Scag Power Equipment SW User Manual

MODEL SW

MODELO SW

OPERATOR’S MANUAL

MANUAL DE OPERADOR

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMATION FOR YOUR SCAG MOWER. READING

THIS MANUAL CAN PROVIDE YOU WITH

ASSISTANCE IN MAINTENANCE AND ADJUSTMENT PROCEDURES TO KEEP YOUR

MOWER PERFORMING TO MAXIMUM EFFICIENCY. THE SPECIFIC MODELS THA T THIS

BOOK COVERS ARE CONTAINED ON THE

INSIDE COVER. BEFORE OPERA TING YOUR

MACHINE, PLEASE READ ALL THE INFORMATION ENCLOSED.

PART NUMBER 03099

WARNING:

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all shields in place, especially the grass discharge chute.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wire and ignition key.

* If a mechanism becomes clogged, stop the engine before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as other manuals that came

with your mower.

* Keep others off the tractor (only one person at a time)

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident pre vention are dependent upon the awareness,

concern, prudence, and proper training of the personnel involved in the

operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

SW32-13KA with a serial number of 7300001 to 7309999

SW36A-13KA with a serial number of 7310001 to 7319999

SW36A-13KH with a serial number of 7320001 to 7329999

SW36A-15KA with a serial number of 7330001 to 7339999

SW48A-15KA with a serial number of 7340001 to 7349999

SW48A-17KA with a serial number of 7350001 to 7359999

SW52A-17KA with a serial number of 7360001 to 7369999

Always use the entire serial number listed on the serial number

tag when referring to this product.

TABLE OF CONTENTS

ÍNDICE

SUBJECT PAGE

TEMA PÁGINA

Introduction ...........................................................................................................1

Introducción.............................................................................................................16

General Safety Instructions ................................................................................. 1

Instrucciones generales de seguridad .................................................................... 16

Signal Wor ds..........................................................................................................1

Palabras de señal....................................................................................................16

Symbols ................................................................................................................. 2-3

Símbolos ................................................................................................................. 17-18

Before Operating ................................................................................................... 4

Antes de operar.......................................................................................................19

While Operating.....................................................................................................4

Mientras opera.........................................................................................................19

Maintenance and Storage.....................................................................................5

Mantenimiento y almacenaje ...................................................................................20

Initial Run-In Procedures......................................................................................6

Procedimientos de arranque inicial..........................................................................21

Mower Operation ................................................................................................... 6

Operación del cortacésped ..................................................................................... 21

Cutter Deck Belt Adjustments .............................................................................7

Ajustes de las correas de la plataforma de corte ....................................................22

Transmission Drive Belt ....................................................................................... 8

Correa de transmisión ............................................................................................. 23

Drive Control Adjustments .................................................................................. 8

Ajustes de control motriz.........................................................................................23

Cutter Deck Adjustments .....................................................................................8

Ajustes de la plataforma de corte............................................................................23

Blade Height Adjustments ................................................................................... 9

Ajuste de altura de las cuchillas .............................................................................. 24

Cutter Blades.........................................................................................................9

Cuchillas de corte ...................................................................................................24

WE SUPPORT OPE

TECHNICIAN

CERTIFICATION

I

TABLE OF CONTENTS

(CONTINUED)

ÍNDICE

(continuación)

SUBJECT PAGE

TEMA PÁGINA

Lubrication and Maintenance Chart ....................................................................10

Lubricación y mantenimiento...................................................................................25

Troubleshooting Cutting Conditions .................................................................. 11-13

Identificación de fallas en las condiciones de corte ................................................26-28

Tec hnical Specifications.......................................................................................14-15

Especificaciones técnicas ....................................................................................... 29-30

Notes .....................................................................................................................31

Notas .....................................................................................................................31

Illustrated Parts List

Listas ilustradas de piezas

SWM-32", 36" Cutter Decks........................................................................ 32-33

Plataforma de corte - SWM-32, -36...............................................................32-33

SWM-48", 52" Cutter Decks........................................................................ 34-35

Plataformas de corte - SWM-48, -52.............................................................34-35

Engine Deck..................................................................................................36-37

Plataforma del motor......................................................................................36-37

Handle Assembly .........................................................................................38-39

Componentes de las manijas........................................................................ 38-39

Instrument Panel..........................................................................................40

T ab lero de control...........................................................................................40

Peerless T ransmission................................................................................ 41

T ransmisión P eerless.....................................................................................41

Engine Deck Wire Harness - 14 Kawasaki................................................ 42

Cableado de la plataforma del motor - Kawasaki 14.....................................42

Wire Harness W/Relay .................................................................................42

Cableado con relev ador.................................................................................42

Handle Wire Harness-Manual Start............................................................42

Cableado de las manijas - Arranque manual.................................................42

Engine Deck Wire Harness-Kohler (Single Cyl.) & 17 KA........................43

Cableado de la plataforma del motor - K ohler (monocilíndrico) y 17KA 43

Replacement Decals.....................................................................................44-45

Calcomanías de repuesto........................................................................... 44-45

Warranty Statement.......................................................................Inside Back Co ver

Garantía...................................................................................................Contraportada

II

INTRODUCTION

Your mower was built to the highest standards in the

industry. However, the prolonged life and maximum

efficiency of your mower depends on you following the

operating, maintenance and adjustment instructions in

this manual.

We encourage you to contact your dealer for repairs.

All Scag dealers are informed of the latest methods to

service this equipment and provide prompt and efficient

service in the field or at their service shop. They carry a

full line of Scag service parts.

A replacement Operator's Manual is available from your

Scag Servicing Dealer or by contacting Scag Power

Equipment, Service Department at P.O. Box 152,

Mayville, WI 53050. Please indicate the complete

model and serial number of your Scag product.

USE OF OTHER THAN ORIGINAL SCAG

REPLACEMENT PARTS WILL VOID THE

WARRANTY.

SIGNAL WORDS

This symbol means “Attention! Become Alert! Your

Safety is Involved!". The symbol is used with the

following signal words to attract your attention to safety

messages found on the decals and throughout this

manual. The message that follows the symbol contains

important information about safety. To avoid injury and

possible death, carefully read the message! Be sure to

fully understand the causes of possible injury or death.

Signal Word:

It is a distinctive word on safety decals and throughout

this manual that alerts the viewer to the existence and

relative degree of the hazard.

The “Right” and “Left”, “Front” and “Rear” of the

machine are referenced from the operator’s perspective when in the normal operating position and facing

the forward travel direction.

GENERAL SAFETY INSTRUCTIONS

READ THIS OPERATOR'S MANUAL and

instructions furnished with attachments.

Perform only those maintenance procedures described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Scag

Dealer. To ensure optimum performance and safety,

always purchase genuine SCAG replacement parts

and accessories.

Your safety and the safety of others depends

significantly upon your knowledge and understanding

of all correct operating practices and procedures of

this machine.

The signal word “DANGER” denotes that an extremely

hazardous situation exists on or near the machine that

could result in high probability of death or irrepairable

injury if proper precautions are not taken.

WARNING:

The signal word “WARNING” denotes that a hazard

exists on or near the machine that can result in injury or

death if proper precautions are not taken.

CAUTION:

The signal word “CAUTION” is a reminder of safety

practices on or near the machine that could result in

personal injury if proper precautions are not taken.

