Page 1

TC125

TC150

TC400

TC650

TEMPERATURE CALIBRATORS

USER’S MANUAL

Manual revision: 15 March, 2001

SCSMANP004

Copyrighted © 2001

Page 2

User’s manual TC calibrators

Thank you

for purchasing a Tek Know temperature calibrators.

The Tek Know products are manufactured by Scan-Sense AS in accordance with our high quality standards in design, choice of components and workmanship in order to achieve maximum customer satisfaction and to fulfil our vision to be our customers “First Choice”.

The TC125, 150, 400 and 650 are designed and

manufactured by :

Scan-Sense AS T el. +47 33 36 30 00

Bekkeveien 163 Fax: +47 33 36 30 01

N-3173 Vear www.scansense.no

NORWAY post@scansense.no

2

Page 3

User’s manual TC calibrators

Contents

1.1 Certification 5

1 .2 W arranty 6

1.3 Notice 6

1.4 Safety 7

2. INTRODUCTION 9

3. CALIBRATORS TC650 & TC400 11

3.1 PREP ARA TION 11

3.1.1 Preparing the Heating calibrators for use. 11

3.1.2 Power Requirements TC400 & TC650 13

3.1.3 Fuses 12

3.2 GETTING ST ARTED 13

3.2.1 Power On 13

3.2.2 Celsius – Fahrenheit Setting 14

3.2.3 Default setting 14

3.3 HOW TO EXECUTE CALIBRA TIONS 15

3.3.1 Calibration Procedure 15

3.3.2 Calibration at High T emperatures 16

3.3.3 Precaution 16

3.3.4 Test of thermostats 17

3.4 CALIBRA TION HINTS 18

3.4.1 Time Constants 18

3.4.2 High Accuracy 19

3.4.3 Heat loss to the Surroundings 20

3.4.4 Cleaning of block and Insert 2 0

4.0 CALIBRATORS TC125 & TC150 21

4.1 PREP ARA TION 21

4.1.1 Preparing the TC125 & TC150 for use 21

4.1.2 Power Requirements 21

4.1.3 Fuses 22

4.2 GETTING ST ARTED 22

4.2.1 Power on 22

4.2.2 Celsius – Fahrenheit setting 23

4.2.3 Default setting TC125 & TC150 2 4

3

Page 4

User’s manual TC calibrators

4.3 HOW TO EXECUTE CALIBRATIONS 25

4.3.1 Calibration Procedure TC125 & TC150 2 5

4.3.2 Calibration at Low T emperatures 2 6

4.3.3. Precaution 27

4.3.4 Test of Thermostats 27

4.4 CALIBRA TION HINTS 28

4.4.1 Time constants 28

4.4.2 High Accuracy 2 9

4.4.3 Heat loss to the Surroundings 29

4.4.4 Cleaning of Block and Insert 3 0

4.4.5 Method of calibration 30

5. RS 232 INTERF ACE 31

6. TECHNICAL SPECIFICA TIONS 32

6.1 TC125 & TC150 32

6.2 TC650 & TC400 33

4

Page 5

User’s manual TC calibrators

1.1 Certification

Scan-Sense AS certifies that this product meets its published

specifications at the time of shipment from the factory . Scan-Sense AS

further certifies that its calibration measurements are traceable to

Norwegian Accreditation Standards and to the calibration facilities of

other International Standards Organisation members (FSO).

Scan-Sense AS declares that the following products :

TC125, TC150, TC400 and TC650

confirm to the following standards :

EN 500081-1 : 1992

EN 500082-1 : 1992

EN 61010 : 1993

EN 60742-1

IEC 801-2

DS 5104

5

Page 6

User’s manual TC calibrators

1.2 Warranty

These Tek Know products are warranted against defects in material

and workman-ship for a period of one year from date of shipment.

During the warranty period, Scan-Sense will, at its option, either repair

or replace products that prove to be defective.

