Page 1

Your number one name for EMC

for chassis- and

PCB-mounting

SINGLE PHASE FILTERS

SCHAFFNER

Page 2

Single-phase filters for chassis- and PCB-mounting

CONTENTS

General information

Introduction to single-phase filters............2

Filter selection chart...................................3

Understanding EMC standards &

filter specifications......................................4

EMC measurement & engineering

services .......................................................8

Ordering information...................................9

Technical data

FN 22.........................................................10

FN 250.......................................................12

FN 332.......................................................14

FN 343.......................................................16

FN 346.......................................................18

FN 350.......................................................20

FN 352Z.....................................................22

FN 357.......................................................24

FN 401.......................................................26

FN 402.......................................................28

FN 405.......................................................30

FN 406.......................................................32

FN 410.......................................................34

FN 420.......................................................36

FN 610.......................................................38

FN 612.......................................................40

FN 660.......................................................42

FN 670.......................................................44

FN 680.......................................................46

FN 685.......................................................48

FN 700Z.....................................................50

FN 9675.....................................................52

Mechanical Data ..............................54 - 60

Addresses and contact information ........61

SCHAFFNER

Page 3

In today’s world, more electrical energy is

being generated at increasing levels of

power, and more and more low power

energy is being used for the transmission

and processing of data. The result is vastly

increased ‘electronic smog’ or noise. This

noise can disrupt, and even destroy,

electronic devices: an unacceptable

situation, and shortly an illegal one in

certain markets. The electronics

industry must strive to protect

equipment against such ‘noise’.

Noise, or interference, travels two ways.

Switches - such as semiconductors - can

emit interference, and be susceptible to it.

The same is true for data processing

equipment. The most common method of

protection is the use of powerline filters

coupled with screening or gasketting

materials.

The mains, or powerline, filter is the key

element in eliminating mains-borne

interference. This filter not only has to

meet the requirements of electro-magnetic

compatibility (EMC), but safety aspects as

well. For some applications, the filter also

has to prevent the radiation of classified

information from the mains line (‘Tempest’

applications). Other applications require a

filter to protect equipment from

destructive voltages on the power line, like

those caused by lightning or nuclear

explosion (NEMP).

Schaffner’s breadth of product range, the

high attenuation characteristics of our

filters under various load

conditions, our dedication to

quality - and above all our

organization’s unique

experience in filter design

and manufacturing spanning more than 25

years - is your guarantee of

excellence.

Total commitment to

quality

Schaffner’s aim is to provide

our customers with faultfree products. To achieve

this, 100% of our products

undergo rigorous final

testing. To ensure high quality we have

instituted a system which meets all the

stringent requirements of the ISO 9001 /

EN 29001. The phrase ‘Quality Assurance’

is not just a slogan for us; it is applied in

practice, and the Schaffner brand truly

stands for reliability and quality.

Schaffner’s single-phase filter range

provides an off-the-shelf solution for the

vast majority of electronic equipment

noise problems. Our standard product

range is particularly wide, embracing both

chassis-mounting and PCB-mounting

types, allowing users to select an optimal

choice in both performance and cost

efficiency terms.

Chassis-mount types

In general, chassis mount filters provide a

higher performance solution, in metal

cases for optimum connection to earth

and good high frequency performance.

With the space available for up to three

circuit stages for attenuation of noise,

users can usually find an option with the

performance to provide an off the shelf

solution for even the most difficult of EMC

problems (to retrofit an EMC solution to an

existing design for instance). Schaffner

offers chassis-mounting versions for a

very wide range of power levels - from less

than 1A to 55A - covering a majority of

higher power office equipment and low to

medium power industrial applications.

At the lower power levels, users have the

additional choice of opting for a PCB-

mounting version (see following section),

or an IEC inlet type which typically handle

currents of up to 6-10A and are ideal for

small office and industrial equipment. The

associated IEC 950 specification is a key

safety requirement for computer and

office/business equipment, developed to

provide a consistent world standard,

which in turn simplifies the certification

process. The standard specifies

requirements intended to ensure safety

against electrical and fire hazards for the

operator and layman who may come into

contact with the equipment, and where

specifically stated, for service personnel.

IEC 950-compliance is required for

products shipped in Europe, and has

either already become - or is in the

process of becoming - a de-facto standard

in all other world markets. It has been

adopted by European countries under

EN60950, and by the USA under UL 1950.

Two filter families in this catalogue are

available with IEC inlets, one of which is

compliant with IEC 950 (request separate

IEC inlet/IEC 950 catalogue for full details

of Schaffner’s range).

PCB-mount types

PCB filters are designed for compactness

and ease of assembly, and avoid the need

for extra mounting components and

installation operations necessary with

chassis styles, but at the expense of finite

available space for filtering circuitry.

Consequently, they typically offer just a

single stage of attenuation, with limitations

on the maximum power handling

capability (up to 6.5A

current ratings). This

typically makes these filters

ideal for those companies

who have planned for EMC

protection throughout the

equipment design process,

and are completing

equipment protection with

these low cost components.

When designing these

components in, care needs

to be taken to provide a low

impedance connection to

earth, and to minimize the

potential for any noise

2

Powerline filters

- a vital element of today’s electronic designs

Page 4

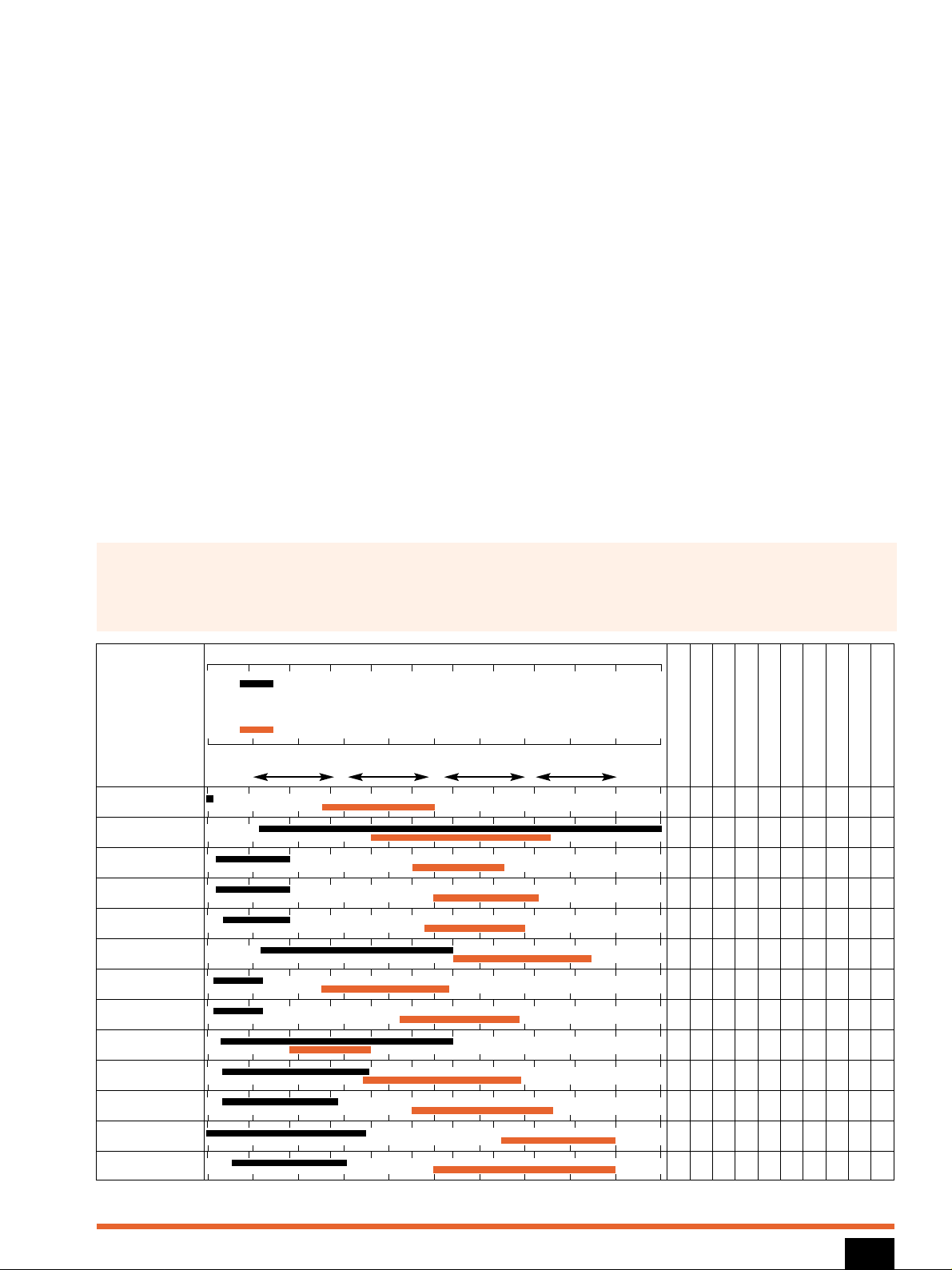

Filter family

FN 22 ✓

FN 250, 350 ✓✓

FN 332 ✓✓

FN 343 ✓✓

FN 346 ✓✓

FN 352Z ✓✓✓

FN 401 ...406 ✓✓

FN 410 ✓✓

FN 610, 612 ✓

FN 660, 670 ✓✓✓ ✓

FN 680, 685 ✓✓ ✓

FN 700Z ✓✓✓✓✓

FN 9675/76 ✓✓ ✓

3

radiation from the mains inlet connection.

Time to market

The key reasons for choosing ready-made

filters are convenience, compactness and

cost. Although you can design your own

mains inlet and filter using discrete

components, or have a custom solution

designed and assembled for you, the

timescales involved in getting safety

approvals will often rule this approach

out, especially for higher volume products

such as photocopiers which necessitate

very fast design cycles.

Ready-made chassis- and PCB-mount

filters provide a convenient single-source

solution, with the additional benefits of

custom-engineered housings for

compactness. The following guide to

Schaffner’s single-phase products - with

brief details on key parameters - will help

you to identify one or more filters for

closer review of specifications (there are

some 170 options available in the total

range). From this initial selection, a

review of the circuit diagram and detailed

specifications in the following pages will

tell you if the module is suitable for your

application, allowing you to choose a unit

(or units) for trial.

Schaffner is one of the world’s leading

suppliers of EMC equipment, and our

extensive experience allows us to offer

one of the widest EMC filtering ranges

available - spanning both generalpurpose and specialist needs like

TEMPEST. This breadth of range greatly

assists designers, allowing optimum

choices to be made, whether the need is

for maximum performance or lowest cost.

Our worldwide organization - with its

numerous application engineering teams will gladly help your engineers select and

trial suitable power line filters, and

provides an efficient support structure to

assist multi-national organizations with

dispersed design and manufacturing

facilities.

As a review of this catalogue will show

you, Schaffner designs power line filters

using high grade components in order to

optimize reliability. And we construct

modules under the control of the most

advanced quality system. Whichever

power line filter you choose, you can rely

on Schaffner’s quality.

5 1015202530354045505 101520253035404550

19

standard

current rating (A)

Attenuation

middle high very high

with earth line choke

with overvoltage protection

2 stage

3 stage

with IEC inlet

for SMPS

for medical equipment

NEMP, TEMPEST

for printed-circuit mounting

for motor drives

Schaffner’s chassis- and PCB-mounting filter range

Rapid selection Using the current rating and attenuation performance indicators, together with the major features shown on the

right, this table allows you to quickly identify a ‘short list’ of filter families which are potentially suitable for your application, for

subsequent detailed investigation using the technical specifications on the following pages.

Page 5

This section introduces the

standards and regulations

associated with EMC protection,

and provides detailed information

to help you understand filter

design and specifications. It will

help you identify for your application the right specifications and

type of filter.

Interference protection standards

Until recently most countries have had

their own regulations and standards

governing electro-magnetic interference

(EMI) or radio frequency interference (RFI).

However, on the 1 January 1992 the

European Directive 89/336/EMC on

electro-magnetic compatibility (EMC)

came into force. This directive brings a

common approach to EMC to every

member state of the European Union.

Common standards will be used

throughout Europe to ensure that

technical trade barriers are removed. As

well as controlling EMI emissions from

equipment, the directive also calls for

equipment to be immune to external

electro-magnetic disturbances.

The task of elaborating the standards to

be used has been given to the European

organisation called CENELEC. The

member countries of CENELEC are:

Austria Italy

Belgium Luxembourg

Denmark Netherlands

Finland Norway

France Portugal

Germany Spain

Greece Sweden

Iceland Switzerland

Ireland United Kingdom

Most of the European standards will be

based upon international standards from

CISPR and IEC. The numbering system

used in the European standards is:

EN xx yyy

EN = European Norm. xx = 50 denotes that

the standard is a standard of CENELEC

origin; xx = 55 means the standard is

based on a CISPR standard yyy; xx = 60

means the standard is based on an IEC

standard yyy.

