Page 1

SCAN A/S - DK-5492 VISSENBJERG

Scan 58 - series

ASSEMBLY- AND INSTRUCTIONS MANUAL

Congratulations on your new Scan wood-burning stove

You have purchased a product by one of Europe’s leading manufacturer’s of wood-burning stoves, and we are sure that you will have years of plea-

sure with your purchase. To make the best possible use of your stove, it is important that you follow our advice and instructions.

Please read this Assembly- and instructions manual before you start to assemble your stove.

Page 2

2

CONTENTS

Table of contents

Technical data .............................................................................................. 3

Installation

Safety

Technical data and dimensions

Dimension sketch for Scan 58 - series

Type plate

Assembly ...................................................................................................... 10

Transport brackets

Service box

Additional accessories

Positioning your wood-burning stove

Positioning near to non-flammable materials

Distance to furniture

Diatance to fl ammable walls

Product registration number

Adjusting screws

Load bearing foundation

Floor plate

Existing chimney and pre-fabricated element chimney

Connection between stove and steel chimney

Requirements for chimney

Connection with 90° elbow pipe

Fitting the stove onto the plinth

Fresh air intake

Closed combustion system

Connecting piece top outlet

Preparing the stove for rear outlet

Wall-hung model

Fitting the Scan 58 wall-hung model

Scan 58-9 and Scan 58-10

Scan 58-9 and Scan 58-10 with high top

Accessories .................................................................................................. 20

Mounting of high top for Scan 58-7 and Scan 58-8

Wall mounting kit for Scan 58 with high top

Heat accumulating stones for high top

Fitting the soapstone top

Fitting a storage door

Instruction for use ................................................................................... 26

CB technique

Primary air

Secondary air

Baffl e plates

Ash drawer

Handle for riddling grate

Instructions for heating ......................................................................... 27

Lighting

Handling fuel

Maintenance .............................................................................................. 29

Troubleshooting ........................................................................................ 31

Page 3

TECHNICAL DATA

3

Installation

The house owner is responsible for ensuring that all necessary national and local safety measures are observed during installation and

fitting and also responsible for observing the fitting and operating

instructions detailed in this manual.

When you install any kind of fireplace or stove, you must inform the

local authorities. You are also responsible for calling in a chimney

sweep to inspect and authorize the installation.

To ensure best-possible functionality and safety for your installation,

we advise you to call a professional fitter. Our Scan Dealer will be able

to recommend a qualified fitter in your area. For information on Scan

Dealers, please go to www.scan.dk.

Safety

Any changes made to the product by the dealer, installer or user

could result in the product and safety functions not functioning

as intended. The same applies to the fitting of accessories or extra

equipment not supplied by Scan A/S. This could also be the case if

parts that are necessary for the operation and safety of the stove are

dismantled or removed.

Technical data and dimensions

Materials: steel plate, cast iron, galvanised sheet, skamol

Surface treatment: Senotherm

Max. wood length: 33 cm

Weight Scan 58: ca. 100 kg

Weight Scan 58-9 and Scan 58-10: ca. 160 kg

Weight Scan 58-7 and Scan 58-8 with high top: ca. 120 kg

Weight Scan 58-9 and Scan 58-10 with high top: ca. 200 kg

Weight heat-accumulating stones: ca. 86,5 kg

Connecting piece internal diameter: 135 mm

Connecting piece external diameter: 148 mm

Approval type: Intermittent fuelling

Test in compliance with EN 13240

Basic data for the Scan 58 - series

CO Emission at 13% O2: 0,11% 1338 mg/Nm

3

Dust @ 13% O2: 44 mg/Nm

3

Nox @ 13% O2: 119 mg/Nm3

Nominel output: 5,5 kW

Amount of smoke: 6 g/sek

Sub-pressure EN 13240: 12 Pa

Recommended sub-pressure in connecting piece: 18-20 Pa

Required combustion air supply: 16,5 Nm3/h

Fuel: Wood

Fuel consumption: 1,8 kg/h

Amount of fuel: 1,4 kg

Scan 58 excl. high top

Efficiency: 76%

Chimney temperature EN 13240: 271 °C

Temperature in connecting piece: 350 °C

Scan 58 incl. high top

Efficiency: 80%

Chimney temperature EN 13240: 228 °C

Temperature in connecting piece: 300 °C

Intermittent fuelling means normal use of a woodstove. In other

words, you should let the fire die down until only the embers are left,

before refuelling.

The Scan 58-series was build in compliance with the homologized

product type specified in the Assembly- and Instructions Manual

provided with the product.

