Page 1

Schaffner Group | Nordstrasse 11 | 4542 Luterbach | Switzerland

T +41 32 681 66 26 | F+41 32 681 66 30 | www.schaffner.com

User and Installation Manual

Ecosine evo Passive Harmonic Filters

Ecosine evo FN 3440/FN 3441 (50 Hz) for 380–415 VAC

FN 3450/FN 3451 (50 Hz) for 440–500 VAC

FN 3442/FN 3443 (60 Hz) for 380–415 VAC

FN 3452/FN 3453 (60 Hz) for 440–480 VAC

Page 2

Schaffner Group

User and Installation Manual

Ecosine

®

evo

October 2018

2/50

© All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means without the prior written permission of Schaffner International Ltd. The information in this

manual is subject to change without notice. Every precaution has been taken in the preparation of this

manual. Schaffner assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

Revision: 05 (October 2018)

The most current edition of these instructions (PDF format) can be obtained from www.schaffner.com

or from

your local Schaffner sales representative.

Other technical documentation of our products is also available in the download area of www.schaffner.com

Document name:

User and Installation Manual ecosine evo Rev05.pdf

Version history

Revision

Date

Description

01

November 2016

Initial version

02

03

February 2017

July 2017

FN 3441/51/53 and IP 20 types added

SCCR

04

January 2018

Update filter selection table of FN3441/51/53 (min. required Lac, Ldc

included)

Add thread size and torque for finger guard

05

October 2018

Add new filter series FN 3 442 and FN 3443 (60 Hz, 380VAC)

Page 3

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

3/50

i. Ecosine evo passive harmonic filter

Ecosine evo product highlights

Schaffner ecosine evo passive harmonic filters are configurable products which provide a tailored solution to

each specific problem of current harmonics mitigation of 3-phase non-linear loads.

The eight product lines, FN 3440/FN 3441, FN 3450/FN 3451, FN 3442/FN 3443 and FN 3452/FN 3453 are

applicable for low voltage 50 Hz and 60 Hz systems and they are particularly suitable for AC and DC motor

drives, battery chargers and other power electronics applications with 6-pulse front-end rectifiers.

Ecosine evo passive harmonic filter technology represents an evolution of the previous generations of

passive harmonic filters and introduces following aspects of novelty:

| Ecosine evo is designed for the most demanding harmonic mitigation tasks. Ecosine evo filters

FN 3440, FN 3450, FN 3442 and FN 3452 are designed for three-phase diode and thyristor rectifier,

to achieve THID ≤5% even without DC-link choke included in the drive. If there is 8% DC link choke

present in the drive, ecosine evo filters FN 3441, FN 3451, FN 3443 and FN 3453 help to achieve 5%

THID @ rated power. The new generation ecosine evo filters guarantee compliance with the toughest

requirement of IEEE-519 and other stringent international power quality standards.

| Ecosine evo demonstrates superior partial load performance. The excellent performance of

ecosine evo filters not only reflects on mitigating harmonic current and bringing the THID down to 5%

(diode rectifiers @ rated power), but also introducing minimum reactive power, even at partial or no

load condition. The displacement power factor remains at cosφ >0.98 @ 50% load.

| The modular concept of ecosine evo offers optimal tailored solution. Ecosine evo are

configurable filters, optional modules includes fan with aux. power supply, fan without aux. power

supply, trap disconnect jumper and RC damper modules. Optimal solutions can be achieved by

merely plugging a new module according to different installation conditions and drive setups.

| Most compact design, robust, reliable and ready to use.

| The Schaffner ecosine evo product configurator (myecosine.com

) supports customers in evaluating

the best suited filter type.

| The upgraded version of the Schaffner power quality simulator SchaffnerPQS3 (pqs.schaffner.com)

provides the possibility to simulate ecosine evo passive harmonic filters within an electrical system. It

furthermore offers quick and accurate performance checks.

This user manual is intended to support designers, installers, and application engineers with filter selection,

installation, application, and maintenance. It provides helpful solutions to overcome harmonics mitigation

challenges and answers frequently asked questions.

If you require additional support, please feel free to contact your local Schaffner representative.

Page 4

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

4/50

ii. Performance Guarantee

Selecting and installing the appropriate ecosine evo passive harmonic filter in a variable frequency AC drive

application,variable speed drive application within our published technical specifications we guarantee that

the input current distortion will be less than or equal to 5% THID for standard ecosine evo series filters at

rated power. Ecosine evo filters can also provide similar performance in other drive applications such as

constant torque, DC drives or other phase controlled rectifiers, e.g. SCR drives, but actual THID levels can

vary by load and/or speed and/or firing angle of thyristors and therefore cannot be guaranteed. Consult your

local Schaffner representative for assistance when applying ecosine filters on these types of equipment.

Minimum system Requirements

The guaranteed performance levels of this filter will be achieved when the following system conditions are

met:

| Type of load: Any 3-p hase equ ipment with front-end six-pulse diode rectifier, with

(FN 3441/43/51/53) or without DC-link choke (FN 3440/42/50/52).

| Type of source: 3-phase power line without neutral

| Line impedance: <3% (calculated for the rated filter power)

| Line frequency: 50 Hz ±1 Hz (FN 3440/41, FN 3450/51), 60 Hz ±1 Hz (FN 3442/43, FN 3452/53)

| Line voltage: Nominal line voltage ±10%

| Line voltage unbalance: <1%

| Line voltage distortion: THVD <2%

If a properly sized and installed filter fails to meet the 5% THID level, Schaffner will provide thenecessary

application engineering support or filter replacement at no charge.

iii. Important user notice

Schaffner ecosine evo harmonic filters are designed for the operation on the input (grid) side of power

electronic equipment with six-pulse rectifier front-ends in balanced three-phase power systems, like typically

used in AC or DC motor drives and high power DC supplies. Filter suitability for a given application must be

determined by the user on a case by case basis. Schaffner will not assume liability for any consequential

downtimes or damages resulting from use or application of ecosine filters outside of their specifications.

Ecosine filters are not designed for single-phase or split-phase app licat io ns.

Page 5

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

5/50

iv. General Safety Notes and Installation Guidelines (Cautions and Warnings)

Page 6

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

6/50

Content

Version history .......................................................................................................................................... 2

i. Ecosine evo passive harmonic filter .................................................................................................. 3

Ecosine evo product highlights ........................................................................................................................ 3

ii. Performance Guarantee ...................................................................................................................... 4

Minimum system Requirements .............................................................................................................. 4

iii. Important user notice .......................................................................................................................... 4

iv. General Safety Notes and Installation Guidelines (Cautions and Warnings) ................................ 5

Content ....................................................................................................................................................... 6

1. Ecosine evo passive harmonic filter designation.............................................................................. 8

1.1 Distinguishing between FN 3440/FN 3441, FN 3450/FN 3451, FN 3442/FN 3443 and FN 3452/FN 3453

......................................................................................................................................................................... 8

1.2 Explanation of ecosine evo designation .................................................................................................... 8

2. Filter selection ..................................................................................................................................... 11

2.1 Filter selection table FN 3440/FN 3441 (50 Hz, 3×380 … 415 VAC) ...................................................... 13

2.2 Filter selection table FN 3450/FN 3451 (50 Hz, 3×440 … 500 VAC) ...................................................... 14

2.3 Filter selection table FN 3442/FN 3443 (60 Hz, 3×380 … 415 VAC) ...................................................... 15

2.4 Filter selection table FN 3452/FN 3453 (60 Hz, 3×440 … 480 VAC) ...................................................... 16

2.5 Filter configurations and designations if external air flow is available for cooling ................................... 17

2.6 Filter configurations and designation with embedded ventilation ............................................................ 18

2.7 Filter configurations and designation if external aux. power supply for the fan is available ................... 19

3. Filter description ................................................................................................................................. 20

3.1 General electrical specifications FN 3440/FN 3441 (50 Hz filters) .......................................................... 20

3.2 General electrical specifications FN 3450/FN 3451 (50 Hz filters) .......................................................... 21

3.3 General electrical specifications FN 3442/FN 3443 (60 Hz filters) .......................................................... 22

3.4 General electrical specifications FN 3452/FN 3453 (60 Hz filters) .......................................................... 23

3.5 Additional electrical spe cif ic ations ........................................................................................................... 24

3.6 Cooling requirement ................................................................................................................................ 24

3.7 Mechanical frame sizes ........................................................................................................................... 25

3.8 Ecosine evo filter footprint ....................................................................................................................... 27

3.9 Filter performance ................................................................................................................................... 28

3.10 Functional diagram ................................................................................................................................ 30

4. Modular Design: How to choose optional modules ........................................................................ 31

5. Filter appearance and elements ........................................................................................................ 33

5.1 IP 00 version, frame size A - F ................................................................................................................ 33

5.2 IP 00 version, frame size G - H ............................................................................................................... 34

5.3 IP 20 version ............................................................................................................................................ 35

6. Performance estimation using SchaffnerPQS ................................................................................. 36

7. Filter application.................................................................................................................................. 37

8. Filter installation.................................................................................................................................. 38

9. Filter maintenance .............................................................................................................................. 45

9.1 Maintenance schedule ............................................................................................................................. 45

9.2 Fan ........................................................................................................................................................... 46

Page 7

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

7/50

9.3 Power capacitors ..................................................................................................................................... 46

9.4 Electrical connections .............................................................................................................................. 46

10 Trap circuit disconnect ...................................................................................................................... 48

11. Troubleshooting ................................................................................................................................ 49

Disclaimer ................................................................................................................................................ 50

Page 8

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

8/50

1. Ecosine evo passive harmonic filter designation

1.1 Distinguishing between FN 3440/FN 3441, FN 3450/FN 3451, FN 3442/FN 3443 and FN 3452/FN 3453

Before going into the details of the designation, it is important to be aware of the difference between

FN 3440 and FN 3441, FN 3450 and FN 3451, FN 3442 and FN 3443, FN 3452 and FN 3453. FN 3440, FN

3450, FN 3442 and FN 3452 are used for motor drives without dc-link choke. They are similar to FN 3441, FN

3451, FN 3443 and FN 3453 except there is one choke less in FN 3441, FN 3451, FN 3443 and FN 3453

series as they are meant to be used for motor drives with dc-link choke (8%) included. In other w ords, there

are three chokes (line choke, trap choke and load choke) included in filter series FN 3440, FN 3450, FN 3442

and FN 3452, whereas there are only two chokes (line choke, trap choke) included in filter series FN 3441,

FN 3451 FN 3443 and FN 3453 series.

