Schaffner ecosine FN3540,ecosine FN3541,ecosine FN3545 Maintenance Manual

www.myecosine.com

English version

Maintenance Manual

Ecosine active sync

Schaffner Group|Nordstrasse 11|4542 Luterbach|Switzerland

T +41 32 681 66 26|F +4132 681 66 30|www.schaffner.com

2 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

© All rights reserved, even and especially in cases of proprietary rights applications.

We also retain sole power of disposal, including all ri ghts relating to copyi ng, transmission and

dissemination.

Revision: 01 (March 2018)

The most current edition of these instructions (PDF format) can be obtaine d from your contact

of the Schaffner service organization.

Other technical documentation of our products is also available in the download area of our

website www.schaffner.com

Document name:

Maintenance Manual for FN35xx Cabinet

Version history

Revision Date Description

01

March 2018

Initial version

3 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

Table of Contents

1 Introduction 4

1.1 Purpose 4

1.2 Additional Resources 4

2 General Safety Notes and Insta llation Guidelines 5

3 Environmental Conditions / E x cl usion of wa rranty 6

4 Welcome 8

4.1 About this manual 8

4.2 Who should read this guide 8

4.3 Personnel qualification 8

4.4 Get help 8

4.5 Get training 8

4.6 Contact us 9

5 CABINET 380VAC-415/480VAC 3-/4-WIRE 10

5.1 Maintenance schedule 10

5.2 Wear parts 10

5.3 Maintenance instruction 11

5.3.1 Check operation, clean cabinet fans, fan guard of cabinet, filter pads,

internal fan, fan guard of inter nal f an and air pat h 11

5.3.2 Replace filter pads 19

5.3.3 Spare parts 19

5.3.4 Replace cabinet fans, fans 4 – 7 20

5.3.5 Replace internal fan, fan 8 26

5.3.6 Replace Main fuses 29

5.3.7 Replace Power Supply fuses 32

5.3.8 Remove Power Module from cabinet 34

5.3.9 Dismantling process 34

4 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

1 Introduction

1.1 Purpose

The ecosine active sync User and Installation Manual provide information for unpacking,

installation and commissioning of the filter and describe mechanical and electrical installation

of the filters. It contains basic information about parameters and communication as well as

troubleshooting information.

The instructions are intended for use by qualified personnel. Reading and following these

instructions is mandatory. Particular attention need to be given to the general safety notes

and installation guidelines (cautions and warnings)! Keep these instructions available with

the filter(s) at all time s.

Installation of the ecosine active sync filter, inspections for proper operation, and certain

troubleshooting measures may only be performed by qualified personnel. All other measures

may be performed by people who have read these instructions.

1.2 Additional Resources

The Schaffner group does provide a number of additional resources available at

schaffner.com to understand power quality in general and product in particular.

The ecosine active sync filter maintenance manual provides information on maintenance and

testing for field service technicians, as well as disassembly and assembly instructions for

wear parts.

5 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

2 General Safety Notes and Installation Guidelines

6 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

3 Environmental Conditions / Exclusion of warranty

This document classifies groups of environmental parameters and their severities to which

ecosine active harmonic filters are subjected when mounted for stationary use at weather

protected locations under use conditions, including periods of erection work, down time,

maintenance and repair. The lifetime of electronic equipment is depending on the

environmental conditions they are exposed to. Especially in harsh environments lifetime is

reduced due to the corrosiveness of the atmospheric environment. Generally corrosion in

micro or power electronics depends on several variants such as the package type, materials

involved, assembly processes, moisture, inorganic and organic contaminants, atmospheric

pollutants, temperature, thermal stress and electrical bias. To increase the lifetime Schaffner

provides all ecosine active filters with the ability to work within pollution degree 2 (PD2) and

does use coated PCB’s according to IEC61721-3-3. Schaffner standard PCB construction

complies with class 3C2. Please carefully read the provided information and check if your

application fulfills the required specifications as Schaffner expressly points out that the

manufacturer's warranty shall lapse with immediate effect if ecosine active sync harmonic

filters are transported, stored, installed or operated outside their published specifications.