1

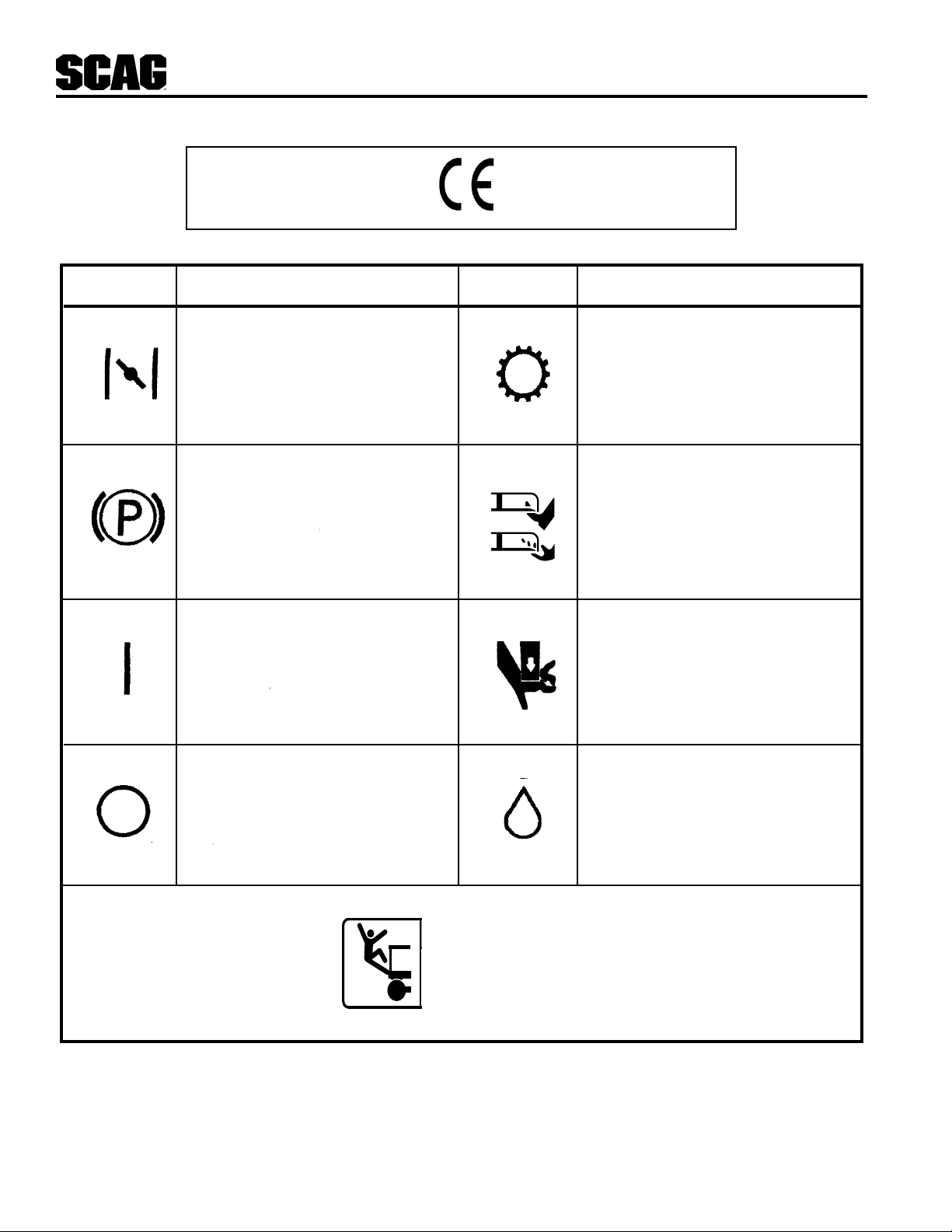

ISO Symbols

CE Mark

SYMBOL DESCRIPTION

Parking Brake

On/Start

SYMBOL DESCRIPTION

TransmissionChoke

Spinning Blade

48071S

Spring T ension on Idler

Off/Stop

Oil

WARNING

Falling Hazard

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

2

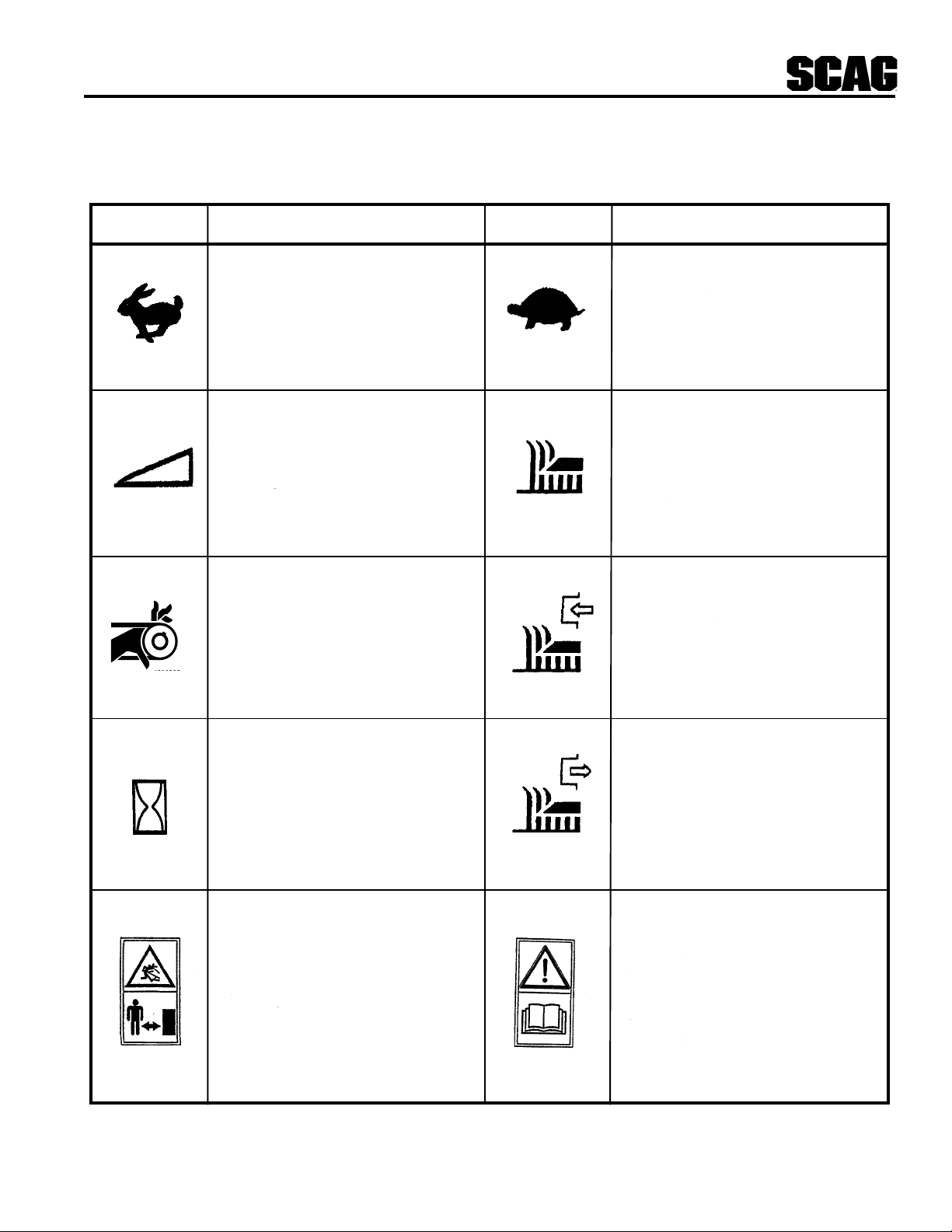

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

SlowFast

481039S

Continuously variable - Linear

Pinch Point

Hourmeter/elapsed operating hours

Cutting element - Basic symbol

Cutting element - Engage

Cutting element - Disengage

Keep bystanders away

Read operator's manual

3

BEFORE OPERATING

1. Know the controls and how to stop quickly.

2. Do not allow children to operate the machine. Do

not allow adults to operate the machine without

proper instruction.

