Page 1

MODEL TS

ACCESSORY FOR:

STT - ALL MODELS

STC - MODELS ABOVE SERIAL NUMBER 7630001

OPERATOR’S MANUAL

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMATION

FOR YOUR SCAG ACCESSOR Y. READING THIS

MANUAL WILL PROVIDE YOU WITH MAINTENANCE AND ADJUSTMENT PROCEDURES

TO KEEP YOUR ACCESSORY PERFORMING

TO MAXIMUM EFFICIENCY. THE SPECIFIC

MODELS THAT THIS BOOK COVERS ARE CONTAINED ON THE INSIDE COVER. BEFORE

OPERATING YOUR MACHINE, PLEASE READ

ALL THE INFORMATION ENCLOSED.

© 2004

SCAG POWER EQUIPMENT

DIVISION OF MET ALCRAFT OF MA YVILLE, INC

WWW.SCAG.COM

P ART NO. 03158

PRINTED 8-2004

PRINTED IN USA

Page 2

WARNING

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all safety shields in place.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wire.

* If a mechanism becomes clogged, stop the engine and wait for all moving

parts to come to a complete halt before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as the Operator's Manual that came

with your mower .

* Keep others off the tractor (only one person at a time).

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident prevention are dependent upon the awareness,

concern, prudence, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

TS with a part number of 9269

Page 3

1.1 INTRODUCTION

2.1 SAFETY INFORMATION

This manual has been prepared to provide the

information you need to correctly assemble, operate,

and maintain this Tiger Striper. Read it carefully and

keep it for future reference.

The replacement of any part on this product by other

than the manufacturer's authorized replacement part

may adversely affect the performance, durability or

safety of this product.

USE OF OTHER THAN ORIGINAL SCAG

REPLACEMENT PARTS WILL VOID THE

WARRANTY.

If additional information or service is needed that is

not outlined in this manual, please contact your Scag

Power Equipment dealer. Scag dealers are trained in

the latest service methods and carry a full line of Scag

replacement parts.

When ordering parts, always provide the complete

model of this Tiger Striper.

All information provided in this manual is based upon

information available at the time of printing. Scag

Power Equipment reserves the right to make changes

at any time without notice or obligation.

1.2 DIRECTION REFERENCE

-NOTE-

To avoid personal injury, it is imperative that all

safety instructions be observed.

1. Read this operator's manual and the

operator's manual that is supplied with the

machine this attachment is used on.

A replacement manual is available from your

authorized Scag Service Dealer or by contacting:

Scag Power Equipment, Service Department at P.O.

Box 152, Mayville, WI 53050. You may also contact

us through our website at www.scag.com. Please

indicate the complete model number of your Scag

product when ordering a replacement manual.

2. Before removing the Tiger Striper, disengage the

mower, stop the engine and wait for all

movement to stop.

3. ALWAYS turn the engine OFF, remove the key

and wait for all movement to stop before

servicing, cleaning or removing the Tiger Striper.

4. Do not modify or alter any component of the

Tiger Striper attachment or mower.

5. Do not allow any passengers to ride on the

mower.

The "Right" and "Left", "Front" and "Rear" of the

machine are referenced from the normal operating

position.

2.2 OPERATING INSTRUCTIONS

To operate the Tiger Striper, you will need to lower

the roller to the operating position. The Tiger Striper

can be easily removed or locked in the transport

position whenever the machine is being transported

or when striping is not needed.