Important

Ecosine active sync harmonic filters (AHF) listed below are IP20

or IP54 devices to be installed in an environment in compliance

with the requirements named in this document.

All AHF must be installed in a clean, dry location, e.g. in

sufficiently ventilated or air-conditioned electric cabinets or closed

electric rooms. Contaminants such as oils, liquids, corrosive

vapors, abrasive debris, dust and aggressive gases must be kept

out of the filter enclosure.

WARNING: Conductive dust may cause damage to ecosine

active sync harmonic filters. Ensure that installation site of

ecosine active sync is free of conductive dust.

Products

FN3540/41 series, 3/4-wire filters, models 60A

FN3545 series, 3/4-wire filters, models 60…300A

Overvoltage class

(EN50178)

Ecosine active sync are designed according to EN 50178

overvoltage class III

Storage environmental

specifications

(IEC 60721-3-1, EN50178)

Climate conditions for storage class 1K3:

• Temperature range: -25°C to +55°C

• Relative humidity: < 95%, no condensation

• Atmospheric pressure: 70KPa to 106KPa

Transportation

environmental

specifications

(IEC 60721-3-2, EN50178)

Climate conditions for transport class 2K3:

• Temperature range: -25°C to +70°C

• Relative humidity: < 95%, no condensation

• Atmospheric pressure: 70KPa to 106KPa

7 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

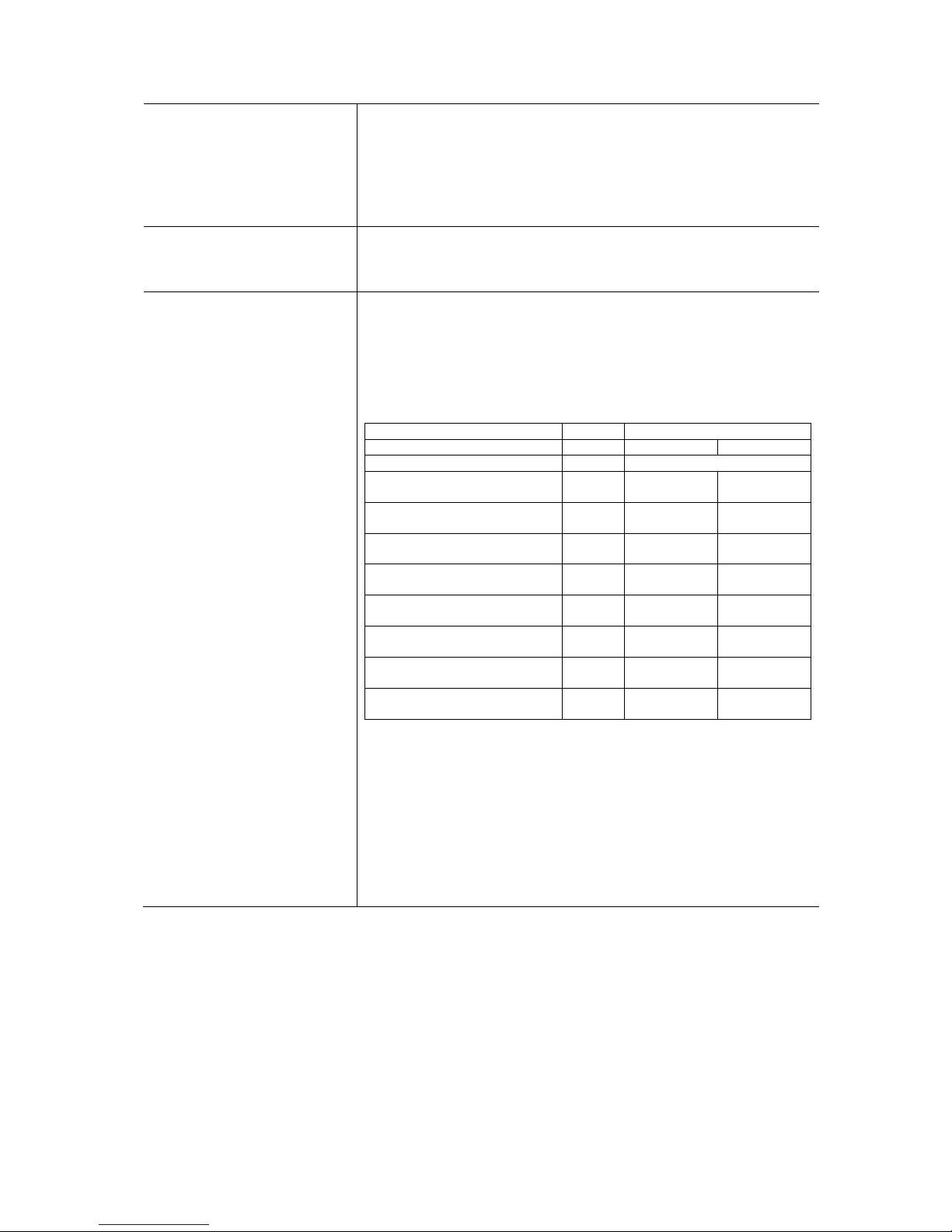

Operation environmental

specifications

(IEC 60721-3-3, EN50178)

Climate conditions for operation class 3K3:

• Temperature range: 0°C to +40°C

• Relative humidity: < 95%, no condensation

• Atmospheric pressure: 70KPa to 106KPa

Degree of pollution

(IEC 61010, EN50178)

Pollution conditions for operation class PD2

Corrosive levels

(IEC 60721-3-3)

Corrosive levels for storage, transport and operation Class

3C2

(3)

:

• Applies to locations with normal levels of contaminants,

