Page 1

65

ASSEMBLY AND INSTRUCTIONS MANUAL SCAN 65

UK

SCAN

UK - ASSEMBLY AND INSTRUCTIONS MANUAL

SCAN

65

Page 2

2

65

UK

SCAN

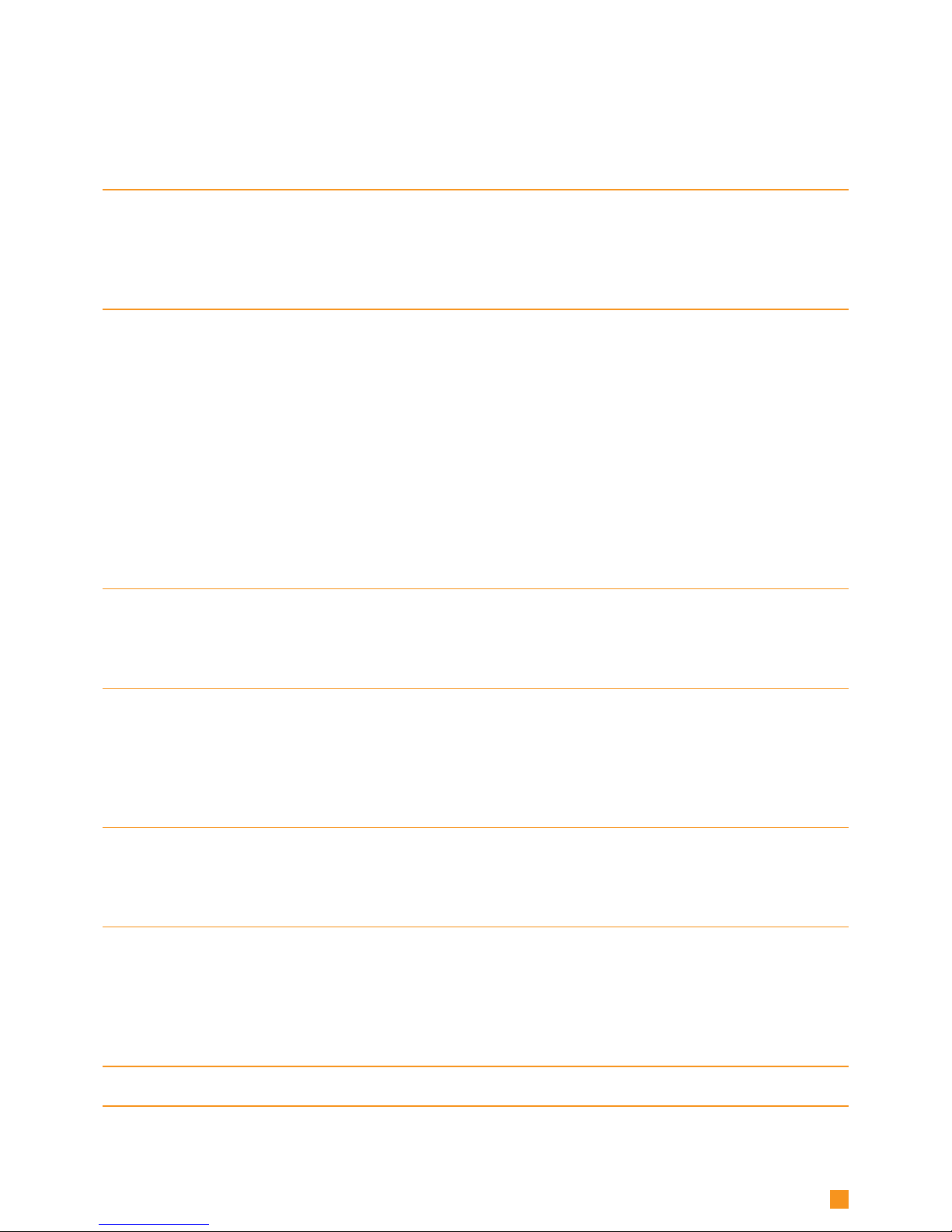

Scan 65-1

Steel sides

Scan 65-2

Steel sides

and side windows

Scan 65-1 LB

Lowbase,

steel sides

Scan 65-2 LB

Low base, steel

sides and side

windows

Scan 65-3

Natural stones

Scan 65-4

Natural stones,

and side windows

Scan 65-5

Steel sides,

baking oven

Scan 65-6

Steel sides,

baking oven

and side windows

Scan 65-7

High Top,

natural stones

Scan 65-8

High Top,

natural stones

and side windows

Scan 65-9

High Top,

steel sides

Scan 65-10

High Top,

steel sides

and side windows

You have purchased a product by one of Europe’s leading manufacturers of

wood-burning stoves, and we are sure that you will have years of pleasure from your

purchase.

To make the best possible use of your stove, it is important that you

follow our advice and instructions. Read through this Assembly and Instruction

Manual carefully before you start to assemble your stove.

CONGRATULATIONS

ON YOUR NEW SCAN

WOOD-BURNING STOVE

Page 3

3

TABLE OF CONTENTS

¬¬

TECHNICAL DATA 4

Installation 4

Safety 4

The clean air act 1993 and smoke control areas 4

Technical data and dimensions 5

Dimension sketch 6

Type plate 10

Product registration number 10

¬¬

ASSEMBLY 11

Tools needed for mounting of the stove 11

Loose parts 11

Additional accessories 11

Disposal of packaging 11

Fresh air intake 11

Closed combustion system 12

Existing chimney and pre-fabricated element chimney 12

Connection between built-in stove and steel chimney 12

Requirements for chimney 12

Positioning the stove at a non-flammable wall 12

Distance to furniture 12

Safety distance 13

Removal of packaging 15

Handle and door 15

Height adjustment of stove 16

Fitting the flue connection piece 16

Fitting the natural stones 18

Fitting the natural stone top 19

Open plinth 20

Heat-storage system 20

Load-bearing foundation 21

Floor plate 21

Mounting the UK - screw 21

¬¬

INSTRUCTIONS FOR USE 22

CB-technology (Clean Burn) 22

Primary air 22

Secondary air 22

Baffle plate 22

Ash container 22

Handle for riddling grate 22

¬¬

INSTRUCTIONS FOR HEATING 24

Environmentally-friendly firing 24

Lighting 24

Continuous operation 25

Warning about over-firing 25

Firing in the spring or autumn 25

The function of the chimney 25

Using your stove in various weather conditions 25

General notes 26

Chimney fire 26

¬¬

HANDLING OF THE FUEL 27

Selecting wood/fuel 27

Preparation 27

Storing 27

Moisture 27

Use of the following as fuel is illegal 27

Calorific value of the wood 27

¬¬

MAINTAINANCE 28

Sweeping the chimney and cleaning the stove 28

Checking the stove 28

Servicing 28

Combustion chamber lining 28

Gaskets 28

Painted surfaces 28

Baffle plates and combustion chamber lining 29

Cleaning the glass 30

Disposal of stove parts 30

¬¬

TROUBLESHOOTING 31

¬¬

WARRANTY 32

Page 4

YOU GET THE BEST USE OF

THE STOVE BY USING

A TOP-DOWN

LIGHTING METHOD

SEE

"INSTRUCTIONS FOR HEATING"

PLEASE NOTE!

TECHNICAL DATA

INSTALLATION

¬ The house owner is responsible for ensuring that installation and assembly are in accordance with national and local

building regulations as well as the information provided in this Assembly and Instructions Manual.

¬ When you install any kind of fireplace or stove, you must inform the local building and housing authorities. In addition

you are obliged to have the installation inspected and approved by a local chimney sweep prior to commissioning.

¬ To ensure best-possible functionality and safety for your installation, we advise you to call a professional fitter. Your Scan

dealer will be able to recommend a qualified fitter in your area. For information on Scan Dealers, please go to www.scan.dk.

SAFETY

Any changes made to the product by the dealer, fitter or user could result in the product and safety functions not functioning as

intended. The same applies to the fitting of accessories or extra equipment not supplied by Scan A/S. This could also be the case

if parts that are necessary for the operation and safety of the stove are dismantled or removed.

THE CLEAN AIR ACT 1993 AND SMOKE CONTROL AREAS

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a smoke control area.

It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed boiler if located in a designated smoke

control area. It is also an offence to acquire an "unauthorized fuel" for use within a smoke control area unless it is used in an "exempt" appliance ("exempted" from the controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorize smokeless fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests with Ministers in the devolved

administrations for those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, applies in Northern

Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke control areas have been "authorized" in Regulations and that appliances used to burn solid fuel in those areas (other than "authorized" fuels) have been exempted by an Order

made and signed by the Secretary of State or Minister in the devolved administrations.

¬ Further information on the requirements of the Clean Air Act can be found here: www.smokecontrol.defra.gov.uk

¬ Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of Clean Air Act requirements”

¬ The secondary air valve has been modified, so that is does not close completely but has an opening corresponding to the

position used at the lowest emission test (See page 21).

¬ You can use any type of wood as fuel.

