Page 1

SBE 21 SeaCAT Thermosalinograph

Conductivity and Temperature Recorder

with RS-232 Interface

User’s Manual

Sea-Bird Electronics, Inc.

13431 NE 20

Bellevue, Washington 98005 USA Manual Version #027, 02/21/13

Telephone: 425-643-9866 SBE 21 Firmware 5.0a and later

Fax: 425-643-9954 90488 Interface Box Firmware 3.1b and later

E-mail: seabird@seabird.com Seasave V7 Version 7.22.4 and later

Website: www.seabird.com SBE Data Processing Version 7.22.4 and later

th

Street

Page 2

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

2

Page 3

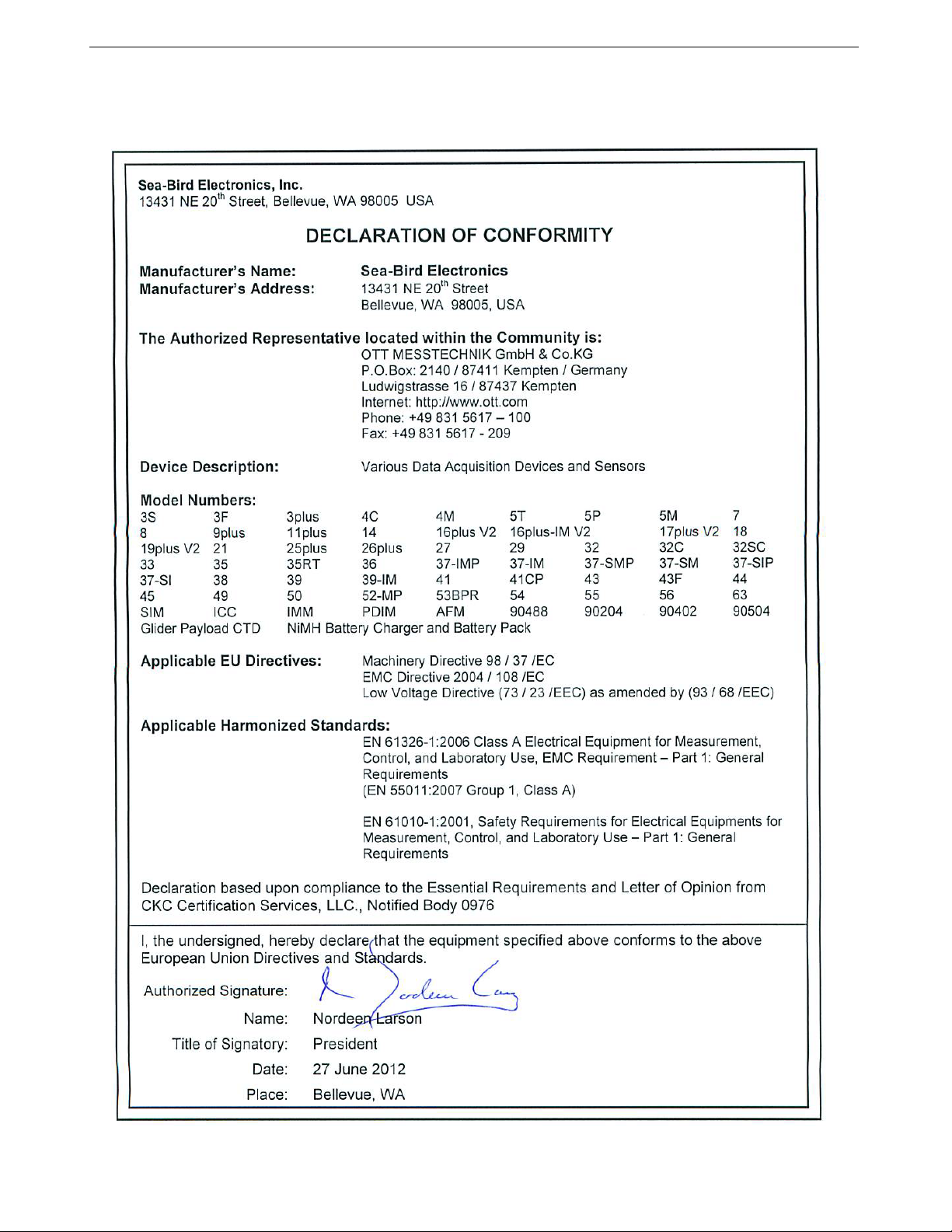

Manual revision 027 Declaration of Conformity SBE 21

Declaration of Conformity

3

Page 4

Manual revision 027 Table of Contents SBE 21

Table of Contents

Limited Liability Statement ................................................................ 2

Declaration of Conformity .................................................................. 3

Table of Contents ................................................................................. 4

Section 1: Introduction ........................................................................ 6

About this Manual .............................................................................................6

Unpacking SBE 21 .............................................................................................7

Section 2: Description of SBE 21 ........................................................ 8

System Description ............................................................................................8

Specifications ................................................................................................... 10

Dimensions and Bulkhead Connectors ............................................................ 11

Data I/O ........................................................................................................... 12

Data Storage ..................................................................................................... 12

Remote Temperature Sensor (optional) ........................................................... 12

Section 3: Installing System .............................................................. 13

Installing Software ........................................................................................... 13

System Schematic and Installation Guidelines ................................................ 14

Mechanical Installation .................................................................................... 16

Electrical Installation ....................................................................................... 17

Section 4: Setting Up SBE 21 ............................................................ 19

Setting Communications Parameters in Interface Box..................................... 19

Power and Communications Test and SBE 21 Setup in Seaterm .................... 19

Command Descriptions .................................................................................... 24

Checking SBE 21 Configuration (.xmlcon or .con) File in Seasave ................ 39

Data Formats .................................................................................................... 41

Notes on SBE 38 Remote Temperature Data Format ............................... 42

Section 5: Setting Up NMEA Interface ............................................ 43

NMEA Operating Modes ................................................................................. 43

