OPERATION AND MAINTENANCE MANUAL

1. Introduction

1.1. General

1.2. Technical data

1.3. System description

2. Installation

2.1. General criteria and material required

2.2. Components mounting

2.3. Water intake

2.4. Hydraulic connections

2.5. Electric connections

3. Operating procedures

3.1. Remote panel commands

3.2. First start-up procedure

3.3. Normal operations

4. Maintenance

4.1. Shutdown procedure

4.2. Maintenance and recurrent inspections

4.3. Troubleshooting

5. Safety cautions

6. Warranty

1

Rev. 2011

1. Introduction

1.1 General

Thank you for choosing a Schenker Watermaker which we know will give you years of

service, making life onboard more enjoyable.

To ensure the maximum efficiency of your Schenker Watermaker and its trouble free working,

Please read this manual and to keep it onboard for reference.

The Modular 60 watermaker uses Schenker’s patented ENERGY RECOVERY SYSTEM which

amplifies the pressure of common low pressure pumps, and recoups all the hydraulic energy back

from the membrane. This saves on the use of power, allowing the Modular 60 to be run directly

from the vessels batteries.

The ENERGY RECOVERY SYSTEM operating components are reduced to a minimum, thanks

to two internationally patented solutions that eliminate the need for pilot valves.

The lack of high-pressure pumps ensure that the system is silent and vibration free. It also means

that no adjustments are required when the system is started up.

2

1. Introduction

1.2 Technical data

WATERMAKER GROUP

Dimensions

Length: 68 cm

Width: 20 cm

Height: 30 cm

Net weight: 24 Kgs.

Connections:

Seawater intake holder for hose int. diam. 16 mm.

Salt water outlet holder for hose int. diam. 16 mm.

Fresh water outlet compression fitting for hose int. diam. 6 mm. int. X 8 mm. external

PUMPS GROUP

Dimensions

Length: 34 cm

Width: 19 cm

Height: 35 cm

Net weight: 7 Kg.

Connections:

Seawater intake holder for hose int. diam. 16 mm.

Salt water outlet holder for hose int. diam. 16 mm.

Filter: 5 micron polyestere pleated type

Power supply: 12 Vdc +/- 20% (version 30M12)

24 Vdc +/- 20% (version 30M24)

Power consumption: average of 110 Watt

Production performance: 35 Lit/h +/- 20% @ seawater 25 °C - salinity 35.000 ppm

Seawater temperature range: 13°C - 35 °C @ salinity 35.000 ppm

Quality of water produced: average of 400 ppm TDS

CEE conformity: In compliance with directives 89/392 CEE sect.1 (general safety

machines requirements) , 89/336 CEE (electromagnetic

compatibility).

3

1. Introduction

1.3 System description

The Modular system comprises of two separate units:

PUMP AND FILTER GROUP.

This unit picks-up the sea water up and sends it to the watermaker at pressure (about 6,5 –7

Bar). The pumps are fitted with a safety cut off switch, calibrated at about 9 Bar. The pressure

switch can be adjusted by an 2 mm. allen key. To make the allen

key adjustment to the pressure switch pictured, the cover to the

connector must be removed. This gives access to make an

adjustment by inserting the allen key without removing the

connector itself. Turning the allen key clockwise increases the

preset pressure, and turning anti clockwise decreases the preset

pressure. The movement required is very small.

(1/4 turn = 1 BAR).

This action will not be required in normal circumstances as the

unit has been pre calibrated at the factory. Before changing the settings please call a Schenker

Service Point. The grey box contains the power relays that activate the pumps electric motors.

