2-PORT POP-UP SOCKET BOX

3-PORT POP-UP SOCKET BOX

KNIFE / SPICE / KEY / BAKERS’ BOX

INSTRUCTIONS AND INSTALLATION GUIDE

WE RECOMMEND THAT ALL ‘CUT-OUT’ PROCESSES

AND/OR ANY ‘CUSTOM TOP’ FABRICATION SHOULD BE

DONE BY YOUR SPECIALIST WORKTOP PROVIDER

In either of these surface-mount methods, it is also possible to ‘personalise’ the unit, by replacing the

steel top with a piece of matching material to the work top if required.

OPTION 1

OPTION 2

OPTION 2

in shallow rebate

for a ‘flush’ finish

Maximum thickness of any material is 12mm. The Collar can be adjusted upwards to relevel it with that

new material. Then please follow counterbalance “re-weight” instructions shown later in this guide.

2.5mm

OPTION 3

OPTION 4

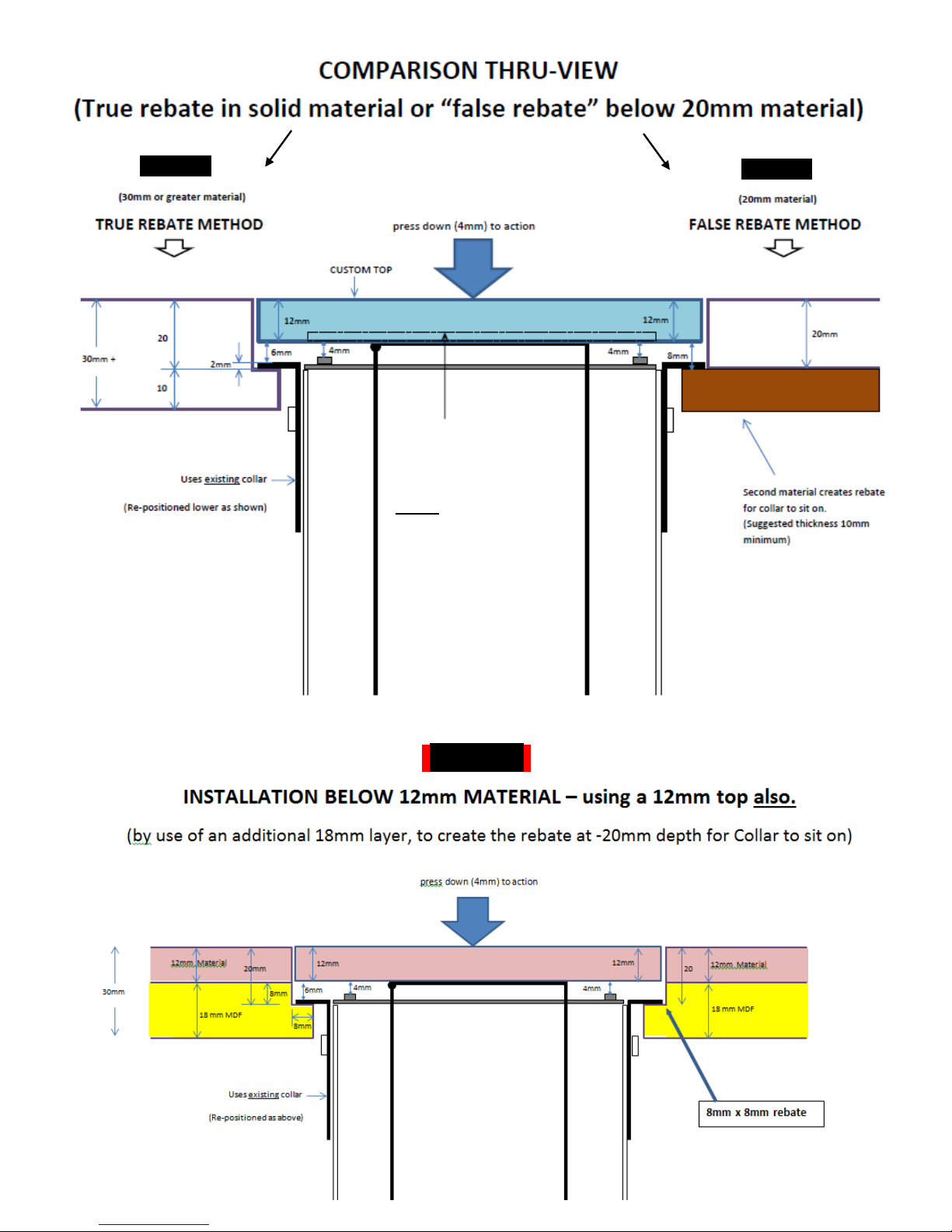

This method involves the installation of the unit at exactly 20mm below the Counter-top surface so that the

product can be fully disguised into its location with a custom top that matches its surroundings. This is

known as an “Inset” or rebated method. The maximum thickness of this custom top is also 12mm.