¬ This stove has been recommended as suitable for use in smoke control areas when burning wood.

Page 5

5

TECHNICAL DATA AND DIMENSIONS

Intermittent operation in this context means normal use

of a wood-burning stove. In other words, you should let

the fire die down until only the embers are left before

refueling.

This stove is produced in accordance with type approval

for the product, which also covers the product’s Assembly

and Instruction Manual.

The Declaration of Performance (DoP) is available from

www.scan.dk

*

65-1, 65-3, 65-5, 65-7 & 65-9

-Test in compliance with EN 13240

CO Emission at 13% O

2

0,08 %

CO Emission at 13% O

2

975 mg/Nm

3

Dust @ 13% O

2

<20 mg/Nm

3

Nox @ 13% O

2

104 mg/Nm

3

Efficiency 82 %

Energy efficiency index 110

Energy efficiency class A+

Nominel output 6 kW

Chimney temperature EN 13240 221 °C

Temperature in flue conn. piece 300 °C

Amount of smoke 5 g/sek

Sub-pressure EN 13240 12 Pa

Recommended sub-pressure in

connecting piece

15-18 Pa

Required combustion air supply 13,3 m

3

/h

Fuel Wood

Fuel consumption 2 kg/h

Amount of fuel required to light 1,5 kg

65-2, 65-4, 65-6, 65-8 & 65-10

-Test in compliance with EN 13240

CO Emission at 13% O

2

0,1 %

CO Emission at 13% O

2

1221 mg/Nm

3

Dust @ 13% O

2

<20 mg/Nm

3

Nox @ 13% O

2

117 mg/Nm

3

Efficiency 79 %

Energy efficiency index 106

Energy efficiency class A

Nominel output 6 kW

Chimney temperature EN 13240 240 °C

Temperature in flue conn. piece 305 °C

Amount of smoke 6 g/sek

Sub-pressure EN 13240 12 Pa

Recommended sub-pressure in

connecting piece

15-18 Pa

Required combustion air supply 12,5 m

3

/h

Fuel Wood

Fuel consumption 2 kg/h

Amount of fuel required to light 1,5 kg

Materials

Steel plate

Cast iron,

Galvanised sheet

Vermicolite

Surface treatment Senotherm

Max. wood length 30 cm

Weight Scan 65-1 /2 ca. 123 kg

Weight Scan 65-1 /2 Low base ca. 118 kg

Weight Scan 65-3 ca. 180 kg

Weight Scan 65-4 ca. 168 kg

Weight Scan 65-5/6 ca. 162 kg

Weight Scan 65-7 ca. 258 kg

Weight Scan 65-8 ca. 246 kg

Weight Scan 65-9/10 ca. 162 kg

Connecting piece internal diameter 144 mm

Connecting piece external diameter 148 mm

Approval type Intermittent fuelling*

Page 6

6

A-A ( 1 : 10 )

Bund

154

9

0

*

*

*

1

1

4

A-A ( 1 : 10 )

Top

Bund

1

9

0

3

8

0

9

0

*

*

*

1

1

4

A-A ( 1 : 10 )

Top

Bund

1

1

3

2

7

2

2

1

0

*

*

*

*

1

0

1

2

*

490

1

9

0

3

8

0

154

9

0

*

*

*

1

1

4

1

1

1

1

*

*

A-A ( 1 : 10 )

Bund

7

2

2

1

0

*

*

*

*

1

0

1

2

*

154

9

0

*

*

*

1

1

4

1

1

1

1

*

*

A-A ( 1 : 10 )

Top

Bund

1

1

3

2

490

2

1

0

*

*

*

*

7

2

1

0

1

2

*

1

1

1

1

*

*

3

8

0

1

9

0

154

1

1

4

9

0

*

*

*

A-A ( 1 : 10 )

Bund

2

1

0

*

*

*

*

7

2

1

0

1

2

*

1

1

1

1

*

*

154

9

0

*

*

*

B

A

C

A-A ( 1 : 10 )

Top

Bund

3

8

0

1

9

0

154

1

1

4

9

0

*

*

*

A-A ( 1 : 10 )