3. If the operator(s) or mechanic(s) can not read

English it is the owner's responsibility to explain this

material to them.

4. Remove all debris or other objects that might be

picked up and thrown by the cutter blades. Keep all

bystanders away from the mowing area.

5. Keep all shields, safety devices, and decals in place.

If a shield, safety device or decal is defective or

damaged, repair or replace it before operating.

Also, check all nuts, bolts and screws for proper

tightness, to assure the machine is in safe operating

condition.

6. Do not operate the machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing which could get caught in

moving parts. Always wear long pants and substantial shoes. Wearing safety glasses and safety shoes

is advisable and required by some local ordinances

and insurance regulations.

9. Before attempting to start the engine, shift the

transmission into neutral, move the blade engagement switch to the OFF position, and move the

neutral latches to neutral.

WHILE OPERATING

1. Do not operate the machine under the influence of

alcohol or drugs.

2. Start the engine when the neutral latches are in the

neutral lock position, the cutter blades are disengaged, and the transmission is in neutral.

3. Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous

and could possibly be deadly.

4. Using the machine demands attention. To

prevent loss of control:

A. Mow only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not drive close to a drop-off, ditch, creek

bank, or other hazard.

D. Reduce speed when making sharp turns and

when turning on hillsides.

E. Always be sure of your footing. Keep a firm

hold on the handles and walk---never run.

F. Do not operate where conditions are slippery.

7. The owner/user can prevent and is responsible for

accidents or injuries occuring to themselves, other

people or property.

8. Fill the fuel tank with clean, fresh gasoline, with a

minimum octane rating of 87. Avoid spilling gasoline. Gasoline is highly flammable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill the tank while the engine is hot or

running.

C. Do not smoke while handling gasoline.

D. Fill the fuel tank outdoors and up to approxi-

mately 1" (25 mm) below the bottom of the filler

neck.

E. Wipe up any spilled gasoline.

5. The discharge chute must always be installed and in

the down position on the side discharge cutter deck

except when the Scag optional grass catcher or

mulching plate are properly installed. If the discharge area should plug, shut the engine off and wait

for all movement to stop before removing the

obstruction.

6. Disengage the blades and wait for them to stop

before crossing gravel drives, walks or roads.

7. Shut the engine off and wait until the blades come to

a complete stop before removing the grass catcher

container.

8. Never raise the cutter deck while the blades are

rotating.

4

9. Always park the mower and/or start the engine on a

level surface.

10. If the cutting blades should strike a solid object or

the equipment should start to vibrate abnormally,

stop the engine, disconnect the spark plug wire, and

check immediately for the cause. Vibration is

generally a warning of trouble. Check the machine

for damaged or defective parts. Repair any damage

before starting the engine or operating the cutter

deck. Be sure the blades are in good condition and

the blade bolts are tight.

11. Reduce speed and exercise extreme caution on

slopes and in sharp turns to prevent tipping or loss

of control. Be especially cautious when changing

directions on slopes.

15. Use only Scag approved attachments and accessories.

Scag Approved Attachments:

RS-2

RS-ZT

GC-F4

GC-4D

Scag Approved Accessories:

Mulch Master

Traction Plus

Adjust-A-Grip

Turbo Baffle

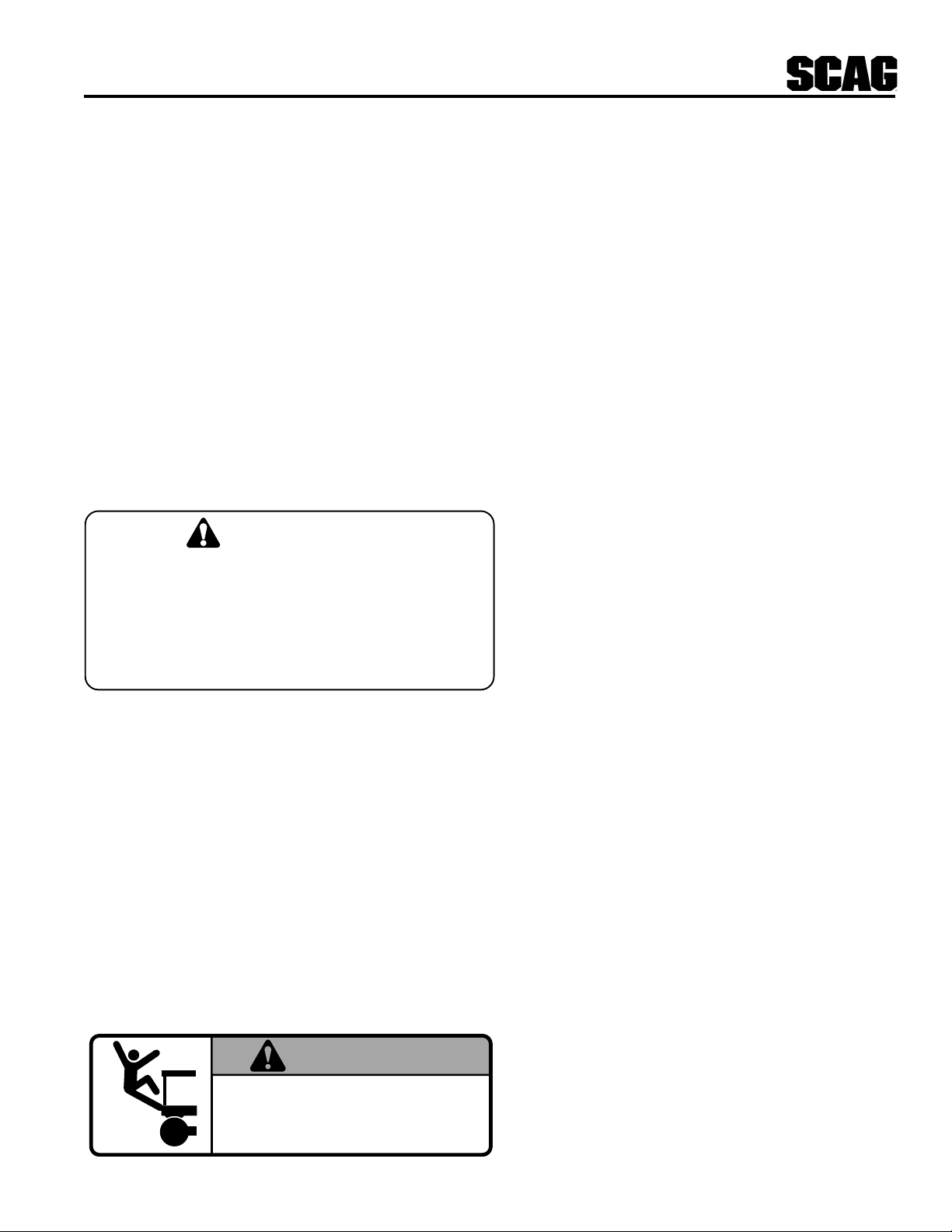

Using unapproved attachments, (especially "stand-up"

riding attachments) may be hazardous.