Once the European standard is complete

the individual members of the European

Union will produce national harmonised

standards and will usually give their

harmonised standard a national number,

eg the British harmonised standard of EN

55011 is BS EN 55011.

Types of standards:

Basic standards

describe the general

and fundamental rules for meeting the

requirements. Terminology, phenomena,

compatibility levels, measurement, test

techniques and classification of EM

environments are so described within.

Generic standards refer to specific

environments. They set minimal EMI levels

which equipment in these environments

must meet. Where no product specific

standards exist then the generic standards

are to be used. Generic standards

describe household and industrial EMI

environments.

Products standards are for specific

products or product groups. These

standards are coordinated with the

generic standards.

In countries outside Europe other

standards will be used, such as the FCC in

the USA. Table 1 shows the main

European standards.

Permissible noise limits

The various standards set down limits for

conducted EMI emissions. These limits are

measured in voltage and given in dBµV

where 0dB is 1µV. The interference is

measured using measurement equipment

which has defined bandwidths and

receivers. The two receivers used are a

quasi-peak detector, and an average

detector.

To ensure repeatability of the

measurements, the impedance of the

mains supply must be constant. The

standards calls for a defined artificial

mains network - sometimes called a line

impedance stabilisation network (LISN) which gives a defined impedance to the

noise and also helps filter any noise on the

mains which may affect the

measurements.

Figure 1 shows the limits of EN 50081-1

the European generic standard for

residential, commercial and light industrial

environments, and Figure 2 of EN 50081-2,

the European generic standard for the

industrial environment.

Above 30MHz, radiated noise interference

is measured instead of conducted noise.

This takes place on an open field test site

using defined antennas.

Understanding EMC standards

and filter specifications

4

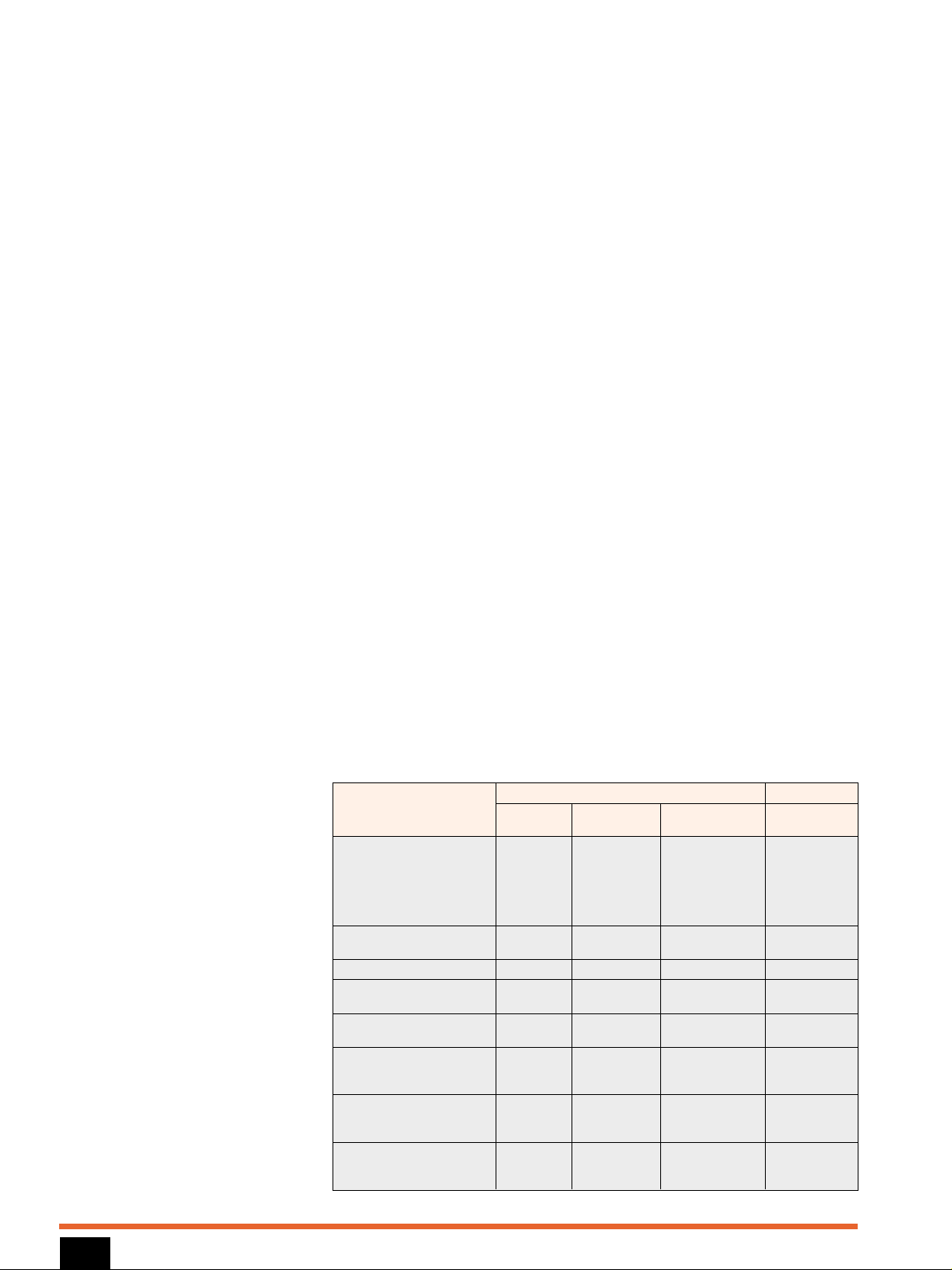

Table 1. European EMC standards

Product type

Household appliances &

portable tools: vacuum

cleaners, washing

machines, heating,

cooking equipment,

dimmers

Luminaires with

discharge lamps

TV receivers

Information Technology

Equipment (ITE)

Mains signalling

equipment

Industrial, scientific and

medical eqpt. designed

to generate RF energy

Industrial electronic

power and control

equipment

Industrial non-electronic

equipment

Harmonics

EN60555-2

EN60555-2

EN60555-2

EN60555-2

Voltage

fluctuations

EN60555-3

Radio

interference

EN55014

EN55015

EN55013

EN55022

EN50065-1

EN55011

EN50081-2

EN50081-2

(if producing RF

interference)

Immunity

All

aspects

EN50082-1

EN50082-1

EN55020

EN55024

all parts

EN50082-2

EN50082-2

EN50082-2

Emissions

Page 6

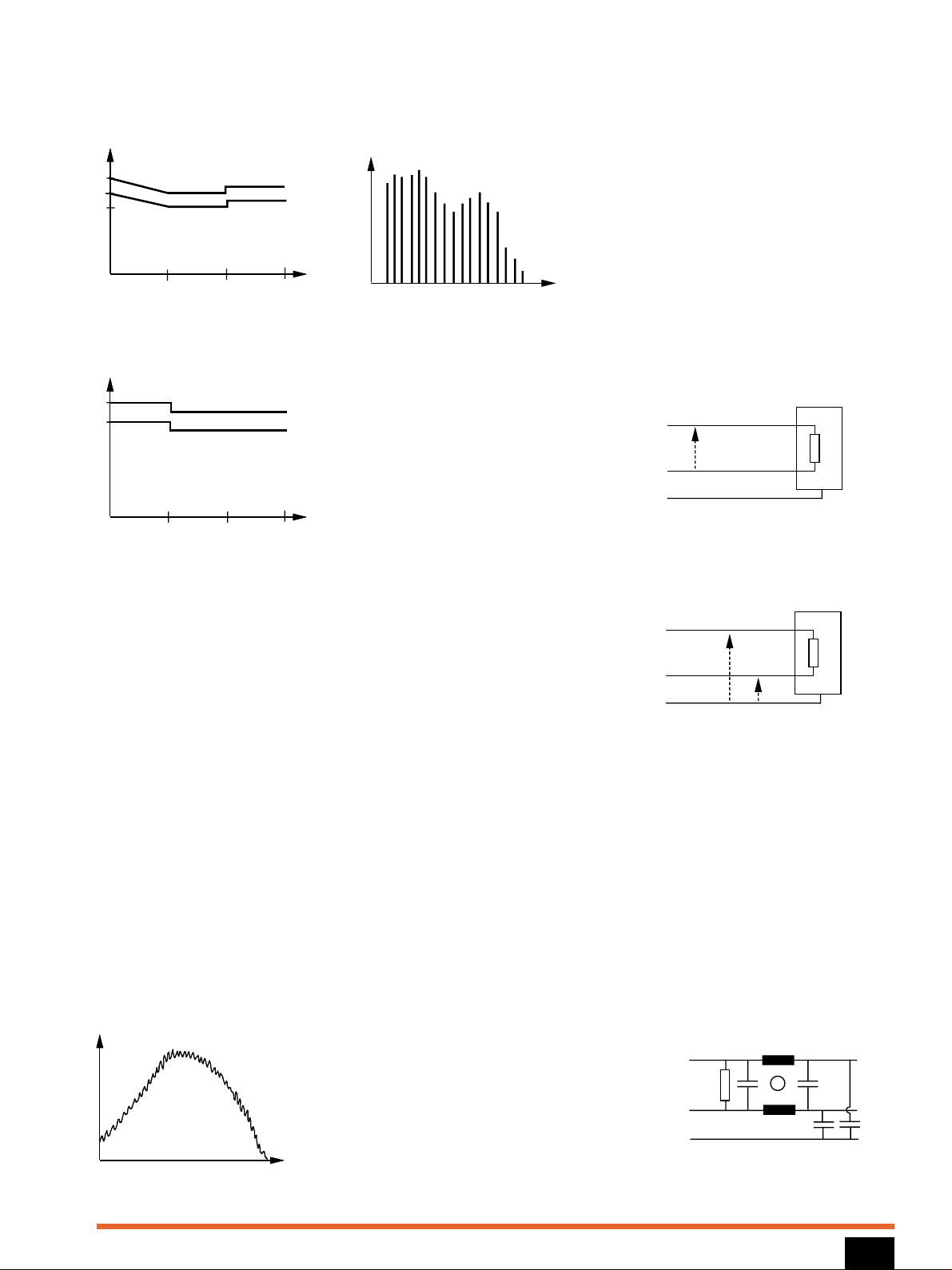

Frequenz Hz

Pegel

dB

Figure 1. Permissible interference limits

for EN 50081-1

Figure 2. EN 50081-2 limits

Interference sources and

spectrums

The most common source of conducted

EMI is power electronic products such as

switched mode power supplies (SMPS),

pulse width modulated (PWM) frequency

converters or motor drives, and phase

angle controllers.

The emissions spectrum typically starts off

very large at low frequency and rolls off as

frequency increases. The point at which

the noise falls below the permitted limits

depends on several factors, the most

important being the frequency of

operation and the rise time of the

semiconductor devices.

Interference spectrums generated can be

either continuous, as in the case of phase

angle controllers, (Figure 3) or discrete

which is typical of the SMPS (Figure 4).

Figure 3. Continuous spectrum

Figure 4. Discrete spectrum

Interference propagation

EMI can propagate by two means:

• by radiation - where the energy can be

coupled either through magnetic or

electric field, or as an electro-magnetic

wave between the source and the victim

• by conduction - where the EMI energy

will propagate along power supply lines

and data cables

Radiated and conducted EMI cannot be

thought of as totally separate problems,

because noise conducted along a cable

may be radiated as the cable acts as an

antenna. The radiation will increase as the

cable length becomes comparable to the

wavelength of the noise. Also, the cable

will act as a receiving antenna and pick up

radiated interference.

Below around 150MHz, the most efficient

radiating devices in a system are usually

the power supply and data cables. Proper

filtering of these cables will reduce

radiation due to the cables as well as

conducted interference.

Above around 150MHz, PCB tracks and

short internal cables will start to become

efficient antennas. To reduce this radiation

a PCB should be laid out to reduce track

length and loop areas; ground planes

should be used if possible. Decoupling of

digital ICs is very important and shielding

may be necessary.

Interference types

To understand the problems associated

with conducted EMI it is first necessary to

understand the two modes of conducted

noise: differential mode (or symmetrical

mode) and common mode (or

asymmetrical mode). Differential mode

interference creates a voltage between the

phases of the system and is independent

of earth; the differential mode currents

flow along one phase and returns along

another phase (Figure 5).

Common mode noise creates a voltage

between each phase and the earth. The

common mode currents flow from the

noise source to the earth (usually via a

parasitic capacitance) along the earth path

and returns along the phases. (See Figure

6) A power line filter must be designed to

attenuate both common mode and

differential mode interference.