Bund

154

1

1

4

9

0

*

*

*

C

D

B

A

D

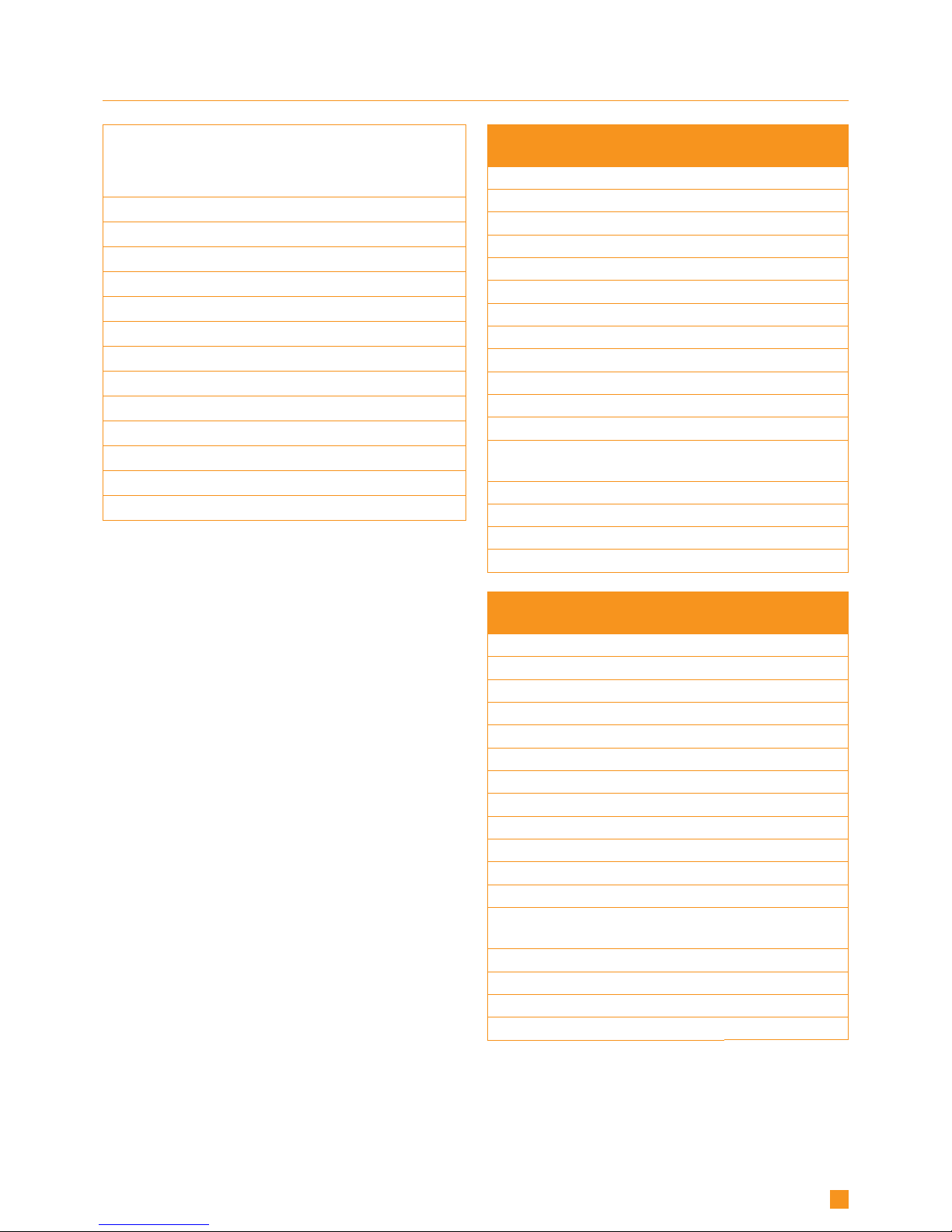

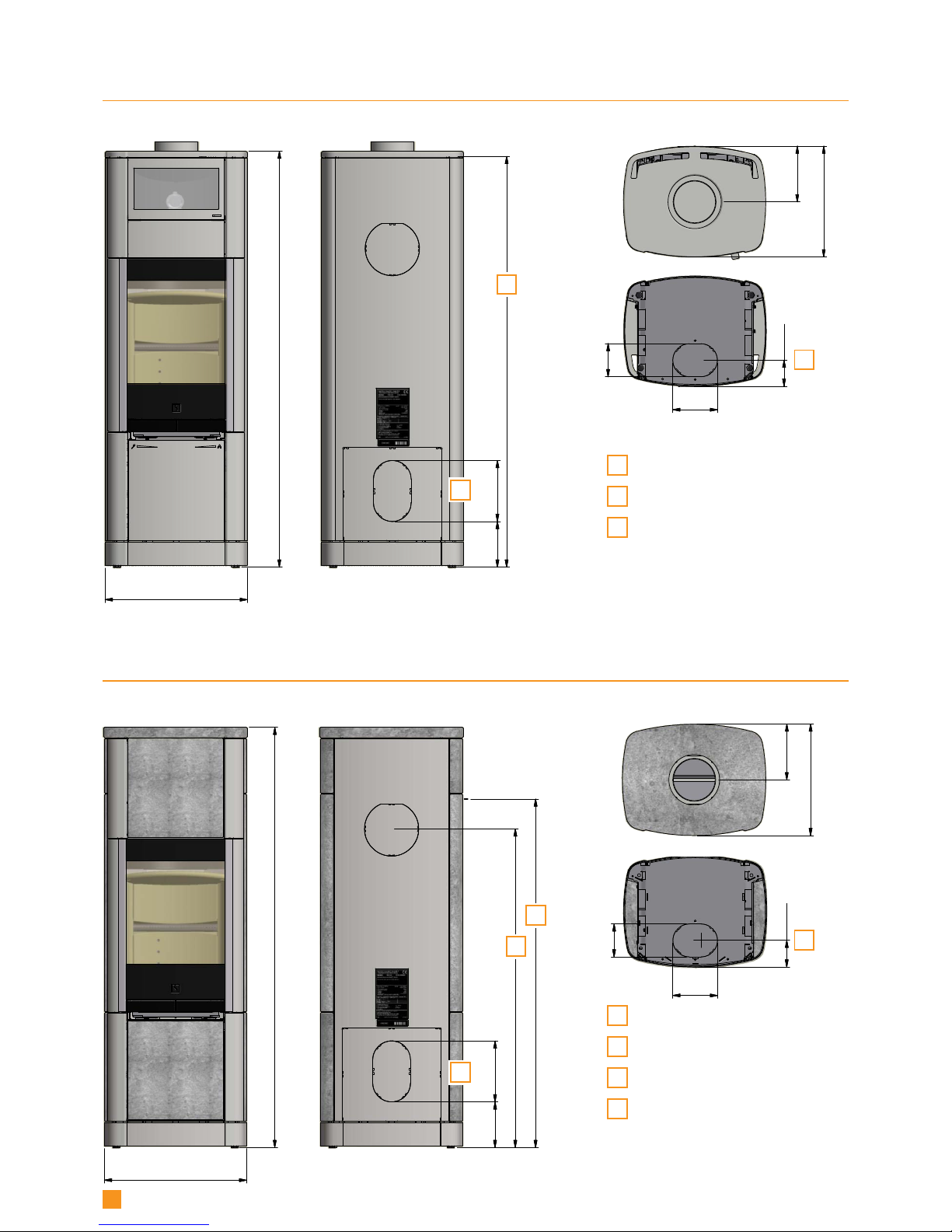

DIMENSION SKETCH SCAN 65-3 AND 65-4 (NATURAL STONES)

DIMENSION SKETCH

A

Centre rear outlet

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

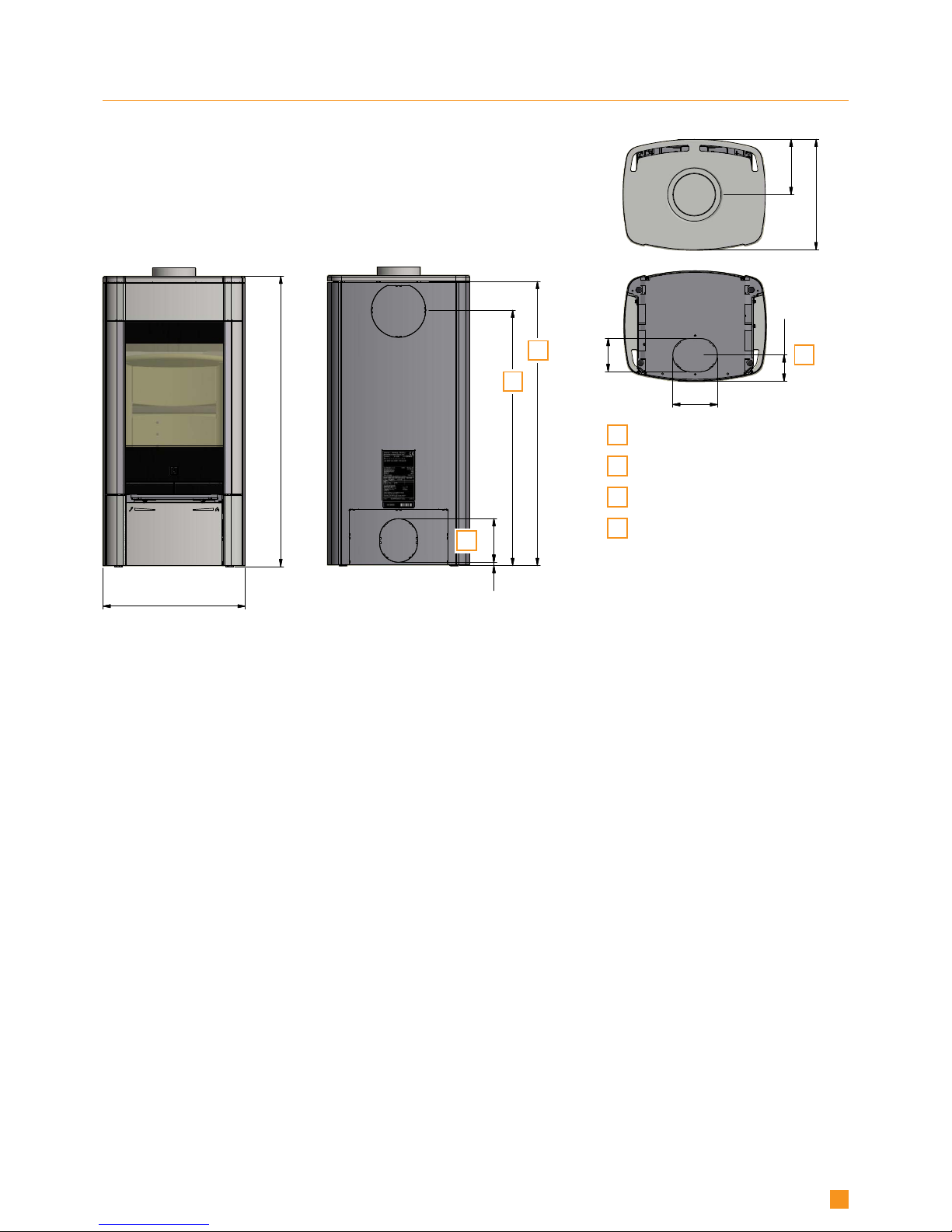

SCAN 65-1 AND 65-2

A

Centre rear outlet

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

Page 7

7

490

1

0

0

0

1

2

1

5

0

9

7

9

8

8

0

154

1

1

4

9

0

1

9

0

3

8

0

B

A

C

A-A ( 1 : 10 )

Top

Bund

3

8

0

1

9

0

154

1

1

4

9

0

*

*

*

A-A ( 1 : 10 )

