Compaktejector SCPi FS RP

Operating Instructions

WWW.SCHMALZ.COM EN-US · 30.30.01.01602 · 01 · 10/18

Note

The operating instructions were originally written in German and have been translated into English. Store

in a safe place for future reference. Subject to technical changes without notice. No responsibility is taken

for printing or other types of errors.

Published by

© J.SchmalzGmbH, 10/18

This document is protected by copyright. J.SchmalzGmbH retains the rights established thereby. Reproduction of the contents, in full or in part, is only permitted within the limits of the legal provisions of

copyright law. Any modifications to or abridgments of the document are prohibited without explicit written agreement from J.SchmalzGmbH.

Contact

J. Schmalz GmbH

Johannes-Schmalz-Str. 1

72293 Glatten, Germany

T: +49 7443 2403-0

schmalz@schmalz.de

www.schmalz.com

Contact information for Schmalz companies and trade partners worldwide can be found at:

www.schmalz.com/salesnetwork

2 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

Contents

EN-US · 30.30.01.01602 · 01 · 10/18 3 / 58

Contents

1 Important information ...................................................................................................................................7

1.1 Note on using these operating instructions ......................................................................................... 7

1.2 The technical documentation is part of the product ........................................................................... 7

1.3 Warnings in this document.................................................................................................................... 7

1.4 Symbol..................................................................................................................................................... 7

2 Fundamental Safety Instructions...................................................................................................................8

2.1 Standards of Technology ....................................................................................................................... 8

2.2 Emissions ................................................................................................................................................. 8

2.3 Intended Use........................................................................................................................................... 8

2.4 Non-Intended Use .................................................................................................................................. 8

2.5 Personnel Qualification.......................................................................................................................... 9

2.6 Modifications to the Ejector .................................................................................................................. 9

3 Product description.......................................................................................................................................10

3.1 Description of the Ejector .................................................................................................................... 10

3.1.1 Suction of the Workpiece (Vacuum Generation) .................................................................... 10

3.1.2 Depositing the Workpiece (Blowing Off) ................................................................................ 10

3.1.3 Pneumatic Air Saving Function................................................................................................. 11

3.2 Operating Modes ................................................................................................................................. 11

3.3 Ejector Designation .............................................................................................................................. 11

3.4 Ejector Structure................................................................................................................................... 12

3.5 Display and Operating Element in Detail ........................................................................................... 13

4 Technical Data ...............................................................................................................................................14

4.1 Display Parameters ............................................................................................................................... 14

4.2 Electrical Parameters ............................................................................................................................ 14

4.3 General Parameters.............................................................................................................................. 15

4.4 Mechanical Data................................................................................................................................... 15

4.4.1 Performance Data...................................................................................................................... 15

4.4.2 Factory Settings ......................................................................................................................... 15

4.4.3 Dimensions................................................................................................................................. 16

Contents

4 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

4.4.4 Pneumatic Circuit Plan .............................................................................................................. 17

5 General Description of Functions ................................................................................................................18

5.1 Digital Switching Outputs (SIO)........................................................................................................... 18

5.2 IO-Link................................................................................................................................................... 18

5.3 Operating and Menu Concepts ........................................................................................................... 19

5.3.1 Navigating in the Menu ............................................................................................................19

5.3.2 Enabling Vacuum Switches and Editing Parameters ...............................................................19

5.3.3 Displaying the Basic Settings (Slide Show)............................................................................... 20

5.3.4 Basic Menu .................................................................................................................................21

5.3.5 Extended Functions Menu (EF) .................................................................................................22

5.3.6 Info menu (INF).......................................................................................................................... 23

5.4 Error Display ......................................................................................................................................... 24

6 Transport and storage ..................................................................................................................................25

6.1 Checking the Delivery .......................................................................................................................... 25

7 Installation.....................................................................................................................................................26

7.1 Installation Instructions........................................................................................................................ 26

7.2 Installation ............................................................................................................................................ 26

7.3 Pneumatic Connection ......................................................................................................................... 27

7.3.1 Connecting the Compressed Air and Vacuum .........................................................................27

7.3.2 Instructions for the Pneumatic Connection .............................................................................28

7.4 Electrical Connection............................................................................................................................ 28

7.4.1 Operating the Vacuum Switch in SIO Mode ............................................................................30

7.4.2 Operating the Vacuum Switch in IO-Link Mode...................................................................... 30

8 Functions of the Vacuum Switch .................................................................................................................31

8.1 Overview of Functions ......................................................................................................................... 31

8.2 Monitoring the Operating Voltage..................................................................................................... 32

8.3 Switching Points ................................................................................................................................... 32

8.3.1 Switching Point Mode and Switching Point Logic................................................................... 32

8.3.2 Two-Point Mode ........................................................................................................................32

8.3.3 Window Mode ...........................................................................................................................33

Contents

EN-US · 30.30.01.01602 · 01 · 10/18 5 / 58

8.3.4 Condition Monitoring Mode (Leakage Measurement)........................................................... 33

8.3.5 Diagnostics Mode ......................................................................................................................34

8.4 Teach-in for Switching Points .............................................................................................................. 34

8.5 Additional Switching Point Settings ................................................................................................... 35

8.5.1 Switch-on and Switch-off Delay ............................................................................................... 35

8.5.2 Transistor Function ....................................................................................................................35

8.6 Display Screen....................................................................................................................................... 35

8.6.1 Vacuum Unit ..............................................................................................................................35

8.6.2 Display Alignment .....................................................................................................................36

8.6.3 ECO Mode ..................................................................................................................................36

8.7 Access Rights......................................................................................................................................... 36

8.7.1 PIN Code for Write Protection ..................................................................................................36

8.7.2 IO-Link Device Access Locks ...................................................................................................... 36

8.8 Device Identification ............................................................................................................................ 37

8.9 User-Specific Localization .................................................................................................................... 37

8.10 System Monitoring and Diagnostics.................................................................................................... 37

8.10.1 Minimum and Maximum Values............................................................................................... 37

8.10.2 Counters ..................................................................................................................................... 37

8.10.3 Status Signals .............................................................................................................................38

8.10.4 Leakage Measurement .............................................................................................................. 38

8.11 System Commands................................................................................................................................ 38

8.11.1 Resetting to Factory Settings .................................................................................................... 38

8.11.2 Calibrating the Vacuum Sensor ................................................................................................39

9 Operation ......................................................................................................................................................40

9.1 General Preparations ........................................................................................................................... 40

10 Troubleshooting............................................................................................................................................ 41

10.1 Help with Malfunctions ....................................................................................................................... 41

10.2 List of Error Numbers ........................................................................................................................... 42

10.3 Warnings and Error Messages in IO-Link Mode ................................................................................. 43

11 Maintenance.................................................................................................................................................. 44

Contents

6 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

11.1 Safety .................................................................................................................................................... 44

11.2 Cleaning the Ejector............................................................................................................................. 44

11.3 Replacement of the Device with a Parameterization Server ............................................................. 44

12 Warranty........................................................................................................................................................ 46

13 Spare and Wearing Parts, Accessories......................................................................................................... 47

13.1 Spare and Wearing Parts ..................................................................................................................... 47

13.2 Accessories ............................................................................................................................................ 47

14 Decommissioning and recycling ..................................................................................................................48

14.1 Disposing of the Ejector....................................................................................................................... 48

14.2 Materials Used ...................................................................................................................................... 48

15 Appendix .......................................................................................................................................................49

15.1 SCPi_CE_30.30.01.01667-00.pdf ........................................................................................................... 50

15.2 SCPi_Data Dictionary_01.pdf ............................................................................................................... 51

16 Notes..............................................................................................................................................................57

Important information

EN-US · 30.30.01.01602 · 01 · 10/18 7 / 58

1Important information

1.1Note on using these operating instructions

The J.SchmalzGmbH is generally referred to as Schmalz in these operating instructions.

These operating instructions contain important notes and information about the different operating

phases of the product:

• Transport, storage, start of operations and decommissioning

• Safe operation, required maintenance, rectification of any faults

The operating instructions describe the product at the time of delivery by Schmalz.

1.2The technical documentation is part of the product

1. For problem-free and safe operation, follow the instructions in the documents.

2. Keep the technical documentation in close proximity to the product. The documentation must be accessible to personnel at all times.

3. Pass on the technical documentation to subsequent users.

ð Schmalz is not liable for damage or malfunctions that result from failure to heed these instructions.

If you still have questions after reading the technical documentation, contact the Customer Service Center

on:

www.schmalz.com/services

1.3Warnings in this document

Warnings warn against hazards that may occur when handling the product. This document contains three

levels of danger that you can recognize by the signal word.