By distinguishing between FN 3440, (FN 3450, FN 3442, FN 3452) as well as FN 3441 (FN 3451, FN 3443,

FN 3453) Schaffner is able to provide optimized solutions for different drive types:

| If there is no DC-link choke present in the motor drive, FN 3440, FN 3450, FN 344 2, FN 3452 filter

series help to reduce THID to 5% @ rated power.

| If there is a minimum 8% DC-link choke present in the motor drive, FN 3441, FN 3451, FN 3443, FN

3453 filter series reduce THID to 5% @ rated power

In case you have difficulties to decide for the right filter, please contact your local Schaffner representative for

support.

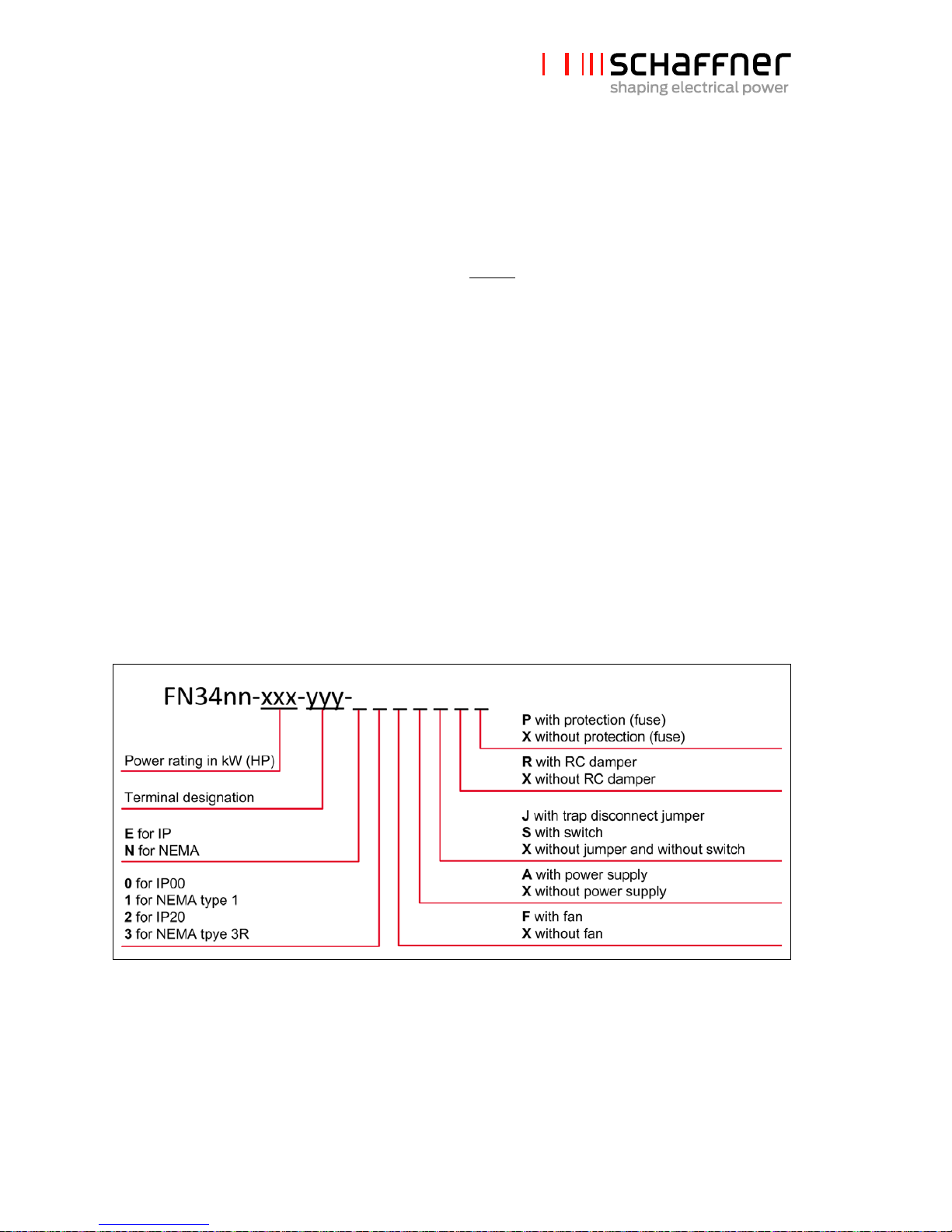

1.2 Explanation of ecosine evo designation

Ecosine evo is the new generation of Schaffner passive harmonic filter. They are introduced w ith a new

designation system, which contains of 4 sections connected with ‘-’ as shown in

Figure 1 Ecosine evo designation

Page 9

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

9/50

| The first part of the designation ‘FN 34nn-xxx-yyy-_ _ _ _ _ _ _’ distinguishes between the six

ecosine evo filter series.

FN 3440

FN 3441

FN 3450

FN 3451

FN3442

FN3443

FN 3452

FN 3453

For 6

-pulse diode rectifier

without DC-link choke

For 6

-pulse diode rectifier

with 8% DC-link choke

For SCR rectifier

Operating

frequency 50 Hz 50 Hz 60 Hz 60 Hz

Nominal operating voltage

3x 380 to 415 VAC 3x 440 to 500 VAC

3x 380 to 415

VAC

3x 440 to 480

VAC

| The second part of the designation ‘FN 34nn-xxx-yyy-_ _ _ _ _ _ _’ indicates the motor drive power

rating, in kW for 50 Hz filters and in HP for 60 Hz filters. Please note that ecosine evo filters are not

using current rating in the designation anymore.

| The third part of the designation ‘FN 34nn-xxx-yyy-_ _ _ _ _ _ _’ indicates the power terminal type.

For more information please see Table 1.

| The fourth part of the designation ‘FN 34nn-xxx-yyy- _ _ _ _ _ _ _’ contains seven slots, the first two

slots reveal the protection category of the filter, e.g. E0 and E2 represent IP 00 and IP 20 enclosure,

while N1 and N3 respresent NEMA type1 and NEMA type 3R, respectively. The following five slots

represent the presence (F,A,R,J,P) or absence (X) of optional modules in the filter, as shown in

Figure 1. Please find more information in section 2.4, 2.5 and 2.6.

Schaffner offers an online Product Configurator (myecosine.com

) and the Schaffner Power Quality

Simulator SchaffnerPQS3 (pqs.schaffner.com) to select and verify the most suitable ecosine evo filter for

your application.

Examples of ecosine evo filter designations:

FN 3440-22-115-E0XXJRX: Filter for 50 Hz, 380–415 V AC grid, motor drive power rating 22kW without DC-

link choke present, with 20 m m

2

terminals, open frame (IP 00), filter contains trap disconnect jumper module

and RC damper module.

FN 3441-22-115-E2FAXXX: Filter for 50 Hz, 380–415 V AC grid, motor drive power rating 22kW with 8% DC-

link choke present, with 20 m m

2

terminals, IP 20 enclosure, filter contains Fan module and auxiliary power

supply module.

FN 3452-150-116-E0XXXXX: Filter for 60 H z, 440–480 V AC grid, motor drive power rating 150HP with no

DC-link choke present, with 24mm

2

terminals, open frame (IP 00), filter contains no optional modules.

FN 3452-150-116-N1XXJRX: Filter for 60 H z, 440 –480 V AC grid, motor drive power rating 150HP with no

DC-link choke present, with 24mm

2

terminals, NEMA type 1 enclosure, filter contains trap disconnect jumper

module and RC damper module.

Page 10

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

10/50

Table 1 Ecosine evo filter power terminals designation

Page 11

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

11/50

2. Filter selection

Ecosine evo passive harmonic filters need to be carefully selected and configured in order to enjoy maximum

benefits. Besides the enclosed selection tables and the product datasheets included in the online configurator

(myecosine.com

), Schaffer advices to verify the selection by using the Schaffner Power Quality Simulator tool

SchaffnerPQS3, avai lab le at pqs.schaffner.com.

Step 1: Grid frequency

Determine, whether the system in consideration will be operated in a 50 Hz or 60 Hz electricity grid, and

select the corresponding filter series according to the following table:

50

Hz grid Europe, Middle East, parts of Asia, parts of South America

FN 3440/FN 3441

FN 3450/FN 3451

60

Hz grid North and Central America, parts of Asia, parts of South America FN 3442/FN 3443

FN 3452/FN 3453

Note: a 50 Hz filter will not provide satisfying harmonics mitigation in a 60 Hz grid, and vice versa.

Step 2: Grid voltage

Verify that the grid configuration is suitable for standard ecosine evo passive harmonic filters according to the

following table:

50 Hz grid

Nominal voltage 380–415 V AC

TN, TT, IT configuration

50 Hz grid

Nominal voltage 440–500 V AC

TN, TT, IT configuration

60 Hz grid

Nominal voltage 380–415 V AC

TN, TT, IT configuration

60 Hz grid

Nominal voltage 440–480 V AC

TN, TT, IT configuration

Step 3: Rectifier type, presence of DC-link choke in drive

FN 3440

FN 3441

FN 3450

FN 3451

FN3442

FN3443

FN 3452

FN 3453

For 6

-pulse diode rectifier

without DC-link choke

For 6

-pulse diode rectifier

with 8% DC-link choke

For SCR rectifier

Note: For 6-pulse diode rectifier with DC-link choke smaller than 8%, it is recommended to choose

FN 3440, FN 3450, FN 3442 or FN 3452 if 5% THID is required.

Step 4: Rectifier/Drive input power

The individual filter must be selected with respect to the rectifier/motor drive input power in kW respectively in

HP. It is important to match rated filter power as close as possible with the effective input power of the

rectifier/drive.