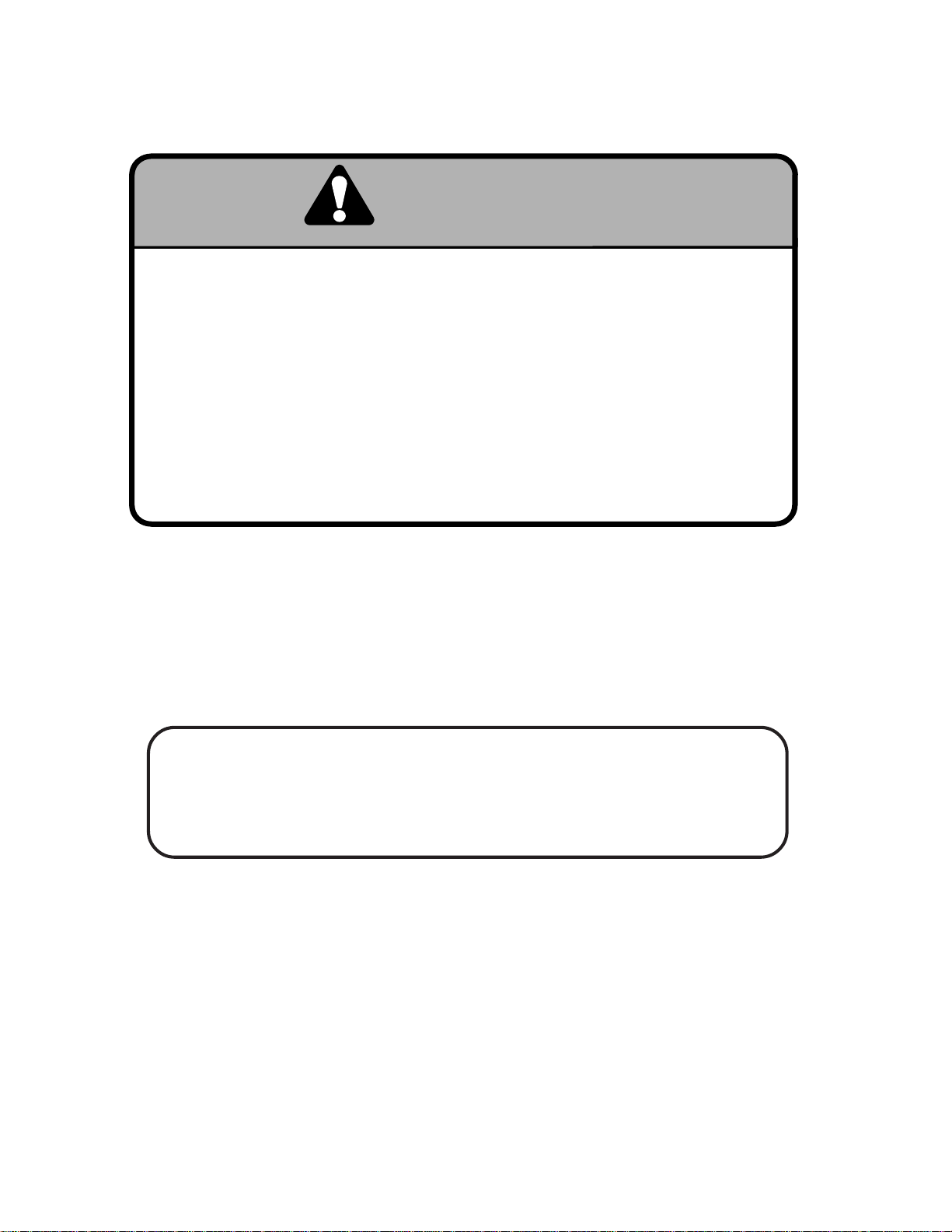

1. To unlock the Tiger Striper from the transport

position, lift up slightly on the handle and turn the

lock pin until the small roll pin lines up with the

slot. See Figure 2-1 on page 2.

1

Page 4

3. Repeat on opposite side.

Roll Pin

Lift Up on

Handle

Push and Turn Pin to line

up Roll Pin with Slot

to Unlock

FIGURE 2-1

2. Repeat this procedure on the opposite side.

The machine is now ready to operate.

2.3 REMOVING THE TIGER STRIPER

The Tiger Striper can be easily removed whenever

the machine is being transported or when striping is

not needed. To remove the Tiger Striper, follow the

instructions below.

1. Prepare the machine so there is easy and safe

access to the work area. Remove the key and

maintain all safety related work procedures.

Always wear eye and hand protection.

2. Lock the Tiger Striper up in the transport

position by lifting upward on the handle, push

and turn the lock pin 90 degrees. The small roll

pin must be out of the slot in the bracket to lock

in the transport position. See Figure 2-2.

Roll Pin

4. Once the Tiger Striper is locked in the transport

position, remove the quick pins securing the

Tiger Striper to the mounting brackets. See

Figure 2-3

Remove Quick Pins

FIGURE 2-3

5. Slide the Tiger Striper off of the mounting

brackets.

6. To install the Tiger Striper, slide the assembly on

to the mounting brackets and reinstall the quick

pins. Once the Tiger Striper has been reinstalled,

follow Section 2.2 Operating Instructions for

proper operation.

3.1 ASSEMBLY INSTRUCTIONS - STT

-NOTE-

Use the illustrated parts list as a part

number reference when following the

assembly instructions.

FIGURE 2-2

Push and

Turn Pin to

Lock

1. Remove all packaging materials. Lay out the

mounting hardware and the Tiger Striper

assembly for easy access.

2. Prepare the machine so there is easy and safe

access to the work area. Remove the key and

maintain all safety related work procedures.

Always wear eye and hand protection.

