Schaffner FN 3025,FN 3026 Installation Manuallines

Schaffner EMV AG Nordstrasse 11 CH-4542 Luterbach

T +41 32 681 66 26 F +41 32 681 66 30 www.schaffner.com

safety for electronic systems

Installation guidelines FN 3025 and FN 3026

Thank you for choosing Schaffner FN 3025/FN 3026 filters to solve your EMC challenges. Please

follow the guidelines below to ensure a satisfying and reliable filter function for many years of

operation.

1. General guidelines

Q Mount the filter on a clean conductive surface (or DIN-rail) free of paint or lacquer.

Q Install the filter as close as possible to the noise source, using short direct wire connections.

Q Protect the filter from liquid, excessive dust and aggressive gases.

Q Do not expose the filters to conditions beyond specifications in the datasheet.

2. Installation and electrical connection

FN 3025/FN 3026 are delivered with

closed plastic safety covers and

unfastened terminals. To install the

filter please proceed as follows:

Q Mount the filter on a metal surface

with four appropriate screws and

washers or snap it onto a TS 35

DIN-rail.

Q First connect the green/yellow wire

to the earth stud of the filter.

Q Gently lift the two hinged plastic

covers.

Q Connect phase wires with cable

lugs by pushing down and

tightening the screws.

2004-176C

Q Please note the torque

recommendation on top of the

filter.

Q Push the covers back into their

locked position to finish the filter

installation.

Schaffner EMV AG

Installation guidelines FN 3025/FN 3026

2 of 2

3. Recommendations for the mechanical installation of FN 3025

10A types 20A types 30A types 50A types

Screw M4 (hex cap) M4 (hex cap) M4 (hex cap) M5 (hex cap)

Washer M4 (flat- & spring-

washer)

Tool ¼ inch nut

wrench size 7mm

M4 (flat- & springwasher)

¼ inch nut

wrench size 7mm

M 4 (flat- & springwasher)

¼ inch nut

wrench size 7mm

M5 (flat- & springwasher)

¼ inch nut

wrench size 8mm

Torque According to the property class of the screws and material grade of the mounting

area.