Bund

154

1

1

4

9

0

*

*

*

D

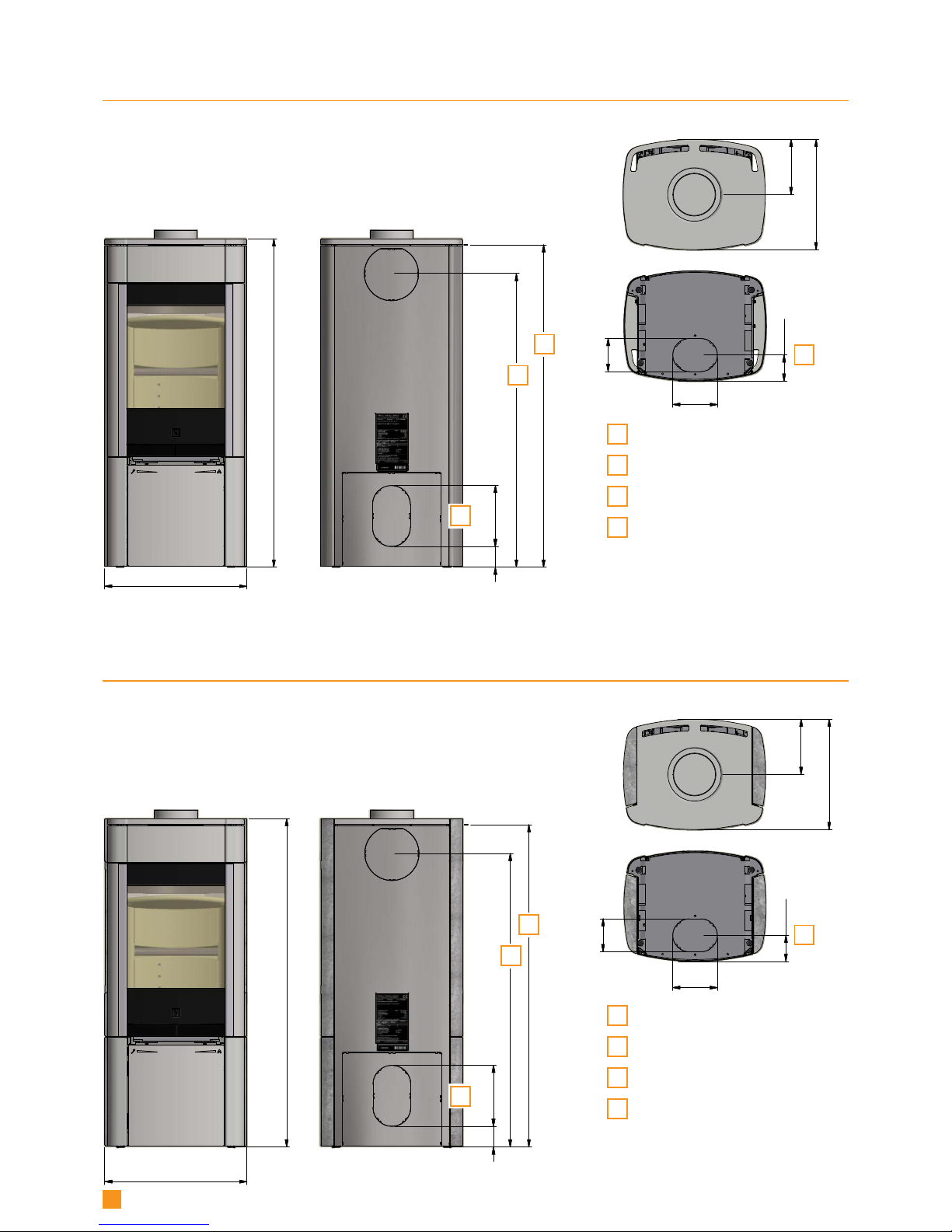

DIMENSION SKETCH SCAN 65-1 AND 65-2 (LOW BASE)

A

Centre rear outlet

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

Page 8

8

A-A ( 1 : 10 )

Top

Bund

154

1

1

4

9

2

*

*

*

1

9

2

3

8

4

A-A ( 1 : 10 )

Bund

154

1

1

4

9

2

*

*

*

A-A ( 1 : 10 )

Top

Bund

490

154

1

1

4

9

2

*

*

*

1

2

0

1

*

*

1

9

2

3

8

4

1

4

4

8

1

5

8

2

1

0

*

*

*

*

1

0

9

8

*

A-A ( 1 : 10 )

Bund

154

1

1

4

9

2

*

*

*

1

2

0

1

*

*

1

5

8

2

1

0

*

*

*

*

1

0

9

8

*

Top

Bund

1

4

3

3

490

154

1

1

4

9

2

*

*

*

1

5

8

2

1

0

*

*

*

*

1

4

1

5

*

*

3

8

2

1

9

2

Bund

154

1

1

4

9

2

*

*

*

1

5

8

2

1

0

*

*

*

*

1

4

1

5

*

*

C

A-A ( 1 : 10 )

Bund

154

1

1

4

9

0

*

*

*

B

C

D

D

Top

Bund

154

1

1

4

9

2

*

*

*

3

8

2

1

9

2

B

A

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

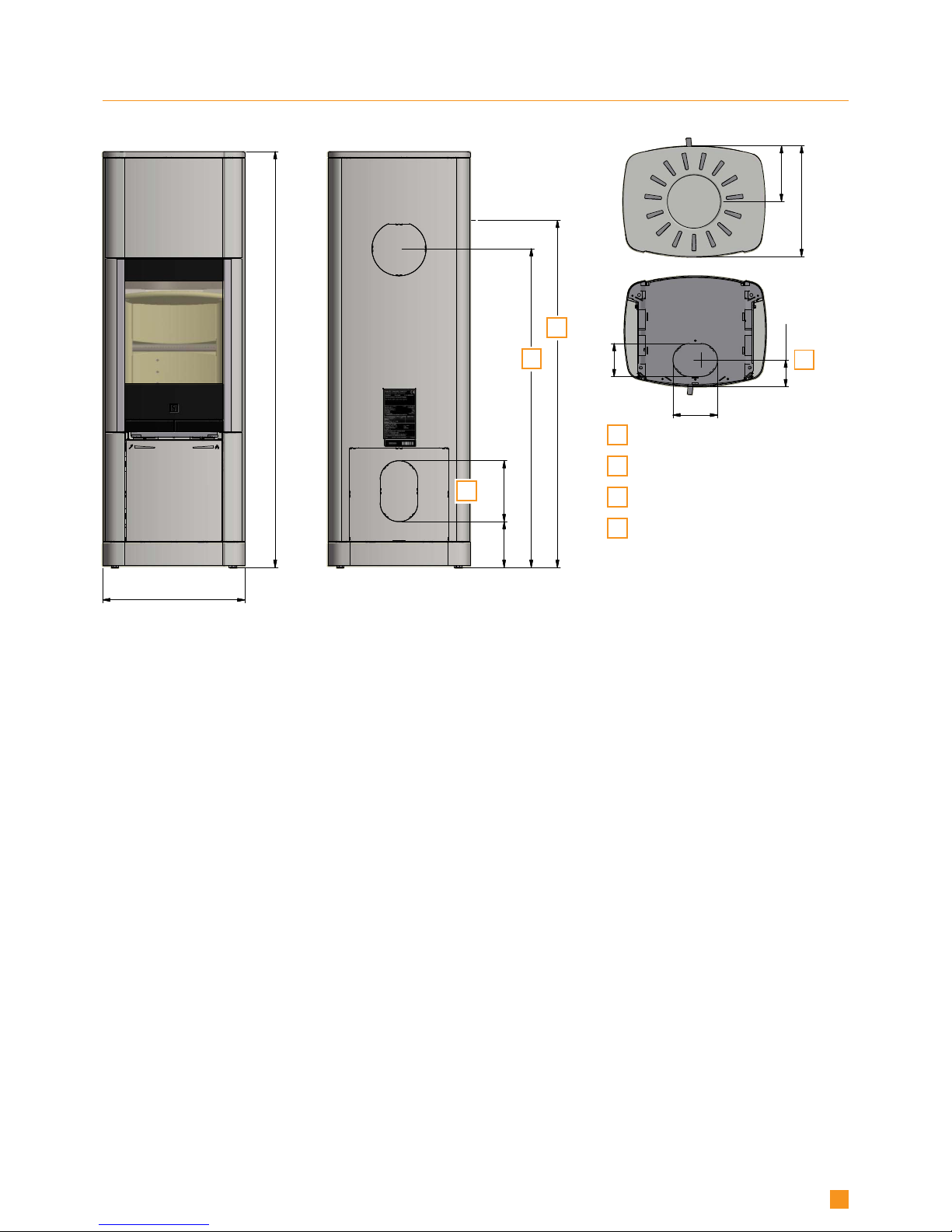

A

Centre rear outlet

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

DIMENSION SKETCH SCAN 65-7 AND 65-8 (HIGH TOP + NATURAL STONES)

DIMENSION SKETCH SCAN 65-5 AND 65-6 (HIGH TOP + BAKING OVEN)

In order to get full use of the baking oven, this model must be connected with a top outlet.

Page 9

9

A-A ( 1 : 10 )

Top

Bund

490

154

1

1

4

9

2

*

*

*

1

4

3

3

3

8

2

1

9

2

1

5

8

2

1

0

*

*

*

*

1

0

9

8

*

1

1

9

6

*

*

A-A ( 1 : 10 )

Bund

154

1

1

4

9

2

*

*

*

1

5

8

2

1

0

*

*

*

*

1

0

9

8

*

1

1

9

6

*

*

A-A ( 1 : 10 )

Bund

154

1

1

4

9

2

*

*

*

B

C

D

A-A ( 1 : 10 )

Top

Bund

154

1

1

4

9

2

*

*

*

3

8

2

1

9

2

A

A

Centre rear outlet

B

Height to the beginning of the

connecting piece at top outlet

C

Fresh air intake bottom

D

Fresh air intake at the back

of the stove

All measurements are in millimeters

DIMENSION SKETCH SCAN 65-9 AND 65-10 (HIGH TOP + STEEL SIDES)

In order to get full use of the heat accumulating stones, this model must be connected with a top outlet.

Page 10

10

Scan 65-1 - 65-3 - 65-5 - 65-7 - 65-9

Freestanding room heater fired by solid fuel

Standard:

Fuel type:

Operation type:

The appliance can be operated in a shared flue.

Country

EN 13240 Dop 90065600

Wood

Intermittent

EUR

Norway

Classification

Intermittent

Certificate/Standard

EN 13240

Approved by

RWE Power AG

Teknologisk Institut

Dust at 13% O2: < 20 mg/Nm³

Flue gas temperature: 300°C

Nominal heat output: 6 kW

Efficiency: 82%

Scan A/S DK 5492 Vissenbjerg

Minimum distance to combustible materials

Side: 350 mm - Back: 150 mm - Front: 1000 mm

CO emission at 13% O2:

Follow assembly- and instructions manual.

Use only recommended fuels.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 05-2015

0,08% 975 mg/Nm³

Schweiz

Germany

RWE Power AG

RWE Power AG

Scan 65-2 - 65-4 - 65-6 - 65-8 - 65-10

Freestanding room heater fired by solid fuel

Standard:

Fuel type:

Operation type:

The appliance can be operated in a shared flue.

