Scag Power Equipment SSZ User Manual

MODEL SSZ

OPERATORS MANUAL

OPERATORS MANUALOPERATORS MANUAL

OPERATORS MANUALOPERATORS MANUAL

THIS MANUAL CONT AINS THE OPERA TING

INSTRUCTIONS AND SAFETY INFORMA TION

FOR YOUR SCAG MOWER. READING THIS

MANUAL CAN PROVIDE YOU WITH ASSISTANCE IN MAINTENANCE AND ADJUSTMENT PROCEDURES TO KEEP YOUR MOWER

PERFORMING TO MAXIMUM EFFICIENCY.

THE SPECIFIC MODELS THAT THIS BOOK

COVERS ARE CONTAINED ON THE INSIDE

COVER. BEFORE OPERATING YOUR MACHINE, PLEASE READ ALL THE INFORMATION ENCLOSED.

PART NUMBER 03057

WARNING:

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all shields in place, especially the grass discharge chute.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wire and ignition key .

* If a mechanism becomes clogged, stop the engine before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as other manuals that came

with your mower .

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident prevention are dependent upon the awareness,

concern, prudence, and proper training of the personnel inv olved in the

operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

SSZ-18CV-48 with a serial number of 4200001-4209999

SSZ-22CV with a serial number of 4230001-4239999

SMZ-48 with a serial number of 4210001-4219999

SMZ-52 with a serial number of 4240001-4249999

SMZ-61 with a serial number of 4250001-4259999

Always use the entire serial number listed on the serial number

tag when referring to this product.

®

TABLE OF CONTENTS

SUBJECT PAGE

General Safety Instructions...................................................................... 1-3

Safety Instructions ............................................................................ 1-2

Hydraulic Safety................................................................................ 3

Adjustments............................................................................................... 3-6

Neutral Adjustment ........................................................................... 3-4

Straight Line Running Adjustment .................................................... 4-5

Cutter Deck Drive Belts .................................................................... 5

Drive Belt Replacement .................................................................... 6

..........................................................................................................

Initial Run, Inspection, And Operating Instructions .............................. 6-8

Maintenance ............................................................................................... 8-9

Free Wheeling .................................................................................. 8

Cutter Blades.................................................................................... 8

Curb Climbing................................................................................... 9

Cutter Deck Adjustment.................................................................... 9

Lubrication & Maintenance Chart............................................................ 10

Troubleshooting Cutting Conditions ...................................................... 11-13

Specifications For Scag SSZ Zero-Turn Rider........................................ 14-15

MEMBER

Equipment & Engine

c

Training Council

WE SUPPORT OPE

TECHNICIAN

CERTIFICATION

I

TABLE OF CONTENTS

(CONTINUED)

SUBJECT PAGE

Illustrated Parts List................................................................................... 16-35

SMZ-48", 52", 61", Cutter Decks....................................................... 16-17

Cutter Deck Controls 48", 52", & 61" Decks...................................... 18-19

Sheet Metal Components ................................................................. 20-21

Hydraulic Components ..................................................................... 22-23

BDU-10L Hydraulic Pump ................................................................ 24

Hydro-Gear Axle Assembly .............................................................. 25

Traction Drive Components .............................................................. 26-27

Brake And Steering Controls ............................................................ 28-29

Instrument Panel And Electrical Components................................... 30-31

Wiring Diagram-Kohler Adapter........................................................ 3 2

Wire Harness With Relay .......................................................................... 32

Wire Harness, Main ................................................................................... .33

Replacement Decals ..................................................................................34-36

Warranty Statement.............................................................. Inside Back Co ver

II

Your mower was built to the highest standards in the industry. However, your mower is only as

safe as you, the operator, make it. Carelessness or error on the part of the operator may result in

serious bodily injury. Hazard control and accident prevention depend upon the awareness, concern, prudence, and proper training of the personnel involved in the operation, transport, and

storage of this equipment. Make sure every operator is properly trained and thoroughly familiar

with all of the controls and safety instructions before operating the equipment.

SAFETY INSTRUCTIONS

WARNING:

Do not operate the mower on steep slopes.

Riding lawn mowers can tip over when used on an

excessive slope. To check a slope, attempt to

back up with the cutter deck down. If the wheels

slip when backing up a slope, stay off the slope.

If you are in doubt about hillside operation, stay

off the slope.

Always back up when loading a machine on ramps

or tilt bed trailers.

1. Know the controls and how to stop quickly . READ

THIS OPERATOR’S MANUAL and instructions

furnished with any attachments. A replacement

Operator's Manual is available from your Scag

Servicing Dealer. To order, contact your dealer with

the complete model number and serial number of your

Scag product.

2. Do not allow children to operate this machine. Do

not allow adults to operate this machine without

proper instruction.

7. Disengage the power to attachments, stop the

engine, and remove the key before making any

repairs or adjustments.

8. Disengage the power to attachments when

transporting the machine or when attachments are

not being used.

9. T ake all possible precautions when leaving the

machine unattended including disengaging the

power to attachments, lowering the attachments,

setting the parking brake, and removing the key .

10. Do not stop or start suddenly when going up or

down a hill. Mow up and down the face of slopes;

never mow across slopes.

11. Reduce speed and be very careful when operating on

slopes or making sharp turns to prevent tipping or

loss of control. Be especially cautious when

changing direction on slopes. If necessary to turn

on a hill, always turn downhill.