In worktop materials of 30mm thickness and above, the installation is achieved by sitting the collar on a

rebate shelf within the material.

For materials of 20mm thickness, installation is achieved by sitting the collar on a “false” rebate, created

by using a second material below it.

30 mm +

20 mm

B - ‘INSET’ or REBATED – The Unique Custom (“chameleon”) Installation)

20 mm

Material 2

on or in surface

NB. If your Worktop material is only 12mm thick (e.g. Corian or Silestone) please see thru-view Option 5

There are 2 (and only 2) positions to fit an S-Box™ unit:

Either: A - Surface-mounted

Or: B - ‘Inset’ at -20mm below surface.

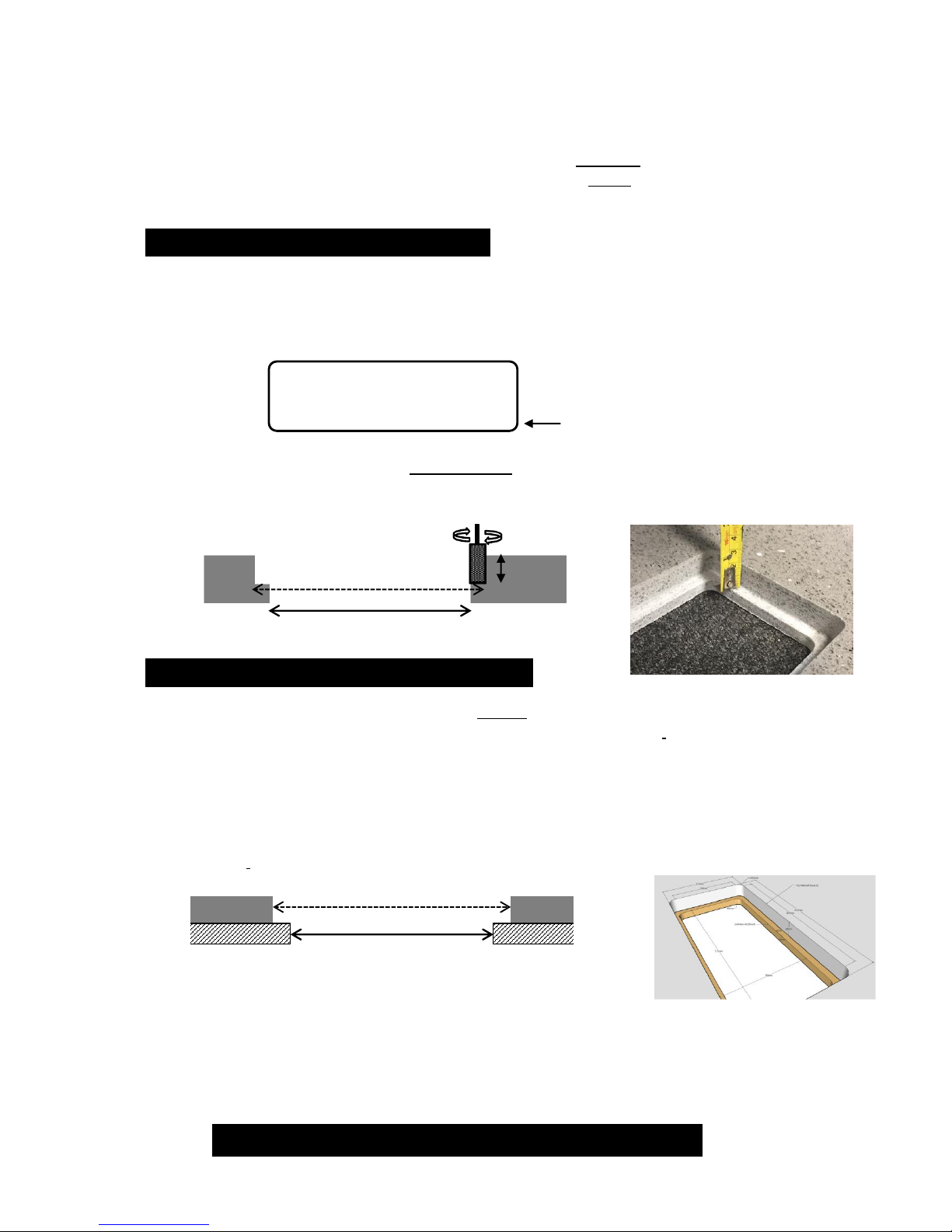

This simplest installation method is to insert it straight into a cut-out hole →

The fitted collar sits neatly on the worktop surface. Its own weight will keep it there. Please do not use any

adhesive or sealant. (A shallow rebate can also be used if preferred to create a flush finish)

A - SURFACE MOUNT

or

DIMENSIONS FOR THE PRINCIPAL ‘CUT-OUT’ HOLE FOR ALL INSTALLATIONS ARE:

A B

2-PORT POWER BOX = 98mm x 211mm

3-PORT POWER BOX = 115mm x 295mm

KNIFE/SPICE/KEY/CHEF = 115mm x 425mm

FOR A SURFACE MOUNT INSTALLATION

THIS IS ALL YOU NEED. THE UNIT DROPS

STRAIGHT INTO THIS HOLE AND THE COLLAR

SITS NEATLY ON THE WORKSURFACE

8mm radius

corners

A

B

PLAN VIEW

[FOR ‘FLUSH MOUNT’ INSTALLATION AN

ADDITIONAL 8mm WIDE SHALLOW REBATE

SHOULD BE ROUTED AT 2.5mm DEPTH, WITH

10mm RADIUS CORNERS TO NEATLY ACCEPT THE

8mm RADIUS CORNERS OF THE COLLAR ITSELF]

8mm

2.5mm

10mm radius

corners

Remove Steel Top

by unscrewing the

3 dome nuts.

Then fix custom

top instead using

double sided tape