Figure 5. Differential mode interference

(V

DM)

Figure 6. Common mode interference

(V

CM)

Mains filters

Maximum power transfer occurs when

source and load impedances are matched.

A power line filter is an inductor-capacitor

network that aims to cause maximum

mismatch between impedances, and

therefore reduces the amount of EMI

power to be transferred from the noise

source onto the power line cable. Figure 7

shows a typical single-phase power line

filter.

Figure 7. A typical single-phase power

line filter

5

0.15

Frequency (MHz)

0.5 5

30

Level

(dBµV)

66

79

73

60

Quasi-peak

Average

INDUSTRIAL

VDM

Line

Neutral

Earth

VCM

VCM

Line

Neutral

Earth

Level

(dBµV)

66

Quasi-peak

Average

LIGHT INDUSTRIAL & DOMESTIC

46

56

0.15

Frequency (MHz)

0.5 5

30

60

50

56

46

Frequency Hz

Level

dB

Live

Neutral

Earth

L1

L2

R

Cx Cx

Cy

Level

(dB)

Frequency (Hz)

Level

(dB)

Frequency (Hz)

Level

dB

Frequency Hz

Line

Page 7

The inductors L1 and 2 are usually wound

- in a current compensated fashion - on a

toroidal core. This winding method allows

flux due to differential mode currents and

mains currents to cancel each other, while

common mode currents will be added

together. This gives a large inductance to

common mode currents and ensures that

the inductor will not be saturated by the

large magnetic flux produced by the mains

current.

The capacitors placed between the

phases, known as ‘X’ class capacitors

must offer a high pulse voltage rating and

are used to attenuate differential mode

interference. The capacitors between the

phase lines and earth, known as ‘Y’ class

capacitors must have a more stringent

rating and are used to attenuate common

mode interference. The value of the Y

capacitor is restricted by the permissible

leakage current allowed. The maximum

leakage current is governed by standards

and regulations and depends upon the

type of equipment. The leakage current is

given by:

I

L

=2· π·U·f·c

where I

L

is the leakage current; U the

voltage across the capacitor; f the

frequency of the mains voltage across the

capacitor, and c the capacitance.

Mains filters should be mounted as close

as possible to power entry so that high

frequency interference does not bypass

the filter. IEC inlet modules are ideally

suited for this task.

To achieve higher attenuation or an

increase in the effective working

frequency range more complex filters than

the one shown in Figure 7 can be made

using more common mode or differential

mode inductors and capacitors.

Insertion loss

The insertion loss characteristics for each

filter shown on the datasheets, are

measured in accordance with CISPR 17.

Two test conditions are employed: one

using 50Ω termination impedances, the

other using an input impedance of 0.1Ω

and an output impedance of 100Ω (and

reverse conditions). Both test methods

can be found in section 4.2 of CISPR 17,

and in ‘CISPR 17 Measurements’, a

document published by Schaffner and

available on request.

In the 50Ω test condition, two sets of

insertion loss curves are given. One is

common (asymmetrical) mode insertion

loss. The other one for differential mode

interference.

In general, Schaffner filters perform

against common mode interference in the

manner shown by the 50Ω insertion loss

tests. But in differential mode, the 50Ω is

not representative of effective

performance. Therefore Schaffner includes

the 0.1/100Ω differential mode test to

show how a filter will perform in real life

situations.

For this 0.1/100Ω test condition, only

differential mode insertion loss is given. In

this test, mismatched impedances

illustrate effective filter performance in a

piece of equipment.

Both types of insertion loss testing is

carried out without load current. In

equipment under load, the inductance and therefore the insertion loss - may

change due to saturation. To allow for this

Schaffner measures the inductance

variation with current. A typical filter has

an inductance variation as shown in Figure

8. CISPR17, and/or the application note

‘Everything you wanted to know ...’ can

provide more detailed information.

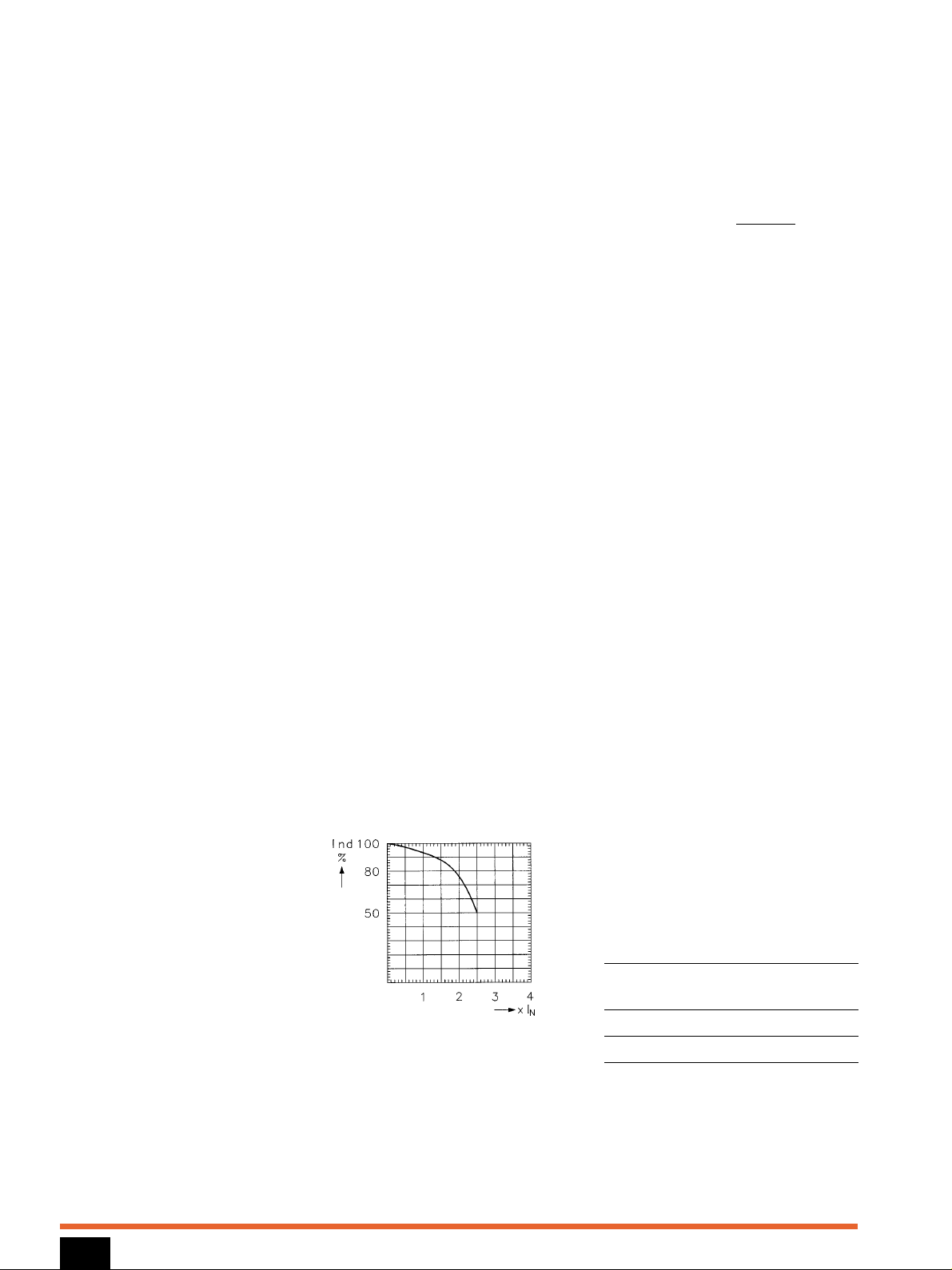

Figure 8. Typical saturation curve

General technical data

All technical data are given at 25ºC unless

otherwise specified.

Current ratings

The current ratings given for each type is

the maximum allowable current authorised

by safety agencies at an ambient

temperature of 40°C. Current at other

temperatures is shown in the derating

curve, or can be ascertained by the

formula:

I = I

N

√(85 - θ)/45

Voltage ratings

The maximum rated voltage is 250V at

50/60Hz unless otherwise stated on the

individual datasheets. Use of capacitors

within Schaffner filters which conform to

IEC 384 - 14 permit operation at voltages

of 10% above this value.

High voltage testing

The high voltage rating of our filters is

devided into two specifications, one for

type testing and one for production

testing. This is in accordance with

guidelines laid down in various IEC

recommendations. Type testing shall be a

minimum of 2121 VDC for a minimum of 60

seconds between all terminals. However,

the discharge resistor inside the filter shall

be removed for this test according to IEC

recommendations. All values given in this

catalogue are 100% production tests for a

minimum of two seconds. Repetition of

voltage tests shall not exceed 80% of the

specified values.

Leakage current

The leakage current to ground for each

type is given as a maximum value per

phase, at 230V/50Hz.

Safety approvals Filters in this catalogue

are approved by the major world safety

approval agencies. Each datasheet

indicates the current safety approval

status. The relevant file numbers for our

filters are:

UL E64388 Test: UL 1283

CSA LR 44788 Test: CSA 22.2

No. 8-M1986

SEV Test: IEC 939

VDE 7226-4730-10.. Test: VDE 0565-3

SEMKO Test: IEC 939

Almost all of the filters in this catalogue

meet the requirements of IEC 950 for

Class I and Class III installations with

Basic and Supplementary Insulation. For

further information see Schaffner’s

application note ‘IEC 950’.

6

Page 8

Flammability class All filters in this

catalogue are UL 94V2 or UL94V0.

MTBF figures In addition to safety

approvals, Schaffner filters also have the

high reliability shown in the MTBF (mean

time between failure) values given for each

filter family. This is the lowest typical value

for any filter in the particular family and is

calculated according to Mil-HB 217-F, for

maximum rated current and voltage in an

ambient temperature of 40°C. MTBF is

stated in hours.

Components The component values

given in the detailed product pages are

nominal. The value of inductors and

capacitors can vary from this nominal

value. The tolerance and test conditions

for these components is shown in the

following table:

Parameter - Tol. + Tol. Test

Inductance 30% 50% 1kHz

Capacitance 20% 20% 1kHz

Resistance 10% 10% DC

Climatic classification Schaffner filters

fulfil the requirements of the HPF climatic

classification according to DIN 40040

(ambient temperature -25 to +85°C).

Filters with a connecting cable - such as

types FN 0.8 to FN 20 meet the

requirements of the HSF climatic

classification (ambient temperature

-25 to +70°C).

The letters of the climatic classification are

coded as follows:

1st letter: Lower temperature limit:

H

≅ -25°C

2nd letter: Upper temperature limit:

S ≅ +70°C P ≅ +85°C

3rd letter: Permissible humidity (relative):

F ≅ 75% yearly average

95% highest value for 30 days

85% highest for all other days

According DIN IEC 68 Part 1, the climatic

category is given by three numbers,

separated by /

Sample: 25/085/21

1st number: Lower temperature limit:

-25°C

2nd number: Upper temperature limit:

+85°C

3rd number: Humidity, 90-95% R.H.

21 days

Filters with a greater temperature range,

for special applications and for military

use, are available on request.

Filters with earth line chokes

It is possible to get interference induced

on all cables of a system simultaneously.

In this case the same noise will also be

induced onto the earth cable. A standard

filter will reduce the noise on the phase

lines but not on the earth. The noise on the

earth line will then be able to enter the

equipment and may cause the equipment

to malfunction. To reduce this interference

earth line chokes may be fitted or

incorporated into the filter. The earth line

choke will also provide extra attenuation

for normal common mode currents.

Care must be taken not to bypass earth

line chokes in systems. For example a PC

may have a filter with an earth line choke

fitted, if this PC is connected to a printer

that is powered from the mains supply,

and if the printer does not have an earth

line choke, the noise may find a path from

the mains into the printer and along the

data cable into the PC bypassing the earth

line choke in the PC.

Filters for medical equipment

For enhanced safety in medical

applications, Schaffner offers ‘B’ versions

of many of its filters, offering lower

leakage current (3µA typical), a discharge

resistor, and higher potential test values

(for example FN 326B).

Special filters for NEMP

A nuclear electro-magnetic pulse (NEMP)

is a high intensity, short duration, electromagnetic field produced as a result of a

nuclear explosion outside the atmosphere

(exo-atmospheric). The most critical threat

for technically highly developed nations is

an exo-atmospheric burst (at an altitude of

more than 40 km) producing a NEMP

inducing in antennas, power transmission

networks etc, such high voltages and

currents that it may leave a whole

continent without power, telephone or

radio communications. Electronic

equipment can be protected against a

NEMP if it is placed in special room or

housing which screen it from the electro-

magnetic fields, and if all feed lines to

these areas are protected with voltage

limiting devices such as varistors, gas

discharge tubes and suppressor diodes.

