SCHMERSAL bp308 Installation Manual

Installation manual

System “bp308”

General instructions

Safety instructions

Commissioning

EU Type Examination

Manufacturer: Böhnke + Partner GmbH Control systems

- Member of the SCHMERSAL Group -

Heinz-Fröling-Straße 12

51429 Bergisch Gladbach

Germany

Tel.: +49 2204 9553-0

Fax: +49 2204 9553-555

www.boehnkepartner.de

Hotline: Tel.: +49 2204 9553-444

Mail: service@boehnkepartner.de

Release: October 2020

Copyright: © Böhnke + Partner GmbH Control systems, 2020

This manual in its entirety is protected by copyright.

All rights, especially the right of translation, presentation, reproduction, duplication by

photocopying or in some other ways, storage on electronic medium and modification as

a whole or in parts are reserved for the publisher.

This manual does not provide information on our overall delivery options.

In spite of the care taken in creating texts, illustrations and programs, we accept no legal

liability whatsoever for possible mistakes or their consequences.

The common names, trade names, product identifications etc. in this document may also

be registered brands even if they are not specifically identified and as such are subject

to statutory provisions.

Böhnke + Partner GmbH, BlueModus, WinMOS®300, CANwizard®, Lift2CLOUD®

Installation manual of

system “bp308” - Contents 3

Contents

1 General information ..................................................................................................7

1.1 Thank you ..................................................................................................................7

1.2 Intended use ..............................................................................................................8

1.3 Documentation references .......................................................................................8

2 Safety instructions ....................................................................................................9

2.1 Qualified personnel...................................................................................................9

2.2 Safety instructions for control system ....................................................................9

2.3 Installer and operator requirements ...................................................................... 12

3 Product certificates................................................................................................. 13

3.1 Declaration of conformity ....................................................................................... 13

3.2 EU Type Examination ............................................................................................. 14

3.3 EU Type-examination certificate BPL-03 with SMZ .............................................. 15

3.4 Voluntary type examinations ................................................................................. 23

3.4.1

Compliance of product deviating from the norm with requirements of the directive

2014/33/EU ............................................................................................................... 23

3.4.2

Return from inspection operation after use of the pit inspection control by operating

controls ...................................................................................................................... 26

4 Standards ................................................................................................................ 31

4.1 EMC Directive .......................................................................................................... 31

4.2 EN 81 ........................................................................................................................ 32

5 The control system “bp308” .................................................................................. 33

5.1 Product and functional description ....................................................................... 33

5.2 Summary of the functions of bp308 ...................................................................... 34

5.3 Decentralised lift control system ........................................................................... 36

5.4 The group system ................................................................................................... 36

5.4.1

Priority calls ............................................................................................................... 37

5.4.2

Presentation of group in WinMOS®300 ..................................................................... 37

5.5 Components for bp308 ........................................................................................... 39

5.6 Versions of bp308 ................................................................................................... 40

5.7 Brief description of bp308 ...................................................................................... 40

5.7.1

Overview ................................................................................................................... 40

5.7.1.1 Top view .................................................................................................................... 40

5.7.1.2 Left side view ............................................................................................................. 41

5.7.1.3 Bottom view ............................................................................................................... 41

5.7.1.4 Right side view .......................................................................................................... 42

5.7.2

Technical features ..................................................................................................... 43

5.7.3

Control panel and LCD in bp308 ............................................................................... 44

5.7.3.1 Standard view ............................................................................................................ 44

5.7.3.2 Lift status bar ............................................................................................................. 44

5.7.3.3 Safety circuit status bar ............................................................................................. 45

5.7.3.4 Control panel ............................................................................................................. 45

5.7.4

Setup menu ............................................................................................................... 46

5.7.5

Service menu ............................................................................................................ 47

5.7.6

Call menu .................................................................................................................. 48

5.7.7

Information menu ...................................................................................................... 49

5.7.8

Terminal mode .......................................................................................................... 49

5.7.9

Monitor program LPCmon ......................................................................................... 50

4 Installation manual of system “bp308” - Contents

5.7.9.1 Start of the monitor program ..................................................................................... 50

5.7.10 Memory for the program and parameters ................................................................. 51

5.7.10.1 General information ................................................................................................... 51

5.7.10.2 Battery ....................................................................................................................... 52

5.7.10.3 Replacement ............................................................................................................. 53

5.7.10.4 Software update ........................................................................................................ 53

5.7.11 Control system bp308 in the control cabinet with inverter ........................................ 55

5.7.12 Easy servicing thanks to clear structure.................................................................... 57

5.7.13 Optional equipment ................................................................................................... 58

5.7.13.1 Uninterruptible Power Supply (UPS) ......................................................................... 58

5.7.13.2 Operational readiness of the UPS system ................................................................ 58

6 Installation and assembly ....................................................................................... 61

6.1 Storage, transport and operating conditions ........................................................ 61

6.2 Preparations ............................................................................................................ 62

6.3 Installation of system module of bp308 ................................................................ 63

6.4 Installation of the control system .......................................................................... 63

6.5 Assembly of the car terminal box .......................................................................... 64

6.6 Installation of absolute encoder system ............................................................... 64

6.6.1

Absolute encoder AWG-05 ....................................................................................... 65

6.6.1.1 Absolute encoder fastening sets ............................................................................... 65

6.6.1.2 Installation in the shaft............................................................................................... 65

6.6.1.3 Installation on the car ................................................................................................ 65

7 Electrical connection .............................................................................................. 67

7.1 Preparations ............................................................................................................ 67

7.2 Interference suppression measures and notes .................................................... 68

7.3 Connections for cable shields ............................................................................... 72

7.4 Names in circuit diagrams ...................................................................................... 72

7.5 Safety circuit ........................................................................................................... 73

7.6 Electrical installation .............................................................................................. 74

7.7 Cable entry control cabinet .................................................................................... 74

7.8 Bus connections ..................................................................................................... 75

7.8.1

Electrical bus medium ............................................................................................... 75

7.8.2

Cable colours ............................................................................................................ 75

7.8.3

Network topology ....................................................................................................... 76

7.8.4

Examples for a correct topology ................................................................................ 77

7.8.4.1 Individual control system ........................................................................................... 77

7.8.4.2 Two-part group with a line ......................................................................................... 78

7.8.4.3 Two-part group with two lines ................................................................................... 79

7.8.4.4 Two-part group with three lines ................................................................................. 80

7.8.5

Connector pin assignments ....................................................................................... 81

7.8.6

Node numbers of CAN components ......................................................................... 82

7.9 Flat travelling line to car terminal box ................................................................... 82

7.10 Activation of inverter .............................................................................................. 83

7.10.1 Activation via CAN-Bus ............................................................................................. 83

7.10.2 DCP-connection to inverter ....................................................................................... 83

7.10.3 Parallel wiring with RVM-01 ...................................................................................... 84

7.11 Connection of absolute encoder (AWG) ................................................................ 86

7.12 Group connection ................................................................................................... 86

7.13 Data lines for remote diagnosis ............................................................................. 87

7.14 Analogue telephone line ......................................................................................... 87

Installation manual of system “bp308” -Contents 5

7.15 Ethernet ................................................................................................................... 87

7.16 Connection of the emergency call system ............................................................ 88

8 Commissioning ....................................................................................................... 89

8.1 Preparations ............................................................................................................ 90

8.1.1

Before first switch-on ................................................................................................. 90

8.2 Technical information about the control system .................................................. 90

8.3 Checklist before switching on the control system ............................................... 97

8.4 Connecting the mains voltage ............................................................................... 99

8.5 Checking the parameters of control system and drive ...................................... 100

8.5.1

Checking the bus lines ............................................................................................ 100

8.5.2

Checking the termination ........................................................................................ 100

8.5.3

Checking the CAN parameters ............................................................................... 101

8.5.4

Checking the DCPconnection ................................................................................. 101