SURFACE MOUNT THRU-VIEWS

Custom Top option - Collar still sits on countertop but steel top has been EXCHANGED for an

alternative one ↓ Please note that any custom top CANNOT be thicker than 12mm.

Using Top and Collar as supplied ↑

- STAGE 1 (Preparing the S-Box™)

Remove and discard the existing Steel top - by unscrewing its 3 dome nuts.

>

Loosen the 6 Collar screws and press it down - so that it is level with the pattress metal. (See below).

P.S. The pattress is the flat skirt plate shown below.

This re-creates the clearance required below the later new top - so that when it is pressed down it will

engage and disengage the catch mechanism inside the unit. Re-tighten the collar screws (with the

new top temporarily ↓ in position) so that the required 20mm total is achieved (as below)

<< 4-5 mm clearance

for ‘press down’ action

Note:

MAX THICKNESS OF ANY

CUSTOM TOP IS 12mm

20mm

‘INSET’ (REBATED)

*PLEASE NOTE*

THESE STAGE 1 INSTRUCTIONS ARE TO ENABLE THE

CONVERSION OF A UNIT THAT HAS A STEEL TOP AND

COLLAR ALREADY FITTED WHEN IT WAS DELIVERED.

IF YOU HAVE A UNIT THAT IS ALREADY PREPARED FOR A

CUSTOM TOP (i.e. S-BOX CHAMELEON) YOU MAY SKIP

TO STAGE 2.

YOUR “ADAPTED” UNIT WILL LOOK

LIKE THIS ↓

A PRE-PREPARED “CHAMELEON”

MODEL LOOKS LIKE THIS →

Both can be inserted into the 20mm rebate

and both are ready to receive the custom top

STAGE 2 (Preparing the rebate)

There are two ways of installing the S-Box below the work-surface. Both involve the creation of a rebate

at -20mm datum. The method you chose depends entirely on the thickness of the worktop material:

>For 30mm material and above (e.g. Granite) - the rebate is made within the material itself.