2

Page 5

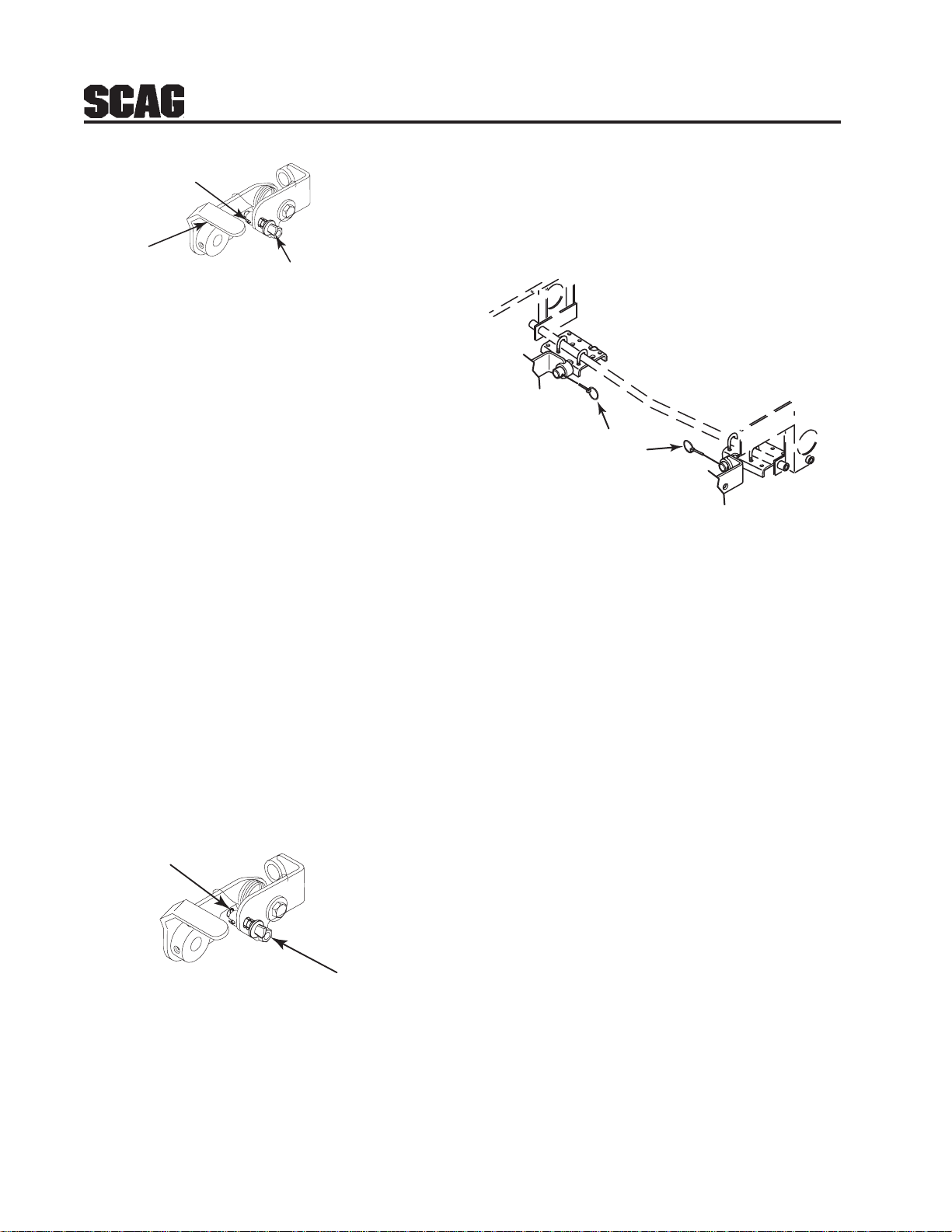

3. Attach the mounting brackets to the cross bar

between the wheel motor brackets using (4) ubolts and (8) serrated flange nuts. See Figure

3-1. Do not tighten the hardware.

5. Install the left and right hand Striper Stop

Brackets (p/n 423953 & p/n 423954) to the

frame and secure with (4) 3/8-16 x 1" bolts and

(4) elastic stop nuts. See Figure 3-2.

-NOTE-

If the Tiger Striper is installed on an STT with

a serial number below 7219999, part

number 423966 mounting spacer will need to

be installed between the mounting bracket

and cross bar. See Figure 3-1.

(4x) U-Bolts

Mounting

Bracket

(8x) Serrated Flange

Nuts

Mounting

Bracket

STT with a serial number of 7219999 or Below

(4) 3/8-16 Elastic

Stop Nut

423953 L.H.

Stop Bracket

(4) 3/8-16 x 1" Bolt

423954 R.H.

Stop Bracket

FIGURE 3-2

6. Install the Tiger Striper roller assembly to the

mounting brackets and secure with the quick

pins.

7. Once the Tiger Striper roller assembly is installed

and secure, tighten the mounting hardware on

both mounting brackets.