4. Recommendations for the electrical connection of FN 3025/FN 3026

10A types 20A types 30A types 50A types

Flex wire 1.3 - 2.5mm2 4 - 6mm2 8 - 10mm2 16 - 20mm2

AWG type wire AWG 16 -

AWG 13

AWG 12 AWG 10

AWG 8 - AWG 7 AWG 5 - AWG 4

Screw (included) M4 M4 M4 M5

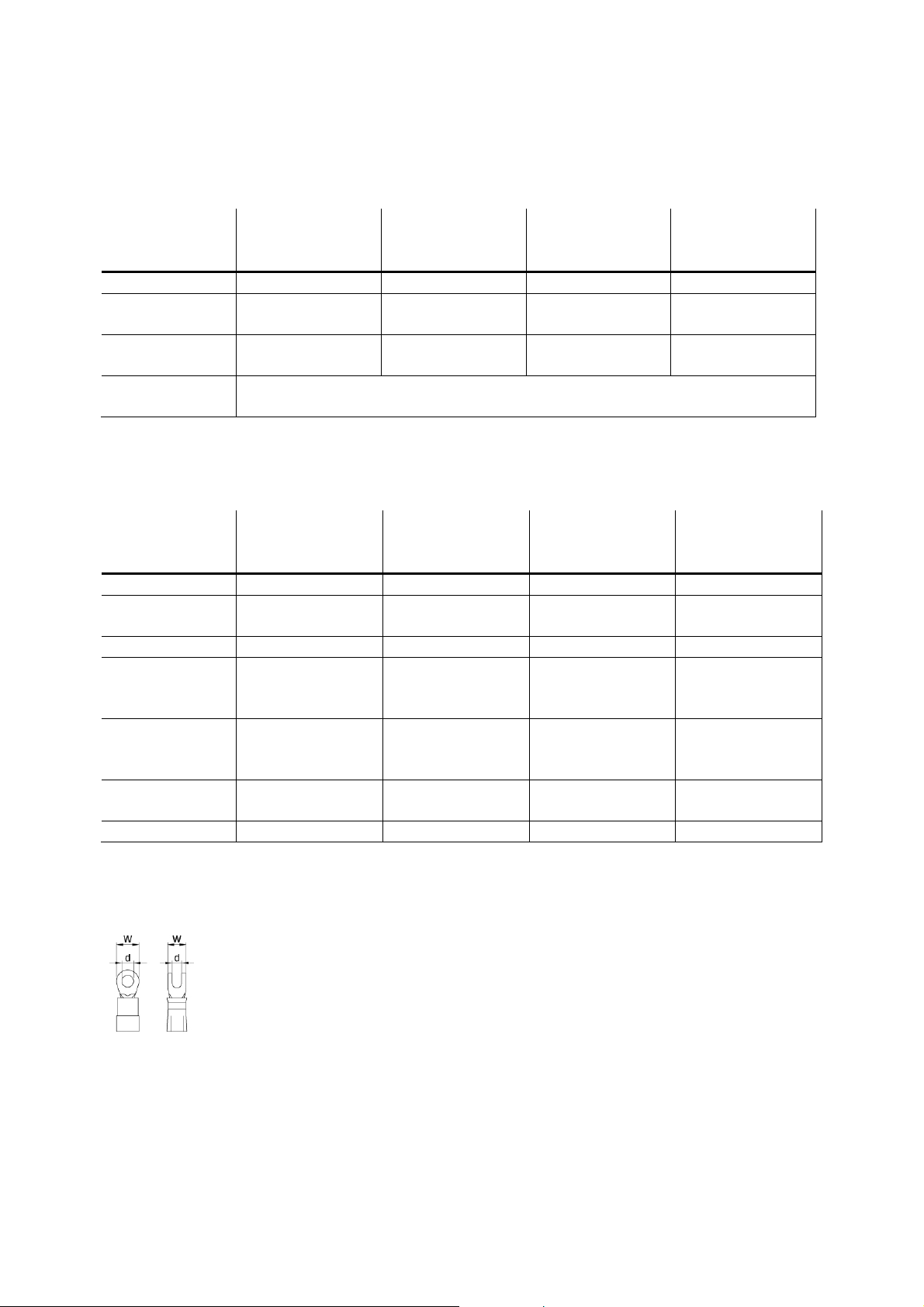

Ring/fork lug

(W/d)*

Lug thickness:

– One lug used:

– Two lugs used:

Tool Cross recessed

max. 11mm

(9.5mm)/

min. Ø4.3mm**

1.0mm

0.8mm

wrench #2

max. 11mm

(9.5mm)/

min. Ø4.3mm**

1.0mm

0.8mm

Cross recessed

wrench #2

max. 11mm

(9.5mm)/

min. Ø4.3mm**

1.0mm

0.8mm

Cross recessed

wrench #2

max. 16.5mm

(15mm)/

min. Ø5.3mm**

1.5mm

1.0mm

Cross recessed

wrench #2

Torque 1.0 - 1.2Nm 1.0 - 1.2Nm 1.0 - 1.2Nm 1.9 - 2.2Nm

* Schaffner recommends the use of insulated and UL-recognized ring lugs or fork lugs of the

appropriate size.

** Specification in () relates to earth connector.

Indicated wire sizes are for field wiring; wire size may be reduced for chassis/cabinet wiring, especially

when fixing two wires in one terminal (respect your local cabinet installation standards).

The installation guidelines above need to be obeyed to ensure the expected filter function. All relevant

electrical and mechanical data can be found in the FN 3025/FN 3026 datasheet or the installation

guidelines. For further information please contact your local Schaffner partner.

www.schaffner.com

April 2007

2004-176C

Loading...

Loading...