Setting Up and Testing NMEA ........................................................................ 44

Troubleshooting NMEA Interface ................................................................... 46

Setting Up SBE 21 Configuration (.xmlcon or .con) File ................................ 46

Section 6: Operating System ............................................................. 47

Acquiring Real-Time Data with Seasave ......................................................... 47

Uploading SBE 21 Data from Memory ........................................................... 50

Processing Data ................................................................................................ 53

Section 7: Routine Maintenance and Calibration ........................... 55

Corrosion Precautions ...................................................................................... 55

Removing Sensor/Electronics Module from SBE 21 Water Jacket ................. 55

Cleaning and Storage ....................................................................................... 56

Sensor Calibration ............................................................................................ 57

Section 8: Troubleshooting ................................................................ 58

Problem 1: Unable to Communicate with Interface Box ................................. 58

Problem 2: Unable to Communicate with SBE 21 ........................................... 58

Problem 3: Unable to View Data in Seasave

(Real-Time Data Acquisition program) ........................................................... 59

Problem 4: Scan Length Error in SBE Data Processing .................................. 59

Problem 5: No Data Recorded ......................................................................... 59

Problem 6: Nonsense or Unreasonable Data .................................................... 59

Problem 5: Salinity Lower than Expected ....................................................... 60

Problem 6: Program Corrupted ........................................................................ 60

4

Page 5

Manual revision 027 Table of Contents SBE 21

Glossary .............................................................................................. 61

Appendix I: Functional Description ................................................. 62

Sensors ............................................................................................................. 62

Sensor Interface ............................................................................................... 62

Real-Time Clock .............................................................................................. 62

Power ............................................................................................................... 62

Appendix II: Electronics Disassembly/Reassembly ........................ 63

Appendix III: Command Summary ................................................. 65

Appendix IV: AF24173 Anti-Foulant Device .................................. 67

Appendix V: Replacement Parts ...................................................... 71

Appendix VI: Manual Revision History .......................................... 73

Index .................................................................................................... 75

5

Page 6

Manual revision 027 Section 1: Introduction SBE 21

Section 1: Introduction

This section includes contact information and photos of a standard

SBE 21 shipment.