(4x) U-Bolts

Mounting

Spacer

Mounting

Bracket

Mounting

Spacer

Mounting

Bracket

(8x) Serrated Flange

Nuts

FIGURE 3-1

4. The edge of the mounting bracket should be

under the wheel motor mounting plate for proper

installation. See Figure 3-1.

8. Follow Section 2.2 Operating Instruction for

proper operation.

3.2 ASSEMBLY INSTRUCTIONS - STC

-NOTE-

Use the illustrated parts list as a part

number reference when following the

assembly instructions.

1. Remove all packaging materials. Lay out the

mounting hardware and the Tiger Striper

assembly for easy access.

2. Prepare the machine so there is easy and safe

access to the work area. Remove the key and

maintain all safety related work procedures.

Always wear eye and hand protection.

3

Page 6

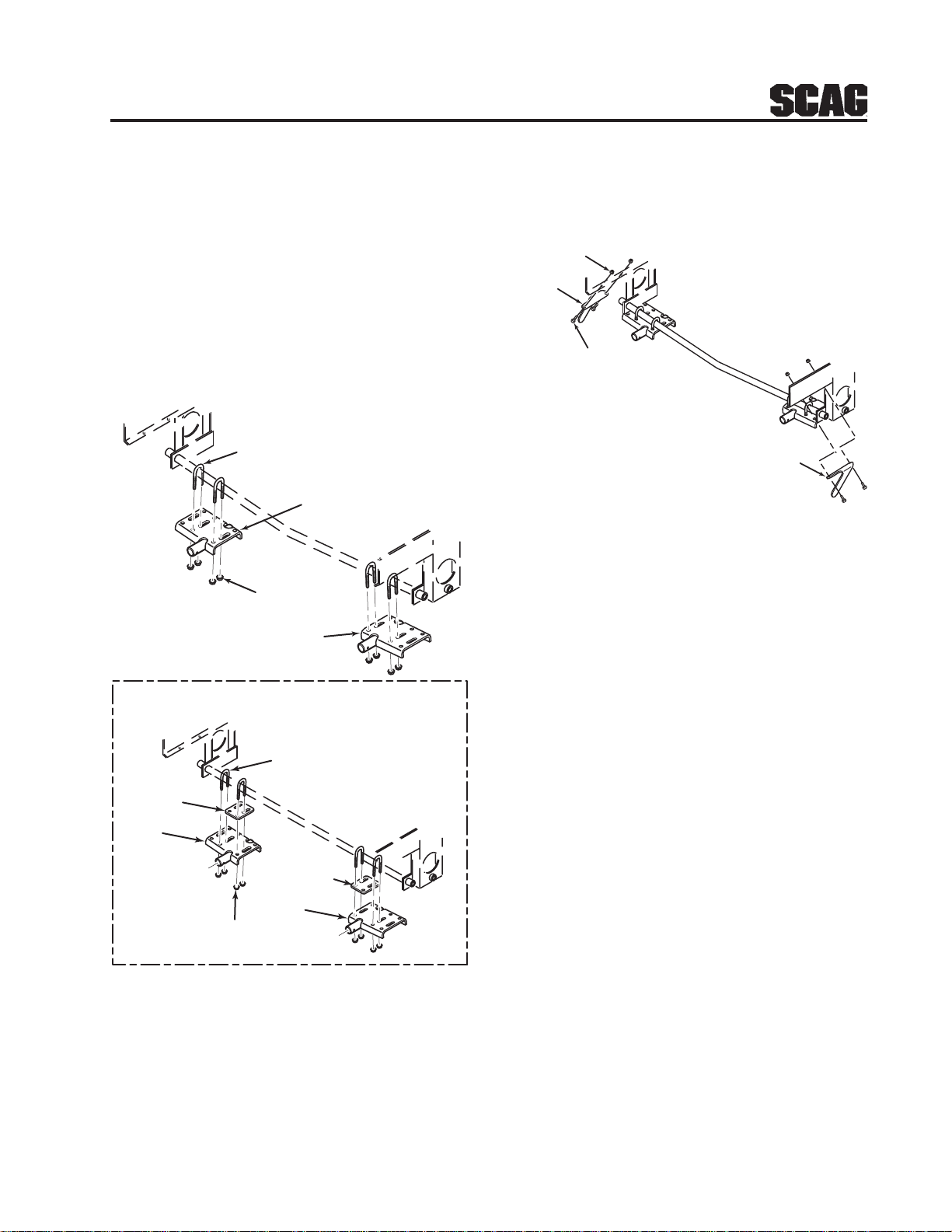

3. Attach the mounting brackets to the cross bar

between the wheel motor brackets using (4)

u-bolts and (8) serrated flange nuts. See Figure

3-3. Do not tighten the hardware.