Signal word Meaning

WARNING Indicates a medium-risk hazard which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a low-risk hazard which, if not avoided, could result in minor or

moderate injury.

NOTE Indicates a danger that leads to property damage.

1.4Symbol

This sign indicates useful and important information.

ü This symbol represents a prerequisite that must be met before installation and maintenance work.

4 This sign represents an action to be performed.

ð This sign represents the result of an action.

Actions that consist of more than one step are numbered:

1. First action to be performed.

2. Second action to be performed.

Fundamental Safety Instructions

8 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

2Fundamental Safety Instructions

2.1Standards of Technology

The ejector is built in accordance with the latest standards of technology and is shipped safely, however,

hazards can arise during use.

WARNING

Failure to follow the instructions in this manual can lead to life-threatening injuries!

4 Read the operating instructions carefully and observe the contents.

2.2Emissions

The ejector emits noise due to the operation of compressed air.

WARNING

Noise pollution due to the escape of compressed air

Hearing damage!

4 Wear ear protectors.

4 The ejector must only be operated with a silencer.

2.3Intended Use

The ejector is designed to generate a vacuum for gripping and transporting objects when used in conjunction with suction cups. Operation is via a controller using external solenoid valves.

Neutral gases are approved as evacuation media. Neutral gases include air, nitrogen and inert gases (e.g.

argon, xenon and neon).

The product is intended for industrial use.

Intended use includes the observance of the technical data and the installation and operating instructions

in this manual.

2.4Non-Intended Use

WARNING

Extraction of hazardous media, liquids or bulk material

Personal injury or damage to property!

4 Do not extract harmful media such as dust, oil mists, vapors, aerosols etc.

4 Do not extract aggressive gases or media such as acids, acid fumes, bases, biocides, dis-

infectants or detergents.

4 Do not extract liquids or bulk materials, e.g. granulates.

Schmalz accepts no liability for damages caused by non-intended usage of the ejector. In particular, the

following are considered non-intended use:

• Use in potentially explosive atmospheres

• Use in medical applications

• Lifting people or animals

Fundamental Safety Instructions

EN-US · 30.30.01.01602 · 01 · 10/18 9 / 58

• Evacuation of objects that are in danger of imploding

2.5Personnel Qualification

Unqualified personnel cannot recognize dangers and are therefore exposed to higher risks!

1. Only instruct qualified personnel to perform the tasks described in this manual.

2. The product may only be operated by persons who have undergone appropriate training.

3. Electrical work and installations may only be carried out by qualified electrical specialists.

4. Assembly and maintenance work may only be carried out by qualified personnel.

The following target groups are addressed in this manual:

• Installers who are trained in handling the product and can operate and install it

• Technically trained service personnel performing the maintenance work

• Technically trained persons who work on electrical equipment

2.6Modifications to the Ejector

Schmalz assumes no liability for consequences of modifications over which it has no control:

1. The ejector must be operated only in its original condition as delivered.

2. Use only original spare parts from Schmalz.

3. The ejector must be operated only in perfect condition.

Product description

10 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

3Product description

3.1Description of the Ejector

3.1.1Suction of the Workpiece (Vacuum Generation)

The Venturi nozzle on the ejector is activated and deactivated using the Suction command.

In the NO (normally open) version, the Venturi nozzle is continuously sucking. As soon as compressed air is

present at the ejector, the Venturi nozzle becomes active and the ejector generates a vacuum (suction). As

soon as there is no compressed air at the ejector, the Venturi nozzle is deactivated.

An integrated sensor records the vacuum generated by the Venturi nozzle. The value is evaluated using

electronics, displayed via the display and output via the IO-Link process data. The measured value serves

as the basis for the various condition monitoring analysis functions in IO-Link mode.

The ejector has an integrated, pneumatically controlled, air saving function and automatically regulates

the vacuum in Suction mode:

• The integrated, pneumatically controlled, air saving function switches off the Venturi nozzle as soon

as the set vacuum limit value, deactivation value A, has been reached (factory setting).

• When objects with dense surfaces are picked up, the integrated non-return valve prevents the vacuum from dropping.

• If the system vacuum drops below the activation limit value E due to leaks, the Venturi nozzle is

switched back on.

• Depending on the vacuum, the switching point SP1 is set once a workpiece is picked up safely. This

enables the further handling process.

• The enable signal is only reset when rP1 is not reached (> See ch. 3.1.3).

The air saving function is integrated in the ejector via a pneumatic controller. The limit values A and E

cannot be changed.

The display and the LED status display show the current process states, for example the current vacuum

level is displayed.

If small volumes are to be evacuated, the set deactivation value A might be exceeded considerably before the vacuum is switched off. This system behavior does not constitute an error.

3.1.2Depositing the Workpiece (Blowing Off)

In Blow off mode, the vacuum circuit of the ejector is supplied with external compressed air at the corresponding compressed air connection. This ensures that the vacuum drops quickly, depositing the workpiece quickly as well.

NOTE

Compressed air at both compressed air connections at the same time

Damage to the ejector

4 Do not apply compressed air to both compressed air connections at the same time!

When blowing off, make sure that the compressed air supply for vacuum generation is switched off.

Product description

EN-US · 30.30.01.01602 · 01 · 10/18 11 / 58

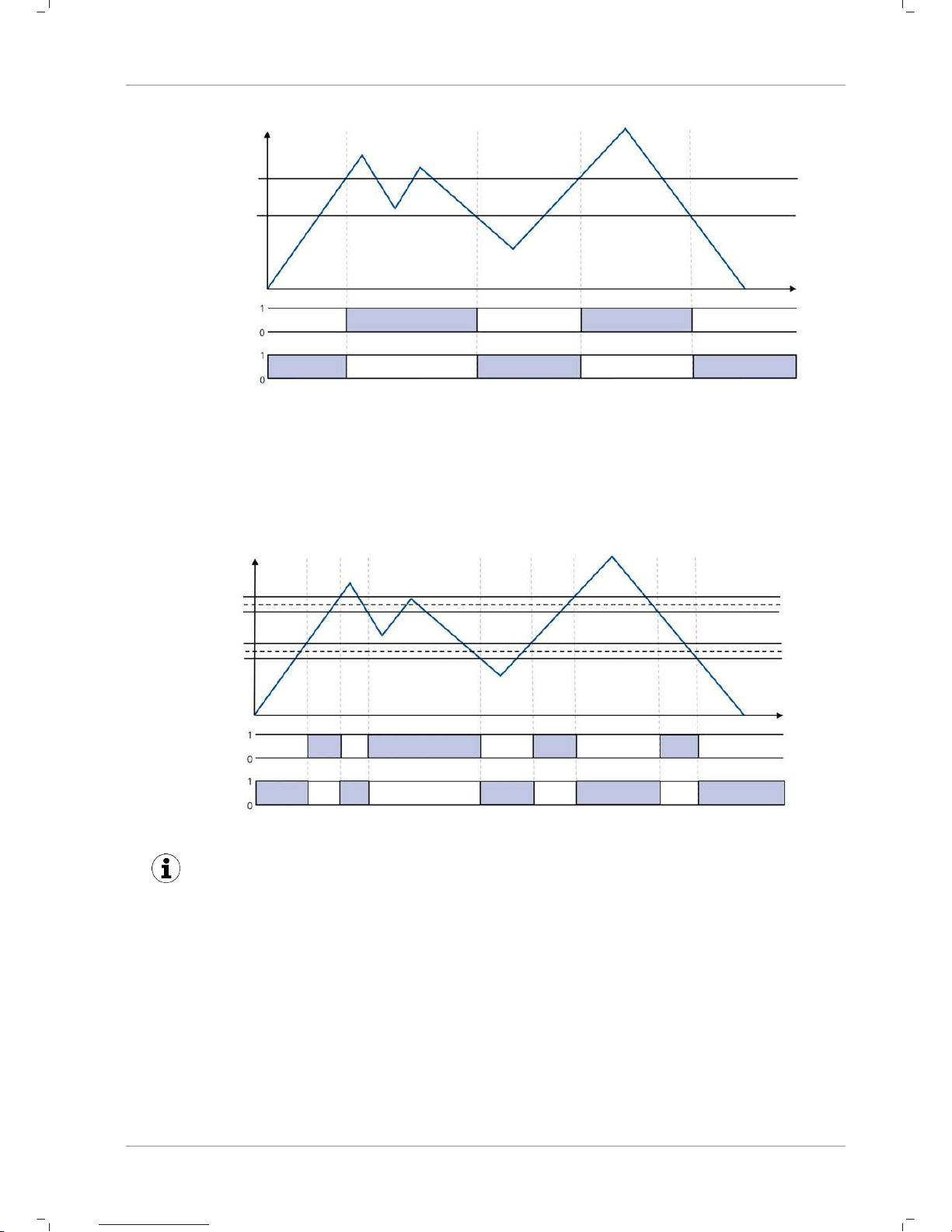

3.1.3Pneumatic Air Saving Function

The ejector includes a pneumatically operated air saving function. When compressed air is applied to compressed air connection 1 (> See ch. (See chap. Ejector structure)), the ejector automatically controls the

vacuum. When the set deactivation value A is reached, the ejector switches off the Venturi nozzle. If the

system vacuum drops below the activation value E due to leaks, the Venturi nozzle is switched back on.