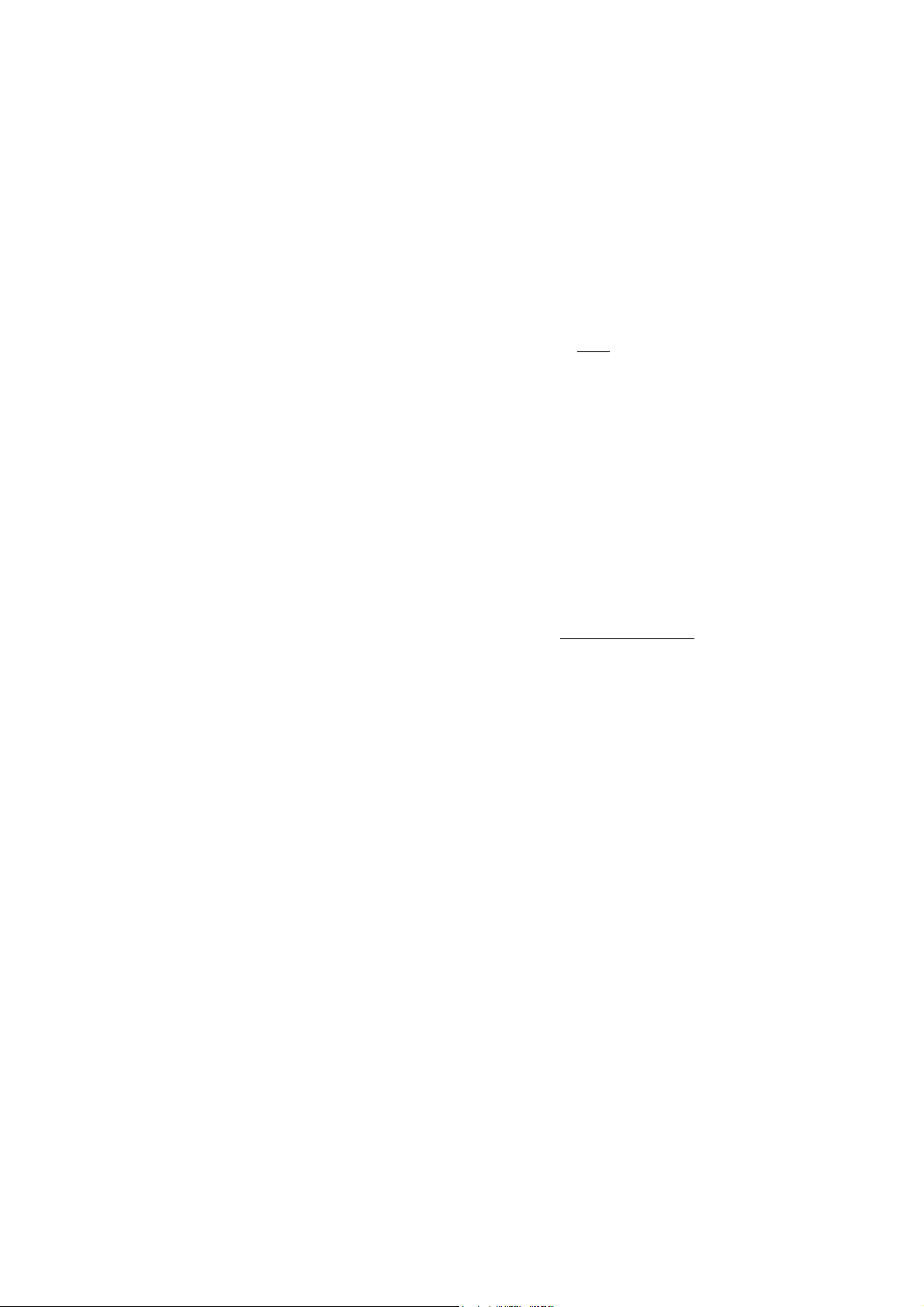

The filter housing contains a 5 micron filter cartridge, and its job is to filter impurities that may

damage the watermaker unit. A red push-button is positioned on the top of the housing to purge

air from the pumps unit during start-up operations.

Close to the pump is installed an accumulator. It dampens the pumps pressure oscillations during

the watermaker functioning. The accumulator needs to be pre-charged of air through the apposite

valve (similar to the common tire valves) located on the device. The pre-charged air pressure is

about 2,8 Bar.

4

WATERMAKER GROUP.

1. Reverse osmosis membranes

2. Manometer

3. Flow meter

4. Depressurization valve

The watermaker group is constituted of the following components:

The Reverse osmosis membranes, inside the silver high-pressure vessel are used to separate the

intake high-pressure seawater into two flows: one for the salt-water waste and one for fresh water

production.

Energy Recovery System. Amplifies the pressure supplied by the pump and recovers the

hydraulic energy back from the membranes. The ERS device makes periodic cycling by a

hydraulically controlled automatic valve. The cycles are noticeable through a” beat” issued

periodically by the watermaker unit. The unit contains two cylinders, and a central body housing

the hydraulic valves.

