Page 1

SCAN 39

INSTRUCTIONS FOR

INSTALLATION AND USE

This manual is accompanied by a

pamphlet with General Instructions

for Installation.

Edition 01.02.07 - GB

MONTERINGSVEJLEDNING

med brugs- og fyringsanvisning

Indhold:

G

ene

relle råd og anvisninger . . . . . . . . . .2-3

Reklamationsret

Type- og miljøgodkendelse

Udpakning

Tilbehør til din pejs

Montering af kakler og fedtsten

Kvalitetskontrol

Anmeldelsespligt

Skorstenstjek

Skorstensløsninger

Bærende underlag

Brændbar eller ikke brændbar væg

Gulvplade

Varmefordeling

Justerskrue

Typeskilt

Produktionsnr.

Servicepakke

M

onte

ringsvejledning. . . . . . . . . . . . . . . . .4-7

Tilslutning til eksisterende/muret skorsten

Tilslutning topafgang til stålskorsten

Forbrændingsluft udefra

Brugs- og fyringsanvisning . . . . . . . . . . .8-10

Vedligeholdelse af pejseovnen

Håndtering af brændsel

Optænding og fyring

Fejlsøgning . . . . . . . . . . . . . . . . . . . . . . . . 11

SC

AN

3

B

R

U

G

S

A

N

V

IS

N

I

NG

T

i

l

d

e

n

n

e

B

r

u

g

s

a

n

v

i

s

n

i

n

g

h

ø

r

e

r

o

g

s

å

e

n

g

e

n

e

r

e

l

M

o

n

t

e

r

i

n

g

s

v

e

j

l

e

d

n

i

n

g

.

U

d

g

a

v

e

0

3

.

0

3

-

D

K

M

O

N

T

E

R

I

N

GSV

E

J

L

E

D

N

IN

G

m

e

dbrugs

-

o

g

fy

r

in

gs

anv

is

ni

n

g

I

n

dh

old

:

G

e

n

e

r

e

l

l

e

r

å

d

o

g

a

n

v

i

s

n

i

n

g

e

r

.

.

.

.

.

.

.

.

.

.

2

-

3

R

e

k

l

a

m

a

t

i

o

n

s

r

e

t

T

y

p

e

-

o

g

m

i

l

j

ø

g

o

d

k

e

n

d

e

l

s

e

U

d

p

a

k

n

i

n

g

T

i

l

b

e

h

ø

r

t

i

l

d

i

n

p

e

j

s

M

o

n

t

e

r

i

n

g

a

f

k

a

k

l

e

r

o

g

fe

d

t

s

t

e

n

K

v

a

l

i

t

e

t

s

k

o

n

t

r

o

l

A

n

m

e

l

d

e

l

s

e

s

p

l

i

g

t

S

k

o

r

s

t

e

n

s

t

j

e

k

S

k

o

r

s

t

e

n

s

l

ø

s

n

in

g

e

r

B

æ

r

e

n

d

e

u

n

d

e

r

l

a

g

B

r

æ

n

d

b

a

r

e

l

l

e

r

i

k

k

e

b

ræ

n

d

b

a

r

v

æ

g

G

u

l

v

p

l

a

d

e

V

a

r

m

e

f

o

r

d

e

l

i

n

g

S

e

l

v

l

u

k

k

e

n

d

e

l

å

g

e

J

u

s

t

e

r

s

k

r

u

e

T

y

p

e

s

k

i

l

t

P

r

o

d

u

k

t

i

o

n

s

n

r

.

S

e

r

v

i

c

e

p

a

k

k

e

M

o

n

t

e

r

i

n

g

s

v

e

j

l

e

d

n

i

n

g

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

-

7

T

i

l

s

l

u

t

n

i

n

g

t

i

l

e

k

s

i

s

t

e

r

e

n

d

e

/

m

u

r

e

t

s

k

o

r

s

t

e

n

T

i

l

s

l

u

t

n

i

n

g

t

o

p

a

f

g

a

n

g

t

i

l

s

t

å

l

s

k

o

r

s

t

e

n

F

o

r

b

r

æ

n

d

i

n

g

s

l

u

f

t

u

d

e

f

r

a

B

r

u

g

s

-

o

g

f

y

r

i

n

g

s

a

n

v

i

s

n

i

n

g

.

.

.

.

.

.

.

.

.

.

.