MAINTENANCE AND STORAGE

1. Allow only trained personnel to service the machine.

WARNING:

DO NOT operate on steep slopes. To check a

slope, attempt to back up it (with the cutter deck

down). If the machine can back up the slope

without the wheels slipping, reduce speed and use

extreme caution. ALWAYS FOLLOW OSHA

APPROVED OPERATION.

12. Do not touch the engine or muffler while the engine

is running or soon after it is stopped. These areas

could be hot enough to cause a burn.

13. Before leaving the operator’s position or leaving the

mower unattended, shift the transmission into

neutral, place the neutral latches in the neutral lock

position, and move the blade engagement switch to

OFF. Shut the engine OFF and remove the key.

14. Do not pass or stand on the grass discharge side of

any mower with the engine running. Stop operation

when another person approaches.

1. Disconnect the spark plug wire from the spark plug

to prevent accidental starting of the engine when

servicing, adjusting or storing the machine.

2. If the mower must be tipped to perform maintenance or adjustment, remove the battery, drain the

gasoline from the fuel tank and the oil from the

crankcase.

3. To reduce potential fire hazard, keep the engine free

of excessive grease, grass, leaves and accumulations

of dirt.

4. Be sure the machine is in safe operating condition by

keeping nuts, bolts, and screws tight. Check the

blade mounting bolts and nuts frequently to be sure

they are tight.

5. If the engine must be running to perform a maintenance adjustment, keep hands, feet, clothing and

other parts of the body away from the cutter deck

blades and other moving parts.

WARNING

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

6. Do not overspeed the engine by changing governor

settings. To be sure of safety and accuracy, have an

authorized dealer check maximum engine speed with

a tachometer.

7. The engine must be shut off before checking the oil

5

or adding oil to the crankcase.

8. Allow the engine to cool before storing the mower in

any enclosure such as a garage or storage shed.

Make sure the fuel tank is empty if the machine is to

be stored in excess of 30 days. Do not store the

mower near any open flame or where gasoline fumes

may be ignited by a spark.

MOWER OPERATION

1. Read and understand the safety instructions

before attempting to operate this machine.

2. Before starting the engine:

9. Always store gasoline in a safety-approved, red

container.

10. Be careful when servicing the battery as it contains acid, which is corrosive and could cause

burns to skin and clothing.

11. Batteries release explosive gases when being

charged or discharged. Keep batteries away from

any source of sparks and/or flame.

INITIAL RUN-IN PROCEDURES

(FIRST DAY OF USE OR APPROXIMATELY 10 HOURS)

1. Check the belts for proper tension at 2, 4 and 8

hours. Adjust as needed.

2. Check the steering control rods for neutral

adjustment. (See Adjustments, page 6)

3. Check the tires for proper pressure.

Caster Wheels 25 psi.

Drive Wheels 15 psi.

4. Check for loose hardware. Tighten as needed.

5. Check the safety switches for proper adjustment:

* The engine will crank, but not start if the

machine is not in neutral.

* On electric start machines, the engine will not

crank if the PTO switch is on.

* The engine should crank and start if the

machine is in neutral and the PTO engagement

switch is OFF.

* Check the oil level in the engine.

* Fill the fuel tank with clean, fresh, lead-free

gasoline.

* Open the fuel valve on the bottom of the fuel

tank.

-NOTE-

Use gasoline with an octane rating no less than

87.

* The transmission must be in NEUTRAL.

* The blade clutch switch must be in the OFF

position.

* The operator's presence levers must be

released.

* The neutral latches must be in the neutral

lock position.

* The key switch must be on.

3. Start the engine:

* Choke as required. If the engine is cold, pull

the choke knob out. When the engine starts,

slowly push the choke in. If the engine stalls,

repeat the above operation. When the engine

is warm, choking may not be necessary.

4. Engage the cutter blades by depressing the operator

presence levers and pulling the blade clutch switch

into the ON position. Push the switch to the OFF

position to disengage the cutter blades.

6. Apply lubricant to all the grease fittings.

Lubricant was applied at the factory. This is

just a precautionary check to make sure that

all the fittings have been lubricated.

PULL UP TO ENGAGE

PUSH DOWN TO DISENGAGE

390S0138

6

-NOTE-

SC400G

BELT

WASHER

"J" BOLT

NUT

CUTTER DECK DRIVE BELT TENSION

ALIGNMENT IDLER - L.H.

END OF L-SHAPED

BRACKET

BEL T TENSION

ADJUSTMENT IDLER

CUTTER DECK

ADJUSTMENT

IDLER

CHECK BLADE DRIVE

BEL T TENSION HERE

SC402G

DISCHARGE

AREA

When PTO is engaged or (possibly) disengaged,

a squealing sound from the underside of the

machine is normal. It is caused by the electric

clutch plates meshing as the cutter blades come

up to speed. For best equipment life, engage the

clutch with the engine at 3/4 throttle, not under

full load.

WARNING:

To avoid serious bodily injury and damage to the

transmission, the machine must be at a full stop

before shifting between gears or shifting between

forward and reverse.

5. Shift the transmission into gear for the desired

mowing speed.

-NOTE-

Top speed is suggested only for transport!