Note that if the rectifier/drive is being operated very close to its rated power, then the filter can be selected by

the motor drive’s nominal power rating. However, if the drive will be operated e.g. at only 66% of its rated

power, then a smaller filter should be selected in order to get maximum harmonics mitigation performance

and the optimum in terms of cost, size, and weight. In that case the customer is responsible to ensure that

Page 12

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

12/50

ecosine passive harmonic filter will be operated within specification. This is particular important in terms of

overload.

Please refer to the following examples:

Example 1:

Power line rating: 400 V, 50 Hz

Drive rating: 380–500 V, 50–60 Hz, 15 kW, 22.5 A, B6-diode rectifier without DC-link choke

Planned rectifier/drive input real power: 15kW (100% of drive rating)

Recommended filter according to the filter selection table FN 3440: Type FN 3440-15-113

Example 2:

Power line rating: 400 V, 50 Hz

Drive rating: 380–500 V, 50–60 Hz, 15 kW, 22.5 A, B6-diode rectifier with an 8% DC-link choke

Planned rectifier/drive input real power: 15 kW (100% of drive rating)

Recommended filter according to the filter selection table FN 3441: Type FN 3441-15-113

Example 3:

Power line rating: 500 V, 50 Hz

Drive rating: 380–500 V, 50–60 Hz, 15 kW, 18 A, B6-diode rectifier without DC-link choke

Planned rectifier/drive input real power: 15 kW (100% of drive rating)

Recommended filter according to the filter selection table FN 3450: Type FN 3450-15-113

Example 4:

Power line rating: 500 V, 50 Hz

Drive rating: 380–500 V, 50–60 Hz, 15 kW, 18 A, B6-thyristor rectifier

Planned rectifier/drive input real power: 15 kW (100% of drive rating)

Recommended filter according to the filter selection table FN 3450: Type FN 3450-15-113

Example 5:

Power line rating: 400 V, 50 Hz

Drive rating: 380–500 V, 50–60 Hz, 15 kW, 22.5 A, diode rectifier

Planned rectifier/drive input real power: 10 kW (66% of drive rating)

Recommended filter according to the filter selection table FN 3440: Type FN 3440-11-113

Example 6:

Power line rating: 480 V, 60 Hz

Drive rating: 380–500 V, 50–60 Hz, 30 H P, 41 A, diode rectifier

Planned rectifier/drive input real power: 30 HP (100% of drive rating)

Recommended filter according to the filter selection table FN 3452: Type FN 3452-30-113

Oversizing of passive har m onic filters is not recommended because of the inherent lower harmonic mitigation

performance at partial load as well as higher cost, size, and weight.

Please refer to Table 2 - Table 9 to select suitable filters.