About this Manual

This manual is to be used with the SBE 21 SeaCAT Thermosalinograph

Conductivity and Temperature Recorder. It is organized to guide the user from

installation through operation and data collection. We have included detailed

specifications, command descriptions, maintenance and calibration

information, and helpful notes throughout the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Please contact us with any comments or

suggestions (seabird@seabird.com or 425-643-9866). Our business hours are

Monday through Friday, 0800 to 1700 Pacific Standard Time (1600 to 0100

Universal Time) in winter and 0800 to 1700 Pacific Daylight Time (1500 to

0000 Universal Time) the rest of the year.

6

Page 7

Manual revision 027 Section 1: Introduction SBE 21

SBE 21

Software, and Electronic Copies of

Grounding cable

I/O cable

Jackscrew kit

4-pin

Interface Box)

Unpacking SBE 21

SeaCAT/Sealogger

RS-232 and Navigation

PN 90488 –

Interface Box

NMEA Interface test cable

(Interface Box to NMEA device

simulation computer)

Shown below is a typical SBE 21 shipment.

I/O cable

(SBE 21 to Interface Box)

AC power cable for

Interface Box

(Interface Box to computer)

MS connector

assembly

(for SEACAT data

I/O connector on

50369 5-pin

MS connector

assembly

(for NMEA Input

connector on

Interface Box)

7

(from SBE 21)

4-pin RMG-4FS pigtail with

locking sleeve (from SBE 21

to Interface Box)

Cell cleaning solution

(Triton X-100)

Software Manuals and User Manual

Page 8

Note:

Manual revision 027 Section 2: Description of SBE 21 SBE 21

Section 2: Description of SBE 21

This section describes the functions and features of the SBE 21,

including specifications and dimensions.

System Description

The SBE 21 SeaCAT Thermosalinograph is an externally powered, highaccuracy, conductivity and temperature recorder, designed for shipboard

determination of sea surface (pumped-water) conductivity and temperature.

Data is simultaneously transmitted to a computer’s serial port and stored in

64 Mb FLASH RAM memory, allowing both real-time data acquisition and

independent data logging. An internal lithium back-up battery in the SBE 21

supports the real-time clock when the main power supply is off.

The SBE 21 is connected by cable to PN 90488 - SeaCAT/Sealogger

Seasave 7.18 or later also

supports acquisition of data from a

NMEA device connected directly

to the computer (instead of the

interface box).

RS-232 and Navigation Interface Box. The Interface Box is AC-powered,

provides isolated DC power and an optically-isolated RS-232 data interface for

the SBE 21, and provides power and a NMEA 0183 receiver for a NMEA

device (not supplied by Sea-Bird). The Interface Box appends NMEA

information to the SBE 21 data stream.

The platinum-electrode glass conductivity cell’s unique internal-field

geometry eliminates proximity effects. This feature is critically important in

thermosalinographs, where the cell must operate in a water jacket’s confined

volume. The internal-field cell also allows the use of expendable AF24173

Anti-Foulant Devices (supplied).

For corrosion resistance, only plastic, titanium, and the glass/platinum

conductivity cell are exposed to seawater. Valves control seawater circulation

and fresh water flushing. The sensor assembly is easily removed for cleaning

and calibration.

The PVC base or back plate may be drilled for mounting to the ship. Seawater

connections (for normal use) and fresh water connections (for cleaning) are

PVC pipes with 1-inch (25.4 mm) U.S. standard NPT threads. Mating female

fittings are provided, and can easily be adapted to locally available pipe sizes.

