Page 1

USER’S MANUAL

TC2000

PORTABLE TEMPERATURE

CALIBRATOR

A universal stable and accurate temperature well for

calibrating

and verifying temperature sensors

Manual revisjon: June, 2002

Copyrighted © 2002

Page 1

Page 2

TC2000 user’s manual

Thank you

for purchasing a Tek Know temperature calibrator.

The Tek Know products are manufactured by Scan-Sense AS in

accordance with our high quality standards in design, choice of

components and workmanship in order to achieve maximum customer

satisfaction and to full our vision to be our customers “First Choice”.

The TC2000 is designed and manufactured by:

Scan-Sense AS Tel: + 47 33 36 30 00

Bekkeveien 163 Fax: + 47 33 36 31 80

N-3173 Vear www.scansense.no

NORWAY post@scansense.no

Scan-Sense AS reserves the right to make improvments or alterations

to our products without incurring any responsibility to make the same

improvments or alterations to products previously sold.

SCAN-SENSE AS

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted in any form by any means, electronic, mechanical, photocopying,

recording, or otherwise without the prior permission of Scan-Sense AS.

All efforts have been made to ensure the accuracy of this handbook. We at Scan-Sense

are always striving to improve our products and handbooks, therefore we would greatly

appreciate being informed of any errors found in our product or in its manual. The above

notwithstanding, Scan-Sense can assume no responsibility for any errors in this

handbook or of their consequenses.

Page 2

Page 3

TC2000 user’s manual

Contents

1 Introduction ...................................................................................................... 5

1.1 Certication ..................................................................................................... 5

1.2 Warranty ......................................................................................................... 5

1.3 Conventions used in this document ................................................................. 5

1.4 Introduction to dry-block calibrators ................................................................. 7

2 Preparation ...................................................................................................... 8

2.1 Unpacking and inspection ............................................................................... 8

2.2 Items supplied with the unti ............................................................................. 8

2.3 Input power connection ................................................................................. 10

3 Getting started ............................................................................................... 11

3.1 Operation controls and connections .............................................................. 11

3.1.1 Software Startup ........................................................................................... 12

3.1.2 LCD display ................................................................................................... 13

3.1.3 Well and insert ............................................................................................... 13

3.1.4 Numerickeypad................................................................................................14

3.1.5 Power on / off ................................................................................................. 14

3.1.6 RS232 Communicatiion ................................................................................. 14

3.1.7 Sensor connection ......................................................................................... 14

3.2 Sensor positioning, connection and calibration accuracy .............................. 15

3.3 Procedure to run calibration .......................................................................... 16

3.4 Procedure to run a liquid bath calibration ...................................................... 17

3.4.1 Calibrating a thermostat .................................................................................18

3.4.2 Calibrating a sensor .....................................................................................18

3.5 Finish the calibration ..................................................................................... 21

3.6 Defaults values .............................................................................................. 22

3.7 Pre-calibration cleaning of well and insert ..................................................... 23

3.7.1 Procedure for cleaning the interior of the temperature well and insert .......... 23

3.7.2 Procedure for cleaning the exterior of the insert ............................................ 24

3.7.3 Instructions for handling Liquid-lled Insert ................................................... 24

4 Operational menus, controls and indicators .................................................. 25

4.1 Introduction .................................................................................................... 25

4.2 Main Menu ..................................................................................................... 25

4.3 Manual Calibration ........................................................................................ 26

4.4 Conguration ................................................................................................. 27

4.4.1 Reference seonsor selection ......................................................................... 27

4.4.2 Reference sensor conguration ................................................................... 27

4.4.3 Reference correction ..................................................................................... 28

4.4.4 Test sensor .................................................................................................... 30

Page 3

Page 4

TC2000 user’s manual

4.5 System information ........................................................................................32

4.6 Settings ..........................................................................................................32

4.7 Automatic calibration ......................................................................................33

4.8 Semi automatic calibration .............................................................................35

4.9 Calibration report ........................................................................................... 37

4.10 Software upgrade utility ..................................................................................38

5 Technical tips ................................................................................................. 39

5.1 General information regarding accurate dry-block calibrations ..................... 39

5.2 The importance of testing instrument validation ............................................ 40

5.3 The importance of a traceable standard ........................................................ 40

5.4 Correct positioning of the probe in the temperature block ............................. 40

5.5 Calibrating a short-stem probe .......................................................................41

5.6 Using the calibrator as a reference when adjusting measuring devices

(meters/gauges) ............................................................................................ 42

5.7 The Time Constant inuence on temperature-well mass ............................... 42

5.8 When to take the calibration reading ............................................................. 42

5.9 The importance of cleanliness to attain high accuracy results ...................... 43

5.10 Insulating with glass wool to minimize cold/heat loss to surrounding air ....... 43

6 Specications ................................................................................................ 44

7 Electrical specications ................................................................................. 44

Page 4

Page 5

TC2000 user’s manual

1 Introduction

1.1 Cerication

Scan-Sense AS certies that the TC2000 complies with its published

list of specications at the time it was manufactured. Scan-Sense AS

also certies that its calibration measurements are traceable to

Norwegian Accreditation and to the calibration facilities of other

International Standards Organization (ISO) members. Scan-Sense AS

conrms that the TC2000 complies with the following standards:

EMC EN61326-1:1997+A1:1998: APP.A, immunity

test requirements for equipment intended for use in

industrial locations, as amended by EC Directive 9

2/31/Eec and the European Low Voltage Directive IEC

61010-1:90 + A1:92 + A2:95, amended by 93/68/EEC.

To ensure compliance, please use screened/shielded

serial communication leads (RS232).

1.2 Warranty

This product is guaranteed free from defects in material and

workmanship for one (1) year from the date of shipment. During this

warranty period, Scan-Sense AS will, as its option, either repair or

replace the TC2000 should it prove defective. The product must

be returned to a service facility designated by Scan-sense AS

for warranty service or repair (see our worldwide adress le http://

www.scansense.no). The foregoing warranty will not apply to defects

resulting from improper or inadequate maintenance by the purchaser,

purchaser-supplied software or interfacing, unauthorized modication

or misuse, operation exceeding the environmental specications for

the TC2000, or improper site preparation or maintenance. No other

warranty is expressed or implied by Scan-Sense AS, and Scan-Sense

AS shall not be liable for any direct, indirect, special, incidental or

consequential damages, whether based on contract, tort, or any other

legal theory.

1.3 Conventions used in this document

We have provided this section of the User’s Manual to help you

identify noteworthy symbols, terms and conventions used in this

manual. Look for the following:

Page 5

Page 6

TC2000 user’s manual

CAUTION:

Is used when a procedure may cause damage to equipment

or affect operation

WARNING:

Is used when a procedure may cause personal injury to the

reader or other persons

A SYMBOL USED AS A WARNING

TO DENOTE A HAZARD

CONFORMITÉ EUROPÉENNE

GROUND OR EARTH

Terms and denitions:

The term “insert” is interchangable with “insert adapter” as an

equipment identier for the 2-inch diameter, 6-inch long aluminum

insert pleced into the temperature well.

We dene calibration as being able to compare the ability of the

equipment to perform to a known standard. Temperature calibration

provides a means of quantifying uncertainties in temperature

measurement in order to optimize sensor and/or system accuracy.

LCD is a term meaning a quarter (1/4) VGA LCD screen.

CARE is a memory jogger to ensure best results and safe use of

the equipment.

Connect only to the correct power voltage/frequency (read the label

in the case).

Always clean the temperature well and insert before use, and always

remove the insert from the temperature well before moving or tran sporting the TC2000.

Replace worm connection cables (only with approved connection

cables).

Earthed (or grounded) power sources only should be used.

Page 6

Page 7

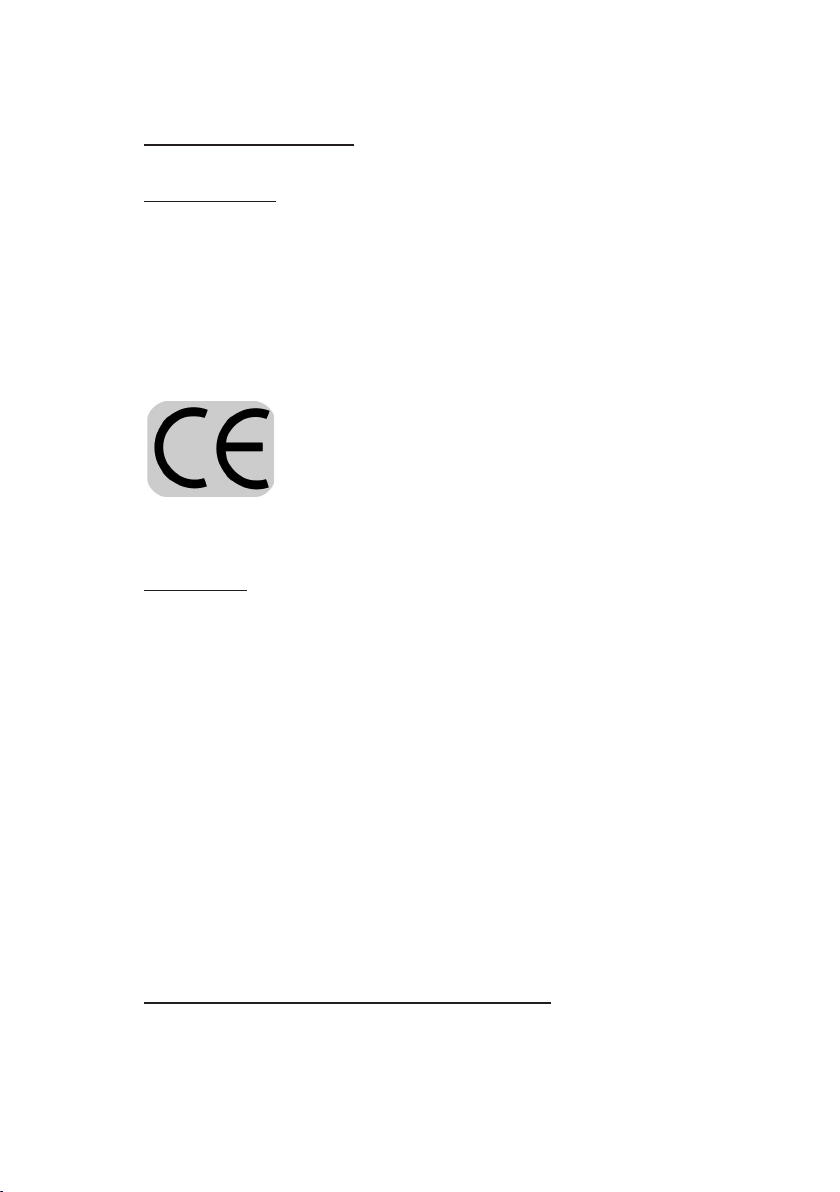

1.4 Introduction to dry-block calibrators

Dry-block calibration units provide the reliable heat (or cold)

source needed to verify the accuracy of industrial sensors such as

RTDs, thermocouples, thermostats, bi-metal thermometers or liquid in-glass thermostats. The TC2000 is designed to provide all the

advantages offered by “dry well” temperature calibrators: Convenience

of size, weight, speed, portability temperature range, stability and

software interaction via RS232 communication port. It is also designed

to be “user friendly”.