8.6 First travel with the return control ....................................................................... 102

8.7 First travel with inspection ................................................................................... 103

8.8 Inspection control Shaft pit .................................................................................. 104

8.8.1

Reset by means of key switch ................................................................................. 104

8.8.2

Reset by means of landing call ............................................................................... 104

8.9 Sequence of a regulated two-speed drive ........................................................... 107

8.9.1

Disconnection points for the high travelling speed .................................................. 108

8.10 Sequence of a direct travel-in with DCP .............................................................. 109

8.11 Setting up the copying tool .................................................................................. 109

8.11.1 Installing the delay switch ....................................................................................... 110

8.11.2 Basic settings .......................................................................................................... 111

8.11.3 Setting travel with the absolute encoder ................................................................. 112

8.11.4 Travel speeds .......................................................................................................... 113

8.11.5 Deceleration through S81/S82 in the end stops in case of normal operation ......... 114

8.12 First travel in the normal operation ..................................................................... 115

8.13 Setting up the emergency call device.................................................................. 117

8.14 Setting up the group connection ......................................................................... 117

8.15 Setting up the remote diagnosis .......................................................................... 117

8.16 Setting up the modem .......................................................................................... 118

8.17 Setting up a networkconnection .......................................................................... 118

8.18 Completion of commissioning ............................................................................. 118

9 Troubleshooting .................................................................................................... 119

9.1 Monitoring routines .............................................................................................. 119

9.2 Malfunction information ....................................................................................... 121

9.3 Reporting of malfunctions .................................................................................... 121

9.4 Malfunction stack .................................................................................................. 122

9.5 Malfunction list ...................................................................................................... 122

9.6 Messages ............................................................................................................... 123

9.7 Repair .................................................................................................................... 123

10 Maintenance .......................................................................................................... 125

Appendix ........................................................................................................................... 126

A) Menu navigation bp308 ........................................................................................ 126

B) Update of the firmware via USB stick .................................................................. 127

Index ............................................................................................................................... 128

6 Installation manual of system “bp308” - Contents

1 General information

1.1 Thank you

Thank you for the confidence you have placed in us by purchasing “bp308” of

Böhnke + Partner GmbH. Please take the time to read this installation manual and

documentation on components carefully. Improper handling results in a high risk

of injury. Follow all the instructions and you will save a lot of time and questions

during installing the system.

“Installation manual” stands for the whole documentation that we have prepared to

provide our customers with comprehensive information on our company and

product range. To obtain a better overview, the manual has been divided into

several parts. The “Installation manual” tells you about the hazards and risks,

which can result in serious health problems and economic damage in case of

incorrect behaviour. Furthermore, it will provide you with the necessary information

on commissioning of the control system. The installation manual is supplied with

every control system and is thus part of the complete control system

documentation.

If you still have questions, contact us:

Böhnke + Partner GmbH Control systems

- Member of the Schmersal Group -

Heinz-Fröling-Straße 12

51429 Bergisch Gladbach

Germany

Tel.: +49 2204 9553-0

Fax: +49 2204 9553-555

Hotline: +49 2204 9553-444

www.bp308.de

www.boehnkepartner.de

info@boehnkepartner.de

Installation manual of system “bp308” - General information 7

1.2 Intended use

The control system ≫bp308≪ is an equipment for using in lifts.

1.3 Documentation references

This manual does not provide information on our overall delivery options. All

information only serves to describe the product and must not be regarded as

granted characteristics in the legal sense. Any claims for damages against us,

irrespective of the legal basis, are excluded unless we are guilty of deliberate intent

or gross negligence. We do not assume any guarantee that the specified circuits

or procedures are free of copyrights of third parties.

Reproduction, even in extracts, is permissible only with the consent of

Böhnke + Partner GmbH and with precise reference to the source.

Böhnke + Partner logo and company name are protected trademarks.

The information in this manual is regularly checked. The necessary corrections are

included in subsequent editions.

Hazard warnings and special information are given in this technical manual in the

following way and highlighted with a corresponding symbol.

CAUTION!

This symbol is used when inaccurate compliance with or failure to comply with

instructions or procedures can result in damages to the device, injuries or fatal

accidents.

WARNING!

This symbol is used when inaccurate compliance with or failure to comply with

instructions or procedures can result in injuries or fatal accidents due to electric

current.

NOTE!

This symbol is used to bring attention to a specific characteristic.

8 Installation manual of system “bp308” - General information

2 Safety instructions

NOTE!

Before installing and commissioning this device, please read these safety

instructions and warnings carefully and follow all the warning signs attached to the

device. Make sure the warning signs are legible and replace missing or damaged

signs.

2.1 Qualified personnel

Qualified personnel within the meaning of the documentation or warnings on the

product are persons, who are familiar with setup, assembly, commissioning,

operation and maintenance of the product and have the relevant qualifications for

the activity, e.g.:

Training and briefing or authorisation to switch on and off, earth and label the

current circuits and devices according to the standards of the safety technology.

Training and briefing in maintenance and use of appropriate safety equipment

according to the standards of the safety technology.

First-aid training.

2.2 Safety instructions for control system

ATTENTION!

Excerpts from chapter 5 of “DGUV 209-053 Activities performed on lifts” (edition

02/2017):

5.1 Notification

Before starting work on an existing lift, the fitter must notify the person using

(operating) the lift or his representative and inform him about the extent of work

and expected duration of work.

After the work is completed, a notice of departure must be given.

…

5.2 Blocking the lift

Before beginning work on a lift, the fitter must safely block it and put up a sign that

is clearly visible and durable and says, for example, “Lift out of service”, at every

shaft access.

…

5.3 Safety of shaft accesses

Open shaft accesses must be blocked such that unauthorised persons (third

parties) are prohibited from entering them. Work for which doors of the lift shaft

have to be opened must only be carried out when the lift car is behind them. If this

is not possible, additional measures must be taken.

…

Installation manual of system “bp308” - Safety instructions 9

5.4 Assistance by another person

If a fitter is performing an activity, which requires the presence of another person,

this person must be an expert or trained in hazards.

…

5.5 Implementation of work

5.5.1 Entering and leaving the car roof

The car roof may be entered only in the presence of experts. Before entering the

car roof, the emergency brake switch (“emergency stop”) and, if accessible, the

inspection switch on the car roof must be switched on and their functioning checked.

The shaft doors may be closed only after the inspection control system is switched

on. The functioning of the emergency brake switch and the inspection switch is

checked, e.g. by closing the doors and enabling the landing call. The lift must not

move in the process.

Before leaving the car roof, the effectiveness of the shaft door contact with the exit

doors must be checked, the emergency brake switch enabled and after opening

the shaft door the inspection switch must be unlocked again. The emergency brake

switch may be unlocked again only after leaving the car roof.

…

5.5.2 Shaft lighting

Before beginning work in the shaft, sufficient lighting must be ensured, e.g. switch

on the shaft lights and carry along a network-independent light.

5.5.3 Stay and travels in the shaft

There should not be more people on the car roof and more material must not be

taken along than is necessary for carrying out the work. Load-bearing capacity and

usable area must be kept in mind. Driving on the car roof is permissible only when

there is no one present in the hazard zone.

It is forbidden to carry out work during the travel. Inspections (visual inspections)

are only permissible during downward travels. There is a danger of crushing during

upward travels, e.g. at counterweights and shaft fittings (see section 5.2.5.7 DIN

EN 81-20).

…

5.5.4 Electrical hazard

After the main switch is switched off, voltage may remain in various equipment and

components of the lift.

…

5.5.5 Bridging of safety equipment and control lines

It is strictly forbidden to bridge safety equipment, control lines and the switches. If

it is not possible to avoid bridging in order to carry out work, it may be done only if:

- the person carrying out the work is trained in it

- the bridges are suitable and clearly recognisable for everyone.

…

The bridges must be removed immediately after the work is completed.

10 Installation manual of system “bp308” - Safety instructions

5.5.6 Switching agreements for time

Agreements for carrying out switching processes or car movements are

forbidden at a certain time.