Communication with the SBE 21 is over an internal, 3-wire, RS-232C link,

providing real-time data transmission. Commands can be sent to the SBE 21 to

provide status display, data acquisition setup, data retrieval, and diagnostic

tests. Output format is raw, hexadecimal data. The SBE 21 samples using one

of the following user-programmable schemes:

• Continuously at 4 Hz: At pre-programmed 3- to 600-second intervals,

the SBE 21 averages all the data from within the sampling interval, stores

the average in memory, and sends the average to the computer (through

the Interface Box).

• At pre-programmed intervals: At pre-programmed 3- to 600-second

intervals, the SBE 21 takes one sample, stores the sample in memory, and

sends the sample data to the computer (through the Interface Box).

A standard SBE 21 can record the output of an optional remote temperature

sensor (SBE 38), allowing for the measurement of sea surface temperature

with minimum thermal contamination from the ship’s hull. A stainless steel

and plastic in-line pipe mount is available for safe below-waterline installation

of the remote temperature sensor (see Section 3: Installing System).

8

Page 9

Notes:

Manual revision 027 Section 2: Description of SBE 21 SBE 21

A standard SBE 21 is supplied with:

• Bulkhead connectors:

one 4-pin I/O connector

one 6-pin connector for A/D inputs (four single-ended or

two differential channels – customer selects desired configuration at

time of purchase)

one 4-pin connector for remote temperature sensor

one 1-pin connector for ground to ship’s hull

• 64 Mbyte FLASH RAM memory

• Anti-foulant device attachments and expendable AF24173 Anti-Foulant

Devices on each end of the conductivity cell.

• PN 90488 – SeaCAT/Sealogger RS-232 and Navigation Interface Box,

providing power to the SBE 21, an optically isolated RS-232 interface, a

NMEA 0183 input port for NMEA data, and power for a NMEA device.

SBE 21 options include:

• Remote temperature sensor (SBE 38) and mounting kit

• Auxiliary A/D sensors (mounts not supplied)

Future upgrades and enhancements to the SBE 21 firmware can be easily

installed in the field through a computer serial port and the I/O connector on

the SBE 21, without the need to return the SBE 21 to Sea-Bird.

The SBE 21 is supplied with a powerful Windows software package,

©

• Help files provide detailed

information on the software.

• Separate software manuals contain

detailed information on Seasave V7

and SBE Data Processing.

• Sea-Bird also supplies an older

version of Seasave, SeasaveWin32. However, all Seasave

instructions in this manual are

written for Seasave V7. See

Seasave-Win32’s manual and/or

Help files if you prefer to use the

older software.

• Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

Seasoft

• Seaterm –terminal program for easy communication and

• Seasave V7 –program for acquiring, converting, and displaying real-time

• SBE Data Processing - program for calculation and plotting of

V2, which includes:

data retrieval.

or archived raw data.

conductivity, temperature, data from auxiliary sensors, and derived

variables such as salinity and sound velocity.