Country

EN 13240 Dop 90065601

Wood

Intermittent

EUR

Norway

Classification

Intermittent

Certificate/Standard

EN 13240

Approved by

RWE Power AG

Teknologisk Institut

Dust at 13% O2: < 20 mg/Nm³

Flue gas temperature: 305°C

Nominal heat output: 6 kW

Efficiency: 79%

Scan A/S DK 5492 Vissenbjerg

Minimum distance to combustible materials

Side: 500 mm - Back: 150 mm - Front: 1000 mm

CO emission at 13% O2:

Follow assembly- and instructions manual.

Use only recommended fuels.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 05-2015

0,10% 1221 mg/Nm³

Schweiz

Germany

RWE Power AG

RWE Power AG

6500000

Typeskilt 65-2, 65-4, 65-6, 65-8 og 65-10 (med sideglas)

Typeskilt 65-1, 65-3, 65-5,65-7og 65-9 (uden sideglas)

Product registration number

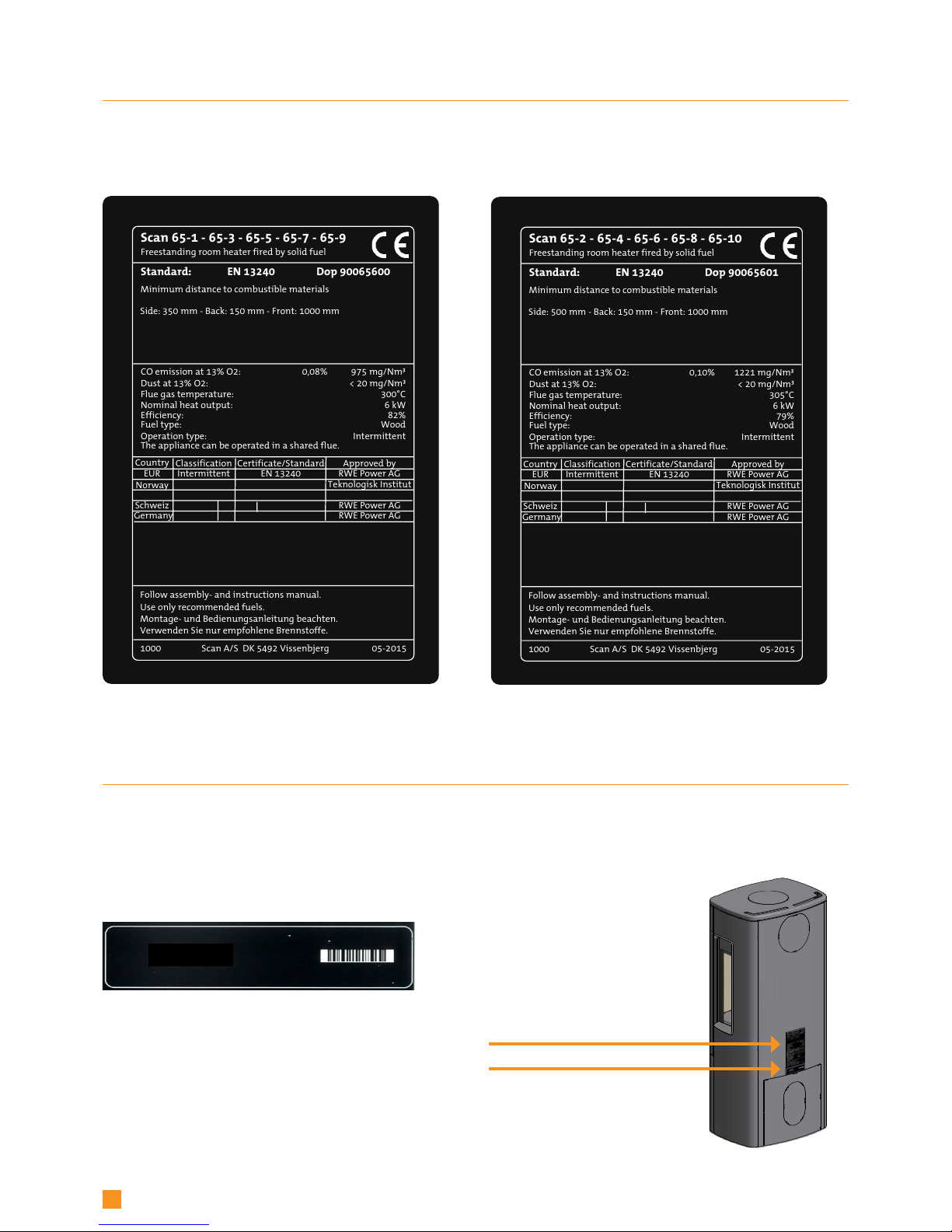

Type plate

Product registration number

TYPE PLATE

All Scan wood-burning stoves are fitted with a type plate that specifies the approval standards and the distance to flammable

materials.

The type plate is located at the rear of the stove.

PRODUCT REGISTRATION NUMBER

All Scan wood-burning stoves are provided with a product registration number. Please make a note of this number at the rear

page of this manual; you will always need to quote it when contacting your dealer or Scan A/S.

The product registration number is located at the rear of the stove.

Page 11

11

ASSEMBLY

TOOLS NEEDED FOR MOUNTING OF THE STOVE

¬ Spirit level ¬ Open-end spanner

¬ Cutting nippers

LOOSE PARTS

The loose parts are located in the stove's ash drawer.

¬ Glove ¬ Seal for the connecting piece

¬ 4 pcs. screws for fastening the connecting piece ¬ Scan 65-3 and Scan 65-4: 4,5 m gasket

¬ Fresh air intake ¬ Scan 65-7 and Scan 65-8: 7 m gasket

¬ 1 pcs. screw M5x6, must be placed for United Kingdom

ADDITIONAL ACCESSORIES

¬ Small shaped floor plate in glass or steel ¬ Large shaped floor plate in glass or steel

¬ Natural stones top plate for stove with rear outlet ¬ Natural stones top plate for stove with top outlet

¬ Scan 65-7/8 and 65-9/10: Heat accumulating stones

DISPOSAL OF PACKAGING

Your Scan stove may come supplied with the following packaging:

Wood packaging

The wood packaging can be reused and after final use can be incinerated as a CO2 neutral

product or sent for recycling.

Polystyrene top Send for recycling or waste disposal

Foam Send for recycling or waste disposal

Plastic bags Send for recycling or waste disposal

Stretch/plastic film Send for recycling or waste disposal

FRESH AIR INTAKE

In a well-insulated house, the air used up by the burning process has to be replaced. This particularly applies to houses with

mechanical ventilation. There are different ways of making sure that an air exchange takes place. The most important thing is to

ensure that there is a supply of air to the room where the wood stove is located. The external wall vent must be located as close

to the wood stove as possible, and you must be able to close it when you are not using the wood stove.

National and local building regulations must be followed with regard to the connection of fresh-air intake.

Page 12

12

External

combustion air

through the floor

External

combustion air

through the wall

CLOSED COMBUSTION SYSTEM

You should use the closed combustion system for the wood-burning stove if you live in a newly-built, airtight home.

External combustion air is connected through a ventilation pipe via the wall or floor.

It must be possible to shut off the ventilation pipe with a valve, when the stove is not in use. Minimum

Ø 100 mm ventilation pipe,

maximum length: 6 metres with a maximum of one bend. We recommend smooth steel pipes.

The connecting piece for fresh air inlet is delivered separately with the stove.

If you want external combustion air via a wall, remove the cover plate at the rear of the stove with a pair of cutting pliers.

NOTE: if the stove has a fresh air connexion or closed combustion,

the ventilation pipe must be open, when the stove is in use!

Remove the cover plate at the back of the stove or the

cover plate at the bottom of the wood compartment

store, as shown in "Fitting the flue connection piece in

the top outlet". Connect outside air to the connection

piece underneath the combustion chamber.

EXISTING CHIMNEY AND PRE-FABRICATED ELEMENT CHIMNEY

If you intend to connect your stove to an existing chimney, it makes sense to contact an authorised Scan dealer, or a local chimney sweep, for advice. These experts will also let you know if your chimney needs renovating.

¬ When connecting a pre-fabricated element chimney, follow the manufacturer’s connection instructions for the

relevant chimney type.

CONNECTION BETWEEN BUILT-IN STOVE AND STEEL CHIMNEY

Your Scan dealer, or local chimney sweep, can advise you on choosing a make and type of steel chimney. This ensures that the

chimney will match your wood-burning stove.

REQUIREMENTS FOR CHIMNEY

The chimney must have a minimum internal diameter of 148 mm and have a T400 designation, with G for the soot fire test.

The requirements to the chimney and the flue pipe in terms of safety distances must be met.

¬ Choosing the wrong length or diameter of steel chimney could impair functionality.

¬ Always comply exactly with the instructions provided by the steel chimney supplier.