The following diagram shows the air saving function.

The output is set to "on" when switching point SP1 is reached. If the reset value rP1 is not reached, the

output is set to "off."

Vacuum

[mbar]

Vacuum on

Time [s]

A

SP1

E

rP1

OUT=on

OUT=off

3.2Operating Modes

The vacuum switch can be operated in two operating modes. Users can choose between direct connection

to discrete inputs (standard I/O = SIO mode) or connection through the communication line (IO-Link class

A).

If the device is connected to the supply voltage, it is ready for operation. This is the normal operating

mode, in which the vacuum switch is operated by the system controller. A differentiation is made between SIO mode and IO-Link mode.

The vacuum switch is parameterized via the available menus or via IO-Link.

3.3Ejector Designation

The breakdown of the item designation (e.g. SCPi 15 NO-FS RP-VD M12-5) is as follows:

Feature Specifications

Type of ejector SCPi

Nozzle size 1.5mm

Control Normally open (NO)

Type of external control Externally controlled FS

Type of internal control Pneumatically controlled RP

Type of display Vacuum digital VD

Electrical connection M12, 5-pin connector

Product description

12 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

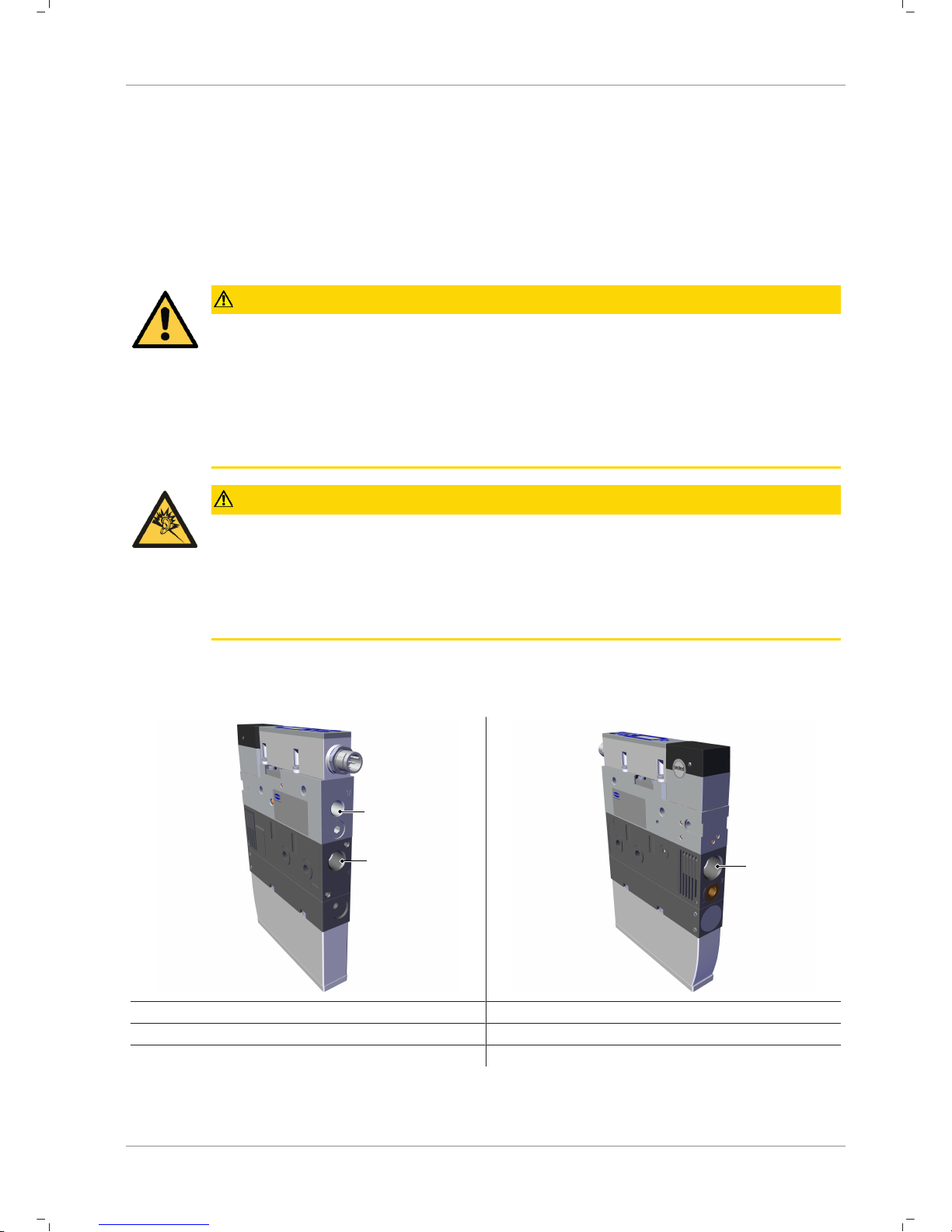

3.4Ejector Structure

1

2

3

4

5

6

7

8

9

11

10

1 Silencer 2 Type plate 1

3 4x mounting holes 4 Position of pneumatic controller

5 Vacuum switch with control and display el-

ement

6 Electrical connection, M12, 5-pin

7 Compressed air connection 1A (blow off) 8 Compressed air connection 1 (suction)

9 Bypass for exhaust air 10 Type plate 2

11 Vacuum connection

Product description

EN-US · 30.30.01.01602 · 01 · 10/18 13 / 58

3.5Display and Operating Element in Detail

The simple operation of the vacuum switch is ensured by 3 buttons, the 3-digit display, as well as 2 LEDs

for status information.

1

2

3

4

5

6

1 Menu button 2 Display

3 LED switching point 1 4 Down button

5 Up button 6 LED switching point 2

Switching points are indicated using two orange LEDs. Depending on the selected operating mode, the

LEDs of the switching points SP1 and SP2 indicate the level of the current system vacuum in relation to the

set limit values.

Detailed information on the meaning of the LEDs in the respective operating modes can be found in the

explanations of the operating modes (> See ch. Functions of the Vacuum Switch).

Technical Data

14 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

4Technical Data

4.1Display Parameters

Parameter Value Unit Note

Display 3 Digit Red 7-segment LED display

Resolution ±1 mbar —

Accuracy ±3 % FS T

amb

= 25° C, based on FS final value (full-scale)

Linearity error ±1 % —

Offset error ±2 mbar After zero-point adjustment, without vacuum

Temperature influ-

ence

±3 % 5° C < T

amb

< 50° C

Display refresh rate 5 1/s Only affects the 7-segment display

Idle time before the

menu is exited

1 min The display mode is accessed automatically when no set-

tings are made in a menu.

4.2Electrical Parameters

Parameter Symbol Limit values Unit Note

min. typ. max.

Supply voltage U

s

19.2 24 28.8 V

DC

PELV

1)

Power consumption from U

S

2)

I

S

— 40

4)

— mA US = 24.0V

Voltage of signal output

(PNP)

U

OH

US-2 — U

s

V

DC

I

OH

< 100mA

Voltage of signal output

(NPN)

U

OL

0 — 2 V

DC

I

OL

< 100mA

Current of signal output

(PNP)

I

OH

— — 100 mA Short-circuit-proof

3)

Current of signal output

(NPN)

I

OL

— — -100 mA Short-circuit-proof

3)

Reaction time of signal outputs

t

O

1 — 200 ms Adjustable

1) The power supply must correspond to the regulations in accordance with EN60204 (protected extra-low

voltage). The signal outputs are protected against reverse polarity.

2) Plus the output currents

3) The signal output is protected against short circuits. However, it is not protected against overloading.

Constant load currents of > 0.1A can lead to impermissible heating and subsequent destruction of the

vacuum switch.