experienced in urban areas with industrial activities

• Levels:

Environmental parameter

Units

(1)

Class 3C2

(2)

Mean value

Max value

Sea salt Salt mist

Sulphur dioxide

ppm

cm3/m3

0.3

0.11

1.0

0.37

Hydrogen sulphide

ppm

cm3/m3

0.1

0.071

0.5

0.36

Chlorine

ppm

cm3/m3

0.1

0.034

0.3

0.1

Hydrogen chloride

ppm

cm3/m3

0.1

0.066

0.5

0.33

Hydrogen fluoride

ppm

cm3/m3

0.01

0.012

0.03

0.036

Ammonia

ppm

cm3/m3

1.0

1.4

3.0

4.2

Ozone

ppm

cm3/m3

0.05

0.025

0.1

0.05

Nitrogen oxides

ppm

cm3/m3

0.5

0.26

1.0

0.52

(1)

The values given in cm3/m3 have been calculated from the values

given in mg/m3 and refer to a temperature of 20 °C and a pressure

of 101,3 kPa. The table uses rounded values.

(2)

Mean values are expected long-term values. Maximum values are

limit or peak values, occurring over a period of time of not more than

30 min per day.

(3)

IEC 60721-3-3 is only applied to the coated PCB covered areas

and not the entire device. The unprotected areas, such as

connections, terminations and exposed magnetics, may not survive

these exposure levels over tim e.

8 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

4 Welcome

4.1 About this manual

This manual is meant to provide comprehensive information on maintenance requirements of

Ecosine

®

active harmonic filters. The issues discussed in this guide cover the basic

maintenance schedule, necessary wear parts as well as practical aspects of working with

Ecosine

®

active harmonic filters. The guide will familiarize you with the required hardware

checks and settings to conduct various maintenance tasks.

4.2 Who should read this guide

The primary audience for this book is anyone interested in or responsible for maintenance of

Ecosine

®

active harmonic filters. To fully understand the guide, you should have a good

knowledge of electronic and electrical systems and at least some basic power quality habits.