The product must be returned to a service facility designated by Scan-

Sense for warranty service or repair. The foregoing warranty will not

apply to defects resulting from improper or inadequate maintenance by

buyer, buyer supplied software or interfacing, unauthorised modification

or misuse, operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

No other warranty is expressed or implied. Scan-Sense shall not be

liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

1.3 Notice

All rights reserved. Reproduction of any part of this manual in any form

what so-ever without Scan-Senses expressed written permission is

forbidden.

All efforts have been made to ensure the accuracy of this manual.

However, should any errors be detected, Scan-Sense would greatly

appreciate being informed of them.

The above notwithstanding, Scan-Sense can assume no responsibility

for any errors in this manual or of their consequences.

6

Page 7

User’s manual TC calibrators

1.4 Safety

!

WARNING

The warning sign denotes a hazard. Such warning labels are fitted to

several places on the calibrators. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury or loss of

life. Do not proceed beyond a warning sign until the indicated conditions

are fully understood and met. If you are in doubt please contact your

nearest Tek Know dealer.

A dry block calibrator is constructed in such a manner that it is impossible

to operate it without generating hot areas that can be of danger. It is

very important the operator in charge of the calibrator is aware of the

potential dangers and that he relays this information to any other future

user.

There are no operational switches or buttons inside the calibrator that is

needed during operation. Opening the calibrator during operation is very

dangerous due to high temperatures and high voltages. The calibrator is

only to be opened by qualified service personnel.

After the calibrator has been operated it may be very hot. Do not turn

off the calibrator if the temperature is above 400°C. The correct

procedure is to set the setpoint to 50°C. and allow it to cool below

100°C.

If the calibrator switches itself down during operation, this can be due

to the internal safety trip switch. In these cases please contact your

dealer because a new fuse will have to be installed.

7

Page 8

User’s manual TC calibrators

Failure to ground the temperature calibrator properly can result in

personal injury . Use grounded ac power outlet.

Place the temperature calibrator on an even surface and make sure

that the air inlet for the fan is not blocked. Connect the power cable to

the temperature calibrator and press the Line switch on the bottom

panel to turn it on. The calibrator must not be covered. The calibrator

must be used in an environment with free space of 0.5 m. above and

0.1 m, open space on either side and with satisfactory ventilation or

temperature control.

8

Page 9

User’s manual TC calibrators

2. INTRODUCTION

The TC calibrators user manuals are intended to be used with the Tek

Know portable calibrators TC125, TC150, TC400 and TC650. The

TC Calibrators are constructed with a dry temperature variable well,

with a special designed temperature controller. A digital controller with

a dedicated CPU gives the TC calibrators flexible controllability . Digital

control provides for adaptive control of the temperature, which saves

the operator time, and assures high accuracy and easy setting of

temperatures. The local LCD displays both the set temperature and

reference temperature simultaneously.

The display of the TC400 & TC650 has a resolution of 0.1°C, however

the PID controller works with a resolution of 0.01°C.Effectively this

means that a better stability than stated in the specifications may be

obtained. In order to obtain this, the calibration conditions must be ideal.

First and foremost, the ambient temperature must be kept stable state

and longer stabilisation time for the calibrator must be allowed. This is

to compensate for the temperature influence on the electronics. They

come in a dedicated instrument case with assessories such as cable

and inserts.