…

5.6 Completion of activities

After completion of activities, all equipment, especially the safety equipment

related to the work, must be checked for proper functioning.

After carrying out repairs subject to approval, the lift may be operated again only

after obtaining approval of an approved monitoring body (ZÜS).

Installation manual of system “bp308” - Safety instructions 11

2.3 Installer and operator requirements

ATTENTION!

The control system “bp308” is built to state-of-the-art standards and is safe to

operate. Hazards occur only when untrained personnel use devices incorrectly

or for unintended purposes.

Smooth and safe operation of devices requires proper transport, storage, setup

and assembly as well as careful operation and maintenance.

Refrain from any working method that impairs safety of the devices.

Unauthorised modifications and alterations, which may impair safety of the

devices, are not permitted.

During operation, the drive units have dangerous, live, moving or rotating parts.

Hence, they can cause injuries or material damage, for example, if the

necessary covers are removed without permission or in case of poor

maintenance.

Only qualified personnel may be assigned to work on the devices. The

personnel must always have the supplied operating instructions and all the

product documents available during work and follow them consistently. It is

forbidden for unqualified personnel to work on or near the devices.

The operator is responsible for bringing the drive into a safe state in case of

failure of the devices because otherwise it can result in injuries or material

damage.

The packaging material must be disposed of in an environmentally friendly way;

recycle paper, plastic, metal, electronic components etc.

WARNING!

Before each intervention, disconnect the devices from the mains and check the

absence of voltage.

12 Installation manual of system “bp308” - Safety instructions

3 Product certificates

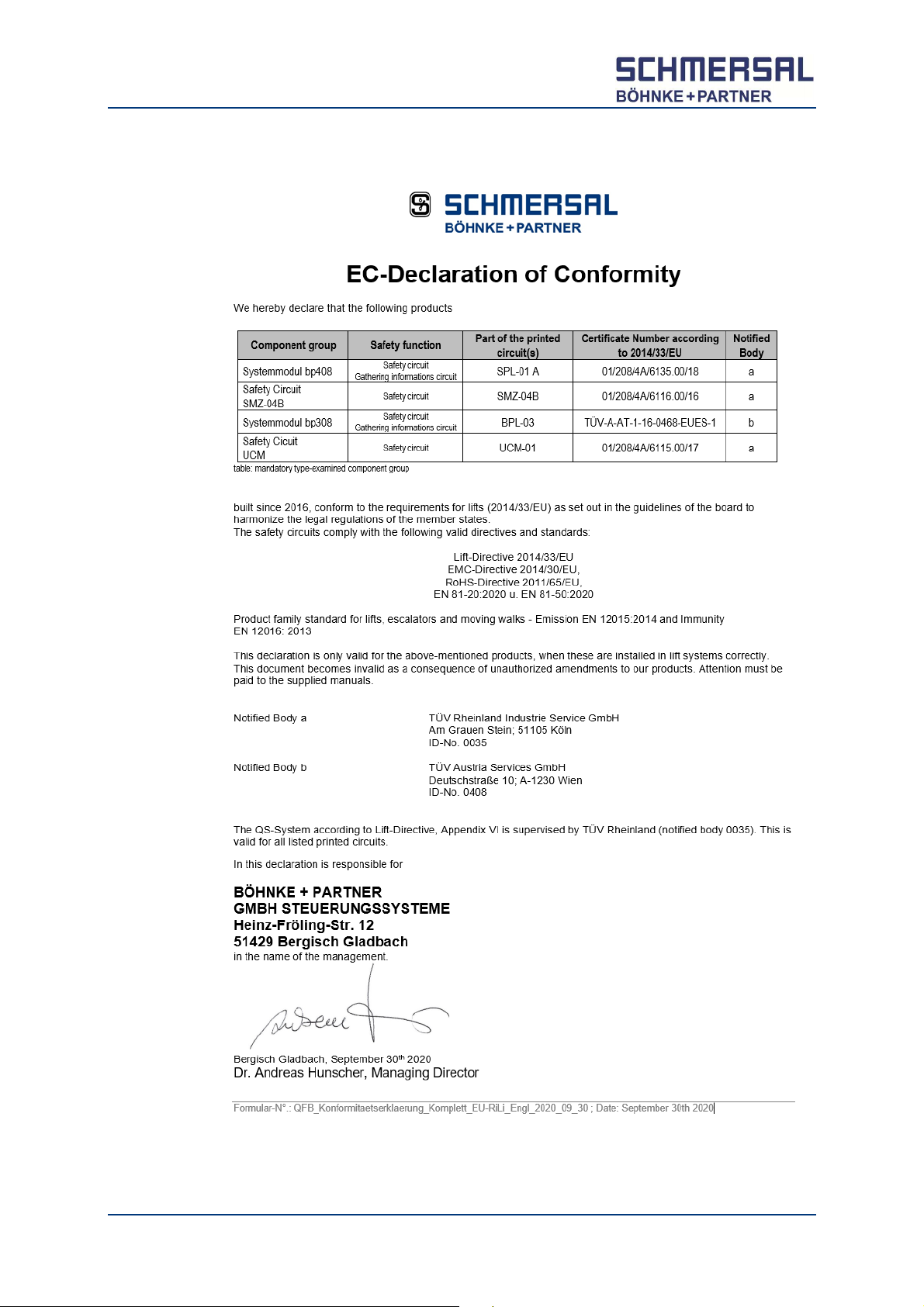

3.1 Declaration of conformity

Figure 1:

Declaration of conformity

Installation manual of system “bp308” - Product certificates 13

3.2 EU Type Examination

The system module bp308 contains an electronic monitoring unit for the safety

circuit and a pre-control for the contactors. Moreover, a safety circuit (SMZ) is

located on the circuit board. The safety circuit can be used in the following cases

of EN 81-20/-50 and EN 81-1/-2:

Preparatory measures with lift car and shaft door open

Levelling with lift car and shaft door open

Re-levelling with lift car and shaft door open

Detection of an unintended movement of the lift car with open doors (UCM).

