Schaffner ECOsine FN3416,ECOsine FN3418 User Manual

Schaffner Group Nordstrasse 11 4542 Luterbach Switzerland

T +41 32 681 66 26 F +41 32 681 66 30 www.schaffner.com

energy efficiency and reliability

User Manual

ECOsine™ – Passive Harmonic Filters

FN3416 (50Hz) & FN3418 (60Hz) Economy Line

September 2012

1/43

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

2/43

ECOsine™ – Passive Harmonic Filters

FN3416 (50Hz) & FN3418 (60Hz) Economy Line

Schaffner ECOsine™ harmonic filters represent an economical solution to the challenge of load-applied

harmonics mitigation in three-phase power systems. With a plug-and-play approach and more compact

dimensions than comparable products, they can be quickly installed and easily commissioned. They

increase the reliability and service life of electrical installations, help utilize electric system capacity

better, and are the key to meet Power Quality standards such EN61000-3-12. ECOsine™ filters help to

reduce the costly waste of electricity.

This user manual is intended to support designers, installers, and application engineers with filter

selection, installation, application and maintenance. For additional helpful tips for overcoming harmonics

mitigation challenges, please also consult the more detailed user manual of the ECOsine™ FN3410

(50Hz) and FN3412 (60Hz) full performance filters.

If you require additional support, please feel free to contact your local Schaffner partner.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

3/43

Important user notice

Schaffner ECOsine™ harmonic filters are designed for the operation on the input (grid) side of power

electronic equipment with six-pulse rectifier front-ends in balanced three-phase power systems, like

typically used in AC or DC motor drives and high power DC supplies. Filter suitability for a given

application must be determined by the user on a case by case basis. Schaffner will not assume liability

for any consequential downtimes or damages resulting from use or application of ECOsine™ filters

outside of their specifications. ECOsine™ filters are not designed for single-phase or split-phase

applications.

ECOsine™ filters with protection category IP20/NEMA1 must be mounted in a clean, dry location.

Contaminants such as oils, corrosive vapors and abrasive debris must be kept out of the enclosure.

These filter enclosures are intended for indoor use, primarily to provide a degree of protection against

contact with enclosed equipment. These enclosures offer no protection against airborne contaminants.

Important safety considerations

Note: Filter installation has to be carried out by a trained and certified electrician or technician, who is

familiar with installation and safety procedures in three-phase power systems.

Warning: High voltage potentials are involved in the operation of ECOsine™ filters. Always remove

power before handling energized parts of the filter, and let ample time elapse (> 1 minute) for the

capacitors to discharge to safe levels.

Warning: Follow the installation instructions closely. Ensure that fans and cooling slots are free from

obstructions that could inhibit efficient air circulation. Do not operate the filter in ambient conditions

outside of specifications.

Note: Do not operate ECOsine™ filters on unsymmetrical loads, on linear loads, or with single-phase

equipment.

Note: Always use an upstream disconnect or protection device as required by most national and

international electric codes.

Note: Always connect the filter to protective earth (PE) first, then continue with the wiring of the phase

connectors.

Note: Follow the Schaffner instructions closely when doing maintenance work. Use exclusively spare

parts recommended and approved by Schaffner.

Note: Always practice the safety instructions defined by your company when handling, installing,

operating, or maintaining ECOsine™ harmonic filters.

Note: In case of uncertainty and questions please contact your local Schaffner partner for assistance.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

4/43

Content

1. Part number coding ............................................................................................................................... 5

2. Filter description ................................................................................................................................... 6

2.1 General electrical specifications FN 3416 (50Hz filters) .................................................................... 6

2.2 General electrical specifications FN 3418 (60Hz filters) .................................................................... 7

2.3 Additional electrical specifications ..................................................................................................... 8