>For 20mm material (e.g. Quartz) - the rebate is “created” using a second material below it (e.g. MDF)

‘TRUE’ REBATE in 30+ mm material:

Firstly cut the standard primary hole for insertion of the box itself (= DIMENSIONS A x B)

A 98mm X B 211mm (2-port) A-115mm x B-295mm (3-port) A-115mm x B- 425mm (storage units)

(We suggest an 8mm radius setting for this primary cut)

Then create a further 8mm wide rebate at 20mm depth from the top of the work-surface, on which to

mount the S-Box, and its collar, in its new position. The radius of the collar’s corners is 8mm, so we

suggest that you use a maximum 10mm radius for the rebate-routing process.

‘FALSE’ REBATE BELOW 20mm material:

This is where the rebate is being “created” using a second material below. The upper hole now

becomes the Master cut in the worktop material. So 16mm needs to be added to both the

A and B dims above to allow the collar to pass through to sit on the second material below.

Cut-outs for the UPPER MATERIAL for this method are:

POWER BOXES > 114mm x 227mm (2-port) or 131mm x 311mm (3-port)

STORAGE BOXES > 131mm x 441mm

It is the LOWER material that requires the Standard Dimensions A x B for the collar to sit on ↓

After either of the above methods has been completed,

the new top can now be created.

This should be carefully made to “marry” neatly with the larger rebated hole dimension.

Top requires correct radius (slightly less than the hole) and a gap of 1-1.5mm all way round to ensure

clearance. As a guide: TOP DIMENSIONS = 111mm x 224mm (2-port)

= 128mm x 308mm (3-port)

= 128mm x 438mm (STORAGE BOXES)

A B A x B

REMINDER! – MAX THICKNESS OF ANY CUSTOM TOP IS 12mm

(A+16mm) x (B+16mm)

A/B

= (A+16mm) x (B+16mm)

8mm radius

corners

20

STAGE 3 (Re-weighting the counterbalance)

The new top will be heavier than the standard stainless steel one it is replacing, so the internal

counterweight box will firstly require some of the weights (provided) adding to it, to re-instate the

correct “lift”.

To do this, place the new top temporarily where the SS one used to be: ↓

Then open the front plate as shown below: ↓

Info:

These fixings are

T20 star screws >

You can now add the required amount of extra weight into the recess, until you are happy

with its pace of lift (when the new top is added more permanently later)

> >

Take the New Top off and introduce the S-Box unit into its rebated hole.

NB. In “CHAMELEON” Models this

tape is already be fitted for you →

Apply good quality double-sided

tape (e.g. 3M) to the plate ↗

Peel back the tape and place the custom top into position.

Using Tape allows you to have a few goes at getting the perfect position for the top before pressing it

firmly home and letting the tape adhesive to bond and cure.

Any final “fine-tuning” of levels, if still required, can be achieved by adjusting the male ball’s position

so that in the closed (catch-engaged) position, your new top and adjacent surface are perfect. By

twisting the threaded ball part, and holding the top nut, the position of the ball can be raised or

lowered by the tiniest of amounts.

You can now fix the front back on - and ENJOY YOUR CUSTOMISED POP-UP SOLUTION!

Please Note:

All electrical connections for the Power Box unit must be carried out by a fully Qualified Electrician.

STAGE 4 (Adding the new top)

OPTION 3

OPTION 4

OPTION 5

Original position of

steel top.

If still present, it

MUST be removed

before any custom

top is fitted.

3-PORT DIMENSIONS

2-PORT DIMENSIONS

STORAGE BOX DIMENSIONS (Knife, Spice etc)

WARRANTY AND OTHER INFORMATION

AFTER 6 -12 MONTHS USE (PARTICULARLY IN VERY WARM or CENTRALLY HEATED

ENVIRONMENT) THE INTERNAL RUNNERS MAY REQUIRE A TINY AMOUNT OF RE-LUBRICATION

TO MAINTAIN THE UNIT’S SMOOTH OPERATION.

S-Box™ is a registered trademark of Cardinal IP Limited

The S-Box™ product innovation is protected by Patents - registered to Cardinal IP Limited

Cardinal Innovations Limited

Battye Street, Bradford

West Yorkshire, ENGLAND BD4 8AG

Tel: +44 (0)1274 386820 Email: sales@the-sbox.com

Web: www.the-sbox.com

WE RECOMMEND THAT ALL ‘CUT-OUT’ PROCESSES

AND/OR ANY ‘CUSTOM TOP’ FABRICATION SHOULD

BE DONE BY YOUR SPECIALIST WORKTOP PROVIDER

Loading...

Loading...