12. W atch for holes, rocks, roots in the terrain, and

other hidden hazards. Keep away from dropoffs.

13. W atch for traffic when crossing roadways or

operating near roadways.

3. Do not carry passengers. Never mow toward or near

anyone.

4. Clear the area of objects such as wires, sticks, and

rocks that can be picked up and thrown by the

mower blades.

5. Disengage all attachment clutches and engage the

parking brake before attempting to start the engine.

6. Disengage all attachment clutches and engage the

parking brake before leaving the operator’s position.

14. When using any attachments, never directly

discharge materials towards bystanders or allow

anyone near the mower while it is operating.

15. Handle gasoline with care - it is highly flammable.

a. Use an approved gasoline container only.

b. Never remove the fuel cap while the engine is

running or hot. Allow the engine to cool for

several minutes before removing the cap and

adding gasoline. Never fill the fuel tank

indoors. Always clean up spilled gasoline.

c. Do not run the engine indoors.

1

SAFETY INSTRUCTIONS - CONT’D

16. Keep the machine and attachments in good

operating condition. Make sure all safety devices

and shields are in place and operate the equipment

as intended.

17. Keep all nuts, bolts, and screws tight to be sure

equipment is in safe operating condition.

18. Never store the equipment with gasoline in the tank

in a building where fumes may reach an open flame

or spark. Allow the engine to cool before storing

the machine in any enclosure.

19. To reduce fire hazard, keep the engine free of

grass, leaves, or excess lubricants.

20. If the machine or attachments strike a foreign

object, disengage the power to the attachments and

stop the engine immediately . W ait for all moving

parts to stop, then inspect for damage. Repair the

damage before restarting or operating the

equipment.

25. Perform only the maintenance described in this

manual. If additional maintenance or major repairs

are needed, contact an authorized Scag Servicing

Dealer. To ensure optimum performance and safety,

always purchase genuine Scag replacement parts

and accessories. Never use “WILL FIT” replacement parts and accessories made by another manufacturer. Using such parts may void the warranty.

WARNING:

Do not operate the machine while wearing sandals,

tennis shoes, sneakers, or shorts. Also, do not wear

loose fitting clothing which could get caught in moving parts. Always wear long pants and substantial

shoes.

Wearing safety glasses and safety shoes is

.

advisable.

21. Do not change the engine governor settings or

overspeed the engine.

22. When using the machine with a mower:

a. Mow only in daylight or good artificial light.

b. Never dismount the machine to adjust the

cutting height while the engine is running.

c. Shut the engine off and remove the key before

removing the grass catcher or unclogging the

chute.

d. Check the blade mounting bolts frequently for

proper tightness.

23. Disengage the power to the blades before backing

up. Do not mow in reverse unless absolutely

necessary and then only after careful observation of

the entire area behind the mower.

24. The discharge chute must be installed and be in the

down position on a side discharge mower except

when the optional grass catcher or the mulching

plate is completely installed. If the discharge chute

clogs, shut the engine off, remove the key , and wait

for all movement to stop before removing any

obstruction.

CAUTION:

Stop the engine and remove the key from the

ignition before making any adjustments. Wait for

all moving parts to come to a complete stop before beginning work.

Engine and drive unit can get hot during operation.

Allow the engine and drive components to cool

before making any adjustments.

WARNING:

To prevent personal injury or equipment damage,

do not operate the machine without the cutter deck

properly mounted.

2

HYDRAULIC SAFETY

1. Hydraulic fluid is under high pressure. If you need

service on your hydraulic system, please see your

dealer.

WARNING:

Keep your body and hands away from pin holes or

nozzles that eject fluid under high pressure. Use

paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under high pressure may

have sufficient force to penetrate your skin and cause

serious injury. If fluid is injected into your skin, a

physician familiar with this form of injury must remove it surgically within a few hours or gangrene

may result.

FREE

WHEEL

POSITION

RUN

POSITION

Figure 1

DUMP VALVE

LEVER

SC200G

2. Make sure all hydraulic fluid connections are tight

and all hoses and lines are in good condition before

applying pressure to the system.

ADJUSTMENTS

Neutral Adjustment

1. Set the machine up on jack stands so the drive

wheels are free to rotate. Block the caster wheels to

prevent an accident if the machine should accidentally fall off the jack stands.

2. Run Position: Move the dump valve lever (on the

Left Hand side of mower) behind the hook on the

frame to close the hydraulic dump valves on the

pump. (See Figure 1)

Free Wheel Position: Pull lever back and to the

left, then push forward to relieve pressure. (See

Figure 1)

3. Start the engine and check if one or both of the

drive wheels are turning.