Attending Schaffner International training courses is considered helpful.

4.3 Personnel qualification

Any maintenance actions on Ecosine® active harmonic filter has to be performed only by

skilled electricians who additionally must be familiar with the instructions in the Installation

and Operation Manual as well as this Maintenance Manual.

CAUTION

Caution

Maintenance tasks should only be performed by trained and skilled personnel to

avoid damages to the unit or injuries of personnel.

WARNING

Warning

Changing of wear parts may cause malfunction of device and can cause injuries

of

personnel if not properly performed.

4.4 Get help

Schaffner believes in the value of service and partnering. We do offer help with a lot of

topics. In order to provide the most successful help Schaffner does operate a service

organization and worldwide service centers. We do also closely collaborate with a growing

network of qualified and authorized service partners to maintain our high service quality on a

global approach.

4.5 Get training

Do you need training? Schaffner can offer a training course comprised of lecture and handson workshops designed to introduce you to the fundamental concepts of power quality,

Ecosine

®

harmonic filters and filter maintenance.

We also offer customized training courses designed to meet your specific needs. Please

contact your local Schaffner service organization or Schaffner representative to discuss how

we can help you achieve success in your power quality efforts.

9 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

4.6 Contact us

Schaffner – More than just filters. Schaffner is in the unique position of being able to support

the user with problem analyses, engineering advice, testing and measurement support,

custom products, and a worldwide customer service organization. Our goal is to ensure that

you obtain the level of support you actually need. Toward this objective, we invite you to

contact your local Schaffner representative at any time that we may be of service to you. You

can find out more about us and your local contact on our corporate website or you may

contact us via email:

Service URL: www.schaffner.com/service/

Service E-mail for APAC: apac-pqservice@schaffner.com

Service E-mail for EMEA: emea-pqservice@schaffner.com

Service E-mail for India: india-pqservice@schaffner.com

Service E-mail for USA: usa-pqservice@schaffner.com

10 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

5 CABINET 380VAC-415/480VAC 3-/4-WIRE

5.1 Maintenance schedule

Year after start

operation

Maintenance job

1 2 3 4 5 6 7 8 9 10 11 12

Check operation, clean cabinet

fans, fan guard of cabinet, filter

pads, internal fan, fan guard of

internal fan and air path

Replace filter pads

Replace cabinet fans

Fans 4-7

Replace internal fan

Fan 8

Replace main fuses

Replace Power Supply fuses

F5-F7

Table 1: Maintenance schedule

5.2 Wear parts

Required

amount /

filter

Description Part # Classification

1x

AHF EXHAUST FILTER PFA GEN II SP

(Set includes 10 pcs.)

819135 Wear part

1x

AHF FAN 120 CABINET GEN II SP

(Set includes 4 fans)

819130 Wear part

1x

AHF FAN 92 CABINET GEN II SP

(Set includes 1 fan)

819132 Wear part

3x

(1)

AHF FUSE 100A 600V CABINET GEN II SP

(1)

3 pcs. per installed Power Module are needed

819127 Wear part

1x

AHF FUSE 10.3X38 8A 690V CABINET GEN II SP

(Set includes 3 fuses)

819131 Wear part

Table 2: Wear parts

11 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

5.3 Maintenance instructi on

Attention!