Special filters for TEMPEST

Telecommunication or data processing

equipment can radiate signals, or

propagate them along power lines,

providing a mechanism for unauthorised

persons to access classified information.

The study and blocking of such sensitive

signals is known as TEMPEST. Mains

filters with high attenuation over a large

frequency range are necessary. An

optimum filter solution can only be found

by an exact specification of requirements.

The FN 700Z filter series has been used in

many TEMPEST applications. Other

suitable filters are available on request.

Customer-specific filters

Schaffner’s standard range of filters

cover the majority of customers’

requirements. But depending on the

application, specific criteria might need to

be considered. With our many years of

experience, as well as the flexibility and

capability of our five development centers

located throughout the world, Schaffner

can offer companies an efficient and

reliable custom engineering service. To

date, Schaffner has produced over 4000

custom filters, ranging from 0.1 amps up

to 1200 amps, from a matchbox size to

rack mount designs, with up to 23 input

connections, used in all forms of

environments from offices to submarines

to factories to military armoured vehicles.

7

Page 9

SCHAFFNER

EMC measurement and

engineering services

8

In addition to offering one of the

world’s most comprehensive

ranges of standard filter products,

Schaffner offers the full

complement of measurement

and engineering services to

support equipment manufacturers

and users.

EMC testing

Schaffner operates the most sophisticated

EMC test facilities available anywhere

today - with extensive investment in

screened rooms, specialist test

equipment, and application engineering

teams - distributed at seven locations

throughout the world. Services available at

these locations include:

• Faraday cage and open field testing

• harmonics instrumentation for current

and voltage to the 49th harmonic

• radio emission measurements to CISPR,

EN, VDE, FCC, Mil or SEV

• simulation of electro-magnetic fields

• simulation of short-term DC or AC mains

failures

• simulation of transient parasitic voltages

• electro-static discharges to IEC 801-2,

VDE 0843 part 2 specifications

• AC and DC insulation testing

Engineering services

Schaffner has the largest world

engineering experience in solving EMC

problems. In addition to testing and

measuring services Schaffner can provide

the expert engineering support to help you

bring your equipment to market quickly

and efficiently; services available include:

• custom filter design

- to optimize filter performance, and

solve space, layout, mounting or

connection problems

• circuit and equipment design

- advising on circuit and equipment or

enclosure design to overcome EMC

problems

• turnkey component design and build

Expert EMC Support

Page 10

SCHAFFNER

Ordering information

9

For all single-phase filters (except FN 22)

FN 250 & - x / y

connections 01 = solder-lug

02 = pin for PCB mounting

03 = clamp terminal with M4 screw

05 = AMP fast-on

06 = solder-lug/fast-on combination

07 = wire

10 = screw feed-through

13 = AMP fast-on

16 = mini fast-on

23 = clamp terminal

29 = terminal block

33 = terminal block

38 = AMP fast-on

current rating (A)

A = low leakage (small Y capacitors)

B = medical version (without Y capacitors)

Z = surge voltage protection

filter type

for details see

mechanical data pages

Examples:

FN 670-1.8/07 Type FN 670; current rating 1.8A; with wire connections

FN 350-55/33 Type FN 350; current rating 55A; with safety terminal block connections

Page 11

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /2 or

/3 to determine the component value.

See Mechanical Data (pages 59 and 60) for

full details of housings and connections.

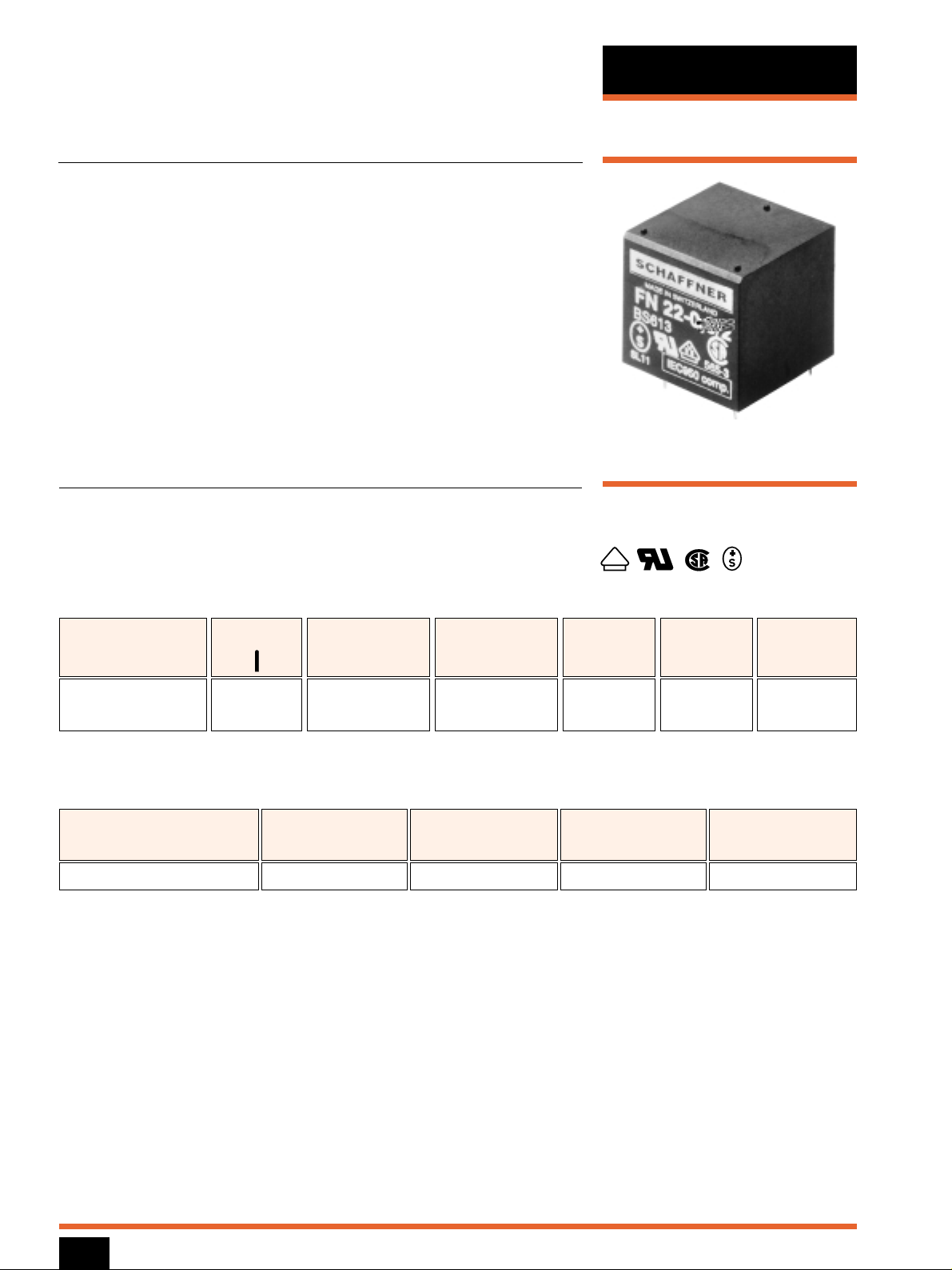

SCHAFFNER

47 2.2

15 2.2

Capacitance

Cx Cy

nF nF

0.8 (0.95)

0.8 (0.95)

Current ratings

A at 40°C (25°)

FN 22 -0.8 /2

FN 22 -0.8 /3

Family

✓

✓

Connections

KA1

KA1

Housing

10

0.3

Inductance

L

mH

2000 1700

Filter type

190

Maximum

leakage

µ

A/phase

250 50/60

Maximum operating

voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 2,750,000 hours.

Additional specifications

Approvals

V

E

D

FN 22

30

30

Weight

g

Provided in a compact plastic housing suitable for use with automatic

assembly equipment, this PCB-mounting filter offers good basic

performance, with a profile which suits equipment designs such as

monitors, terminals and power supplies.