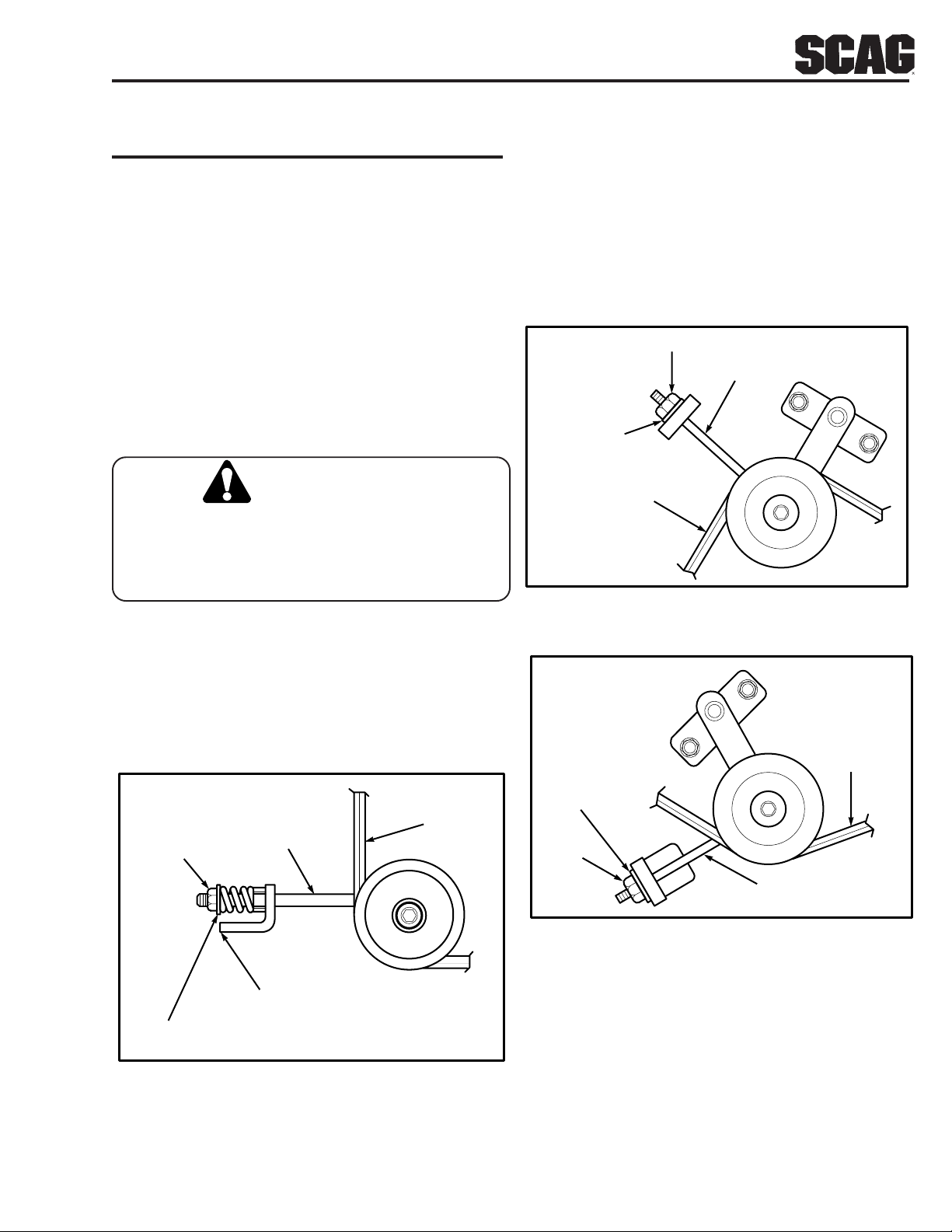

4. Adjust each drive wheel separately by using the

turnbuckles located under the seat. Loosen the jam

nut on the turnbuckle. (See Figure 2)

5. If the drive wheel is rotating forward, adjust the

turnbuckle clockwise. If the drive wheel is rotating

rearward, adjust the turnbuckle counterclockwise.

Adjust until the drive wheel stops turning. (See

Figure 2)

JAM NUT

Adjust TURNBUCKLE

clockwise or

counterclockwise until drive

wheels stop rotating

SC201G

Figure 2

3

ADJUSTMENTS - CONT’D

ESC202G

CASTER WHEELS

25 PSI

DRIVE WHEELS

12 PSI

Neutral Adjustment Cont'd

6. Tighten both the jam nuts to secure the neutral

position.

7. Adjust the other drive wheel if necessary .

8. Actuate the hand control levers forward and reverse.

Allow the levers to self-center and check that the

drive wheels remain in neutral.

NOTE: The neutral return mechanisms on the

fenders are adjusted at the factory . Readjustment

should not be necessary .