4) Mean value

Technical Data

EN-US · 30.30.01.01602 · 01 · 10/18 15 / 58

4.3General Parameters

Parameter Symbol Limit value Unit Note

min. typ. max.

Working temperature T

amb

5 — 50 °C —

Storage temperature T

Sto

-10 — 60 °C —

Humidity H

rel

10 — 90 % r.h. Free from condensation

Degree of protection — — — IP65 — —

Operating pressure p 4 4.2 7 bar —

Operating medium Air or neutral gas, 5µm filtered, with or without oil, class 3-3-3 compressed

air quality in acc. with ISO 8573-1

4.4Mechanical Data

4.4.1Performance Data

Version SCPi-15 SCPi-20 SCPi-25

Nozzle size 1.5mm 2.0mm 2.5mm

Max. vacuum1 [%] 870

Suction rate1 [l/min] 75 135 185

Max. blow off capacity 1 [l/min] 300

Air consumption 1 [l/min] 115 190 290

Air consumption for blow off1 [l/min] 310

Sound level1, unobstructed suction

[dBA]

75

Sound level1, suction [dBA] 72

Weight [kg] 0.64

All values at ambient conditions of T = 20° C and 1000mbar ambient pressure

1)

at 4.5 bar

4.4.2Factory Settings

In the factory setting, switching point 1 is set in two-point mode (3), and switching point 2 is set in condition monitoring mode (128). The signals are in the NO state.

Part no. Activation

value E

[mbar]

Switching

point SP1

[mbar]

Reset point

rp1 [mbar]

Switching

point SP2

[mbar]

Reset point

rp2 [mbar]

Leakage

limit L2

[mbar/s]

10.02.02.05400

-520 -450 -440 -570 -500 100

10.02.02.05450

10.02.02.04521

10.02.02.05436

-630 -550 -540 -680 -610 100

10.02.02.05438

10.02.02.05440

Technical Data

16 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

Display code Parameter Value of the factory setting

Xy1

Window hysteresis 1 20mbar

d51

Switch-on delay 1 0ms

dr1

Switch-off delay 1 0ms

Xy2

Window hysteresis 2 100mbar

d52

Switch-on delay 2 0ms

dr2

Switch-off delay 2 0ms

P-n

Signal type/transistor function

PNP switch = P-n

uni

Vacuum unit

Vacuum unit in mbar = -bA

Eco

ECO mode

Deactivated = oFF

d15

Display alignment

Standard = 5td

Pin

PIN code 000

Factory settings

4.4.3Dimensions

B d d1 G1 G2 G3 G4 G5 H H1 H2 H3

22.8 6.6 5.5 G1/4"

-IG

G3/8"

-IG

M12x

1-AG

M4-IG G1/8"

-IG

170 98 460 87.5

H4 H5 L L1 L2 L3 L4 X1 X2 X3 Y2 Y3

76 127.5 118 126.5 112 67.5 36.75 27.5 14 58 30 10

All specifications are in mm

Technical Data

EN-US · 30.30.01.01602 · 01 · 10/18 17 / 58

4.4.4Pneumatic Circuit Plan

General Description of Functions

18 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

5General Description of Functions

5.1Digital Switching Outputs (SIO)

To operate the standard digital inputs of the automation technology or to directly control the electrical

consumers, the switch has two digital outputs.

In the delivery state, the signal output OUT 1 is assigned the function switching point 1, parts control, and

the signal output OUT 2 is assigned the switching point 2, leakage monitoring. They are configured in the

EF menu (Extended Functions) via the associated menu items 0u1 and 0u2.

The electrical status of both of the outputs OUT1 and OUT2 thus corresponds with the logical status of

switching points 1 and 2 regardless of the switching point parameters that have been set:

• Switching point mode and switching point logic

• Switching thresholds and hysteresis (function depends on mode set)

• Switch-on and switch-off delay times

• Electrical transistor functions PNP or NPN

The electrical signal outputs are adjustable with regard to the switching behavior on the device. In the EF

menu or via IO-Link, a choice can be made between the PNP and NPN signal types for each signal output.

The setting is independent of the version.

The vacuum switch is factory set to PNP.

5.2IO-Link

The vacuum switch can be operated in IO-Link mode to enable intelligent communication with a controller. The parameters of the vacuum switch can be set remotely using IO-Link mode.

The vacuum switch provides many additional functions besides the two switching signals via the IO-Link

communication.

• The actual measurement value is provided live using the process data.

• Warnings and error statuses that occur are reported to the master via the IO-Link event mechanism.

• More precise information regarding the system status is retrieved using the acyclical communication

channel (known as ISDU parameters).

• Within the framework of the ISDU channel, all settings (e.g. switching point modes and delay times)

for the vacuum switch are read or overwritten.

• In addition to the identification data that can be accessed from the control menu such as the part

number and serial number, additional information regarding the identity of the ejector can be retrieved. It also provides memory for user-specific information, for example the installation or storage

site.

The following diagram shows the alignment of the 2byte process input data for the vacuum switch.

PD in

byte no.

0 1

Bit no. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Contents Measured value (14 bit) SP2 SP1

The bits SP1 and SP2 reflect the logical status of switching points 1 and 2.

The measured value is displayed as 14bit unsigned vacuum in millibar (vacuum positive).

A detailed description of all the device parameters can be found in the data dictionary.

General Description of Functions

EN-US · 30.30.01.01602 · 01 · 10/18 19 / 58

5.3Operating and Menu Concepts

The unit is operated via three buttons on the foil keypad. The parameters are set via software menus. The

current system status and the settings are shown on a display.

The operating structure is divided into three menus:

• The basic menu

• The menu for extended functions (EF)

• The info menu (INF)

Setting of the vacuum switch in the basic menu is sufficient for standard applications. An extended functions menu (EF) is available for applications with special requirements.

If settings are changed, undefined states of the system may occur for a short time (for approx. 50ms).

The following information can be shown on the display:

• The current vacuum measurement value

• The selected menu item

• The setting values

• Error messages

In the basic operating menu state, the actual measurement value of the vacuum is displayed on the basis

of the chosen display unit. All units are available in millibar, kilo pascal, inch-hg and PSi. The measured

value is displayed as a positive compared to the ambient air pressure.

After setting a parameter via the operating menu, the power supply of the switch must remain

stable for at least 3 seconds, otherwise there may be a loss of data and the resulting error

E01 occurs.

The menus will automatically close if no button is pressed for 1 minute.

The display also returns to the basic status when an error status occurs so that the error number can be

displayed. A menu can be called up and used again afterward.

If parameters are changed using the IO-Link, the menu will also close. The instruction dAt will then appear on the display for 2 seconds.

5.3.1Navigating in the Menu

The basic menu can be reached from the basic status by pressing the DOWN BUTTON or the UP BUT-

TON . Scrolling through the menu is also possible using these buttons. When the desired menu item

has been found, select it using the MENU BUTTON . If there is a submenu ("EF" and "INF"), this can

also be browsed in the same manner using the DOWN and UP buttons.

5.3.2Enabling Vacuum Switches and Editing Parameters

Enabling Vacuum Switches

Using the Extended functions (EF) menu, the vacuum switch can be protected against unintentional access

by means of a PIN code P1n.

If you attempt to change a parameter value, the message "P.I.n" will appear in the display and changes to

enter the 3-digit PIN code. It is also possible to exit the menu in the meantime.

How to enable the vacuum switch:

1. Press the button

ð The display changes to input

2. Use the or buttons to enter the first digit of the PIN code

General Description of Functions

20 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

3. Confirm using the button

ð The display changes to the middle digit.

4. Enter the remaining digits in the same way.

5. To enable the device using the menu, press the button

ð When entering a valid PIN the message VnC appears.

ð The entry of an invalid PIN is rejected with the message LoC.

The lock is activated again automatically 1 minute after the selected menu or function is exited.

The PIN code 000 must be set for permanent deactivation of the lock.

Tips and Tricks for Parameter Setting

• By pressing the or button for approx. 3 seconds, the value to be changed is

scrolled through quickly

• If you exit the changed value by briefly pressing , the value will not be applied.

Editing the parameters

If a menu item has been selected, the current value first appears in the display. With parameters that can

be set, the adjustable digit or the whole value will flash. These values can be changed using the and

buttons. When doing so, the possible settings are run through cyclically. For numerical valuesconsist-

ing of 3 digits, the button is used to move to the next highest digit. At the end of the editing process,

the button is pressed again after the last number. The new value then appears on the display without

flashing.

If the new value is invalid, the display shows one of the following messages instead and the old value remains:

• Oor (out of range) means that the new value is generally outside the value range

• inC (inconsistent) means that the value overlaps with the current setting of another parameter,

e.g. rP1 > SP1

To cancel the editing process, buttons and can be simultaneously pressed at any time.