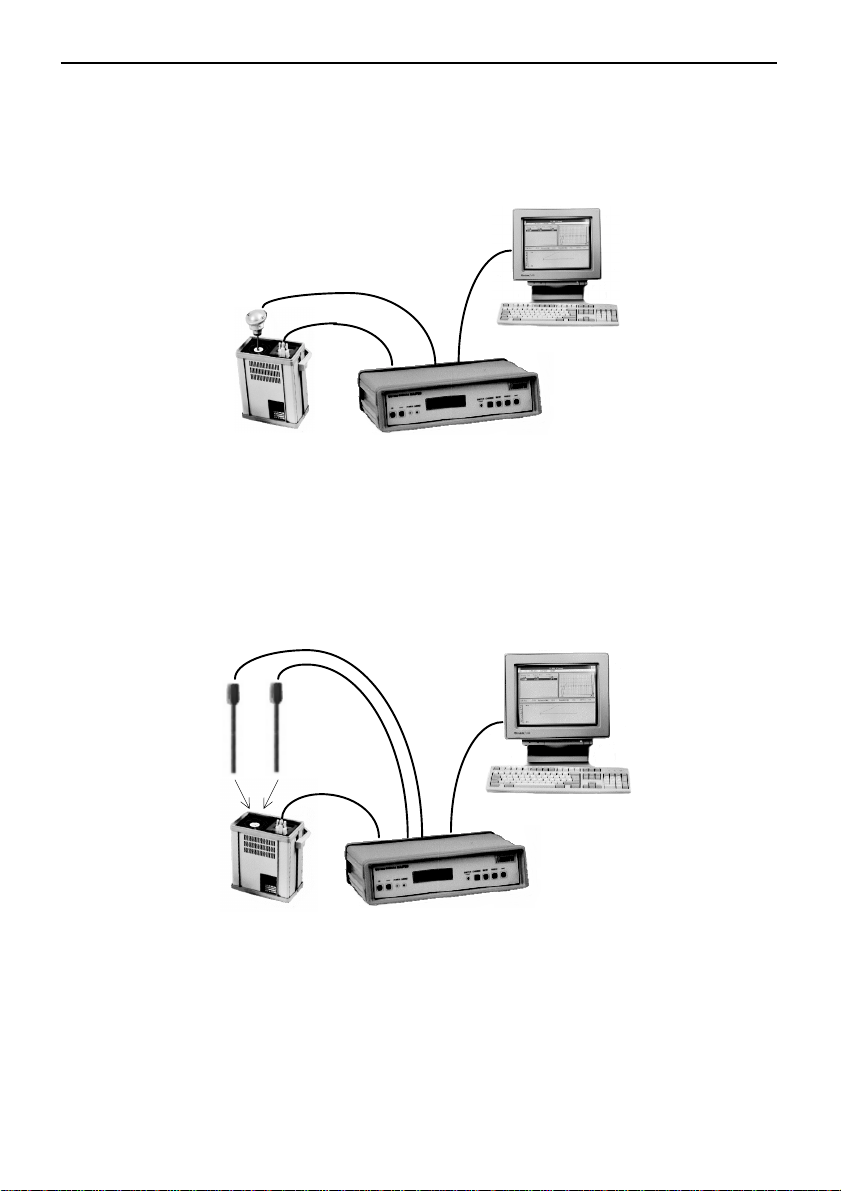

The communication port RS-232 comes as a standard feature, for use

with a computer in the calibration process. T ek Know provides optional

calibration software for temperature. The TC calibrators together with

the SC200 calibration software and SM300 Signal master will give you

an automatic calibration system.

9

Page 10

User’s manual TC calibrators

Pt 100 channel B

Figure 2-1, ‘Automatic calibration with internal reference’

RS232 Port 2

RS232 Port 1RS232 Port 1

PC with SC200

Signal Master SM300TC Calibrator

10

Ref. Pt 100

channel A

Pt 100

channel B

RS 232 port 1

RS 232 port 2

PC with SC200

Signal Master SM300TC Calibrator

Figure2-2, ‘Automatic calibration with external reference’

Page 11

User’s manual TC calibrators

3. CALIBRATORS TC400 & TC650

3.1 PREPARA TION

3.1.1 Preparing the heating calibrators for use.

Table 3-1. Items included with the TC400/650

temperature calibrators:

• T emperature calibrator: TC400 or 650

• Carrying case

• Power cord

• Test cable for thermostats

• T ool for changing inserts

• Insertion tube with 6.5 mm hole.

• Insertion tube with 10.5 mm hole.

• Calibration certificate

• User`s manual

3.1.2 Power requirements for TC400 & TC650

The TC400 & TC650 temperature calibrators areportable instruments

that require no physical installation other than connection to a grounded

ACpower source. Do not connect AC power until you have verified

that the line voltage is correct and that the proper fuse is installed.

Otherwise damage to the equipment may occure.