-Note-

The Tiger Striper cannot be installed on an

STC with a serial number below 7630001.

(4x) U-Bolts

Mounting

Spacer

Mounting

Bracket

Mounting

Spacer

(8x) Serrated Flange

Nuts

Mounting

Bracket

4.1 LAWN STRIPING

HOW DOES LAWN STRIPING WORK?

The “stripe” that you see on the lawn is actually light

reflecting off the blades of grass. The direction in

which the grass is bent determines the “light” or

“dark” stripe. When the blades of grass are bent

away from you, the grass appears lighter in color

because light is reflecting off of the length of the

blade. When the blades of grass are bent towards

you, the stripe appears darker as you are looking at

more of the tips of the blades (a smaller reflective

surface) and the shadows under the blades of grass.

Cutting a lawn in the up/down, north/south, east/

west,

opposing directions provides the best stripe

effect.

You may find that certain grasses have a more

noticeable stripe (stripe easier) than others. Cutting

the grass at a different height can sometimes change

the intensity of the stripe. A slightly higher cut

(example: 3" versus 2.5") can provide more grass to

be bent over, thus producing a more noticeable

stripe. In some types of grass, this may have the

opposite or no effect.

FIGURE 3-3

4. The edge of the mounting bracket should be

under the wheel motor mounting plate for proper

installation. See Figure 3-3.

5. Install the Tiger Striper roller assembly to the

mounting brackets and secure with the quick

pins.

6. Once the Tiger Striper roller assembly is installed

and secure, tighten the mounting hardware on

both mounting brackets.

7. Follow Section 2.2 Operating Instruction for

proper operation.

Grass that tends to be "stiff" and resists bending will

not yield a stripe as well as a softer grass that bends

easily.

Note that you do not need to cut the grass in order to

stripe it. The roller simply needs to be in the

unlocked/engaged position. You may find that when

creating more advanced, overlapping striping

patterns, you can complete the job faster by applying

the overlaying stripes without the blades engaged.

Striping can be used to draw attention to particular

landscape features. It can be used to further

enhance the finished, manicured cut that your Scag

mower delivers.

4

Page 7

LAWN STRIPING GUIDELINES

A stripe pattern can add richness and depth to any

lawn. Here are some guidelines to help produce

various patterns and to enhance your striping

techniques.

Basic stripe pattern:

Begin by mowing the perimeter around the property

(Reference Figure 4-1). Next, mow in opposing

directions through the remaining property (as shown

in Figure 4-1). Take care when turning at the end of

each row to prevent turf damage. A simple "Y"

type turn at the end of each row will reduce the

chance of turf damage while setting the mower up

for the next row to be mowed.

"Checkerboard" pattern:

Begin by mowing the perimeter around the property

(Reference Figure 4-1). Next, mow in opposing

directions (North and South or East and West)

through the remaining portion of the property (as

shown in Figure 4-1). Take care when turning at the

end of each row to prevent turf damage. A simple

"Y" type turn at the end of each row will reduce the

chance of turf damage while setting the mower up

for the next row to be mowed.

Now, travel in the opposite direction of the original

mowing pattern (if you were mowing North and

South, now mow East and West, etc). Reference

Figure 4-2.

Finish the job by mowing the perimeter again. This

will remove any stripe pattern irregularities left from

turning at the end of each row and delivers a

finished look.

FIGURE 4-1

Finish the job by mowing the perimeter again. This

will remove any stripe pattern irregularities left from

turning at the end of each row and delivers a finished

look.

FIGURE 4-2

"Diagonal or Criss-Cross" pattern:

This pattern is achieved using the same techniques as

the "Checkerboard" pattern. Simply apply the stripes in a

diagonal direction. See Figure 4-3.