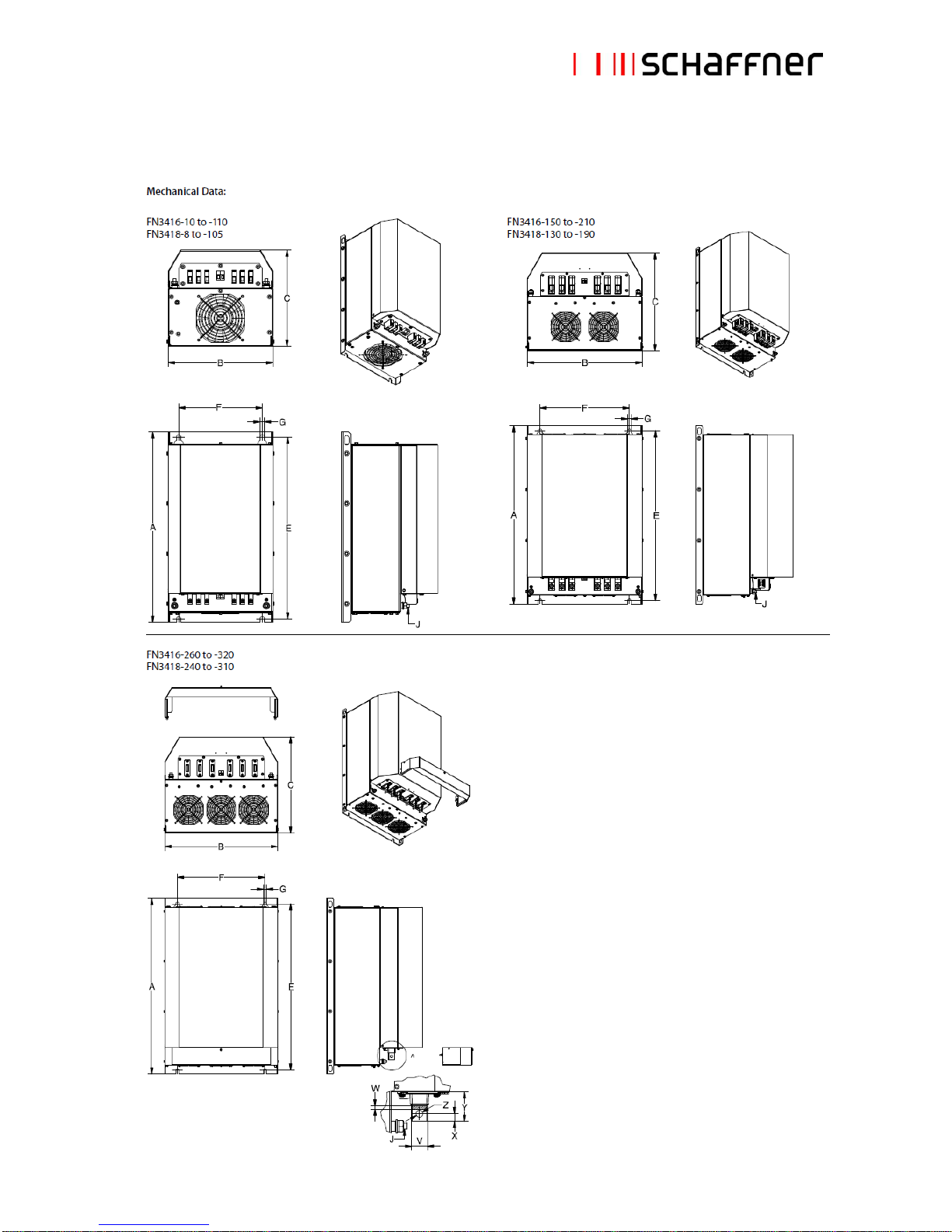

2.4 Mechanical specifications .................................................................................................................. 9

2.5 Performance characteristics ............................................................................................................ 11

2.6 Function diagram ............................................................................................................................. 14

2.7 External filter elements (Frank: new picture needed) ...................................................................... 15

2.8 Audible noise ................................................................................................................................... 16

3. Filter purpose and function ................................................................................................................ 17

4. Filter selection ..................................................................................................................................... 20

5. Filter application .................................................................................................................................. 23

6. Filter installation .................................................................................................................................. 24

7. Filter maintenance ............................................................................................................................... 29

8. Special considerations ....................................................................................................................... 31

8.1 Over-temperature contact and load disconnect ............................................................................... 31

9. Troubleshooting .................................................................................................................................. 32

10. FAQ – Frequently asked questions ................................................................................................. 33

11. Custom design input form ................................................................................................................ 36

Appendix I: International standards ...................................................................................................... 37

I. Engineering recommendation G5/4-1 ................................................................................................. 37

II. International standard EN 61000-3-12............................................................................................... 39

III. IEEE Std 519-1992 ........................................................................................................................... 42

Appendix II: Declaration of conformity ................................................................................................. 43

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

5/43

1. Part number coding

FN 34xx xx -xxx -xx

Connection style

33 = safety terminal block 10mm2

34 = safety terminal block 25mm2

35 = safety terminal block 50mm2

40 = safety terminal block 95mm2

44 = safety terminal block 6mm2

99 = copper bus bars in different sizes

Rated, unfiltered load (drive input) current [A]

Blank = standard voltage rating

Filter family

3416 = filter for 50Hz, 380-500V grids

3418 = filter for 60Hz, 380-480V grids

Schaffner standard filter

Examples:

FN 3416-60-34: Filter for 50Hz, 380-500V grids, 60A drive input current, with 25mm2 terminals, for

diode or SCR (thyristor) rectifier front-end.