11

Page 12

User’s manual TC calibrators

Table 3-2. Power requirements for heating calibrators

100 Volt 110 Volt 230 Volt

Input Voltage 90 to 110 V 100 to 130 V 198 to 250 V

Frequency 50 to 60 Hz 50 to 60 Hz 50 to 60 Hz

Power consumption: 1600 W 1600 W 1600 W

Failure to ground the temperature calibrator properly can result in

personal injury . Use a grounded AC power outlet. Place the temperature

calibrator on an even surface and make sure that the air inlet for the fan

is not blocked. Connect the power cable to the

temperature calibrator and press the Line switch on

!

WARNING

m, open space on either side and with satisfactory ventilation or

temperature control.

the bottom panel to turn it on. The calibrator must not

be covered. The calibrator must be used in an

environment with free space of 0.5 m. above and 0.1

3.1.3 Fuses

The fuses used in the TC400 and TC650, 100 & 110Volt versions are

ø 6,3 x 32 mm ceramic 15 amp (slow).

The fuses used in the TC400 and TC650 -230 Volt versions are

ø 5 x 20 mm glass 10 amp (slow).

The fuses are placed next to the mains switch.

12

Page 13

3.2 GETTING ST ARTED

3.2.1 Power On

When the TC650 or TC400 is switched on the LCD display

on the front panel will show:

TC650 V 4.0

S.n. xxxxxx - ddmmyy

x denotes the serial no. of the calibrator and ddmmyy is the

date of last calibration of the calibrator.

V 4.0 indicates the software version no. of the calibrator.

After 10 sec. the display will show:

User’s manual TC calibrators

RE F. xxx.xxx C

SETPKT. xxx.xxx C

13

Page 14

User’s manual TC calibrators

3.2.2. Celsius – Fahrenheit setting

T o change the temperature notation press simultaneously the temperature

setting buttons é and ê while switching on the power to the calibrator .

The display will show :

C / F ?

After 2 sec. the display will show :

CELS. FAHR.

UP DOWN

Press the temperature setting button é for displaying the temperature

in Celsius. Press the temperature setting button ê for displaying the

temperature in Fahrenheit.

3.2.3 Default setting

The default setpoint setting for the

TC650 & TC400 is 30°C.

14

Page 15

User’s manual TC calibrators

3.3 HOW TO EXECUTE CALIBRA TIONS

3.3.1 Calibration procedure for TC400 and TC650

1. Move the adjustable handle to one side and turn on

the main switch.

2. Select an insertion tube that best fits the sensor to be tested.

3. Place the insertion tube in the thermo well and put the sensor

to be tested in the insertion tube. Insure that there is a good

contact between sensor and insertion tube.

Note: The insention tube and the well must be clean.

4. The sensor to be tested must be placed as close as possible

to the bottom of the thermo well in order to obtain the best

possible calibration result.

5. The calibration temperature Set Point is selected by means of

the arrow keys é and ê on the front panel of the calibrator.

It is indicated on the second line on the display SETPK.

6. The temperature in the thermo well is indicated in the first

line of the display REF .

7. The reference temperature will stabilise to the SETPKT.

When the reference temperature has been within ± 0.2°C of

the setpoint for 3 min. a * is visible after the last digit of the

REF. temperature. After 7 min. a second * appears behind

the SETPKT temperature, the calibrator is now stable to

within ± 0.1°C.

REF. 250.00*C

SETPKT. 250.00*C

15

Page 16

User’s manual TC calibrators

The temperature control within the TC400 and TC650 uses a specially

designed PID controller.Refer to chapter 3.4 for general requirements

to obtain the specified accuracy.

3.3.2 Calibration at high temperatures

The TC650 can generate temperatures up to 650 °C. The TC400 can

generate temperatures up to 400 °C. When using the calibrators at

these high temperatures, drafts may affect the stability of the calibrator .

In order not to expose the electronics to high temperatures over a longer

period of time we do not recommend to use the calibrator for more than

30 min. a time in the range 600-650 °C. If the calibrator os left at high

temperature for approximately 45 minutes, the setpoint will automatically

be set to 50°C.