Before starting to work on the device, ensure that it is switched off,

disconnected from the grid and capacitors are discharged

5.3.1 Check operation, clean cabinet fans, fan guard of cabinet, filter pads,

internal fan, fan guard of internal fan and air path

5.3.1.1 Tool list

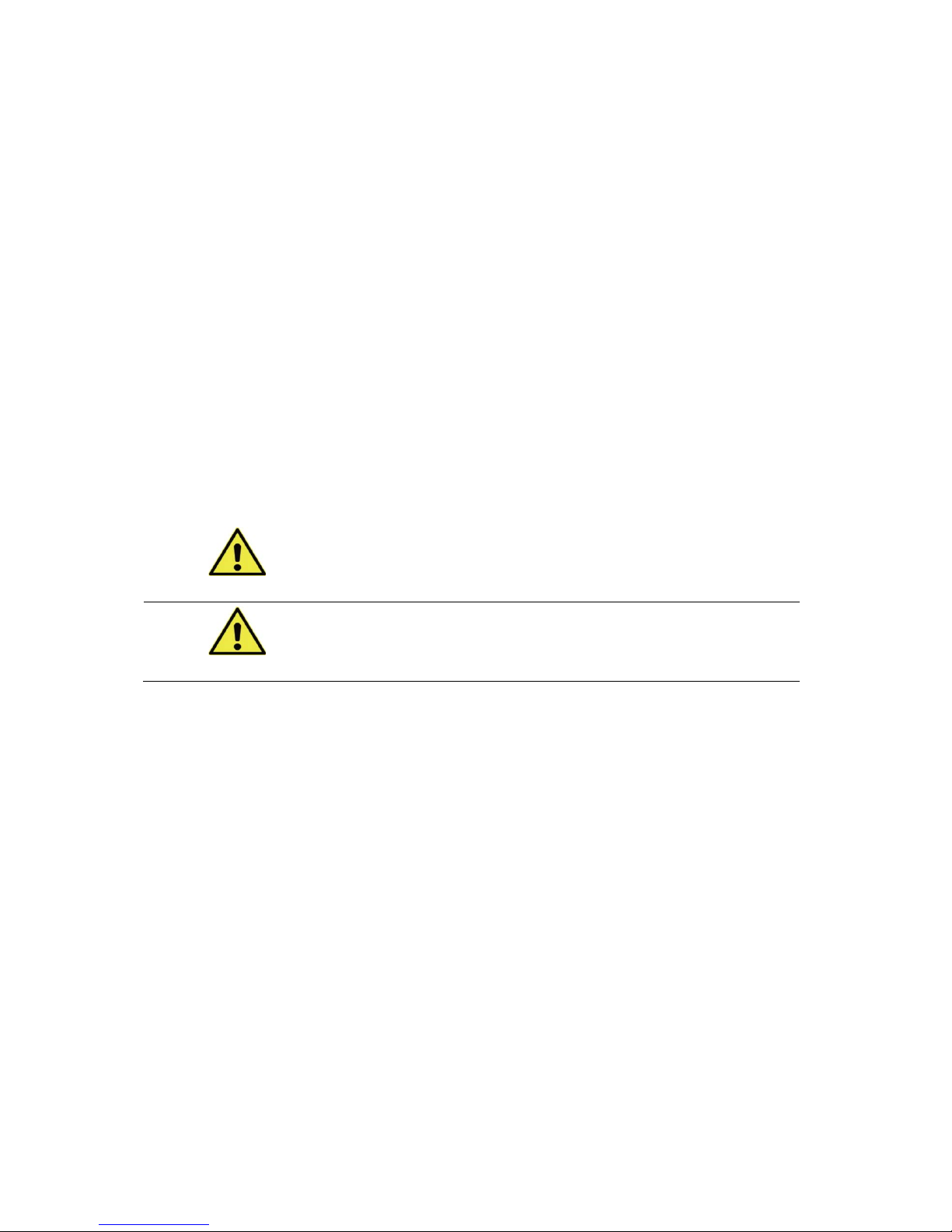

CLEANING M ATERIAL L IST