14 Installation manual of system “bp308” - Product certificates

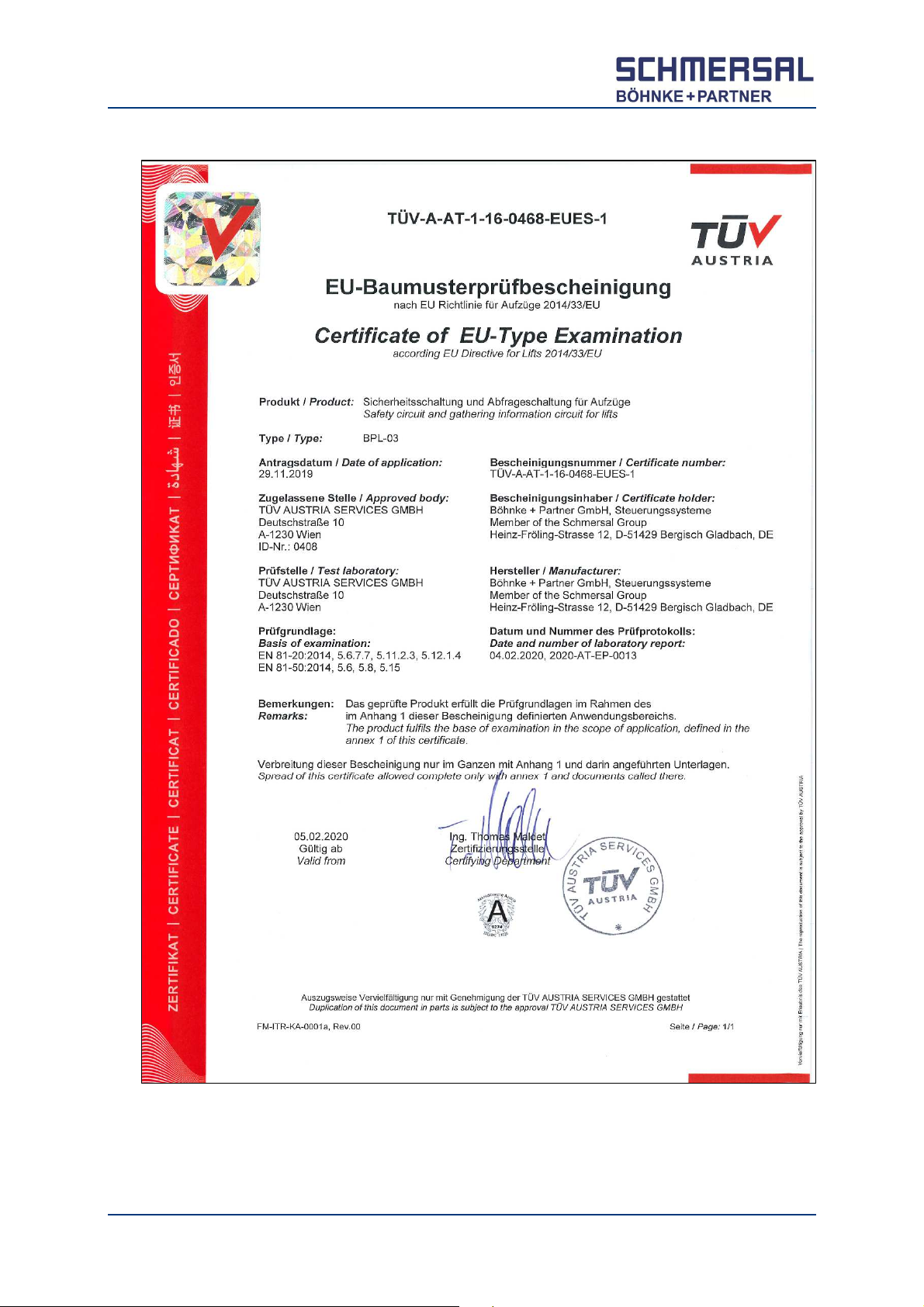

3.3 EU Type-examination certificate BPL-03 with SMZ

Figure 2:

System module bp308 – Safety circuit and gathering informationcircuit for lifts BPL-03

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

Installation manual of system “bp308” - Product certificates 15

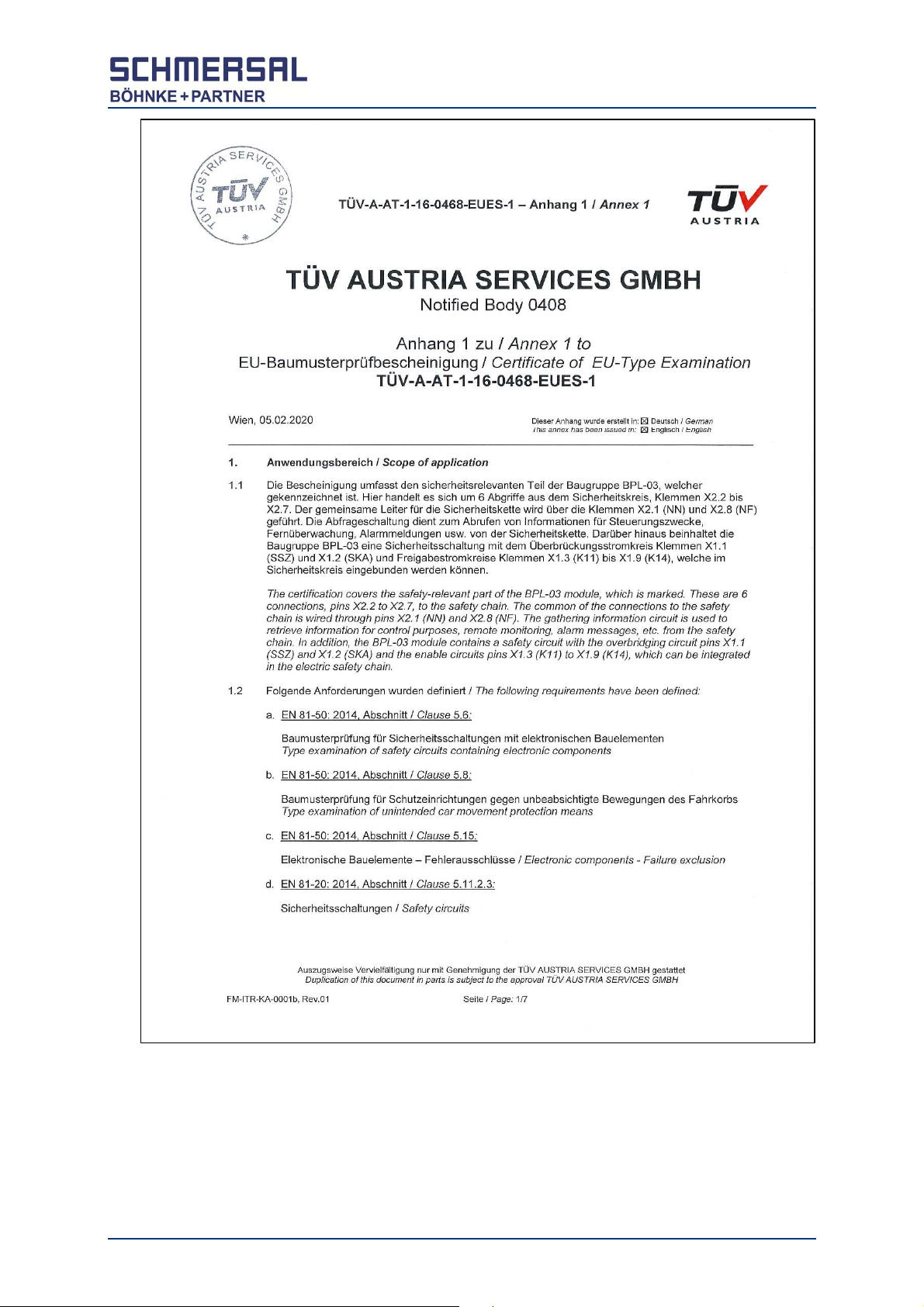

Figure 3:

Type Examination BPL-03 – Annex 1 Page 1/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