3.3.3 Precaution

Please pay attention to the fact that RTD’s and thermocouples will

react quickly to temperature changes. Filled bulbs will react more slowly,

even if the TC650 & TC400 have stabilised, the sensor to be tested

may not yet have arrived at the indicated temperature. So when testing

filled bulbs or similar, please allow ample time for temperature

stabilisation. Some sensors are placed in long protection or extension

tubes and can not always be totally immersed in the thermo well.

16

!

WARNING

The metal tube may conduct heat or cold away from the

thermo well and this may affect the calibration. This can

be prevented by using insulation material on the part of the

sensor that is not immersed in the well. The part of the

sensor which is not immersed in the calibrator.

Never store the TC650 & TC400 in the carrying case

before the temperature in the thermo well is below 50°C.

Page 17

User’s manual TC calibrators

3.3.4 Test of thermostats

The TC650 & TC400 have a built-in test functions for thermostats.

Connect the alligator clips to the on-off function of the thermostat to the

calibrator. The test light on the front of the calibrator will indicate when

the on-off function of the thermostat is activated. Please pay attention

to the fact that thermostats react slowly to temperature changes.

17

Page 18

User’s manual TC calibrators

3.4 CALIBRATION HINTS

3.4.1 Time constants

The TC650 & TC400’s reference sensors are mounted in the heatingcooling block and will react quickly to temperature changes (small time

constant). The sensors being tested have a larger time constant due to

larger mass and longer distance to the heating-cooling elements.

Consequently the temperature curve for the reference sensor and the

sensor being tested will be different. See figure 3-1.

Figure 3-1 ‘ Temperature Response ‘

A certain overshoot will take place when approaching the Set point.

This speeds up stabilisation time for calibrations. This however only

applies to the reference temperature, as the sensor tested has a larger

mass and reacts more slowly to temperature changes, see fig. 3-1.

Consequently always make sure that before performing a calibration,

that the indicator for stable temperature in the calibrator (a * is shown

in the display after the SETPKT . temperature) is present and also take

into consideration the mass of the sensor being tested. When the TC650

& TC400 calibrators are used with the SC200 software in semiautomatic mode the PC will inform when the sensor being tested has

obtained its stabilisation.

18

Page 19

User’s manual TC calibrators

3.4.2 High accuracy

Dry block calibrators accuracy and performance to a given specification

is dependent on the fact that it reproduces the conditions for under

which it was calibrated.

There are several factors that may have affect on the accuracy of the

calibrators. There are variations in the sensor diameter , length, thermoconductivity, the active element’s position in the sensor, cleanness of

the sensor and fit in the insert from the one used during the calibrator’s

calibration.

For setpoint temperatures above 400 °C it is important that the insert

block and sensor is clean and free from dust and

oxidisation products.

Always approach the setpoint value from a lower temperature.

The TC400 and TC650 are calibrated dry using a Ø 6mm Industrial

Standard Reference Pt-100 sensor placed in the bottom of a 6,5mm

drilled insert.

Undrilled insertion tubes optional are availablefor custom drilling.

In these cases Scan-Sense can not guaranty for the calibrators

specifications.

To facilitate such calibration Scan-Sense can supply insertion tubes

with 2 or more holes according to specifications.

19

Page 20

User’s manual TC calibrators

3.4.3 Heat losses to the surroundings

When calibrating or testing a long sensor that is partly exposed when

mounted in the calibrator, a heat loss to the surroundings will result.

This is especially true when the sensor has a large mass that is exposed.

This heat loss will affect the accuracy , and may be as much as 0.5°C to

1.0°C. As a general rule, this error when minimal is the exposed length

of the sensor is < 1/4 of the length of the sensor. We recommend that

the exposed part of the sensor is insulated. See figure 3-2.

Figure 3-2 ‘ Insulation ‘

Different insulating materials may be used, but it is important that it can

withstand the operating temperatures and has a good insulation characteristic.It should be flexible so that it can be tucked around the sensor.

Consult Scan-Sense for further information.

