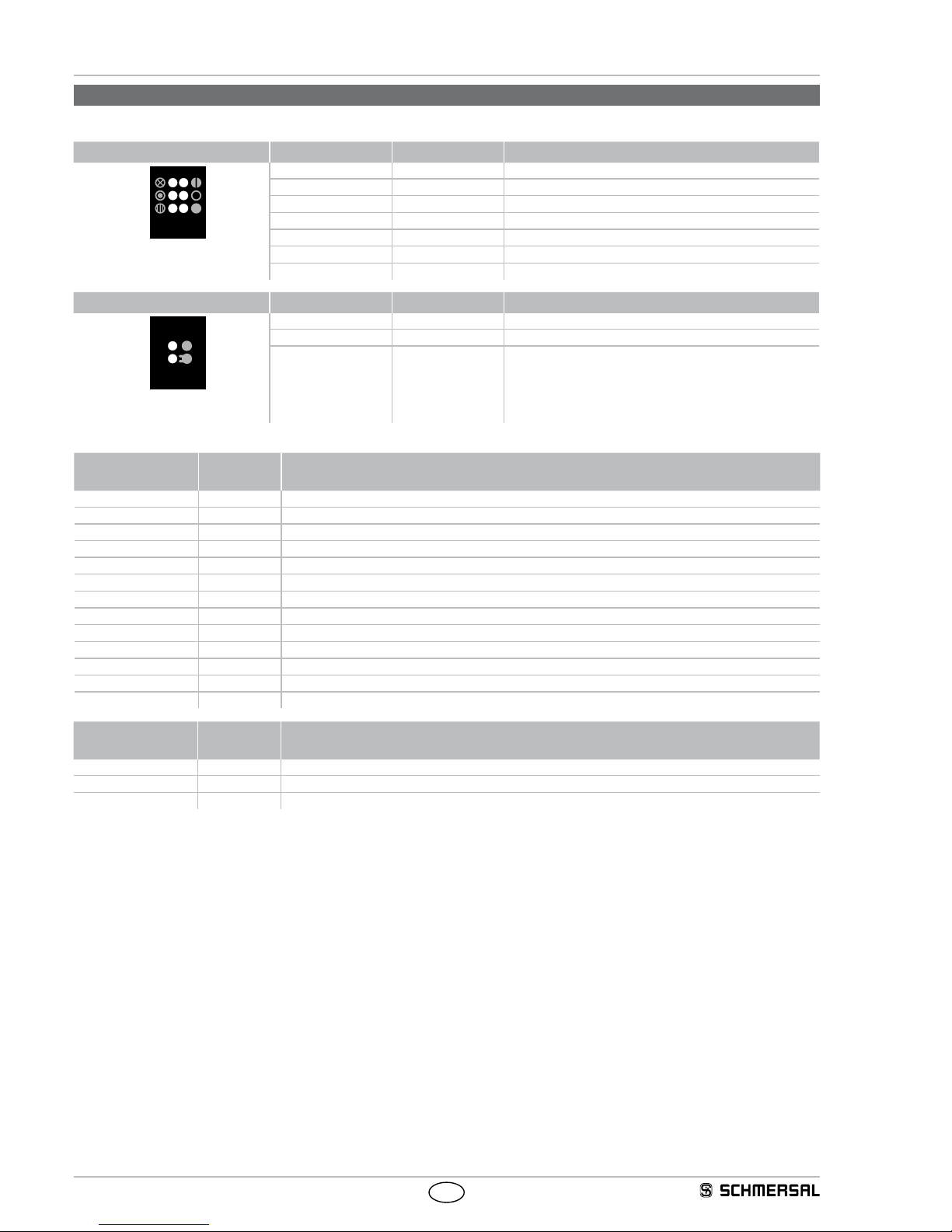

6.1 LED status information

Receiver Function LED colour Description

Multifunction

Blanking

Signal reception

Restart

OSSD OFF

OSSD ON

Protection

field

Multifunction yellow-green Function display, Beam coding

Blanking blue Protection field(s) inactive (blanking)

Signal reception orange Evaluation of the signal reception, signal quality set-up mode

Restart yellow Input for command device, AOPD is waiting for enable signal

OSSD OFF red Safety switching output in OFF state

OSSD ON green Safety switching output in ON state

Transmitter Function LED colour Description

Transmitting

Protection

field

Status

Transmitting orange Transmitter active

Status green Function display, Beam coding

Receiver

LED Status LED Description

OSSD ON On Protection field clear

flashing Diagnostic mode active

OSSD OFF On Safety switching output in OFF state

flashing Diagnostic mode active, error output refer to Fault diagnostic table

Restart On Start or restart interlock (manual reset) active, signal expected at input restart interlock

Signal reception ON/flashing Signal reception too low, check alignment and installation height between transmitter and receiver

Cleaning the black profile cover, set-up mode - signal state indicator

Blanking 1 flash Fixed blanking of the protection field(s)

2 flash Floating blanking, max. 1 beam

3 flash Floating blanking, more beams

4 flash Floating (max. 1 beam) and fixed blanking of protection field(s)

5 flash Variable (multiple beams) and fixed blanking of protection field(s)

Multifunction flashing Beam coding A is active

Transmitter

LED Status LED Description

Transmitting On Standard operation, transmitter active

flashing Configuration error

Status flashing Beam coding A is active

19

SLC 420

SLG 420

Operating instructions

Safety light curtain/safety light grid

EN

6.3 Extended diagnostic

By means of the optional SLC 420 configuration software and the

NSR-0801 BUS converter, an extended diagnostic can be executed.