FN 3418-240-99: Filter for 60Hz, 380-480V grids, 240A drive input current, with copper bus bar,

for diode or SCR (thyristor) front-end.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

6/43

2. Filter description

2.1 General electrical specifications FN 3416 (50Hz filters)

Nominal operating voltage:

3x 380 to 500VAC

Voltage tolerance range:

3x 342 to 550VAC

Operating frequency:

50Hz ±1Hz

Network:

TN, TT, IT

Nominal motor drive input current rating: 1)

10 to 320A @ 45°C

Nominal filter input current rating: 1)

7A

rms

to 240A

rms

@ 45°C

Nominal motor drive input power rating:

4 to 200kW

Total harmonic current distortion THID: 2)

According to EN61000-3-12, table 3

<10% @ rated power (with Ldc)

<15% @ rated power (without Ldc)

Total demand distortion TDD: 2)

According to IEEE 519, table 10-3

Partially weighted harmonic distortion PWHID:

<22% @ rated power

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage behavior: 3)

No load: +10%

Full load: -5%

High potential test voltage: 4)

P E 2500VAC (1min)

SCCR: 5)

100kA

Protection category:

IP20

Pollution degree:

1, 2 (according to EN 61800-5-1, EN 50178)

Cooling:

Natural convection cooling (4 to 7.5kW)

Internal forced cooling (11kW and above)

Overload capability:

1.6x rated current for 1 minute, once per hour

2x rated current for 10 seconds, once per hour

5x rated current for 1 second, once per hour

Capacitive current at low load:

<30% of rated input current, at 400VAC

<37% of rated input current, at 500VAC

Ambient temperature range:

-25°C to +45°C fully operational

+45°C to +55°C derated operation 6)

-25°C to +70°C transportation and storage

Flammability class:

UL 94V-2 or better

Insulation class of magnetic components:

H (180°C)

Design corresponding to:

UL 508, EN 61558-2-20, CE (LVD 2006/95/EC)

MTBF @ 45°C/500V (Mil-HB-217F):

200’000 hours

MTTR:

<15 minutes (capacitors and fans)

Lifetime (calculated):

Min. 15 years

Safety monitoring functions:

Over-temperature of magnetic components

Safety monitor output signal:

NO switch

1)

ECOsine™ filters reduce RMS input and peak current by reducing harmonic currents and improving true power factor.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different results, depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <5%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

I

derated

= I

nominal

*(70°C-T

amb

)/25°C

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

7/43

2.2 General electrical specifications FN 3418 (60Hz filters)

Nominal operating voltage:

3x 380 to 480VAC

Voltage tolerance range:

3x 342 to 528VAC

Operating frequency:

60Hz ±1Hz

Network:

TN, TT, IT

Nominal motor drive input current rating: 1)

8 to 310A @ 45°C

Nominal filter input current rating: 1)

5A

rms

to 250A

rms

@ 45°C

Nominal motor drive input power rating:

5 to 250HP

Total harmonic current distortion THID: 2)

According to EN61000-3-12, table 3

<10% @ rated power (with Ldc)

<15% @ rated power (without Ldc)

Total demand distortion TDD: 2)

According to IEEE 519, table 10-3

Partially weighted harmonic distortion PWHID:

<22% @ rated power

Efficiency:

>98% @ nominal line voltage and power

Drive dc-link voltage behavior: 3)

No load: +10%

Full load: -5%

High potential test voltage: 4)

P E 2500VAC (1min)

SCCR: 5)

100kA

Protection category:

IP20

Pollution degree:

1, 2 (according to EN 61800-5-1, EN 50178)

Cooling:

Natural convection cooling (5 to 15HP)

Internal forced cooling (20HP and above)

Overload capability:

1.6x rated current for 1 minute, once per hour

2x rated current for 10 seconds, once per hour

5x rated current for 1 second, once per hour

Capacitive current at low load:

<30% of rated input current, at 460VAC

Ambient temperature range:

-25°C to +45°C fully operational

+45°C to +55°C derated operation 6)

-25°C to +70°C transportation and storage

Flammability class:

UL 94V-2 or better

Insulation class of magnetic components:

H (180°C)

Design corresponding to:

UL 508, EN 61558-2-20, CE (LVD 2006/95/EC)

MTBF @ 45°C/460V (Mil-HB-217F):

200’000 hours

MTTR:

<15 minutes (capacitors and fans)

Lifetime (calculated):

Min. 15 years

Safety monitoring functions:

Over-temperature of magnetic components

Safety monitor output signal:

NO switch

1)

ECOsine™ filters reduce RMS input and peak current by reducing harmonic currents and improving true power factor.

2)

System requirements: THVD <2%, line voltage unbalance <1%

Performance specification for six-pulse diode rectifiers. SCR rectifier front-ends produce different results, depending upon

the firing angle of the thyristors.

3)

Conditions: line impedance <5%

4)

Repetitive tests to be performed at max. 80% of above levels, for 2 seconds.

5)

External UL-rated fuses required.