The EC declaration of conformity is available from www.scan.dk

Page 4

TECHNICAL DATA

1

1

3

8

1

7

5

9

9

8

*

175***

1

1

1

2

*

*

350500

108Ø

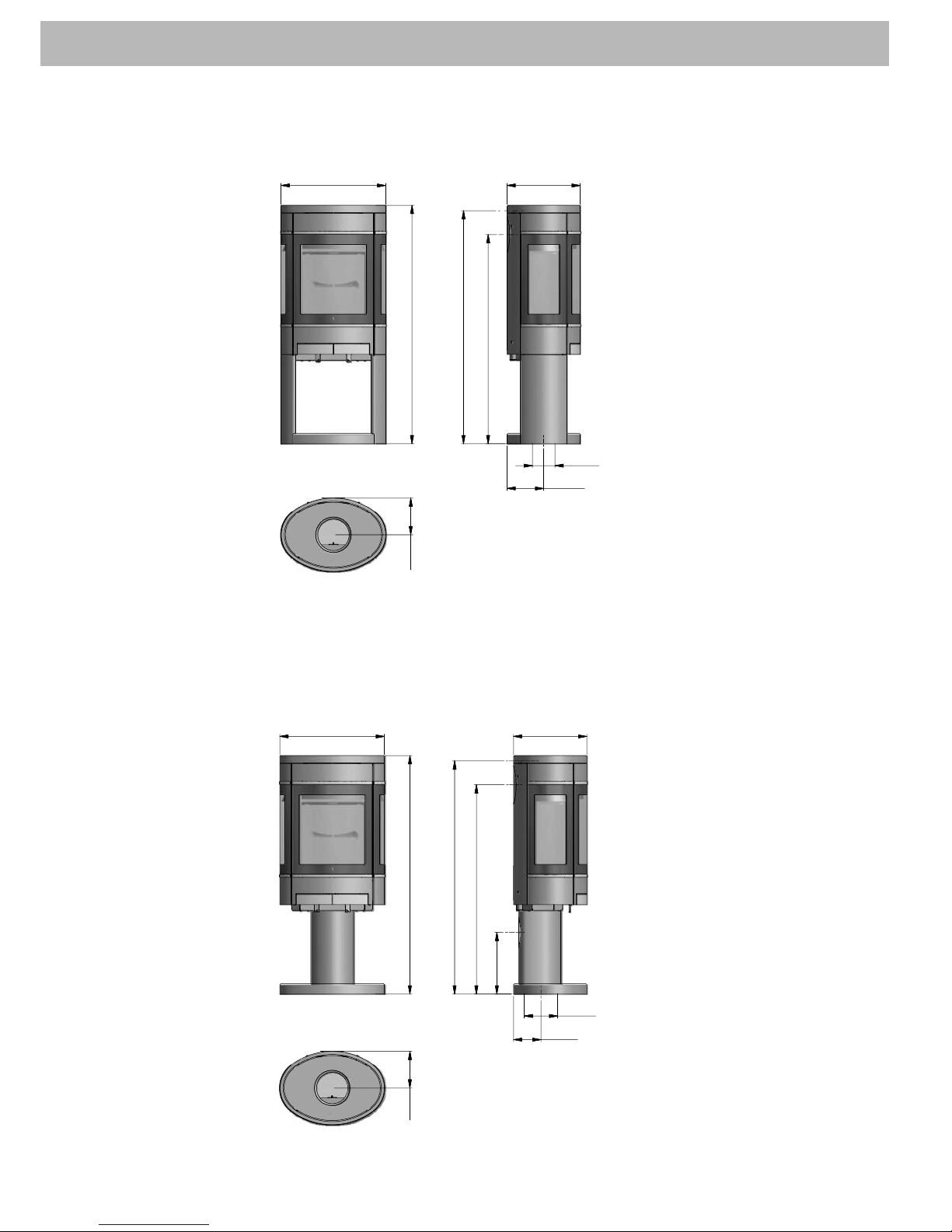

Dimension sketch Scan 58 with "see through" plinth

* Centre rear outlet

** Height to the beginning

of the connecting piece

at top outlet

*** Centre of fresh air in take bottom

**** Centre of fresh air intake

rear

* Height to the begin ning of the connecting

piece at top outlet

** Centre of fresh air in take bottom

*** Centre of fresh air in take rear

Dimension sketch Scan 58 with pedestal plinth

1

1

3

8

500

1

7

5

350

1

1

1

2

*

*

2

9

4

*

*

*

*

131***

160Ø

9

9

8

*

4

Page 5

TECHNICAL DATA

5

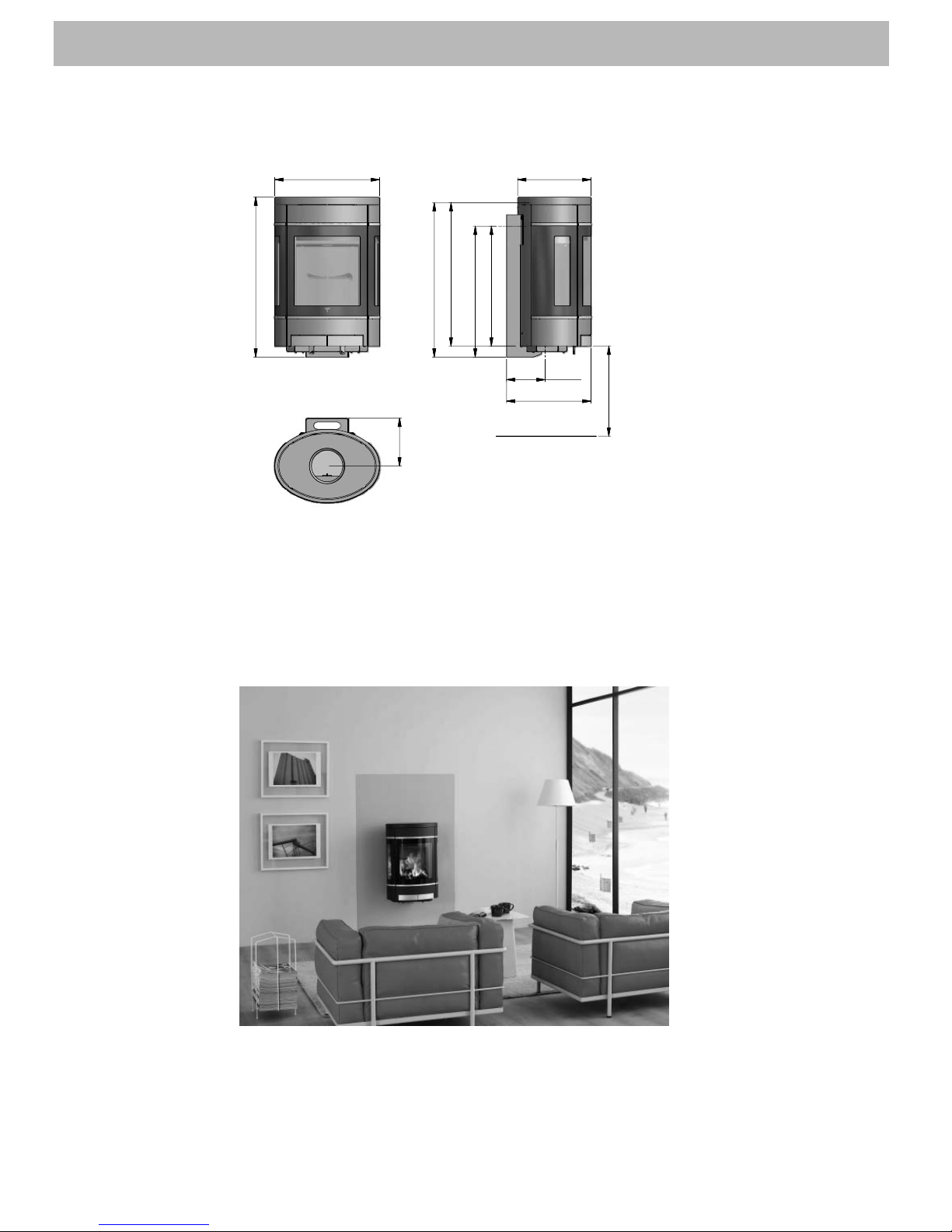

500 350

403

7

6

4

6

2

4

*

5

7

2

*

7

3

6

*

*

6

8

4

*

*

4

3

0

*

*

*

*

2

2

8

184***

Dimension sketch Scan 58 Wall-hung model

* Centre rear outlet

** Height to the beginning

of the flue pipe at top

outlet

*** Centre of fresh air in take bottom

**** Minimum clearance

above flammable mate

rial

Page 6

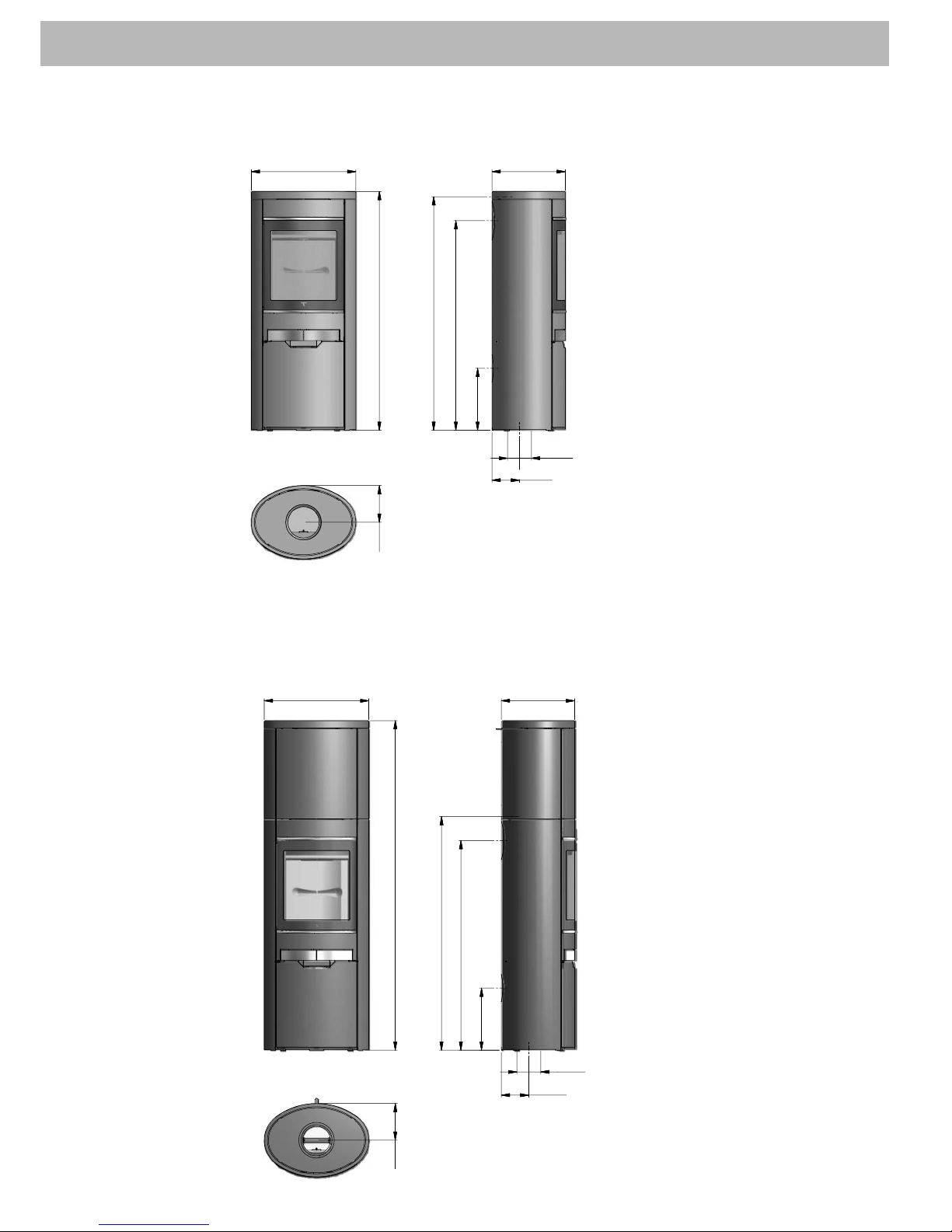

500 350

1

5

7

2

2

9

6

*

*

*

131***

114Ø

1

1

1

4

*

*

1

7

5

1

0

0

0

*

TECHNICAL DATA

6

500 350

1

1

4

0

1

1

1

4

*

*

2

9

6

*

*

*

*

1

0

0

0

*

1

7

5

114Ø

131***

Dimension sketch Scan 58-7 and Scan 58-8

* Centre rear outlet

** Height to the beginning

of the connecting piece

at top outlet

*** Centre of fresh air in take bottom

**** Centre of fresh air intake

rear

* Height to the begin ning of the connecting

piece at top outlet

** Centre of fresh air in take bottom

*** Centre of fresh air in take rear

Dimension sketch Scan 58-7 and Scan 58-8 with high top

Page 7

TECHNICAL DATA

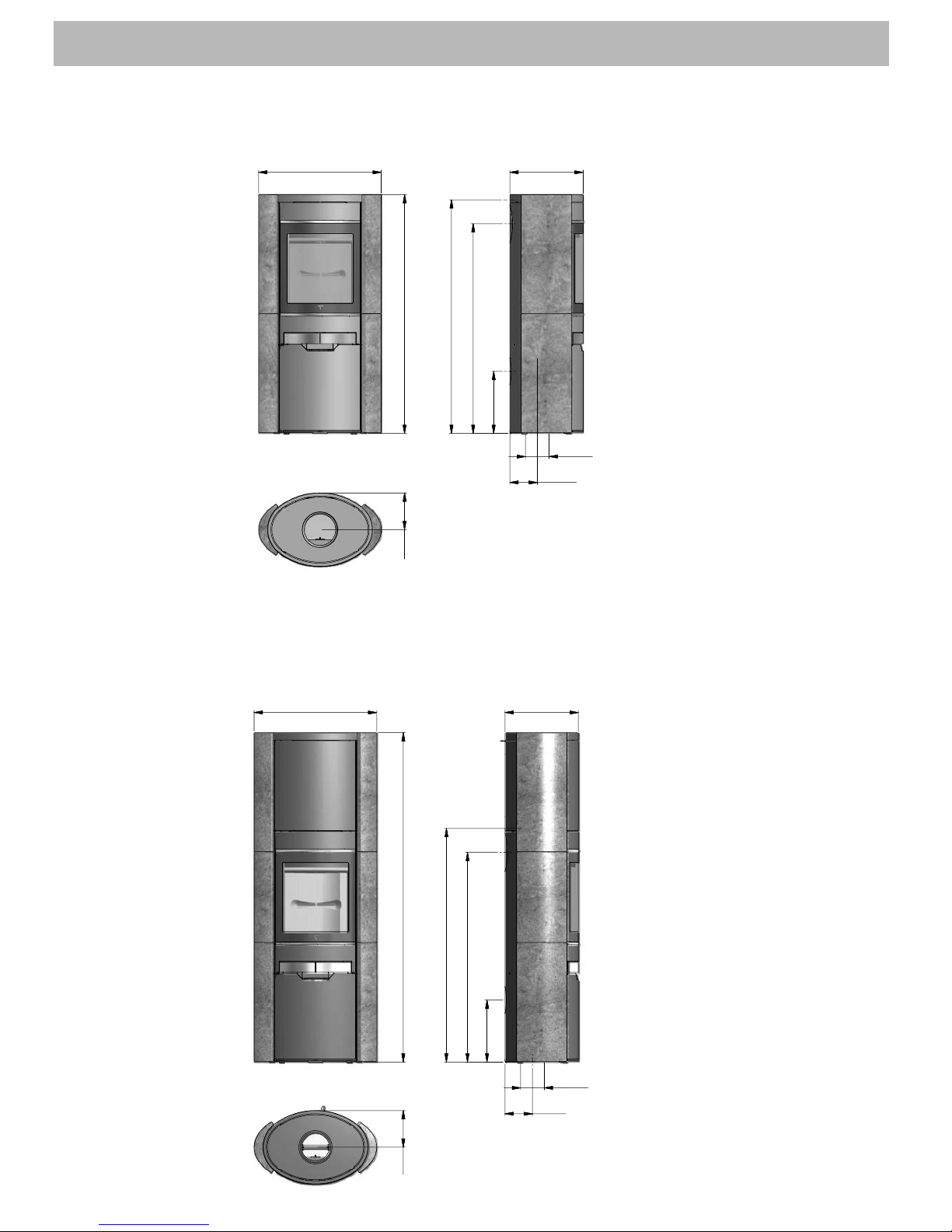

7

350

1

7

5

1

1

1

4

*

2

9

6

*

*

*

114Ø

131**

1

5

7

2

1

0

0

0

586

* Height to the begin ning of the connecting

piece at top outlet

** Centre of fresh air in take bottom

*** Centre of fresh air in take rear

Dimension sketch Scan 58-9 and Scan 58-10 with high top

1

1

4

0

586 350

2

9

6

*

*

*

*

1

0

0

0

*

114Ø

131***

1

7

5

1

1

1

4

*

*

Dimension sketch Scan 58-9 and Scan 58-10

* Centre rear outlet

** Height to the beginning

of the connecting piece

at top outlet

*** Centre of fresh air in take bottom

**** Centre of fresh air intake

rear

Page 8

TECHNICAL DATA

8

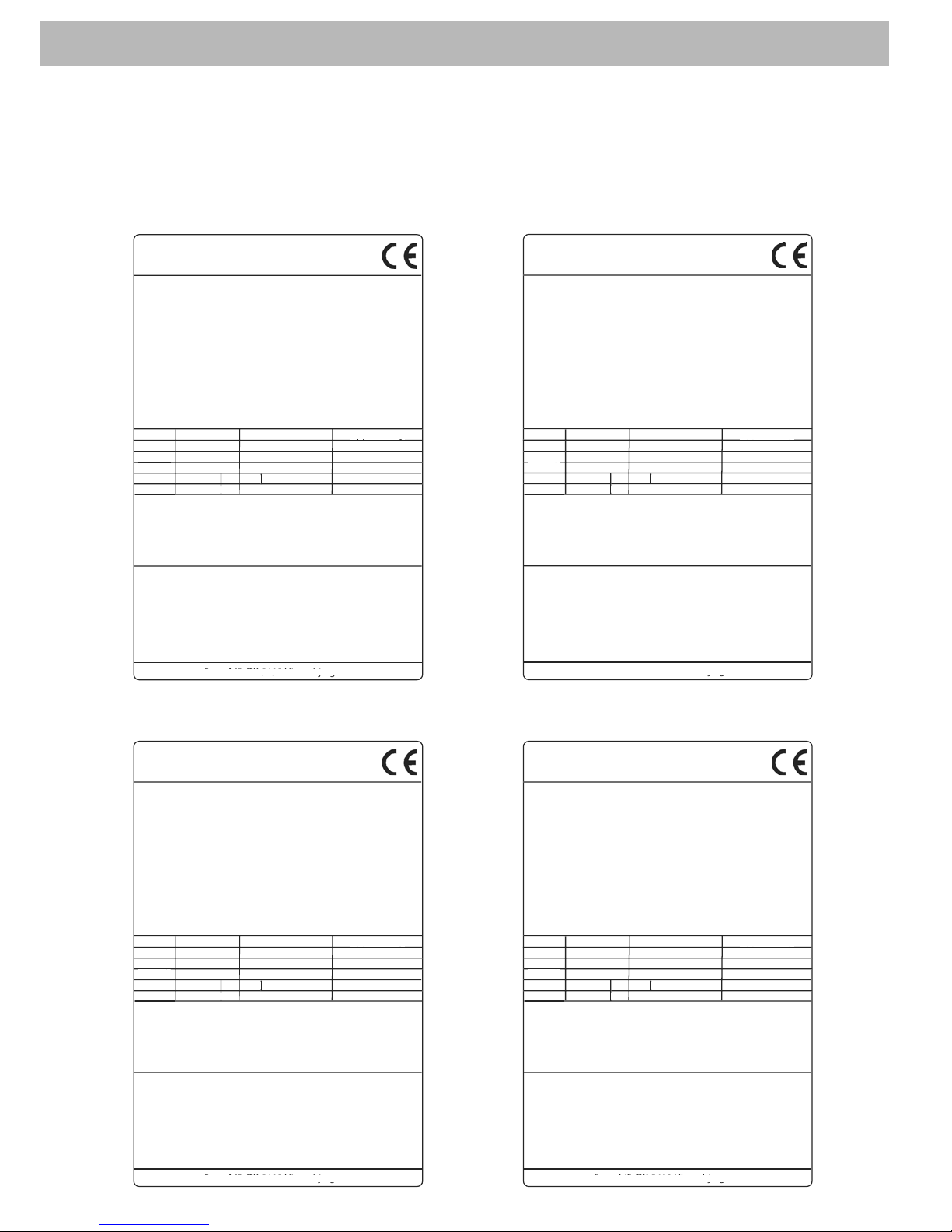

Scan 58-3 & Scan 58-6 (with full lateral glass panes)

Scan 58-3 + Scan 58-

6

Freestanding room heater fired by solid fue

l

Standar

d:

Fuel type:

Operation type:

The appliance can be operated in a shared flue.

C

ountry

E

N 13240 EC no. 90

358602

Wood

Intermittent

EU

R

Norway

y

Classification

Intermittent

Klasse

2

C

ertificate/Standard

EN 13

240

SINTEF 110-029

8

Approved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm³