POSITIONING THE STOVE AT A NON-FLAMMABLE WALL

There are no demands concerning the distance to non-flammable materials, but we recommend a distance of 50 mm in order to

facilitate the cleaning of the stove, the flue pipes and the chimney and to prevent possible damages to the wall.

DISTANCE TO FURNITURE

Distance to furniture from glass: 1000 mm.

You should however assess whether furniture or other items might become excessively dry due to being too close to the stove.

Page 13

13

50

50

100

50

50

700

700

960

700

700

2

53

50

50

100

700

700

960

50

700

800

760

700

860

860

100

100

50

300

50

3

2

4

800

760

700

50

300

50

700

50

5

0

m

m

Møbleringsafstand: XXX mm.

Brandbart materiale

Brandmur

Flammable material

Fire wall, e.g. 50 mm Jøtul Firewall, 110 mm brick

or other material with corresponding fireproof and

insulating abilities

All distances are in mm.

All distances are minimum distances

SAFETY DISTANCE

European, national and local regulations concerning safety distances for wood-burning stoves must be complied with.

DISTANCE

These distances apply for an insulated flue pipe all the way down to the stove, having a minimum of 30 mm insulation.

TO FLAMMABLE WALL PROTECTED BY A FIRE WALL

65-2, 65-4, 65-6, 65-8 and 65-10 (with side windows)

65-1, 65-3, 65-5,65-7 and 65-9 (without side windows)

Page 14

14

150

500

340

745

150

350

340

595

150

500

5

3

6

250

778

250

340

745

513

150

350

340

595

100

363

628

100

3

2

4

50

500

745

240

50

350

595

240

50

500

250

250

778

5

3

6

745

240

513

50

350

2

5

3

595

240

50

50

313

578

65-2, 65-4, 65-6, 65-8 and 65-10 (with side windows)

Parallel installation

65-2, 65-4, 65-6, 65-8 and 65-10 (with side windows)

Parallel installation

65-2, 65-4, 65-6, 65-8 and 65-10 (with side windows)

45° corner installation

65-2, 65-4, 65-6, 65-8 and 65-10 (with side windows)

45° corner installation

DISTANCE TO FLAMMABLE MATERIALS, WITH UNINSULATED FLUE PIPE

These distances apply for an insulated flue pipe all the way down to the stove, having a minimum of 30 mm insulation.

DISTANCE TO FLAMMABLE MATERIALS, WITH INSULATED FLUE PIPE

65-1, 65-3, 65-5,65-7 and 65-9 (without side windows)

Parallel installation

65-1, 65-3, 65-5,65-7 and 65-9 (without side windows)

Parallel installation

65-1, 65-3, 65-5,65-7 and 65-9 (without side windows)

45° corner installation

65-1, 65-3, 65-5,65-7 and 65-9 (without side windows)

45° corner installation

Page 15

15

1

2

3

4

REMOVAL OF PACKAGING

Check that the stove is not damaged before starting to install it.

Remove the screws securing the stove to the pallet

Remove the protection between the baffle plates,

before taking the stove into use!

Put back the upper plate on the pins,

as the protection pushes the plate upwards

Fit the plastic plugs from the service box

into the transport protection holes

HANDLE AND DOOR

NOTE: When the stove is new, the door may stand out a little from the stove,

and the handle may feel tight, as the stove has to be fired a couple of times,

before the gasket “settles”. This is quite normal.

Handle

Page 16

16

1

2

3

HEIGHT ADJUSTMENT OF STOVE

The stove has four adjustment screws under the stove. Use the adjustment screws to get the stove to stand straight and level.

If the floor plate is used, the stove must be adjusted so that the plate can be placed under the front of the stove.

NOTICE: It is very important that the stove is level to allow an optimal function of the door. Please note that once mounted the stove

can no longer be adjusted!

Ajustment screw

Fasten the connecting piece with screws from the ash

drawer and replace the top plate.

Lift the top plate and connecting piece off the stove

Mount the ceramic gasket on the

connecting piece

4 pcs. M5X10 mm

screws

FITTING THE FLUE CONNECTION PIECE

The stove is prepared from the factory for top outlet.

The connecting piece is placed loosely in the top outlet of the stove. The gasket for the connecting piece and the screws for

fastening the connecting piece are in the stove’s ash drawer.

IN THE TOP OUTLET

Page 17

17

5

4

7

3

6

1

2

Cover plate

Remove the cover. This is to be used later as a seal

and cover at the top of the smoke outlet.

Lift the heat shield off the stove and cut the cover

plate free using cutting pliers at the fastening points.

Remove the heat shield

Fit the cover and tighten it.

Replace the top plate

Cut off the cover plate from the rear plate with cutting

pliers at the fastening points

Fit the connecting piece with the four screws found in

the stove’s ash drawer. Hook the heat shield onto the

stove

4 pcs.

M5X10 mm screws

Lift the top plate and connecting piece off the stove

Mount the ceramic gasket on the

connecting piece

FITTING THE FLUE CONNECTION PIECE

The stove is prepared from the factory for top outlet.

The connecting piece is placed loosely in the top outlet of the stove. The gasket for the connecting piece and the screws for

fastening the connecting piece are in the stove’s ash drawer.

IN THE REAR OUTLET

Page 18

18

=

65-3

65-4

65-7 65-8

FITTING THE NATURAL STONES

Scan 65-3, 65-4, 65-7 and 65-8 are delivered with loose natural stone plates for mounting on the sides of the stove.

It is a natural material, wherefore there might be differences in structure and form.

Each natural stone must be mounted with distance bushings and screws which are already mounted in the stones.

The delivered gasket (4,5/7 m) should be cut in appropiate lengths and sticked onto the sides of the stove as shown below.

Gasket

Hook the natural stone

sides onto the stove

Page 19

19

FITTING THE NATURAL STONES

FITTING THE NATURAL STONE TOP

You can buy a natural stone top as an accessory.

Place the stone top on the steel top plate.

(ACCESSORY)

Page 20

20

DATO:

SIGN:

Krog Iversen & Co A/S

DK-5492 Vissenbjerg

©

TG.NR:EMNE:

90068058

klargøring til vægbeslag

12-05-2015

hms

Scan 68

VÆGT:

AREAL:

N/A

N/A

OPEN PLINTH

If you want an open plinth, remove the wood compartment

door and its stop as well as the large cover plate at

the back of the stove.

Cover plate

to be removed

Do not remove

the radiation plate

65-9 and 65-1065-7and 65-8

Cut off this plate from

the heat shield in order to

make place for the heat

accumulating stones

The vent for adjustment

of the convection air is

placed at the back of the

high top

Open Closed

(ACCESSORY)HEAT-STORAGE SYSTEM

Heat-storage stones are available for Scan 65-7, 65-8, 65-9 and 65-10.

Heat-storage stones are made from a special material with a high

heating capacity. The stones are heated up during the firing and gives

off the heat again after the firing, which means that the stove stays

warm for a longer time.

¬ Firing with the vent open will give a quicker heating. Firing with the

vent closed will extend the heating time of the stove.

Page 21

21

Small shaped floor plate

in glass or steel

Large shaped floor plate

in glass or steel

(ACCESSORY)

A

MOUNTING THE UK - SCREW

UK ONLY! IMPORTANT!

Scan 65 has been recommented as suitable for use in smoke control areas when burning wood logs and when fitted with a

mechanical stop to prevent secondary air control closure beyond the 35mm open position.

NOTE: In order to a achieve this, the screw (M5 x 6)

must be placed as shown in the pictures, to prevent

that the secondary air valve can be closed completely.

LOAD-BEARING FOUNDATION

All items in our product range come under the category of lightweight fireplaces and stoves and do not normally require any reinforcement of the beam structure. They can be positioned on ordinary beams/floor.

You should of course make sure that the foundation on which the stove is positioned can indeed support the weight of the stove

and, where applicable, a steel chimney, if you have opted for this solution.

FLOOR PLATE

If you are placing the stove on a flammable floor, you must comply with the national and local regulations on the size of any

non-flammable subsurface required to cover the floor around the stove.

Your local Scan dealer can advise you on regulations concerning protection of flammable materials in the vicinity of your stove.

The floor plate’s function is to protect the floor and flammable material against any sparks that may occur. A floor plate can be

made of steel or glass, but the stove can also be erected on clinker concrete, natural stone or similar materials.

This Scan wood-burning stove has an integrated floor plate at the bottom and can thus be erected directly on flammable

material without the need for further protection underneath the stove.

Page 22

22

INSTRUCTIONS FOR USE

CB-TECHNOLOGY (CLEAN BURN)

The stove is equipped with CB technology. In order to ensure optimal combustion of gases released during the combustion

process, air passes through a specially developed system of channels. The heated air is conducted into the combustion chamber

through the holes in the rear lining of the combustion chamber and at the baffle plates. This airflow is controlled by the rate of

combustion and cannot therefore be regulated.

NOTE: The wood must never be placed higher than the tertiary holes at the rear of the burn chamber (This does not apply at a

cold start).