•

compact PCB-mounting design

•

auto-insertion machine friendly

Compact PCB-mounting filter

Standard types

10

Page 12

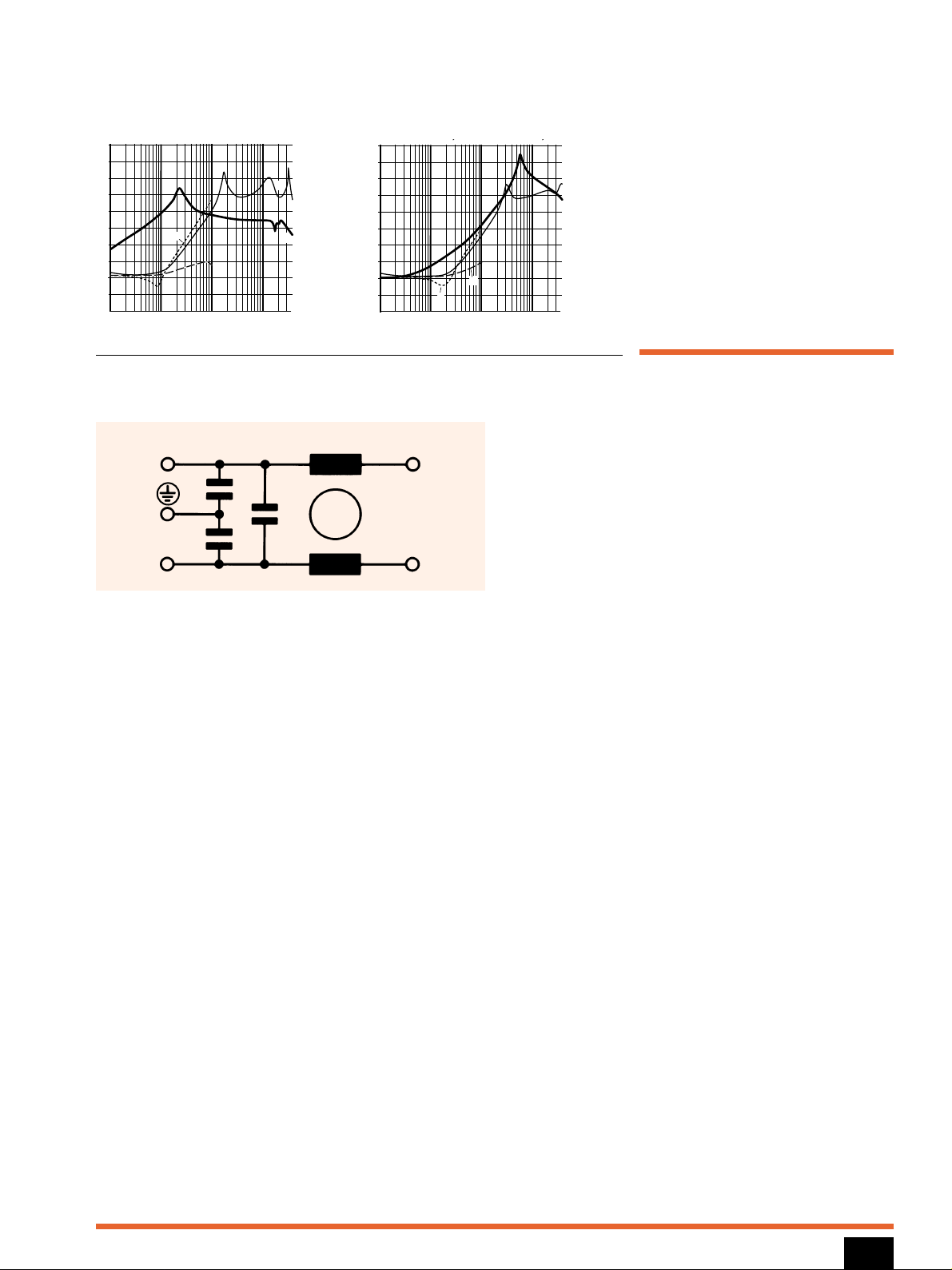

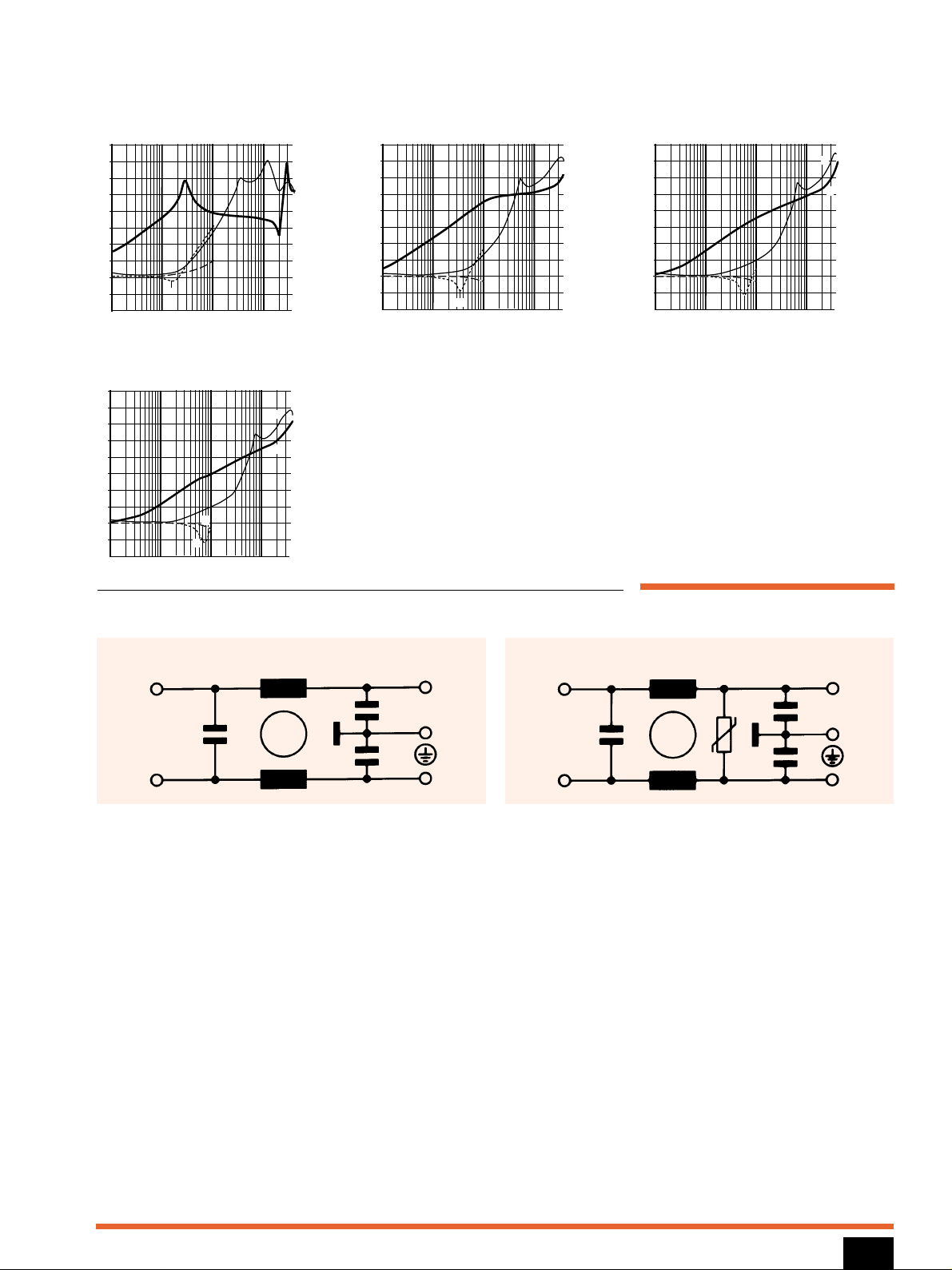

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

FN 22-0.8/2 types

FN 22-0.8/3 types

Electrical schematics

10k 100k 1M 10M

-20

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

y

y

B

D

A

C

N

2xL

Cx

FN 22

LINE

LOAD

2xCy

E

P

N'

P'

See tables for component values.

11

Page 13

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 250-6/07 is a 6A

filter with wire connections.

See Mechanical Data (pages 58 and 60) for

full details of housings and connections.

6 (6.9)

12 (13.8)

20 (23)

Current ratings

A at 40°C (25°)

FN 250 -6 /??

FN 250 -12 /??

FN 250 -20 /??

Family

/07

/07

/07

Connections

K11

K22

L4

Housing

2.5

6

8

Power

loss

W

5.7

2.7

1.9

Inductance

L

mH

0.47/0.47 15

1/1 15

2.2/2 15

Capacitance

Cx/Cx

1

Cy

µF nF

2000 1100

Filter type

0.47

0.47

0.22

Res.

R

M

Ω

1300

Maximum

leakage

µ

A/phase

250 50/60

Maximum operating

voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 295,000 hours.

Additional specifications

Approvals

FN 250

240

310

600

Weight

g

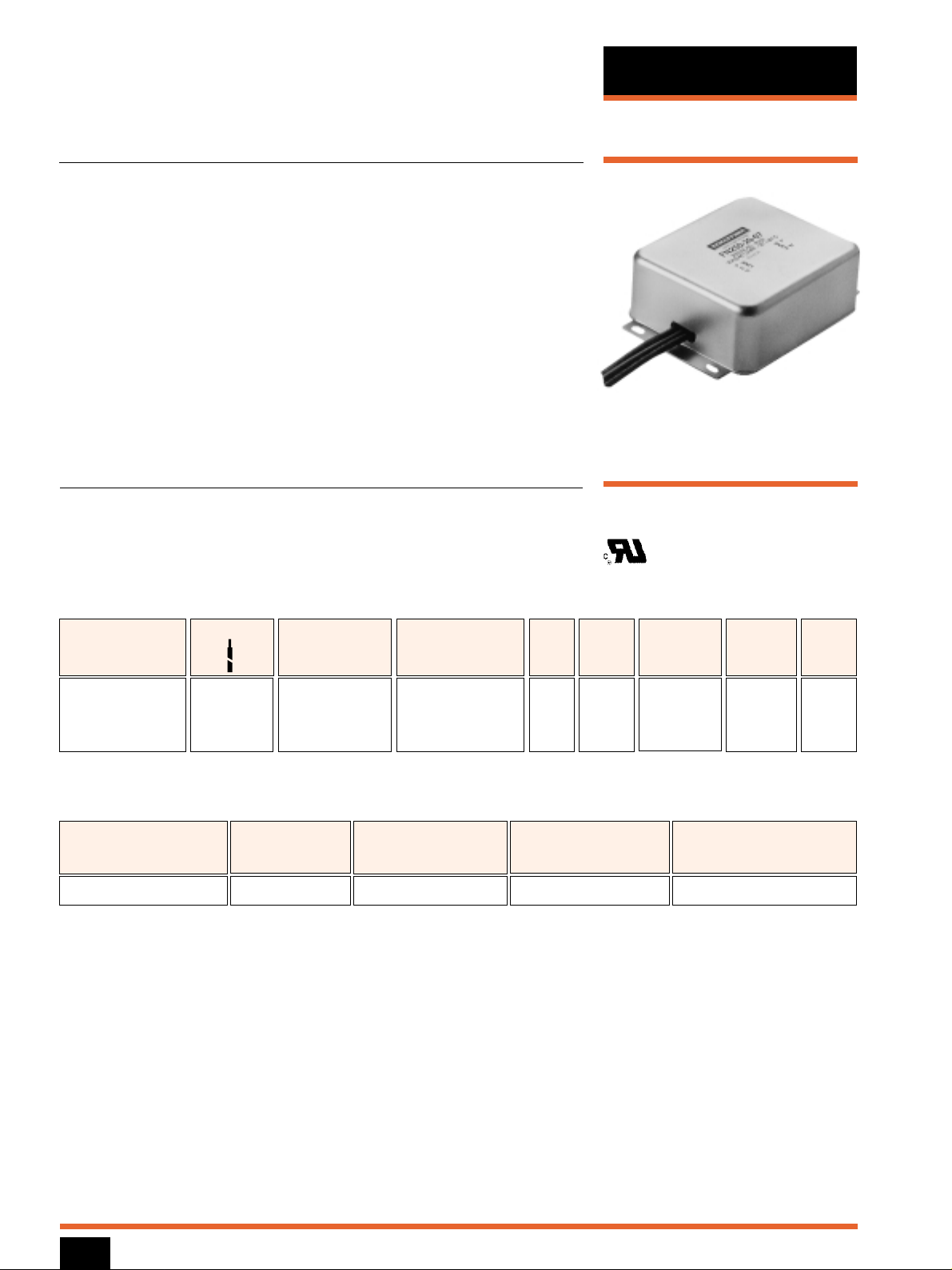

High inductance and capacitance values optimized for common mode

attenuation in the 0.1-1MHz range make this filter ideal for a large variety

of motor drive applications. Long wire connections give great installation

flexibility, simplifying assembly for drive manufacturers.

•

6 to 20A current ratings

•

compact housings with long wire connections

•

meets EN55011(A) for drives with motor cables <20m

Input filter for motor drives

Standard types

12

SCHAFFNER

Page 14

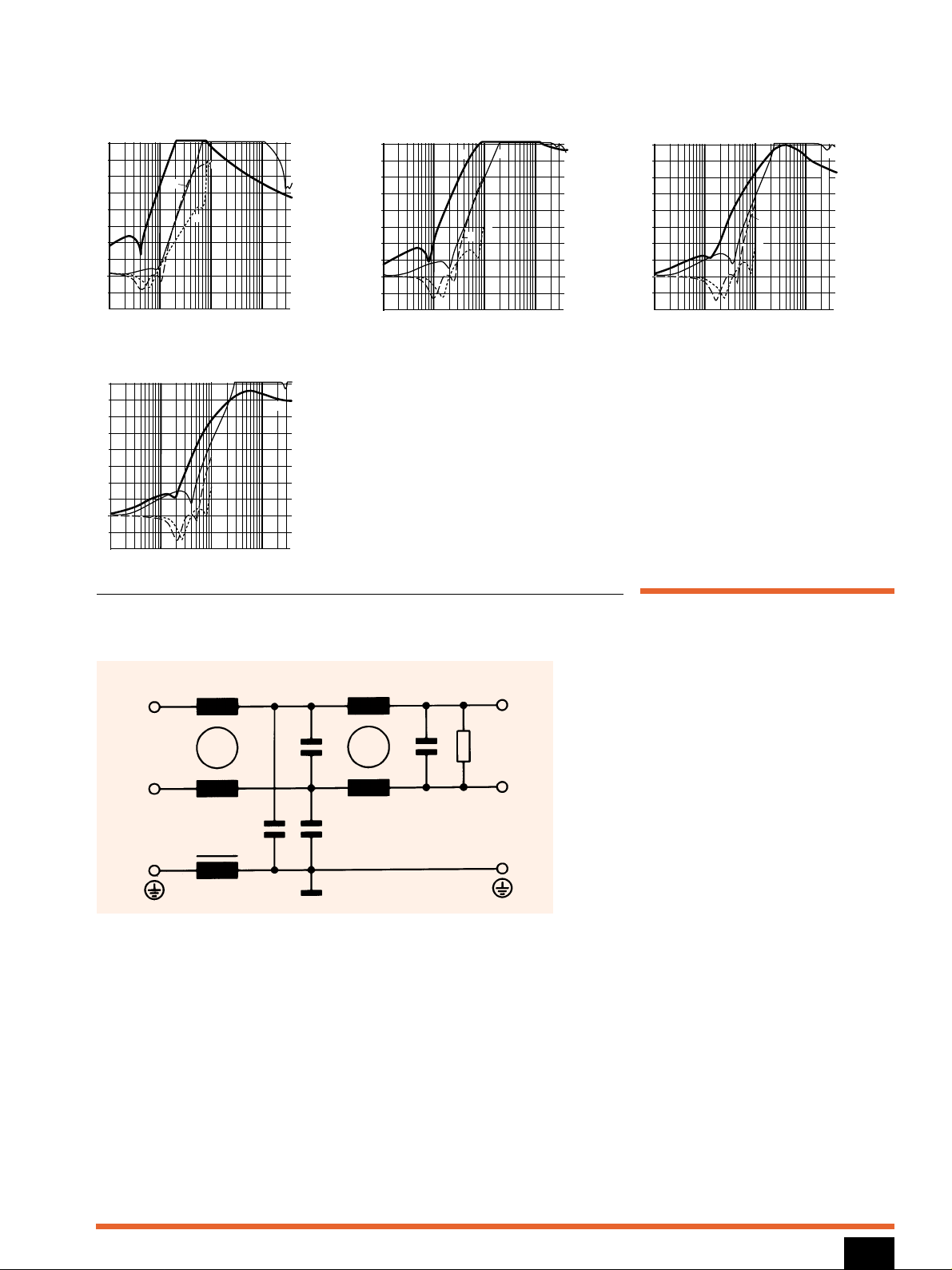

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

6 amp types

12 amp types

20 amp types

Electrical schematics

dB

70

60

50

40

30

20

10

0

-10

-20

10k 100k 1M 10 M

A

B

C

D

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

Cx

R

Cx1

FN 250

LINE

LOAD

2xCy

E

P

N'

P'

See tables for component values.