Flue gas temperature: 350°C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to combustible materials

:

Sid

e: 600 mm - Back: 250 mm - Front: 1000 mm

C

O emission at 13% O2:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten

.

Verwenden Sie nur empfohlene Brennstoffe

.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0,11% 1338 mg/Nm

³

Schwei

z

Germany

y

LRV 1

1

BStV 1

VKF N 18900

F

SPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Type plates

All Scan wood-burning stoves are fitted with a type plate, that specifies the approval standards and the distance to flammable materials.

The type plate on the Scan 58-7, Scan 58-8, Scan 58-9 and Scan 58-10 is located in the magazine under the combustion chamber.

Scan 58-1 & Scan 58-4 (without lateral glass panes)

Scan 58-1 + Scan 58-4

Freestanding room heater fired by solid fuel

Standar

d:

Fuel type:

Operation type

:

The appliance can be operated in a shared flue

.

Countr

y

E

N 13240 EC no. 90

358600

Woo

d

Intermitten

t

E

UR

Norway

y

Classificatio

n

Intermitten

t

Klasse 2

Certificate/Standar

d

EN

1324

0

SINTEF 110-02

98

App

roved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm

³

Flue gas temperature: 350°C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to combustible materials

:

Sid

e: 350 mm - Back: 250 mm - Front: 1000 m

m

CO emission at 13% O2

:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0

,11% 1338 mg/Nm³

Schwei

z

Germany

y

LRV 11

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Scan 58-2 & Scan 58-5 (with half lateral glass panes)

Scan 58-2 + Scan 58-

5

Freestanding room heater fired by solid fuel

Standar

d:

Fuel type:

Operation type

:

The appliance can be operated in a shared flue

.

Countr

y

E

N 13240 EC no. 90

358601

W

ood

Intermitten

t

E

UR

Norway

y

Classificatio

n

Intermitten

t

Klasse 2

Certificate/Standar

d

EN 1324

0

SINTEF 110-029

8

App

roved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm

³

Flue gas temperature: 350°C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to com

bustible materials:

Sid

e: 600 mm - Back: 250 mm - Front: 1000 m

m

CO emission at 13% O2

:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0

,11% 1338 mg/Nm³

Schwei

z

Germany

y

LRV 11

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Scan 58-1 Wall & Scan 58-4 Wall (without lateral glass panes)

Scan 58-1 Wall + Scan 58-4 Wa

ll

Wall mounted room heater fired by solid fue

l

Standar

d:

Fuel type:

Operation type:

The appliance can be operated in a shared flue.

C

ountr

y

E

N 13240 EC no. 90

358611

Wood

Intermittent

E

UR

Norway

y

Classification

Intermittent

Klasse

2

C

ertificate/Standard

EN 13240

SINTEF 110-029

8

Approved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm³

Flue gas temperature: 350°C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to com

bustible materials:

Sid

e: 350 mm - Front: 1000 m

m

C

O emission at 13% O2:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten

.

