Schick S3 Master Instructions Manual

Original

Instructions

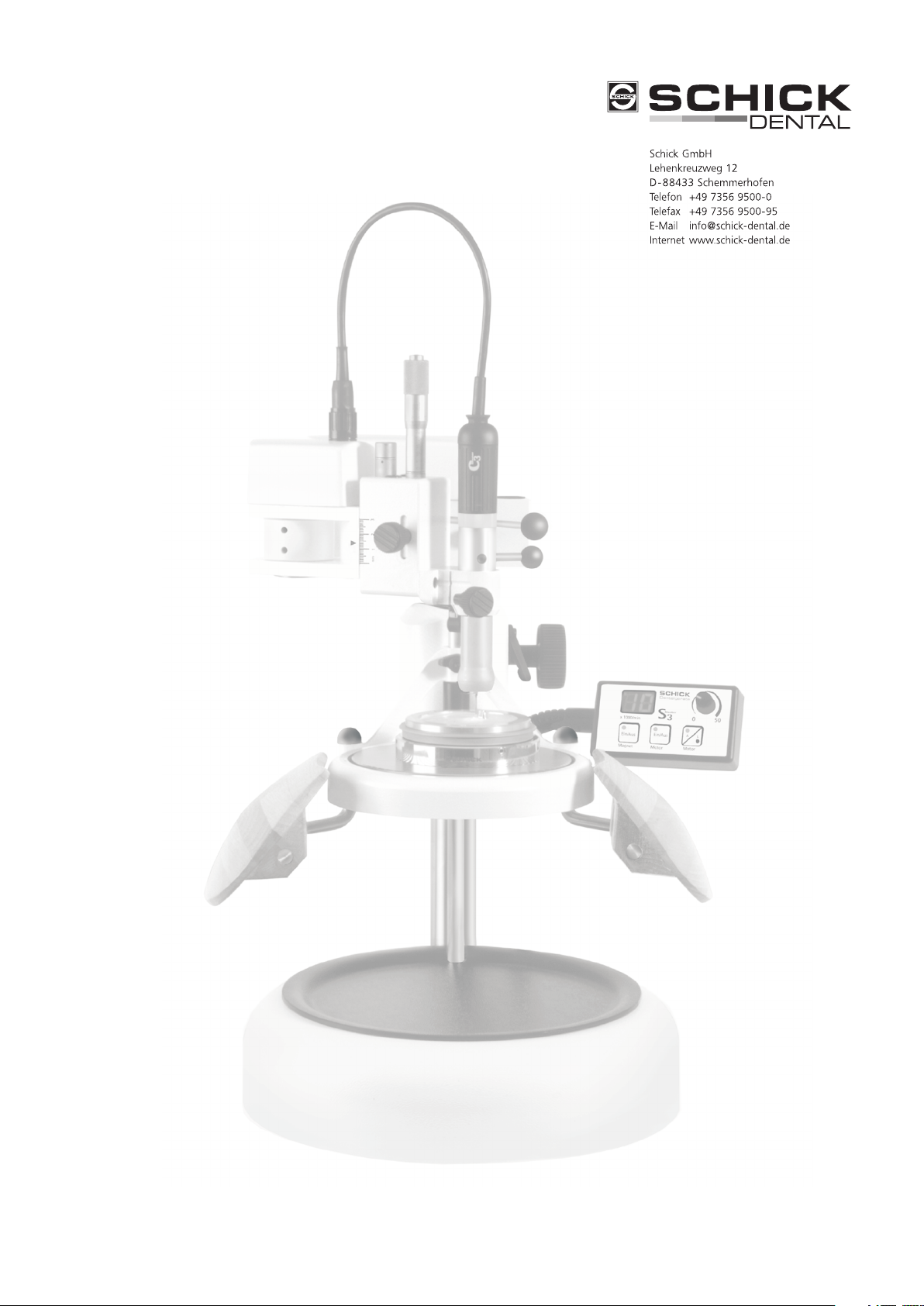

SCHICK - Milling machine S3 Master

We are pleased that you decided to buy a highly

developed piece of equipment from SCHICK and

would like to wish you every success when working

with your new milling machine S3 Master.