FIGURE 4-3

5

Page 8

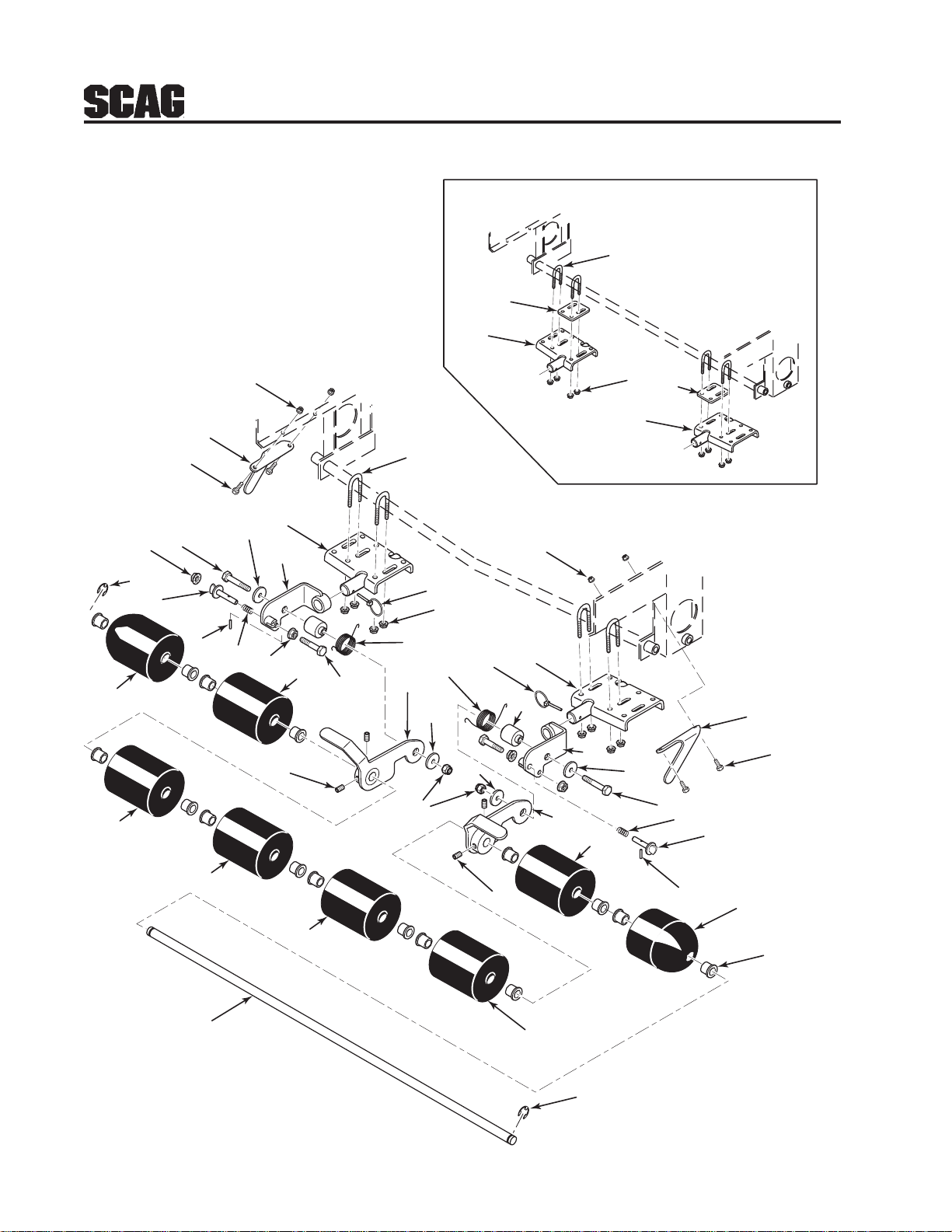

TIGER STRIPER ASSEMBLY - STT

STT with a serial number of 7219999 or Below

4 (4x)

30

5

26

27

21

27

15

30

17

25

3 (4x)

6

7

12

10

1 (4x)

2

3 (4x)

5

12

6

20

8

27

13

23

7

8

9

10

11

4 (4x)

14

31

24

6

16

18

15

1 (4x)

17

16

19

6

22

27

29

27

23

27

9

11

26

28

STT-TS Exploded View

6

Page 9

TIGER STRIPER ASSEMBLY - STT

Ref. Part

No. Number Description

1 04021-09 Nut, Elastic Stop 3/8-16

2 423953 Striper Stop, L.H.

3 04001-19 Bolt, Hex Head 3/8-16 x 1"

4 04100-01 U-Bolt, 5/16-18 x 1"

5 451660 Mounting Bracket Weldment, LH.

6 04041-11 Flatwasher, 3/8-.406 x 1-1/2" 7 Gauge

7 04001-22 Bolt, Hex Head 3/8-16 x 2-3/4"

8 04019-04 Nut, Serrated Flange 3/8-16

9 04050-02 Retaining Ring, .750 External "E"

10 461777 Pin, Lift Latch

11 04060-01 Pin, Slotted Spring .156 x 3/4"

12 482896 Spring, Lock Pin

13 04001-31 Bolt, Hex Head 3/8-16 x 2-1/2"

14 482894 Spring, Torsion L.H.

15 04019-03 Nut, Serrated Flange 5/16-18

16 04066-02 Quick Pin, .188 Dia.

17 451661 Mounting Bracket Weldment, R.H.

18 482895 Spring, Torsion R.H.

19 43648 Hub, Striper

20 451669 Pivot Weldment, L.H.

21 451670 Pivot Weldment, R.H.