The TC2000 has a numeric keypad, or softkey controls, for setting

the well temperature. Menus are used to dene other data for the

TC2000. The display shows the dened “Set temperature”

and the resulting “Reference temperature” for the well temperature.

Connection points at Channel A and B allow a variety of sensor hook ups and an RS232 connection for local PC or remote computer.

The dry well in the calibrator is heat or cold source, and a reference

thermometer. That is, the thermometer (or sensor to be tested)

is placed in the well and its reading is compared to the reading of the

temperature in the calibrator’s display. The calibrator’s display shows

both the dened temperature, as set by the operator, and the actual

temperature that is measured by the internal reference sensor in the

well.

Figure 1: Dryblockschematics

EXTERNAL REF.

CALIBRATOR DISPLAY

INTERNAL REF.

SENSOR TO BE TESTED

PELTIER ELEMENTS

HEATING BLOCK

COMPARISON

Page 7

Page 8

TC2000 user’s manual

2 Preparation

2.1 Unpacking and inspection

* Inspect the packing container for any sign of damage. If the shipping

cartong is damaged, contact the carrier/shipper.

* Remove the unit from its packing container and inspect it for visible

signs of damage.

* Check that the equipment received matches the inventory. Report

ny discrepancies to Scan-Sense AS’s designated agent.

* Record any discrepancies from the inventory and/or visible damage

to the unit; see Figure 3 TC2000 orientation and location of items.

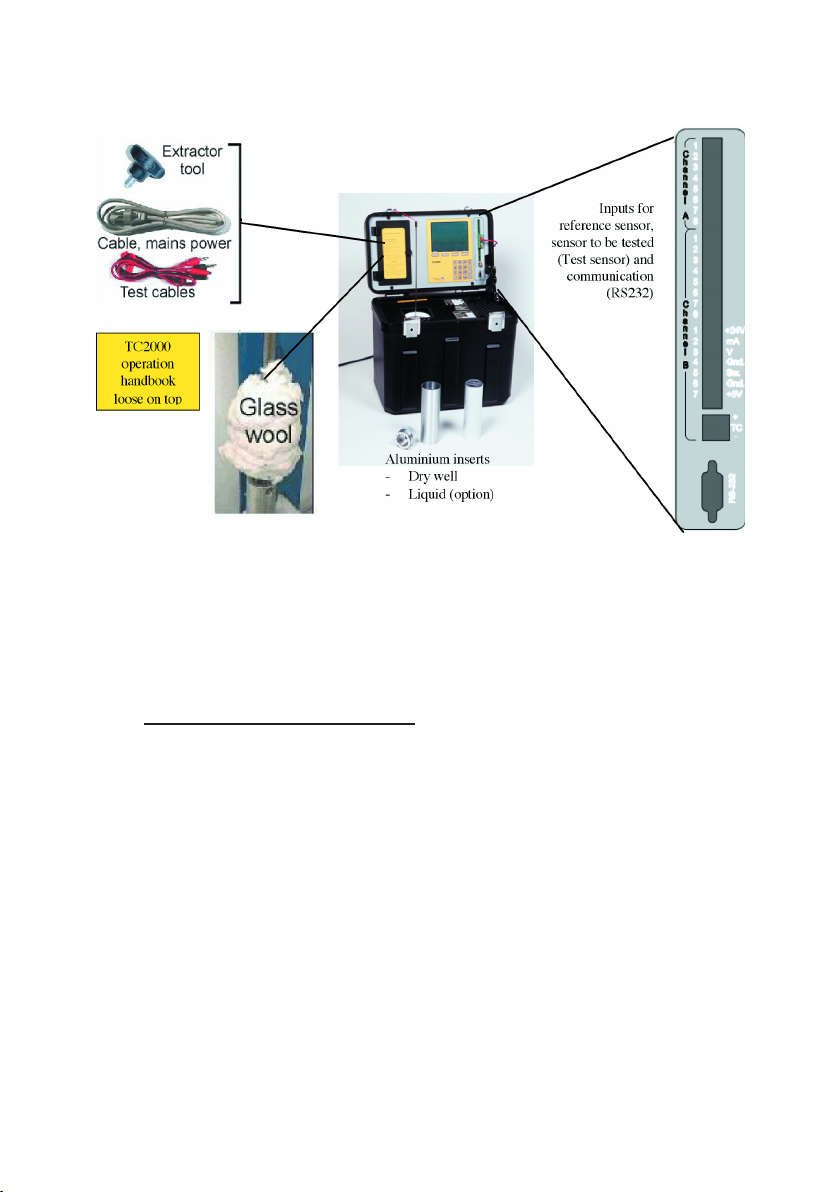

2.2 Items supplied with the unit

The cables, insert etc. that are used with the TC2000 are located in

compartments within the unit. The TC2000 Parts List identies each

by part name and part number.

TC2000 PARTS LIST

DESCRIPTION OF ITEM: (1 OF EACH ITEM)