We wrote these instructions to enable

you to get accustomed to your new piece of

equipment and to provide you with the correct

operating and maintenance instructions.

Index

Index

1.

List of contents .................................................................................................

2.

Range of applications........................................................................................

!

3.

General information / Safety information....................................................

4.

Setting up .........................................................................................................

5.

Short instruction into operation.........................................................................

.

6.

Picture milling machine S3 Master / operating elements....................................

7.

Operation.........................................................................................................

Exchanging the rotary instruments....................................................................

8.

7.1 3D Milling arm

7.2 Operating unit

7.3 Integrated arm supports

7.4 Height-adjustable milling table

7.5 Motor technology

Page

3

4

4-5

6

7

8

9-12

13

Replacing the chuck..........................................................................................

9.

Maintenance and care......................................................................................

10.

Possible faults..................................................................................................

11.

Technical data / accessories..............................................................................

12.

Declaration of conformity.................................................................................

13.

2

13

14

14

15

16

Range of applications

Serial parts

Milling machine S3 complete

consisting of:

milling machine S3

Foot-switch (Magnet-coupling)

Foot-switch (Motor)

S3 Master milling spindle with cable

Light equipment

Mains cable

Collet chuck Ø 2,35 mm

stop for short tools

Chuck key

Art.-No.

2500/5

2520/5

2110

2560

9400/07

2510

2160

4114

4918

4115

Counter stay wrench

Hexagon socket wrench w.a.f. 2

Hexagon socket wrench w.a.f. 4

Dust protection cover

optionally

Collet chuck Ø 3 mm

stop for short tools

6223

W602000200

W602000400

2502

4117

4925

3

Range of Applications / General information

2. Range of Applications

The S3 Master milling machine is designed for use in dental laboratories

when trimming crowns and bridges, respectively acrylic and chrome cobalt dentures.

Highest precision, consistent quality control und minor maintenance are the merits

of the S3 Master which has been developed under assistance of recognized experts

in milling technics.

This novel construction - the model is moved up and down by means of the height

adjustable milling table - is unique, and grants the technician ergonomic, relaxed sitting

during work.

The 3D integrated arm supports are also outstanding and support optimal the guidance

of the milling hand. This ergonomic construction allows optimal results through relaxed

working.

Conditions of environment:

- interior 5° - 40°

- up to 2.000 meter over sea level

Categorie of overvoltage: II

Grade of pollution: 2

3. General Information

- Ascertain that your mains supply coincides with the data in the rating

plate

- The milling machines S3 Master are not suitable for the following applications:

- in areas where there is a risk of explosion

- for medical applications

- Ensure that all regulatory requirements are observed during use (always waer

protective glasses).

- Under no circumstances should the milling machine be cleaned with

compressed air

- To keep the precision and the lifetime of the chuck always insert a rotary instrument

or the pin, supplied with the unit, (37) - even if the motor stands still.

- Recycling

WEEE-Reg.-Nr. DE 78620387

4

Safety informations

3. Safety informations

ATTENTION:

- accessories like transfer unit, graphite lead holder, paralleling mandrel or similar

are not allowed to be used in the milling spindle.

The spindle may be started by mistake!

- Water-cooled turbines are only indicated to use in connection with a SCHICK

suction tub to avoid defects at the elctrical equipment and corrosion.

- When using rotary instruments, do not exceed the maximum speeds laid

down by their manufacturer.

- Repairs and other technical procedures must only be carried out by suitable

qualified personnel, authorized by SCHICK.

- SCHICK do not guarantee the S3 Master milling unit should it not have

been used in accordance with the instructions

- For defects occured by using the S3 Master milling machine in another way

or by inappropriate handling the manufacturer rejects any liability.

!

These instructions should be readily accessible and are best kept

close to the milling machine itself !

5

Loading...

Loading...