The software provides the status information of the component and can

represent the individual light beams. This feature enables an optimal

adjustment of the light curtain. The diagnostic mode is signalled by

the OSSD ON and OSSD OFF LED‘s at the receiver. In diagnostic

mode, protective mode is disabled, the ODDS outputs being locked.

The change from diagnostic mode to protective mode is automatically

realised after voltage reset, when the BUS converter is no longer

integrated and the connecting cable of the sensor is reconnected.

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.

8. Appendix

8.1 Contact

Consultancy / Sales:

K.A. Schmersal GmbH & Co. KG

Möddinghofe 30

D-42279 Wuppertal

Tel:+49 (0) 202 64 74 -0

Fax:+49 (0) 202 64 74- 100

You will also find detailed information regarding our product variety on

our website: www. schmersal.com

Repair handling / shipping:

Safety Control GmbH

Am Industriepark 2a

D-84453 Mühldorf / Inn

Tel.: +49 (0) 8631-18796-0

Fax: +49 (0) 8631-18796-1

6.2 Fault diagnostic

After the operating voltage for the light barrier has been switched on, the safety-monitoring module performs an internal self-test. When a fault is

detected, a corresponding flashing pattern is emitted at the receiver through the LED OSSD OFF (red). Each fault display is followed by a onesecond delay.

LED OSSD OFF Fault feature Action

Red and yellow LEDs

flash together

Wiring error for function selection

(restart interlock, automatic mode)

Check connection at the receiver, bridge 1 or bridge 2 must be wired

(refer to Wiring)

1 x flash Wiring fault Bridge operating mode, check wiring and signal level

2 x flashes Fault with the external power supply UB = 24V / DC ± 10%, power source and primary voltage check.

A system reset is performed after three error indications.

3 x flashes Error input contactor control Check connection at contactor control input, check short-circuit

to +UB and 0V. Check function status

4 x flashes Errors at the OSSD outputs Check the connections of both outputs, short-circuit of both OSSDs,

connection to signal level 0V or 24V, deactivate cross-wire short

monitoring downstream of the system inputs

5 x flashes Error configuration data Check and save the parameter setting with the BUS converter

NSR-0801

6 x flashes Error blanking Check the blanked area(s) with the selected parameterisation,

repeat the configuration in the parameter setting (PC software)

and adapt if necessary

7 flashes Other errors, diagnostic Restart the system, exchange components if there is a

permanent fault diagnosis

20

EN

SLC/SLG420-B-EN

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

9. EU Declaration of conformity

K. A. Schmersal GmbH & Co. KG

Möddinghofe 30, D - 42279 Wuppertal

Postfach 24 02 63, D - 42232 Wuppertal

Phone: +49 - (0)2 02 - 64 74 - 0

Telefax: +49 - (0)2 02 - 64 74 - 1 00

E-Mail: info@schmersal.com

Internet: http://www.schmersal.com

Place and date of issue: Mühldorf, September 15, 2016

Authorised signature

Klaus Schuster

Managing Director

Authorised signature

Christian Spranger

Managing Director

EU Declaration of conformity

Original Safety Control GmbH

Am Industriepark 2a

84453 Mühldorf / Inn

Germany

We hereby certify that the hereafter described components both in their basic design and construction conform

to the applicable European Directives.

Name of the component: SLC 420 / SLG 420

SLC 420 IP69K / SLG 420 IP69K

Type: See ordering code

Description of the component: Safety light curtain / safety light grid

Relevant Directives: Machinery Directive

EMC-Directive

RoHS-Directive

2006/42/EC

2014/30/EU

2011/65/EU

Applied standards: EN 61496-1:2013,

EN 61496-2:2013,

EN ISO 13849-1:2008 + AC:2009

EN 62061:2005 + A1:2013

Notied body for the prototype test: TÜV Nord Cert GmbH

Langemarckstr. 20, 45141 Essen

ID n°: 0044

EC-prototype test certicate: No. 440205013144611

Person authorized for the compilation

of the technical documentation:

Oliver Wacker

Möddinghofe 30

42279 Wuppertal

The currently valid declaration of conformity can be

downloaded from the internet at www.schmersal.net.

Loading...

Loading...