Page 13

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

13/50

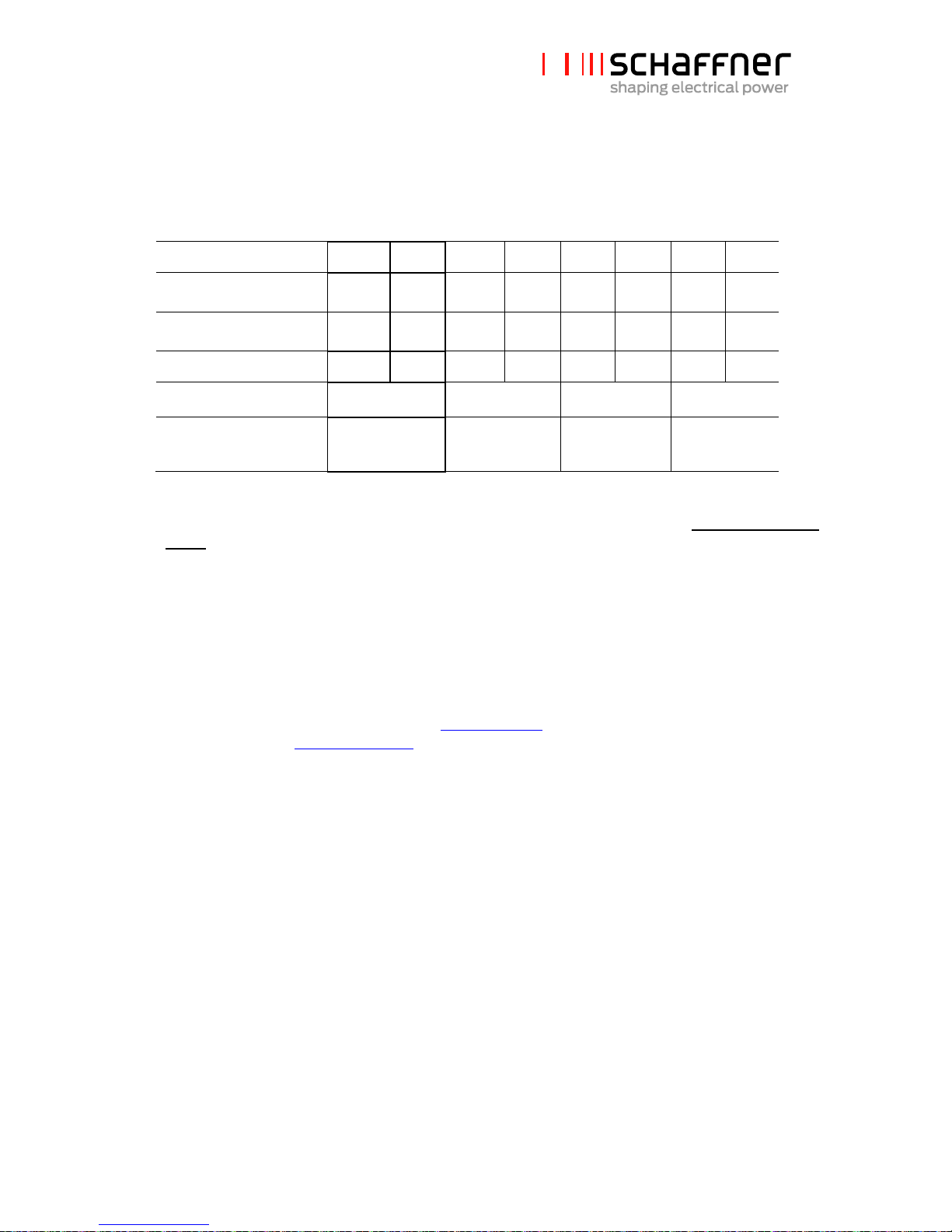

2.1 Filter selection table FN 3440/FN 3441 (50 Hz, 3×380 … 415 VAC)

Table 2 FN 3440 filter selection table

Table 3 FN 3441 filter selection table

Page 14

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

14/50

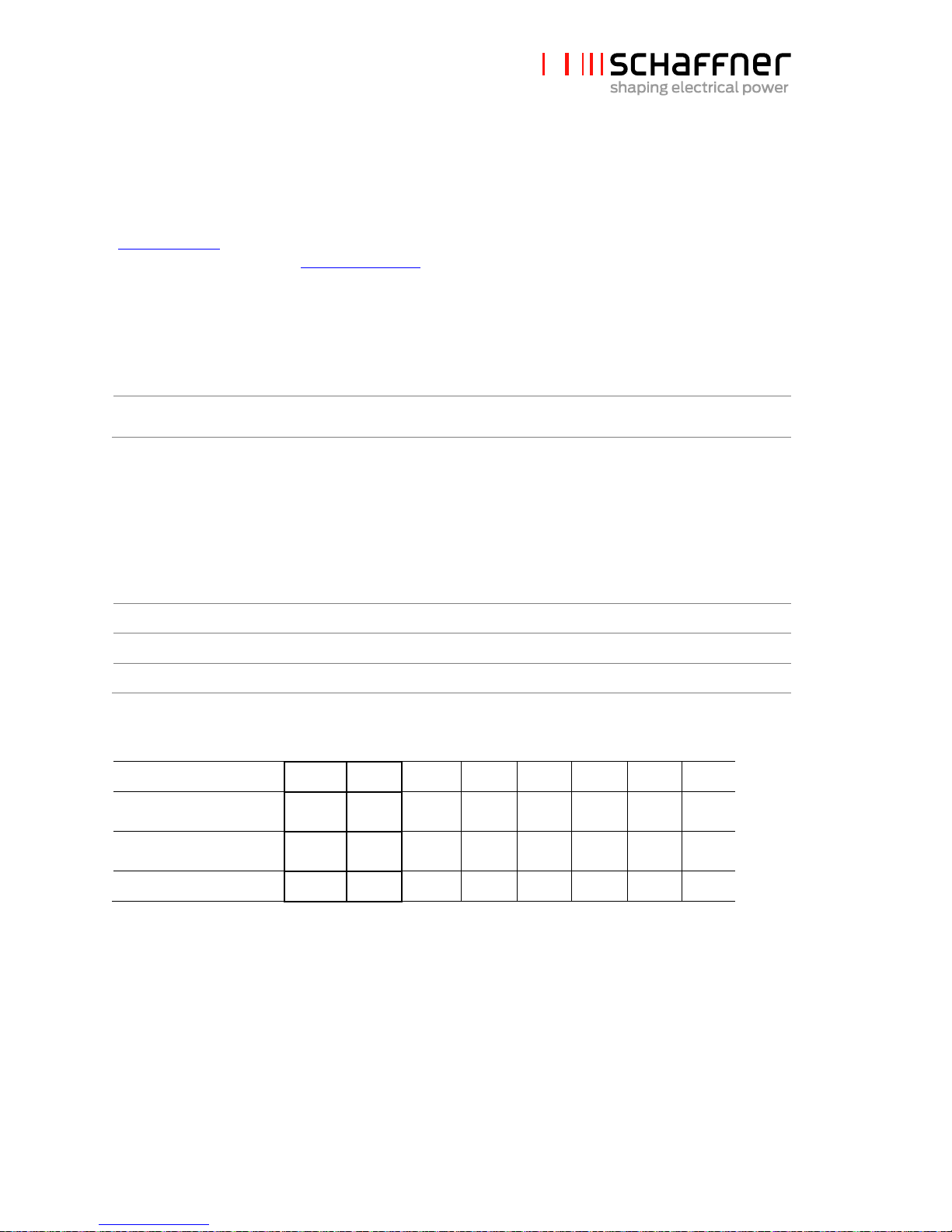

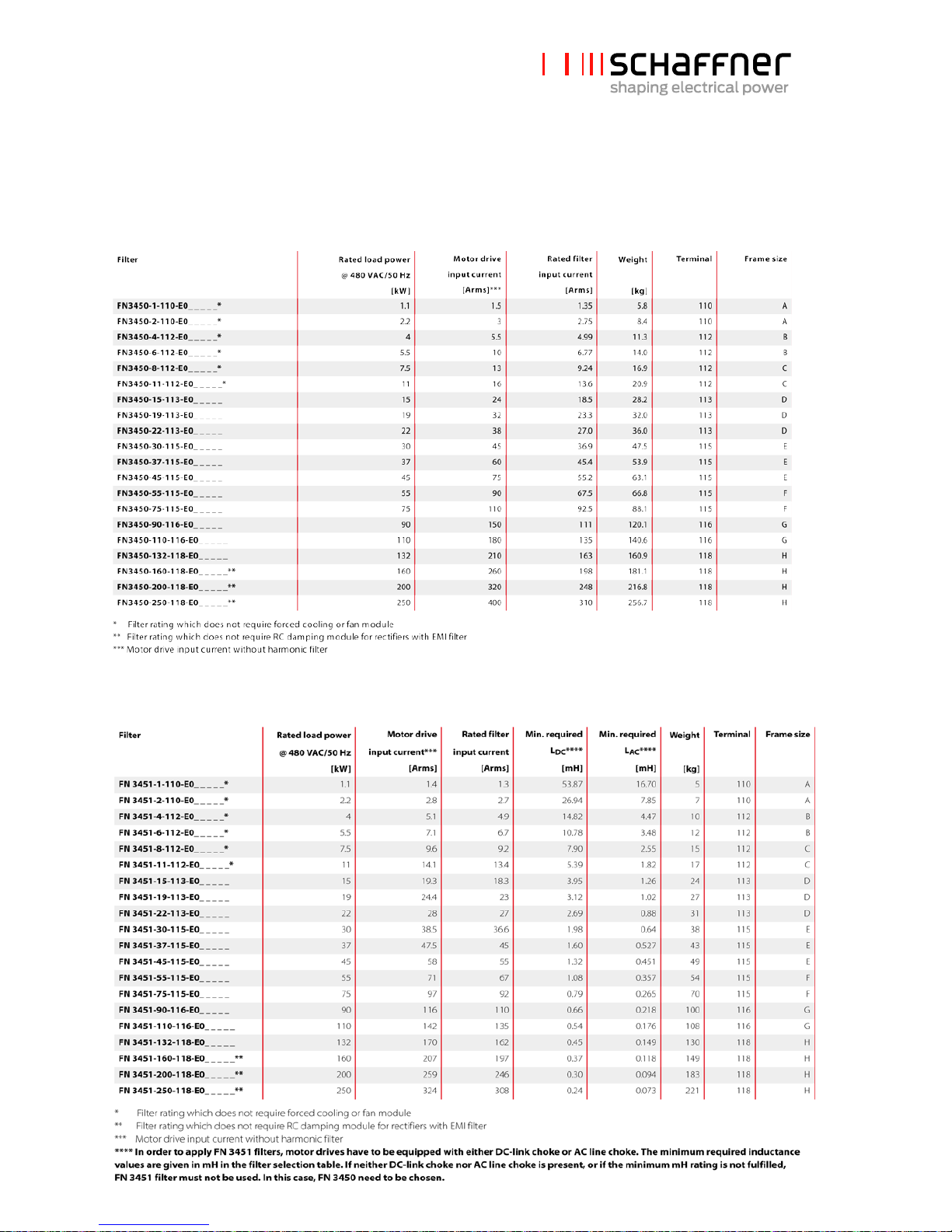

2.2 Filter selection table FN 3450/FN 3451 (50 Hz, 3×440 … 500 VAC)

Table 4 FN 3450 filter selection table

Table 5 FN 3451 filter selection table

Page 15

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

15/50

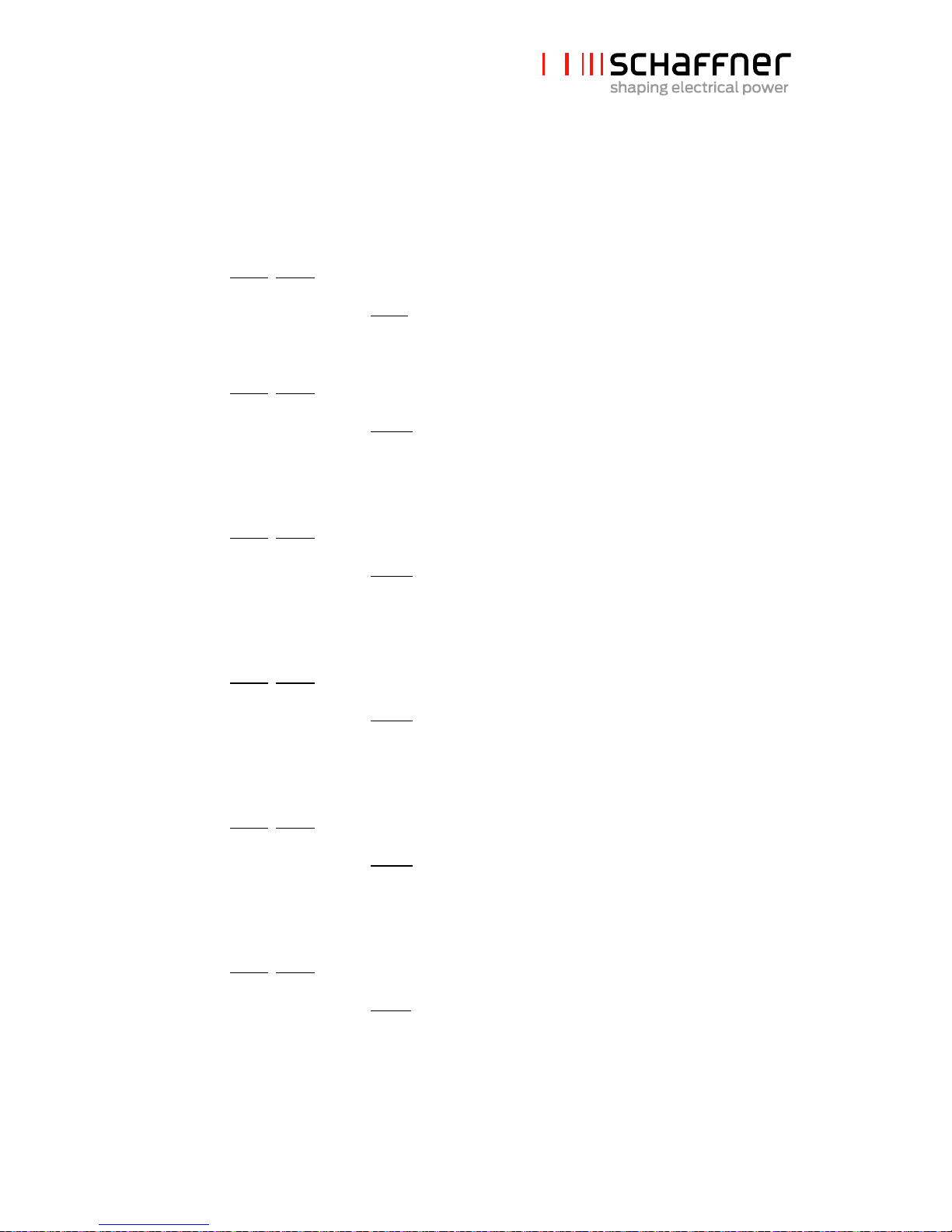

2.3 Filter selection table FN 3442/FN 3443 (60 Hz, 3×380 … 415 VAC)

Table 6 FN 3442 filter selection table

Table 7 FN 3443 filter selection table

Page 16

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

16/50

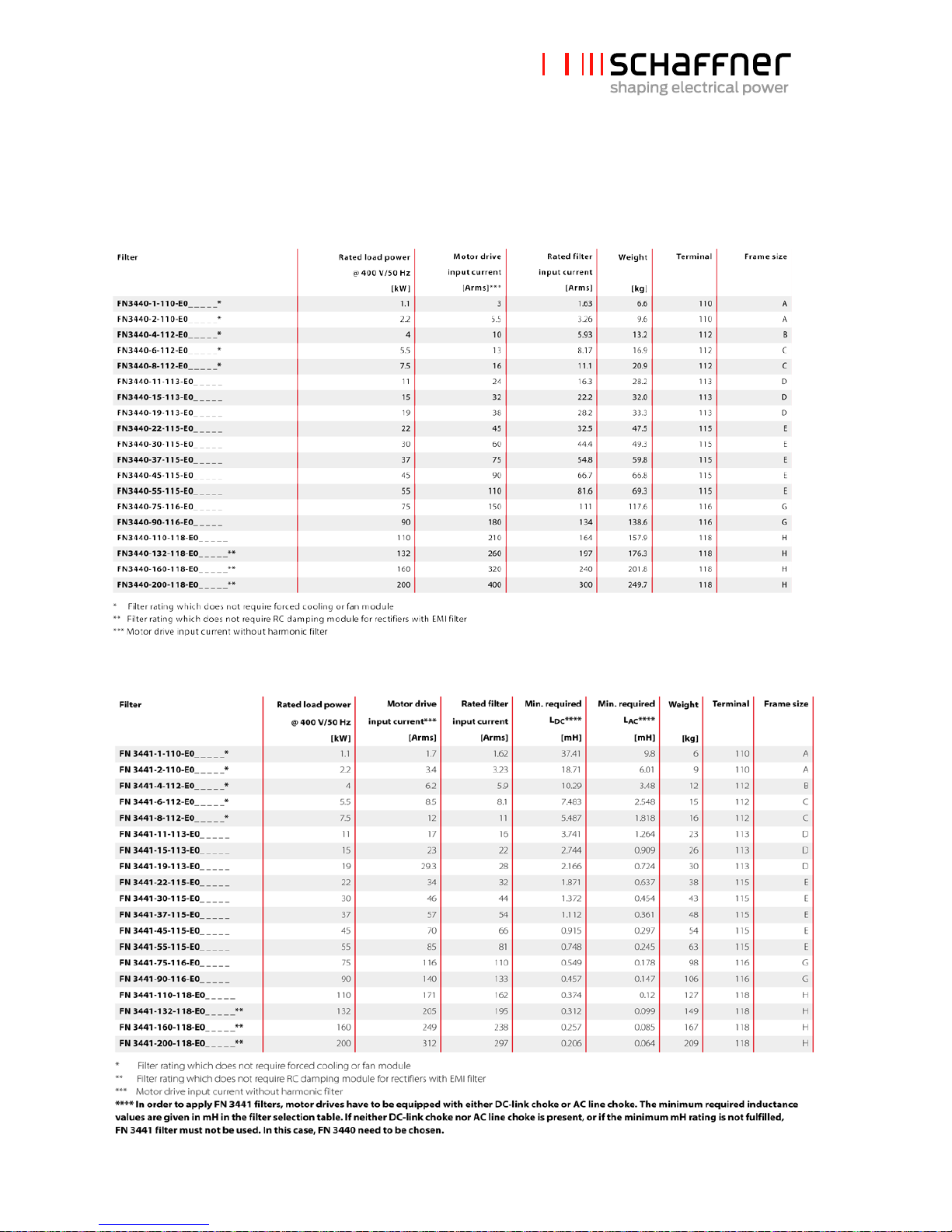

2.4 Filter selection table FN 3452/FN 3453 (60 Hz, 3×440 … 480 VAC)

Table 8 FN 3452 filter selection table

Table 9 FN 3453 filter selection table

Page 17

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

17/50

2.5 Filter configurations and designations if external air flow is available for cooling

If there is external air flow available for cooling in the installation, then the filters do not contain fan and do

not contain aux. power supply.

The filter configurations are shown in Table 10 and Table 11, if external air flow is available for cooling,

Table 10 FN 3440, FN 3450, FN 3452 filter configurations if external air flow available for cooling

Table 11 FN 3441, FN 3451, FN 3453 filter configurations if external air flow available for cooling

Page 18

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

18/50

2.6 Filter configurations and designation with embedded ventilation

If external air flow for cooling is not available, then the filters contain embedded ventilation, which means the

filters contain fan and aux. power supply.

The open frame filter configurations are shown in Table 12 and Table 13, if external air flow is not available

and embedded ventilation is equipped.

Table 12 FN 3440, FN 3450, FN 3452 filter configurations with embedded ventilation

Table 13 FN 3441, FN 3451, FN 3453 filter configurations with embedded ventilation

Remark: Frame sizes A, B, C do not require air-flow for cooling hence they are not equipped with FAN and

AUX.

Page 19

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

19/50

2.7 Filter configurations and designation if external aux. power supply for the fa n is available

If there is an external 24 V DC power supply available to the fan, then the filters contain fan but do not

contain auxiliary power supply, user should provide aux. power supply to the fan.

The open frame filter configurations are sh o wn in Table 14 and Table 15, if external air flow is not available

but external auxiliary power supply for the fan is available.

Table 14 FN 3440, FN 3450, FN 3452 filter configurations if external auxiliary power supply for the fan is

available

Table 15 FN 3441, FN 3451, FN 3453 filter configurations if external auxiliary power supply for the fan is

available

Remark: Frame sizes A, B, C do not require air-flow for cooling and hence they are not equipped with FAN.

Note: FN 3442 and FN3443 filters are available in -E0XXXX, -E0FAXRX, -E0FAJ RX and -E2FAJRX

configurations.

Page 20

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

20/50

3. Filter description

3.1 General electrical specifications FN 3440/FN 3441 (50 Hz filters)

Nominal operating voltage:

3x 380 to 415 V AC

Voltage tolerance range:

3x 342 to 457 V AC

Operating frequency:

50 Hz ±1 Hz

Network:

TN, TT, IT

Nominal motor drive input power rating:

1.1 to 200kW

Total harmonic current distortion THID: 2)

<5% @ rated power 1)

Total demand distortion TDD: 2)

According to IEEE 519

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage: 3)

-5% ~ +10% nominal VDC

High potential test voltage: 4)

P E 2160 VAC (1s)

SCCR: 5)

100kA, fuses according UL class J

Protection category:

IP 00, IP 20

Pollution degree:

PD3 (according to standard IEC 60664-1)

Cooling:

Internal fan cooling or external cooling 6)

Overload capability:

1.6x rated current for 1 minute, once per hour

Capacitive current @ no load:

<20% of rated input current, at 400 V AC

Ambient temperature range:

-25°C to +45°C fully operational

+45°C to +70°C derated operation 7)

-25°C to +85°C transportation and storage

Flammability class:

UL 94V-2

Insulation class of magnetic components:

N (200°C), H (180°C)

Design corresponding to:

Filter: UL 61800-5-1, EN 61800-5-1

Chokes: EN 61558-2-20 or EN 6007 6-6

MTBF @ 45°C/415 V (Mil-HB-217F):

>200,000 hours

MTTR:

<15 minutes (capacitor modules and fan modules)

Lifetime (calculated):

≥10 years

Safety monitor output signal:

Thermal switch NC 180° C (UL-approved) to detect

overload of chokes

1)

THID ~5% at rated power for filter <4kW.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different resul ts , depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <3%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

Please check the inlet air flow required for cooling i n Table 17

7)

I

derated

= I

nominal

×√((70°C-T

amb

)/25°C)

Page 21

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

21/50

3.2 General electrical specifications FN 3450/FN 3451 (50 Hz filters)