Figure 3

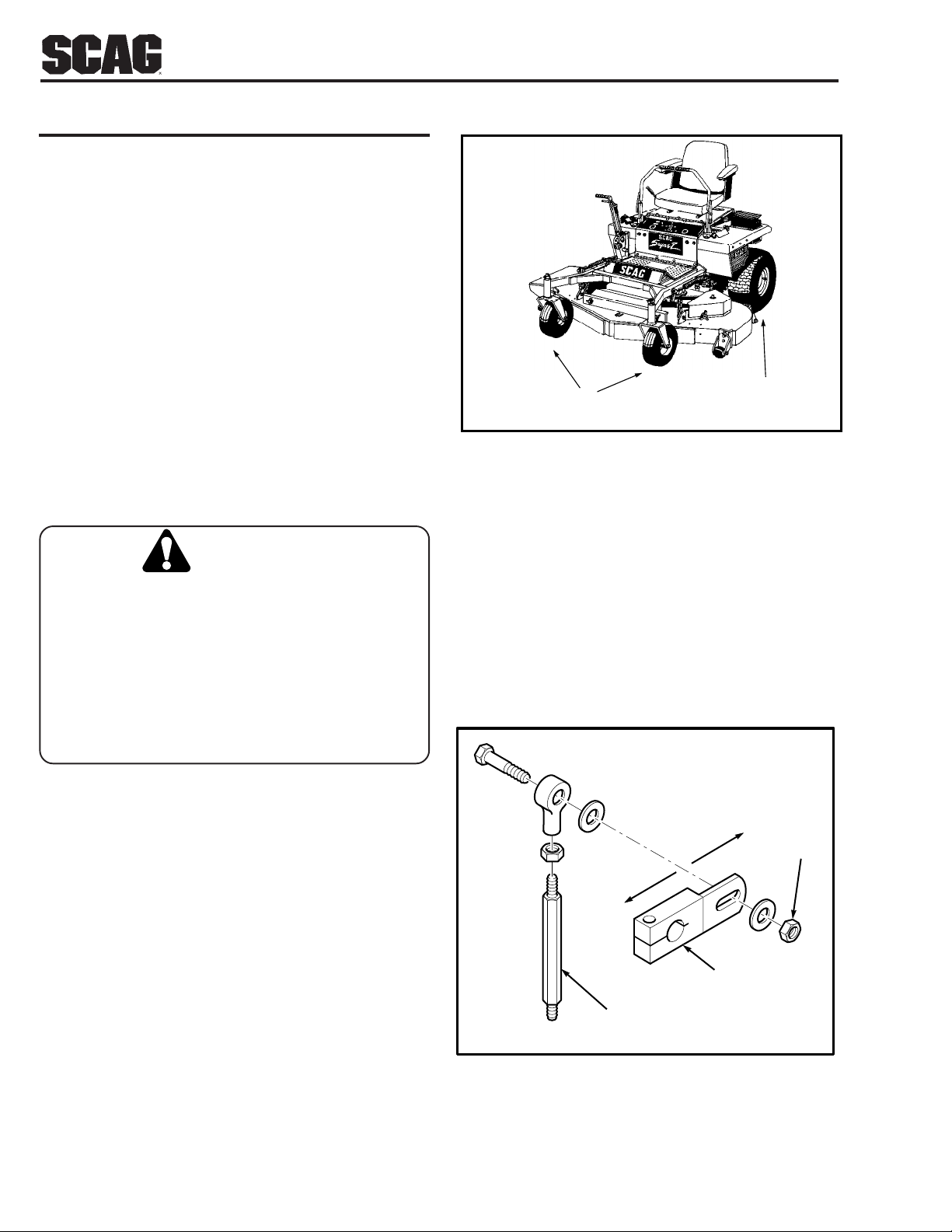

Straight Line Running Adjustment

CAUTION:

Stop the engine and remove the key from

the ignition before making any adjustments.

Wait for all moving parts to come to a complete stop before beginning work.

The engine and drive unit can get hot during operation. Allow engine and drive components to cool before making any adjustments.

1. Before making this adjustment, check the tire

pressure of the drive wheels. Tire pressure for each

wheel must be equal. (See Figure 3) If the tire

pressures are not equal, the machine will pull to the

side with the lower tire pressure.

NOTE:Make this adjustment only on the LH

pump. The RH pump has a fixed speed and

cannot be adjusted.

2. Locate the turnbuckle for LH pump under the

operator seat in front of the hydraulic oil tank. (See

Figure 4)

3. Loosen nut securing the turnbuckle to bellcrank.

(See Figure 4)

FASTER

NUT

SLOWER

BELLCRANK

TURNBUCKLE

SC203G

Figure 4

4

ADJUSTMENTS - CONT’D

Straight Line Running Adj. - Cont'd

4. Adjust the position of the turnbuckle by moving it in

the mounting slot either forward to slow the left

wheel or backward to speed up the left wheel. If

the unit pulls to the right, the left wheel is too fast.

If the unit pulls to the left, the left wheel is too slow .

5. Tighten the jam nut to secure the turnbuckle.

6. Readjust neutral if necessary . (See Figure 2)

3. To adjust the RH blade drive belt: Adjust the RH

belt tension so the belt moves 1/2" with 10 pounds

pressure. Adjust the tension by tightening or

loosening the J-bolt. (See Figure 6 for SMZ-52;

See Figure 7 for SMZ-61 & SMZ-48)

4. Carefully unlatch foot plate support rod and lower

foot plate.

NUT

Drive Belt Replacement

"J" BOLT

Cutter Deck Drive Belts

CAUTION:

Stop the engine and remove the key from the

ignition before making any adjustments. Wait

for all moving parts to come to a complete stop

before beginning work.

1. Lift the foot plate and secure with the foot plate

support rod.