16 Installation manual of system “bp308” - Product certificates

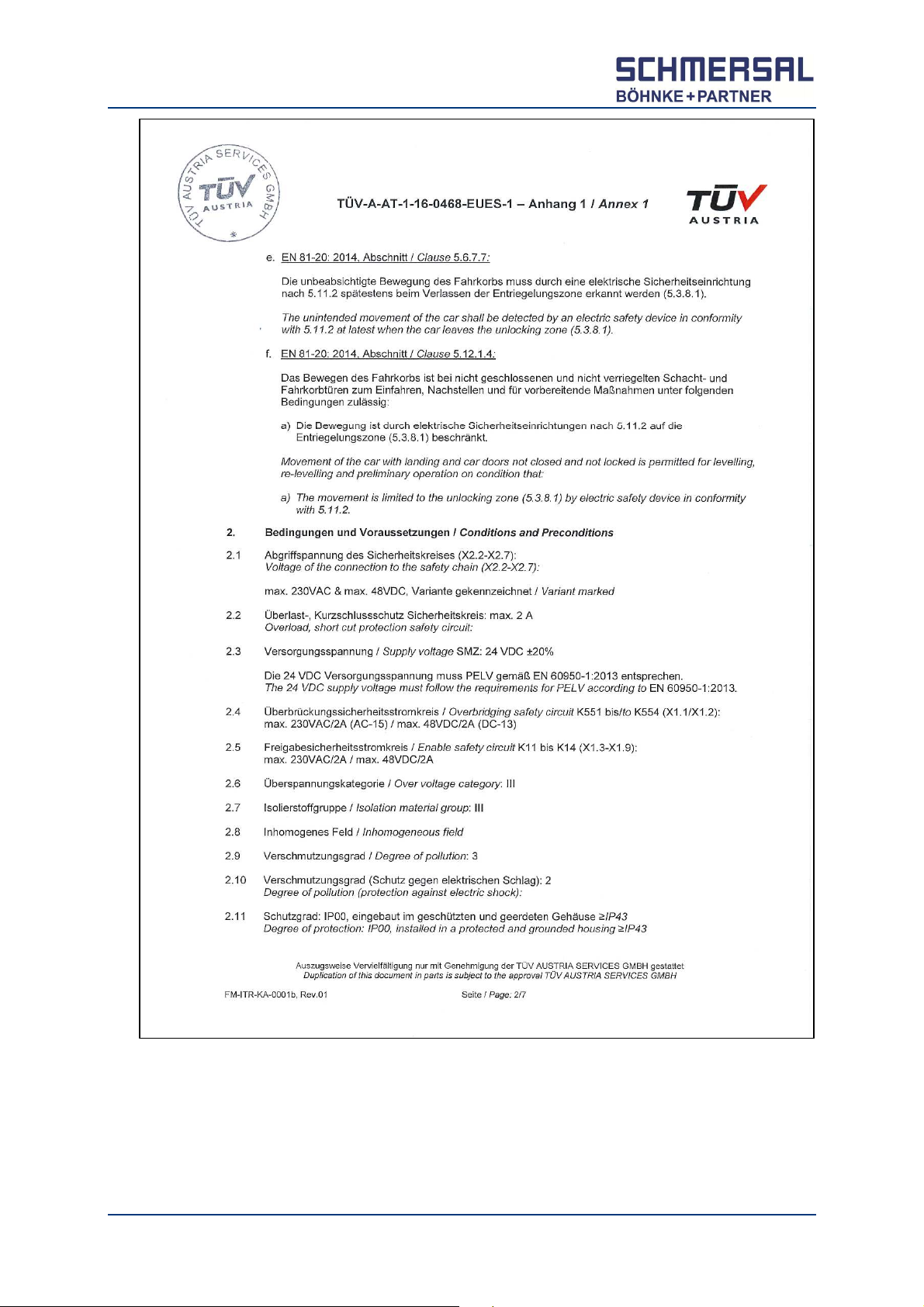

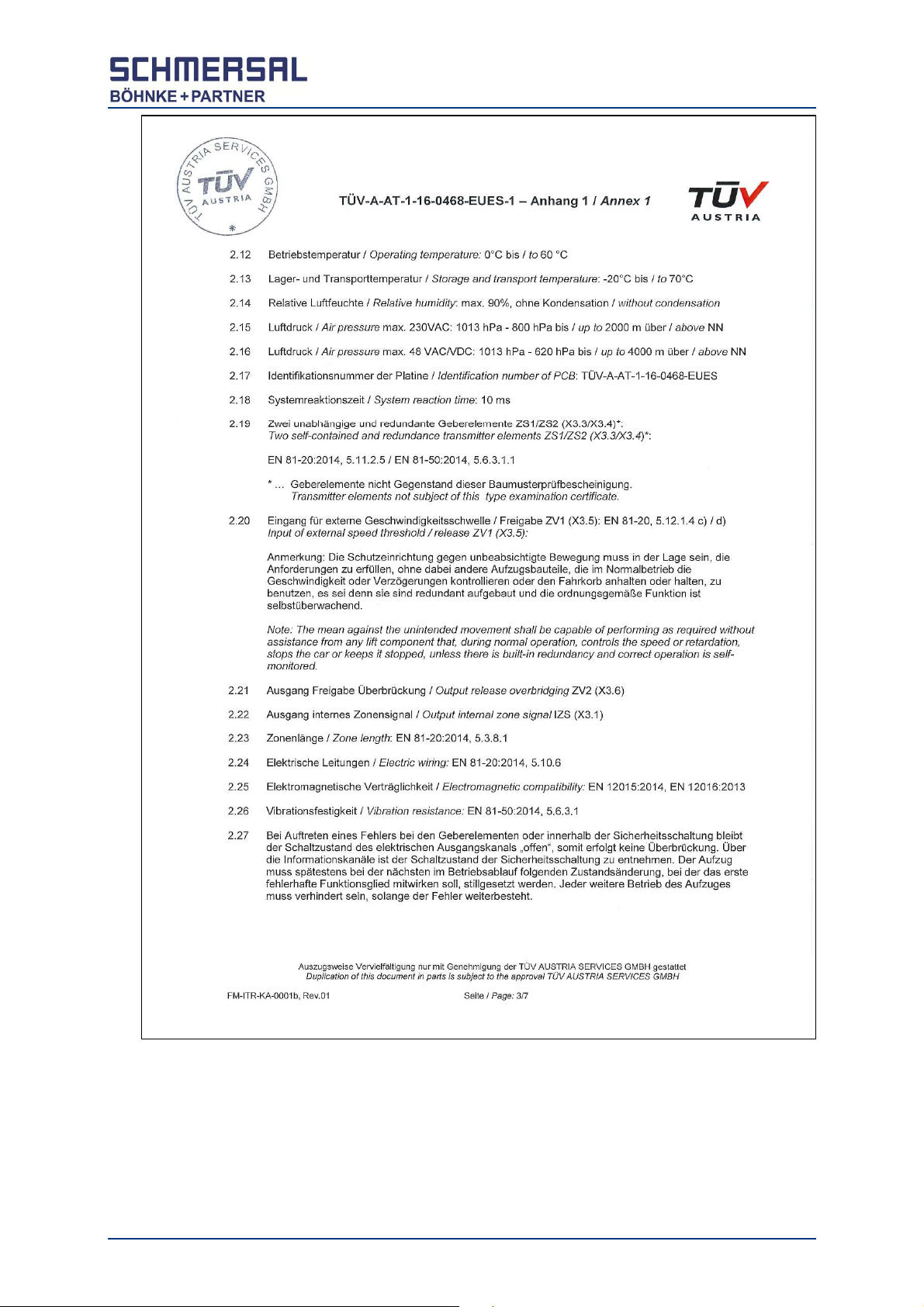

Figure 4:

Type Examination BPL-03 – Annex 1 Page 2/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