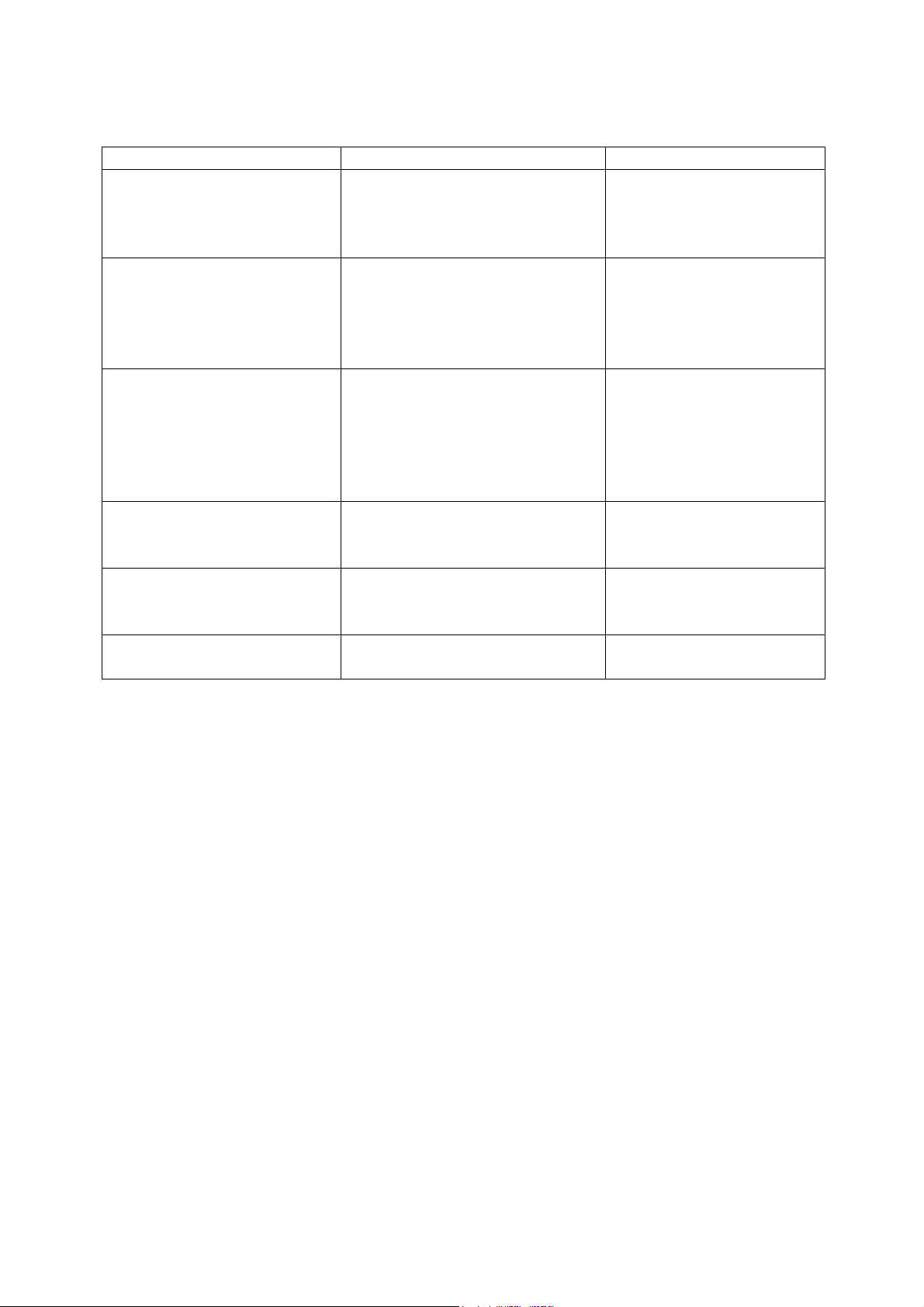

Manometer is located on the front panel, and it measures the running pressure of the pumps.

Flowmeter is located on the front panel, and measures the flow of produced fresh water coming

out of the unit. This is only indicative as the accuracy of the flowmeter is +/- 20%.

Depressurization valve. Is used only during the air bleeding phase, at the first plant start-up.

This is a blue lever located to the right side of the watermaker. Its function is to depressurize

the system and allow air bleeding. The valve remains closed during normal working

conditions and is opened only during the air bleeding operations. The lever need only be

opened halfway (45°) during air bleeding operations.

Positioner: A stainless steel threaded arm, with a black knob, located on the right side of the

unit. Its function is to reset the unit in start up failure when the unit has been stopped in the

exact centre of a cycle. This will only happen with units fitted with a manual flushing system or

when the bypass is activated when fitted with an Analogue control

Reset valve. The valve must be closed during normal functioning (lever perpendicular to the

valve). Such valve has the function to allow the reset in case of a system block. It must be

opened before acting on the valve positioner.

5

Depressurization valve

Reset valve

Positioner

Probe (pressure switch). It is a little steel device, mounted on the aluminum structure. It is

connected to the computer throw the cables PS / PS . Its function is to check the cycling of the

machine .

Computer box . It is an external unit. It has to be installed relatively close to the watermaker, in

a position protected from water. It is connected to the remote panel and controls the functions of

the watermaker automatically.

The microswitches P1and EV allow the direct command of the pump the electrovalve

respectively. They can be used, as an emergency solution, for starting the watermaker in case of

total failure of the electronic computer. In normal condition they have to be switched off.

Emergency

microswitch

Remote panel cable

connector

Electric

connections

6

2. Installation

2.1 General criteria

It is important to plan carefully the activity prior to start the installation works, evaluating any

possible alternative solution. The fundamental choices to make are:

Finding of seawater intakes and any necessary fittings.

Positioning of main units .

Positioning of pumps operation automatic circuit breakers.

Pipes and electric cables laying.

A well-done installation is the maximum optimization between functionality, accessibility,

installation saving and esthetic. All plant components have been designed to achieve this target.

It is suggested to draw a schematic electric and hydraulic connections layout once an installation

solution is chosen, and enclose it into the manual for further quick reference.