9

Page 10

Manual revision 027 Section 2: Description of SBE 21 SBE 21

SBE 38 remote temperature 3

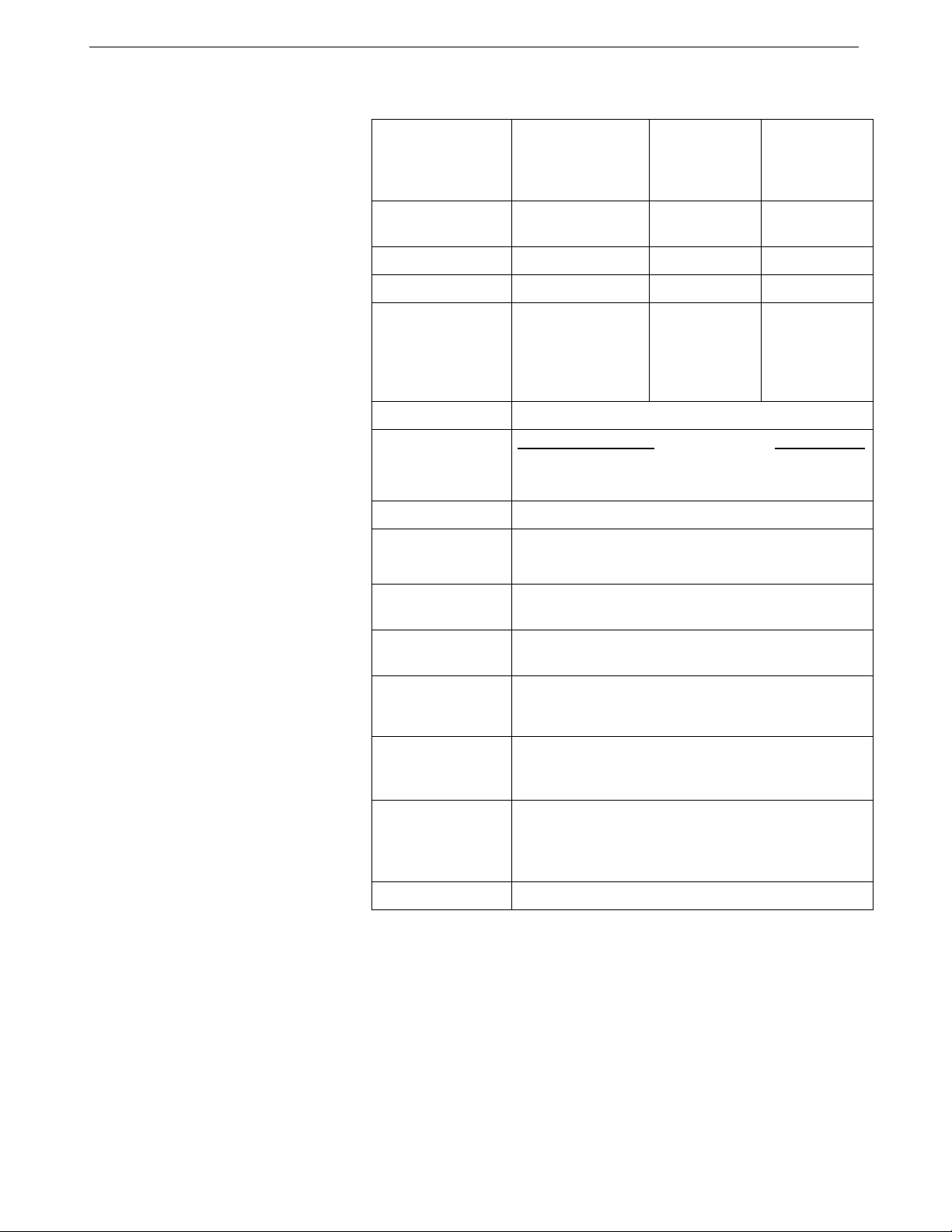

Specifications

Conductivity

(S/m)

Primary

Temperature

(°C)

SBE 38

Secondary

Temperature

(°C)

Measurement

Range

Initial Accuracy

Resolution

Calibration

(measurement outside

these ranges may be

at slightly reduced

accuracy due to

extrapolation errors)

Memory

Data Storage

Real-Time Clock

Sample Rate

Materials

Recommended

Flow Rate

0 to 7 -5 to +35 -5 to +35

0.001 0.01 0.001

0.0001 0.001 0.0003

0 to 7; physical

calibration over

the range 2.6 to

+1 to +32 -1 to +32

6 S/m, plus zero

conductivity (air)

64 Mbyte non-volatile FLASH memory

Recorded Parameter Bytes/sample

temperature and conductivity 6 (3 each)

each external voltage 2

32,768 Hz TCXO accurate to ±1 minute/year

1 sample / 3 seconds to 1 sample / 600 seconds

Sample rate is incremented in 1-second steps

PVC housing, water jacket, piping, and valves;

titanium end cap

1 liter/second (15.8 gallons/minute)