13

Page 15

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 332-6/01 is a 6A

filter with solder lug connections.

See Mechanical Data (pages 57 and 60) for

full details of housings and connections.

1 (1.2)

3 (3.6)

6 (7.3)

10 (12)

Current ratings

A at 40°C (25°)

FN 332 -1 /??

FN 332 -3 /??

FN 332 -6 /??

FN 332 -10A/??

Family

/01

/01

/01

/01

/05

/05

/05

/05

Connections

G1

G1

G1

G1

Housing

10

2

0.8

0.5

Inductance

L

mH

15 2.2

15 2.2

Capacitance

Cx Cy

nF nF

--

1200 26

Surge Energy

current absorption

AJ

2000 1700

2000 350

Filter type

190

190

Maximum

leakage

µ

A/phase

250 50/60

250 50/60

Maximum

operating voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 710,000 hours.

Additional specifications

Approvals

V

E

D

FN 332

65

65

65

70

Weight

g

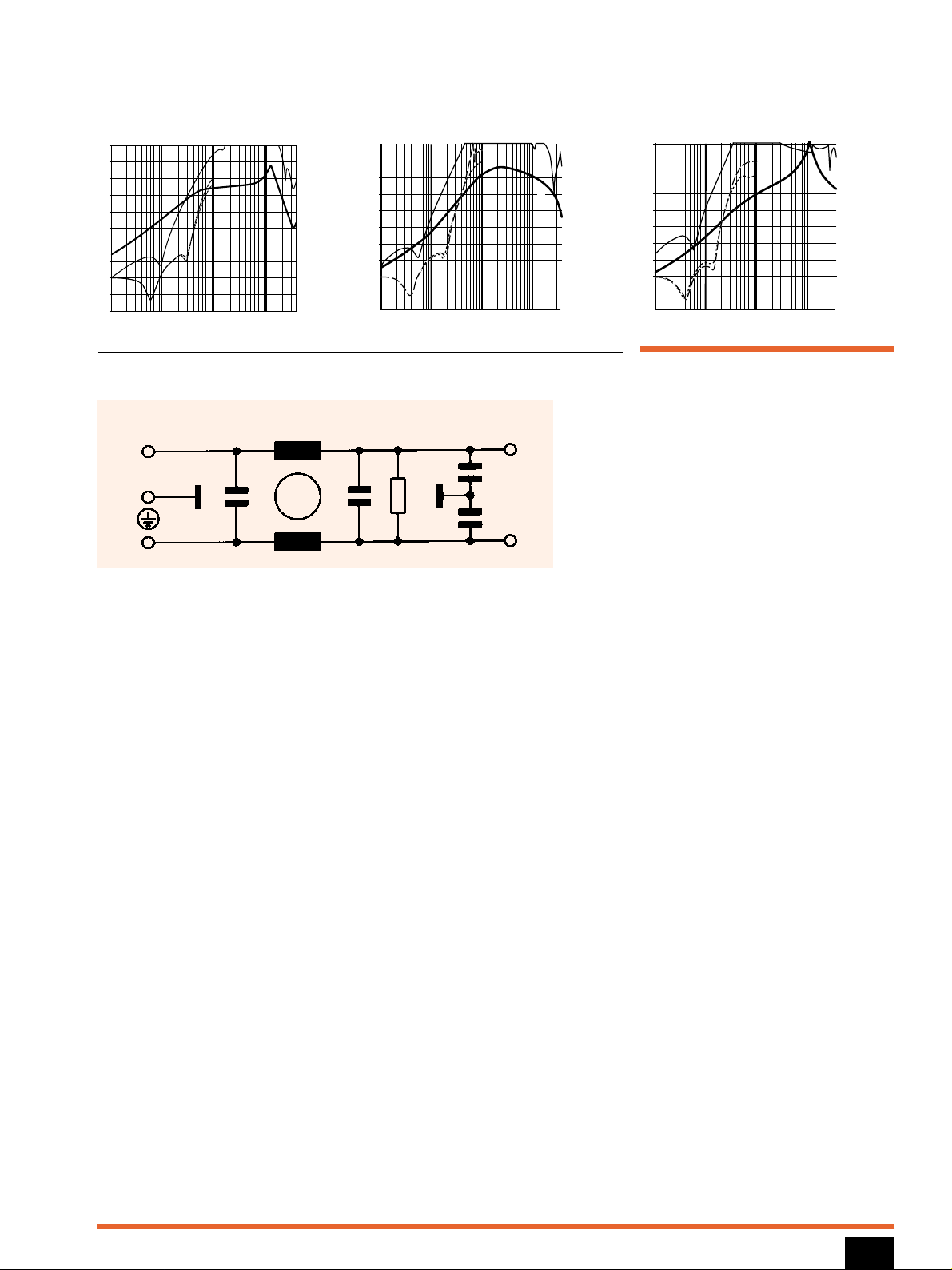

Designed for suppressing high interference levels, this filter is available in

a wide choice of current ratings, and also in an optional Z version with a

varistor for protection against high surge voltages.

•

1 to 10A current ratings

•

compact housing with solder or fast-on connections

•

optional surge voltage protection (Z types)

Performance filter

Standard types

FN 332Z types (surge protected)

14

SCHAFFNER

Page 16

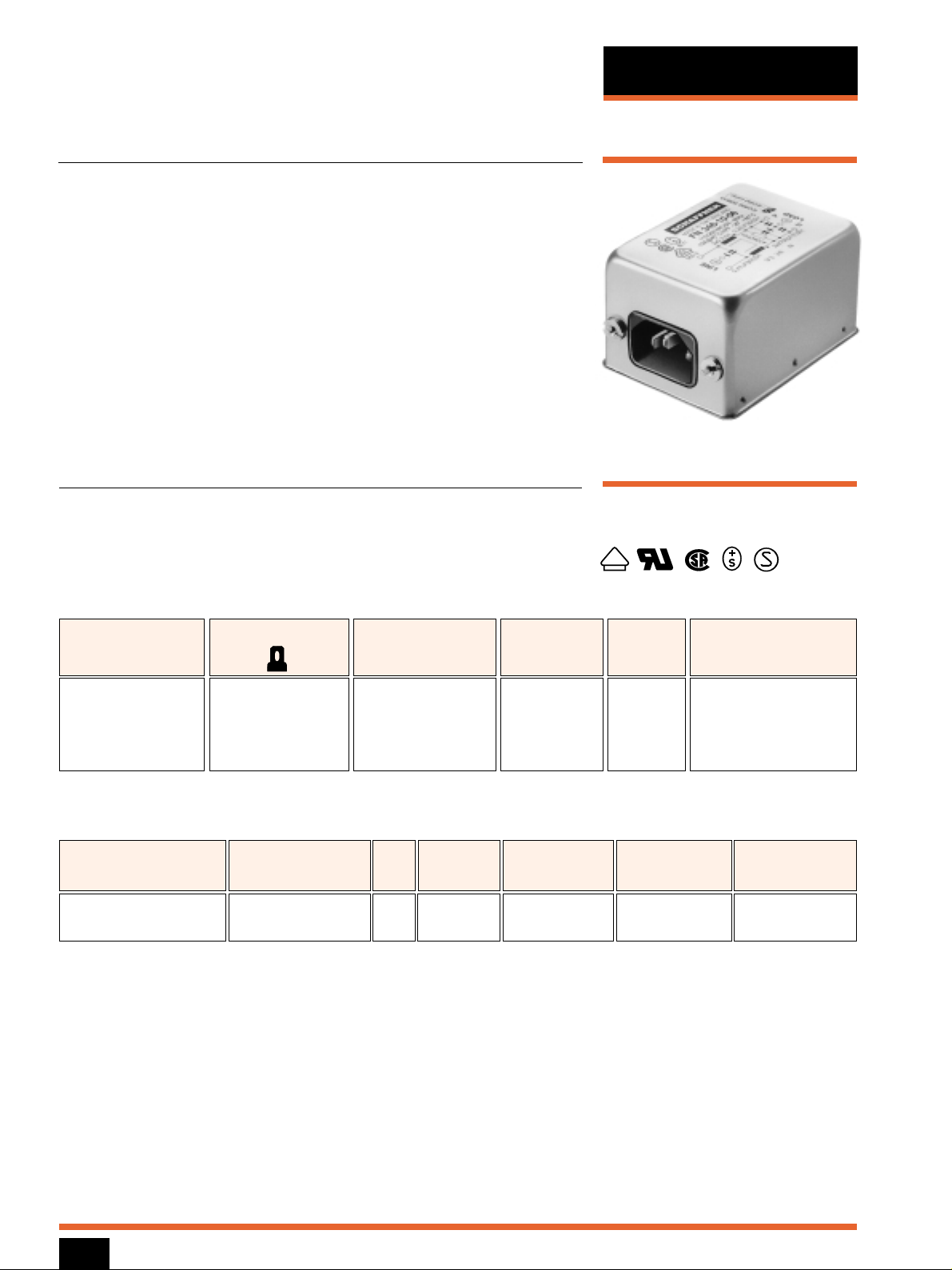

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

1 amp types

10 amp types

3 amp types

6 amp types

Electrical schematics

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

Cx

FN 332

LINE

LOAD

2xCy

P

N'

E'

P'

N

2xL

Cx

Z

FN 332Z

LINE

LOAD

2xCy

P

N'

E'

P'

See tables for component values.

15

Page 17

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 343-3/01 is a 3A

filter with solder lug connections.

See Mechanical Data (pages 57 and 60) for

full details of housings and connections.

1 (1.15)

3 (3.4)

6 (6.9)

10 (11.5)

Current ratings

A at 40ºC (25º)

FN 343 -1 /??

FN 343 -3 /??

FN 343 -6 /??

FN 343 -10 /??

Family

/01

/01

/01

/01

/05

/05

/05

/05

Connections

J2

J2

J2

J2

Housing

5.6/10/0.4

1.1/2/0.4

0.43/0.77/0.4

0.27/0.66/0.4

Inductance

L/L

1

/

L

2

mH

2000 1700

Filter type

100/100 2.2

Capacitance

Cx/Cx

1

Cy

nF nF

190

Maximum

leakage

µ

A/phase

250 50/60

Maximum

operating voltage

VAC Hz

1

Res.

R

MΩ

Hipot test voltage

PN→E P→N

VAC VAC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 970,000 hours.

Additional specifications

Approvals

FN 343

160

160

160

170

Weight

g

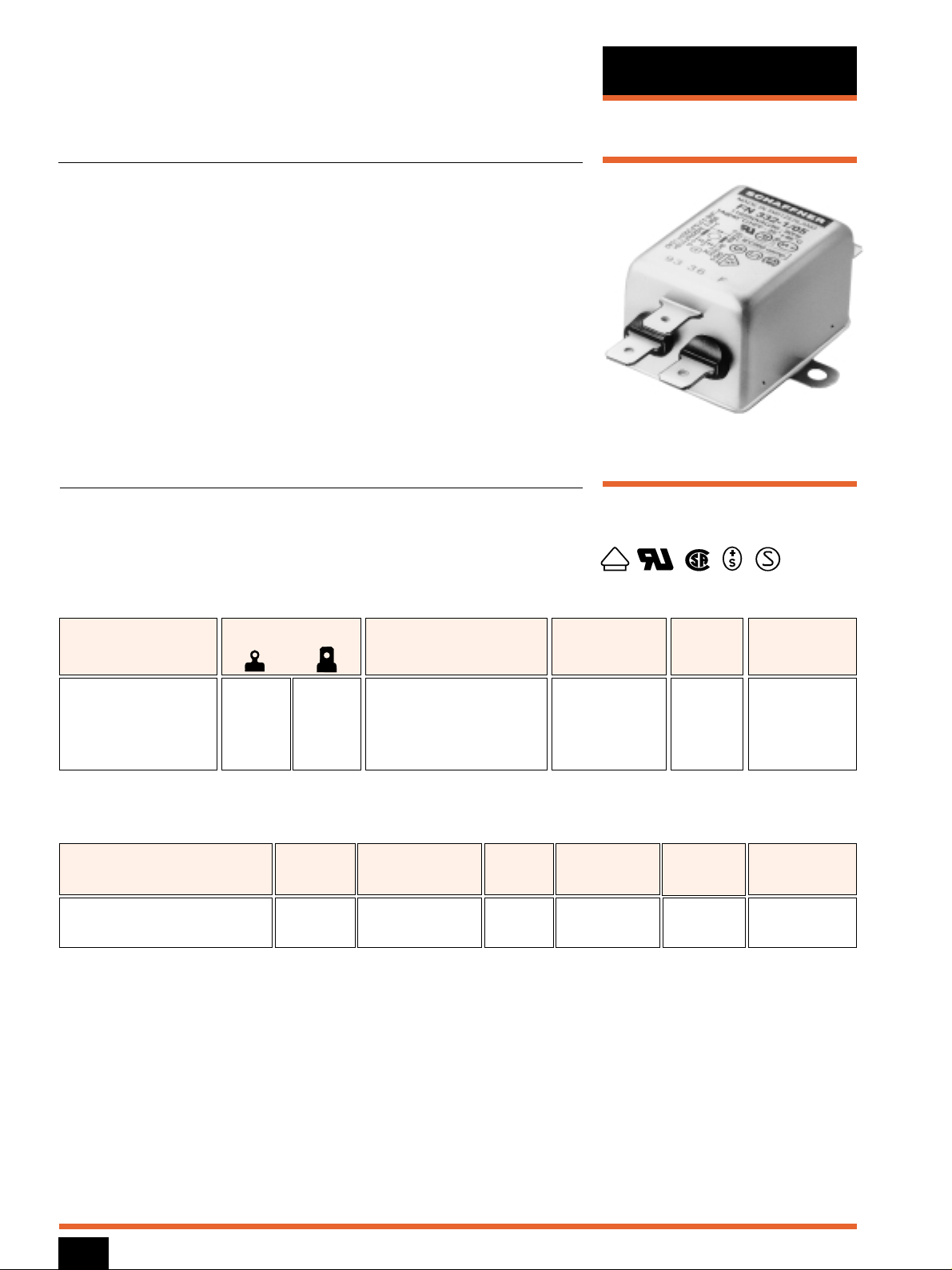

A general-purpose filter with a two-stage design and integral earth line

choke for high performance with good common mode attenuation.