5.3.3Displaying the Basic Settings (Slide Show)

By pressing the button in the basic operating state, the current parameter values of the vacuum switch

listed here are automatically displayed one after the other on the display (slide show):

• The vacuum unit

• The communication mode

• The switching point

• The reset point

• The operating voltage

The display cycle returns to the vacuum display after a complete cycle or can be canceled at any time by

pressing any button.

General Description of Functions

EN-US · 30.30.01.01602 · 01 · 10/18 21 / 58

5.3.4Basic Menu

All of the settings for standard vacuum switch applications can be configured and read from the basic

menu.

1. Use or to select the desired adjustable parameter.

2. Confirm the selection of the parameter with the button.

3. Use the or buttons to set the value of the parameter.

4. To save and exit the menu, press and hold the button.

ð The displayed value flashes to confirm.

Display code Parameter Explanation

5P1 or FX1

Switching point 1 / upper window

point 1

—

rP1 or FL1

Reset point 1 / lower window

point 1

—

hy1 or -L-

Hysteresis switching point 1 (window mode) or leakage limit 1 (CM

mode)

—

5P2 or FX2

Switching point 2 / upper window

point 2

—

rP2 or FL2

Reset point 2 / lower window

point 2

—

hy2 or L-2

Hysteresis switching point 2 (window mode) or leakage limit 2 (CM

mode)

—

tCX

Teach-in function

No / 5P1 / 5P2

CAL

Calibrate zero offset

Calibrate integrated vacuum sensor, No /

yE5

EF

Additional functions Menu: Additional functions

1mF

Information Menu: Information

Overview of the display codes in the basic menu

Calibrating the vacuum sensor

1. Select the parameter or display code CAL with the or buttons.

2. Confirm using the button.

3. Use the or buttons to select YE5.

4. Press the button to confirm.

ð The vacuum sensor integrated in the ejector is now calibrated.

General Description of Functions

22 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

5.3.5Extended Functions Menu (EF)

An "Extended functions" menu (EF) is available for applications with special requirements.

1. In the basic menu, press the or button to select the EF parameter and change to the param-

eter selection of the EF menu by pressing the button.

2. The parameters are set in accordance with the description in the Basic Menu section.

ð The first parameter 0u1 appears on the display.

Display

code

Parameter Explanation

0u1

Switching function,

switching output 1

Define the switching point mode:

H.no / H.nc: Hysteresis function, normally open / normally

closed

F.no / F.nc: Window function, normally open / normally closed

C.no / C.nc: Condition monitoring function, normally open /

normally closed

d.no / d.nc: Diagnosis function, normally open / normally

closed

0u2

Switching function,

switching output 2

Switching function, switching output 2: (see Ou1)

d51

Switch-on delay for

switching point 1

in ms; This parameter is not displayed in the menu if the

switching point is in condition monitoring mode C.no.

dr1

Switch-off delay for

switching point 1

In ms; This parameter is not displayed in the menu if the

switching point is in condition monitoring mode C.no.

d52

Switch-on delay for

switching point 2

In ms; This parameter is not displayed in the menu if the

switching point is in condition monitoring mode C.no.

dr2

Switch-off delay for

switching point 2

In ms; This parameter is not displayed in the menu if the

switching point is in condition monitoring mode C.no.

uni

Vacuum unit Define the displayed vacuum unit

bAr: Vacuum value in millibar

kPa: Vacuum value in kilopascal

IHg: Vacuum value in inch of mercury

PSI: Vacuum value in pound-force per square inch

Eco

Display in ECO mode Set the display

off: ECO mode is deactivated – the display remains on

Lo: Display dimmed by 50%

on: ECO mode is activated – the display switches off

d15

Align the display Std: Standard

Red: Display rotated by 180°

P1n

PIN code Access rights, specify the PIN code, lock the menus

P-n

Signal type Transistor functions of both outputs: PnP / nPn

rE5

Reset No: The values remain unchanged

YES: Reset parameter values to factory settings

Overview of display codes in the Additional functions menu

General Description of Functions

EN-US · 30.30.01.01602 · 01 · 10/18 23 / 58

5.3.6Info menu (INF)

The "Info" (INF) menu is available for reading out system data such as counters, software version, part

numbers and serial numbers.

1. In the basic menu, press the or button to select the 1mF parameter and change to the pa-

rameter selection of the menu by pressing the button.

2. The parameters are set in accordance with the description in the Basic Menu section.

ð The first parameter X1 appears on the display.

Display code Parameter Explanation

X1

Max. vacuum value Highest measured sensor value (since restart)

L0

Min. vacuum value Lowest measured sensor value (since restart)

rXl

Reset vacuum value Reset maximum and minimum values (HI/LO)

cc1

Counter 1 Counter, switching ramp SP1 (non-erasable)

cc2

Counter 2 Counter, switching ramp SP2 (non-erasable)

ct1

Counter 3 Counter, switching ramp SP1 (erasable)

ct2

Counter 4 Counter, switching ramp SP2 (erasable)

rct

Reset erasable counters

Reset erasable counters (Ct1 and Ct2) using YE5

5oC

Software function Firmware revision

Art

Part number Format of the part no., example: 10.02.02.05440

5nr

Serial number Information about the production period

Overview of display codes in the "Info" menu

When specifying the counter valuesor numbers with more than 3 digits, the following special features

must be observed.

The counters and serial numbers are 9-digit whole numbers. These are divided into 3 blocks of 3 numbers

when indicated in the display. Each time a decimal point is displayed to indicate if it is the highest, middle

or lowest block. The display starts with the 3 highest numbers and can be scrolled through using the

or button.

Prompting for the counter values

After confirming the parameter counter 1 or counter 2 with the button, the three decimal places of

the total counter value are displayed (the digits x106). This corresponds to the three-digit block with the

highest perceived value.

Use the buttons to display the remaining decimal places of the total counter value in order. The decimal points show which three-digit block of the complete counter value is shown in the display.

The complete counter value is comprised of the three digit blocks together:

Displayed position 10

6

10

3

10

0

Displayed number block 0.48 61.8 593.

The current complete counter value in this example is 048 618 593.

General Description of Functions

24 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

Prompting for the part number

The part number of the ejector is printed on the label and also stored electronically.

After confirming the part number Art parameter with the button, the first two digits of the part

number are displayed. The remaining digits of the part number are displayed with the button. The

displayed decimal points are part of the part number.

The part number consists of 4 number blocks with a total of 11 digits.

Digit block 1 2 3 4

Displayed number block 10. 02.0 2.00 383

The part number in this example is 10.02.02.00383.

Prompting for the serial number

The serial number indicates the production period of the ejector.

After confirming the serial number parameter with the button, the first three decimal places of the serial number are displayed (the digits x106). This corresponds to the three-digit block with the highest perceived value.

The remaining decimal places of the serial number are displayed with the button. The decimal points

show which three-digit block of the serial number is shown in the display.

The serial number consists of 3 number blocks with a total of 9 digits:

Displayed position 10

6

10

3

10

0

Displayed number block 0.48 61.8 593.

The serial number in this example is 048 618 593.

5.4Error Display

If an error occurs, it appears on the display in the form of an error code ("E number"). The vacuum

switch’s response to an error depends on the type of error.

You can find a list of possible errors and the corresponding codes in the Warnings and Errors section.

Any operation being performed in the menu will be interrupted if an error occurs.

The error code can also be opened as a parameter using IO-Link.

Transport and storage

EN-US · 30.30.01.01602 · 01 · 10/18 25 / 58

6Transport and storage

6.1Checking the Delivery

The scope of delivery can be found in the order confirmation. The weights and dimensions are listed in

the delivery notes.

1. Compare the entire delivery with the supplied delivery notes to make sure nothing is missing.

2. Damage caused by defective packaging or in transit must be reported immediately to the carrier and

J. Schmalz.

Installation

26 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

7Installation

7.1Installation Instructions

CAUTION

Improper installation or maintenance

Personal injury or damage to property

4 During installation and maintenance, make sure that the ejector is disconnected and

depressurized and that it cannot be switched on again without authorization.

For safe installation, the following instructions must be observed:

1. Use only the connections, mounting holes and attachment materials that have been provided.

2. Carry out mounting and removal only when the device is in an idle, depressurized state.

3. Pneumatic and electrical line connections must be securely connected and attached to the ejector.

7.2Installation

The ejector may be installed in any position.