Verwenden Sie nur empfohlene Brennstoffe

.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0,11% 1338 mg/Nm

³

Schwei

z

Germany

y

LRV 1

1

BStV 1

VKF N 18900

F

SPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Page 9

TECHNICAL DATA

9

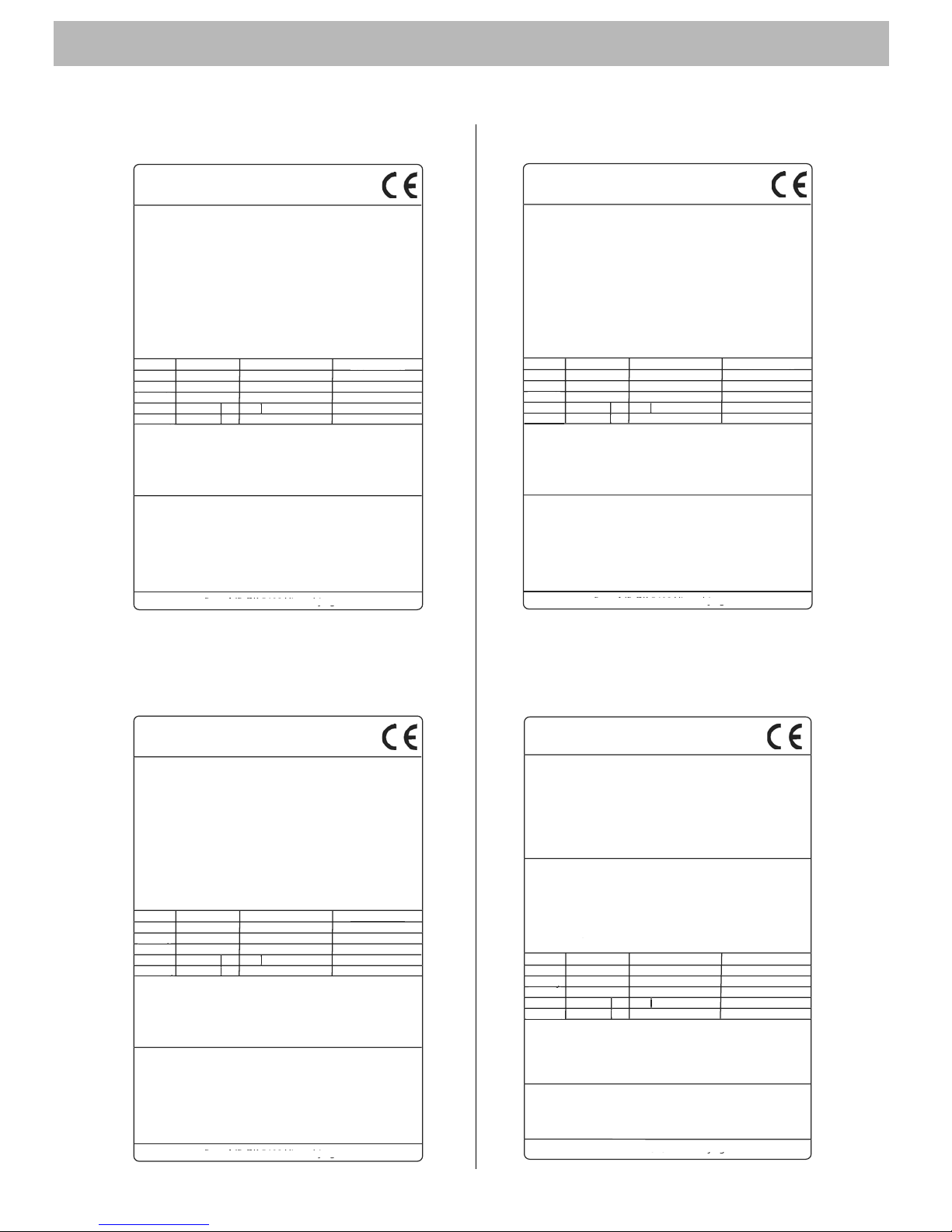

Scan 58-2 Wall & Scan 58-5 Wall (with half lateral glass panes)

Scan 58-2 Wall + Scan 58-5 Wa

ll

Wall mounted room heater fired by solid fuel

Standar

d:

Fuel type

:

Operation type

:

The appliance can be operated in a shared flue

.

Countr

y

E

N 13240 EC no. 90

358612

Woo

d

Intermitten

t

E

UR

Norway

y

C

lassificatio

n

Intermitten

t

Klasse 2

C

ertificate/Standar

d

EN

1324

0

SINTEF 110-02

98

App

roved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm

³

Flue gas temperature: 350°

C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to combustible materials

:

Side:

600

mm - Front: 1

000 mm

C

O emission at 13% O2

:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0,11% 1338 mg/Nm

³

Sch

wei

z

Germany

y

LRV 11

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Scan 58-3 Wall & Scan 58-6 Wall (with full lateral glass panes)

Scan 58-3 Wall + Scan 58-6 Wa

ll

Wall mounted room heater fired by solid fuel

Standard:

Fuel type

:

Operation type

:

The appliance can be operated in a shared flue

.

Countr

y

E

N 13240 EC no. 90

358613

Woo

d

Intermitten

t

E

UR

Norway

y

C

lassificatio

n

Intermitten

t

Klasse 2

C

ertificate/Standar

d

EN 1324

0

SINTEF 110-029

8

App

roved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm

³

Flue gas temperature: 350°

C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to combustible materials

:

Side:

600

mm - Front: 1

000 mm

C

O emission at 13% O2

:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

Verwenden Sie nur empfohlene Brennstoffe.

1000 10-2009

S

can

A/S DK

5492 Vissenbjer

g

0,11% 1338 mg/Nm

³

Sch

wei

z

Germany

y

LRV 11

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Scan 58-7 & Scan 58-8

Scan 58-7 + Scan 58-8

Freestanding room heater fired by solid fue

l

Standar

d:

Fuel type:

Operation type:

The appliance can be operated in a shared flue.

C

ountr

y

E

N 13240 EC no. 9035860

9

Wood

Intermittent

EU

R

Norway

y

Classification

Intermittent

Klasse

2

C

ertificate/Standard

EN 13

240

SINTEF 110-02

98

Approved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust CO emission at 13% O2: 44 mg/Nm³

Flue gas temperature: 350°C

Nominal heat output: 5,5

kW

Efficiency:76

%

Scan A/S DK 5492 Vissenbjerg

M

inimum distance to combustible materials

:

Sid

e: 350 mm - Back: 250 mm - Front: 1000 mm

C

O emission at 13% O2:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten

.

Verwenden Sie nur empfohlene Brennstoffe

.

1000 05-2009

S

can

A/S DK

5492 Vissenbjer

g

0,11% 1338 mg/Nm

³

Schwei

z

Germany

y

LRV 1

1

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Scan 58-7 & Scan 58-8 with high top

S

can 58-7 + Scan 58-8 with high to

p

Freestanding room heater fired by solid fue

l

Standard:

Fuel type

:

Operation type:

The appliance can be operated in a shared flue.

y

C

ountr

y

EN 13240 EC no. 90

358

619

Woo

d

Intermitten

t

E

UR

Norway

y

Austri

aClass

ificati

on

Intermitten

t

K

lasse 2

Certificate/Standar

d

EN

13240

SINTEF 110-0298

15

a B-VG

Approved

by

pp y

RWE Power A

G

S

INTEF - NB

L

RWE Power A

G

Dust at 13% O2: 44 mg/Nm

³

Flue gas temperature: 300

°C

Nominal heat output: 5,5

kW

Efficiency: 80%

Angaben für Österreic

h

W

ärmeleistungsbereich: 3,0 - 6,7 kW

Brennstoffwärmeleistung: 8,4 k

W

Zulässige Brennstoffe: Scheitholz

Prüfbericht

:

FSPS-Wa 1769-A

Scan A/S DK 5492 Vissenbjerg

Minimum distance to com

bustible materials:

Side: 350 mm - Back: 250 mm - Front: 1000 m

m

C

O emission at 13% O2

:

Follow assembly- and instructions manua

l.

Use only recommended fuels.

Montage- und Bedienungsanleitung beachten

.

V

erwenden Sie nur empfohlene Brennstoffe

.

1000 06-2010

Scan A/S DK

549

2 Vissenbjer

g

0

,11% 1338 mg/Nm

³

Schweiz

G

erman

y

y

LRV 11

BStV 1

VKF N 18900

FSPS-Wa 1769-E

N

RWE Power A

G

RWE Power A

G

Page 10

ASSEMBLY

10

Additional accessories

• Large shaped floor plate in glass or steel.

• Small shaped floor plate in steel

• Soap stone top for rear outlet

• Soap stone top for top outlet

• Soap stone top for stove with soap stone sides

• Soap stone top with hole for stove with soap stone sides

• Glass top plate for rear outlet

• Glass top plate for top outlet

• Storage door

• High top (Scan 58-7 and Scan 58-8)

• Wall mounting kit for Scan 58 with high top

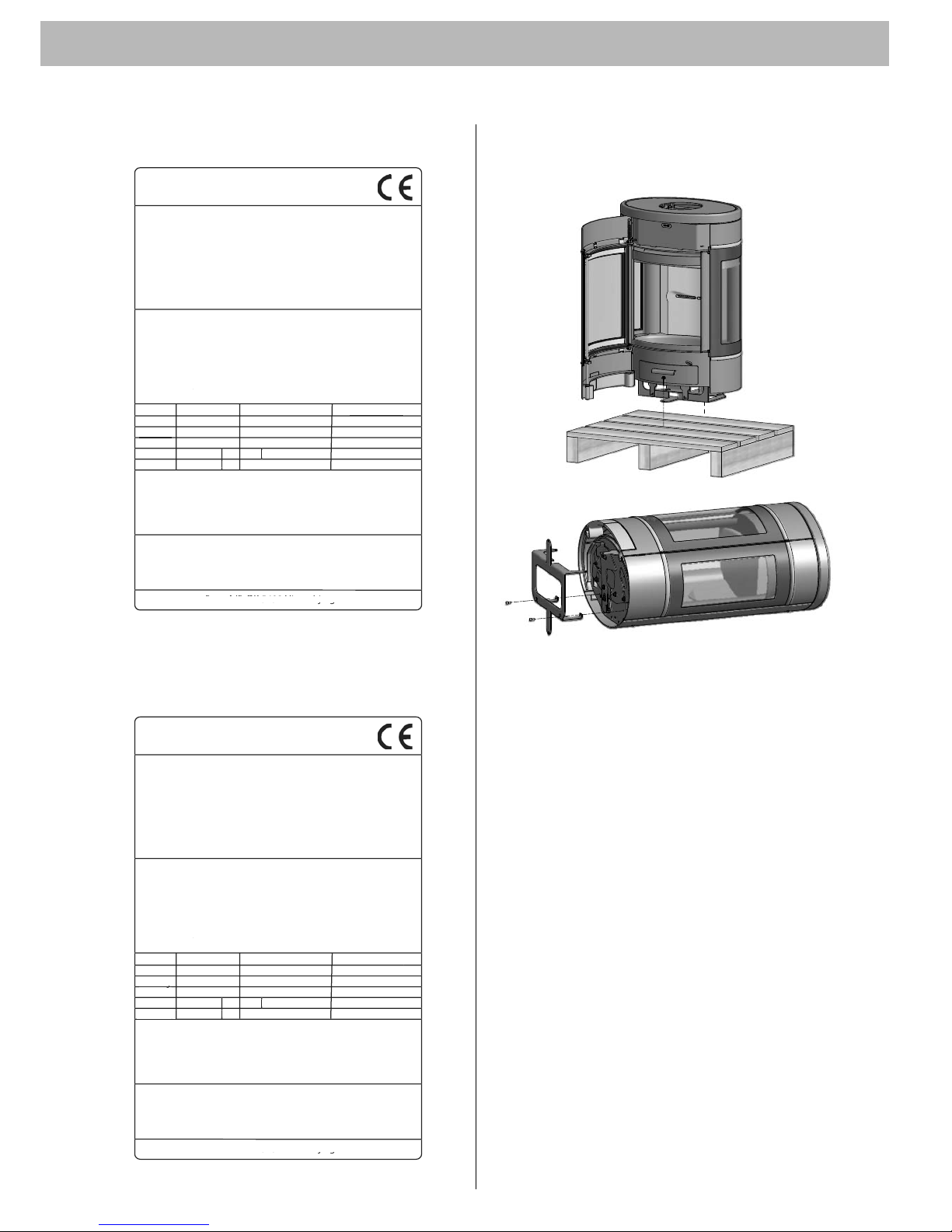

Transport brackets

For Scan 58 with pedestal and see-through base / Scan 58 wall model,

remove the transport brackets as shown below.