* GLASS WOOL, 1 PACK

* TOOL, EXTRACTOR

* CABLE, MAINSPOWER, 100 VAC

DETERMINE TYPE REQUIRED, JAPAN

* CABLE, MAINSPOWER, 110 VAC

DETERMINE TYPE REQUIRED, USA

* CABLE, MAINSPOWER, 230 VAC

DETERMINE TYPE REQUIRED, EUR

* CABLE, MAINSPOWER, 230 VAC,

DETERMINE TYPE REQUIRED, UK

* CABLE, TEST, 1 SET

* USER’S MANUAL

* CALIBRATION CERTIFICATE

* RS232 CABLE

* CONNECTOR KIT

Page 8

Page 9

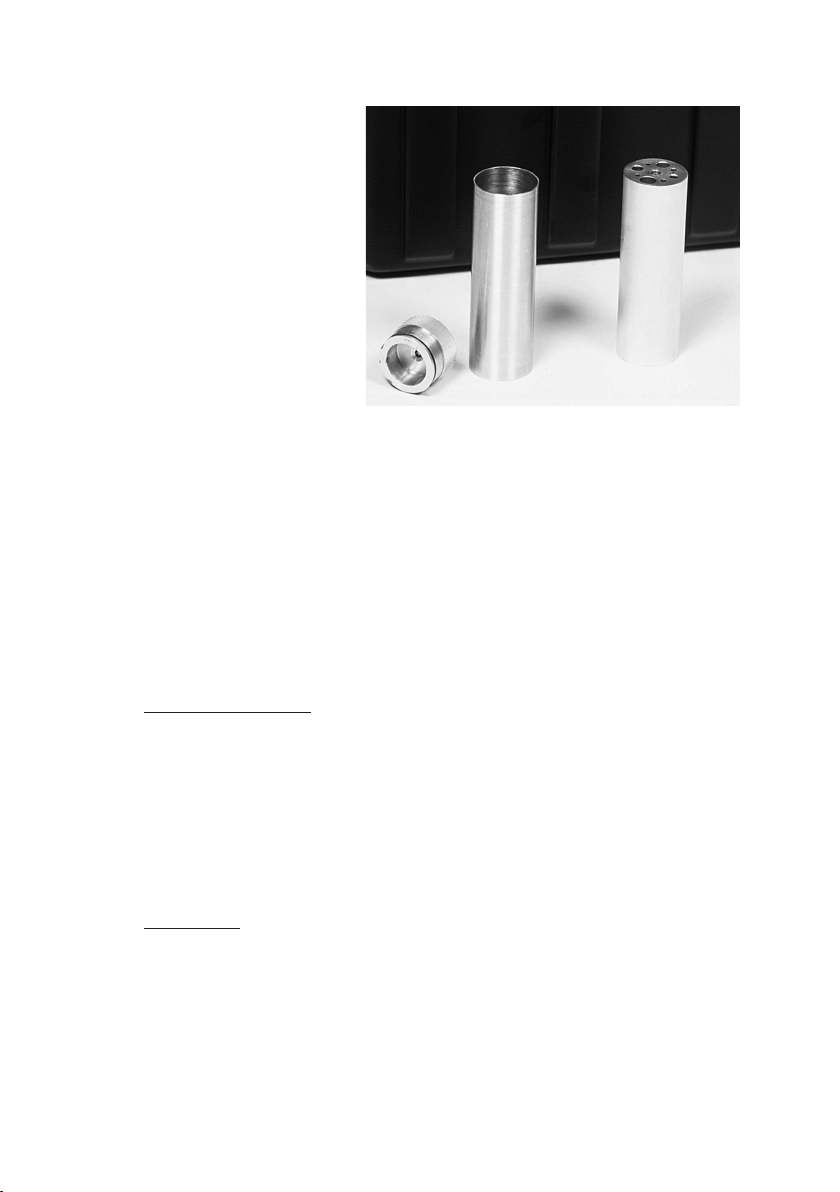

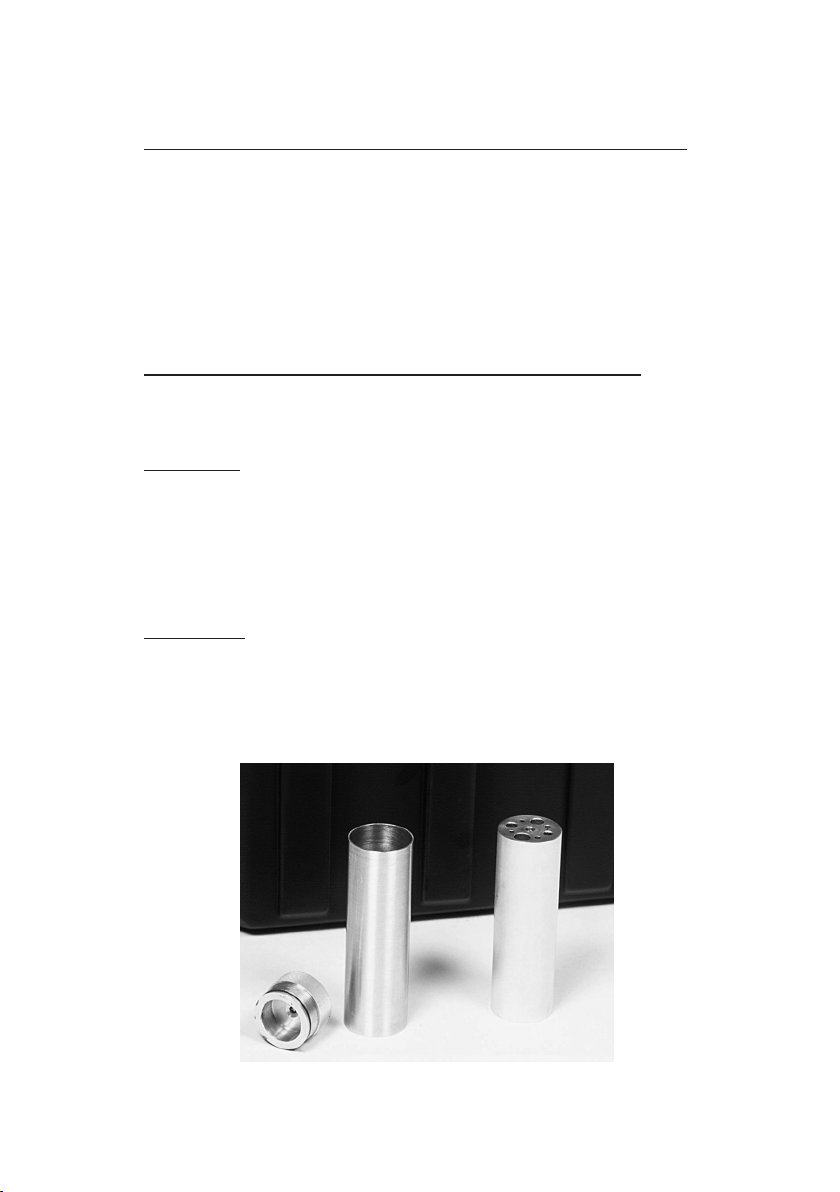

Aluminum inserts

- Dry Well

- Liquid lled (option)

Insert, aluminum, of 2“ x 6” or 50 mm x 150 mm diameter

and lenght with:

2 holes of 6.5 mm bore,

2 holes of 3,5 mm bore,

2 holes of 4,5 mm bore,

1 hole of 8 mm bore,

1 hole of 10 mm bore and

1 hole of 12 mm bore.

OPTIONAL ITEMS

Liquid-lled Insert, aluminium, of 2” x 6” or 50 mm x 150 mm

diameter and lenght with pop-off cap and impeller at bottom.

Insert, aluminum, blank of 2” x 6” or 50 mm x 150 mm ‘

diameter and lenght.

Oil to use with the Liquid-lled Insert.

CAUTION:

Care should be taken to avoid spillover into the temperature

well when using Liquid-lled Inserts. Use only recommended

oil/ liquids to ll the insert. Do not use glass wool with the

Liquid-lled Insert.

Page 9

Page 10

TC2000 user’s manual

Figure 3. TC2000 Orientation and location of items.

2.3 Input power connection

The required power is either 110 VAC or 230 VAC, 50/60 Hz. Always

connect the power cable supplied with your unit to a grounded or

earthed power outlet.

Page 10

Page 11

3 Getting started

This section contains a description of the TC2000 operator control and

connection points to help you get started quickly. The section also

provides instructions for pre-calibration cleaning of the well and

inserts (essential to the process) and step-by-step guidance for

performing a calibration.

3.1 Operation controls and connections

Very little operator interaction is required to begin calibration. The main

operator interaction is via unit’s softkeys (or keypad) and LCD display,

or via a (local) PC or other remote computer. Communication with

the PC is via the unit’s RS232 serial port connector. To begin a

calibration, you must:

* Fit the insert into the well.

* Place the sensor(s) into the well and use glass wool to insulate

the sensor.

* Power on the unit ON.

* Connect the sensor leads in Channel B.

* Congure the sensor to be tested.

* Set the temperature using the TC2000’s LCD display, softkeys or

numeric keypad.

Page 11

Page 12

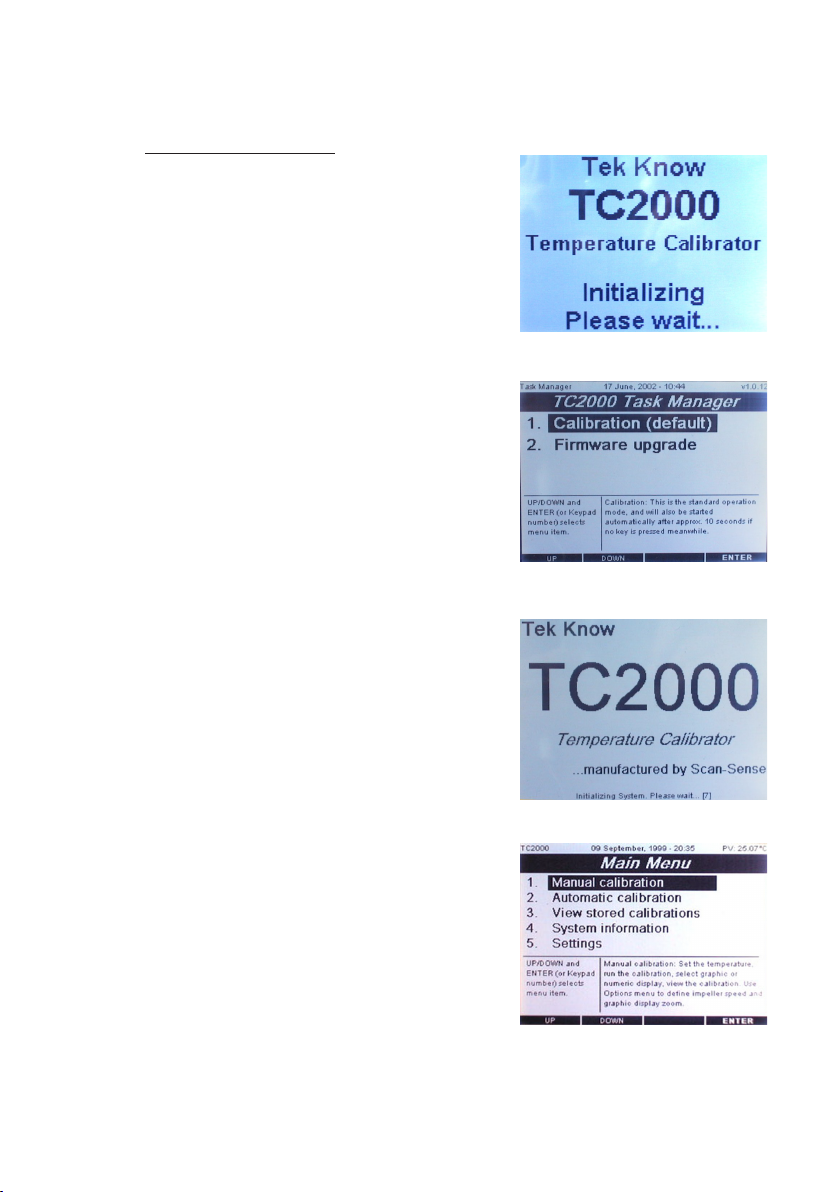

3.1.1 Software startup

When switching on the calibrator the rst

screen that is shown is a startup display

while the internal computer loads the

operating system Windows CE 2.12.

A Tast manager program will apear after

the CE 2.12 is loaded.

The task manager gives two choises

1. Calibration ( which is default) or

2. Firmware upgrade.

TC2000 user’s manual

start and will automatically be selected

after 10 sec. of the Task manager

appearing.

Choise 2. is used when a new software

or modication upgrade is to be entered

into the CE computer.

See seperate section for upgrade...

After choise 1. Calibration is selected

either by pressing enter when 1. is

highlighted or by default the computer

will load the TC2000 application software

This will take a couple of miniutes and the

status wil be shown at the lower part of

the screen viewing a countdown

proceedure. After loading is complete

the main menu screen will be displayed

and the calibrator is ready for calibration

tasks.

Choise 1. calibration is the normal

Page 12

Page 13

TC2000 user’s manual

3.1.2 LCD display

The menus and softkey-controls and information you need to dene

para-meters during a calibration are displyed in the unit’s

LCD (1/4VGA) display.