Nominal operating voltage:

3x 440 to 500 V AC

Voltage tolerance range:

3x 396 to 550 V AC

Operating frequency:

50 Hz ±1 Hz

Network:

TN, TT, IT

Nominal motor drive input power rating:

1.1 to 250kW

Total harmonic current distortion THID: 2)

<5% @ rated power 1)

Total demand distortion TDD: 2)

According to IEEE 51 9

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage behavior: 3)

-5% ~ +10% nominal VDC

High potential test voltage: 4)

P E 2160 VAC (1s)

SCCR: 5)

100kA, fuses according UL class J

Protection category:

IP 00, IP 20

Pollution degree:

PD3 (according to standard IEC 60664-1)

Cooling:

Internal fan cooling or external cooling 6)

Overload capability:

1.6x rated current for 1 minute, once per hour

Capacitive current @ no load:

<20% of rated input current, at 480 V AC

Ambient temperature range:

-25°C to +45°C fully operational

+45°C to +70°C derated operation 7)

-25°C to +85°C transportation and storage

Flammability class:

UL 94V-2

Insulation class of magnetic components:

N (200°C), H (180°C)

Design corresponding to:

Filter : UL 61800-5-1, EN 61800-5-1

Chokes : EN 61558-2-20 or EN 60076-6

MTBF @ 45°C/415 V (Mil-HB-217F):

>200,000 hours

MTTR:

<15 minutes (capacitor modules and fan modules)

Lifetime (calculated):

≥10 years

Safety monitor output signal:

Thermal switch NC 180° C (UL-approved) to detect

overload of chokes

1)

THID ~5% at rated power for filter <4kW.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different resul ts , depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <3%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

Please check the inlet air flow required for cooling in Table 17.

7)

I

derated

= I

nominal

×√((70°C-Tamb)/25°C)

Page 22

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

22/50

3.3 General electrical specifications FN 3442/FN 3443 (60 Hz filters)

Nominal operating voltage:

3x 380 to 415 V AC

Voltage tolerance range:

3x 342 to 456 V AC

Operating frequency:

60 Hz ±1 Hz

Network:

TN, TT, IT

Nominal motor drive input power rating:

1 to 240 HP (0.9 to 177 kW)

Total harmonic current distortion THID: 2)

<5% @ rated power 1)

Total demand distortion TDD: 2)

According to IEEE 519

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage: 3)

-5% ~ +10% nominal VDC

High potential test voltage: 4)

P E 2160 VAC (1s)

SCCR: 5)

100kA, fuses according UL class J

Protection category:

IP 00, IP 20

Pollution degree:

PD3 (according to standard IEC 60664-1)

Cooling:

Internal fan cooling or external cooling 6)

Overload capability:

1.6x rated current for 1 minute, once per hour

Capacitive current @ no load:

<20% of rated input current, at 480 V AC

Ambient temperature

range:

-25°C to +45°C fully operational

+45°C to +70°C derated operation 7)

-25°C to +85°C transportation and storage

Flammability class:

UL 94V-2

Insulation class of magnetic components:

N (200°C), H (180°C)

Design corresponding to:

Filter : UL 61800-5-1, EN 61800-5-1

Chokes : EN 61558-2-20 or EN 60076-6

MTBF @ 45°C/415 V (Mil-HB-217F):

>200,000 hours

MTTR:

<15 minutes (capacitor modules and fan modules)

Lifetime (calculated):

≥10 years

Safety monitor output signal:

Thermal switch NC 180° C (UL-approved) to detect

overload of chokes

1)

THID ~5% at rated power for filter <4kW.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different resul ts , depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <3%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

Please check the inlet air flow required for cooling in Table 17

7)

I

derated

= I

nominal

×√((70°C-T

amb

)/25°C)

Page 23

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

23/50

3.4 General electrical specifications FN 3452/FN 3453 (60 Hz filters)

Nominal operating voltage:

3x 440 to 480 V AC

Voltage tolerance range:

3x 396 to 528 V AC

Operating frequency:

60 Hz ±1 Hz

Network:

TN, TT, IT

Nominal motor drive input power rating:

1.5 to 300 HP (1.1 to 224 kW)

Total harmonic current distortion THID: 2)

<5% @ rated power 1)

Total demand distortion TDD: 2)

According to IEEE 519

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage: 3)

-5% ~ +10% nominal VDC

High potential test voltage: 4)

P E 2160 VAC (1s)

SCCR: 5)

100kA, fuses accor ding UL clas s J

Protection category:

IP 00, IP 20

Pollution degree:

PD3 (according to standard IEC 60664-1)

Cooling:

Internal fan cooling or external cooling 6)

Overload capability:

1.6x rated current for 1 minute, once per hour

Capacitive current @ no load:

<20% of rated input current, at 480 V AC

Ambient temperature range:

-25°C to +45°C fully operational

+45°C to +70°C derated operation 7)

-25°C to +85°C transportation and storage

Flammability class:

UL 94V-2

Insulation class of magnetic components:

N (200°C), H (180°C)

Design corresponding to:

Filter : UL 61800-5-1, EN 61800-5-1

Chokes : EN 61558-2-20 or EN 60076-6

MTBF @ 45°C/415 V (Mil-HB-217F):

>200,000 hours

MTTR:

<15 minutes (capacitor modules and fan modules)

Lifetime (calculated):

≥10 years

Safety monitor output signal:

Thermal switch NC 180° C (UL-approved) to detect

overload of chokes

1)

THID ~5% at rated power for filter <6HP.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different results, depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <3%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

Please check the inlet air flow required for cooling in Table 17.