2. Installation

2.2 Components mounting

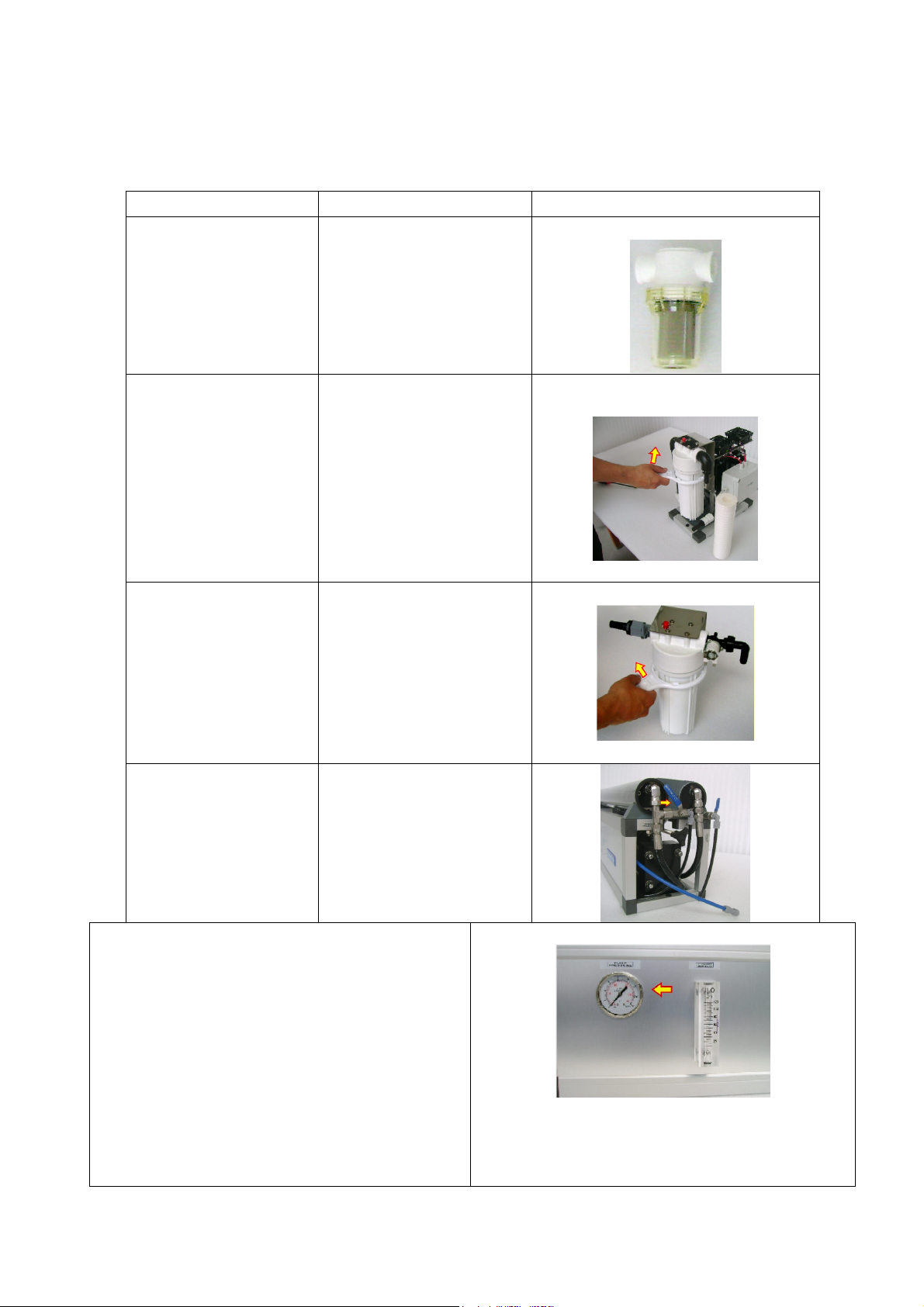

Pumps group.

The pumps are self-priming type. Anyway it suggested to install the pumps group below the

watermaker, as low as possible respect the sea level, and as close as possible respect the sea

water intake.

The pumps need to be installed in an adequately ventilated area to allow cooling and avoiding

condensation. Do not install the pumps unit close to inflammable liquids, as the pump surfaces

can become warm. Avoid locating the pump where a loss of water can cause damage or

jeopardize its safety. Allow sufficient space for access to the casing containing the filter

cartridge.

The pump must be installed horizontally on a suitable base strong enough to support its weight

when the filter housing is full of water.

It may be necessary to create a suitable wooden or fiberglass structure for the unit if an existing

one not available. The base of the pump is equipped with vibration-damping devices, but avoid

installing it on a surface susceptible to vibration.

The pumps unit can be a little noisy in operation. Possible areas for siting are: sink closets, under

berth lockers, wardrobe bases (creating a false floor above it.)

It is not recommended to fit the pumps unit in the engine compartment.

The unit can be fixed on the supporting structure using the screws supplied with the equipment

or the bolts with nuts and washers.

Watermaker group.

The watermaker unit is hydraulic. It can be installed in areas inside exposed to humidity. It can

be installed at any height inside the vessel. Avoid installing the system where a leak will cause

damage to the boat or jeopardize its safety.