22 451667 Hinge Weldment, L.H.

23 04012-06 Set Screw, 3/8-16 x 1/2"

24 04021-09 Nut, Elastic Stop 3/8-16

25 423954 Striper Stop, R.H.

26 461730 Roller Assembly, Striper End (Incl. Item 3)

27 461707 Roller Assembly (Incl. Item 28)

28 48100-24 Bushing, .752 Oilite

29 43653 Roller Shaft

30 423966 Spacer, Striper Mounting

31 451668 Hinge Weldment, R.H.

7

Page 10

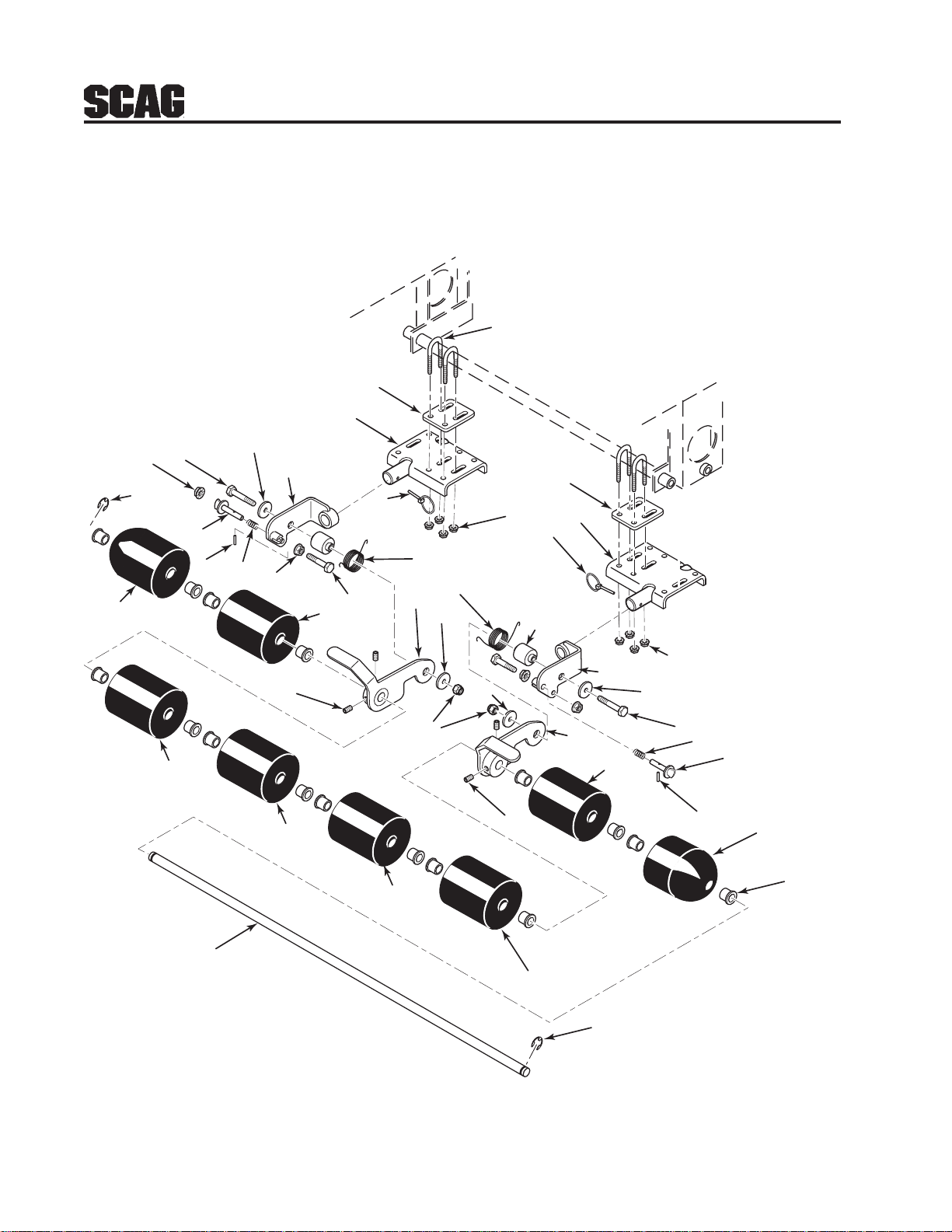

TIGER STRIPER ASSEMBLY - STC

4 (4x)

1

17

26

12

6

20

16

15

14

8

13

25

23

25

25

18

27

6

6

24

23

19

16

1

5

15

21

6

28

25

7

12

10

11

26

3

7

8

9

10

11

25

2

25

9

STC-TS Exploded View

8

Page 11

TIGER STRIPER ASSEMBLY - STC

Ref. Part

No. Number Description

1 423966 Spacer, Striper Mounting

2 43653 Roller Shaft

3 48100-24 Bushing, .752 Oilite

4 04100-01 U-Bolt, 5/16-18 x 1"

5 451660 Mounting Bracket Weldment, LH.