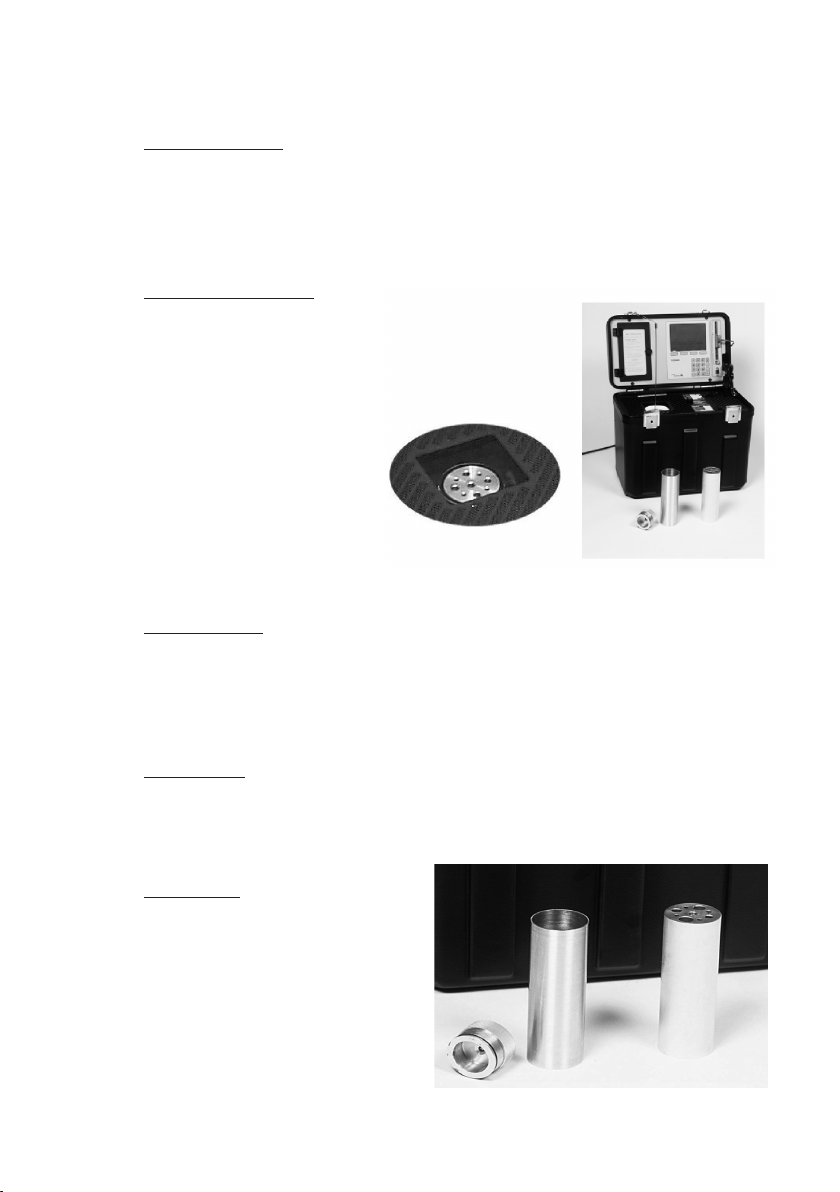

3.1.3 Well and insert

The well is an aluminum

block with a reference

sensor placed at its base.

The well heats or cools

to the temperature you

set. The insert has holes

bored to accommodate

most sensors.The insert

is aluminum and is

precision-turned to t the

well opening. An extractor

tool is provided to remove the insert from the well.

IMPORTANT:

The calibrator is calibrated with the external reference sensor

being insulated with supplied insulation material. to acheive

the same result use insulation round the sensor undergoing

test or calibration.

WARNING:

Handle carefully when extracting a Liquid-lled Insert because

the liquid in the insert will be hot and may cause burns to

any skin surfaces in contact with it.

CAUTION:

Care should be taken to avoid

spillover into the temperature

well when using Liquid lled

Inserts. Use only recommended

oil / liquids to ll the insert.

Do not use glass wool with

Liquid-lled Insert.

Page 13

Page 14

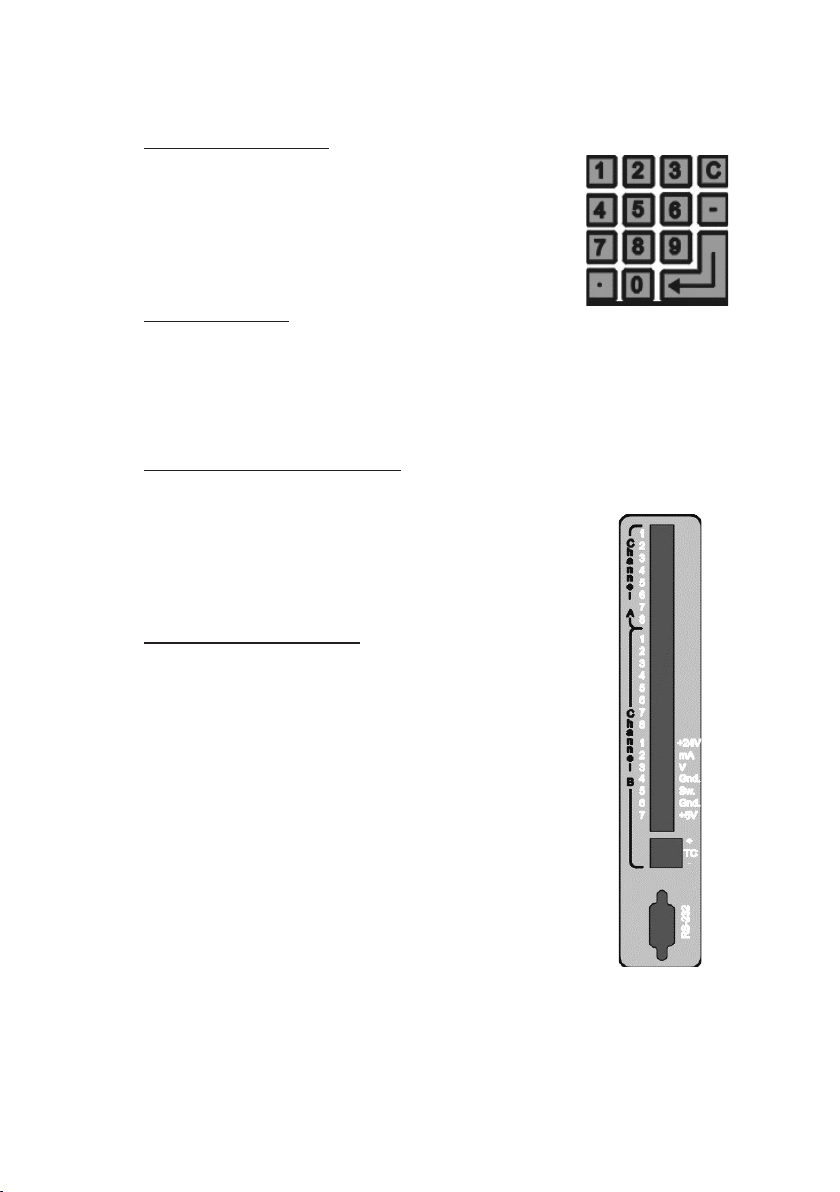

3.1.4 Numeric keypad

The numeric keypad is used for entering

data into the menus. It can also be used

instead of the UP or DOWN softkeys when

setting temperatures.

3.1.5 Power on/off

The power cable connection and the power

ON or OFF control is provided by a swich and-plug connector.

3.1.6 RS232 communication

The RS232 serial communication port is

used to connect the TC2000 to a PC during

re-calibration and for remote operation

when calibrating a sensor.

3.1.7 Sensor connection

Different types of sensors can be connected

for testing. Channel A is for the external

reference sensor. Channel B is for the

sensor under test (test sensor).

TC2000 user’s manual

Page 14

Page 15

TC2000 user’s manual

3.2 Sensor positioning, connection and calibration

accuracy

The calibrator well is always the source for heat or cold for the sensor.

However, it is possible to connect the sensor such that the calibrator

is the reference and the temperature reading is shown at the QVGA

display, or the sensor can be connected to an external measurement

device for the readnig.

You must place the sensor and the reference sensor as close to each

other as possible to ensure an accurant reading, regardless of what

reference and connections you use. To make the calculation accurate

when the sensors are placed at some distance from each other; you

can use a previously determined offset value to dene the correction

factor you need to adjust for the difference-in-distance between

sensors.

Note:

Note:

External ref.

External ref.

Note:

at same level

at same level

External ref.

at same level

Page 15

Page 16

TC2000 user’s manual

3.3 Procedure to run calibration

1. To obtain the best temperature transfer, clean the temperature well

and insert before each use. Instructions are provided in section 3.7.

2. Select the insert to be used and lower it into the temperature well.

3. Lower the temperature sensor into the insert. Use glass wool if it is

necessary to close off the top of the insert to prevent heat or cold

loss. (Glass wool is not to be used in liquid inserts).

4. Power ON the TC2000. The opening menu will appear. If necessary,

refere to the chapter 4 Operation menus, controls and indicators.

5. Connect the temperature sensor to your indicating instrument.

6. Select 2 Conguration to select the type of sensor to be tested.

7. On the Conguration menu, select 4. Test Sensor.

8. On the Conguration menu, select the CONFIG softkey to obtain

wiring information for Channel B.

9. If you are using an external reference sensor, select 2. Reference

sensor.

10. Select the CONFIG softkey to obtain wiring information for Channel A

(refernse sensor).

11. If you are using sensor-correction values, select 3. Sensor

correction and Table.

12. Select the CONFIG softkey to dene the Read value, True value and

tag identier in the table.

13. The default temperature setpoint is 25º Celcius (C). If you

want the temperature denored in F or K, see the Settings menu.

14. Press the MAIN MENU softkey to exit the Conguration menu and

save the new data.

15. Select 1. Calibration mode and use the UP or DOWN softkeys to

dene the temperature.

Page 16

Page 17

TC2000 user’s manual

3.4 Procedure to run a liquid bath calibration

1. Follow 1-15 in chapter 3.3

2. Choose the right liquid for the temperature range:

Water: 0 °C to 98ºC

Oil : 40 °C to 150ºC

NOTE:

Insulation pad has to be used at the top of the insert

during the calibration.

WARNING:

Use eye protection if you are using oil or water above

70ºC to avoide eye injury caused by splashing oil or water

bubbles.

WARNÌNG:

Be sure that you are using oil (liquid) which is approved for

the temperature range that you are working at.