Service box

The service box contains the following:

• Fitting for connecting piece

• Seal

• Safety fitting

• Plastic plugs for transport safety hole at the bottom of

the stove (not used for this Scan model)

• Various tools

• Glove

• Fire starters for first lighting

Scan 58-9 & Scan 58-10

Scan 58-9 + Scan 58-1

0

Freestanding room heater fired by solid fue

l

Standar

d:

Fuel type

:

Operation type

:

The appliance can be operated in a shared flue.

y

C

ountr

y

E

N 13240 EC no. 90

358617

Wood

Intermitten

t

EUR

Norway

y

Class

ificati

on

Intermittent

K

lasse 2

C

ertificate/Standar

d

EN 13

240

SINTEF 110-029

8

Approved

by

pp y

RWE Power A

G

S

INTEF - NBL

Dust at 13% O2: 44 mg/Nm

³

Flue gas temperature: 350

°C

Nominal heat output: 5,5

kW

Efficiency: 76%

Scan A/S DK 5492 Vissenbjerg

Minimum distance to com

bustible materials:

Side: 350 mm - Back: 250 mm - Front: 1000 m

m

CO emission at 13% O2

:

Follow assembly- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

V

erwenden Sie nur empfohlene Brennstoffe

.

1000 06-2010

Scan A/S DK

549

2 Vissenbjer

g

0,11% 1338 mg/Nm

³

Schweiz

G

erman

y

y

LRV 1

1

BStV 1

VKF N 18900

FSPS-Wa 1769-EN

RWE Power A

G

RWE Power A

G

Scan 58-9 & Scan 58-10 with high top

Scan 58-9 + Scan 58-10 with high to

p

Freestanding room heater fired by solid fue

l

Standard:

Fuel type

:

Operation type

:

The appliance can be operated in a shared flue.

y

C

ountr

y

E

N 13240 EC no. 90

358620

Wood

Intermitten

t

EUR

Norway

y

Austri

a

Class

ificati

on

Intermittent

K

lasse 2

C

ertificate/Standar

d

EN

13240

SINTEF 110-02

98

15 a B-V

G

Approved

by

pp y

RWE Power A

G

S

INTEF - NBL

RWE Power A

G

Dust at 13% O2: 44 mg/Nm³

Flue gas temperature: 300°C

Nominal heat output: 5,5

kW

Efficiency: 80

%

Ang

aben für Österreic

h

Wärmeleistungsbereich: 3,0 - 6,7

kW

Brennstoffwärmeleistung: 8,4 k

W

Zulässige Brennstoffe: Scheithol

z

Prüfbericht:

F

SPS-Wa 1769-A

Scan A/S DK 5492 Vissenbjerg

Minimum distance to com

bustible materials:

Side: 350 mm - Back: 250 mm - Front: 1000 m

m

CO emission at 13% O2

:

Follow assem

bly

- and instructions manua

l.

Use only recommended fuels

.

Montage- und Bedienungsanleitung beachten.

V

erwenden Sie nur empfohlene Brennstoffe

.

1000 06-2010

Scan A/S DK

549

2 Vissenbjer

g

0,11% 1338 mg/Nm

³

Schweiz

G

erman

y

y

LRV 1

1

BStV 1

VKF N 18900

FSPS-Wa 1769-EN

RWE Power A

G

RWE Power A

G

Page 11

ASSEMBLY

11

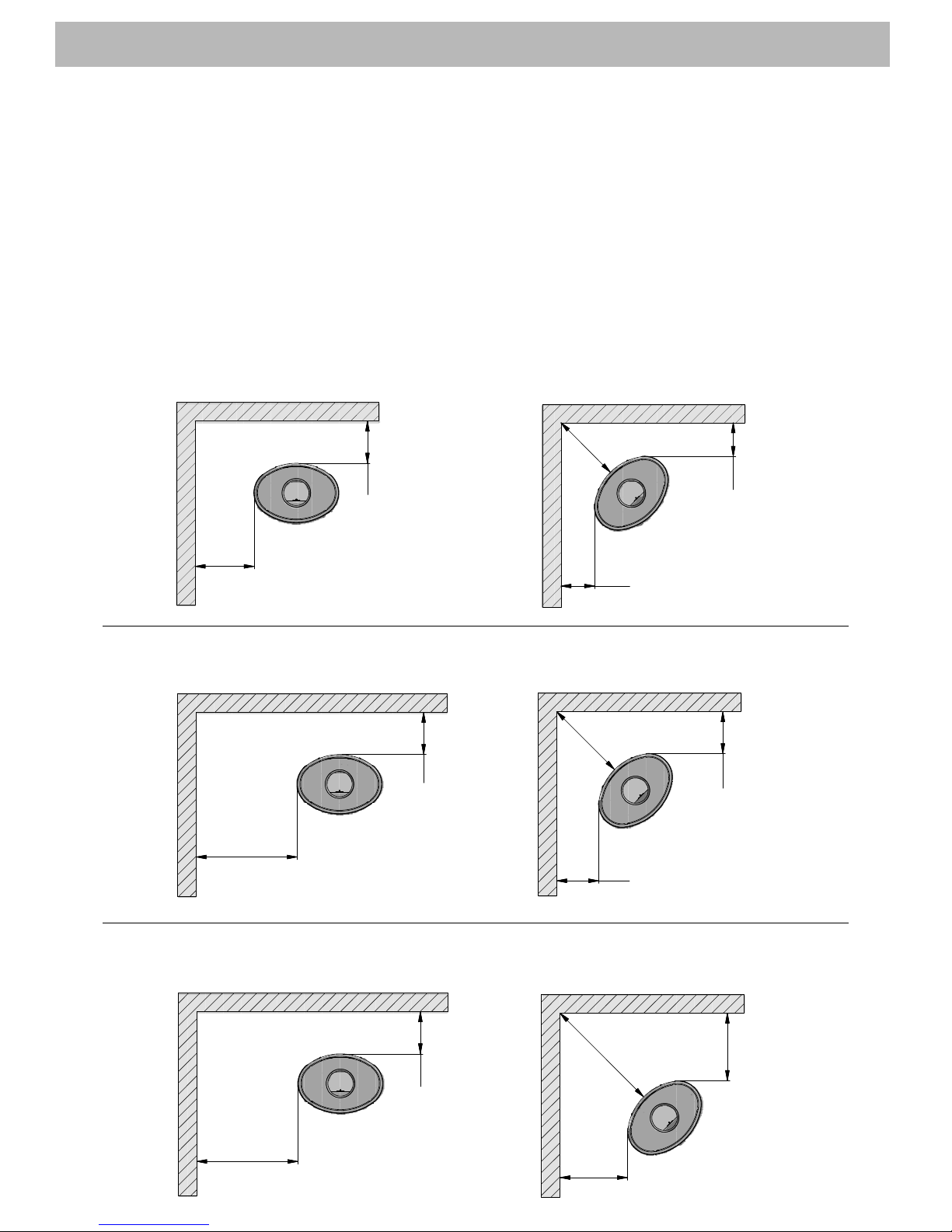

Distance to flammable walls

2

5

0

600

45° Corner installation

Parallel rear wall installation

Positioning your wood-burning stove

The wood-burning stove must be set up so that the stove itself, the flue pipe, and the chimney can all be cleaned.

Position near to non-flammable walls

When positioning near a non-flammable wall, we recommend you keep a minimum distance of 50 mm between the rear of the product and the

wall for cleaning purposes.

Distance to furniture: 1000 mm

But please check to avoid furniture or other furnishings being dried out due to being too close to the stove.

2

5

0

600

2

5

0

350

Scan 58-3 & Scan 58-6 (with full lateral glass panes)

Parallel rear wall installation

Scan 58-2 & Scan 58-5 (with half lateral glass panes)

45° Corner installation

Scan 58-1 & Scan 58-4 (without lateral glass panes)

Scan 58-7, Scan 58-8, Scan 58-9, Scan 58-10 og Scan 58 with high top

Parallel rear wall installation

45° Corner installation

4

0

0

400

70

1

2

5

0

250

48

6

2

0

0

200

4

1

5

Page 12

12 ASSEMBLY

600

350

Scan 58-2 Wall & Scan 58-5 Wall (with half lateral glass panes)

Scan 58-3 Wall & Scan 58-6 Wall (with full lateral glass panes)

Scan 58-1 Wall & Scan 58-4 Wall (without lateral glass panes)

Non-flammable wall

Flammable wall

Non-flammable wall

Flammable wall

Product registration number

Adjusting screws

Adjusting screws

The Scan 58 has four adjusting screws under the plinth of the woodburning stove. Use the adjusting screws to get the stove to stand

vertically.