•

1 to 10A current ratings

•

2-stage design with earth line choke

Two-stage filter

Standard types

16

V

E

D

SCHAFFNER

Page 18

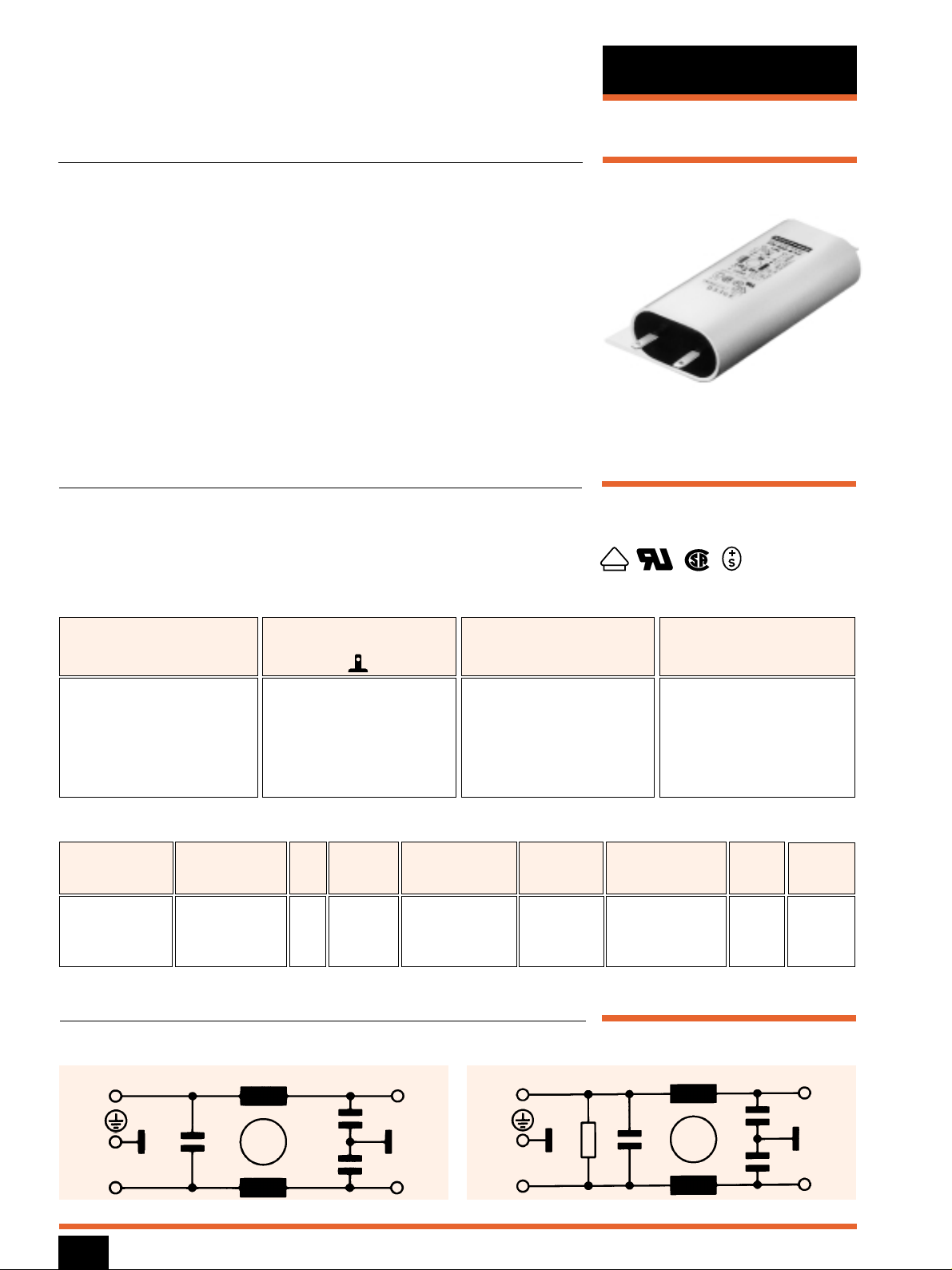

1 amp types

10 amp types

3 amp types

Electrical schematics

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

6 amp types

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

Cx

Cx

R

FN 343

LINE

LOAD

2xL1

L2

2xCy

E

P

N'

E'

P'

See tables for component values.

17

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

Page 19

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 346-10/06 is a 10A

filter with fast-on connections.

See Mechanical Data (pages 56 and 60) for

full details of housings and connections.

1.6 (1.9)

2.5 (3)

6 (7.3)

10 (12)

Current ratings

A at 40°C (25°)

FN 346 -1.6 /??

FN 346 -2.5 /??

FN 346 -6 /??

FN 346 -10 /??

Family

/06

/06

/06

/06

Connections

B27

B27

B27

B27

Housing

34

18

3

0.7

Inductance

L

mH

470/220 4.7

470/220 -

Capacitance

Cx/Cx

1

Cy

nF nF

2000 1700

2000 1700

Filter type

0.47

0.47

Res.

R

M

Ω

410

5

Maximum

leakage

µ

A/phase

250 50/60

250 50/60

Maximum

operating voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 330,000 hours.

Additional specifications

Approvals

V

E

D

FN 346

330

330

330

330

Weight

g

This filter offers IEC 320-compliant power entry with excellent filtering

performance thanks to the use of a U-core plus large inductor and

capacitor components. Very high symmetrical attenuation makes the filter

an ideal choice for switched-mode power supply equipment applications,

and any other form of circuitry involving non-sinusoidal waveforms.

•

up to 10A current ratings

•

very high performance filtering

•

optional medical versions (B types)

High-performance filter

Standard types

B types (medical)

18

SCHAFFNER

Page 20

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

1.6 amp types

10 amp types

2.5 amp types

Electrical schematics

6 amp types

N

2xL

Cx

R

FN 346

LINE

LOAD

2xCy

E

P

N'

E'

P'

See tables for component values.

19

Cx1

Page 21

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 350-55/33 is a 55A

filter with terminal connections suitable for AWG 6/16mm2wire.

See Mechanical Data (pages 55, 58 and 60)

for full details of housings and connections.

8 (9.2)

12 (13.8)

20 (23)

30 (34.5)

55 (63)

Current ratings

A at 40ºC (25º)

FN 350 -8 /??

FN 350 -12 /??

FN 350 -20 /??

FN 350 -30 /??

FN 350 -55 /??

Family

/29

/29

/29

-

-

-

-

/33

/33

Connections

L21

L21

L21

L21

B21

Housing

4.2

5.2

5.7

5.9

8.2

Power

loss

W

10

7.5

3.2

1.3

1

Inductance

L

mH

2800 1700

Filter type

2/0.68 10/47

2.2/1 10/47

2.2/1 10/47

2.2/1 15/47

4.4/1 33/94

Capacitance

Cx/Cx1Cy/Cy

1

µF nF

4900

4900

4900

5300

11000

Maximum

leakage

µ

A/phase

250 50/60

Maximum

operating voltage

VAC Hz

1

Res

R

MΩ

Hipot test voltage

PN→E P→N

VDC VDC

Operating

frequency

Hz

DC to 60

MTBF at 40°C, 230V, per Mil-HB-217F: 420,000 hours.

Additional specifications

Approvals

FN 350

700

900

950

950

1800

Weight

g

High inductance and capacitance values optimized for common and

differential mode attenuation in the lower frequency range make this filter

ideal for a large variety of motor drive applications. Supplied in a

relatively small footprint design with terminal blocks for easy installation

and servicing in industrial environments; also meets IEC 950 extending

applications flexibility.

•

8 to 55A current ratings

•

screwdriver-connect terminations

•

meets EN55011/14/22 VDE 0871/75/78

•

meets IEC 950

High power filter for drives

Standard types

V

E

D

20

SCHAFFNER

Page 22

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

8 amp types

12 amp types

Electrical schematics

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

30 amp types

55 amp types

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

Page 23

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 352Z-6/06 is a 6A

filter with fast-on connections.

See Mechanical Data (pages 55 and 60) for

full details of housings and connections.

6 (7.2)

10 (12)

16 (20)

24 (30)

Current ratings

A at 40ºC (25º)

FN 352Z -6 /??

FN 352Z -10 /??

FN 352Z -20 /??

FN 353Z -30 /??

Family

/06

-

-

-

/29

/29

/33

Connections

3/3/-

5/0.06/0.003

3.5/0.06/0.0035

2.3/0.025/0.035

Inductance

L/L1/L

2

mH

2000 350

Filter type

470/220 3.3/1.5

220/220 15/15

220/220 15/15

470/220 15/15

Capacitance

Cx/Cx1Cy/Cy

1

nF nF

420

1300

1300

1300

Maximum

leakage

µA/phase

B22

B8

B13

B13

Housing

250 50/60

Maximum operating

voltage

VAC Hz

40

Energy

absorption

J

0.47

0.47

0.47

0.23

Res.

R

MΩ

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 230,000 hours.

Additional specifications

Approvals

FN 352Z

575

1320

2950

3100

Weight

g

This filter family provides a high performance two- or three-stage circuit

design with a varistor for protection against high surge voltages of up to

2000A. The 353Z version packages the same circuit design around a

differential mode core for greater compactness.

•

6 to 30A current ratings

•

integral surge voltage protection to 2kA

•

solder or screwdriver connections

Multi-stage filter

Standard types

Page 24

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

6 amp types

10 amp types

Electrical schematics

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

20 amp types

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

30 amp types

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

R Cx Cx1 2xCy

FN 352Z-6

LINE

LOAD

2xL

Cx1 Z

2x

Cy1

E

P

N'

E'

P'

N

2xL

RCx Cx1

Cx1

FN 352Z-10/FN 352Z-20/FN 353Z-30

LINE

LOAD

2xL1 2xL2

Z

2x

Cy1

E

P

N'

E'

P'

See tables for component values.

23

Page 25

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 357-10/29 is a 10A

filter with terminal connections suitable for AWG 10/6mm2wire.

See Mechanical Data (pages 55 and 60) for

full details of housings and connections.

6 (6.9)

10 (11.5)

16 (18.4)

Current ratings

A at 40ºC (25º)

FN 357 -6 /??

FN 357 -10 /??

FN 357 -16 /??

Family

/29

/29

/29

Connections

B7

B7

B11

Housing

5.5

6.2

8.4

Power

loss

W

3.5/0.75

2.8/0.45

2.3/0.4

Inductance

L/L

1

mH

2800 1100

Filter type

1.5/2.2 22/-

2.2/2.2 22/33

3/3 47/47

Capacitance

Cx/Cx1Cy/Cy

1

µF nF

3800

4800

8100

Maximum

leakage

µA/phase

250 50/60

Maximum

operating voltage

VAC Hz

0.1

0.1

0.075

Res.

R

MΩ

Hipot test voltage

PN→E P→N

VDC VDC

Operating

frequency

Hz

DC to 60

MTBF at 40°C, 230V, per Mil-HB-217F: 250,000 hours.