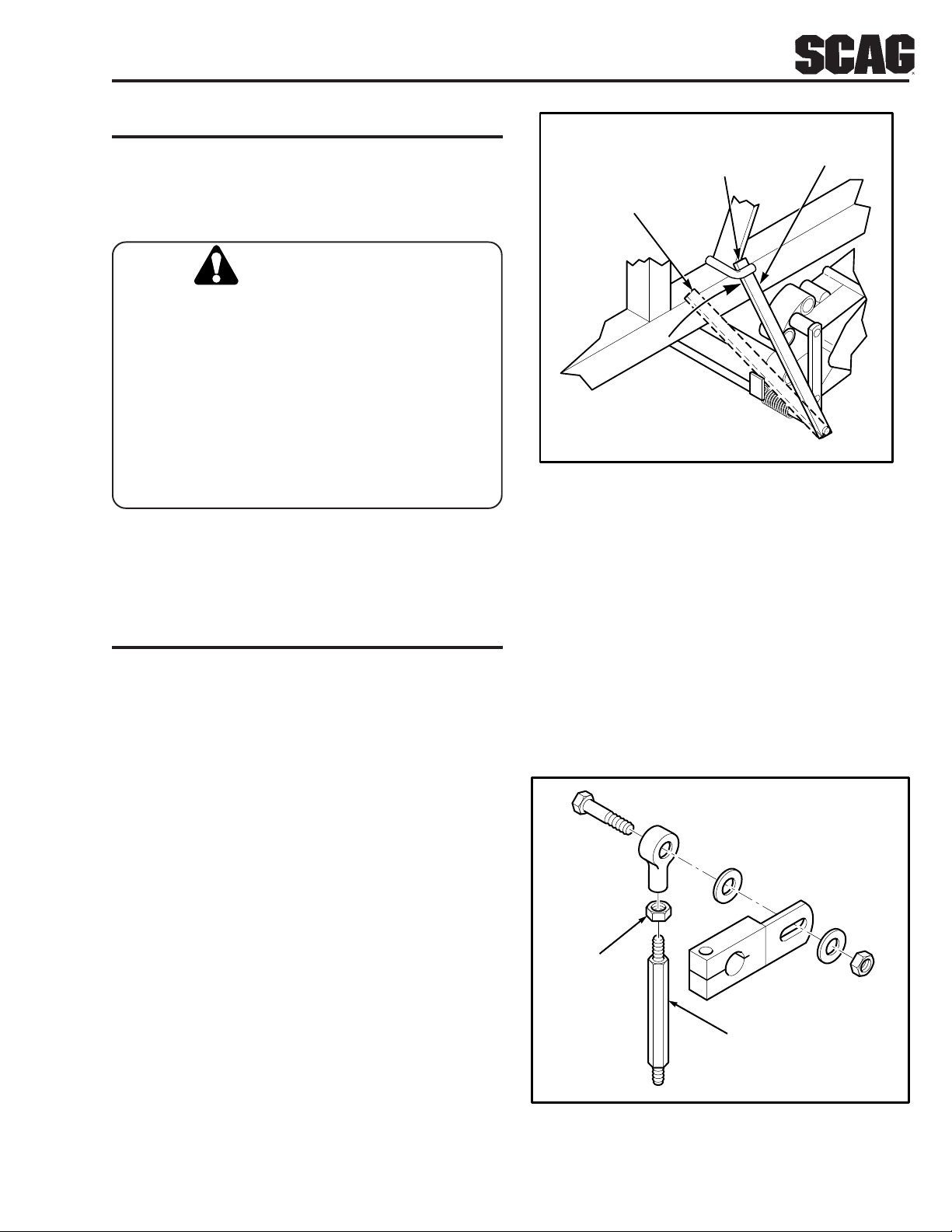

2. T o adjust the cutter deck drive belt: Adjust until the

end of the spring aligns with the end of L-shaped

bracket. (See Figure 5)

BELT

NUT

"J" BOLT

WASHER

BELT

SC205G

Figure 6 - SMZ-52

BELT

WASHER

NUT

END OF L- SHAPED

WASHER

NOTE: Due to initial belt stretching, check this

adjustment after the first 2 , 4 , and 8 hour intervals.

BRACKET

SC204G

Figure 5

"J" BOLT

Figure 7 - SMZ-61 & SMZ-48

5

SC206G

ADJUSTMENTS - CONT’D

Drive Belt Replacement

3. Make sure the engine oil level (10W30) is at FULL

on the dipstick. When performing oil changes, fill

the engine to the full mark on the engine dipstick.

(Approximately 2 quarts will be needed for Kohler

engines) DO NOT OVERFILL.

CAUTION:

When replacing the drive system belt use extreme caution. The idler arm is under spring

tension.

Remove the two 1/4" nuts on the belt guard and remove

the guard. T o remove the old belt, use a 1/2" drive

breaker bar and insert it into the square hole on the idler

arm. Pull the idler arm down until the belt becomes slack

and can be removed easily from the idler pulley . Slowly

move the idler arm up until the stop bolt rests against the

hydraulic tank support. Remove the old belt and mount

the new belt around the engine drive pulley and the two

pump pulleys. Feed the belt up toward the idler pulley.

Pull the idler arm down so that the new belt can easily be

mounted on the idler pulley . Slowly move the idler arm

up until the belt is firmly engaged. Remove the breaker

bar and remount the belt guard. Check to ensure that the

belt is riding properly in all pulleys.

ontrol Handle Position

Hand Control Handle Position

The position of the hand control handles can be adjusted

for operator comfort. Loosen the bolts holding the

handle to the lever bar just enough to allow movement of

the handle. Adjust to position most comfortable for

operator. Retighten the bolts.

4. Check the oil level (SAE 20W50) in the hydraulic

reservoir . The reservoir is under the seat. The oil

level should be 2" below the top of the tank. When

performing oil changes, fill the reservoir until it is 2"

below top of tank. (Approximately 4 quarts will be

needed) DO NOT OVERFILL.

5. Check that all fasteners are tightened properly .

Make sure all safety devices are in place and

working correctly .