Tilt the plinth and adjust the screws before fitting the stove in place.

On the Scan 58-7, Scan 58-8, Scan 58-9 and Scan 58-10 you can also

choose to adjust the adjustment screws in the magazine under the

combustion chamber.

If you are using a shaped floor plate, you should adjust the stove

upwards to allow the plate to be inserted under the front of the stove.

Adjusting screws

Product registration number

Open the door and read the product registration number. Make a

note of the number below. This number must be kept safe, in case

you need to contact us.

Page 13

ASSEMBLY

13

Load bearing underlay

All of the products in our portfolio are classified as light-duty fireplaces; in most cases, there is no need to reinforce the floor, so that you

can typically use the normal floor.

However, you should make sure that the load bearing underlay can

bear the weight of the wood-burning stove and that of the chimney.

Floor plate

If you are setting up the stove on a flammable floor, observe national

and local regulations on the size of the non-flammable underlay that

covers the floor around the stove.

Your local Scan dealer can advise you on regulations concerning

flammable materials in the vicinity of your stove.

The idea behind the floor plate is that it protects the floor and flammable material against sparks.

The floor plate can be made of steel or glass, and the stove can be set

up on brick, natural stone or similar materials.

This Scan wood-burning stove has an integrated floor plate, and

can thus be set up on any flammable material without a protective

underlay.

If you have chosen the Scan 58 wall-hung model, the floor plate must

extend right back to the hanging wall.

Small shaped floor plate for the Scan 58

Large shaped floor plate for the Scan 58

Existing chimney and pre-fabricated element

chimney

If you intend to connect your stove to an existing chimney, it makes

sense to contact an authorised Scan dealer, or a local chimney sweep

for advice. These experts will also let you know if your flue needs

renovating.

When connecting a pre-fabricated element chimney, follow the

manufacturer’s connection instructions for the relevant chimney

type.

Connection between stove and steel chimney

Your Scan dealer, or local chimney sweep, can advise you on choosing

a make and type of steel chimney. This ensures that the chimney

will match your wood-burning stove. As a general rule, the length of

the flue should not be less than 3,5 m measured from the top of the

wood-burning stove.

Choosing the wrong length or diameter of steel chimney could

impair functionality.

Always observe the chimney vendor‘s instructions precisely.

Requirements for chimney

The chimney must be labelled T400 and G for soot testing.

Connection with 90° elbow pipe

If you intend to use an elbow pipe with the Scan 58, we recommend

the use of a curved elbow pipe to improve the draft.

If you are connecting your stove using a sharp elbow bend, the cleanout door should be in the vertical section, such that the horizontal

part can be cleaned through it.

Scan 58 with high top can be fi tted with an elbow pipe provided that

the stove is fi xed to the wall using a special wall mounting kit. This

kit can be purchased from your local Scan dealer.

Page 14

14 ASSEMBLY

4 x allen screws M6x70

A

A

Fitting the stove onto the plinth

There are two plinths for the Scan 58. You can see how to fit these

below. Use the key supplied with the service pack to make the attachment secure.

A

Scan 58 with pedestal plinth

If you have decided to connect external combustion air via the pedestal plinth, mount the connection piece supplied before fitting the

plinth to the stove.

Scan 58 with "see through" plinth

Fresh air intake

In a well-insulated house, the air used up by the burning process

has to be replaced. This particularly applies to houses with mechanical ventilation. There are different ways of making sure that an air

exchange takes place. The most important thing is to ensure that

there is a supply of air to the room where the wood stove is located.

The external wall vent must be located as close to the wood stove as

possible, and you must be able to close it when you are not using the

wood stove.

National and local building regulations must be followed with

regard to the connection of fresh-air intake.

Closed combustion system

If you have decided to use the stove’s closed combustion system, connect the external combustion air using a ventilation pipe passing

through the wall or floor.

It must not be possible to shut off the ventilation pipe with a valve

• Minimum Ø100 mm ventilation pipe, maximum length: 6 m

with a maximum of one bend

The Scan 58 with pedestal plinth

External combustion air can be connected via the pedestal or plinth

base by fitting the connection piece supplied to the pedestal plinth

and connecting outdoor air.

External combustion air via wall

External combustion air via floor

Page 15

ASSEMBLY

15

Connecting piece top outlet

Your wood-burning stove has been prepared for a top outlet by the

manufacturer. Remove the cover plate from the top plate, and fit the

connecting piece, the enclosed seal, and the fittings from the service

package. At the same time, fix the safety fitting crosswise to prevent

damage to the baffle plate when sweeping the chimney.

Connecting

piece

Safety

fitting

B

B

Bracket

Seal for

connecting

piece

Screws for

adjusting

the height

of the top

plate

Screws for adjusting the height

of the frame for

the top plate

The Scan 58 with "see through" plinth

External combustion air can be connected underneath the combustion chamber using the connection piece supplied and connecting

outdoor air.

If you decide on connecting external combustion air through the

bottom of the plinth, unscrew the blanking plate and fit it under the

combustion chamber. Then fit the connection piece supplied under

the plinth as shown below before connecting outdoor air.

Scan 58-7 and Scan 58-8

External combustion air can be connected in the magazine under the

combustion chamber by fitting the connection piece and fresh air

box supplied. Outdoor air can then be connected through the bottom

or rear of the stove.

Scan 58 Wall-hung model

Page 16

16 ASSEMBLY

Preparing the stove for rear outlet

Remove the top plate and the frame for the top plate. The Allen

screws and discs are to be reused, when the stove is assembled again.

To attach the flue pipe, remove the cover plate on the rear plate

and heat shield as follows:

Drill out the four holes in the cover plates with a Ø8 bit and

remove the plates.

4 allen screws M6x10

C

C

Loosen the cast iron cooking plate from the inside and remove.

This is to be used later as a seal and cover at the top of the smoke

outlet.

Fit the separate connecting piece in place from the outside and fix in

place using the bracket and seal supplied in the service pack. Fit the

frame for the top plate.

C

Connecting

piece

Seal for con-

necting piece

Use pliers to cut the anchor points on the heat shield and

remove the shield.

Anchor points

4 discs Ø 6.5 / Ø16 x 1.1

Page 17

ASSEMBLY 17

D

D

Fit the cast iron cooking plate in the smoke outlet. Place the top plate

on the stove.

Bracket

Allen screw

Wall-hung model

Installation must be planned and executed in accordance with natio-

nal and local building regulations.

The stove must only be fitted to a non-flammable wall. There must

be no form of flammable component in the wall. In the case of thin

walls, nor must there be any behind the wall. The load-bearing capa-

city of the wall must be checked under all circumstances.

To ensure correct installation we recommend that a building expert

be commissioned to plan and outline the installation with a view to

subsequent approval.

For wall installation we recommend using the wall brackets supplied.

If a chimney is installed on top of a wall-hung model, the chimney

must be fully self-supporting. It must not rest on the wood-burning

stove. There must be a distance of at least 6 mm between the first

section and the flange on the flue collar (see below). Please consult

a specialist.

Scan A/S disclaims all liability for the installation of wall-hung

wood-burning stoves.

Fitting the Scan 58 wall-hung model

Remove the screws in the rear casing of the stove.

Remove the type plate from the stove and replace it with the type

plate corresponding to the wall model in question. The type plate for

the wall model is packed together with the wall fitting.

First section

Flange on

the connecting

piece

Screws for

adjusting

the height

of the top

plate

Screws for adjusting the height

of the frame for

the top plate

Page 18

ASSEMBLY

18

Fit the wall brackets to the wall. Fit the washers and screws for the rear casing (E). Fasten these only once fitting of the stove is complete.

Hang the stove on the wall bracket. The pegs in the wall bracket must ‘catch’ in the holes at the bottom of the stove (F). Fit and tighten the screws

for the wall bracket and stove (G).

Fitting of the stove is now complete. Tighten the screws and washers in the rear casing (E).

2 x allen screws M5x30

2 x washers

6 allen screws M6x70

E

E

G

G

F

Nose on wall

bracket

F

0

2040668

6

1

0

6

1

3

2

1

5

2

1

7

2

0

33

67

100

268

301

335

368

9

8

,

5

Page 19

ASSEMBLY

19

8 distance bushings for soap stone

8 screws 6 x 30 mm for soap stone

Each soap stone is to be mounted with distance bushings and screws

(pos. H). These are delivered together with the stove. Use a Torx

screwdriver for tightening the screws. You are not to use any electrical tools, as this might tighten the screws too much, resulting in the

soap stones breaking.

Mount the soap stone sides on the stove.

H

H

Scan 58-9 and Scan 58-10

Scan 58-9 and Scan 58-10 are delivered with loose soap stone plates

for mounting on the sides of the stove.

Soap stone is a natural material, wherefore there might be differences in structure and form.

The delivered gasket should be cut in pieces of 1 meter and sticked

onto the sides of the stove, on the outer side of the markings as

shown below.

Gasket

Marking

Page 20

ACCESSORIES

20

12 distance bushings for soap stone

12 screws 6 x 30 mm for soap stone

The high top and the chimney are mounted as described in the section ”Mounting of high top for Scan 58-7 and Scan 58-8 on page 21”.

I

I

Scan 58-9 and Scan 58-10 with high top

4 gaskets each 35 cm

In order to prepare the stove for mounting of soap stones, we refer

to the section ”Scan 58-9 and Scan 58-10”, page 19. However, the soap

stones must be mounted according to the size as shown below (the

smaller stone in the middle).

The delivered gasket should be cut in pieces of 35 cm and sticked onto

the high top of the stove, on the outer side of the markings as shown

below.

Each soap stone must be mounted with distance bushings and

screws (pos. I). These are delivered with the soap stone and the high

top.

Page 21

ACCESSORIES

21

4 x allen screws M6x10

4 discs Ø 6.5 / Ø16 x 1.1

L

Remove the top plate and the frame for the top plate. The Allen

screws and discs (pos. L) are to be reused when the high top is fastened on the stove.

When remounting the frame for the top plate, it should be turned

180°, so that the heat shield turns towards the front of the door of

the stove.

L

Heat shield

Mounting of high top for Scan 58-7 and Scan 58-8

2 x allen screws M5x25

K

K

J

J

Loosen the screws in the bottom

of the high top.