8

-

10

V

e

d

l

i

g

e

h

o

l

d

e

l

s

e

a

f

p

e

j

s

e

o

v

n

e

n

H

å

n

d

t

e

r

i

n

g

a

f

b

r

æ

n

d

s

e

l

O

p

t

æ

n

d

i

n

g

o

g

f

y

r

in

g

F

e

j

l

s

ø

g

n

i

ng

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

1

T

i

l

d

e

n

n

e

m

o

n

t

e

r

i

n

g

s

ve

j

l

e

d

n

i

n

g

h

ø

r

e

r

o

g

s

å

e

n

s

e

p

a

r

a

t

b

r

u

g

s

a

n

v

i

s

n

i

n

g

f

o

r

d

e

n

e

n

k

e

l

t

ep

e

j

s

.

U

dg

a

v

e

0

2

/

0

3

-

D

K

Til d

e

n

n

e

m

o

n

te

ri

n

g

s

v

e

jl

e

d

n

in

g h

ø

re

r

o

g

s

å

e

n

s

e

p

a

ra

t

b

ru

g

s

a

n

v

i

s

n

in

g fo

r

d

e

n

e

n

k

e

l

te p

e

j

s

.

Udgave 02/03 - DK

Approved according to

EN 13240

Page 2

Clean combustion

The SCAN 39 uses the "CB technique" (Clean-Burn) to

ensure an optimally clean combustion. The extra combustion

air is preheated and led into the combustion chamber close

to the ceramic smoke deflector.

Ceramic smoke deflectors

Lift up the lower ceramic smoke deflector, pull out the pins

in the lateral combustion chamber plates and remove the

deflector. The upper deflector is removed in the same way.

You have chosen a product from one of Europe's leading

manufacturers of wood-burning stoves. We are convinced

that your stove will be to your full satisfaction and give you

many hours of pleasure if you follow the advice and instructions of this manual.

Please read this manual as well as the General Instructions

for Installation before beginning the installation

Congratulations on your new SCAN stove!