Additional specifications

Approvals

FN 357

1450

1500

3000

Weight

g

This two-stage filter offers good low-to-medium power performance

aimed at the frequency ranges encountered in typical motor drive

applications, and also lower frequency (sub 100kHz) equipment.

Terminal blocks simplify installation and servicing.

•

6 to 16A current ratings

•

screwdriver-connect terminations

•

meets EN55011/14/22 VDE 0871/75/78

Two-stage filter for motor drives

Standard types

V

E

D

24

SCHAFFNER

Page 26

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

6 amp types

10 amp types

Electrical schematics

Page 27

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 401-1.5/02 is a 1.5A

filter with pin connections.

See Mechanical Data (pages 59 and 60) for

full details of housings and connections.

0.8 (0.95)

1.5 (1.8)

Current ratings

A at 40ºC (25º)

FN 401 -0.8 /??

FN 401 -1.5 /??

Family

/02

/02

Connections

20

20

Inductance

L

mH

2000 1100

Filter type

68 15 2.2

100 – 2.2

Capacitance

Cx Cx

1

Cy

nF nF nF

KA2

KA3

Housing

250 50/60

Maximum operating

voltage

VAC Hz

190

Maximum

leakage

µ

A/phase

1

Res.

R

MΩ

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 1,000,000 hours.

Additional specifications

Approvals

FN 401

30

90

Weight

g

Offering excellent filtering with high component values for good

asymmetric and common mode attenuation, suitable for demanding

applications such as switched-mode power supplies, this filter is supplied

in a low-profile plastic PCB-mount package in a choice of two low power

ratings.

•

0.8-1.5A current ratings

•

compact PCB-mount footprint

•

low profile design

Performance PCB-mount filter

Standard types

26

SCHAFFNER

Page 28

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

0.8 amp types

1.5 amp types

Electrical schematics

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

y

y

B

D

A

C

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

A

C+D

N

2xL

Cx

R

Cx

FN 401 (1.5A)

LINE

LOAD

2xCy

P

N'

E'

P'

N

2xL

Cx

Cx1

FN 401 (0.8A)

LINE

LOAD

2xCy

P

N'

E'

P'

See tables for component values.

27

Page 29

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 402-4/16 is a 4A

filter with mini fast-on connections.

See Mechanical Data (pages 59 and 60) for

full details of housings and connections.

0.5 (0.6)

1 (1.2)

1.6 (1.9)

2.5 (3.0)

4 (4.7)

6.5 (7.5)

Current ratings

A at 40ºC (25º)

FN 402 -0.5 /??

FN 402 -1 /??

FN 402 -1.6 /??

FN 402 -2.5 /??

FN 402 -4 /??

FN 402 -6.5 /??

Family

/02

/02

/02

/02

/02

/02

/07*

/07*

/07*

/07*

/07*

/07*

/16

/16

/16

/16

/16

/16

/38

/38

/38

/38

/38

/38

Connections

KA/KB

KA/KB

KA/KB

KA/KB

KA/KB

KA/KB

Housing

40

10

6

2

1

1

Inductance

L

mH

2000 1700

2500 1700

Filter type

* /07 outputs add 5g to weight

100 2.2

100 -

Capacitance

Cx Cy

nF nF

190

2

Maximum

leakage

µ

A/phase

250 50/60

250 50/60

Maximum

operating voltage

VAC Hz

1

1

Res.

R

M

Ω

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 1,900,000 hours. (standard types); 1,200,000 hours (B types)

Additional specifications

Approvals

FN 402

40

40

40

40

40

40

Weight

g

Provided in a very compact and low profile PCB- or chassis-mounting

plastic enclosure, with a choice of six current ratings and four output

connections, this filter combines great versatility with economy.

•

0.5-6.5A current ratings

•

compact PCB- or chassis-mountable design

•

four connection style choices

•

very low profile

•

optional medical versions (B types)

Low-cost PCB/chassis-mount filter

Standard types

B types (medical)

28

V

E

D

SCHAFFNER

Page 30

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

0.5 amp types

2.5 amp types

1 amp types

Electrical schematics

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

1.6 amp types

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

6.5 amp types

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

4 amp types

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

C

A

See tables for component values.

29

N

L

R

Cx

FN 402

LINE

LOAD

Cy

Cy

P

N'

E'

P'

N

L

Cx

R

FN 402B

LINE

LOAD

Cx

P

N'

P'

Page 31

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 405-6/02 is a 6A

filter with pin connections.

See Mechanical Data (pages 59 and 60) for

full details of housings and connections.

0.5 (0.6)

1 (1.2)

3 (3.6)

6 (6.9)

Current ratings

A at 40°C (25°)

FN 405 -0.5 /??

FN 405 -1 /??

FN 405 -3 /??

FN 405 -6 /??

Family

/02

/02

/02

/02

Connections

KA4

KA4

KA4

KA4

Housing

24

10

2

0.8

Inductance

L

mH

15 2.2

Capacitance

Cx Cy

nF nF

2000 1100

Filter type

190

Maximum

leakage

µ

A/phase

250 50/60

Maximum operating

voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 1,600,000 hours.

Additional specifications

Approvals

V

E

D

FN 405

40

40

40

40

Weight

g

General-purpose filter for PCB mounting applications, supplied in a

plastic housing.

•

0.5-6A current ratings

•

PCB-mounting

•

low profile

PCB-mounting filter

Standard types

30

SCHAFFNER

Page 32

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

0.5 amp types

6 amp types

1 amp types

Electrical schematics

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

3 amp types

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

Cx

FN 405

LINE

LOAD

2xCy

P

N'

E'

P'

See tables for component values.

31

Page 33

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 406-6/02 is a 6A

filter with pin connections.

See Mechanical Data (pages 54 and 60) for

full details of housings and connections.

0.5 (0.6)

1 (1.2)

3 (3.5)

6 (6.9)

Current ratings

A at 40ºC (25º)

FN 406 -0.5/??

FN 406 -1 /??

FN 406 -3 /??

FN 406 -6 /??

Family

/02

/02

/02

/02

Connections

A6

A6

A6

A6

Housing

24

12

2.5

0.78

Inductance

L

mH

2000 1700

2500 1700

Filter type

100 2.2

100 -

Capacitance

Cx Cy

nF nF

190

2

Maximum

leakage

µ

A/phase

250 50/60

250 50/60

Maximum operating

voltage

VAC Hz

1

1

Res.

R

M

Ω

Hipot test voltage

PN→E P→N

VAC VAC

Operating

frequency

Hz

DC to 400

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 1,900,000 hours.

Additional specifications

Approvals

FN 406

36

36

36

36

Weight

g

The FN 406 PCB-mounting EMC filter offers high performance in an

exceptionally compact form, and is ideal for equipment applications

where space is at a premium. With a footprint of just 15 x 45 mm, it

greatly reduces the PCB area required compared with using discrete

components, with a height profile which does not exceed the capacitors

and transformers typically used in circuitry such as switched mode power

supplies. Performance is also enhanced, thanks to an aluminium housing

- providing excellent RF shielding to protect against coupling effects from

nearby components.

•

0.5-6A current ratings

•

aluminium case

•

very compact PCB-mounting design

•

low profile

Ultra-compact EMC filter

Standard types

B types (medical)

V

E

D

32

SCHAFFNER

Page 34

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

0.5 amp types

3 amp types

1 amp types

Electrical schematics

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

C

A

6 amp types

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

C

A

Page 35

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 410-6/02 is a 6A

filter with pin connections.

See Mechanical Data (pages 54 and 60) for

full details of housings and connections.

0.5 (0.6)

1 (1.2)

3 (3.6)

6 (6.9)

Current ratings

A at 40°C (25°)

FN 410 -0.5 /??

FN 410 -1 /??

FN 410 -3 /??

FN 410 -6 /??

Family

/02

/02

/02

/02

Connections

E1

E1

E1

E1

Housing

24/24

10/10

2/2

0.8/0.8

Inductance

L/L

1

mH

33 2.2

Capacitance

Cx Cy

nF nF

2000 1700

Filter type

190

Maximum

leakage

µ

A/phase

250 50/60

Maximum operating

voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 675,000 hours.

Additional specifications

Approvals

V

E

D

FN 410

85

85

85

85

Weight

g

This filter, with its two-stage inductor design, offers high attenuation in a

metal-cased PCB-mounting form.

•

0.5-6A current ratings

•

high attenuation 2-stage design

•

PCB-mounting

Two-stage PCB filter

Standard types

34

SCHAFFNER

Page 36

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

0.5 amp types

6 amp types

1 amp types

Electrical schematics

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

3 amp types

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

N

2xL

Cx

FN 410

LINE

LOAD

Cy

2x

2xL1

E

P

N'

P'

See tables for component values.

35

Page 37

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 422-4/13 is a 4A

filter with mini fast-on connections.

See Mechanical Data (pages 54 and 60) for

full details of housings and connections.

0.6 (0.7)

1 (1.2)

2.5 (3)

4 (4.8)

6.5 (7.3)

Current ratings

A at 40°C (25°)

FN 42? -0.6 /??

FN 42? -1 /??

FN 42? -2.5 /??

FN 42? -4 /??

FN 42? -6.5 /??

Family

/13

/13

/13

/13

/13

Connections

22.5

13

3.4

2

0.75

Inductance

L

mH

150 2.2

100 2.2

150 4.7

Capacitance

Cx Cy

nF n F

2000 1700

2000 1700

2000 1700

Filter type

1

1

Res.

R

M

Ω

190

190

190

Maximum

leakage

µ

A/phase

70

60

70

Weight

g

A7B

A7A

A7B

Housing

250 50/60

250 50/60

250 50/60

Maximum operating

voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VDC

Operating

frequency

Hz

DC to 400

DC to 400

DC to 400

MTBF at 40°C, 230V, per Mil-HB-217F: 625,000 hours.

Approvals

V

E

D

FN 420

This low-cost filter is supplied in a flat case with rounded edges, making

it easy to mount in almost any location - for great versatility and problem

solving. Its medium-performance filter design is aimed at generalpurpose applications.

•

0.6-6.5A current ratings

•

low profile case

•

designed for easy-mounting

Versatile easy-mount filter

FN 420 types

FN 421 types

FN 422 types

N

2xL

Cx

FN 421

LINE

LOAD

2xCy

E

P

N'

P'

N

2xL

Cx

R

FN 420/422

LINE

LOAD

2xCy

E

P

N'

P'

See tables for component values.

Electrical schematics

36

SCHAFFNER

Page 38

FN 420 0.6 amp types

FN 420 4 amp types

FN 420 1 amp types

FN 420 2.5 amp types

10k 100k 1M

10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

D

A

C

Page 39

Filter selection table

Choose the family FN xxx with the required current rating and features, and add /??

to determine input/output (line/load) connection style. Example: FN 610-10/06 is a 10A

filter with fast-on connections.

See Mechanical Data (pages 57, 58 and 60)

for full details of housings and connections.

1 (1.15)

3 (3.4)

6 (6.9)

10 (11.5)

20 (23)

30 (34)

Current ratings

A at 40°C (25°)

FN 610 -1 /??

FN 610 -3 /??

FN 610 -6 /??

FN 610 -10 /??

FN 610 -20 /??

FN 610 -30 /??

Family

-

-

-

-

-

/03

/06

/06

/06

/06

/06

-

/07

/07

/07

/07

-

-

-

-

-

-

-

/10

Connections

F1

F1

F1

F2

J1

L1

Housing

3

2

0.75

0.45

0.48

0.61

Inductance

L

mH

33 2.2

33 0.47

33 -

Capacitance

Cx Cy

nF nF

2000 1700

2500 1700

2500 1700

Filter type

1

1

Res.

R

M

Ω

190

40

2

Maximum

leakage

µ

A/phase

250 50/60

250 50/60

250 50/60

Maximum

operating voltage

VAC Hz

Hipot test voltage

PN→E P→N

VAC VAC

Operating

frequency

Hz

Page 40

Insertion loss

Per CISPR 17; A = 50Ω/50Ω sym, B = 50Ω/50Ω asym, C = 0.1Ω/100Ω sym, D = 100Ω/0.1Ω sym

1 amp types

10 amp types

3 amp types

6 amp types

Electrical schematics

10k 100k 1M

10M

0

10

20

30

40

50

60

70

dB

B

D

A

C

A

B

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

D

C

10k 100k 1M 10M

-20

-10

0

10

20

30

40

50

60

70

dB

B

A

C

D

20 amp types

30 amp types

10k 100k 1M 10M

0

10

20

30

40

50

60

70

B

A

C

D

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

A

C

D

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

A

C

D

1 amp (A types)

3 amp (A types)

10 amp (A types)

10k 100k 1M 10M

0

10

20

30

40

50

60

70

dB

B

A