WARNING:

Gasoline is highly flammable. Be careful when

filling the tank. Do not fill the tank while the

engine is running or hot from operation. Extinguish open flames, matches, and smoking

materials before filling the tank. Do not overfill the tank. Wipe up all gasoline spills.

6. Fill the fuel tank with clean, fresh, lead-free

gasoline with a minimum octane rating of 87.

7. Check the safety interlock system. With the

operator on the seat, the engine must not start unless

the control handles are in the neutral lock position

and the cutter drive is disengaged.

!

INITIAL RUN, INSPECTION, AND

OPERATING INSTRUCTIONS

1. Check that all belts are routed correctly and aligned

properly.

2. Check the cutter blade drive belts for correct

tension.

IMPORT ANT : If the engine is running, the

engine must stop if the operator leaves the seat

when one or both handles are in the drive

position or the cutter drive is engaged.

6

INITIAL RUN, INSPECTION, AND

OPERATING INSTRUCTIONS CONT’D

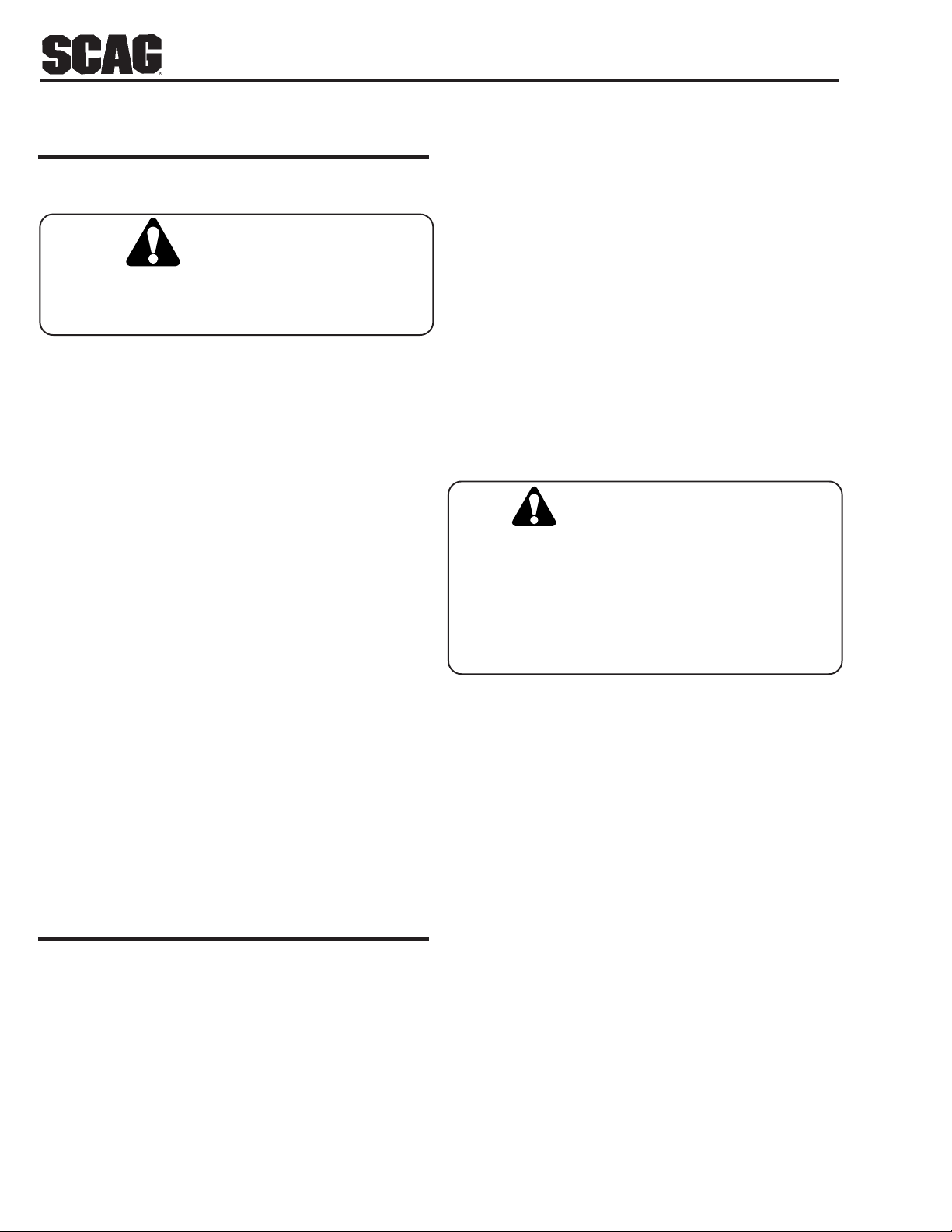

8. T o start the engine:

10. Release the parking brake. Check that the machine

does not creep forward or backward. If the machine

does creep, adjust the neutral control. See “Neutral

Adjustment” instructions.

a. Place the control handles in the neutral lock

position.

b. Push the mower engagement switch to the off

position.

c. Put the parking brake in the engaged position.

d. Adjust the throttle and choke as required.

e. Turn the ignition key to start. Release the

ignition key when the engine starts. The key

will return to the RUN position.

9. Pull the yellow engagement switch out to engage

the cutter drive belts. (See Figure 8) Allow the

belts to run for five minutes.