The hydraulic intake and outlet connections are positioned in the standard version, on the left

hand side of the unit. It is necessary to leave a minimum distance of 20 cm. to allow for pipe

laying. Possible locations of the watermaker group are: engine compartment, under berth lockers,

cockpit lockers. Install the unit where access to valves and instrumentation is visible. The unit is

fitted with rubber mountings to prevent vibration, avoid fitting the watermaker in an area where

there is a lot of vibration. The unit can be fixed on the supporting structure using the screws

supplied with the equipment or the bolts with nuts and washers.

Non return valve.

The non return valve must be installed vertically

and as close as possible to the water inlet.

7

2. Installation

2.3 Water intakes

The necessary hydraulic intakes are:

• Seawater intake

It is ideal a specific sea water intake, size ¾” min. in a central position, well under the water

surface even when the vessel is well heeled over.

The skin fitting is recommended. It must be oriented to the bow of the boat.

As alternative it is possible Tee into an water inlet as long as the following conditions are met:

- 3/4” minimum size,

- No air can be introduced into the system from other use ie: salt water tap in galley

-Must always be under the water surface even when the vessel is well heeled over.

Allow a minimum ½” on-off ball valve on the water intake. The hose connections, especially if

under the seawater level, must be secured with double hose clamps.

It is not advisable to Tee into the engine cooling water intake as it may impair the cooling of the

engine. An easily inspected mesh type filter will be required close to the water intake. The filter

has to be of 50 microns. It is possible to use filters from existing outlets.

• Fresh water intake for washing.

Tee in downstream of the vessel's fresh water pressure system (Domestic water from tank) .

IMPORTANT

Flushing must always be carried out with the pressure water system ON.

The pressure water system must NOT exceed 2.5 BAR.

• Salt-water waste. (After passing through the watermaker)

The salt-water reject fitting must be ½” minimum and preferably above the seawater level.

Again, if required you can tee into an existing skinfitting ie: sink water out, one way valves may

need to be considered. The watermaker waste pipe must be unobstructed when the machine is in

use.

8

2. Installation

water

2.4 Hydraulic connections

Exhausted

discharge

Plumb to

pressure

side of

boat fresh

Pressurized fresh water valve

Elecrovalve

5 micron filter

Swan neck upward - Disharge

Watermaker

Fresh water outlet

“Armovin”

type hose

int. dia.

16 mm.

Pump

Non return valve

Net filter

Water inlet

Active carbon filter

Reinforced hose

PN15 min int.

dia. 16 mm.

All the hydraulic connections (to exception of the fresh water production) have to be realized

with a 16 mm. int. diam. hose and a ½” holder. The hydraulic section that is continuously

under consistent pressure is the pump outlet – 5 m. filter – watermaker inlet connections . For

this section is necessary to use a good quality PN 15 min. reinforced hose. An inadequate hose

could burst, jeopardizing seriously the safety of the boat. The hydraulic connections are:

Low pressure

max 3 bar

-connections sea water inlet- net filter backflow valve inlet.

-connection watermaker’s exhaust

PN 5 stainless steel spring type

hose 16 mm int. diam

discharge - drain outlet.

Medium

pressure –

max 13 bar

-connections fresh water pressurized

system–carbon filter-backflow valve

outlet–pump inlet

-connections pump outlet-5 microns

PN 15 reinforced hose 16 mm

int. diam.)

filter– watermaker inlet.

Low pressure max 3 bar

- Connection to the fresh water tank

Small 6X 8 blue pipe (furnished)

9

PUMP CONNECTIONS:

Connect the in/out hose to the pump as follows:

WATERMAKER CONNECTIONS:

IN – (sea water inlet from the pump) Make use, for this connection, of the external holder located

on the left side of the watermaker (marked IN).

OUT (Discharge outboard) Make use, for this connection, of the holder located on top of

the pressure amplifier, inside the watermaker unit (marked OUT). Create a Swan neck upward,

when the drain outlet on the vessel is positioned below the watermaker unit, in order to guarantee a

water head.

PRODUCTION FRESH WATER CONNECTION

The connection has to be made using the small

hose supplied with the equipment. The

connection has to be made between the

polyethylene pipe that comes out the

watermaker unit (on the right), and the upper

side of the tank, on a ¼” outlet if available.

It is possible, in case of metal tanks, to make a

¼” threaded hole to connect the supplied male

connector.

Another option is to Tee into the tank air vent

hose.There are no particular limits on the

connection length.

Another option is to Tee into the tank air vent hose. This is only possible if the breather pipe section

is more than 16 mm. dia. There are no particular limits on the connection length.

10

2.Installation

2.5 Electric connections

Remote control panel mounting

The remote control panel has the following dimensions:

width 135 mm. height 116 mm.

It can be flush mounted on any surface, providing the area behind is free of moisture and

condensation and there is enough depth to house the rear part of the panel (approx. 8 cm.).

To cut on the mounting surface will have the following dimensions:

width 115 mm. height 97 mm.

Wiring

Power Supply

The Power supply, coming from the service batteries, needs to be connected to the terminals +

and – of the Pump Box. An automatic circuit breaker (16A for 12VDC systems and 10 A for

24VDC systems) must be installed on the power supply. The section of the cables must be

adequate. See the table below:

Voltage Automatic

Volt Ampere

12 16 4 11 10 7 16 5

24 10 2,5 13 4 11 4 11

switch

up to 3 mts 3 - 7 mt. 7-10 mt.

mm2 AVG mm2 AVG mm2 AVG

Cable lenght

Electric cables and switches selection table.