1. Gloves

2. Brush

3. Cleaning paper

4. Alcohol

5. Compressed air

6. Vacuum cleaner

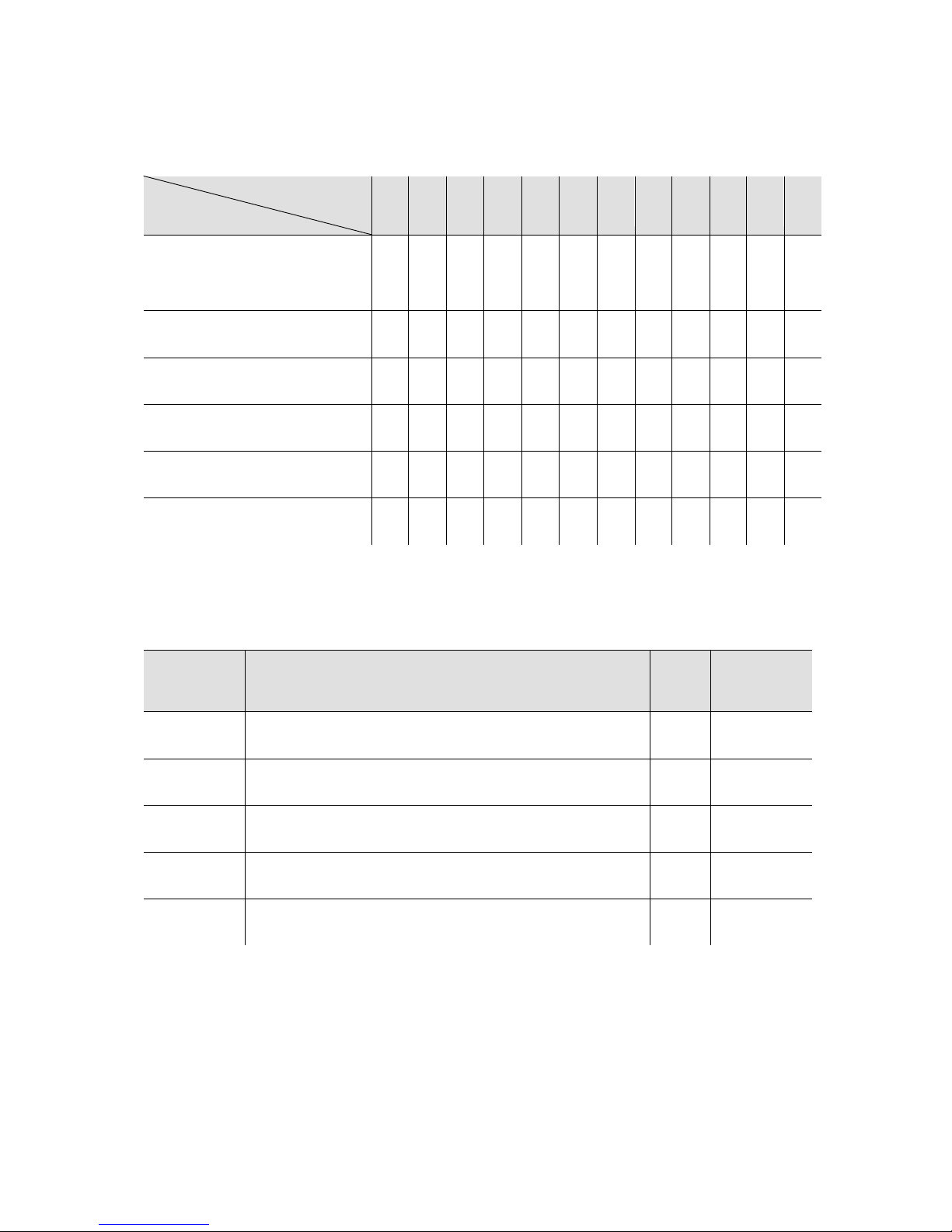

MAINTENANCE TOOL LIST

1. Socket wrench set

2. Torque wrench

3. Screw driver set insulated

4. Combination wrench set 5 mm – 19 mm

5. Pliers set

6. Multimeter with capacitance test (for

example Fluke 175)