Installation manual of system “bp308” - Product certificates 17

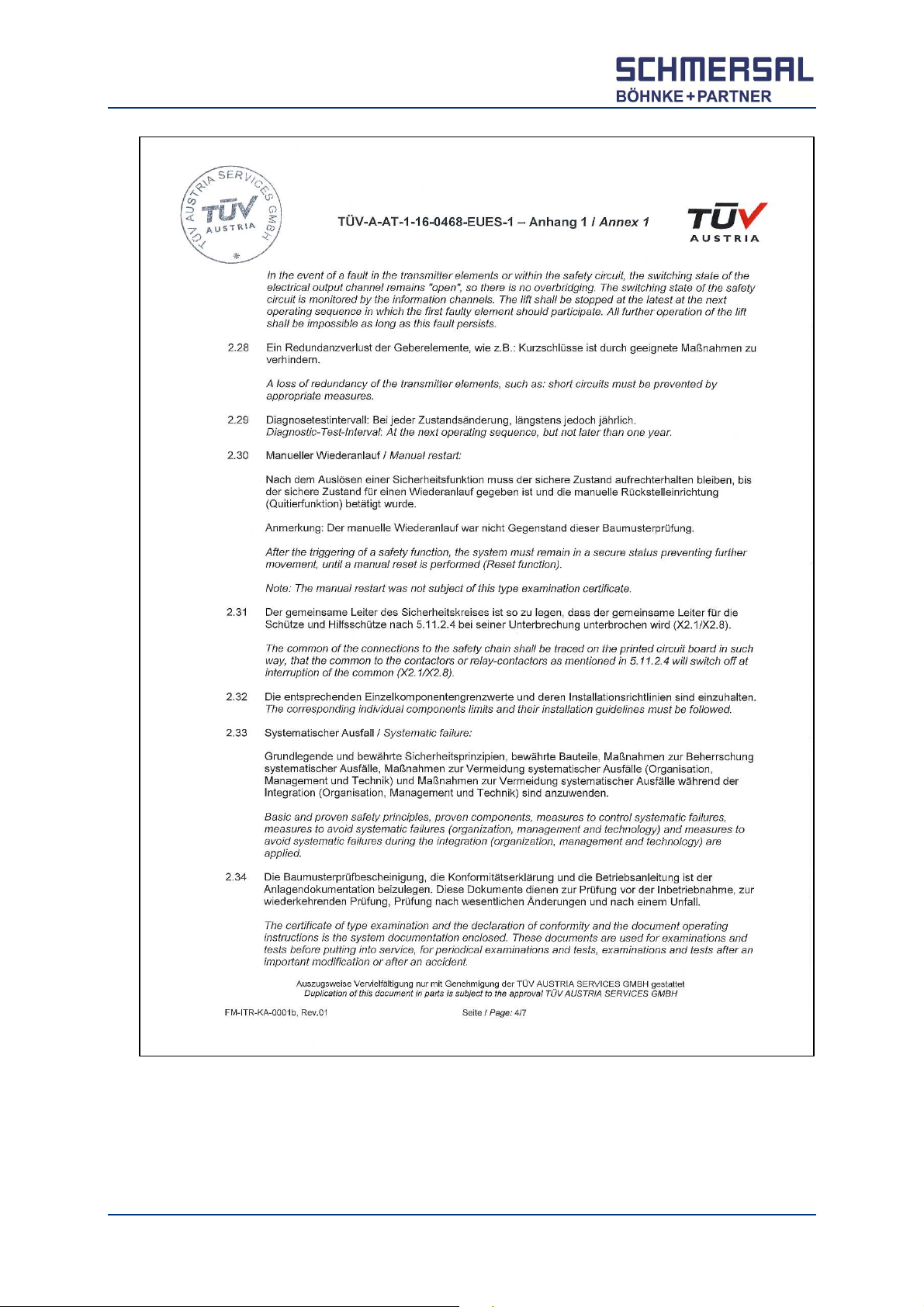

Figure 5:

Type Examination BPL-03 – Annex 1 Page 3/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

18 Installation manual of system “bp308” - Product certificates

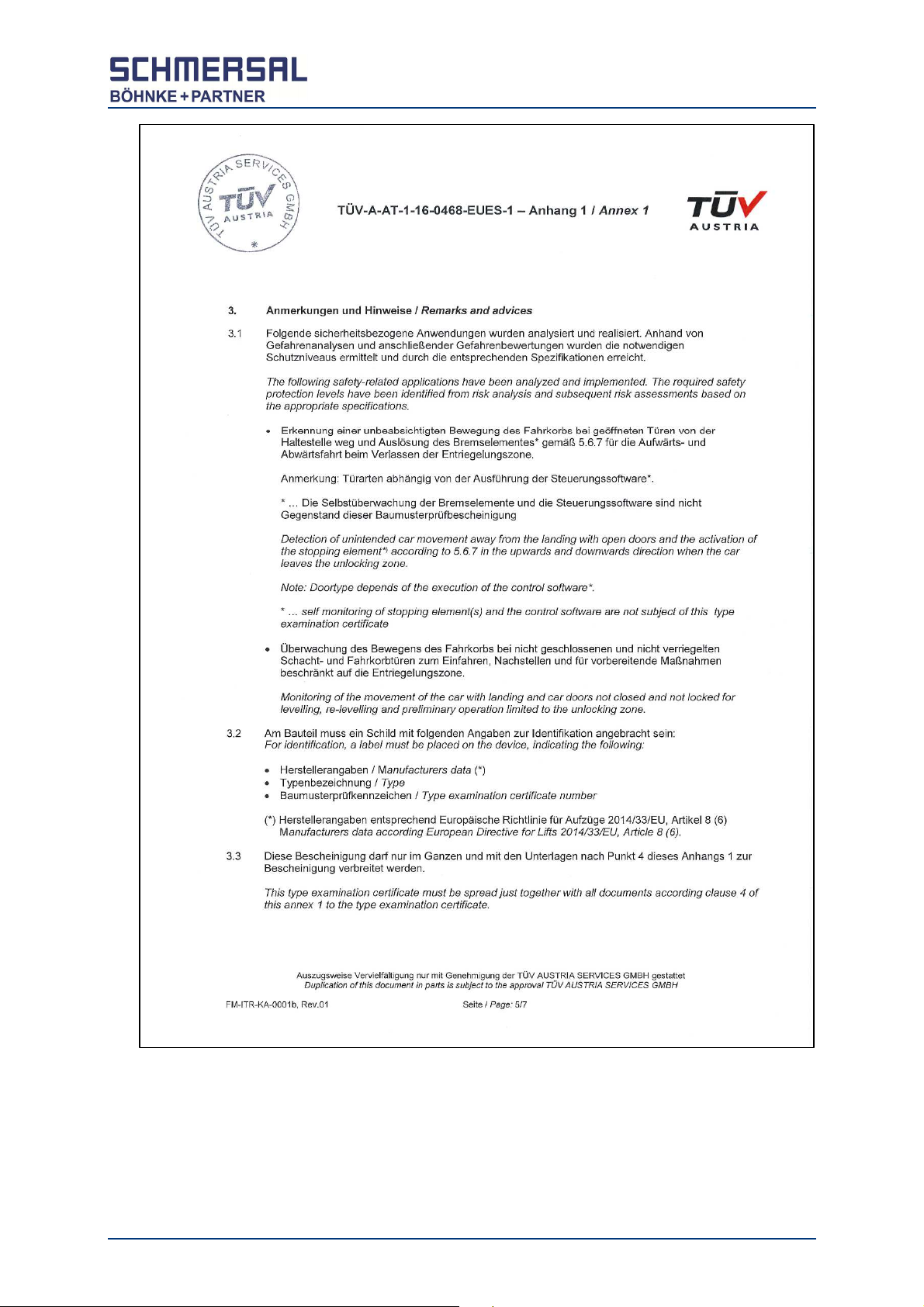

Figure 6:

Type Examination BPL-03 – Annex 1 Page 4/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