3. Select 1. Calibration mode to select the Impeller speed.

4. On the Calibration menu, select OPTIONS and use the

numeric keys to set the impeller speed in %.

5. Impeller speed:

In order to get the best circulation in the liquid and thereby

avoiding gradients, it’s of great importance to select the

correct impeller speed. For example circulated water at too

high speed will produce air bubbles and turbulence, which

could lead to gradients in the liquid.

Gradients may also occur if the circulation is too low. The

amount of sensors to be tested at the same time in the liquid

insert will also have a signicant impact on the circulation.

As a general rule start with the following values if you are

testing a single sensor:

Water: 15% and up depending on amount of sensors.

Viscosity in the range 0 to 98ºC is almost the same.

Oil: 50% and up depending on amount of sensors and

temperature range since the viscosity changes a lot

over the range - 40 to 150ºC.

Page 17

Page 18

TC2000 user’s manual

6. TIPS! You will get an extreme stability (typically +/- 0.001ºC)

and accuracy as a stirred ice bath (0ºC). Just set the impeller

speed to 100% and set point to -3ºC and wait for the freezing

point to come.

3.4.1 Calibrating a thermostat:

Use the test cables to connect the thermostat to Channel B according

to the wiring information provided in the unit’s QVGA display. Use the

UP or DOWN softkeys to dene the temperature, then watch for the

display indicator to show if the switch is closed or open.

3.4.2 Calibrating a sensor:

Use the numeric keypad or UP or DOWN softkeys to dene the

temperature. The displayed Reference sensor temperature (the

temperature measured at the center of the temperature well) will

increase to the set value. When the Reference sensor temperature

has been stable at +/- 0.2ºC for at least 17 minutes (default), a * will

appear in the display to indicate that you can take the reading.

If you require a new setting:

Change the tempterature to the new value and wait for the * in the

display to indicate that you can take the reading.

Calibration mode graphical:

Page 18

Page 19

Page 19

Page 20

TC2000 user’s manual

Page 20

Page 21

Calibration mode numerial:

3.5 Finishing the calibration

7. When nished, adjust temperature to ambient and allow the

temperature well to cool to temperature below 70ºC.

8. Pull the temperature sensor(s) out of the insert.

9. Attach the extractor tool to the insert and pull the insert out of the

temperature well.

10. Switch power OFF.

11. Allow the unit to attain temperature below 70ºC before stowing

accessories.

Page 21

Page 22

TC2000 user’s manual

3.6 Defaults values

It is possible to change some of the parameter values displayed in

the menus.

Default set temperature = 25ºC (not changeable)

Default temperatre units = °C

Default reference sensor = Internal sensor

(located in the TC2000 well)

Default stabilization time = 17 minutes

Default stabilization ∆ T = ±0.2°C

Information is given in chapter’s 4.4 , 4.5 and 4.6 on how to alter

some of these parameters.

The following data is dened during manufacturing and cannot be cannot be changed

during its operation.

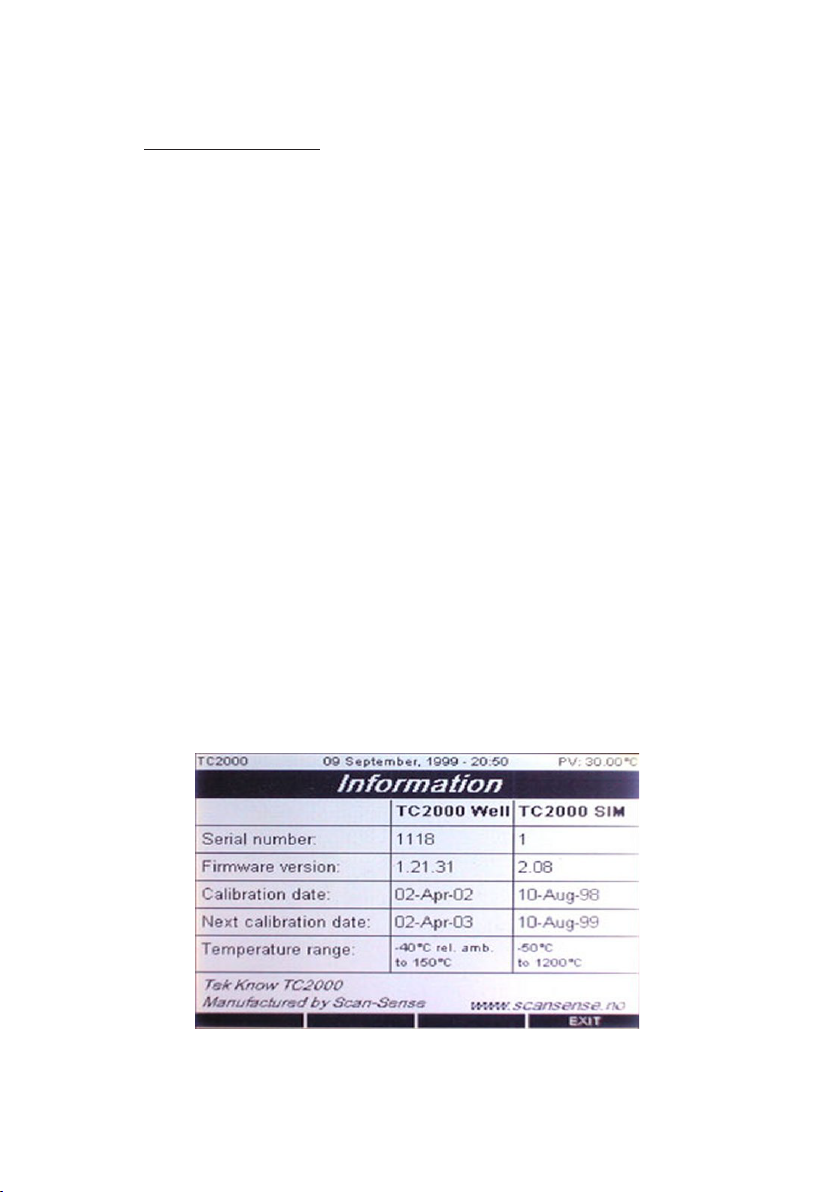

Serial number TC2000 Well Firmw.version TC2000 Well

Serial number TC2000 SIM Firmw.version TC2000 SIM

.

On completion of a calibration, the TCCal software will add the following data:

Calibration date TC2000 Well Next calibration date TC2000 Well

Calibration date TC2000 SIM Next calibration date TC2000 SIM

Page 22

Page 23

3.7 Pre-calibration cleaning of well and insert

If necessary, clean the temperature well (interior) and insert

(interior and exterior) before use. A dirty or oxidized surface can

affect the transfer of heat between the well and the insert and may

also cause the insert to stick in the well and be difcult

to remove.

WARNING:

Use eye protection if you are using compressed air to blow

debris out of the temperature well or insert openings to avoid

eye injury.

3.7.1 Procedure for cleaning the interior of the temperature

well and insert

1. Insert dry, white paper and turn it so as to remove all dust, dirt or

smudges from the interior of the temperature well to ensure optimal

heat trensfer to the temperature sensor.

2. If necessary, use compressed air to blow debris from the interior of

the temperature well and insert. (A small vacuum hose can be used

to extract debris).

3. If necessary, use a cloth with mild soap and water to remove

exessive contamination. Alcohol may also be used for this purpose.

4. Use a rod with a small piece of cloth attached to it (e.g. gun cleaning kit).

5. When using liquid cleaners, ensure that the well, insert and probe

is completely dry before placing the insert to the well.

Page 23

Page 24

TC2000 user’s manual

3.7.2 Procedure for cleaning the exterior of the insert

1. Insert dry, white paper and rub so as to remowe all dust, dirt or

smudges from the exterior surface of the insert to ensure optimal

heat or cold transfer from the temperature well.

2. Wipe clean with a clean, dry, lint-free cloth.

3.7.3 Instructions for handling Liquid-lled Insert

Only use clean oil, water or other liquids that have been authorized

for use in the Liquid-lled Insert.

CAUTION:

Care should be taken to avoid spillover into the temperature

well when using Liqued-lled Inserts. Use only recommended

oil/liquids to ll the insert. Do not use glass wool when using

Liquid-lled Inserts.

WARNING:

Handle carefully when extracting a Liqued-lled Insert

because the liquid in the insert will be hot and cause burns

to any skin surfaces in contact with it.

Page 24

Page 25

4 Operational menus, controls and

indicators

4.1 Introduction

The TC2000 is highly automated and requires minimal operator

interaction during a calibration. Normally, you are only required to set

the temperature necessary for the calibration and to congure the

sensor to be tested.

4.2 Main Menu

The Main Menu contains sub-menus to main available functions.

Menu entries are listed with a unique number. To select Main Menu

functions:

Press the UP or DOWN softkey,

and then press the ENTER softkey,

or

Select the function-number on

the numeric keypad (Do not press

ENTER when using a number from

the numeric keypad).

The selected menu line is inverted

The VGA LCD display will show Information regarding interaction,

controls and the available menus.

NOTE:

The TC2000 uses the dened conguration values until they are

changed. Therefor, it is important to ensure that the values are cor rectly dened before starting a calibration.

When power is swiched on, default opening screens will show until the

calibrator has booted and the main menu screen in visible.

Page 25

Page 26

TC2000 user’s manual

4.3 Manual Calibration

Select choice 1. Manual calibration,

to enter the manual calibration mode,

the Conguration menu will then be

displayed. This will enable you to

congure your reference sensor and

the type of sensor to be tested.

See chapter on Conguration for more

details on how to congure and select a

sensor.

Press Continue to enter into the manual

calibration mode.

The set point temperature can either be

set using the numerical keypad + enter

or using the softkeys. The softkeys will

give setpoint increments of 10°C

Pressing the MAIN MENU softkey will

take you back to the main menu.

Selecting the OPTIONS softkey in the

manual calibration mode will allow you to:

* Set the temperature resolution in the

graphical display using the ZOOM IN

and ZOOM OUT softkeys

* Toggle between the graphic and the

numeric displays.

* Dene the speed of the liquid insert

impeller in % of full speed

( 0 to 100 % in steps of 1 ).