3.4.4 Cleaning of block and insert

In order to obtain maximum and repetitive performance of the calibrator

it is important to keep the temperature well and insert as clean as possible

at all times. Before starting a calibration clean the well, insert and sensor

with fin wire wool or a wire brush. Gun bore cleaning tools are suitable

for this purpose (Not the solvents). Remove the dust from the cleaning

process with a dry cloth or compressed air.

20

Page 21

User’s manual TC calibrators

4.0 CALIBRA TORS TC125 and TC150

4.1 PREP ARATION

4.1.1 Preparing the cooling calibrators for use

Table 4 -1. Items included with the TC125 and TC150

Temperature Calibrator

• Temperature calibrator TC125 or TC150

• Carrying case

• Power cord

• Test cable for thermostats

• T ool for changing inserts

• Silicon oil and syringe

• Insertion tube 3.5 mm hole.

• Insertion tube 6.5 mm hole.

• Calibration certificate

• Users manual

4.1.2 Power requirements for TC125 and TC150

The TC125 and TC150 temperature calibrators are portable instruments

and require no physical installation other than connection to a grounded

ACpower source.

Do not connect AC power until you have verified that

the line voltage is correct and that the proper fuse is

!

WARNING

installed. Otherwise damageto the equipment may

occure.

21

Page 22

User’s manual TC calibrators

Table 1-2. Power requirements for cooling calibrators

110 Volt 230 Volt

Input Voltage 90 to 130 V rms 180 to 260 Vrms

Frequency 47 to 65 Hz 47 to 65 Hz

Power consumption 180 W 180 W

!

WARNING

Failure to ground the temperature calibrator properly can result in

personal injury. Use grounded AC power outlet.

4.1.3 Fuses

The fuse used in TC150 & TC125 is a

ø 5 x 20 mm 2.0 amp (slow) 230 V.

The fuse is placed next to the mains switch.

4.2 GETTING ST AR TED

4.2.1 Power on

When the TC125 or TC150 is switched on the LCD display on

the front panel will show:

22

Page 23

User’s manual TC calibrators

TC125 V 1.0

S.n. xxxxxx - ddmmyy

x denotes the serial no. of the calibrator and ddmmyy is the date of last

calibration of the calibrator. V 1.0 shows the software version no. of

the calibrator.

After 10 sec. the display will show:

RE F. xxx.xx C

SETPKT xxx.xx C

4.2.2 Celsius – Fahrenheit setting

T o change the temperature notation press simultaneously the temperature

setting buttons é and ê while turning on the power to the calibrator.

23

Page 24

User’s manual TC calibrators

The display will show :

After 2 sec. the display will show :

CELS. FAHR.

UP DOWN

C / F ?

Press the temperature setting button é for displaying the

temperature in Celsius.

Press the temperature setting button ê for displaying the

temperature in Fahrenheit.

4.2.3 Default setting TC125 and TC150

The default setpoint for the TC125 and TC150 is 20°C.

24

Page 25

User’s manual TC calibrators

4.3 HOW TO EXECUTE CALIBRA TIONS

4.3.1 Calibration Procedure TC125 & TC150

1. Move the adjustable handle to one side and turn on the main

switch.

2. Select the insertion tube that best fits the sensor to be tested.

3. Place the insertion tube in the thermo well and place the sensor

to be tested in the insertion tube and insure that a close contact

between sensor and insertion tube is obtained

4. The sensor to be tested must be placed as close as possible to

the bottom of the thermo well in order to obtain the best possible

calibration result.

5. The calibration temperature set point is selected by means of

the arrow keys and on the front panel of the calibrator. It is i

ndicated on the second line on the display SETPK.

6. The temperature in the thermo well is indicated on the first line

of the display . REF.

7. The reference temperature will stabilise to the SETPKT.

When the reference temperature has been within ± 0.2°C of

the setpoint for 3 min. a * is visible after the last digit of the

REF. temperature. After 7 min. a second * appears behind the

SETPKT temperature, the calibrator is now stable to within ±

0.1°C.

REF. -15.00 *C

SETPKT. -15.00 *C

25

Page 26

User’s manual TC calibrators

A PID controller is used in the TC125 & TC 150 to control the

temperature. Refer to chapter 4.4 for general requirements to obtain

the specified accuracy.