If you choose to connect the stove with an elbow pipe or a rear outlet, the stove must be mounted to the wall behind the oven using a

special wall mounting kit. This kit can be purchased from your local

Scan dealer. For fitting, see page 24.

It is very important that the base is level and stable.

The type plate delivered with the high top is to replace the type plate

placed on the stove. Remove the existing type plate from the stove

and replace it with the new one. The type plate is to be found in the

compartment under the burn chamber.

Mounting of the high top:

The front plate of the high top is removed as follows:

Loosen the screws (pos. J). Remove the Allen screws (pos. K). Remove

the front of the high top.

Page 22

ACCESSORIES

22

Place the top plate and the frame for the top plate on the stove without fastening them. Mount the chimney.

L

For mounting of the flue collar, see page 15: “Connecting piece top

outlet”.

Mount the high top, adjust the height and tighten it.

Screws

for height

adjustment

of the high

top

Page 23

ACCESSORIES

23

4 x allen screws M6510

4 discs Ø 6.5 / Ø16 x 1.1

Fasten the frame for the top plate (the heat shield must turn towards

the door) with the screws and discs (pos. M) delivered with the high

top.

Remount the front plate for the high top and tighten it.

Tighten the

screws in the bottom of the front

plate.

Screws for

adjusting

the height

of the top

plate

Screws for

adjusting the

height of the

frame for the

top plate

M

M

Heat shield

Page 24

ACCESSORIES

24

Wall mounting kit for Scan 58 with high top

If you choose to connect the stove with an elbow pipe or a rear outlet, the stove must be mounted to the wall behind the oven using a

special wall mounting kit. This kit can be purchased from your local

Scan dealer

See page 21 for how to fit the high top.

Fit the wall mounting kit before connecting the stove to the chimney.

It is important that the stove is mounted securely to the wall

using the right fixings for the specific type of wall.

Safety wire

Casing for wire bushing

Fix to the wall using the

right fixings for the specific type of wall.

Wire bushing

Pointed screw M4x5

Nipple screw Ø8x12.5

Scan 58 high top with elbow pipe

N:

Casing for wire bushing is fixed to the wall

Fasten the safety wire and the wire bushing to the wire bushing

casing using a pointed screw.

N

N

Page 25

ACCESSORIES

25

O

O

O:

Fasten the safety wire to the high top with a nipple screw.

See page 23 for how to fit the top plate and front plate for the high top.

Page 26

ACCESSORIES

26

Fixing hole for fastening

the safety wire in the

high top.

Scan 58 high top with rear outlet

If you have chosen to connect a Scan 58 high top with a rear outlet, there are two more fixing holes in the high top for fastening the safety wire.

Fixing hole for fastening

the safety wire in the

high top.

Page 27

ACCESSORIES

27

Heat accumulating stones for high top

The heat accumulating stones for Scan 58 with high top are made of a special material with a high heating capacity. The stones are heated up

during the firing and gives off the heat again after the firing, which means that the stove stays warm for a longer time.

The vent for adjustment of the convection air is placed at the back of the high top, see page 30 for adjustment of the vent. Firing with the vent

open will give a quicker heating. Firing with the vent closed will extend the heating time of the stove.

The heat accumulating stones are placed in the high top and turned in place around the chimney (1). The second stone is placed next to the first

stone so that they join each other around the chimney (2). The rest of the stones are placed in the same way (3).

Mount the front for the high top, see page 23.

123

Page 28

ACCESSORIES

28

N

N

N

Soap stone top for stove with soap stone sides (Scan 58-9 and Scan

58-10) with and without high top.

Fitting the soapstone top

You can buy a soapstone top for the Scan 58 as an accessory. Remove

the top plate. Refit the four Allen screws and place the soapstone top

in position.

4 x Allen screws M6x10

Removing the top plate

Fitting the soapstone top

Page 29

ACCESSORIES

29

O

P

OP

Fit the brackets and hook the door on (top left corner first).

Put the bottom plate in position.

Fit the rear plate via slots in the stove and holes in the bottom plate.

Slot in the stove Holes in the bottom plate

Fitting a storage door

You can buy a storage door for the Scan 58 with "see through" plinth

as an accessory. Fit this as shown below.

5 x Allen screws M4x10

Magnet for door

Page 30

INSTRUCTION FOR USE

30

100% - 0%0% - 100%

Middle position:

Vent closed

Adjustment of the convection air

in the high top

Side position:

Vent open

Baffle plates

The baffle plates are located in the upper part of the combustion

chamber. The plates hold back smoke, making sure it stays inside

the combustion chamber for a longer time before escaping through

the chimney. This reduces the smoke gas temperature as the gases

have more time to dissipate heat to the wood-burning stove. The

baffle plates must be removed for sweeping; see „Maintaining your

wood-burning stove“. Note that the baffle plates are made of porous,

ceramic material, and can break. Exercise care when working. The

baffle plates are subject to wear and tear, and are not covered by the

warranty.

Ash drawer

Open the glass door to access the ash pan which is located below the

combustion chamber.

Keep the ash pan closed at all times when the wood stove is lit.

The ash drawer must not be overfilled and must therefore be emptied at regular intervals.

Handle for riddling grate

Your wood stove is fitted with a riddling grate which empties the

ash from the combustion chamber into the ash pan when activated.

The riddling grate must be in semi-open position while the wood

stove is lit.

CB Technology (Clean Burning)

Your wood-burning stove is fitted with CB technology. To ensure

optimum burning of the gases released by the burning process, air

is guided by a specially developed system. Pre-heated air is led into

the combustion chamber through the small holes below the baffle

plates. The airflow is driven by the combustion speed, and cannot

be regulated.

Primary air

The primary air regulation mechanism is used for lighting the fire, or

to boost the burning process when you put wood on. The primary air

vent can be 0-30% open if you use hard wood fuel such as oak and

beech. You can close the primary air vent if you use soft wood such

as birch or pine for fuel.

Settings for normal load: 0 - 30%

Secondary air

Secondary air is pre-heated and fed indirectly to the fire. At the same

time, the secondary airflow cleans the glass pane to avoid soot buildup. If you over-restrict the secondary airflow, soot can build up on the

glass pane. The secondary airflow determines the heat output from

your wood stove.

Settings for normal load:. 50 - 70%

Pin to hold the baffle plate

Baffle plate

CB Technology

Primary air

Secondary air

Handle for riddling

grate

Ash pan

Adjustment of air supply

Page 31

INSTRUCTIONS FOR HEATING

31

Environmentally-Friendly Heating

Avoid restricting your wood-burning stove to an extent where no

flames are visible during the degasifying period, as this leads to particularly inefficient heating. The gases released by the wood do not

burn due to the low temperature in the combustion chamber. Part

of the gas condenses in the wood-burning stove and flue system as

soot, and this could lead to your chimney catching fire. The smoke

that exits the chimney is bad for the environment and has an unpleasant smell.

Lighting

We recommend the use of fire starters, or similar products, which are

available from your Scan dealer. Using fire starters helps to light the

wood quicker, and keeps the burning process clean.

Never use liquid lighting fuels!

„Top down“ lighting

2-3 pieces of wood approx. 25 cm long with a weight of approx. 0.4 –

0.6 kg per piece.

1 piece of wood approx. 20 cm long with a weight of about 0.5 kg.

8 - 16 thin sticks of about 20 cm with a total weight of approx. 400 g.

3 fire starters.

Position the large logs in the centre of the combustion chamber 1-2

cm apart as shown. Put half the kindling sticks across the logs in

a criss-cross fashion. Place the smallest log on top of the sticks as

shown and arrange the last sticks in front of the log. Position the

firestarters between the sticks and light.

Set the primary and secondary airflow controls to maximum for

about 20 - 30 minutes. When the larger pieces of wood have caught

fire properly, you can set the primary and secondary airflow to the

desired level.

"Top down" lighting gives a more environmentally friendly start to

your fire and helps to keep the glass areas as clean as possible.

Continuous firing

It is important to reach as high a temperature as possible in the

combustion chamber. This makes the most efficient use of the wood

stove and fuel, and ensures a clean burning process. At the same

time, this avoids soot build-up on the combustion chamber walls and

glass. While the stove is lit, you should not see any smoke, but just air

movement that indicates the burning process.

After completing the lighting phase, you should have a good layer of

embers in the wood stove; you can then start stoking up the stove.

Lay 2-3 pieces of wood, of about 0.4 - 0.6 kg weight with a length of

about 25 cm onto the fire.

Note! The wood must catch fire quickly; this is why we recommend

setting the primary airflow to full power. Running the stove at too

low a temperature and with too little primary air can lead to deflagration of the gases, and thus cause damage to the stove.

When stoking up with wood, always open the glass door carefully

to avoid smoke escaping. Stoke up with wood while the fire is still

burning nicely.

Using your stove in the spring or autumn

Occasional lighting of the stove using the „top down“ lighting method (see above) is recommended in changeable weather such as in

spring/autumn when your heating requirements are not as great.

Why you need a chimney

The chimney is the wood-burning stove‘s motor; it‘s performance

decides how well your stove will work. The draft in the chimney

creates a vacuum in the wood-burning stove. The vacuum draws the

smoke out of the stove, and takes in air through the combustion air

baffle to fuel the burning process. Combustion air is also used for the

airwash system that keeps the window clear of soot.

The draft in the chimney is caused by the difference in temperatures

inside and outside the chimney. The higher the temperature difference is, the better the draft in the chimney will be. It is thus important

for the chimney to reach operating temperature before you adjust

the damper to restrict combustion in the stove (a brickwork chimney

will take longer to reach operating temperature than a steel chimney). It is very important to reach operating temperature as quickly

as possible on days on which the draft in the chimney is poor due to

unfavorable wind and weather conditions. Make sure the fuel ignites

as quickly as possible (with visible flames). Chop the wood into particularly small pieces; use an extra fire lighter etc.

After longer periods of disuse, check the chimney flue for blockage.

You can connect several units to the same chimney. But make sure

check with your chimney sweep to observe local regulations.