7)

I

derated

= I

nominal

×√((70°C-T

amb

)/25°C)

Page 24

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

24/50

3.5 Additional electrical specifications

Ecosine evo passive harmonic filters general electrical specifications refer to operating altitudes up to 2000m

a.s.l. (6600ft).

Operation between 2000m and 4000m (6600ft and 13123ft) requires a derating for current and clearance

according to IEC 60664-1 (table A.2), hereafter enclosed:

Table 16 Altitude correction factors

Remark: Do not use ecosine evo passive harmonic filters in altitudes above 4000m without consulting

Schaffner first.

3.6 Cooling requirement

Inlet air flow requirements for each frame size are listed in Table 17. Please notice that the filters with frame

size A, B and C do not require air cooling. For frame sizes D to H, the required inlet air flow should be fulfilled,

either by including the optional Fan module or by providing sufficient external air flow.

Table 17 Inlet air flow required for cooling

Remark: External air flow is required for the cooling at filter’s inlet as defined in the table only for filters

without embedded ventilati on.

Page 25

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

25/50

3.7 Mechanical frame sizes

Ecosine evo passive harmonic filters are implemented on a base plate or base frame featuring 8 different

frame sizes, Frame A to Frame H, from the lowest to the highest rating. Dimensions and footprint are

provided in section 3.7.

In particular, frame sizes A to C do not require air flow, while frame sizes D to H need embedded fan or

external ventilation, details are provided in filter selection tables, Table 2 to Table 9. The overview of all frame

sizes in IP 00 and IP 20 are shown in Figure 2 and Figure 3.

Figure 2 Overview of all IP 00 frame size versions

Page 26

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

26/50

Figure 3 Overview of all IP 20 frame size versions

Page 27

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

27/50

3.8 Ecosine evo filter footprint

Figure 4 Mechanical Data of FN 3440, FN 3450, FN 3442 and FN 3452

Dimensions in [mm]

Dimensions in [in]

Frame

Drill pattern

Base

Volume

Drill pattern

Base

Volume

R

S

T

U

X

Y Max. Z

R

S

T

U

X

Y Max. Z

A

340 120

7

360 302 160 185 13.4 4.7 0.3 14.2

11.9

6.3

7.3

B 405 120

7

425 370 180 206 15.9 4.7 0.3 16.7

14.6

7.1

8.1

C 460 150

7

483 430 210 221 18.1 5.9 0.3 19.0

16.9

8.3

8.7

D

540 180 11 560 491 260 252 21.3 7.1 0.4 22.0

19.3

10.2

9.9

E 680 220 11 705 635 290 318 26.8 8.7 0.4 27.8

25.0

11.4

12.5

F 730 250 11 752 684 340 343 28.7 9.8 0.4 29.6

26.9

13.4

13.5

G 920 280 11 960 863 353 396 36.2 11.0 0.4 37.8

34.0

13.9

15.6

H

1115 390 11 1150 1053 462 456 43.9 15.4 0.4 45.3

41.5

18.2

18.0

For Dimensions without Tolerances: ISO2768-m/EN22768-m appli es

Figure 5 Dimensions of all frame sizes

Page 28

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

28/50

3.9 Filter performance

Ecosine evo passive harmonic filters achieve 5% THID with 6-pulse diode rectifiers under the following

condition.

Filter is applied to rated voltage and power

THVD <2%, line voltage unbalance <1%

RC damper module is required to be included in the filter if there is EMI filter present in the drive. Typical

expected EMI filter capacitance (phase to star point) are shown in

Table 18 and

Table 19.

Table 18 Typical expected EMI filter capacitance (phase to star point) for series FN 3440/FN 3441 and FN

3450/FN 3451

1.1 kW

1.5 µF

2.2 kW

2.2 µF

4-11kW

3.3 µF

15 to 45 kW

4.7 µF

55 to 200(250) kW

10 µF

Table 19 Typical expected EMI filter capacitance (phase to star point) for FN 3442/FN 3443 and FN 3452/FN

3453

1.5 HP

1.5 µF

3 HP

2.2 µF

5-20HP

3.3 µF

25 to 60 HP

4.7 µF

75 to 300 HP

10 µF

| Note: 132…200 kW of FN 3440/FN 3441 series, 160…250 kW of FN 3450/FN 3451 series

200…240HP of FN 3442/FN 3443 series, and 250…300HP of FN 3452/FN 3453 series do not need

RC damper module when the equivalent phase to star point capacitance of the EMI filter is not bigger

than 10 µF.

| 5% THID is not guaranteed for thyristor rectifier application. The performance of the filter is

dependent on the firing angle of the thyristors.

| Ecosine evo filter performance (THID, power factor and U

dc

) under different load conditions with are

shown in the following charts.

Page 29

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

29/50

THID vs. load (diode rectifier front-ends)

Power factor vs. load (diode rectifier front-ends)

Drive dc-link voltage vs. load (diode rectifier front-ends, with FN 3440 series)

Page 30

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

30/50

3.10 Functional diagram

Filter termin als

Line L1/L2/L3

3 terminal blocks

Load L1’/L2’/L3’

3 terminal blocks

Signal

Connecting terminals to thermal switch NC 180°C (ULapproved) to detect overload in chokes

PE

Protective earth. Threaded stud with washer and nut

Trap disconnect

D1, D2, D3

D1’, D2’, D3’

3 couples of terminals. For optional configurations with TDJ,

wire bridges are installed for immediate operation of the

filter. They allow for the

connection of an external contactor

for load dependent disconnection of the trap circuit, if

needed.

Function blocks

Chokes

Power magnetic components incl. temperature sensors

Capacitors

Power capacitors incl. discharge resistors

Fan

Field replaceable fan for choke air cooling

Power suppl y

Internally generate 24 V DC source for fan supply

RC damper

RC damper module, as option configurable in case of

rectifier equipped with EMI filter

Page 31

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

31/50

4. Modular Design: How to choose optional modules

Ecosine evo passive harmonic filters provide optimized solution for your application by merely plugging a new

module.

The base module of FN 3441, FN 3451, FN 3443 and FN 3453 series contains line choke, trap choke and

trap capacitor, which helps reduce T HID to 5% for motor drives with an 8% DC-link choke present.

Figure 6 Base module of FN 3441, FN 3451, FN 3443 and FN 3453 filter series

The base module of FN 3440, FN 3450, FN 3442 and FN 3452 series contains line choke, load choke, trap

choke and trap capacitor, which helps reduce THID to 5% for motor drives without DC-link choke present.

The base module schematic is shown in Figure 7.

Figure 7 Base module of FN 3440, FN 3450, FN 3442 and FN 3452 filter series

General working principle of ecosine evo filter base modules is shown in Figure 8.

Figure 8 Working principle of ecosine evo base modules (with load choke Lo and with out)

There are five optional modules available for FN 3440/FN 3441, FN 3450/FN 3451, FN 3442/FN 3443 and FN

3452/FN 3453 filters:

| Fan and aux. power supply module

| Fan only module

| Trap disconnect jumper module

| RC damper module

Page 32

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

32/50

Figure 9 shows a summary of optional modules in use with ecosine evo passive harmonic filters.

Figure 9 Optional modules for ecosine evo filter and according to your requirement and installation

Page 33

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

33/50

5. Filter appearance and elemen ts

The very compact and neat design of ecosine evo passive harm onic filters is realized by a two-stage

construction. The filter construction of all frame size are identical, except the position of the load choke. The

load choke is build on the upper-stage of the filter for frame size A- F, and on the lower-stage of the filter for

frame sizes G – H, which are explained in deta il in the f ollow ing sect ions.

5.1 IP 00 version, frame size A - F

The general design of the ecosine evo passive harmonic filter IP 00 versions with fan module, aux. power

supply module, TDJ module and RC damper module (E0FAJRX) is shown in Figure 10.

There are load choke L

o

, trap capacitor Ct, trap disconnect jumper, power terminal and fan module visible on

the upper-stage. The design and construction of the lower-stage is shown in Figure 11. The line choke L

i

,

trap choke L

t

, RC damper module are constructed on the base plate, which contains screw holes for wall

mounting.

Figure 10 Design of ecosine evo filter (Type E0FAJRX, frame size D): Upper-stage

Figure 11 Lower-stage of ecosine evo filter (Type E0FAJRX, frame size D): lower -stage

Page 34

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

34/50

5.2 IP 00 version, frame size G - H

The design of the ecosine evo filter IP 00 versions with fan module, aux. power supply module, TDJ module

and RC damper module (E0FAJRX) is shown in Figure 12.

There are trap capacitor C

t

, trap disconnect jumper, power terminal visible on the upper-stage. The fan

module is visible between the upper and lower stage. The design and construction of the lower-stage is

shown in Figure 13. The line choke L

i

, trap choke Lt, load chock Lo, RC damper module are constructed on

the base plate, which contains screw holes for wall mounting.

Figure 12 Design of ecosine evo filter (Type E0FAJRX, frame size H): Upper-stage

Figure 13 Design of ecosine evo filter (Type E0FAJRX, frame size H): Lower-stage

Page 35

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

35/50

5.3 IP 20 version

Ecosine evo passvie harmonic filters IP 20 versions are shown in Figure 14. IP 20 versions of ecosine evo

filters are additionally equipped with cover and finger guard on top of the IP 00 version filters.

Figure 14 Design of IP 20 version ecosine evo filter with frame size D (left) and frame size H (right)

Parameters of IP 20 enclosure finger guard are shown in Table 20.