Installation manual of system “bp308” - Product certificates 19

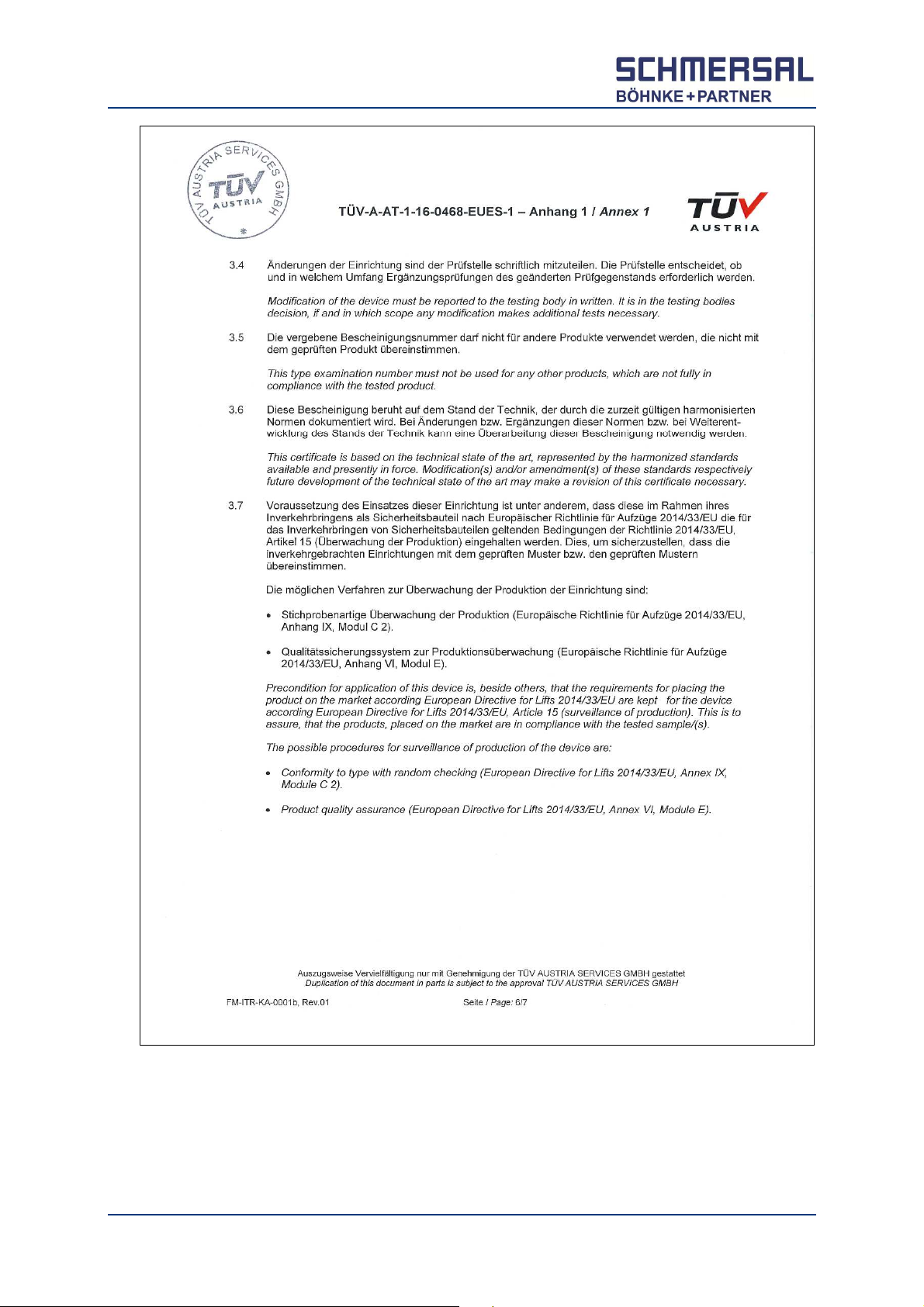

Figure 7:

Type Examination BPL-03 – Annex 1 Page 5/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

20 Installation manual of system “bp308” - Product certificates

Figure 8:

Type Examination BPL-03 – Annex 1 Page 6/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

Installation manual of system “bp308” - Product certificates 21

Figure 9:

Type Examination BPL-03 – Annex 1 Page 7/7

Reg. no. TÜV-A-AT-1-16-0468-EUES-1 dated 2020-02-05

22 Installation manual of system “bp308” - Product certificates

Compliance of product deviating from the norm with requirements of the directive

3.4 Voluntary type examinations

3.4.1 Compliance of product deviating from the norm with requirements of

the directive 2014/33/EU

Figure 10:

Voluntary type examination –

2014/33/EU - Page 1 of 3

Installation manual of system “bp308” - Product certificates 23

Compliance of product deviating from the norm with requirements of the directive

Figure 11:

Voluntary type examination 2014/33/EU - Page 2 of 3

24 Installation manual of system “bp308” - Product certificates

Compliance of product deviating from the norm with requirements of the directive

Figure 12:

Voluntary type examination 2014/33/EU - Page 3 of 3

Installation manual of system “bp308” - Product certificates 25

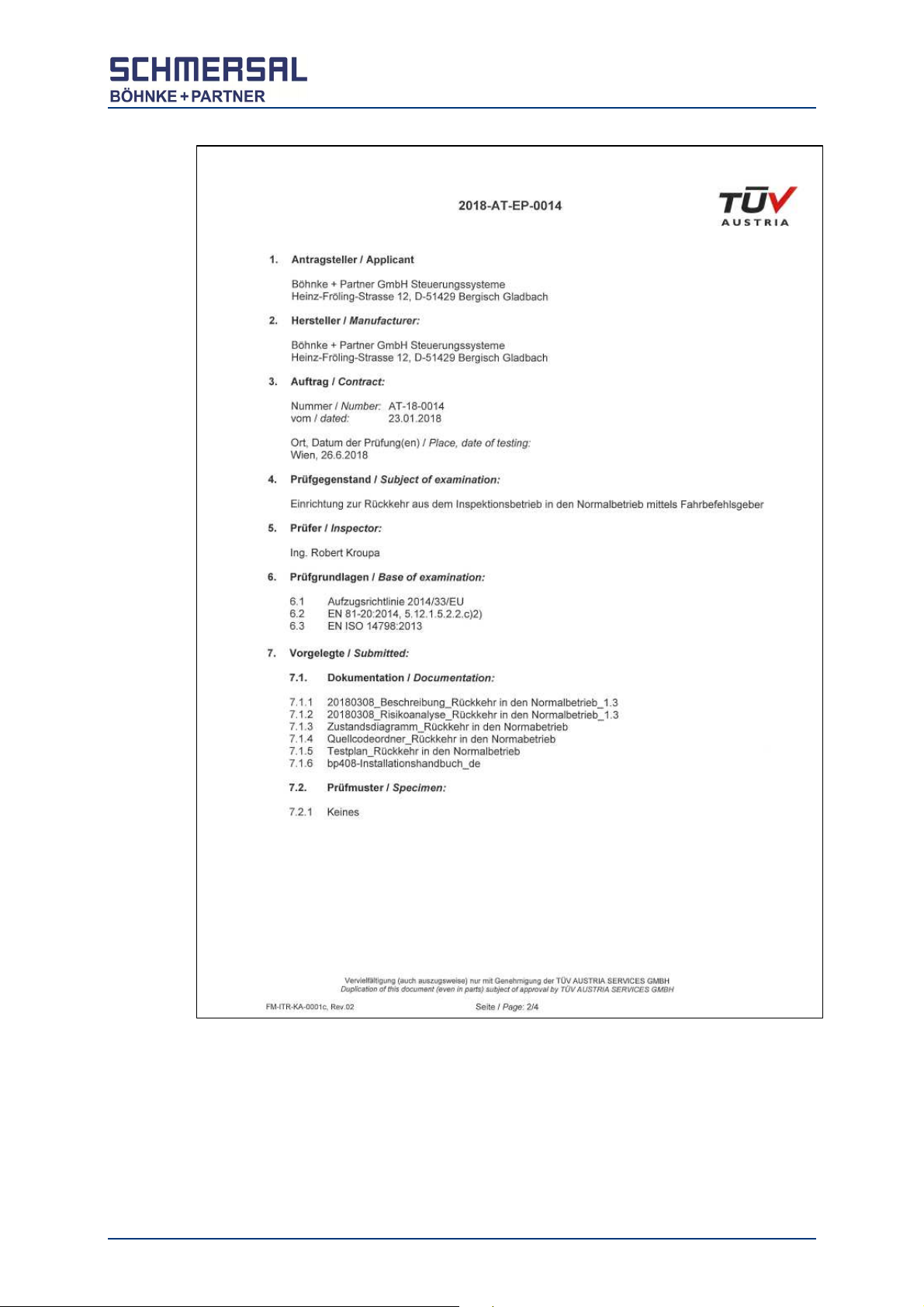

3.4.2 Return from inspection operation after use of the pit inspection

control by operating controls

Figure 13:

Certificate about the examination of a concept concerning a deviation from EN 81-20:2014 :

Return from inspection operation after use of the pit inspection control by operating controls

26 Installation manual of system “bp308” - Product certificates

Figure 14:

Test report on certificate about the examination of a concept concerning a deviation from EN 81-20:2014 :

Return from inspection operation after use of the pit inspection control by operating controls - Page 1 of 4