Default values are:

* Set temperature = 25 ºC

* Swich test = OPEN

* Impeller speed = OFF (0%)

* Graphical resolution = 2 °C / horizontal line

Page 26

Page 27

4.4 Conguration

Important input connection information

to remember:

Channel A is the connector for the

external “Reference sensor”.

Channel B is the connector for the

sensor to be tested “Test sensor”.

4.4.1 Reference sensor selection

The NEXT softkey will allow you to

navigate and change each setting by

stepping up or down in the menu.

Use the SELECT softkey to select

the available settings.

Select 1. Internal, to use the calibrators

internal reference sensor. In the manual

calibration mode window the reference

sensor will be labeled with Internal.

Select 1. Pt100, to use an external

reference sensor.

Then press CONFIG to setup the

external reference sensor.

4.4.2 Reference sensor conguration

The external reference sensor can be

congured as either a 2, 3 or 4 wire

sensor. Use the UP and Down softkeys

to select the appropriate conguration.

Please note that in each conguration

the sensor will be terminated differently

to the 8-pin connector.

See advisory text giving pin connections.

Page 27

Page 28

TC2000 user’s manual

4.4.3 Reference correction

If you have selected an external sensor

as the reference sensor, its correction

values can be placed into the sensor

correction table. Sensor correction

will show the value as None

(internal sensor or no correction data),

and Table (sensor correction data).

The default selection is None.

Reference sensors that have calibration

data values which have been determined

during a calibration, can be placed in a

table to allow correction of the reference

sensor so that the result will be that the

reference sensor works in true

temperature.

1. Use NEXT softkey to move to 2. Sensor correction. The selected

“cell“ 2. Sensor correction will be inverted.

2. Press SELECT softkey to change your options.

3. Press the CONFIG softkey and use the UP or DOWN and

LEFT/RIGHT softkeys to dene the correction information and

tag number for the Pt100. Press EXIT when nished. The

correction values that are placed in the correction table are

normally produced during calibration of the sensor. For example,

when a sensor reads 21.0 temperature (Read value), the display

shows the correct value as 20.0 (True value). Read value is what

the sensor is reading, True value is what it should be reading.

4. Press EXIT to return to the 3. Sensor correction menu.

5. Move to another item in the menu by pressing NEXT, or press

MAIN MENU to save your changes.

When the Sensor correction table for the Pt100 is selected, it will

Page 28

Page 29

always be used whenever the Pt100 is dened as the reference

sensor for this conguration , until you change the conguration.

NOTE: It is very important to remember which reference sensor is

being used, and whether or not you need to use

the sensor correction table. If you are using the internal

temperature reference, return to 2. Reference sensor,

select INTERNAL and OK.

Page 29

Page 30

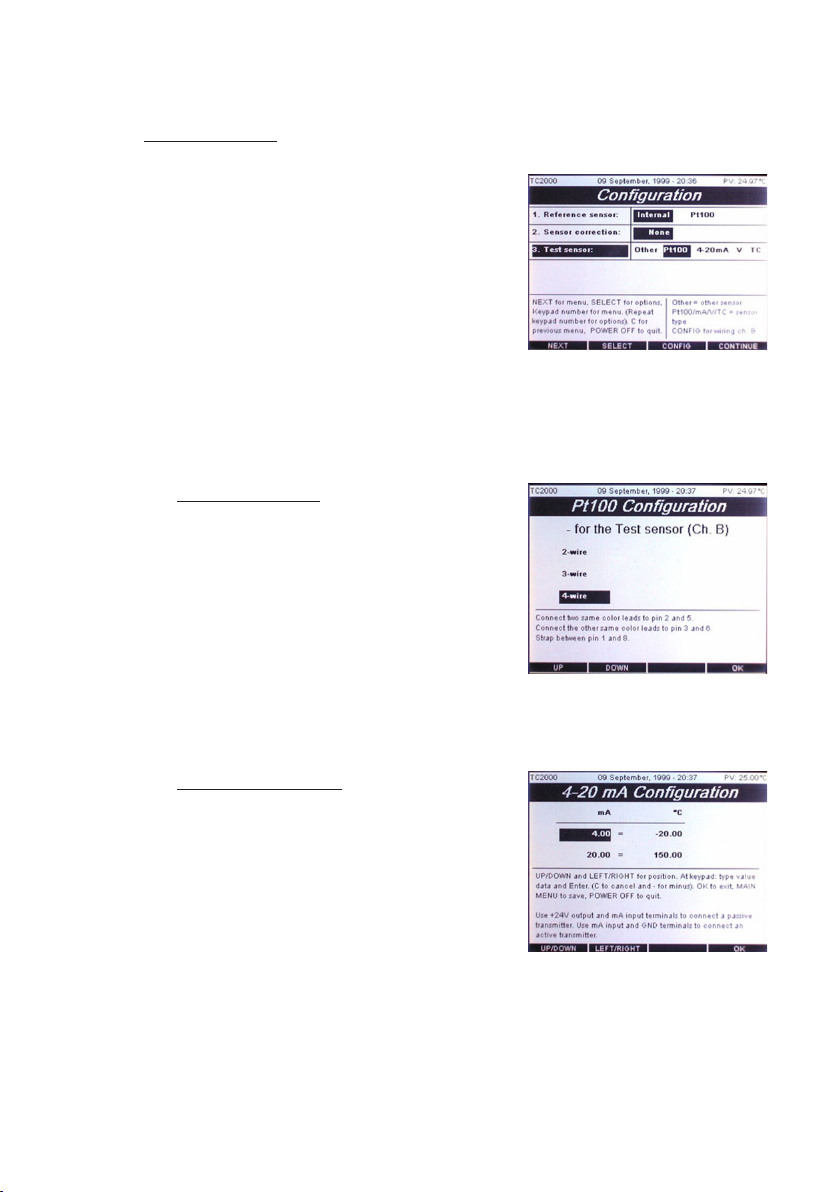

4.4.4 Test sensor

You can use 3. Test sensor: to select the

type of sensor to be tested and to obtain

information for connecting it to Channel B.

The default selection is Pt100.

To make a selection:

Use the NEXT softkey to move to

3. Test sensor: The selected “cell”

3. Test sensor is inverted.

Press SELECT softkey to change your

options.

1. Pt100 selection : Select Pt100 using

SELECT softkey and press CONFIG

softkey to obtain Channel B connection

information.

In CONFIG, use the UP or DOWN

softkeys to select the wiring for

obtaining the connection information

for the Pt100. Press the OK softkey

when nished. Then press CONTINUE

softkey in Conguration to start

manual calibration.

TC2000 user’s manual

2. 4-20 mA selection : Select 4-20mA

using SELECT softkey and press

CONFIG softkey to obtain Channel B

connection information.

In CONFIG, use the UP or DOWN

softkeys to dene the miliamphere

to temperature information from the

4-20 mA sensor, and the wiring

connection information for the 4-20 mA.

Press OK when nished. Then press

CONTINUE softkey in Conguration

to start manual calibration.

Page 30

Page 31

3. Volt selection : Select V using

SELECT softkey and press CONFIG

softkey to obtain Channel B connection

information connection information.

In CONFIG, use the UP or DOWN

softkeys to dene the voltage to

temperature information from the Volt

sensor, and the wiring connection

information for the Voltage snesor.

Press OK when nished.

4. Thermocouple selection : Select TC

using SELECT softkey and press

CONFIG softkey to obtain Channel B

Thermocouple Conguration

In Thermocouple Conguration

select the type of thermocouple using

the UP or DOWN softkeys.Press OK

softkey when nished .

5. Other sensor selection : Select OTHER using SELECT softkey

then press CONTINUE softkey to start the maual calibration

mode without using any of the inputs on channel B.

Other selection is used when the test sensor is connected to

external instrumentation.

Page 31

Page 32

TC2000 user’s manual

4.5 System information

The TC2000 contains the

following data that you cannot

alter during operation of the unit:

* Serial number TC2000 Well TC2000 SIM

* Firmware version TC2000 Well TC2000 SIM

* Calibiration date TC2000 Well TC2000 SIM

* Temperature range TC2000 Well TC2000 SIM

On completion of a re-calibration of TC2000, the TCCal

software will add the following data:

* Next calibration TC2000 Well TC2000 SIM

4.6 Settings

By highlighting either of the sections can

be set :