6)

I

derated

= I

nominal

*(70°C-T

amb

)/25°C

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

8/43

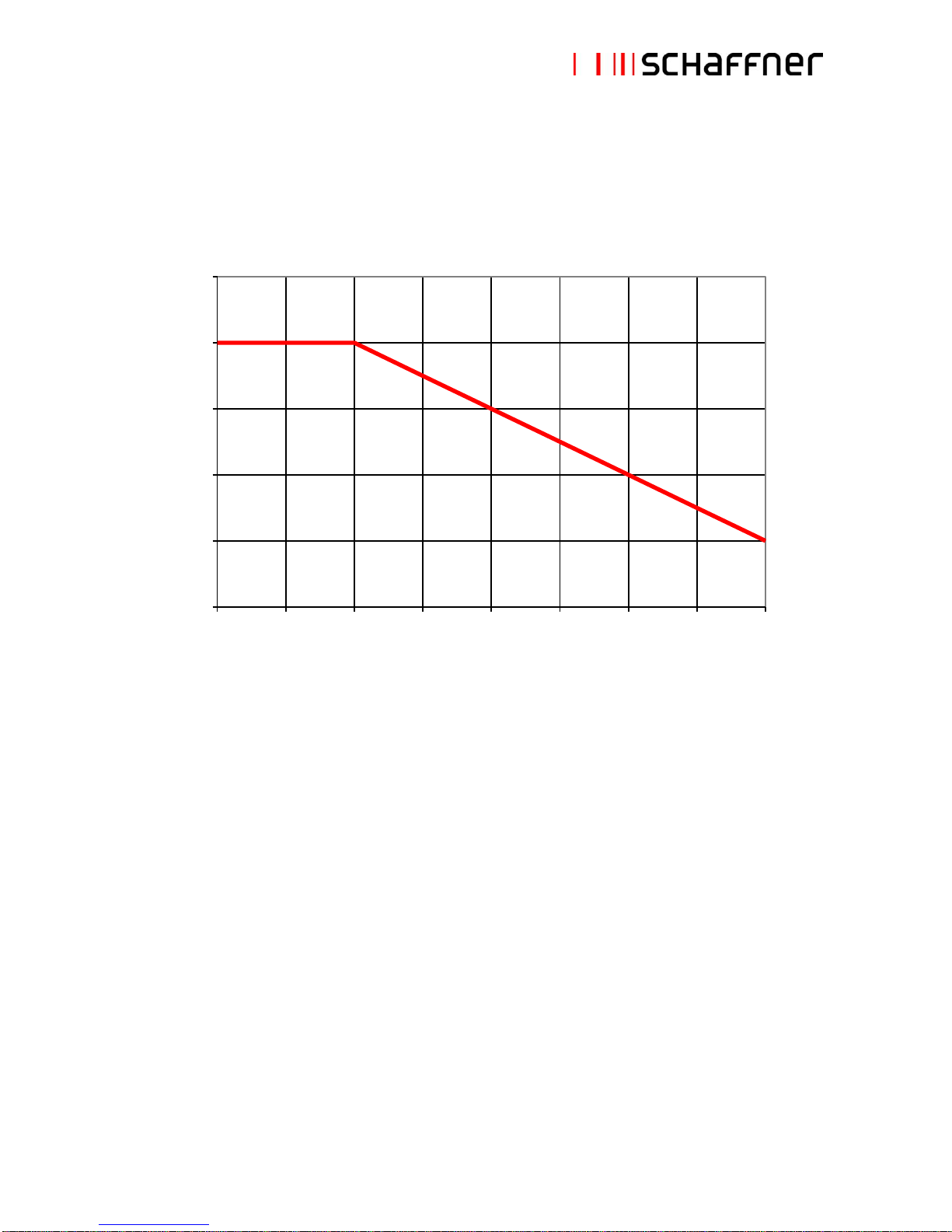

2.3 Additional electrical specifications

ECOsine™ passive general electrical specifications refer to operating altitudes up to 1000m a.s.l.

(3300ft). Operation between 1000m and 4000m (3300ft and 13123ft) requires a derating according to the

table below:

80

85

90

95

100

105

0 500 1000 1500 2000 2500 3000 3500 4000

Altitude a.s.l. [m]

Rated load power [%]

Note: do not use ECOsine™ passive harmonic filters in altitudes above 4000m without consulting

Schaffner first.

ECOsine™ passive filters have been designed and certified acc. UL508, resp. UL508C, so there is no

limitation in terms of altitude up to 4000m for clerance and creepage.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