Installation manual of system “bp308” - Product certificates 27

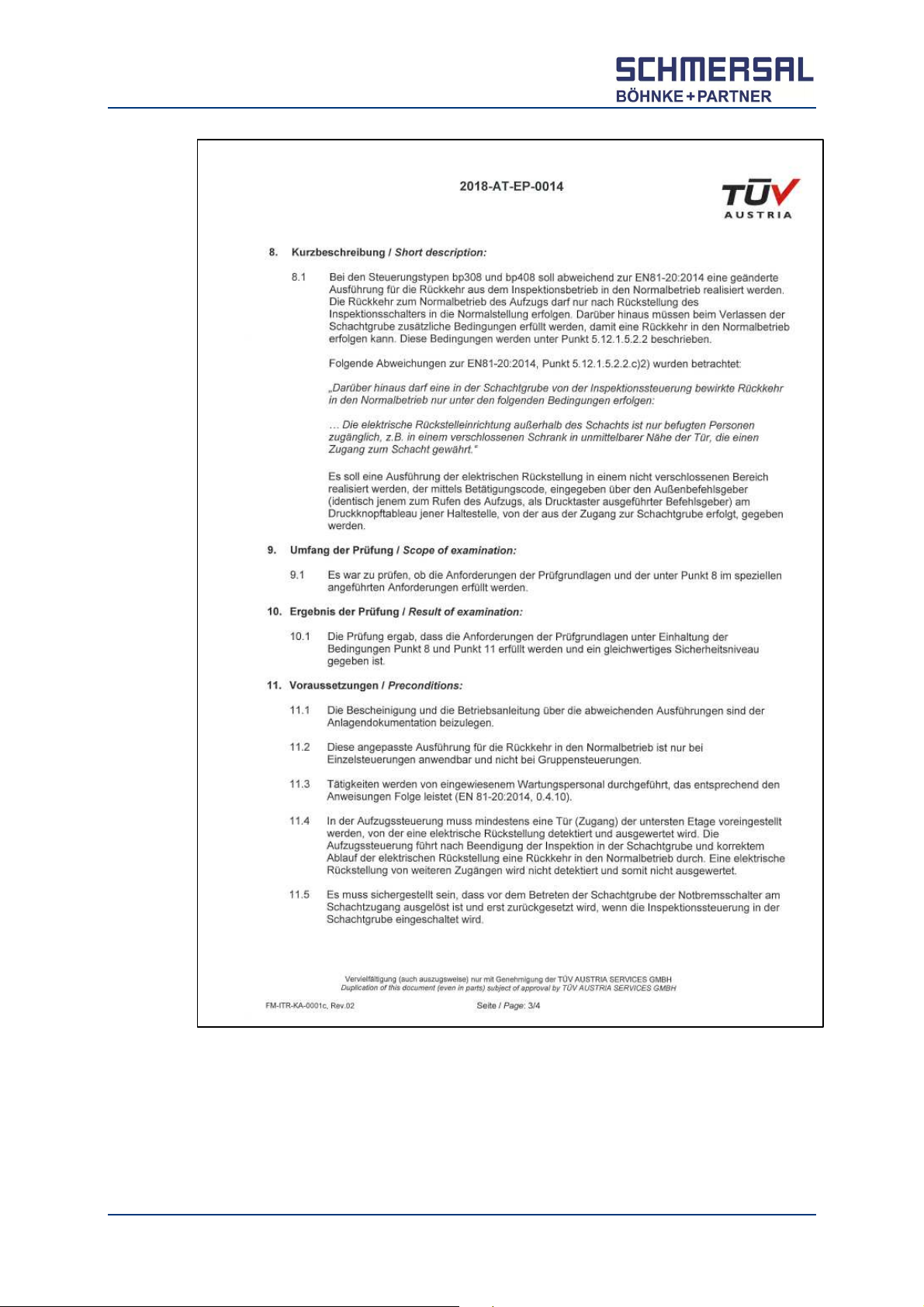

Figure 15:

Test report on certificate about the examination of a concept concerning a deviation from EN 81-20:2014:

Return from inspection operation after use of the pit inspection control by operating controls - Page 2 of 4

28 Installation manual of system “bp308” - Product certificates

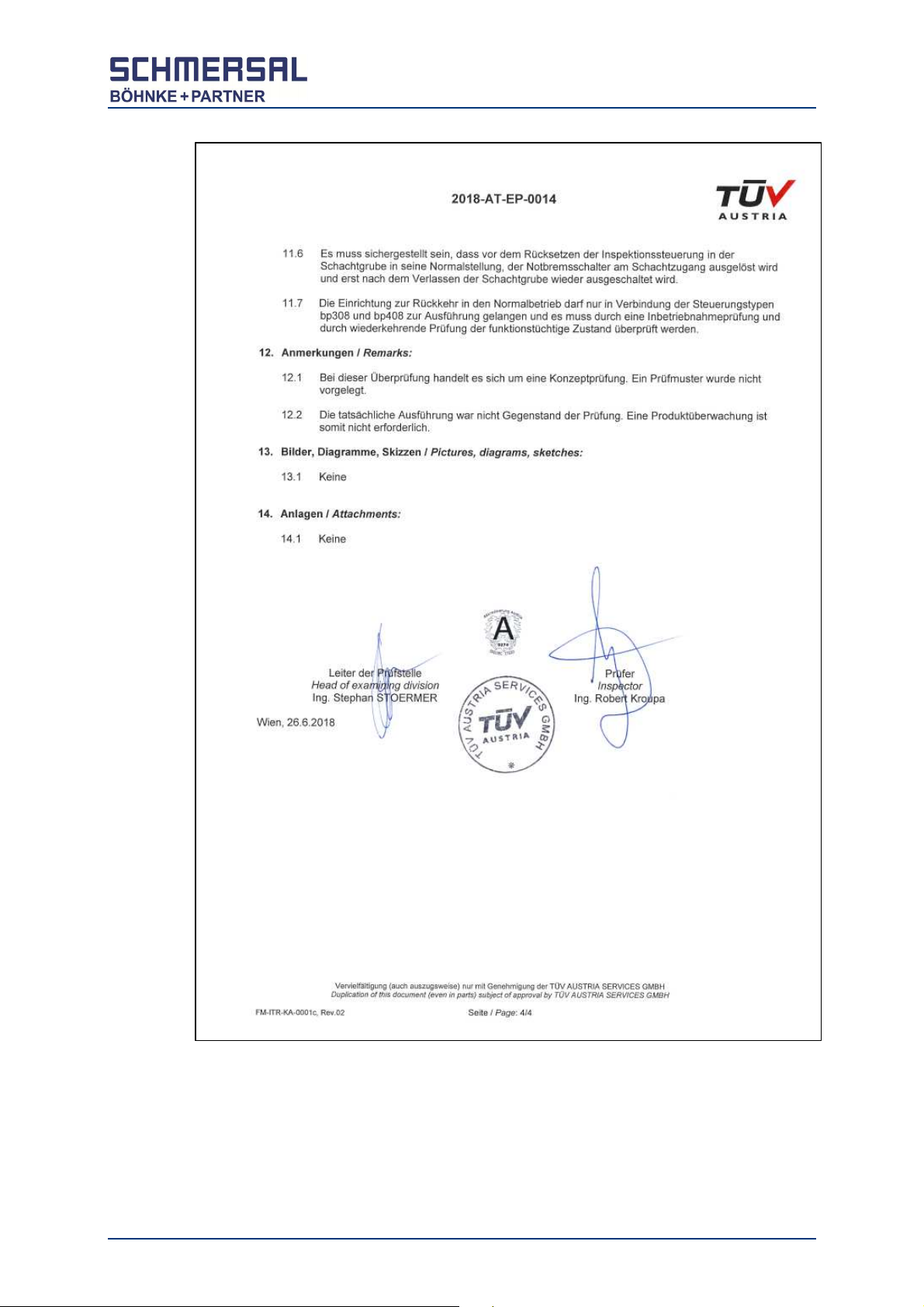

Figure 16:

Test report on certificate about the examination of a concept concerning a deviation from EN 81-20:2014 :

Return from inspection operation after use of the pit inspection control by operating controls - Page 3 of 4

Installation manual of system “bp308” - Product certificates 29

Figure 17:

Test report on certificate about the examination of a concept concerning a deviation from EN 81-20:2014 :

Return from inspection operation after use of the pit inspection control by operating controls - Page 4 of 4

30 Installation manual of system “bp308” - Product certificates

Loading...

Loading...