7. Torx screw driver set insulated

8. Ladder

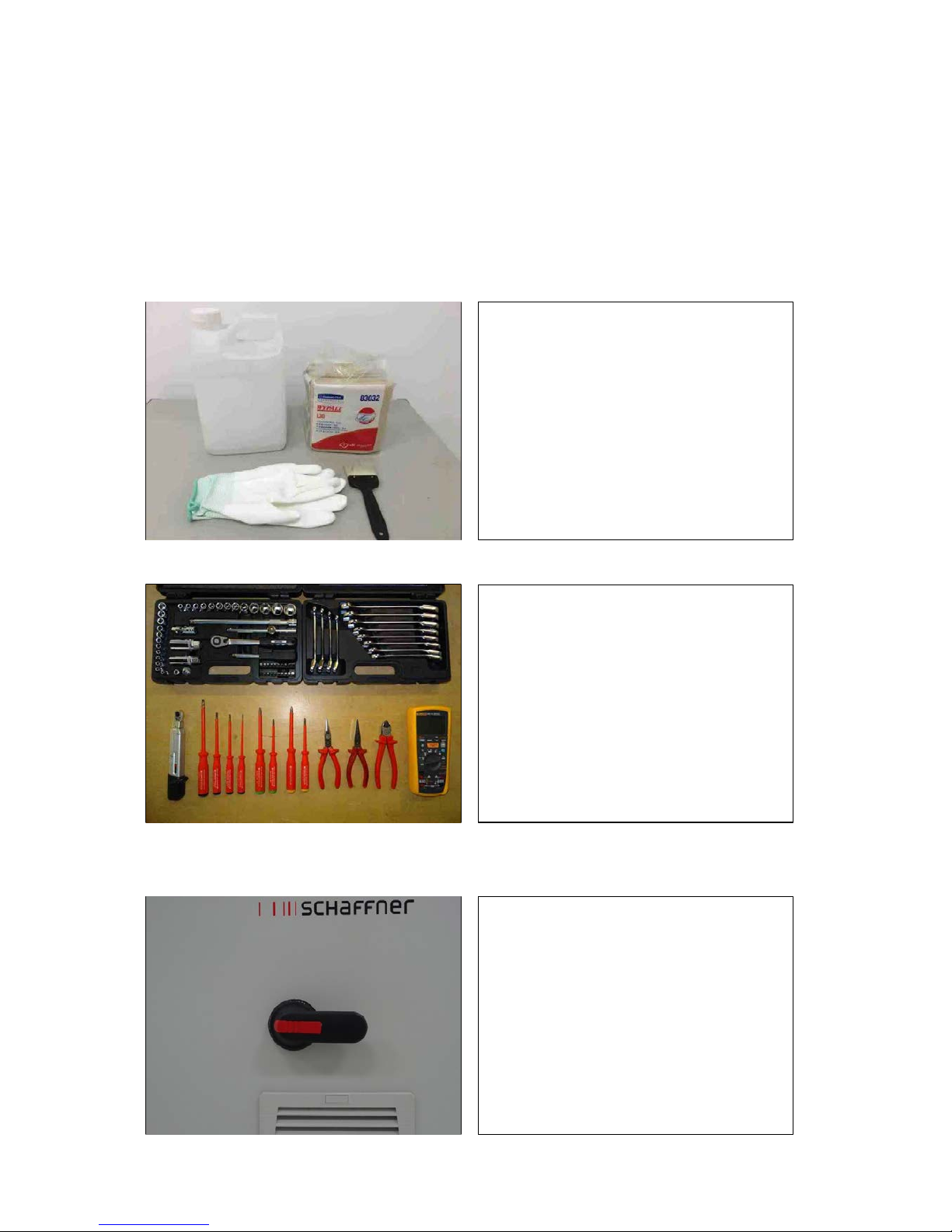

5.3.1.2 Dismantling process

Switch off the main switch and disconn ect the

device from the grid

12 