9/43

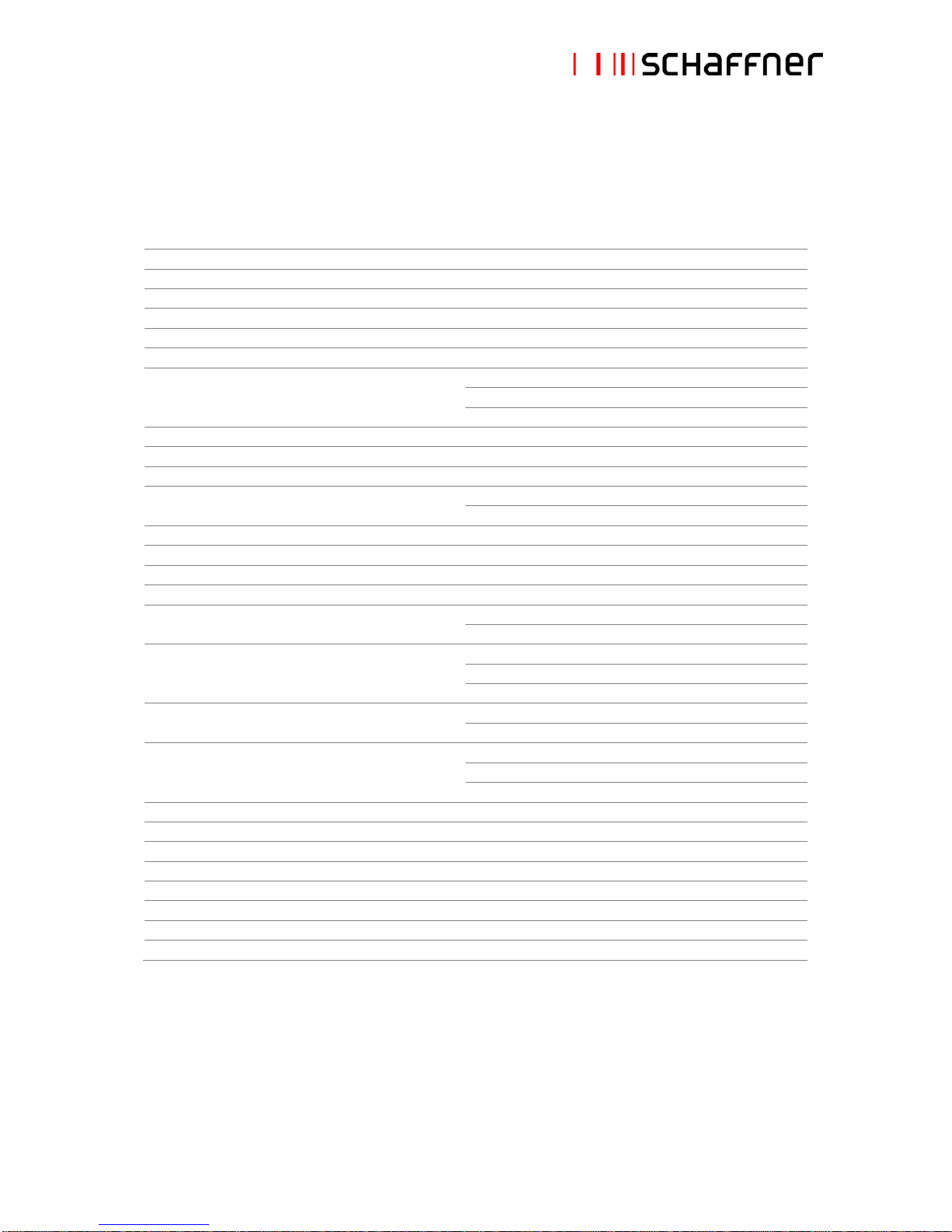

2.4 Mechanical specifications

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

10/43

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

11/43

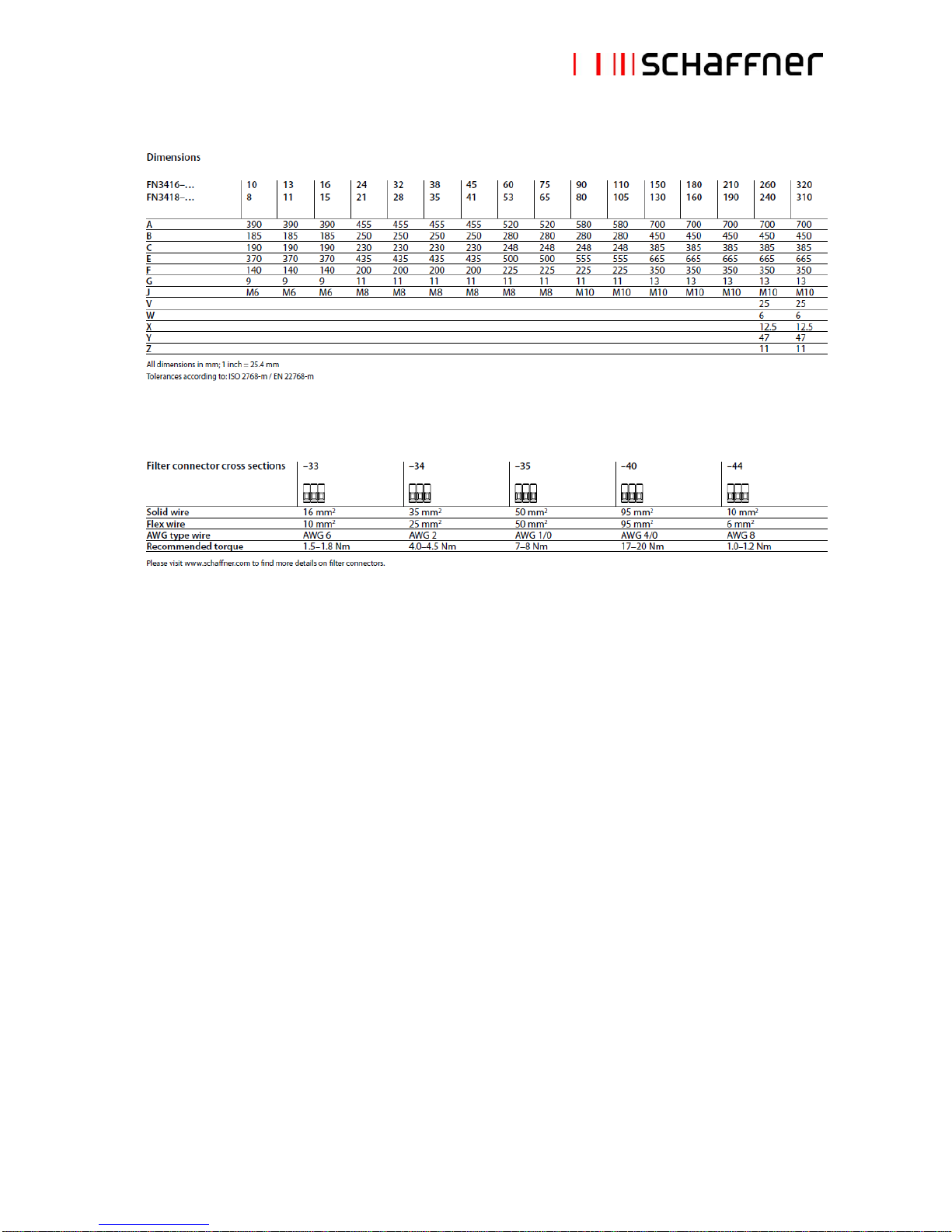

2.5 Performance characteristics

THID vs. load (diode rectifier front-ends)

Note: shown above is the typical performance characteristic of FN3416/18 series in balanced diode

rectifier front-end applications, with and without DC-link choke. In SCR rectifier applications, filter

performance greatly depends upon the firing angle of the thyristors.

Note: the values of EMI-filter components present in the same non-linear load (e.g. motor drive) can

influence the mitigation performance of passive harmonic filters. For Schaffner FN3418 (60Hz) filters the

following boundary conditions exist for the smallest frame sizes:

Filter

Typical

drive dc-linke choke

Max. recommended

EMI-filter X-capacitor

Expected THID *

FN3418-8-44

8.4mH

≤ 1.0µF

~10%

-

≤ 2.2µF

~15%

FN3418-11-44

6.7mH

≤ 1.5µF

~10%

-

≤ 1.5µF

~13%

FN3418-15-44

4.2mH

≤ 3.3µF

~10%

-

≤ 3.3µF

~15%

* System requirements: THVD <2%, line voltage unbalance <1%

All other FN3416 and FN3418 filters are not subject to any such limitations.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