Table 20 Parameters of finger guard of IP 20 enclosure

Frame size Finger guard cross-section width

/diameter

mm

Material

A

11

Plastic

B

11

Plastic

C

11

Plastic

D

12

Plastic

E

14

Metal

F

14

Metal

G

18.5

Metal

H

30

Metal

Page 36

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

36/50

6. Performance estimation using SchaffnerPQS

Ecosine evo passive harmonic filters are included and can thus be simulated with the Schaffner Power

Quality Simulator SchaffnerPQS (pqs.schaffner.com

).

By using SchaffnerPQS users can easily simulate and estimate system performance taking into account the

most important design requirements and system’s boundary conditions. Furthermore, an online product

configurator (myecoine.com

) helps and guides users to select the best filter topology and choose the

appropriate configurable functional options.

Simulate and estimate the

performance of your selected

ecosine evo filters with

Schaffner Power Quality

Simulator SchaffnerPQS3.

Page 37

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

37/50

7. Filter application

Ecosine evo passive harmonic filters are designed to mitigate harmonic current of non-linear loads, in

particular of three-phase diode-type rectifiers. Contrary to “bus-applied or PCC” filters, which are being

installed e.g. at the main feeder, they are specifically designed to be used with either an individual non-linear

load, or with a group of non-linear loads.

One advantage of load-applied filtering is the fact that the upstream power (relative to the harmonic filter) is

clean, i.e. unloaded by the harmonics. This can be of vital importance when the same power bus supplies

both motor drives and sensitive loads. Ecosine evo passive harmonic filters are also suitable for paralleling

lower power non-linear loads on a higher power harmonic filter to improve overall system economy. In this

case the total expected load power of all connected drives must match the filter.

If the expected input power exceeds the rating of the largest available filter, and a custom solution is not

desired, then two or more filters can be wired in parallel. In this mode of operation, it is recommended to use

filters with equal power ratings to ensure proper current sharing.

Page 38

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

38/50

8. Filter installation

Please follow the simple steps below to ensure a safe and reliable filter function for many years. Please do

also always follow the general safety and installation guidelines provided within this document as well as

relevant local, national or international standards that are applicable. Please note that the following

installation steps are applicable for both IP 00 and IP 20 enclosure.

Step 1: Visual inspection

All Schaffner ecosine evo passive harmonic filters have undergone rigorous testing before they left our ISO

9001:2008 certified factories. They are packaged with great care in a sturdy container for international

shipment.

However, carefully inspect the shipping container for damage that may have occurred in transit. Then unpack

the filter and carefully inspect for any signs of damage. Keep the shipping container for future transportation

of the filter.

In the case of damage, please file a claim with the freight forwarder involved immediatel y and contact your

local Schaffner partner for support. Under no circumstances install and energize a filte r w ith v is ib le

transportation damage.

If the filter is not going to be put in service upon receipt, store within the original container in a clean, dry

location, free of dust and chemicals and with respect to named temperature limits, see section 3.2.

Step 2: Mounting

Ecosine evo passive harmonic filters are best installed as close as possible to the non-linear load. Ideally

they are mounted next to the rectifier or motor drive inside the electrical cabinet or control room.

All ecosine evo pass i ve har monic filters FN 3440/FN 3441, FN 3450/FN 3451, FN 3442/FN 3443, FN

3452/FN 3453 are designed for wall-mounting insta ll at ion.

Important:

In order to ensure sufficient air flow, keep a clearance

of min.150mm above and below the filter to walls or

other components.

Additional work to access the device, caused by not

respected clearance distances, will be accounted

separately.

It must be ensured that the environmental temperature

is kept below 45°C with appropriate thermal

management (e.g. cabinet cooling). Filter operation in

environments with higher temperatures require a

temperature derating.

ECOsine™

Drive

>150mm

>

150mm

>100mm

>100mm

Page 39

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

39/50

II

.1 Screw hole positions for wall mounted filters

(as indicated in Table 21):

Table 21 Dimensions of frame sizes

Frame

Drill pattern [mm]

R S T

A

340

120

7

B

405

120

7

C

460

150

7

D

540

180

11

E

680

220

11

F

730

250

11

G

920

280

11

H

1115

390

11

All dimensions in mm; 1 inch = 25.4mm

II

.2 Screw selection: Schaffner recommends zinc coated hex

ribbed flange steel bolts. Respect filters weight for appropriate

choice of screws! Head diameters must not exceed these

dimensions:

M6: d ≤14.2mm, M10: d ≤21.2mm

II

.3 Filter placement:

1. Set screws loose into wall, leave 5mm distance from head to

wall.

2. Lift filter with appropriate crane, smallest types (up to 25kg)

may be lifted manually by two persons.

3. Place filter first onto lower screws…

4. ...then position it through backplane head openings on upper

screws.

5. Fix screws with appropriate torque (depending upon the

material of the back plane and local standards).

R

S

T

d

3.

4.

Page 40

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

40/50

Step 3: Wiring

III.1

Verify safe disconnection of all line side power.

Consult your local safety instruc tions .

III.2

Carefully connect protective earth (PE) wire to

adequate earth potential close to ecosine filter.

Use a wire diameter of equal or bigger size as foreseen

for line/load side power cables – according to your local

codes and safety instructions.

ECOsine™

Drive

>150mm

>150mm

>100mm

>100mm

III.3

Connect PE wire of ecosine filter

with appropriate cable lug to threaded stud.

| torque M5: 4 Nm

| torque M6: 8 Nm

| torque M8: 14 Nm

|

torque M10: 25 Nm

III.4

Connect ecosine load side terminals L1’, L2’, L3’ to respective motor drive or rectifier

inputs.

The third part of ecosine evo designation is a number contains three digits, i.e. FN 3440-11-113,

which indicates power terminal type.

See Table 1 for the recommended wire size and torque. Use stranded copper wire with a

temperature rating of 75°C or higher.

Remarks regarding IP 20 enclosure

1. To connect ecosine evo line and load side terminals, the fingure guard has to be removed

as a first step, and be installed again when the line and load side terminals are

connected. The screw thread and torque value for all the frame sizes are:

| Screw thread: M5

| Screw torque value: 4Nm

2. The metal finger guard for frame sizes E, F and G are equipped

with grommets, whilst figner guard H is equipped with stepped

collars. Modify the stepped collars according to the cable

isolated diameter, 5-10mm margin is recommended to feed the

cable easier.

3. Note that if the cable lug is wider than the cross-section width/diameter of the finger guard

(see Table 20),do not add cable lugs before feeding all cables though the finger guard.

Crimp cable lug when the cables are fed through the finger guard.

4. Install shrinking tube for the uninsulated cable lug to fulfill the clearance and creepage

requirement.

Note: In case the cables on the power terminals are installed without cable lug, it is

recommended to follow the maintenance manual closely. Maintenance manual is available on

your request per Schaffner contact.

Page 41

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

41/50

III.5

Use wired trap circuit or

install external capacitive current control.

For configurations with TDJ option (refer to Tables 4, 5,

6), terminals D1- D1’, D2 - D2’and D3- D3’ are delivered

with installed jumpers. When interconnected via an

external capacitor contactor (not supplied by Schaffner,

except in NEMA 3R type filters) they allow for load

dependent disconnection of the trap circuit, if needed.

Thus capacitive current can be minimized for low load

operation. Estimation of required contactor size: see

box to the right.

THE USE OF CAPACITIVE

SWITCHES/CONTACTORs IS REQUIRED.

OTHERWISE CAPACITOR LIFETIME MAY BE

REDUCED.

III.6

Connect monitor switch TS- TS’

The monitor switch is a relay contact, which is open in

ALARM state. It is constituted by a thermal switch NC

180°C (UL-approved) to detect overload of chokes. It

may either be used to remotely disconnect the dr i ve’s

load via respective input of drive control (check drive

manual) or as alarm sensor for system control unit.

AN ENGAGED MONITOR SWITCH

MUST LEAD TO IMMEDIATE LOAD

SHUTDOWN AND INVESTIGATION

OF THE PROBLEM.

III.7

Connect ecosine line side terminals L1, L2, L3

to power input protection (current limiting fuses – see below).

IP 20 enclosure cable wiring please refer to the remarks for the load side cable wiring (III.4).

Note: For IP 20 filter versions the IP 20 finger guard must be installe d in order to achieve

IP 20 protection. When the finger guard is not installed, Schaffner do not guarantee IP 20

protection.

Contactor performance estimate:

Example: FN 3440-55-115

The nominal power rating in kW

multplies 20% and the grid voltage,

then divided by the nominal voltage

(400 V for FN 3440, 480 V for

FN 3450 and FN 3452) is the

approximate reactive power

Contactor rating =

Page 42

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

42/50

III.8

Fuses

Ecosine evo passive harmonic filters need external over-current protection for compliance with

UL/cUL standard. Fuses and associated fuse holders must be UL listed and rated for 100kA

SCCR supplies. Table 22 and Table 23 show requested fuse current ratings for UL class J and,

where UL compliance is not mandatory, for IEC class gG. The fuse rating is independent of the

supply voltage.

A system with multiple ecosine evo

filters paralleled for a high power load

need each a separate 3-phase line side

fuse block, corresponding to the

respective filter and according to above

table.

The drive’s application manual may

prescribe line-side fuse protection as

well, which in this case either

corresponds to the sum of the filter fuse

ratings or, if lower, would request

separate drive fuses at its input.

An application, having one ecosine

filtering harmonics of several drives,

requires in any case line side fuse

protection of the drives as well as the

correct filter protection according to

Table 22 and Table 23.