Temperature unit °C °F °K

Keypad beep ON OFF

Stabilization time 0 to 1hour

Stabilization span 0 to 20°C

Date and time

can be set

Page 32

Page 33

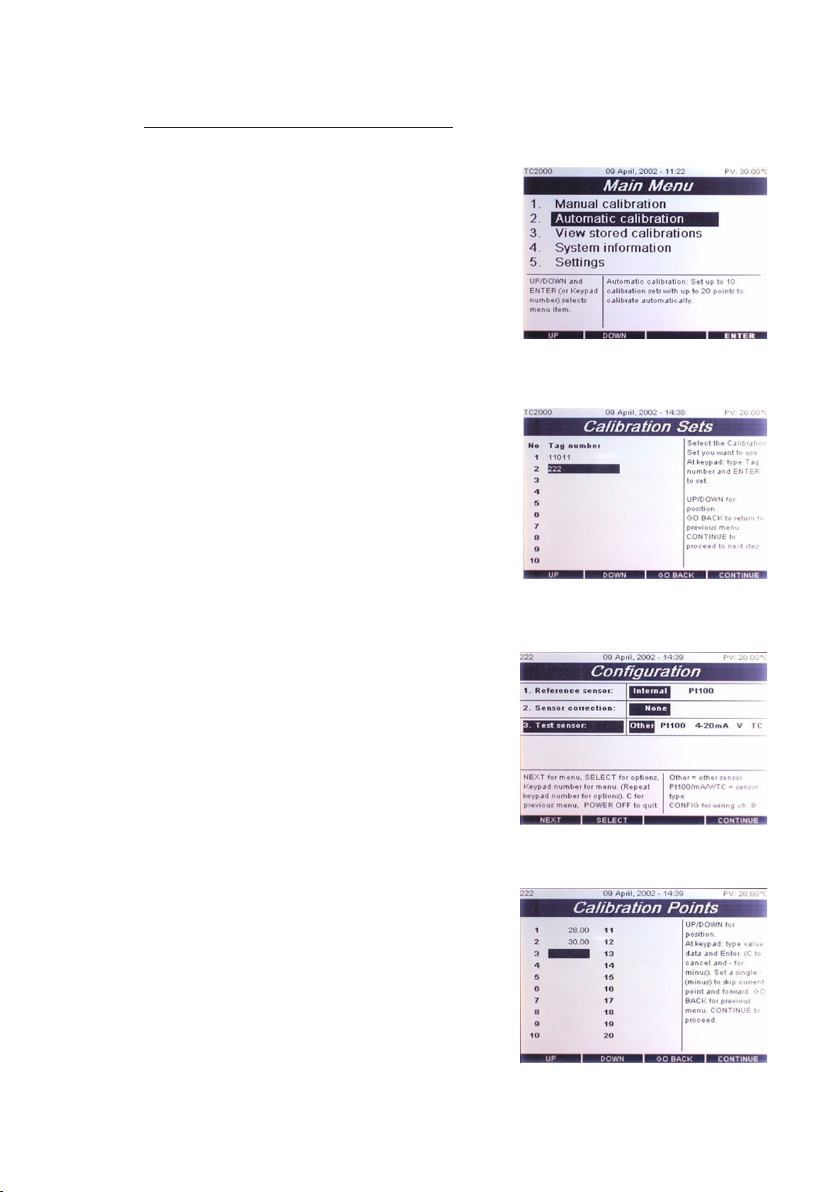

4.7 Automatic calibration

Select choice 2. Automatic calibration,

to enter the automatic calibration mode,

the Calibration Sets menu will then

be displayed. This will enable you to

set up your calibrator to perform an

automatic calibration task.

Each calibration set may consist of up to

20 calibration temperatures.

Up to 10 calibration sets may be

programmed. Each set is identied with a

tag number.

Press continue to enter the conguration

menu for your calibration set.

Select the conguration you want for your

calibration set.

See chapter 4.4 on sensor conguration.

Note the calibration set tag no. is

displayed in the top left corner of the

screen.

Press continue to enter

Calibration Points menu.

TC2000 user’s manual

Up to 20 different calibration point

temperatures can be set using the

numeric keypad.

The temperature range is from

-20°C to + 150°C

Press continue to start the automatic

calibration mode.

Page 33

Page 34

When the automatic calibration has

started the sensor temperatures will

be displayed in a graphical screen.

the calibration will continue automatically

through every set point temperature that

was set in the Calibration Set.

TC2000 user’s manual

one can dene to simulate at stable state

in order to force the TC2000 to make a

measurement and proceed to the next set

point temperature.

Pressing View List in the soft key menu

displays the calibration set points that

have alredy been performed.

After the last calibration set point

temperature has been completed the

Calibration nished menu will show.

In this menu there are options for

dumping the calibration data to a

computer or printing a calibration report

to a serial printer.

See section for serial port setup.

At any stage in the calibration process

Page 34

Page 35

4.8 Semi Automatic calibration

Select choice 2. Automatic calibration,

to enter the automatic calibration mode,

the Calibration Sets menu will then

be displayed. This will enable you to

set up your calibrator to perform an

automatic calibration task.

Each calibration set may consist of up to

20 calibration temperatures.

Up to 10 calibration sets may be

programmed. Each set is identied with a

tag number.

Press continue to enter the conguration

menu for your calibration set.

Select the conguration you want for your

reference sensor. See chapter 4.4

on sensor conguration.

For test sensor select Other to enter the

Semi Automatic Mode.

Press continue to enter

Calibration Points menu.

TC2000 user’s manual

Up to 20 different calibration point

temperatures can be set using the

numeric keypad.

The temperature range is from

-20°C to + 150°C

Page 35

Page 36

Press CONTINUE start the semi-automatic

calibration. The temperature of the well will be

shown on the LCD screen. At any time you may

choose to similate a stable condition of your test

sensor by selecting the SIM.STABLE softkey

option.

When the temperature and sensor is at a stable

state the calibrator will promt you for a

temperature entry of your test sensor. Enter this

using the numerical keypad on the TC2000. The

calibrator will then continue to the next set point

temperature.

TC2000 user’s manual

At any time during the semi-automatic calibration

the Calibration View menu can be activated

to show the progress in the calibration.

After the last set point temperature is stable and

a entry has been made the Calibration Finished

menu will be displaed.

from here you have the choise to dump the

calibration data to an other computer via RS232

or send a calibration report to a serial printer.

Page 36

Page 37

TC2000 user’s manual

4.9 Calibration report

T E M P E R A T U R E

C A L I B R A T I O N R E P O R T

Printing date: 23-Jan-02 14:51 Page 1 of 1

---------------------------------------------------------------------------------------------------------------------------------

Type of instrument : Temp node1

Model : Proto

Manufacturer : ScanSense AS

Serial number : 01

Tag/Id Number : 4

Temperature range : 0 -150 C

Output signal : 0-10 V

Accuracy : 0.5%

---------------------------------------------------------------------------------------------------------------------------------

No Set point Ref value Test value Deviation Date/time

1 28.00 C 28.00 C 29.24 C 1.24 C 9-Apr-02 14:02

2 30.00 C 30.00 C 31.06 C 1.06 C 9-Apr-02 14:19

---------------------------------------------------------------------------------------------------------------------------------

Type of instrument : Temperature Calibrator

Model : Tek Know TC2000 Sensor Interface Module : Input Ch.B OTHER

Manufacturer : Scan-Sense AS

Serial number : (SIM serial no.)

Temperature range : (i henhold til input valg)

Accuracy : (i henhold til input valg)

Calibration cert.no. :

---------------------------------------------------------------------------------------------------------------------------------

Sensor : TC2000 Internal Reference

Manufacturer : Scan-Sense AS

Serial number : 1072

Temperature range : +/- 0.18% F.S.

Calibration cert.no. :

---------------------------------------------------------------------------------------------------------------------------------

Air temperature : 22 C

Air humidity : 70 %

------- -------------------------------------------------------------------------------------------------------------------------

Date calibrated : 9-Jan-02 14:02

Company : ScanSense AS

INSTRUMENT (SENSOR) CALIBRATED

CALIBRATION POINTS

INTERMEDIATE INSTRUMENT

REFERENCE INSTRUMENT

CALIBRATION ENVIRONMENT

CALIBRATION STATUS

Calibrated by : Certied by :

Page 37

Page 38

4.10 Software upgrade utillity

In order to be able to upgrade the

application a program called TC2000

Upgrade Utillity must be run on a PC

and the TC20000 must be connected to

the PC through the serial port.

In the start up proceedure of the

calibrator select Firmware upgrade when

the Task manger appears on the screen.

This will set up the calibrator so that it

can receive a new application software

from the PC.

TC2000 user’s manual

The transfere time and staus will be

displayed on the PC TC2000 Upgrade

Utillity program.

Use a standard TC serial cable for

transfere.

After the transfere is complete the

calibrator will automatically install the

software internal and go to the

Main Menu.

Page 38

Page 39

TC2000 user’s manual

5 Technical tips

We dene “calibration” as being able to compare the ability of the

equipment to perform to a known standard. Temperature calibration

provides a means of quantifying uncertainties in temperature

measurement in order to optimize sensor and/or system accuracy.

This chapter provides general, informative information about dry-block

calibration and tips/hints to help you obtain accurate calibrations

with the TC2000 dry-block calibrator. Dry-block calibration is

recommended for calibrating industrial sensors such as RTD

(Resistive Temperature Device), thermocouples, thermistors, bi-metal

thermostats or liquid-in-glass thermometers, etc., because the dry block provides the reliable heat (or cold) source needed to verify the

accuracy of these devicec.

The dry-block calibrator offers a combination of accuracy, portability

and price for industrial calibration applications. Most dry-well

calibrators will produce a calibration accuracy of better than +/- 0.5ºC.

For comparison of sensors in a dry-well’s temperature block, hole-to hole uniformity is typically +/- 0.05ºC. These uncertainties are well

matched to the typical uncertainties of industrial temperature sensors.

5.1 General information regarding accurate dry-block

calibrations

The dry -block in the calibrator is often used as heat/cooling source

and a reference thermometer - i.e., the thermometer (or sensor to be

tested) is placed in the block and its reading is compared to the

reading of the temperature in the dry-block calibrator’s display. The

calibrator’s display shows both the dened temperature, as set by the

operator, and the actual temperature that is measured by the block’s

internal sensor. To ensure an accurat calibration, always observe the

following when using this type of calibration:

* Ensure the internal reference sensor and the sensor being tested

or calbrated is positioned close togehter in the insert. To do otherwise

will mean you can only guess the accuracy of the temperature shown

at the display.

* Ensure that display-accuracy includes traceable calibration report

with the dry-block calibrator.

* Use accurate reference thermometer during your calibrations.

Page 39

Page 40

TC2000 user’s manual

5.2 The importance of testing instrument validation

Validation of measuring instrument (as well as material measurement)

comprises testing and stamping by responsible calibration authorities

(in accordance with calibration directives). This validation testing

ensures that the measuring instrument meets the demands made

on its characteristic data and its maesuring technology properties,

more especially it determines whether the measurement deviation

contributions re within the error limit(s). Stamping (or marking) the

instrument documents that it has fullled these requirements

at the time of testing, and declares that the condition of the measuring

instrument is expected to remain within the tolerance range until the

date for revalidation (provided it is handled in accordance with the

rules of technology). Laws regulate which measuring instruments are

subject to mandatory validation and which instruments are not.

5.3 The importance of a traceable standard

A treceable standard is a procedure by which the “measurand”,

indicated by a measuring instrument (or a material measurement), is

compared with a national standard. In each level of standard, the

deviation in measurement has been determined beforehand by

calibration to a higher evel standard. This gives a calibration hieratchy

as shown in Figure 2 Calibration hierarchy.