3

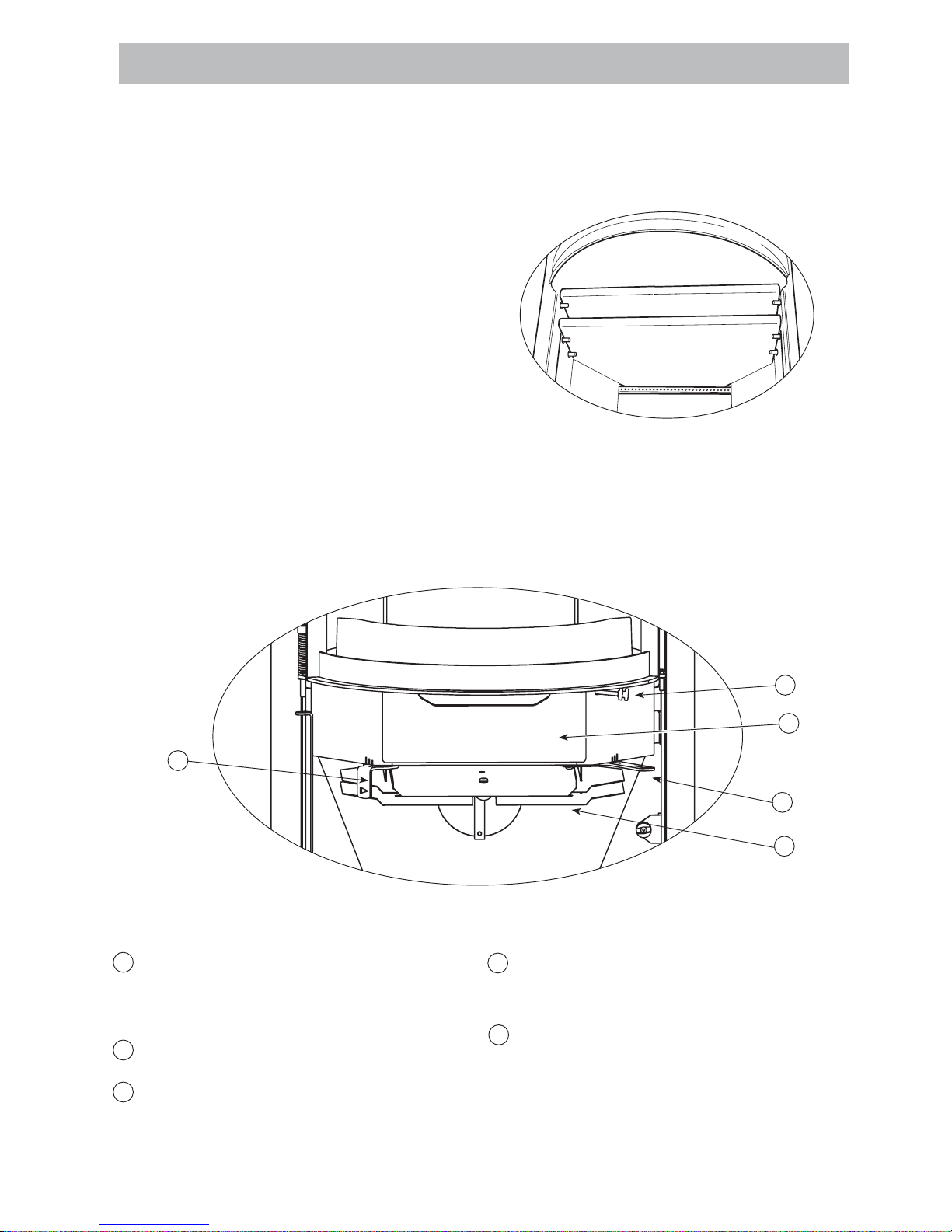

1 Ashtray. When you open the door, you have access to

the ashtray, which is placed below the combustion chamber. Attention! Be careful when you empty ashes from the

stove. There may be embers left for up to 24 hours after

the stove was last used.

Lid for ashtray. Under the ashtray you will find a lid to put

on top of the ashtray when you carry it out for emptying.

3 Handle for shaking grate. The stove is equipped with a

shaking grate. When you activate the grate handle, the

ashes from the combustion chamber are emptied into the

ashtray.

4 Regulation for primary air. Turn the air valve in order to

open. The primary air is used when lighting and refuelling

the stove. It should always be closed during continuous

firing.

5 Regulation for combustion air. Push the button side-

ways. Left position is closed and right position is open.

The air is used for combustion and regulates the output

of the stove.

4

1

2

5

The ashtray, shaking grate, and primary air should always be

closed during continuous firing.

SCAN 39

2

Page 3

Handle

The handle is elegantly integrated on the moulding below the

door. Pull out the handle to open.

Adjustment of the handle

Loosen the screw in the adjustment bushing (1) with a

hexagon spanner. Adjust the handle to the moulding with the

adjustment bushing and tighten the screw again.

Accessories

For this model you can have the following accessories:

Adjustment screws

The stove has two adjustment screws on the bottom that can

be used for levelling the stove.

Self-closing door (BA 1)

The door is prepared with a self-closing function at the factory. If you tighten the spring with the hexagon spanner, the

door will close automatically when you let go of it.

• Lateral covering in soapstone or stainless steel

• Glazed baking tile

• Soapstone-top plate

• Shaped floor plate (steel or glass)

• Connection piece for fresh-air intake

You should read this manual as well as the General Instructions for Installation before beginning the installation.

SCAN 39

1

The stove can be prepared for an external air supply where

fresh air is let directly into the combustion chamber (can also

be done subsequently by the authorized dealer).

Combustion air % Primary air % Max. fuel, kg Fuel consumption, kg/h

90 60 2 2

Adjustment of the air + fuel consumption (EN 13240):

Page 4

Krog Iversen & Co. A/S - DK-5492 Vissenbjerg

1

1

4

1

544

2

0

7

*

*

*

9

5

8

*

*

494

1

5

5

1

0

7

8

*

Warranty conditions

All SCAN wood-burning stoves and inserts are made of firstclass material and are subject to a strict quality control before

they leave the factory. However, if an error should occur,

we back all SCAN wood-burning stoves and inserts with an

extensive, five-year limited warranty.

See also the General Instructions for Installation delivered

with your stove for more details.

* Height to the beginning of the flue pipe at top outlet

** To the middle of the rear outlet

***Connection piece to fresh-air intake

Distances to flammable materials (mm)

Production number

Write the production number of

your stove here so that you have

it at hand in case you need to

contact us.

You can choose between several floor plates in different

shapes and dimensions for your stove. Furthermore, you

can have a specially made, shaped floor plate for the SCAN

39, which is to be placed in front of the stove. Please contact your local authorities concerning the security distances

needed.

200

200

200

500

500

400

Base plate

Radiation area

Radiation area

Base plate

300

300

800

800

Technical info

Emission (% CO at 13% O2): 0,09%

Efficiency: 79%

Rated output: 6 kW

Chimney temperature: 290 C

o

Flue outlet flow: 8.0 g/sec

Recommended low pressure in conn. piece: 15 Pa

Recommended fuel: Wood

Amount of fuel: 2,31 kg

Min./max. (information from the factory): 3-9 kW

Weight: 130-200 kg

Connection piece, int. diameter: 135 mm

Connection piece, ext. diameter: 148 mm

SCAN 39

Loading...

Loading...