12/43

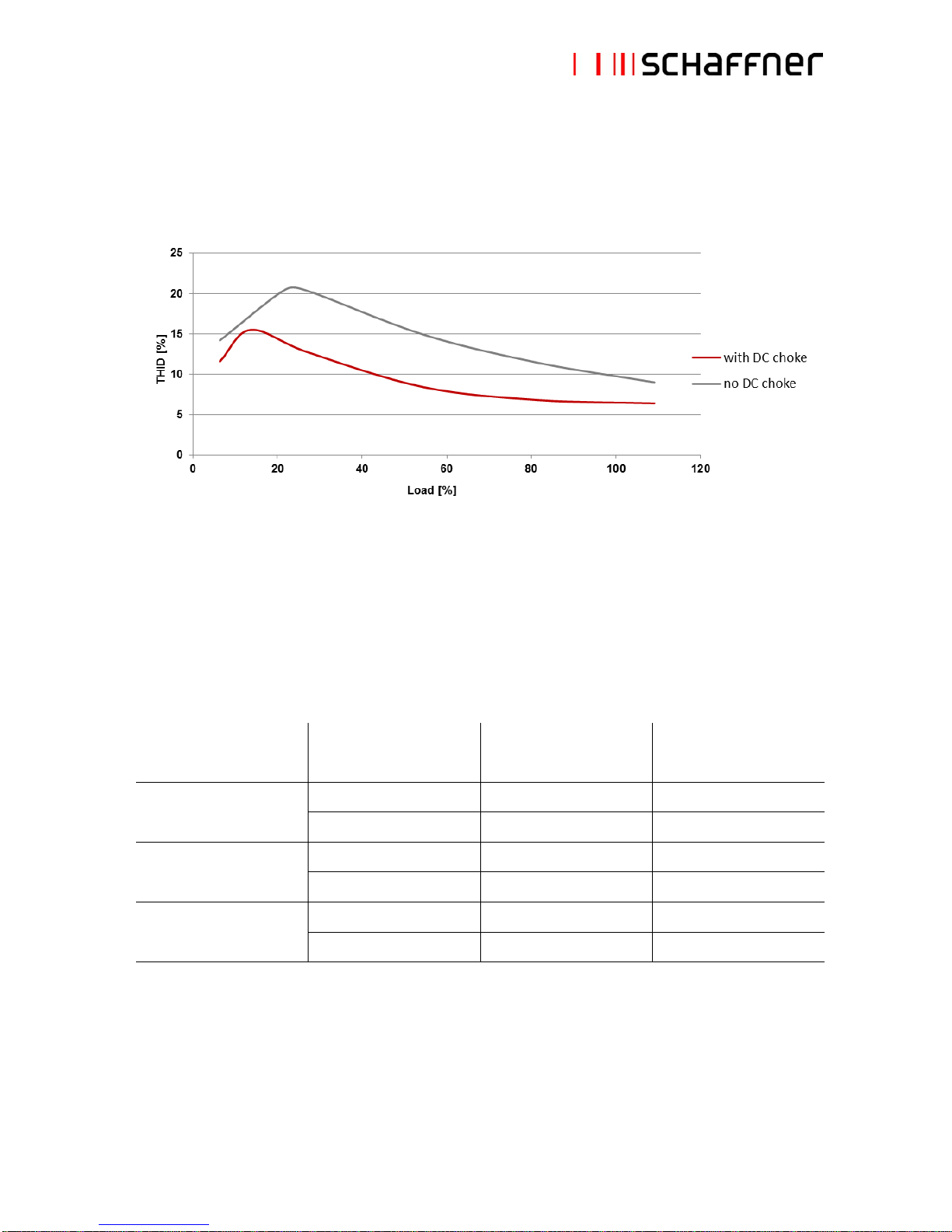

Power factor vs. load (diode rectifier front-ends)

Note: in SCR rectifier applications, filter characteristics greatly depend upon the firing angle of the

thyristors.