DRIVE

M

Ecosine 1

Ecosine 2

Ecosine 3

FUSE

FUSE

FUSE

Ecosine

DRIVE 1

DRIVE 2

DRIVE 3

FUSE

FUSE

FUSE

FUSE

M M M

Page 43

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

43/50

Table 22 Requested fuse current rating for UL class J and for IEC class gG

ecosine evo ecosine evo ecosine evo ecosine evo

Fuse

class J

Fuse

class gG

All FN 3440 All FN 3441 All FN 3450 All FN 3451

rated

A

rated

A

FN 3450-1-110

FN 3451-1-110

2

2

FN 3440-1-110

FN 3441-1-110

2.5

2

FN 3450-2-110

FN 3451-2-110

4.5

4

FN 3440-2-110

FN 3441-2-110

FN 3450-4-112

FN 3451-4-112

8

8

FN 3440-4-112

FN 3441-4-112

FN 3450-6-112

FN 3451-6-112

10

10

FN 3440-6-112

FN 3441-6-112

FN 3450-8-112

FN 3451-8-112

15

10

FN 3440-8-112

FN 3441-8-112

FN 3450-11-112

FN 3451-11-112

20

16

FN 3440-11-113

FN 3441-11-113

FN 3450-15-113

FN 3451-15-113

25

20

FN 3440-15-113

FN 3441-15-113

FN 3450-19-113

FN 3451-19-113

35

35

FN 3440-19-113

FN 3441-19-113

FN 3450-22-113

FN 3451-22-113

40

35

FN 3440-22-113

FN 3441-22-113

FN 3450-30-115

FN 3451-30-115

50

50

FN 3440-30-115

FN 3441-30-115

FN 3450-37-115

FN 3451-37-115

75

63

FN 3440-37-115

FN 3441-37-115

FN 3450-45-115

FN 3451-45-115

80

80

FN 3440-45-115

FN 3441-45-115

FN 3450-55-115

FN 3451-55-115

100

100

FN 3440-55-115

FN 3441-55-115

FN 3450-75-115

FN 3451-75-115

150

125

FN 3440-75-115

FN 3441-75-115

FN 3450-90-116

FN 3451-90-116

175

160

FN 3440-90-116

FN 3441-90-116

FN 3450-110-118

FN 3451-110-118

200

200

FN 3440-110-118

FN 3441-110-118

FN 3450-132-118

FN 3451-132-118

250

224

FN 3440-132-118

FN 3441-132-118

FN 3450-160-118

FN 3451-160-118

300

250

FN 3440-160-118

FN 3441-160-118

FN 3450-200-118

FN 3451-200-118

350

300

FN 3440-200-118

FN 3441-200-118

FN 3450-250-118

FN 3451-250-118

400

400

Page 44

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

44/50

Table 23 Requested fuse current rating for UL calss J

ecosine evo type ecosine evo type ecosine evo type ecosine evo type

Fuse

class J

All FN 3442

ALL FN 3443

All FN 3452

All FN 3453

rated A

FN3442-1-110

FN3443-1-110

FN 3452-1-110

FN 3453-1-110

2

FN3442-2-110

FN3443-2-110

FN 3452-3-110

FN 3453-3-110

4

FN3442-4-112

FN3443-4-112

FN 3452-5-112

FN 3453-5-112

7

FN3442-6-112

FN3443-6-112

FN 3452-8-112

FN 3453-8-112

10

FN3442-8-112

FN3443-8-112

FN 3452-10-112

FN 3453-10-112

15

FN3442-12-112

FN3443-12-112

FN 3452-15-112

FN 3453-15-112

20

FN3442-16-113

FN3443-16-113

FN 3452-20-113

FN 3453-20-113

30

FN3442-20-113

FN3443-20-113

FN 3452-25-113

FN 3453-25-113

35

FN3442-24-113

FN3443-24-113

FN 3452-30-113

FN 3453-30-113

40

FN3442-32-115

FN3443-32-115

FN 3452-40-115

FN 3453-40-115

50

FN3442-40-115

FN3443-40-115

FN 3452-50-115

FN 3453-50-115

60

FN3442-48-115

FN3443-48-115

FN 3452-60-115

FN 3453-60-115

80

FN3442-60-115

FN3443-60-115

FN 3452-75-115

FN 3453-75-115

90

FN3442-80-115

FN3443-80-115

FN 3452-100-115

FN 3453-100-115

125

FN3442-100-116

FN3443-100-116

FN 3452-125-116

FN 3453-125-116

150

FN3442-120-116

FN3443-120-116

FN 3452-150-116

FN 3453-150-116

175

FN3442-160-118

FN3443-160-118

FN 3452-200-118

FN 3453-200-118

250

FN3442-200-118

FN3443-200-118

FN 3452-250-118

FN 3453-250-118

300

FN3442-240-118

FN3443-240-118

FN 3452-300-118

FN 3453-300-118

400

Page 45

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

45/50

9. Filter maintenance

Ecosine evo passive harmonic filters described in this manual are equipped with long life components that

ensure a satisfactory function for many years under normal operating conditions. Any operation under

extreme conditions such as over-temperatures, overvoltage situations, polluted environments etc. reduces

the life expectancy. Following maintenance recommendation will help maximizing filter lifetime.

Warnings:

High voltage potentials are involved in the operation of this product. Always remove line side

power before attempting to perform maintenance, and let ample time elapse for the

capacitors to discharge to safe levels (<42 V). Residual voltages are to be measured both

line to line and line to earth.

Line side power must be disconnected prior to replacement of any part.

9.1 Maintenance schedule

Table 24 Maintenance schedule

year 1 2 3 4 5 6 7 8 9 10 11 12

check and clean fan(s) X X X X X X X X X X X X

replace fan(s) X X

check & tighten el. Connections 1) X X X X X X X X X X X X

check el. values of capacitors X X X X X X

replace power capacitors X

1)

Only external connections need to be checked.

Page 46

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

46/50

9.2 Fan

Schaffner ecosine evo p as s ive harmonic filters are reliable low maintenance products. Many products like

power supplies, inverters or motor drives utilize fans for forced cooling to minimize size and weight. Ecosine

filters are designed with a similar temperature management concept and therefore, fans may have to be

maintained and replaced in certain intervals to sustain the function and value of the product. Fans are 100%

field replaceable without the need to uninstall and disconnect the filter.

Forced cooling devices are needed for the operation of Schaffner ecosine evo passive harmonic filters up to

their nominal rating. Such cooling devices must be checked and cleaned regularly (if installed) to ensure

sufficient air flow at all times.

Note: increased audible noise is a typical indicator of a fan that needs maintenance or replacement also

outside of a maintenance schedule.

Before cleaning or replacing the cooling devices, make sure to consult the recommended maintenance

procedures and schedules of the supplier of the cooling device in use.

9.3 Power capacitors

The power capacitors supplied with the filter modules are high quality components with an expected life time

of up to 100’000 hours (11 years). Nevertheless, their useful service life can be shortened by electrical or

thermal stress beyond their specification.

Power capacitor damage may also be caused by severe abnormal supply voltage peaks (i.e. lightning –

depending upon system protection), but may only be recognizable through the measurement of line side

harmonics distortion. This may be checked with a modern energy meter or by regular checkup with a power

quality analyzer. According to the above considerations, a 2 year inspection interval is advisable.

Note: an inspection should as well be performed after extreme overvoltage situations in the system.

Note: Storage of capacitors

Up to 3 years-long storage, electrolitic capac itors can be operat ed with out any restriction and the nominal

voltage can be applied without any prelim inary preparation. System reliability and life-time expectancy are not

affected.

On the other side, a longer ( >3 yrs) storage of electrolitic capacitors without applying any voltage can

weaken the dielectric properties because of disslution processes. The electrolitic solution is aggressive and it

can affect and weaken the dielectric in the timeframe between production and product commissioning. The

weak points are responsible for the higher leakage current shortly after the device turn-on on site.

The residual current of electrolitic capacitors depends upon time, voltage and temperature. The residual

current increases after long storage without ap plying voltage.

The amplitude of resulting residual current during unit commissioning can be up to 10 times larger on short

term. The capacitor’s residual current assumes the typical expected value at steady state for nominal voltage.

During comissioning after long storage, it is recommended to restore the dielectric characteristics by applying

voltage progressively and with respect to the time frame the filters have been stored.

9.4 Electrical connections

Depending upon the environment and application, electrical connections, in particular threaded bolts and

nuts, can degrade over time by means of losing their initial tightening torque. This holds true not only for the

filter, but for any such joint within an electrical installation.

Therefore, Schaffner recommends to check and tighten all electrical connections on the occasion of a regular

scheduled maintenance of the entire device that incorporates the filter.

Page 47

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

47/50

Check of internal connections within the filters is not needed or should be conducted by a Schaffner service

representative.

Page 48

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

48/50

10 Trap circuit disconnect

The trap circuit disconnec t featur e is a modular option for the purpose of reducing the capacitive current

during low load operation, if needed. With permanently connected trap circuit, cosφ vs. load shows following

characteristics:

When the trap circuit is disconnected, cos(phi) returns to ~0.98. At the same time, the THID will increase.

This may be negligible, since absolute values are low due to reduced load power.

Needed external components (not part of ecosine filter) or system functions for fully automated capacitive

current control:

| Motor load (power factor) monitoring device

| Capacitor contactor

A reduced load system status may be available as system controller output signal. In this case, only adequate

driving of capacitor contactor has to be assured.

Note: It is necessary to take into account overall concept of power factor correction. A system PFC correction

unit with large capacitor banks may become obsolete or massively reduced, when harmonic filters are

installed. In such cases it may not be necessary to install trap circuit disconnect functions.

Recommended settings:

Schaffner recommends to engage and disengage the trap circuit disconnect at following load levels:

Trap circuit status

Proposed load level

Disconnect

When load level drops under 10–15%

Connect

When load level rises above 20–25%

Page 49

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

49/50

11. Troubleshooting

Schaffner Ecosine harmonic filters are high quality products and have undergone rigorous testing and

qualification procedures. Every unit runs through suitable tests in our ISO 9001:2000 factories. Due to this

reason no major issues need to be expected if the filter is installed, operated, and maintained as described in

this document.

In the unlikely event of a problem, please contact your local Schaffner partner for assistance.

Page 50

Schaffner Group

User and Installation Manual

Ecosine evo

October 2018

50/50

Disclaimer

This document has been carefully checked. However, Schaffner does not assume any liability for errors or

inaccuracies. Published specifications are subject to change without notice. Product suitability for an area of

application must ultimately be determined by the customer. In all cases, products must never be operated

outside their published specifications. Schaffner does not guarantee the availability of all published products.

Latest publications and a complete disclaimer can be downloaded from the Schaffner website. All trademarks

recognized.

Loading...

Loading...