4.3.2 Calibration at low temperatures

The TC125 and TC150 can generate a temperature down to -40°C

below ambient temperature. In order to achieve best thermal coupling

to the sensor-undergoing test, a special silicon oil may be used in the

hole between the sensor and insert.

A calibration oil kit is supplied with the cooling calibrators TC125 &

TC150. This is a silicon based oil with a viscosity of 50 and has a

temperature range of -25

material present and comes in a 100 ml plastic bottle. It is supplied

together with a 10ml syringe in a plastic zip bag as a standard accessory

with all cooling calibrators from T ek Know . Additional oil is available

from Scan-Sense in 100ml bottles, order part no. P00267.

°C to + 150°C. The oil has no hazardous

26

Page 27

User’s manual TC calibrators

4.3.3. Precaution

Please pay attention to the fact that RTD’s and thermocouples will

react quickly to temperature changes. Filled bulbs will react more slowly

and even if the TC125 has stabilised, the sensor to be tested may not

yet have arrived at the indicated temperature. So when testing filled

bulbs or similar, please allow ample time for temperature stabilisation.

Some sensors are placed in long protection or extension tubes and can

not always be totally immersed in the thermo well.

The metal tube may direct heat or coldness away from

the thermo well, and this may affect the calibration. Using

!

WARNING

before the temperature in the thermo well is below 50°C.

4.3.4 Test of thermostats

insulating material on the part of the sensor, which is not

immersed in the calibrator, can prevent this.

Never store the TC125 and TC150 in the carrying case

The TC125 and TC150 has a built-in test function for thermostats.

Connect the alligator clips to the on-off function of the thermostat to the

calibrator. The test light on the front of the calibrator will indicate when

the on-off function of the thermostat is activated. Please pay attention

to the fact that thermostats may react slowly to temperature changes.

27

Page 28

User’s manual TC calibrators

4.4 CALIBRATION HINTS

4.4.1 Time constants

The TC125 and TC150’s reference sensor is mounted in the heatingcooling block and will react quickly to temperature changes (small time

constant). The sensors being tested has a larger time constant due to

larger mass and longer distance to the heating-cooling elements.

Consequently the temperature curve for the reference sensor and the

sensor being tested will be different. See fig. 4-1

Figure 4-1 ‘ Temperature Response ‘

A certain overshoot will take place when approaching the Setpoint

typically approximately 0.3°C. This speeds stabilisation time for

calibrations. This however only applies to the reference temperature,

as the sensor being tested has a larger mass and reacts more slowly to

temperature changes, see fig. 4-1.

Consequently make sure that before performing calibration, that the

indicator for stable temperatures in the calibrator (a * is shown in the

display after the SET POINT. temperature) is present and also take

into consideration the mass of the sensor being tested.

When using the TC125 & TC150 software in seem automatic mode the

PC will inform when the sensor being tested has obtained stabilisation.

28

Page 29

User’s manual TC calibrators

4.4.2 High accuracy

Dry block calibrators accuracy and performance to a given specification

is dependent on the fact that it reproduces the conditions for under

which it was calibrated.

There are several factors that may have affect on the accuracy of the

calibrators. There are variations in the sensor diameter , length, thermoconductivity, the active element’s position in the sensor, cleanness of

the sensor and fit in the insert from the one used during the calibrator’s

calibration.

Undrilled insertion tubes optional are available for custom drilling.

In these cases Scan-Sense can not guaranty for the calibrators

specifications. To fabricate such calibration Scan-Sense can supply

insertion tubes with 2 or more holes according to specifications.

4.4.3 Heat loss to the surroundings

When calibrating or testing a long sensor that is partly exposed when

mounted in the calibrator, a heat loss to the surroundings will result.

This is especially true when the sensor has a large mass that is exposed.

This heat loss will affect the accuracy, and may be 0.5°C to 1.0°C.

As a general rule, the exposed length of the sensor should be <1/4 of

the length of the sensor. We recommend that some of the exposed part

of the sensor be insulated.