NOTE: For best belt life, engage the clutch at

3/4 speed and not under load.

NOTE: When the PTO is engaged (or possibly

disengaged), a squealing sound from the under

side of the machine is normal. It is caused by the

electric clutch plates meshing as the mower

comes up to speed.

CAUTION:

CAUTION: Stop the engine and remove the

key from the ignition before making any adjustments. Wait for all moving parts to come

to a complete stop before beginning work.

The engine and drive unit can get hot during

operation. Allow the engine and drive components to cool before making any adjustments.

11. Operate the machine forward and backward.

Check that all the systems function correctly . If the

machine does not move, make sure the hydraulic

dump valve lever near the left wheel is engaged.

(See Figure 1 page3)

T o engage the parking brake, move the lever up and

out into the bracket. T o disengage the parking

brake, pull the lever up and in, away from the

bracket. (See Figure 9)

PULL UP TO ENGAGE

PUSH DOWN TO DISENGAGE

Figure 8

390S0138

PARKING BRAKE

OFF

ON

SC209G1

Figure 9

7

INITIAL RUN, INSPECTION, AND

OPERATING INSTRUCTIONS CONT’D

12. Shut off the engine, remove the key from the

ignition, and wait for all moving parts to stop.

Recheck the cutter deck drive belts for proper

tension. Correct and adjust as necessary .

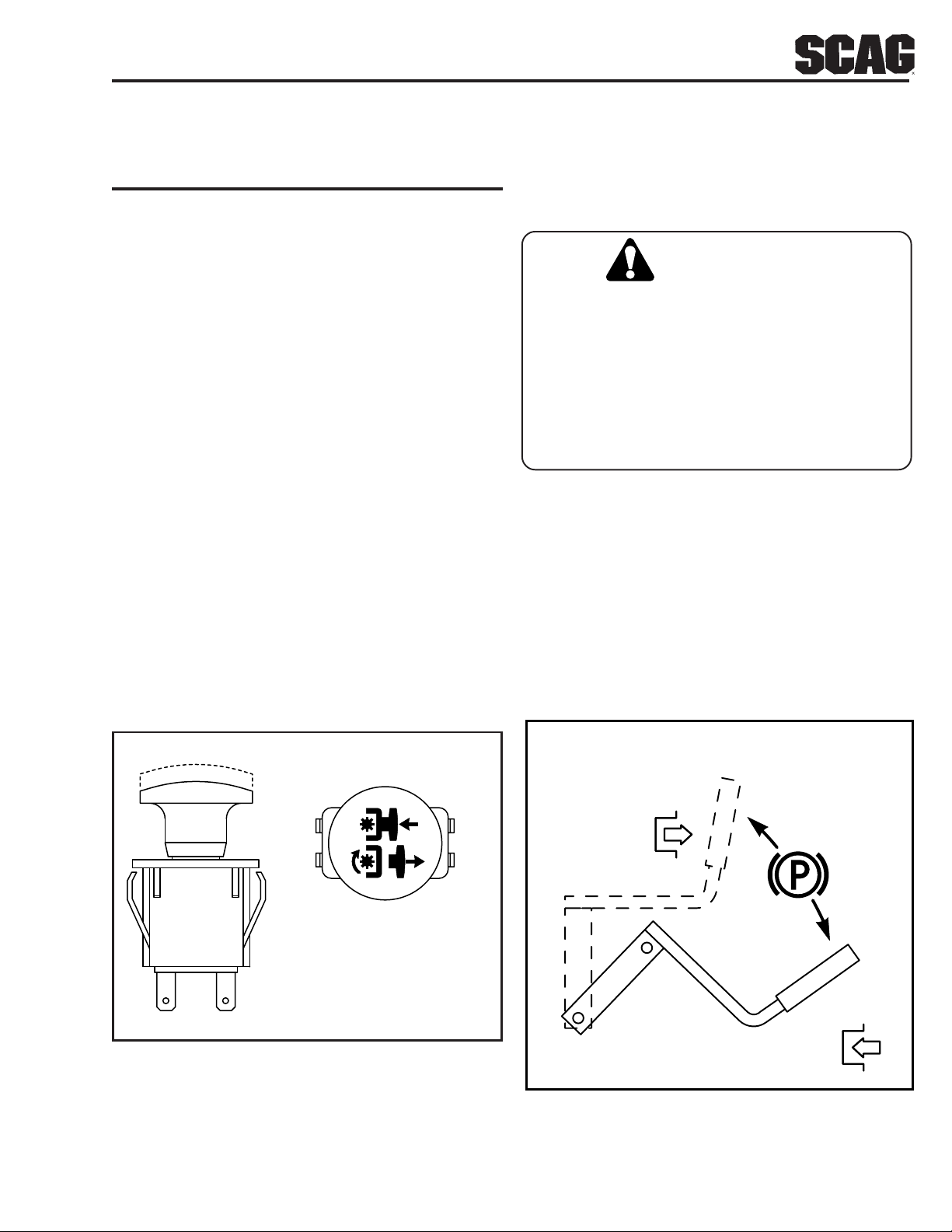

Sharpen the blades as shown on Figures 10 and 11.

Y

X

13. Park the machine on a level area, set the parking

brake, and remove the key from the ignition to

prevent engine starting.

14. Before transporting the machine, latch the seat stop

cable to avoid damage to the seat.