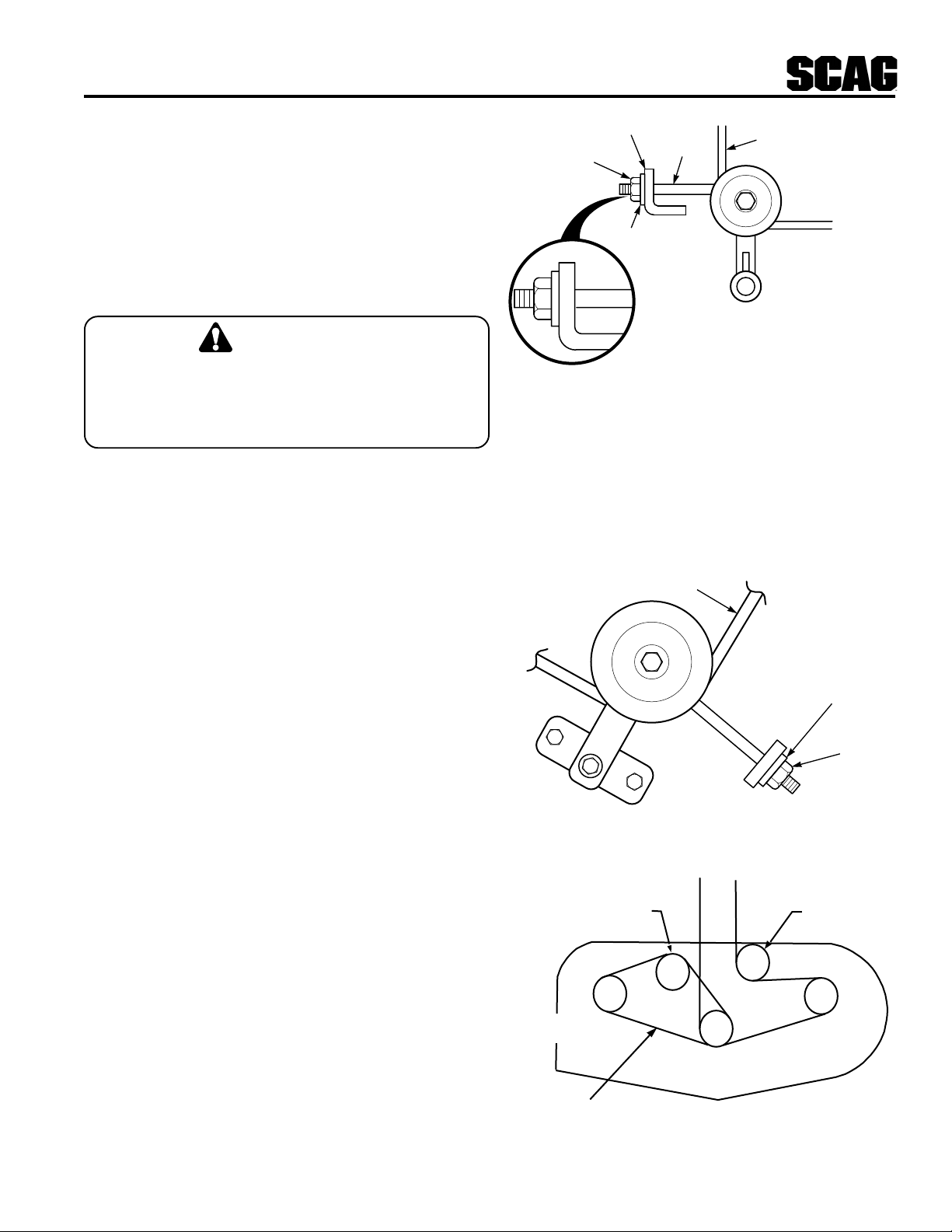

Figure 1

3. Adjust the RH blade drive belt using a belt tension

gauge. Adjust the belt so that the belt moves 1/2"

with 10 pounds of pressure. Adjust the tension by

tightening or loosening the J-bolt nut. (See Figure 2

& 3)

BELT

6. While squeezing the steering brake levers with

both hands, release both neutral latches.

7. When the steering brake levers are released, the

machine will travel straight. To make a right turn,

squeeze the RH lever. To turn left, squeeze the LH

lever.

8. TO STOP, squeeze both levers, lock the neutral

latches, and shift the transmission into neutral.

CUTTER DECK BELT ADJUSTMENTS

1. Remove the belt cover.

2. Adjust the cutter deck drive belt using a belt tension

gauge. Adjust the belt so that the belt moves 1/2"

with 10 pounds of pressure. Adjust the tension by

tightening or loosening the J-bolt nut. (See figure 1)

WASHER

NUT

Figure 2. RH Blade Belt Adjustment

SC401G

ire pressure can be adjusted for

Due to initial belt stretch and to prevent the belt

from slipping, check this adjustment after the

first 2 hours, 4 hours and 8 hours of operation.

-NOTE-

Figure 3. Cutter Deck Belts

7

TRANSMISSION DRIVE BELT

CUTTER DECK ADJUSTMENTS

Adjust the transmission drive belt so that there is about a

3/16" deflection with 10 lbs. of pressure. Adjust by

loosening idler pulley mounting bolt and sliding the idler

left or right to change belt tension.

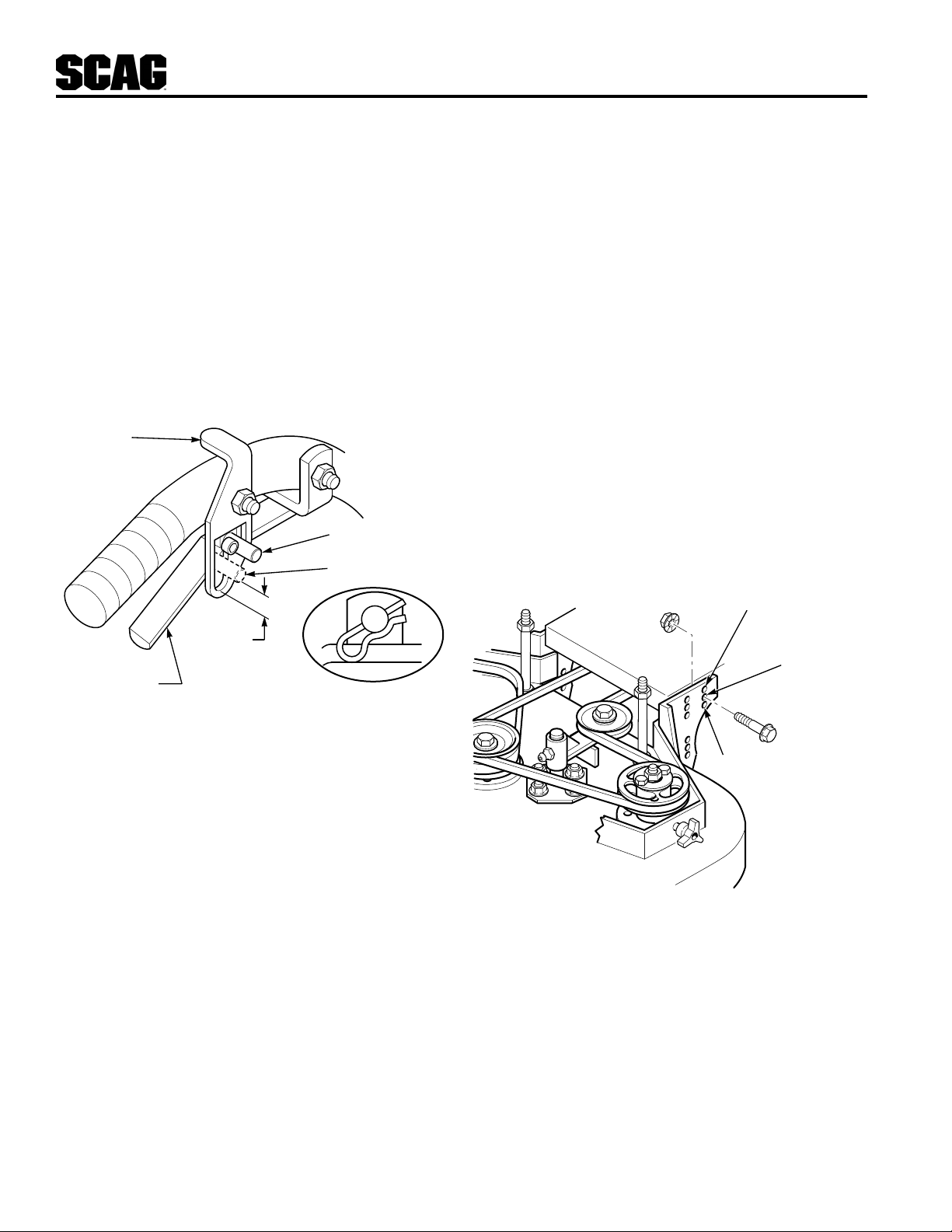

DRIVE CONTROL ADJUSTMENTS

1. Adjust the steering control rods so that there is

approximately 3/4" clearance from the bottom of

the rod to the bottom of the neutral latch slot when

in the drive position. (See Figure 4)

NEUTRAL

LATCH

NEUTRAL LOCK

POSITION

DRIVE POSITION

Due to the many cutting conditions that exist, it is difficult

to suggest a cutter deck setting that will work for every

lawn. There are two adjustments that can be made on

these decks, pitch and height.