When installing the ejector, make sure that the areas around the silencer and the bypass remain free, so

that unimpeded discharge of the escaping air is ensured.

Bypass

Silencer

Four mounting holes for 2x M5 and 2x M6 screws are used to fix the ejector. The ejector is to be fixed

with at least 2 screws, the maximum tightening torque is 6Nm.

Mounting hole 2xM5

Mounting hole 2xM6

Installation

EN-US · 30.30.01.01602 · 01 · 10/18 27 / 58

For start of operations, the ejector must be connected to the controller via the connection plug with a

connection cable. The compressed air required to generate the vacuum and the blow off is connected via

the corresponding compressed air connections. The compressed air supply must be supplied by the higherlevel machine.

The vacuum circuit or gripping system is connected to the vacuum connection.

The installation process is described and explained in detail below.

7.3Pneumatic Connection

CAUTION

Compressed air or vacuum in direct contact with the eye

Severe eye injury

4 Wear eye protection

4 Do not look into compressed air openings

4 Do not look into the silencer air stream

4 Do not look into vacuum openings, e.g. suction cups

CAUTION

Noise pollution due to incorrect installation of the pressure and vacuum connections

Hearing damage

4 Correct installation.

4 Wear ear protectors.

7.3.1Connecting the Compressed Air and Vacuum

1

1A

2

1 Compressed air connection (suction)

1A Compressed air connection (blow off)

2 Vacuum connection

The compressed air connection 1 on the ejector has the size G1/4"-IG.

Installation

28 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

4 Connect compressed air hose. The max. tightening torque is 10Nm.

The compressed air connection 1A on the ejector has the size G1/8"-IG.

4 Connect compressed air hose. The max. tightening torque is 10Nm.

The vacuum connection G3/8"-IG is marked with the number 2 on the ejector.

4 Connect vacuum hose. The max. tightening torque is 10Nm.

7.3.2Instructions for the Pneumatic Connection

Use only screw unions with cylindrical G-threads for the compressed air and vacuum connection!

To ensure problem-free operation and a long service life of the ejector, only use adequately maintained

compressed air and consider the following requirements:

• Use of air or neutral gas in accordance with EN 983, filtered 5 μm, oiled or unoiled.

• Dirt particles or foreign bodies in the ejector connections, hoses or pipelines can lead to partial or

complete ejector malfunction.

1. Shorten the hoses and pipelines as much as possible.

2. Keep hose lines free of bends and crimps.

3. Only use a hose or pipe with the recommended internal diameter to connect the ejector, otherwise

use the next largest diameter.

4. On the compressed air side, ensure that the internal diameter has the necessary specifications so

that the ejector achieves its performance data.

5. On the vacuum side, ensure that the internal diameter has the necessary specifications to avoid high

flow resistance. If the internal diameter is too small, the flow resistance and the evacuation times increase and the blow off times are extended.

The following table shows the recommended line cross-sections (internal diameter):

Performance class Line cross-section (internal diameter) in mm

1)

pressure side Vacuum side

15 6 6

20 6 8

25 8 9

1)

Based on a maximum hose length of 2m.

4 For longer hose lengths, the cross-sections must also be larger.

7.4Electrical Connection

WARNING

By activating/deactivating the product, output signals lead to an action in the production process!

Personal injury

4 Avoid possible danger zone.

4 Remain vigilant.

Installation

EN-US · 30.30.01.01602 · 01 · 10/18 29 / 58

NOTE

Incorrect power supply

Destruction of the integrated electronics

4 Operate the product using a power supply unit with protected extra-low voltage

(PELV).

4 The system must incorporate safe electrical cut-off of the power supply in compliance

with EN60204.

4 Do not connect or disconnect the connector under tension and/or when voltage is ap-

plied.

NOTE

Power load too high

Destruction of the vacuum switch, as there is no protection against overloading!

4 Prevent constant load currents > 0.1A.

The electrical connection is established using a 5-pin M12 connector that supplies the vacuum switch with

voltage, and contains the two output signals.

The maximum line length for the supply voltage, the signal inputs and the signal output is:

• 30m in SIO mode

• 20m in IO-Link mode

Connect the ejector electrically using the plug connection 1 shown in the figure

1

1 Electrical connection plug, M12, 5-pin

ü Provide connection cable with 5-pin M12 plug, taking account of the selected operating mode (de-

termined by the customer).

4 Attach the connection cable to the ejector, maximum tightening torque = hand-tight.

Installation

30 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

7.4.1Operating the Vacuum Switch in SIO Mode

PIN assignment, 5-pin M12 connector

M12 connector Pin Symbol Function

1 U

s

Supply voltage

2 OUT2 Switching point 2, leakage monitoring (factory setting)

3 Gnd

S

Ground

4 OUT1 Switching point 1, parts control (factory setting)

5 — Not used

The electrical connection can be established in the following ways:

1. Direct connection to the controller

Using the Schmalz connection cable, part no. 21.04.05.00080, with connector M12-5 with open end

and 5m length.

2. Connection via an I/O box

Using the Schmalz connection cable, part no. 21.04.05.00158, with connector M12-5 on M12-5 and 1m

length.

7.4.2Operating the Vacuum Switch in IO-Link Mode

PIN assignment, 5-pin M12 connector

M12 connector Pin Symbol Function

1 U

s

Power supply for sensor

2 — —

3 Gnd Ground

4 C/Q IO-Link communication

5 — —

Start of operations

The second output OUT2 for the vacuum switch is deactivated in IO-Link operation.

When operating the switch in IO-Link mode (digital communication), the supply voltage, Gnd and the C/Q

communication cable must be directly connected to the corresponding connections of an IO-Link master

with IO-Link class A parts. When doing so, a new port must be used on the master for each switch; a junction of several C/Q cables is not possible with only one IO-Link master port.

The IO-Link master must be connected in the configuration of the automation system in the same way as

other fieldbus components. To activate the port for IO-Link communication, a software tool from the respective master manufacturer is usually provided (e.g. Siemens PCT, Beckhoff TwinCAT etc.).