PRIMARY AIR

The primary air is used when lighting the stove and must be closed after 10-20 minutes, when the fire has caught well. The primary air can be used continuously when using very hard wood.

Settings for normal load: 0 - 30%

SECONDARY AIR

Secondary air is pre-heated and fed indirectly to the fire. At the same time, the secondary airflow cleans the glass pane to avoid

soot build-up. If you over-restrict the secondary airflow, soot can build up on the glass pane. The secondary airflow determines

the heat output from your wood stove.

Settings for normal load: 50 - 70%

BAFFLE PLATE

The baffle plate is located in the upper part of the combustion chamber. The plate holds back smoke, making sure it stays inside

the combustion chamber for a longer time before escaping through the chimney. This reduces the flue gas temperature as the

gases have more time to dissipate heat to the stove.

The baffle plate must be removed for sweeping; see “Maintenance”. Note that the baffle plate is made of porous, ceramic material, and is liable to break easily. You should therefore handle it with care.

The baffle plate is subject to wear and tear and not covered by the warranty.

ASH CONTAINER

¬ Open the door of the stove to access the ash container under the combustion chamber.

¬ The ash container must always be closed during operation.

¬ The ash container must not be become too full and must therefore be emptied at regular intervals.

¬ Never empty ashes into a flammable container. Ashes can contain glowing embers long after you finish operating

the stove.

HANDLE FOR RIDDLING GRATE

The stove is equipped with a riddling grate that - when activated - empties the ashes from the burn chamber into the ash tray.

¬ The riddling grate must be half open during the firing.

Page 23

23

100%

0%

INSTRUCTIONS FOR USE

Adjustment of air supply,

primary and secondary damper

Baffle plates

Primary air Secondary air

Handle for riddling grate

Ash drawer

CB-technique

SETTINGS

FOR NORMAL LOAD:

Primary air: 0 - 30%

Secondary air: 50 - 70%

Page 24

24

1 2 3

NOTE!

No matter how good your chimney is,

it will not perform well if you do not

use it correctly. Equally, a poor chim-

ney may well give you acceptable

results if you use it correctly.

INSTRUCTIONS FOR HEATING

ENVIRONMENTALLY-FRIENDLY FIRING

Avoid turning down your stove to the point where no flames are visible from

the wood, as this leads to poor combustion and low efficiency. The gases

released from the wood will not be burnt off due to the low temperature in the

combustion chamber. Some of the gases will condense in the stove and flue

system as soot, and this could lead to your chimney catching fire at a later

point. The residual smoke which exits the chimney will pollute the surrounding

area and cause an unpleasant smell.

LIGHTING

We recommend the use of fire lighters, or similar products, which are available from your Scan dealer.

Using fire lighters helps light the wood more quickly and keeps the combustion process clean.

See our video about correct firing on www.scan.dk or scan the QR-code.

NOTE: Never use liquid lighting fuels!

”TOP DOWN” LIGHTING

"Top down" lighting provides an environmentally friendly lighting and helps keep the glass area optimally clean.

¬ 4 pieces of wood approx. 20-25 cm long with a weight of approx. 0.4-0.5 kg per piece.

¬ 15-20 thin pieces of firewood of about 20 cm in length, with a total weight of approx. 0.8 kg.

¬ 4 fire lighters in bag or block form

1

Place the pieces of wood, firewood and fire lighters in the combustion chamber as shown below

2

Set the primary and secondary air controls to maximum for 20-30 minutes (See "Instructions for use")

3

When the large pieces of wood have caught fire, you can adjust the primary- and secondary air to the desired level

NOTE: The wood must never be placed higher than the tertiary holes at the rear of the burn chamber

(This does not apply at a cold start).

Tertiary holes

Scan the QR-code

and see our video

about correct firing.

Page 25

25

CONTINUOUS OPERATION

It is important to obtain as high a temperature as possible in the combustion chamber. This results in best possible use of the

stove and fuel, as well as achieving clean combustion. In this way you will avoid build-up of soot on the combustion chamber

lining and glass pane. During operation, you should not see any smoke; just a movement in the air that indicates combustion is in

progress.

¬ After completing the lighting phase, you should have a good layer of embers in the stove; you can then start operation of it

properly

¬ Add two pieces of wood at a time: they should be about 0,4-0,6 kg in weight and about 20 cm long

NOTE: The wood must catch fire quickly. This is why we recommend setting the primary air flow fully open.

NOTE: Operating the stove at too low a temperature and with too little primary air can lead to gases igniting, which can damage

the stove.

¬ When adding wood, always open the glass door carefully to prevent smoke escaping

¬ Never add wood, while the fire is burning nicely

WARNING ABOUT OVER-FIRING

If the stove is continiously fired with larger amounts of wood than recommended and/or receives too much air, this can cause a

heavy heat development liable to damage both stove and the surrounding walls. We therefore recommend that you always observe the max. recommended amount of fuel (See under ”Technical Data”).

FIRING IN THE SPRING OR AUTUMN

In the spring/autumn transition period, where there is less need for heating, we recommend you light the stove “top down” once,

perhaps adding just two pieces of wood as above to ensure that the combustion chamber lining burns clean again.

THE FUNCTION OF THE CHIMNEY

The chimney is the wood-burning stove’s motor; its performance determines how well your stove will work. The draught in the

chimney creates negative pressure in the wood-burning stove. The negative pressure draws the smoke out of the stove and takes

in air through the combustion air damper to fuel the combustion process. Combustion air is also used for the air wash system

that keeps the window clear of soot.

The draught in the chimney is created by the difference in temperature inside and outside the chimney. The higher temperature

difference, the better draught. This is why it is important that the chimney reaches operating temperature before you reduce the

damper settings to restrict combustion in the stove (a brickwork chimney will take longer to reach operating temperature than a

steel chimney). It is very important that the operating temperature is reached as quickly as possible on days when the draught in

the chimney is poor due to unfavorable wind and weather conditions. You need to get a few flames going as quickly as possible.

Chop the wood extra thin; use an extra fire lighter etc.

¬ After longer periods without use, you must check the chimney flue for blockages.

¬ You can connect several units to the same chimney. You should however first check the relevant regulations in this respect.

USING YOUR STOVE IN VARIOUS WEATHER CONDITIONS

The way the wind affects the chimney can have a big impact on how your stove reacts under various wind loads; you may need to

adjust the airflow to achieve good combustion. Fitting a damper in the flue pipe may also help, as it will allow you to regulate the

draught under changing wind loads. The damper must not close more than 80% of the surface.

Fog and mist can also have a big impact on chimney draught; you may need to use other settings for the combustion air to

achieve good combustion.

Page 26

26

GENERAL NOTES

PLEASE NOTE! Parts of the wood-burning stove, especially the outer surfaces, become hot during use. Due care should be

exercised.

¬ Never empty ashes into a flammable container. Ashes can contain glowing embers long after you finish operating the stove.

¬ When the stove is not in use you can close the dampers to avoid a draught through the stove.

¬ If the stove has not been used for some time, you should check the flue passageways for potential blockages before relighting.

NOTE: Never place flammable material in the radiation zone of the stove!.

CHIMNEY FIRE

In the event of a chimney fire, keep the stove door, the ash container, and all dampers on the stove closed. In an emergency, call

the fire service.

¬ We recommend that you get a chimney sweep to check the chimney before using the stove again.

Page 27

27

The various woods have different calorific values. In other words,

for certain species of wood, you will need to use a greater quantity

to achieve the same heating performance. This Instuction Manual

assumes that you will be using beach, which has a very high

calorific value and is also the easiest wood to get hold on. If you

use oak or beech as fuel, you need to bear in mind that these

wood types have a greater calorific value than for example birch.

To avoid any risk of damage to the stove, you should therefore

make sure to use less fuel in these cases.

CALORIFIC VALUE OF THE WOOD

Wood types kg Drywood/m3Compared to beech

Hornbeam 640 110%

Beech/Oak 580 100%

Ash 570 98%

Maple 540 93%

Birch 510 88%

Pine 480 83%

Fir 390 67%

Poplar 380 65%

HANDLING OF THE FUEL

SELECTING WOOD/FUEL

You can use any type of wood as fuel. However harder woods, such as beech or ash, are generally better for heating, as they burn

more evenly and create less ash. Other woods, such as maple, birch and spruce, are excellent alternatives.

PREPARATION

The best fuel is obtained where the tree has been felled and the wood sawn and split before May 1st. Remember to cut the wood

to match the size of the combustion chamber. We recommend a diameter of 6-10 cm. The length should be about 6 cm shorter

than that of the combustion chamber to leave enough space for air to circulate. If the diameter of the wood is greater than the

above, it should be split down its length. Wood that has been split dries faster.

STORING

You need to store the sawn and split wood in a dry place for 1-2 years before it will be dry enough to burn. Wood dries faster if

you stack it in an airy place. Before using it, it is a good idea to store the wood for a few days at room temperature. Remember

that wood absorbs moisture from the air during autumn and winter.