5.4 Correct positioning of the probe in the temperature

block

The block in the TC2000 Temperature Calibrator can be used as either

a source of heat or cold, or as a thermometer reference. In other

words, the sensor can be placed into the temperature block and its

reading compared to the reading on the TC2000 display or it can be

compared with the reading from an external thermometer.

Page 40

Page 41

How the sensor is placed in the insert is of crucial importance to

obtaining accurate calibration measurements. Regardless of what type

of reference is used (i. e. internal or external) it is crucial that the

sensor and the reference be at an equal distance when placed into

the calibrator’s insert. For example, immersing a 2-inch sensor

assembly into a 6-inch well could yield an error up to 10ºC. This error

is inherent in all dry-well calibrators.

SENSOR TO

BE TESTED

NOTE: INCORRECT WAY

DOING CALIBRATION

INTERNAL REF. SENSOR

5.5 Calibrating a short-stem probe

We recommend the use of a comparison technique when calibrating a

short-stem probe. Do not compare the test reading to the dry-block

display; it will not give you the best results. It is more accurate to use

a reference probe of similar size and diameter. Size and diameter

greatly affect the amount of heat lost to ambient through the

probe stem. Therefore, the closer the sizes match, the more accurate

the comparison.

Your objective should be to achieve identical heat properties inside the

block to ensure that both sensors are sensing the same temperatures

in the same way. Any deviation will cause further error. Therefore, for a

satisfactory result, we recommend that you immerse the reference

probe and the test probe, both of which should be identical in size, into

their bore holes in the insert to exact same depth.

Our new “Liquid-lled Insert” eliminates this problem and can be used

to calibrate short probes of any length using the probe’s internal

sensor as the reference.

Page 41

Page 42

TC2000 user’s manual

5.6 Using the calibrator as a reference when adjusting

measuring devices (meter/gauges)

The temperature calibrator can

also be used as a calibrated

reference when adjusting

measuring devices such as

meters or gaughes. Using a

multi-hole insert allows multiple

meters/gauges to be adjusted at

the same temperature.

NOTE: RECOMMENDED CALIBRATION OF SHORT-STEM PROBES

SENSOR TO

BE TESTED

INTERNAL

REF. SENSOR

EXTERNAL

REF. SENSOR

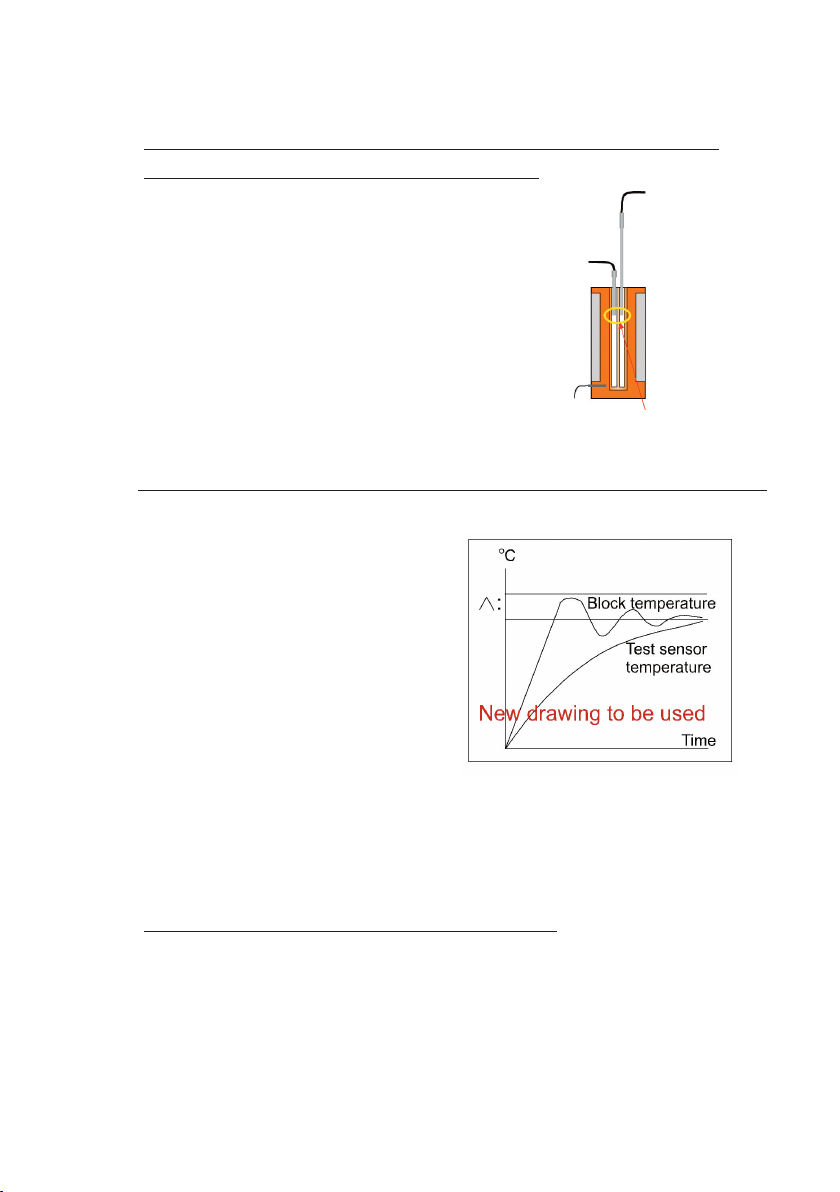

5.7 The Time Constant inuence on temperature-well mass

The sensor being tested has a

large time constant due to larger

mass and longer distance to the

cooling/heating elements.

Consequently, the temperature

curve for the internal reference

sensor and the sensor being

tested (center of insert) will be

different (see Figure 3

Temperature reference).

All Scan-Sense temperature

calibrators have an internal

reference sensor mounted in Figure 3. Temperature reference

the temperature block to react

quickly to temperature changes and thus reduce the resulting time

constant.

5.8 When to take the calibration reading

With the TC2000, when the REF temperature, that is the temperature

at the center of the well, has been stable +/- 0.2ºC for at

east 10 minutes (default value), the display will show the message

“Temperature stable, take reading”. Some temperature overshoot will

occur when approaching the SET temperature. However, this only

applies to the internal reference sensor. The sensor being tested has

Page 42

Page 43

a larger mass bacause of the insert, so it reacts more slowly to

temperature changes; see Figure 3 Temperature reference.

5.9 The importance of cleanliness to attain high accuracy

results

The ability of any dry-block calibrator to provide accurate calibrations

and performance depends on factors such as; sensor length,

sensor diameter, thermal-conductivity, the sensor position in the insert,

etc. cleanliness of the sensor, temperature well and insert is crucial to

the resulting accuracy of each calibration, you must ensure that all

surfacec are clean and free of dust, dirt, smudges and oxidaization.

5.10 Insulating with glass wool to minimize cold/heat loss

to surrounding air

Loss of cold or heat to the surrounding

air will occur when calibrating or testing

a long sensor thet is partly exposed

when it is placed into the calibrator.

When the sensor has a large exposed

mass, this cold or heat loss can affect

the accuracy of the calibration by as

much as 0.5ºC to 1ºC. As a general rule,

the effect of cold or heat loss is minimal

if the length of the part of the sensor that is exposed is less

than (<) 1/4 of its length. We recommend that the exposed part

of the sensore be insulated. Further, we recommend the use of

glass wool for insulation because, although there are different types

of insulating materials available, the material of choice must have

good insulating characteristics and be able to withstand extreme

operating temperatures. It must also be exible enough to be tucked

around the sensor, hence the choice of glass wool. Also bear in

mind that drafts can affect the stability of the calibrator. Please contact

ScanSense for further information.

Page 43

Page 44

TC2000 user’s manual

6 Specications

TEMPERATURE RANGE

Temperature range -40ºC* to +150ºC * Rel. ambient

Accuracy ±0.3ºC

Resolution 0.01ºC

Gradients at 95ºC w/water 0.06ºC

Stability (30 min. after normal stabilisation):

* As a dry block ±0.02ºC

* As a stirred liquid bath ±0.005ºC

* As a stirred ice bath ±0.001ºC

Uncertainty (best) <0.03ºC (depending on ext. ref.)

Well depth 155mm

Well diameter 50mm

Bath volume 261cm³

Thermostat test yes

Serial interface RS232

Power supply 110V(90-130V), 50/60Hz

230V(180-250V), 50/60HZ

Operating temp. 0 to +40°C

Dimensions 406x254x356 mm

Weight 15.5 kg without inserts

7 Electrical specications

INPUTS PORT A: RANGE RES. ACCURACY (% of reading)

Pt100 2, 3 and 4-wire* -50 to 800ºC 0.01ºC ±0.05ºC ±0.009%

Inputs Port B:

Pt100 2, 3 and 4-wire* -50 to 800ºC 0.01ºC ±0.05ºC ±0.009%

Type K -100 to 1370ºC 0.1ºC ±0,25ºC ±0,03%

Typr J -200 to 1200ºC 0.1ºC ±0.25ºC ±0.03%

Type E -200 to 1000ºC 0.1ºC ±0.25ºC ±0.04%

Type T -200 to 400ºC 0.1ºC ±0.25ºC ±0.03%

Type S 0 to 1760ºC 0.1ºC ±0.25ºC ±0.03%

Type R 0 to 1760ºC 0.1ºC ±0.25ºC ±0.03%

Type B +400to 1820ºC 0.1ºC ±0.25ºC ±0.03%

Type N -200 to 1300ºC 0.1ºC ±0.25ºC ±0.05%

Type L

Voltage** 0 to 10V 1µV ±0.25ºC ±0.02%

Current** 0 to 22mA 1µA ±2µV ±0.02%

Cold junction*** 0 to 40ºC 0.1ºC ±2µA ±0.25%

* Pt100 conforms to IEC751 and temperature scalev of ITS-90 TC input temperature drift 90ppm

** All thermocouple inputs are cold junction compensated V and mA input temperature drift 27ppm

*** Will in addition indicate negative inputs but these are not calibrated

Published specications may change without notice!

Page 44

Loading...

Loading...