Auxiliary

Voltage Sensors

Maximum

Safe Operating

Pressure

Input Power

Weight

Auxiliary power out:

up to 500 mA at 10.5 - 11 VDC

A/D resolution: 12 bits

Input range: 0 - 5 VDC

34.5 decibars (50 psi)

SeaCAT/Sealogger RS-232 and Navigation

Interface Box is included with standard SBE 21

order. If testing SBE 21 without Interface Box,

provide 9-14 VDC power.

41 kg (90 lbs)

10

Page 11

Manual revision 027 Section 2: Description of SBE 21 SBE 21

Dimensions and Bulkhead Connectors

Dimensions in millimeters (inches)

11

Page 12

Manual revision 027 Section 2: Description of SBE 21 SBE 21

Example 1: no auxiliary sensors

Note:

Note:

Data I/O

The SBE 21 receives set-up instructions and outputs diagnostic information or

previously recorded data via a three-wire RS-232C link, and is factoryconfigured for 4800 baud, 7 data bits, 1 stop bit, and even parity. SBE 21

RS-232 levels are directly compatible with standard serial interface cards (IBM

Asynchronous Communications Adapter or equal). The communications baud

rate can be changed using Baud= (see Command Descriptions in Section 4:

Setting Up SBE 21).

Data Storage

The SBE 21 has a 64 Mbyte FLASH memory. See Specifications for storage

space required for each parameter.

If FLASH memory is filled to

capacity, sampling and transmission

of real-time data continue, but

excess data is not saved in memory.

The SBE 21 will not overwrite data

stored in memory.

T & C = 6 bytes/sample

Storage space ≈ 64,000,000 / 6 ≈ 10,666,666 samples

Example 2: 4 external voltages, SBE 38 remote temperature sensor

T & C = 6 bytes/sample

External voltages = 2 bytes/sample x 4 voltages = 8 bytes/sample

SBE 38 = 3 bytes/sample

Storage space ≈ 64,000,000 / (6 + 8 + 3) ≈ 3,764,705 samples

Remote Temperature Sensor (optional)

Sea-Bird software (Seasave realtime data acquisition and SBE Data

Processing’s Data Conversion and

Derive modules) uses the data from

the SBE 21’s temperature sensor

to calculate salinity, and then

uses that salinity with the

temperature from the remote

temperature sensor to calculate

density and sound velocity.

The SBE 21 can record the output of an external SBE 38 temperature sensor.

Often, the SBE 21 is mounted in the interior of the vessel. In this configuration

the recorded conductivity is correct, but the water temperature changed as it

passed through the plumbing system. The SBE 38 can be placed in a location

that provides more accurate measurement of the sea surface water temperature.

The ideal location for the SBE 38 is at the seawater intake (before the

pump) near the bow of the ship. This minimizes contamination of the

surface temperature measurement by the ship’s own thermal mass.

To compute salinity, always use the data from the temperature sensor on

the SBE 21, not from the SBE 38. Conductivity has a strong thermal

coefficient; therefore, it is critical to know the temperature of the water when

the conductivity sensor samples it in order to compute salinity correctly. On a

typical installation, there may be 20 to 30 meters of plumbing between the

SBE 38 and the SBE 21. As the water flows through the pipes it changes

temperature dramatically, making the data from the SBE 38 an inaccurate

representation of the temperature when the water reaches the conductivity

sensor. Use the SBE 38 only to report surface temperature, and to calculate

density and sound velocity (density and sound velocity are a function of

salinity and temperature).

Note that the SBE 38 can be added to the system at any time, and does not

need to be part of the original order for the SBE 21. No modifications to the

SBE 21 are required to integrate the SBE 38, other than programming the

SBE 21 to accept the sensor signal and updating the configuration (.xmlcon or

.con) file.