Connections between the pump box and the computer box

3 cables (section 2,5 mm2) will connect the pump box with the computer box.

The cables + / - will provide the power to the computer box.

The cable P1 will provide the command to start the pump.

Connections between the computer box and pressure switch and electrovalve

The pressure switch, positioned on the watermaker, has to be connected to the clamps PS/PS in

the computer box (section 2,5 mm2)

The electrovalve, positioned on the active carbon filter has to be connected to the clamps EV/EV

in the computer box (section 2,5 mm2)

Connection between the computer box and remote panel.

Connect the remote panel to the computer box using pre wired cable supplied (standard length 10

mts.)

11

Wiring connection diagram

Signal pressure

Electrovalve

12

3. Operation

3.1. Remote panel commands

KEYBOARD FEATURES

The panel keyboard has a total of four push button. The display light switches off after 15

minutes of not use. Pushing any button, the display will light again, without activate any other

command. The functions of the push buttons are:

START Used to start the system.

If it is pushed shortly the system starts and the unit will run indefinitely until will be pushed

STOP.

If it is pushed for at least 3 seconds the system starts, and will stop automatically after the

working hours selected with the timer (see menu functions).

It can anyway be stopped before, pushing STOP.

It is used as well to scroll the different options in the single menu.

STOP Used to stop the system.

The system, once pushed STOP, usually doesn’t stop suddenly. It awaits for the correct

positioning of the internal valve (2-3 seconds), and then stops automatically.

If the automatic washing is activated (washing light on), the system, once pushed STOP, will

perform the automatic washing (1 min) before stops.

The push button STOP is used as well to exit from the menu function.

WASHING Used to rinse the system automatically with fresh water.

If it is pushed shortly the system will get ready to perform an automatic washing (1 minute long)

once the system will be stopped.

If it is pushed for at least 3 seconds the system will just perform a 10 minutes rinsing, without

suck up sea water.

MENU Used to enter into the MENU mode and modify some parameters.

Pushing it repeatedly the different MENU options can be scrolled.

On his turn the START push button allows to scroll the different options of the single menu.

The system recognizes the current value without any further command.

The STOP push button allows to exit from the MENU function.

13

Menu options:

• WORKING TIME (timer)

It allows to select the working time of the watermaker (1-6 hours).

The timer is activated if the START button is pushed for more than 3 seconds only.

• BY-PASS

It allows to exclude the sensor (signal pressure switch) that detects the correct cycling of

the ERS. The operation with the by-pass is necessary only in case of malfunctioning of

the signal pressure switch (in example if the system gets blocks, with the message “

SYSTEM BLOCKED”, not as consequence of a real hydraulic problem, but just as

consequence of the malfunctioning of the probe).

The bypass is used also during special operation like the shut down procedure (washing

with chemicals). The bypass activation is automatically removed after one single

production cycle.

Don’t activate the by-pass if not necessary.

• AUTOMATIC START-UP. This function activates automatically the first start up

procedure. The procedure is necessary when a new machine is started for the first time, or

after the filter cartridge replacement, or a general service. The procedure allows to purge

completely the air from the system, and from the seawater and the washing fresh

water hoses. The depressurization valve must be opened before start the

procedure.

• PERIODIC WASHING This function allows a periodic automatic rinsing (every 6-10

days) with fresh water. It can be used before long inactivity periods. The single washing

operation will last about 1 minute. The consumed fresh water, for every washing, is

about 18 liters.

Therefore it is suggested to evaluate if the fresh water reservoir is enough for the

programmed cycles. Selecting NO, the function will be disabled.

To activated the function select the days (6-10), exit from the menu, pushing STOP, and

then push WASHING for 3 seconds.

The display will indicate the remaining day before the first rinsing. The function is

anyway disabled pushing STOP, or after a normal production cycle.

MESSAGES

SYSTEM STANDBY

It indicates that the system is ready to be set and started.

TOTAL HOURS

It indicates that the total, progressive working time of the watermakers.

SYSTEM WASHING

It indicates that the unit is in washing mode (pumps and electrovalve on).

SYSTEM BLOCKED

14

The message must be acknowledged pushing STOP.

This messages means that an hydraulic block of the machine occurred, and then the pumps has

been switched off as safety procedure. In this case is suggested to perform a reset procedure and

investigate on the possible hydraulic origins of the problem.

If the origin of the problem is just a malfunctioning of the signal pressure switch, it is possible to

start again the unit, activating the bypass.

BYPASS WARNING

This message advice or remember that the unit is working in bypass mode (then some safety

functions are disabled).

CHANGE PUMP FILTERS

This is a blinking messages that must be acknowledged pressing the key STOP

This messages suggest to replace the filter of the pump group.

3. Operation

3.2. First start-up procedure

The first start-up procedure is necessary to start the first time a new system, just installed.