See fig. 4-2.

Figure 4-2 ‘ Insulation

29

Page 30

User’s manual TC calibrators

Different insulating materials may be used, but it is important that it can

withstand the operating temperatures and has a good insulation

characteristic. It should be flexible so that it can be tucked around the

sensor. Consult Scan-Sense for further information.

4.4.4 Cleaning of block and insert

In order to obtain maximum performance of the calibrator, it is important

to keep the temperature well and insert as clean as possible. Before

starting a calibration, clean the well and insert. The insert is cleaned

using a dry cloth. Compressed air may be used to clean the well.

4.4.5 Method of calibration

During the calibration of the calibrator a silicon oil was used in the

insert in order to obtain a good thermal conduction between the insert

and the reference thermometer. This silicon oil was used during the

entire calibration of the calibrator.

We recommend therefore that silicon oil be used in the insert when

using the calibrator in order to obtain the same conditions as when the

calibrator was calibrated.

30

Page 31

User’s manual TC calibrators

RS 232 INTERF ACE

The TC Calibrators are supplied with an RS 232 port for connection to

a PC as a standard.

To ease the calibration taskand save man-hours, Scan-Sense have

developed a Windows® based software SC200.By using the SC200

software, automatic calibration can easily be done by the user.

Data can be presented in a calibration report that takes into account the

ISO 9000 specifications, procedures, set-up and traceability.

It will also generate a simple database for your sensors and temperature

circuits. The software will be of a significant time saving factor for the

operator, when at the same time it is almost self instructive in use.

SETUP:

Baudrate : 9600 baud

no parity

8 bits

1 stop bit

9 pin D-SUB female connector,

Tx pin 2

Rx pin 3

Gnd pin 5

The TC Calibrators communicate with the SC200 PC based calibration

software using an eight-byte communications protocol. All parameter

settings and control can be set remotely using the SC200 software.

31

Page 32

User’s manual TC calibrators

6. TECHNICAL SPECIFICA TIONS

6.1 TC125 & TC150

lledoM521CT051CT

*egnarerutarepmeTC°521+otC°04-C°051+otC°04-

egnardetarbilaCC°521+otC°02-C°051+otC°02-

noituloseR10.0C° 10.0C°

ycaruccA3.0±C° 3.0±C°

ytilibatS30.0±C° 30.0±C°

emitgniloocxaMnim02nim02

emitgnitaehxaMnim51nim05

htpedlleWmm011mm011

retemaidlleWmm91mm91

tsettatsomrehTseysey

232SRseysey

egatloveniL)V031-09(011)V031-09(011

noitpmusnocrewoPW081W081

snoisnemiDmm572x521x522mm572x521x522

thgieWgk8,6gk8,6

egnar.pmetlanoitarepO0C° C°04+otC°04+otC°0

* Min. temp is relative to ambient temp.

32

)V062-081(032)V062-081(032

Page 33

User’s manual TC calibrators

6.2 TC650 & TC400

lledoM004CT056CT

*egnarerutarepmeTC°004+otC°05C°056+otC°05

egnardetarbilaCC°004+otC°05C°056+otC°05

noituloseR1.0C° 1.0C°

ycaruccA3.0±C° 5.0±C°

ytilibatS30.0±C° 50.0±C°

emitgnitaehxaMnim21nim81

htpedlleWmm551mm551

retemaidlleWmm62mm62

tsettatsomrehTseysey

232SRseysey

egatloveniLCAV011CAV011

V011-09V011-09

egatloveniLCAV011CAV011

V031-011V031-011

egatloveniLCAV032CAV032

V052-891V052-891

noitpmusnocrewoPW0061W0061

snoisnemiDmm572x521x522mm572x521x522

thgieWgk3,7gk3,7

egnar.pmetlanoitarepO0C° C°04+otC°04+otC°0

33

Page 34

User’s manual TC calibrators

Notes:

34

Page 35

Notes:

User’s manual TC calibrators

35

Page 36

User’s manual TC calibrators

Notes:

36

Loading...

Loading...