No matter how good your chimney is, it will not perform well if you

do not use it correctly. On the other hand a poor chimney, may give

you acceptable results if you use it correctly.

Using your stove in various weather conditions

Wind blowing on the chimney can have a great effect on how your

stove reacts in various wind conditions; you may need to adjust the

airflow to achieve good burning results. Fitting a damper in the

flue pipe may also help as it will give you the ability to regulate the

draught in changing wind conditions.

Fog can also have a great influence on how well a chimney draws;

you may again need to adjust the airflow settings to achieve good

burning results.

Stove with glass panes on three sides

The Scan 58 with side panes has a “glass-cleaning channel” that conducts secondary air downwards across all three glass panes of the

combustion chamber. This airflow acts as a curtain of air providing

some protection against the glass panes getting dirty. It is however

unavoidable that such a large area of glass will get dirty. This is not

due to any defect with the stove.

Page 32

INSTRUCTIONS FOR HEATING

32

For security reasons it is not allowed to store flammable materials

under the combustion chamber of the Scan 58.

General Notes

Your wood stove is not designed for continual heating for periods of

over 24 hours.

Please note! Parts of the wood-burning stove, especially the outer

surfaces, become hot during use. Please exercise due care.

Never empty ashes into a flammable container. Ashes can contain

glowing embers long after you finish using your wood stove.

While the stove is not in use you can close the valves to avoid draught

through the stove.

After longer breaks you should check the smoke outlet paths for

blockages before lighting.

Chimney fires

In case of a chimney fire, keep the stove door, the ash drawer, and

all the valves on the stove closed. In case of emergency, call the fire

service.

Handling fuels

Selecting Wood/Fuel

You can use any type of wood as firewood, however, harder types,

such as beech, ash, are generally better for heating as they burn more

evenly and create less ash. Other wood types like maple, birch and

spruce are excellent alternatives.

Handling

Firewood is best if you fell the tree, and saw and split the wood,

before May 1st. Remember to cut the logs to match the size of your

wood-burning stove‘s combustion chamber. We recommend a diameter of 6-10 cm. The length should be about 6 cm shorter than that

of the combustion chamber to leave enough space for air to circulate.

Firewood with a greater diameter needs splitting. Split wood dries

faster.

Storing

You need to store the sawn and split firewood in a dry place for 1-2

years before burning. Wood dries faster if you stack it in an airy place.

Before use, store the firewood for a few days at room temperature.

Note that wood absorbs moisture during the autumn and winter

seasons.

Moisture

To avoid environmental issues, and for optimum burning, wood

has to be perfectly dry to be suitable for use as firewood. The max.

residual moisture in the wood should not exceed 20%. A moisture

content of 15-18% yields best results. As an easy way of checking if

wood is dry, just knock two pieces of wood together. If the wood is

moist, the sound will be dull.

If you use damp wood, most of the heat it produces will be used to

evaporate the water. The temperature in the wood stove does not

rise, and the room is not sufficiently heated. Of course, this is not

economical, and it will cause soot build up on the glass pane, in the

stove, and in the chimney. Burning moist wood also causes pollution.

Understanding units for measuring wood

Various units of measurement are used for wood. Before you buy wood,

it makes sense to familiarise yourself with the terms. There are various

brochures, in public libraries for example, that cover this topic.

Use of the following as fuel is illegal

Painted, pressure impregnated, or glued wood, driftwood from the

sea. Never burn chipboard, plastics, or chemically treated paper.

These materials are dangerous to humans, to the environment, your

wood stove, and your chimney. To keep a long story short – make sure

you burn only quality firewood.

Firewood fuel value

The fuel value is different for different types of wood. In other words,

you need to use more wood of certain types to achieve the same heating performance. This Instruction Manual assumes that you will be

using beech, which has a very high fuel value, and is also a wood that

is easy to procure. If you use oak or beech wood fuel, note that these

wood types have a greater fuel value than, say, birch. Make sure you

use less fuel to avoid damage to the wood-burning stove.

Wood types Kg Dry wood/m3 Compared to

beech

Hornbeam 640 110%

Beech/Oak 580 100%

Ash 570 98%

Maple 540 93%

Birch 510 88%

Pine 480 83%

Fir 390 67%

Poplar 380 65%

Page 33

MAINTENANCE

33

1. Lift up the baffle plate, and remove the pin that holds the baffle

plate in place.

2. Lower the baffle plate.

3. Turn the baffle plate sideways inside the stove.

Maintaining your wood-burning stove

Apart from regular chimney sweeping, your wood-burning stove does

not require any regular maintenance.

Coated surfaces

Clean your wood-burning stove by dusting with a dry, lint-free cloth.

If the topcoat is damaged, you can purchase a repair spray from your

authorised Scan dealer. As slight differences in colour are possible,

spray a larger area to achieve a natural transition for best results.

For best results, apply repair spray when the wood-burning stove is

hand-hot.

Cleaning the glass

Our wood-burning stoves are designed to prevent serious soot build

up on the glass. The best way to achieve this is to make sure you have

a sufficient combustion air supply. It is also important to use dry

wood, and have a correctly dimensioned chimney.

Even if you follow all of our instructions, a slight film of soot can build

up on the glass. You can easily remove this build up by cleaning with

a dry cloth and glass cleaner. Your authorised Scan dealer stocks a

special glass cleaner for this purpose.

Combustion chamber lining

Slight cracks can appear in the combustion chamber lining due to

moisture, or to the heating/cooling process. These cracks have no

influence on the heating performance or lifetime of your stove.

However, if the lining starts to crumble, you must replace it. The combustion chamber lining is not covered by the warranty.

See page 30 for how to fit the combustion chamber sides in stoves

with steel panels.

Seals

All wood-burning stoves have seals made of ceramic material fitted to

the stove, the doors, and/or the glass. These seals are subject to wear

and tear, and must be replaced when necessary.

Chimney sweeping and cleaning your

wood-burning stove

Follow national and local chimney sweeping regulations. We

recommend having the wood-burning stove cleaned regularly by the

chimney sweep.

Before starting to clean your wood-burning stove, and sweep the flue

pipe, we recommend first removing the baffle plates.

Use only original replacement parts for maintenance and repairs of

your stove.

Note! Make sure the stove is cold before starting maintenance or

repair work.

Removing the baffle plates

Be very careful when removing the baffle plates from the stove.

Lift up the lower baffle plate, remove the pin, and remove the baffle

plate.

Lift up the upper baffle plate, pull it back, and take it out.

Checking the stove

Scan A/S recommends that you check your stove thoroughly after

sweeping/cleaning. Check all visible surfaces for cracks. Check that

all joints are tight and that the seals sit correctly. Worn or deformed

seals should be replaced.

Page 34

MAINTENANCE

34

4. Remove the baffle plate.

Fitting the combustion chamber sides in stoves with steel panels

1. Remove the lower baffle plate.

2. Fit the combustion chamber sides.

The wide edge should be facing out towards the door when you fit the combustion chamber sides.

Page 35

TROUBLESHOOTING

35

Smoke escaping

• Damp wood

• Chimney not drawing properly

• Chimney is not properly dimensioned for the stove

• Check if the smoke gas pipe/chimney are blocked

• Is the chimney the right height for its surroundings?

• At rear outlet, check that the flue pipe does not obstruct the

chimney draught

• Vacuum in room

• The door is opened before the embers have burned down

sufficiently

Wood burning too quickly

• The air valves are set incorrectly

• The baffle plates is incorrectly mounted or missing

• Inferior firewood (waste wood, pallets etc.)

• Chimney too large

Soot build-up on glass

• Incorrect secondary airflow setting

• Excessive primary air

• Damp wood

• Wood pieces too large on lighting

• Inferior firewood (waste wood, pallets etc.)

• Chimney not drawing sufficiently

• Vacuum in room

Excessive soot build-up in chimney

• Poor burning (more air required)

• Damp wood

The surface of the stove is turning grey

• Overheating (see instructions for heating)

Poor heating performance of stove

• Damp wood

• Not enough wood

• Inferior wood quality with low fuel value

• Baffle plates are not fitted correctly

Odour coming from stove

• The lacquer on the stove hardens when you use the stove for the

first time; this can cause an odour. Open a window or a door for

ventilation, and make sure the stove is heated up sufficiently to

avoid odours later.

• When heating up and cooling down, the stove may make some

clicking noises. These are due to the huge temperature differences to which the material is exposed and do not indicate any

product defects.

Warranty

All wood-fired Scan products are made of high-quality materials and

subject to strict quality controls before leaving the factory. We give a

warranty of 5 years on manufacturing errors or defects.

You must quote your stove‘s product registration number when you

contact us or your authorised Scan dealer with a warranty claim.

The warranty covers all parts which in the opinion of Scan A/S require

repair or replacement due to manufacturing or construction error

The warranty applies to the original purchaser of the product only,

and is not transferable (except on prior sale).

The warranty covers only damage caused by manufacturing or construction errors.

The following parts are not covered by the warranty

• Wear and tear parts, such as the combustion chamber liners,

baffle plates, riddling grate, glass, tiles, and seals (except for

defects which were present on delivery).

• Defects caused by external chemical and physical influences

during transportation, storage and assembly, or at a later time.

• Soot build-up caused by poor chimney draught, damp wood, or

improper use.

• Costs of additional heating in connection with a repair.

• Transport costs.

• Costs for setting up, removing the wood stove.

This warranty is void

• In case of incorrect installation (the installer is responsible for

observing and complying with legal requirements and local

bylaws, along with this Assembly- and Instructionsmanual for

the wood-burning stove and accessories).

• In case of improper use, and/or use of prohibited fuels, nonoriginal spares (see this Assembly- and instructions manual).

• If the product registration number of the stove has been removed or damaged.

• In case of repairs that do not comply with our instructions or

instructions by an authorised Scan dealer.

• In case of any manipulation of the original state of this Scan

product or its accessories.

• This warranty is only valid in the country to which this Scan

product was originally supplied.

Always use original replacement parts, or parts recommended by the

manufacturer.

Page 36

Scan A/S - DK-5492 Vissenbjerg

Version:

GB 90358500-5

24.03.2011

Loading...

Loading...