The purpose of the procedure is basically purge out the air from the system.

It can be used as well after a filter replacement, or after other maintenance operations.

Preliminary checks:

Verify that all components are connected correctly.

Verify that the filters cartridges are installed.

Verify that the seawater valve, and the possible drain valve, are opened.

Verify that the reset valve is closed (lever orthogonal to the body valve) and the positioner

completely unscrewed.

Verify that the small gray valve on the active carbon filter is opened and the fresh water

pump of the boat is on.

Verify that the fresh water tanks are full enough (at least 50 liters) to perform the first

washing operations.

Start-up procedure:

1. Open halfway the depressurization valve (45°).

2. Activate the start up procedure throw the function of the MENU (select the specific function

in the menu mode, exit from menu mode pushing STOP, and start the procedure pushing

START).

3. Close the depressurization valve when the display shows the specific message.

The procedure lasts about 3 minutes. It can anyway stopped anytime pushing STOP.

After the procedure the system is ready to start normally.

15

3. Operation

3.3. Normal operation procedure

• It is always strictly recommended to select the automatic washing, pushing

WASHING.

Production without timer.

-Push shortly the button START.

The control will open the depressurization valve, helping the inlet pump hose to get filled with

water. Then the pump(S) will start after 5 seconds.

The display will show the increasing production time.

-Push STOP to stop the unit.

If the washing has been selected, the system will start the washing procedure, and then will stop

automatically after 1 minute.

Production with timer.

-Select the timing (1-6 hours) throw the specific timer menu (the system will hold as well the

previous setting.)

-Push the button START for more than 3 seconds.

The display will show the decreasing production time.

The system will stop after the selected hours, performing before, if selected, the automatic

washing.

Anyway the system can be stopped at any time pushing STOP.

Single washing operation (10 min. last)

-Push washing for more than 3 seconds.

The display will indicate the remaining time. It is possible anyway to stop the operation at

anytime pushing STOP.

Periodic washing

-Select the days (6-10) in the washing menu

- Exit from the menu pushing STOP

- Push WASHING for 3 seconds.

The display will indicate the remaining day before the first rinsing.

The function is anyway disabled pushing STOP, or after a normal production cycle.

16

ATTENTION

If the watermaker get air, (or if some other problem occurs) the automatic hydraulic valve may

stop in a central position. This means that pressure on both sides of the valve are the same and

the unit is effectively stalled and has to be manually restarted.

In this case the working pressure goes up suddenly (up to 9 Bar) and the pumps are switched off

from the pumps pressure switch. The pumps then have the tendency to try to restart when the

pressure decreases, and then to jam again, resulting in a typical start-stop noise. After approx. 20

sec. the computer recognize the problem , and turn off the pumps, and the message “WARNING

SYSTEM BLOCKED” is displayed.

This event, besides being very unusual, does not damage the system, but it is necessary to reset

the valve with the following simple procedure:

RESET PROCEDURE

1. Turn the system off.

2. Open the reset valve (lever in horizontal position).

3. Screw the positioner knob clockwise until it can be moved no further.

10 turns at least are necessary.

4. Unscrew the positioner knob up to the original position, until when it is blocked

back.

5. Close the reset valve (lever in vertical position).

6. Restart the system

17

4. Maintenance

4.1 Shutdown procedure

It is necessary to perform the shutdown procedure before effecting standstills longer than 3

months, for instance before laying up for winter.

The purpose of the shutdown is to clean the unit of possible deposits of limestone, and to inhibit

the growth of microorganisms that may reduce the reverse osmosis membrane's efficiency.

The following equipment is necessary in order to perform the shutdown operation:

1 ea. recipient 20 liters minimum capacity (a bucket of such capacity could also be suitable).

Two 16 mm. linen hoses of a length that allow them to be fed into the same container

A prepared shutdown solution SCHENKER CLEANING 1.

Tools for de-assembling hoses (screwdrivers, pliers, etc.)

Hydraulic connections diagram to perform the shutdown.

Shutdown procedure :

1. Collect approx. 15 liters of unchlorinated fresh water into the bucket. The water produced by

the watermaker itself could be fine.

2. Empty the entire content of the SCHENKER CLEANING 1 solution into the picked water,

and mix carefully following the indications on the pack. Wear a protection mask in order to

avoid inhaling product dusts. The water temperature doesn't have to be lower than 25°C

preferably.

3. Close the grey valve on the active carbon filter.

4. Disconnect watermaker unit drain hose and the pumps suction hose.

5. Connect two hose pieces to the drain and to the pump suction.

6. Insert the end side of the hoses into the bucket, verifying that the hoses have been properly

dipped in the solution and that they don't inhale air.

7. Open the depressurization valve at 45°.

8. Activate the by-pass

9. Start the watermaker and leave it on for approx. 20 min., checking that the hoses are

properly positioned in the container, to avoid drawing air or spilling the liquid into the boat.

10. Stop the watermaker , disconnect hose pieces, and connect the pump suction and drain

original hoses.