Functions of the Vacuum Switch

EN-US · 30.30.01.01602 · 01 · 10/18 31 / 58

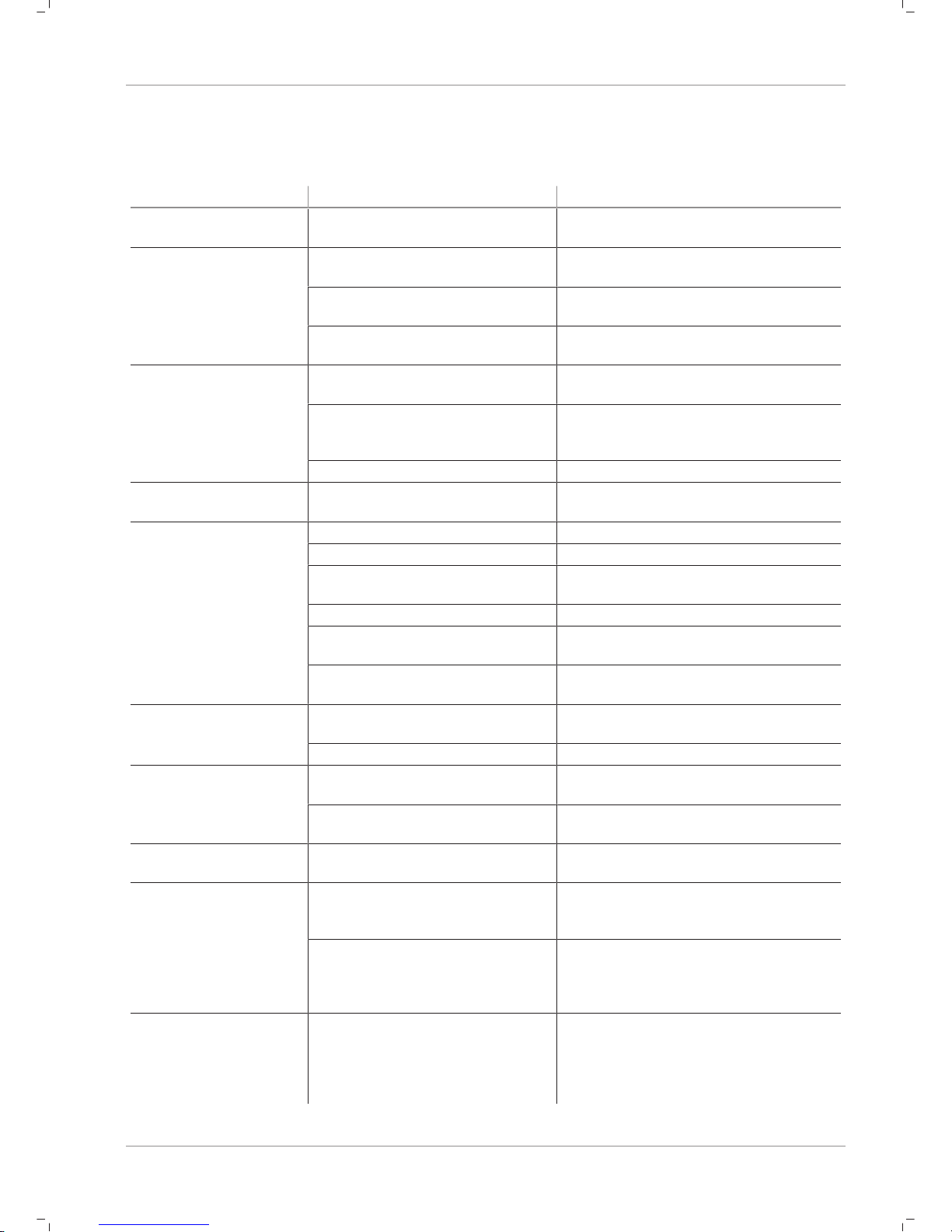

8Functions of the Vacuum Switch

8.1Overview of Functions

Description Availability Parameter See section

SIO IO-Link

Switching point setting

5P1 / FX1

rP1 / FL1

hy1 / L-1

5P2 / FX2

rP2 / FL2

hy2 / L-2

(> See ch. 8.3.)

Switching point mode and logic

0u1 / 0u2

(> See ch. 8.3.1)

Teach-in

tCX

(> See ch. 8.4)

Switch-on and switch-off delay

d51 / dr1

d52 / dr2

(> See ch. 8.5.1)

Transistor function

P-n

(> See ch. 8.5.2)

Display unit

uni

(> See ch. 8.6.1)

Display alignment

dI5

(> See ch. 8.6.2)

Eco mode

Eco

(> See ch. 8.6.3)

Menu PIN, access rights

P1n

(> See ch. 8.7.1)

IO-Link device access locks — (> See ch. 8.7.2)

Part number

Art

(> See ch. 5.3.6)

Software version

5oc

(> See ch. 5.3.6)

Serial number

5nr

(> See ch. 5.3.6)

IO-Link identification data — (> See ch. 8.8)

User-specific identification — (> See ch. 8.9)

Voltage measurement — (> See ch. 8.2)

Minimum and maximum values

X1 / L0

(> See ch. 8.10.1)

Counters

cc1 / cc2

ct1 / ct2

(> See ch. 8.10.2)

Warnings and errors

e.g. E02

FFF / -FF

(> See ch. 10.2)

System status — (> See ch. 8.10.3)

Condition monitoring (CM) —

Reset to factory settings

rE5

(> See ch. 8.11.1)

Calibrate zero position

CAL

(> See ch. 8.11.2)

Reset maximum and minimum value

rxl

(> See ch. 8.10.1)

Reset counters

rct

(> See ch. 8.10.2)

Functions of the Vacuum Switch

32 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

8.2Monitoring the Operating Voltage

The vacuum switch measures the amount of its operating voltage US with a resolution of 100mV.

When the valid voltage range is left, corresponding error statuses (> See ch. 10.2 and 10.3) are triggered.

In the undervoltage range, the switch delays all inputs by the user.

8.3Switching Points

In the following, the switching point number is always denoted by an "x" when information

applies equally to both switching points. SPx therefore stands for both SP1 and SP2.

8.3.1Switching Point Mode and Switching Point Logic

Both switching points are identical in terms of function and can be parameterized independently of one

another.

There are 4 different switching point modes to choose from:

• Two-point mode H.no / H.nc

• Window mode F.no / F.nc

• Condition monitoring mode C.no / C.nc

• Diagnostics mode D.no / D.nc

In this case, there is a differentiation between the switching point logic NO (normally open) and NC (normally closed). A change in the switching point logic from NO to NC causes a logical inversion of the electrical switching outputs, the switching point bits in the IO-link process data and the orange LED display(s)

on the switch.

The condition monitoring and diagnostics modes cannot be activated simultaneously for both

switching points. That means that when a switching point is already parameterized to C.no,

C.nc, D.no or D.nc, the other can only adopt the modes H.no, H.nc, F.no or F.nc.

8.3.2Two-Point Mode

The two-point mode is a threshold switch with hysteresis.

When the measurement value increases, the switching point will be active when the switch-on threshold

SPx is reached and remains on until it falls below the reset threshold rPx. The following must always apply

for switching thresholds and reset thresholds: |SPx| > |rPx|. The hysteresis is therefore defined by the difference |SPx – rPx|.

Functions of the Vacuum Switch

EN-US · 30.30.01.01602 · 01 · 10/18 33 / 58

Pressure p

[mbar]

Time t

Switching point SP

Reset point rP

Output NO

Output NC

8.3.3Window Mode

In window mode, the switching point is active when the measurement value is between the upper window point FHx and the lower window point FLx. Outside this window, the switching point is inactive. If

necessary, a common switching hysteresis Hyx can be set, which symmetrically applies to both window

points. For the parameters of the upper window point FHx, lower window point FLx and hysteresis Hyx,

the following must always apply: |FHx| > |FLx| + Hyx

Pressure p

[mbar]

Switching point FH

Switching point FL

Output NO

Output NC

Time t

Hysteresis

Hysteresis

}

}

When switching from two-point mode to window mode, the current switching points SPx and

rPx are interpreted as window points FHx and FLx. They are the same internal parameters (also

see the data dictionary). If the resulting set of parameters are not valid in the new mode (e.g.

hysteresis too big in window mode), it is not possible to switch the mode because the difference must be at least 30mbar.

8.3.4Condition Monitoring Mode (Leakage Measurement)

The condition monitoring switching point mode is used to monitor the quality of a vacuum suction system. In this case, the vacuum switch can measure the vacuum leakage in millibars per second between

two drainage cycles. The switching point is then activated when a leakage exceeds its maximum permissible setting, which can be configured.

Functions of the Vacuum Switch

34 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

The detection of an external suction cycle is carried out using the adjustable limit values SPx and rPx that

indicate the limits for picking up and depositing a workpiece. The threshold for the maximum permissible

leakage is set using the parameter L-x in millibars per second. The following diagram shows the case of a

typical suction cycle where the system indicates a leakage and the vacuum generator drains many times:

Pressure p

[mbar]

Switching point SP

Reset point rP

Output

Suction cycle

begins

New

suction cycle

Suction cycle

ends

Time t

Peak recognition activates

leakage measurement

Low

leakage

Low

leakage

High

leakage

Another application for Condition monitoring mode occurs if the regulation threshold of the vacuum system is never achieved and the vacuum generator permanently sucks. In this case, if the end vacuum is

20mbar lower than the start vacuum, the switching point will also be activated.

For a very tight vacuum system where the second case shown always occurs in normal operation and indicates no error, Condition monitoring mode is not suitable.

8.3.5Diagnostics Mode

Diagnostics mode monitors the internal warnings and error messages of the switch. When an error message (error code in display or ISDU 130) or warning (CM bit in ISDI 146) appears, the switching point is activated.

Diagnostics mode also includes the functions of Condition monitoring mode. That means the switching

point is also activated when the leakage measurement results in a warning.

8.4Teach-in for Switching Points

A teach-in function is available to make it easier to set the limit values. This only affects one switching

point on one occasion and changes nothing on the selected switching point mode or switching point

logic.

ü To cancel a teach-in process, the required switching point must first be selected. This is done via IO-

Link, via ISDU 58 or in the menu item "tCX" in the basic menu.

4 In the menu, the teach-in starts immediately when the button is pressed; if it is done via IO-link,

the appropriate system command has to be written via ISDU 2 first.

ð The switch-on threshold SPX or FHx is set for teach-in in such a way that it is 20% below the actual

required measurement value. The reset threshold for vacuum values is set at 50mbar below the

switch-on threshold. The associated hysteresis for window mode is set at 10mbar for vacuum values.

ð After a successful teach-in process, an automatic display cycle of the newly set values appears in the

display.

Functions of the Vacuum Switch

EN-US · 30.30.01.01602 · 01 · 10/18 35 / 58

8.5Additional Switching Point Settings

8.5.1Switch-on and Switch-off Delay

For each switching point and each associated limit value, a delay time can be set, with the exception of

condition monitoring mode. Here, this parameter can only be defined for the switching point SP1. In Condition monitoring mode, the parameters dSx and drx are also not shown on the display.