PITCH is the angle of the blades (comparing front to

rear). A 1/4" downward pitch (front of deck down) is

recommended for best cutting performance.

HEIGHT is the nominal distance the blade is off of the

ground. This measurement is made with the blades

pointed side to side and distance is measured between

cutting tip and ground. (Also see Blade Height Adjust-

ment, next page)

Changes to the cutting height can be achieved by repositioning the cutter deck. (This adjustment will also effect

the pitch of the deck.) There are three available positions (see Figure 5).

LOW CUT (1 3/4" to 3")

3/4"

STEERING

BRAKE LEVER

SC404GB

Figure 4. Steering Control Rod Adjustment

2. Adjust the steering brake rods so that the brakes

do not apply until the steering levers are pulled tight

to the handles. When the steering levers are

locked in the neutral position the machine should

move freely.

MID RANGE

(2 1/2" to 3 3/4")

HIGH CUT

(3 1/4" to 4 1/2")

CUTTER DECK HEIGHT ADJUSTMENT

Figure 5. Cutting Height Adjustment

SC405G

8

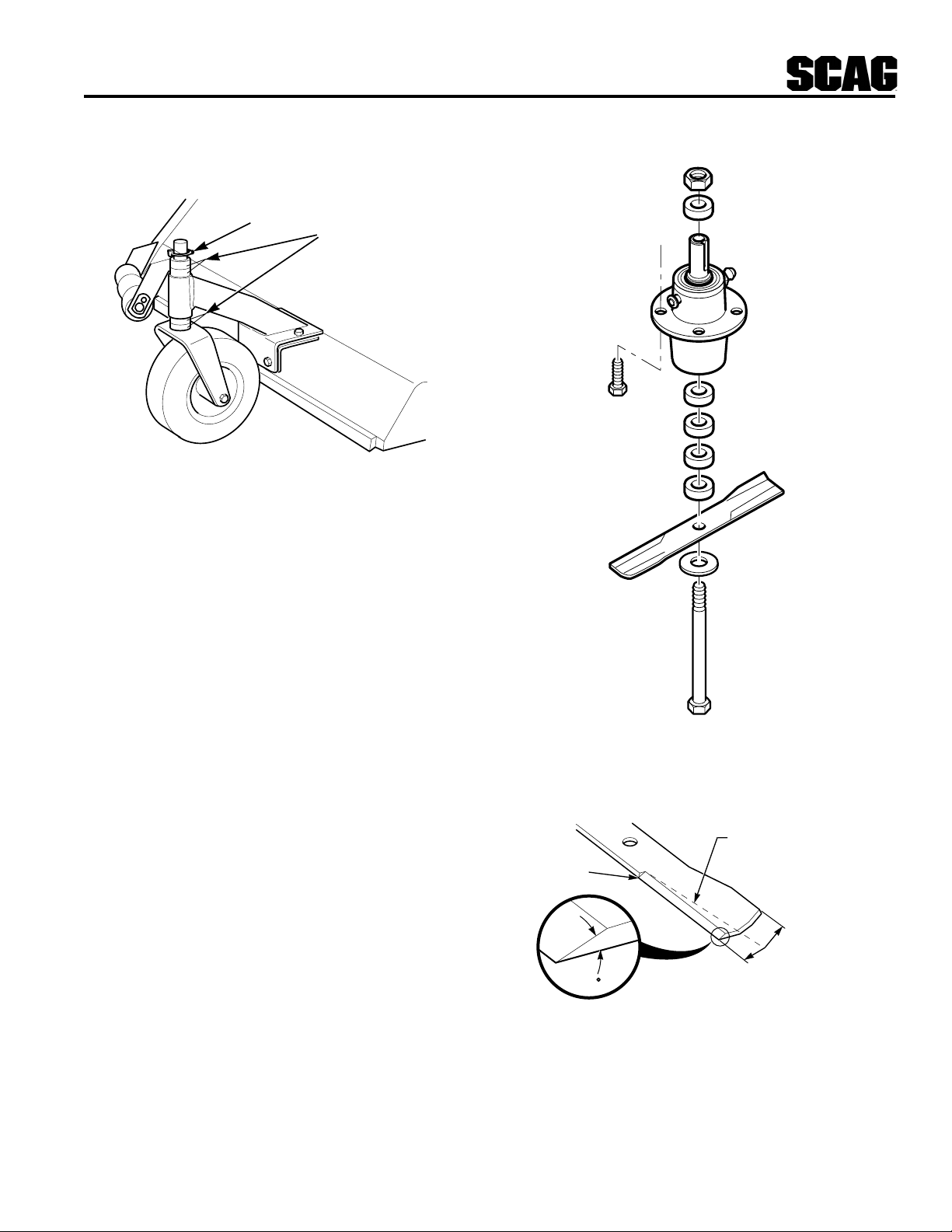

Caster spacers also can be repositioned to change

cutting heights and to change the pitch of the deck. (See

Figure 6)

Pin

Spacers

2002SGB005

Figure 6. Caster Wheel Spacers

BLADE HEIGHT ADJUSTMENT

Adjusting the blade height can be done by moving any

number of the five smaller 1/4" spacers on the blade

mounting bolts to the top of the spindle shaft or below

the spindle shaft.

-NOTE-

All blades should be positioned equally.

For best cut and discharge, a minimum of three spacers

should be installed between the blade and the spindle.

(See Figure 7)

CUTTER BLADES

Do not sharpen beyond 1/3 of the width of the blade.

(See Figure 8)

-NOTE-

Dress the blade with a file. Using a wheel

grinder may burn the blade. Check the balance

of the blade. If blades are out of balance, vibration and premature wear of spindle assembly can

occur. See your authorized Scag dealer for

blade balancing or special tools if you choose to

balance your own blades.

Do Not Cut In

2002 SC407G

Figure 7. Blade Spacers

Angle Blade Back

X

X Must NOT Exceed

30

1/3 Blade Width

Figure 8. Blade Sharpening

2002SGB033

9

LUBRICATION & MAINTENANCE

BREAK-IN

8 HOURS (DAILY)

40 HOURS (WEEKLY)

+ Grease spindle until grease comes out the relief valve.