Schaffner Group

User Manual

ECOsine™ – Passive Harmonic Filters Economy Line

September 2012

13/43

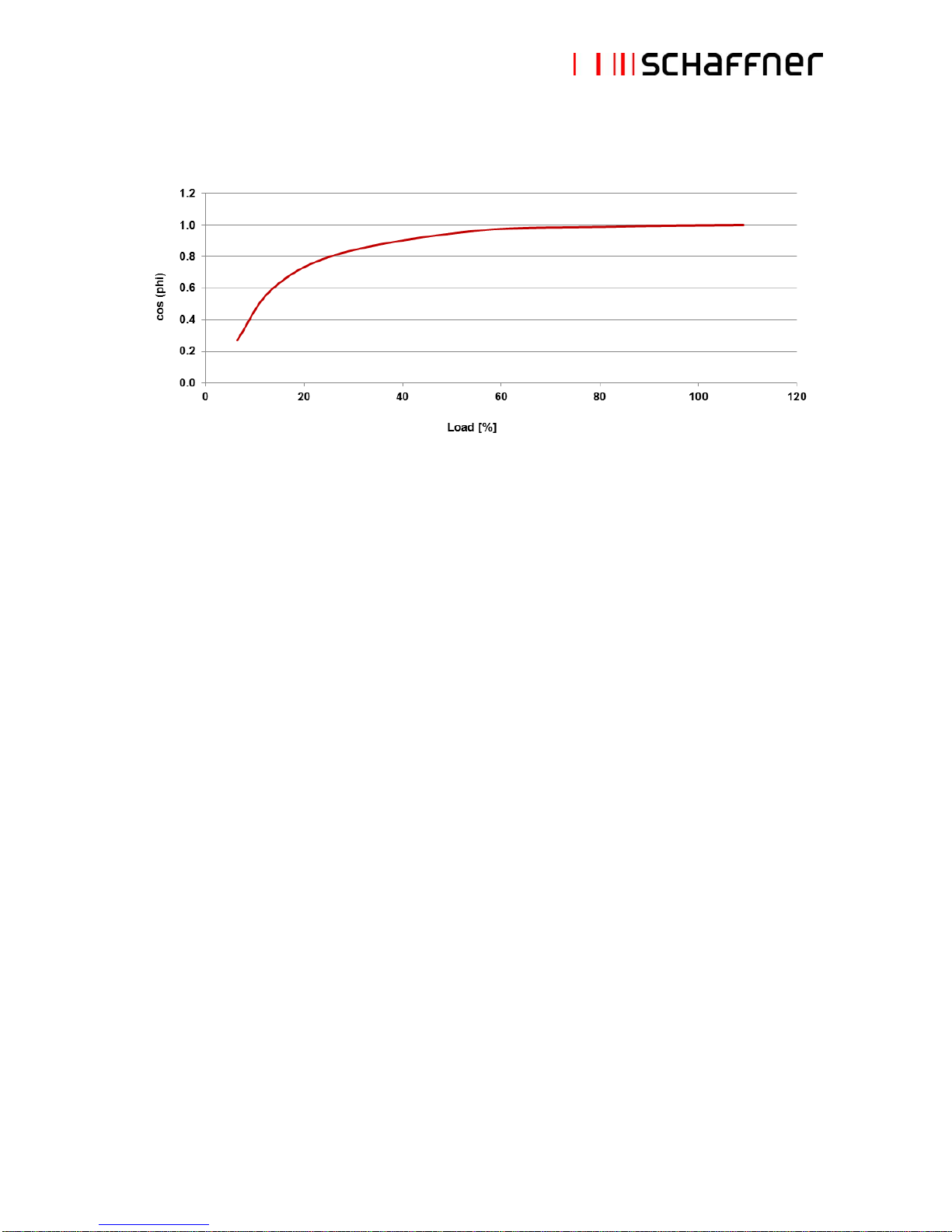

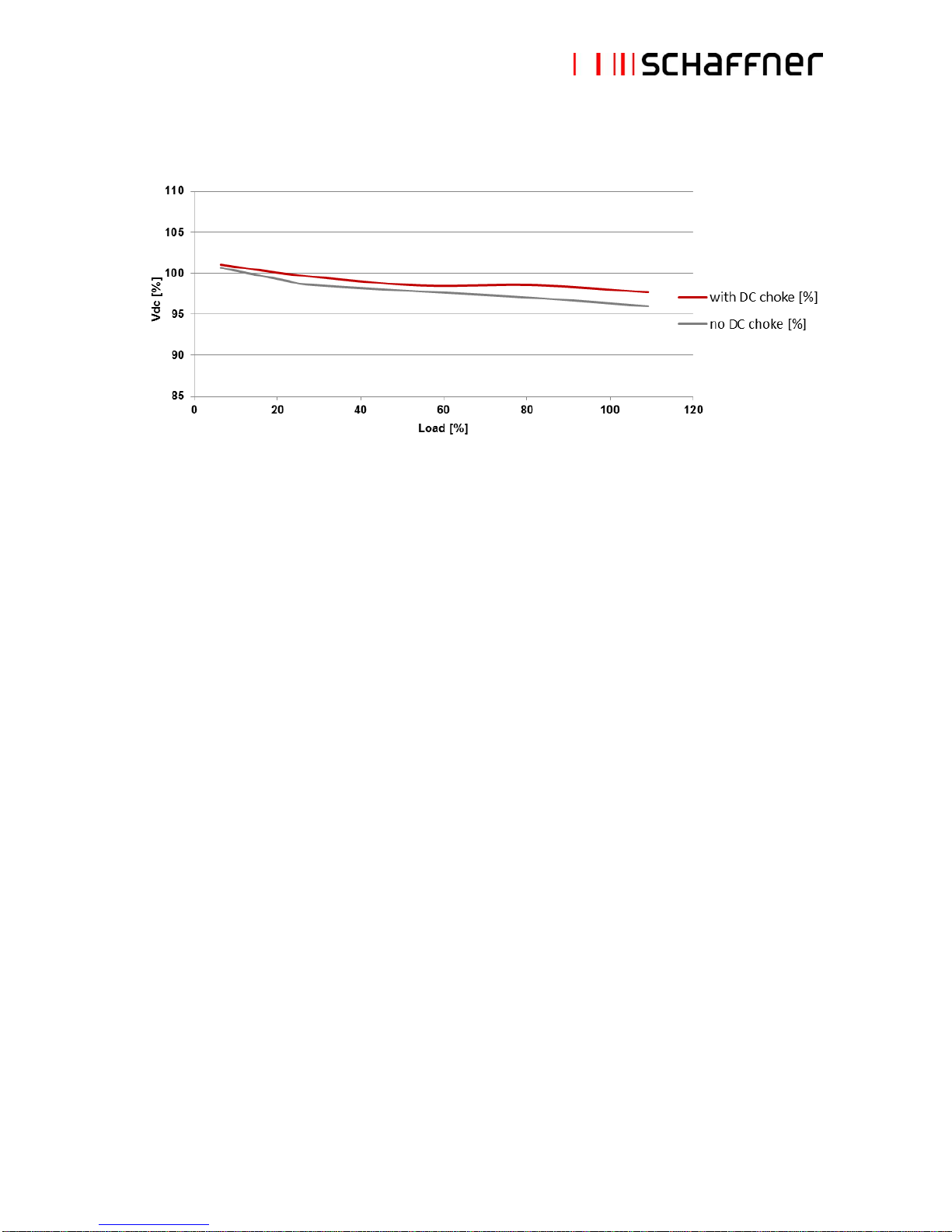

Drive dc-link voltage vs. load (diode rectifier front-ends)

Note: in SCR rectifier applications, filter characteristics greatly depend upon the firing angle of the

thyristors.

Loading...

Loading...