Due to the switch-on and switch-off delay, short-term fluctuations of the measurement signal can be hidden. In this case, the switch delay dSx is based on a situation in which the measurement value increases

(from the absolute value). Accordingly, the reset delay drx is based on a decreasing measurement value.

The following diagram shows the option to set the delay times using two-point mode:

Pressure p

[mbar]

Switching point SP

Reset point rP

Output NO

Output NC

Time t

Legend:

Switch-on delay (ds)

Reset delay (dr)

8.5.2Transistor Function

The electrical characteristic of the switching outputs can be switched between PNP switching ("plus

switching" or also "24V switching") and NPN switching ("zero switching" or also "GND switching"). Both

switching outputs can always be set together, which does not affect the IO-Link operation.

The transistor function is set in the EF menu under the parameter P-n.

8.6Display Screen

8.6.1Vacuum Unit

The physical unit that is used to display the measured values as well as the limit valuesand hystereses on

the display can be set via the EF menu under the menu item uni or via IO-Link:

Unit Display code, setting parame-

ters

Display unit

Bar

bAr

mbar

Pascal

kPA

kPa

Inch Mercury

iXg

inHg

Pound-force per square inch

P5i

Psi

The selection of the vacuum unit affects only the display, it has no effect on the display of the values via

IO-Link. These are always measured in mbar, see (> See ch. data dictionary).

Functions of the Vacuum Switch

36 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

8.6.2Display Alignment

The display alignment can be rotated by 180 degrees using the parameter di5 to adapt to the installation position of the ejector.

When rotated, the decimal point on the far right is no longer displayed and is therefore missing from the

display of the counter statuses and serial numbers.

8.6.3ECO Mode

The ejector offers the option to switch off the display or to dim the display to save energy.

ECO mode can be activated and deactivated in the EF menu under the menu item Eco or via the IO-Link.

• ECO mode (ECO mode "on"), the display is switched off 1 minute after the last button is pressed.

• ECO mode "Lo": 1 minute after the last button is pressed, the numerical display will reduce to 50%

of its normal brightness.

The display is reactivated by pressing any button or by an error message.

If you activate ECO mode using IO-Link, the display will immediately enter energy-saving

mode.

8.7Access Rights

8.7.1PIN Code for Write Protection

A PIN code can be used to prevent the parameters from being changed using the operating menu.

A PIN is recommended because carrying out parameterization while the device is in operation

can change the status of signal inputs and outputs.

The PIN code is entered in the EF menu under the menu item P1N or via IO-Link.

The current settings are still displayed in a locked state.

The PIN is set to 000 on delivery, meaning access to the parameters is not locked. To activate the write

protection, a PIN code between 001 and 999 must be entered via the menu or IO-Link.

If write protection is activated with a customer-specific PIN, the desired parameters are changed within

one minute of the correct code being entered. If no changes are made within one minute, write protection is automatically reactivated. A PIN of 000 must be reset to permanently deactivate the lock.

Full access to the device is still possible via IO-Link even if a PIN is enabled. The current PIN can also be

read out and changed/deleted (PIN = 000) via IO-Link.

8.7.2IO-Link Device Access Locks

In IO-Link mode, the "Device access locks" default parameter is available to prevent changes to parameter

values using the user menu or IO-Link. You can also prevent the use of the Data storage mechanism described in IO-Link Standard V1.1.

Bit Meaning

0 Parameter write access locked

(Parameters cannot be changed via IO-Link)

1 Data storage locked

(Data storage mechanism is not triggered)

2 Local parametrization locked

(Parameters cannot be changed via the user menu)

Coding for the device access locks

Functions of the Vacuum Switch

EN-US · 30.30.01.01602 · 01 · 10/18 37 / 58

A menu lock using the Device access locks parameter has a higher priority than the menu PIN. In other

words, this lock cannot be bypassed by entering a PIN and remains in SIO mode.

It can only be canceled via IO-Link, not via the ejector or the vacuum switch itself.

8.8Device Identification

The IO-Link protocol provides a range of identification data for compliant devices that can be used to

uniquely identify a device. This product contains even more advanced identification parameters.

The parameters are ASCII character strings that adapt their length to the relevant content.

The following parameters can be queried:

• Manufacturer's name and website

• Product, series and exact type name

• Part number and development status

• Serial number and date code

• Version status of the hardware and firmware

8.9User-Specific Localization

The following parameters are available for each vacuum switch when saving user-specific information:

• Identification of the installation location

• Identification of the storage location

• Equipment labeling from the circuit diagram

• Installation date

• Geo-location

• Web link to the relevant IODD

The parameters are ASCII character strings with the maximum length given in the data dictionary. They

can also be used for other purposes if necessary.

8.10System Monitoring and Diagnostics

8.10.1Minimum and Maximum Values

The maximum and minimum vacuum and operating voltage values that were measured since the last

switch-on are logged by the switch and can be queried.

The maximum and minimum values can be reset via IO-Link during operation using the appropriate system commands.

For the vacuum, it is possible to query the values using the INF menu via the parameters X1 and Lo. The

values are reset using the parameter rxL.

8.10.2Counters

The vacuum switch has two non-erasable counters cc1 and cc2 as well as two erasable counters ct1

and ct2 in the INF menu.

These counters count the positive switching ramps of the switching points 1 and 2:

Designation Display code or param-

eter

Description

Counter 1

cc1

Counter for positive switching ramps SP1 (non-erasable)

Counter 2

cc2

Counter for positive switching ramps SP2 (non-erasable)

Counter 3

ct1

Counter for positive switching ramps SP1 (erasable)

Counter 4

ct2

Counter for positive switching ramps SP2 (erasable)

Functions of the Vacuum Switch

38 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

The average switching frequency of the air saving function can be determined using the difference between counters 1 and 2.

The erasable counters ct1 and ct2 can be reset to 0 during operation via IO-Link by using the appropriate

system commands.

In the operating menu, this is possible via the INF menu and the parameter rct.

The storage of the non-erasable counter readings only occurs every 500 steps. That means that when the

operating voltage is switched off, up to 499 steps of the counter are lost.

8.10.3Status Signals

The current status of the ejector, i.e. whether errors or warnings are active, can be queried in various

ways:

• Using the standard "Device status," "Detailed device status" and "Error count" IO-Link parameters

• Using the "Active error code" and "Condition monitoring" parameters

• Using the "Extended device status," which transmits the entire display of the device status with classification of the severity level of errors and warnings.

8.10.4Leakage Measurement

If one of the switching points for the vacuum switch is set to Condition monitoring mode, the actual leakage measured can be read in millibars per second.

8.11System Commands

8.11.1Resetting to Factory Settings

All adjustable parameters for the vacuum switch are reset to factory settings using this function.

WARNING

By activating/deactivating the product, output signals lead to an action in the production process!

Personal injury

4 Avoid possible danger zone.

4 Remain vigilant.

The function is executed in the EF menu under the parameter re5 or via IO-Link:

1. Press the button.

ð When the menu is locked, enter the valid PIN code.

2. Use the or button to select the menu item EF.

3. Confirm using the button.

ð 0u1 appears on the display.

4. Use the button to select the parameter re5.

5. Press the button.

ð YE5 appears on the display.

6. Press the button again.

ð The vacuum switch is reset to the factory settings.

ð The display flashes briefly and then returns to the display mode.

Functions of the Vacuum Switch

EN-US · 30.30.01.01602 · 01 · 10/18 39 / 58

The Reset to factory settings function does not affect:

• Counter statuses

• The zero-point adjustment of the sensor

• The maximum and minimum values of the measurements

8.11.2Calibrating the Vacuum Sensor

As the production conditions for the internally integrated vacuum sensor can vary, we recommend calibrating the sensor once it is installed in the ejector. To calibrate the vacuum sensor, the system's vacuum

circuit must be open to the atmosphere.

The function for zero-point adjustment of the sensor is performed in the basic menu under the parameter

CAL or using IO-Link.

1. Press the button

ð The menu changes to input

2. Press the or button until cal appears in the display

3. Confirm with the button

4. When YE5 appears, press the button to confirm.

ð The vacuum sensor is now calibrated.

A zero offset is only possible in the range of ± 3% around the theoretical zero position.

When the permissible limit is exceeded by ±3%, error code E03 will appear in the display.

Operation

40 / 58 EN-US · 30.30.01.01602 · 01 · 10/18

9Operation

9.1General Preparations

WARNING

Extraction of hazardous media, liquids or bulk material

Personal injury or damage to property!

4 Do not extract harmful media such as dust, oil mists, vapors, aerosols etc.