Compatible Greases: Lidok EP #2 (found at industrial shops)

Ronex MP (Exxon service stations)

Shell Alvania (Shell service stations)

100 HOURS (BIWEEKLY)

Mobilux #2 (Mobil service stations)

Super Lub M EP #2 (Conoco service stations)

500 HRS OR ANNUALLY

PROCEDURE

X

X

X Check engine oil Do not over fill

X Remove debris from under belt cover More often if needed

X Sharpen cutter blades More often if needed

X Grease spindle bearings + US Lithium MP White Grease 2125

X Clean air filter More often if needed

X Check belt tension

X Check tire pressure Add or adjust as required

X Change engine oil See engine mfg. information

X Replace air filter More often if needed

X Grease caster wheel bearings Chassis grease

X Grease caster wheel pivot shafts Chassis grease

X Grease idler pulley bracket on cutter deck Chassis grease

X Grease drive wheel bearings Chassis grease

X Grease transmission couplers Chassis grease

X Grease idler bracket LH & RH Chassis grease

X Check all hardware for proper tightness More often if needed

Check all hardware for proper tightness

Change engine oil and filter at 5 hours

X Adjust air gap on electric clutch Contact your Scag dealer for information about

making this adjustment

COMMENTS

10

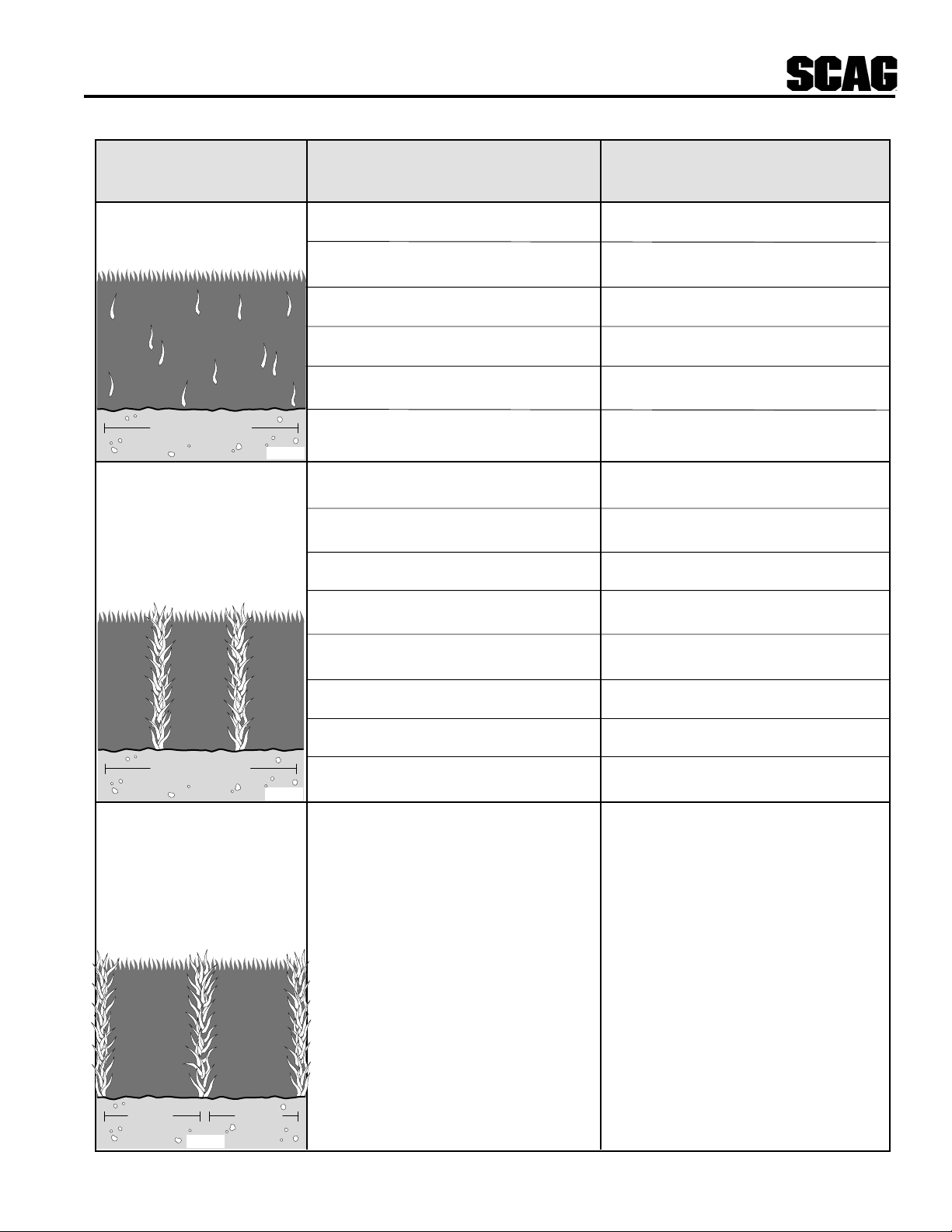

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Stringers - Occasional Low engine RPM Run engine at full 3600 RPM

Blades of Uncut

Grass Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Dull blades, incorrect sharpening Sharpen blades