Chemical Cleaning Kits:

Schenker No 1 is an acid based organic cleaner. This is used for 'pickling' the watermaker when

not in use and as part of the general cleaning process. See 4.1 Shutdown procedure. Schenker

No 2 is an alkaline base organic cleaner. If the watermaker has been left standing without

pickling or has a 'bag egg” smell, cleaning with Schenker No2 will remove this.

18

4. Maintenance

4.2 Verifications and periodic maintenance

The following periodic procedures are to be followed to maintain trouble free operation:

OPERATION

Strainer check and

cleaning

5 micron cartridge

replacement

Every 5 days

Every 15-20 days in

average conditions (4

hours/day usage).

Anyway replace it when

the message

CHANGE PUMP FILTERS

appears.

EVERY PROCEDURE

Check and clean

Unscrew anticlockwise the filter

holder.

Active carbon filter

replacement

Purge periodically

the air from the

system, opening at

45° for a couple of

minutes the

depressurization

valve

Check the pressure on the manometer located on

the front panel.

The working pressure depends on many factors

such as water temperature, salinity level of

seawater, battery voltage, cleanliness of

membranes and type of installation.

The pressure, under mid range working

conditions is approx. 6,5-7 BAR. There is a

small pressure loss , in the range of 0,2 Bars,

during the cycle.

Every 6 months

Close the grey valve

before open the filter

Every 15 days

19

4. MAINTENANCE

4.3 TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Pump do not start

Pump start but stop at high

pressure

While functioning the

pump starts-stops

High pressure heads during

commutation (> 0,2 Bar)

Low production / high

pressure (> 7,5 Bar)

Leaking in the plant

Probe (system pressure switch ) troubleshooting:

If the system goes frequently in blocked position (generating the message SYSTEM BLOCKED)

without hydraulic problems, this could possible that the origin of fault is a malfunctioning of the

probe (pressure switch)

The pressure switch can be tested with following procedure:

1. De-connect the pressure switch cables.

2. Activate the by-pass and start the system.

3. Check with a meter in ohm position, between the cables PS/PS, the functioning of the

pressure switch. If working, the pressure switch closes and open the circuit alternatively each

3-4 seconds.

4. If the pressure switch is always close or open during the functioning of the watermaker, it is

out of service and must be replaced.

Pressure switch burned or

disconnected

Total electronic failure

System is blocked

Dirty pump filter

Dirty membranes

Trouble in the cycling system

Pump pressure switch not

calibrated

Dirty filter or membranes

Accumulator pressure low

Cold sea water

Filter clogged

Dirty membranes

Loose connectors

ERS loss

Restore

Activate the pump with

the miscoswitch

Perform Reset

Replace cartridge

Perform cleaning cycle

Contact a Schenker service

point

Increase the pump pressure

switch calibration

(see pag. 4)

Clean or replace

Inflate at a pressure of 2,8

Bar

Normal operation

Clean filter

Perform cleaning cycle

Tighten connectors

Contact a service point

20

5. SAFETY WARNINGS.

Do not touch the pump (which can reach high temperatures) when the plant is functioning.

Do not locate the pump near objects either inflammable or that can deteriorate if exposed to

high temperature.

Check if the plant is correctly installed eventually contacting a Schenker service point.

Verify that the hoses used for installation are in keeping with the indicated specifications.

The water produced using clean sea water will have an average quality of 400 ppm TDS.

Unless the correct cleaning procedures are carried out in accordance with this manual, there

may be bacteria present in the produced water. Therefore avoid drinking the water produced

by the plant if an UV sterilizer has not been installed.

Avoid using the plant where water is polluted (ports, or close to built-up areas, etc.)

Children and inexperienced people shall not touch or operate the plant.

Check periodically that no leakage is present. Do not switch on the plant when the boat is

unattended. Avoid installing the plant where an eventual leakage may cause damages and

jeopardize the safety of the boat.

Unqualified and non-Schenker personnel shall not perform any maintenance work.

21

6. WARRANTY

The equipment and the relevant accessories are guarantee 12 months starting from the date on the

delivery document of the merchandise. The guarantee does not include expendable materials

(cartridges, active-carbon filters, membranes, etc.). The “ERS” pressure amplification device is

guaranteed 36 months, provided that the annual maintenance is performed in one of Schenker

service point.

The guarantee covers every fault or defect of materials and parts and it is limited to the

replacement or repair of faulty parts. The expenses for the device disassembly and reinstallation

on the boat and for the transport of the equipment from or to our Service Point or our factory

will be on customer account.

The under guarantee delivered parts transport will be at customer’s own risk.

In case of repairs under guarantee, directly performed by our technicians on the customer boat,

the faulty parts replacement cost will be on Schenker account, while manpower and travel

expenses will be charged to the customer. The guarantee does not include the faults caused by

negligence in operating, maintenance and installation of the device (if they are not performed by

an authorised Schenker Service point).

If non-authorized personnel perform the disassembly, every obligation of this guarantee will

automatically lapse. Schenker Italia can not be held liable for any direct or indirect damage

caused by the malfunctioning of the equipment, limiting its responsibility to the repair and

replacement of faulty parts.

22

Loading...

Loading...