Ecosine® active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

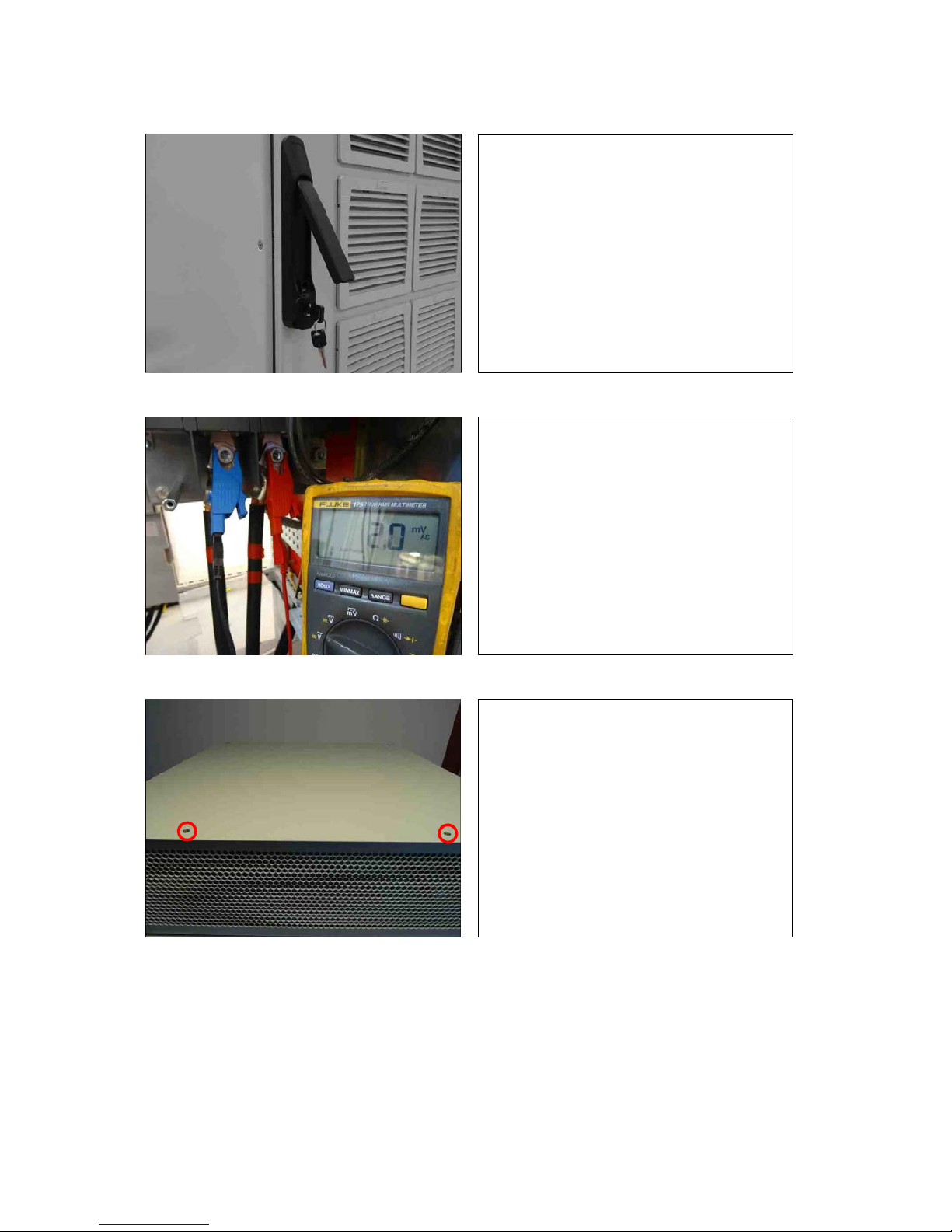

Open the front door

Check the device

for loss of voltage

Remove the 2 screws on top with a torx T20

screw driver

Loading...

Loading...