MAINTENANCE

g

Free Wheeling

T o release the drive wheels, so the machine will roll

without the engine running, pull the dump valve lever

back from the hook on the frame, move it to the left, and

push it forward to relieve the pump pressure. The lever

is on the LH side of the machine. (See Figure 1 on page

3)

Cutter Blades

DO NOT CUT IN,

LEAVE ORIGINAL

STARTING POINT

Figure 10

Do not sharpen (X) beyond 1/3 of blade width (Y).

ANGLE BLADE

BACK

THE EDGE OF BLADE SHOULD

BE AT A 30 DEG. ANGLE

30

Figure 11

SC210G

SC211G

WARNING:

The blade is sharp! A blade at rest can cause

severe cuts. Rotating the blade can cut fingers off. Always lift deck using handles provided.

Suggestion: Dress the blade with a file. Wheel grinders

may burn the blade.

Curb Climbing

8

MAINTENANCE - CONT'D

g

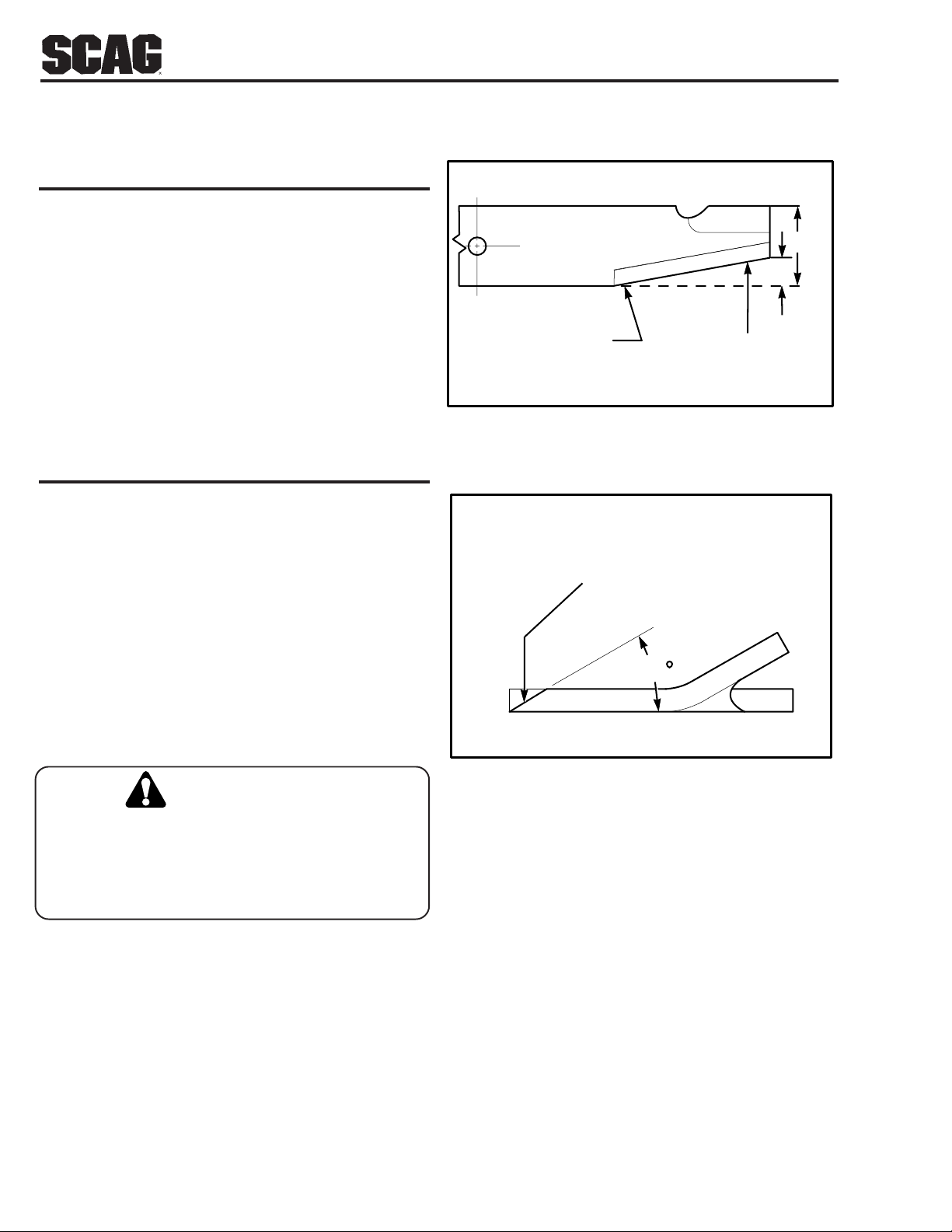

Curb Climbing

When driving a riding mower up and over a curb, first

raise the cutter deck to the highest position. Then, drive

it in reverse and at an angle so that the back drive

wheels go over the curb one at a time. When both drive

wheels are over the curb, turn the machine so that both

front caster wheels contact the curb at the same time.

(See Figure 12)

SC212G

Figure 12

Cutter Deck Adjustment

Poor cutting performance of your Scag SSZ can be an

indication that you cutter deck may need to be adjusted.

If you have checked that your blades are properly

sharpened and not bent please take your machine to an

authorised Scag servicing dealer for proper repairs.

For assistance in troubleshooting cutting performance

conditions please see pages 11-13.

9

Loading...

Loading...