Deck plugged, grass accumulation Clean underside of deck

Width of Deck

SGB020

Belts slipping Adjust belt tensions

Streaking - Strips of Dull, worn blades Sharpen blades

Uncut Grass in Cutting

Path Incorrect blade sharpening Sharpen blades

Low engine RPM Run engine at full 3600 RPM

Belt slipping Adjust belt tension

Deck plugged, grass accumulation Clean underside of deck

Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Width of Deck

SGB018

Bent blades Replace blades

Streaking - Strips of Not enough overlapping Increase the overlap of each

Uncut Grass Between between rows pass

Cutting Paths

Width

of

Deck

SGB019

Width

of

Deck

11

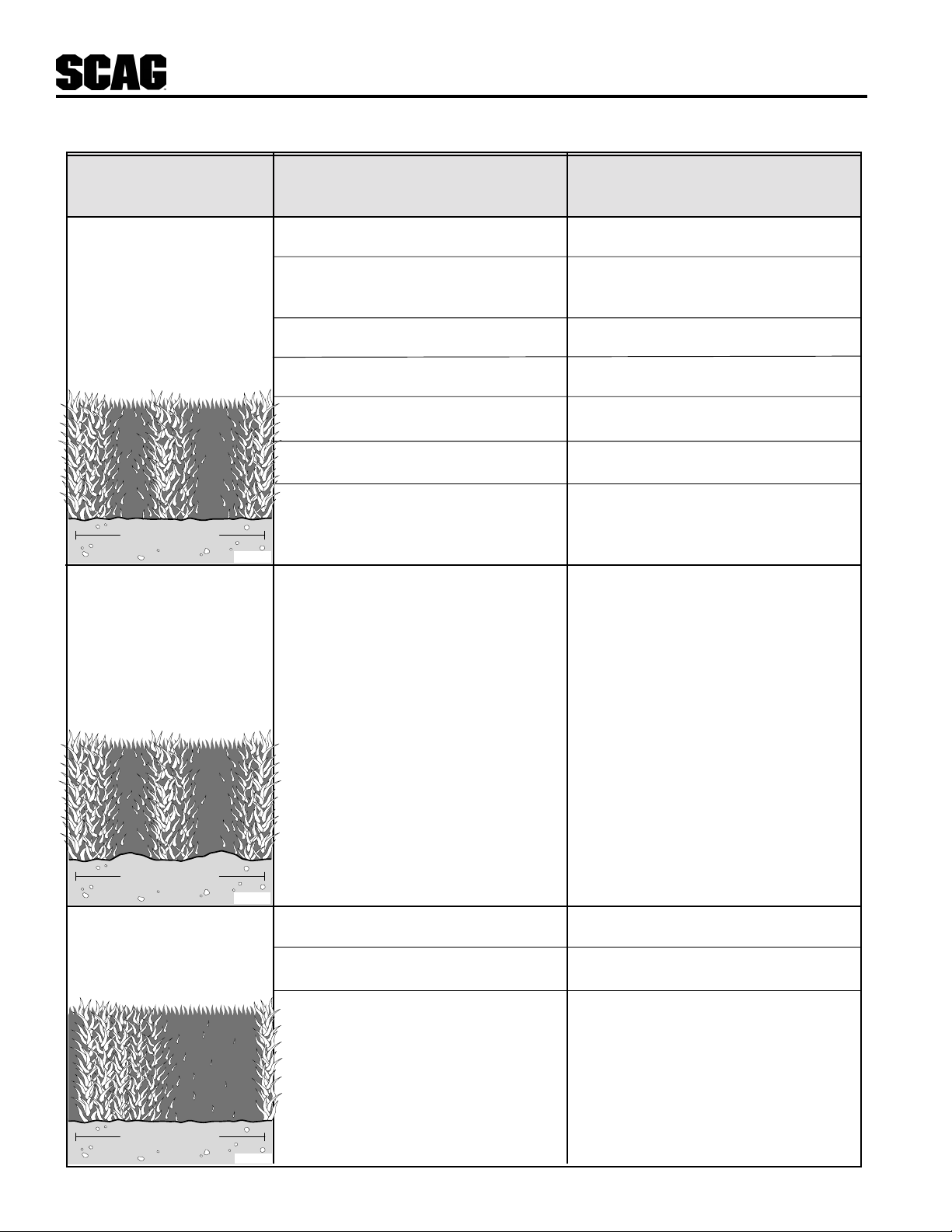

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Uneven Cut on Flat Lift worn off of blade Replace blade

Ground - Wavy

High-Low Blade upside down Mount with cutting edge toward

Appearance, ground

Scalloped Cut, or

Rough Contour Deck plugged, grass accumulation Clean underside of deck

Too much blade angle (deck pitch) Adjust pitch and level

Deck mounted improperly See your authorized SCAG dealer

Bent spindle area See your authorized SCAG dealer

Dull blade Sharpen blade

Width of Deck

SGB020

Uneven Cut on Uneven ground May need to reduce ground speed,

Uneven Ground - raise cutting height, and/or change

Wavy Appearance, direction of cut

High-Low Scalloped

Cut, or Rough Contour

Width of Deck

SGB021

Sloping Ridge Across Tire pressures not equal Check and adjust tire pressure

Width of Cutting Path

Wheels uneven Check and adjust tire pressure

Deck mounted incorrectly See your authorized SCAG dealer

Width of Deck

SGB023

12

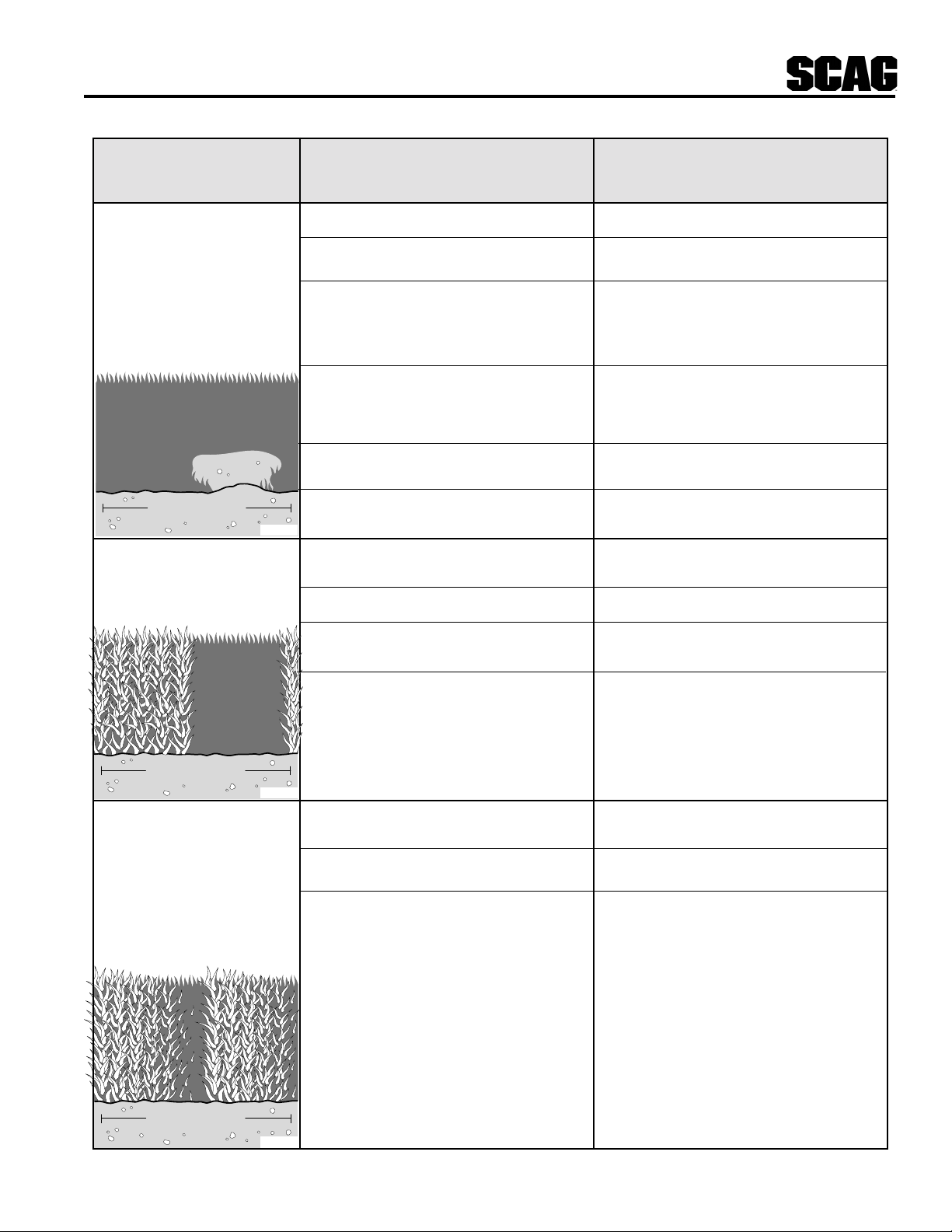

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Scalping - Blades Low tire pressures Check and adjust pressures

Hitting Dirt or

Cutting Very Close to Ground speed too fast Slow speed to adjust for conditions

the Ground

Cutting too low May need to reduce ground speed,

raise cutting height, change direction

of cut, and/or change pitch and level

Rough terrain May need to reduce ground speed,

raise cutting height, and/or change

direction of cut

Ground speed too fast Slow speed to adjust for conditions

Width of Deck

SGB022

Wet grass Cut grass after it has dried out

Step Cut Blades not mounted evenly Adjust pitch and level

Ridge in Center of

Cutting Path Bent blade Replace blade

Internal spindle failure See your authorized SCAG dealer

Mounting of spindle incorrect See your authorized SCAG dealer

Width of Deck

SGB024

Slope Cut - Sloping Bent spindle mounting area See your authorized SCAG dealer

Ridges Across Width

of Cutting Path Internal spindle failure See your authorized SCAG dealer

Bent deck housing See your authorized SCAG dealer

Width of Deck

SGB025

13

Loading...

Loading...