MOISTURE

To avoid problematic impact on the environment and to ensure optimum operating economy, the wood should be perfectly dry

before it can be used as fuel. If you use wood that is too damp, most of the heat it produces will be used up in evaporating the

water. The stove will accordingly not increase in temperature, nor emit heat to the room as a result. This is obviously poor economy, and it will cause soot build-up on the glass pane, in the stove and in the chimney. Operation using moist wood also pollutes

the environment.

¬ Maximum wood moisture content should not exceed 20%. A moisture content of 15-18% will deliver best efficiency.

¬ An easy way of checking wood moisture content is to knock the ends of the two pieces of wood together. If the wood is moist,

the sound will be slightly muffled.

USE OF THE FOLLOWING AS FUEL IS ILLEGAL

NOTE: It is absolutely prohibited to fire with painted, pressure impregnated or glued wood, or sea driftwood.

NOTE: Nor should you ever burn chipboard, plastics, or treated paper. These contain substances that are hazardous to human

health, to the environment, your stove, and your chimney.

In short - make sure you only use proper wood.

Page 28

28

MAINTAINANCE

SWEEPING THE CHIMNEY AND CLEANING THE STOVE

Follow national and local regulations for sweeping the chimney. We recommend having the stove cleaned regularly by a chimney

sweep.

Before cleaning the stove and sweeping the chimney, the baffle plate must be removed (See "Removing the baffle plate").

NOTE: All service and reparation must be done, when the stove is cold.

CHECKING THE STOVE

Scan A/S recommends that you check your stove thoroughly after sweeping/cleaning. Check all visible surfaces for cracks.

Check that all joints are tight and that the gaskets are correctly seated. Worn or deformed gaskets should be replaced.

SERVICING

We recommend that the stove is thoroughly serviced at least every two years by a qualified fitter. Remember only to use original

spare parts.

The service should include the following:

¬ Lubricate hinges using copper grease.

¬ Check the gaskets. Replace any that are broken or have turned hart.

¬ Check the combustion chamber lining and the grate.

¬ Check heat-insulating materials.

COMBUSTION CHAMBER LINING

Slight cracks can appear in the combustion chamber lining due to moisture or sudden heating/cooling. These cracks have no

influence on the output or lifetime of your stove. However, if the lining starts to crumble and fall out, you must replace it.

The combustion chamber lining is not covered by the warranty.

GASKETS

All wood-burning stoves have seals made of ceramic material fitted to the stove, the door and/or the glass. These seals are

subject to wear and tear and must be replaced when necessary.

Gaskets are not covered by the warranty.

PAINTED SURFACES

Clean your wood-burning stove by wiping it down with a dry, lint-free cloth.

If the paint finish gets damaged, you can purchase repair paint in spray form from your Scan dealer. As slight differences in

colour shade are possible, we recommend you spray a larger area to achieve a natural blend. For best results, apply repair spray

when the stove is warm enough for you to just keep your hand on it, but no hotter.

NOTE: Make sure to air the room thoroughly after applying spray paint.

Page 29

29

A

65-2, 65-4, 65-6, 65-8 and 65-10

(with side windows)

65-1, 65-3, 65-5, 65-7 and 65-9

(without side windows)

Upper

baffle plate

Lower

baffle plate

Upper

baffle plate

Holder for

upper

baffle plate

Be very careful when removing

the baffle plates from the stove

BAFFLE PLATES AND COMBUSTION CHAMBER LINING

¬ Lift up the lower baffle plate, remove the pins and take out the baffle plate.

¬ Lift the upper baffle plate to the back of the combustion chamber. Remove pins. Pull the plate free from the baffle plate

holder and remove it.

¬ Lift the combustion chamber lining’s sides, remove them from the rear cover and take them out. Note that the combustion

chamber lining’s sides support the rear cover so this could fall when the sides are removed.

¬ Remove the rear cover

Page 30

30

Scan 65-5 and Scan 65-6

CLEANING THE GLASS

Our wood-burning stoves are designed to prevent serious soot build-up on the glass. The best way to achieve this is to make sure

you have a good supply of combustion air. It is also very important that the wood is dry and the chimney correctly dimensioned.

Even if you operate the stove in accordance with our instructions, a slight film of soot may still accumulate on the glass.

You can

easily remove this film by wiping the glass down with a dry cloth and then with a cloth dampened with glass cleaner.

¬ Please note that the glass cleaner is not to get into contact with the gaskets, as this can discolour the glass permanently.

¬ The glass cleaner must not come into contact with the painted surfaces, as these can be damaged.

CLEANING THE GLASS PLATE IN THE BAKING OVEN

The glass plate is easy to take out for cleaning.

DISPOSAL OF STOVE PARTS

Steel/cast iron Send for recycling

Glass Dispose of as ceramic waste

Combustion chamber lining Vermiculite and chamotte are not recyclable. Dispose of as waste.

Baffle plate Vermiculite is not recyclable. Dispose of as waste.

Gaskets Dispose of as waste

Page 31

31

31

TROUBLESHOOTING

SMOKE ESCAPING

¬ Damp wood ¬ Chimney not drawing properly

¬ Chimney is not properly dimensioned for the stove ¬ Check if the smoke gas pipe/chimney are blocked

¬ Is the chimney the right height for its surroundings? ¬ Vacuum in room

¬ At rear outlet, check that the flue pipe does not obstruct the chimney draught

¬ The door is opened before the embers have burned down sufficiently

WOOD BURNING TOO QUICKLY

¬ The air valves are set incorrectly ¬ The baffle plates is incorrectly mounted or missing

¬ Inferior firewood (waste wood, pallets etc.) ¬ Chimney too large

SOOT BUILD-UP ON GLASS

¬ Incorrect secondary airflow setting ¬ Excessive primary air

¬ Damp wood ¬ Wood pieces too large on lighting

¬ Inferior firewood (waste wood, pallets etc.) ¬ Chimney not drawing sufficiently

¬ Vacuum in room

WHITE SHADOW ON THE INSIDE OF THE GLASS

¬ Over-firing (See "Instructions for heating") ¬ Too much primary air

¬ Vacuum in the room

EXCESSIVE SOOT BUILD-UP IN CHIMNEY

¬ Poor burning (more air required) ¬ Damp wood

THE SURFACE OF THE STOVE IS TURNING GREY

¬ Overheating (see instructions for heating)

POOR HEATING PERFORMANCE OF STOVE

¬ Damp wood ¬ Not enough wood

¬ Inferior wood quality with low fuel value ¬ Baffle plates are not fitted correctly

SMELL AND SOUND OF THE STOVE

¬ The lacquer on the stove hardens when you use the stove for the first time; this can cause an odour. Open a window or a door

for ventilation, and make sure the stove is heated up sufficiently to avoid odours later.

¬ When heating up and cooling down, the stove may make some clicking noises. These are due to the huge temperature differ-

ences to which the material is exposed and do not indicate any product defects.

Page 32

32

WARRANTY

All wood-fired Scan products are made of high-quality materials and subject to strict quality controls before leaving the factory.

We give a warranty of 5 years on manufacturing errors or defects.

You must quote your stove‘s product registration number when you contact us or your authorized Scan dealer with a warranty

claim.

The warranty covers all parts which in the opinion of Scan A/S require repair or replacement due to manufacturing or construction error

The warranty applies to the original purchaser of the product only, and is not transferable (except on prior sale).

The warranty covers only damage caused by manufacturing or construction errors.

THE FOLLOWING PARTS ARE NOT COVERED BY THE WARRANTY

¬ Wear and tear parts, such as the combustion chamber liners, baffle plates, riddling grate, glass, and seals (except for defects

which were present on delivery).

¬ Soap stones. This is a natural material, wherefore there might be differences in structure, colour, and form as well as grinding

marks. The soap stone can be smoothened with fine grinding paper. Smaller “scars” and holes can be repaired with soap stone

powder that you can get at your dealer’s.

¬ Defects caused by external chemical and physical influences during transportation, storage and assembly, or at a later time.

¬ Soot build-up caused by poor chimney draught, damp wood, or improper use.

¬ Costs of additional heating in connection with a repair.

¬ Transport costs.

¬ Costs for setting up, removing the wood stove.

THIS WARRANTY IS VOID

¬ In case of incorrect installation (the installer is responsible for observing and complying with legal requirements and local

bylaws, along with this Instructions manual for the wood-burning stove and accessories).

¬ In case of improper use, and/or use of prohibited fuels, non-original spares (see this instructions manual).

¬ If the product registration number of the stove has been removed or damaged.

¬ In case of repairs that do not comply with our instructions or instructions by an authorized Scan dealer.

¬ In case of any manipulation of the original state of this Scan product or its accessories.

¬ This warranty is only valid in the country to which this Scan product was originally supplied.

Always use original replacement parts, or parts recommended by the manufacturer.

Page 33

33

NOTES

Page 34

34

Page 35

35

Page 36

14.09.2018

SCAN A/S | Glasvænget 3-9 | DK-5492 Vissenbjerg | www.scan.dk

Edition:

UK 90065500

Product registration number

Quote this number at all enquiries

Loading...

Loading...