6 04041-11 Flatwasher, 3/8-.406 x 1-1/2" 7 Gauge

7 04001-22 Bolt, Hex Head 3/8-16 x 2-3/4"

8 04019-04 Nut, Serrated Flange 3/8-16

9 04050-02 Retaining Ring, .750 External "E"

10 461777 Pin, Lift Latch

11 04060-01 Pin, Slotted Spring .156 x 3/4"

12 482896 Spring, Lock Pin

13 04001-31 Bolt, Hex Head 3/8-16 x 2-1/2"

14 482894 Spring, Torsion L.H.

15 04019-03 Nut, Serrated Flange 5/16-18

16 04066-02 Quick Pin, .188 Dia.

17 451661 Mounting Bracket Weldment, R.H.

18 482895 Spring, Torsion R.H.

19 43648 Hub, Striper

20 451669 Pivot Weldment, L.H.

21 451670 Pivot Weldment, R.H.

22 451667 Hinge Weldment, R.H.

23 04012-06 Set Screw, 3/8-16 x 1/2"

24 04021-09 Nut, Elastic Stop 3/8-16

25 461707 Roller Assembly (Incl. Item 3)

26 461730 Roller Assembly, Striper End (Incl. Item 3)

27 451668 Hinge Weldment, L.H.

**L.H. Mounting Bracket is used on the Right Side on STC

**R.H. Mounting Bracket is used on the Left Side on STC

9

Page 12

NOTES

10

Page 13

LIMITED WARRANTY- COMMERCIAL ACCESSORY

Any part of the Scag commercial accessory manufactured by Scag and found, in the reasonable judgment of Scag,

to be defective in material or workmanship, will be repaired or replaced by an Authorized Scag Service Dealer without

charge for parts and labor.

The Scag accessory, including any defective part, must be returned to an Authorized Scag Service Dealer within

the warranty period. The expense of delivering the accessory to the dealer for warranty work and the expense of

returning it back to the owner after repair or replacement will be paid for by the owner. Scag’s responsibility in respect

to claims is limited to making the required repairs or replacements, and no claim of breach of warranty shall be cause

for cancellation or rescission of the contract of sale of any Scag machine. Proof of purchase will be required by the

dealer to substantiate any warranty claim. All warranty work must be performed by an Authorized Scag Service

Dealer.

This warranty is limited to 90 days from the date of original retail purchase for any Scag accessory that is used for

commercial purposes, or any other income-producing purpose including rental use.

This warranty does not cover any accessory that has been subject to misuse, neglect, negligence, or accident, or

that has been operated in any way contrary to the operating instructions as specified in the Operator's Manual. The

warranty does not apply to any damage to the accessory that is the result of improper maintenance, or to any

accessory or parts that have not been assembled or installed as specified in the Operator's Manual.

The warranty does not cover any accessory that has been altered or modified. In addition, the warranty does not

extend to repairs made necessary by normal wear, or by the use of parts or accessories which, in the reasonable

judgment of Scag, are either incompatible with the Scag mower or adversely affect its operation, performance or

durability. This warranty does not cover engines and electric starters, which are warranted separately by their

manufacturer.

Scag Power Equipment reserves the right to change or improve the design of any accessory without assuming any

obligation to modify any accessory previously manufactured.

All other implied warranties are limited in duration to the 90 day warranty period. Accordingly, any such implied

warranties including merchantability, fitness for a particular purpose, or otherwise, are disclaimed in their entirety

after the expiration of the appropriate ninety day warranty period. Scag’s obligation under this warranty is strictly

and exclusively limited to the repair or replacement of defective parts and Scag does not assume or authorize anyone

to assume any other obligation for them. Some states do not allow limitations on how long an implied warranty lasts,

so the above limitation may not apply to you.

Scag assumes no responsibility for incidental, consequential or other damages including, but not limited to, expense

for gasoline, oil, expense of delivering the machine to an Authorized Scag Service Dealer and expense of returning

it back to the owner, mechanic’s travel time, telephone or telegram charges, rental of a like product during the time

warranty repairs are being performed, travel, loss or damage to personal property, loss of revenue, loss of use of

the mower, loss of time, or inconvenience. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Page 14

© 2004

SCAG POWER EQUIPMENT

DIVISION OF MET ALCRAFT OF MAYVILLE, INC

WWW.SCAG.COM

PART NO. 03158

PRINTED 8-2004

PRINTED IN USA

Loading...

Loading...