12

Page 13

Notes:

Manual revision 027 Section 3: Installing System SBE 21

Section 3: Installing System

This section provides instructions for:

• Installing software

• Mounting and wiring the SBE 21 and Interface Box, including system

schematic and installation guidelines, mechanical installation, and

electrical installation

Installing Software

Seasoft V2 was designed to work with a PC running Windows XP service

• Help files provide detailed

information on the software.

Separate software manuals on the

CD-ROM contain detailed

information on Seasave V7 and

SBE Data Processing.

• Sea-Bird also supplies an older

version of Seasave, SeasaveWin32. However, all Seasave

instructions in this manual are

written for Seasave V7. See

Seasave-Win32’s manual and/or

Help files if you prefer to use the

older software.

• It is possible to use the SBE 21

without the Seaterm terminal

program by sending direct

commands from a dumb terminal or

terminal emulator, such as Windows

HyperTerminal.

• Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

pack 2 or later, Windows Vista, or Windows 7.

If not already installed, install Sea-Bird software programs on your computer

using the supplied software CD.

1. Insert the CD in your CD drive.

2. Install software: Double click on SeasoftV2.exe. Follow the dialog box

directions to install the software. The installation program allows you to

install the desired components. Install all the components, or just install

Seaterm (terminal program), Seasave V7 (real-time data acquisition), and

SBE Data Processing (data processing).

The default location for the software is c:\Program Files\Sea-Bird. Within that

folder is a sub-directory for each component.

13

Page 14

Manual revision 027 Section 3: Installing System SBE 21

Valves are show in normal operating position.

Notes:

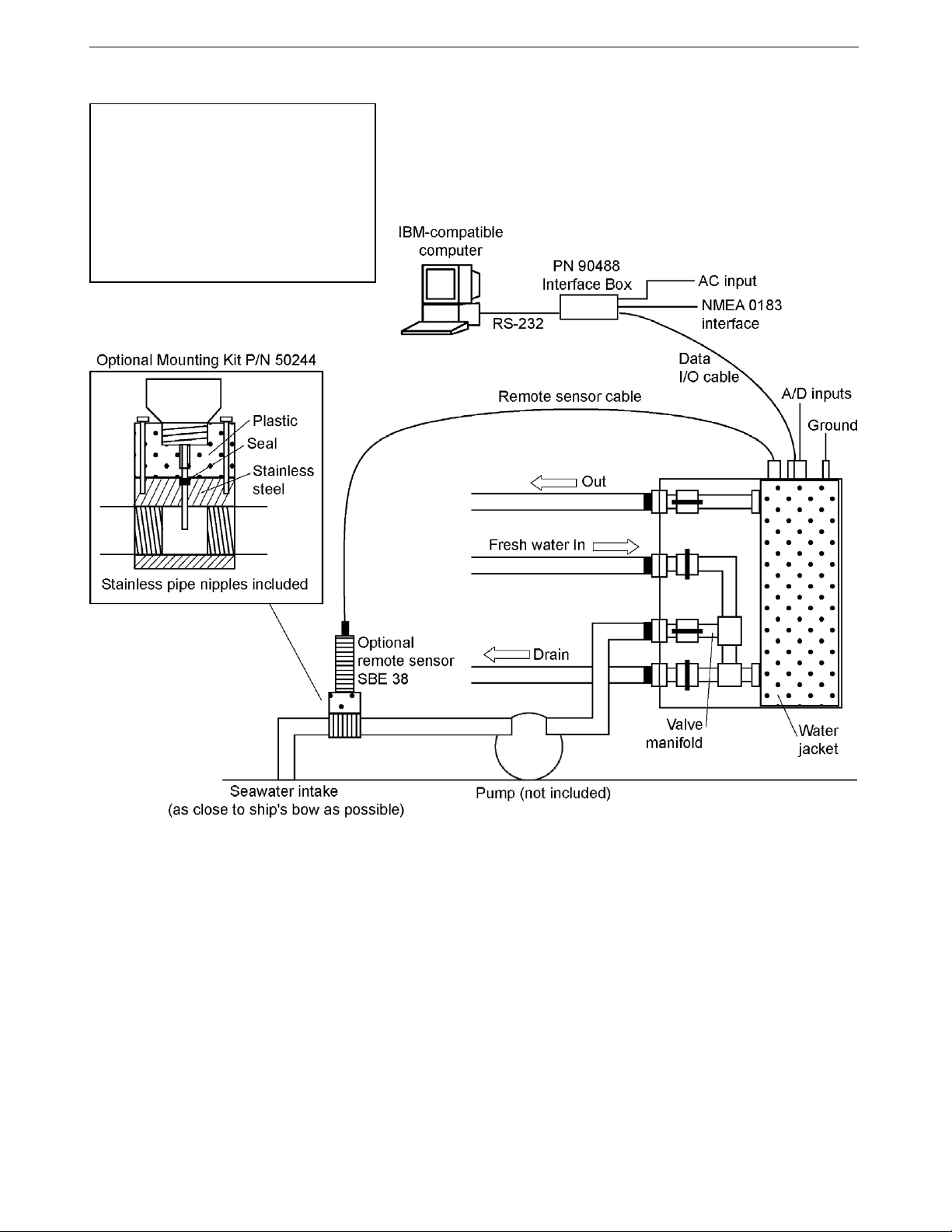

System Schematic and Installation Guidelines

• The SeaCAT/Sealogger RS-232 and

Navigation Interface Box is included

with a standard SBE 21 order. If testing

the SBE 21 without the Interface Box,

provide 9-14 VDC power.

• Seasave 7.18 or later also supports

acquisition of data from a NMEA device

connected directly to the computer

(instead of the Interface Box).

Valves are open when handle is horizontal,

closed when handle is vertical.

Sea-Bird does not provide detailed installation instructions for the SBE 21 and

remote temperature sensor, given the unique nature of every ship and type of

installation. The installation of the SBE 21 should be done by qualified

shipfitters, with the oversight of a competent ship designer or naval architect.

14

Page 15

Manual revision 027 Section 3: Installing System SBE 21

Consider the following:

• The SBE 21 can be mounted anywhere it will fit that is accessible for

maintenance and cleaning. For safety, mount the SBE 21 above the

water line.

If the remote temperature sensor is not used, mount the SBE 21 as

close to the seawater intake as possible to avoid thermal

contamination of long plumbing runs. Thermal contamination will not

affect salinity accuracy, but the SBE 21 will report the temperature of

the water when it reaches the instrument.

If the remote temperature sensor is used, the SBE 21 can be mounted

in the ship’s lab or other convenient location.

The maximum recommended cable length from the SBE 21 to the

Interface Box is 100 meters.

• Sea-Bird does not recommend or supply a pump. The pump should be

able to provide 1 liter/second (15.8 gallons/minute) flow. Pressure at the

SBE 21 is limited to 34.5 decibars (50 psi).

• Bubbles in the plumbing of a flow-through system are a common problem

and will cause noisy salinity data. To minimize bubbles:

Place the pump below the water line to push rather than pull

the water.

Locate the SBE 21’s hull intake as deep as possible, as far as possible

from bubble sources (bow wake, propeller, etc.)

• Depending on the chosen design of a permanent seawater supply

(including pump, intake fitting, pipes, etc.), a de-bubbling device may be

needed to separate bubbles from the water before it enters the SBE 21.

Note that a de-bubbler may cause additional temperature errors for the

SBE 21’s primary temperature sensor; salinity accuracy (and accuracy of

an optional remote temperature sensor) is not affected. Not all ships

require de-bubblers, but many do for best quality salinity data. Large

single point salinity spikes can be removed with the Wild Edit module in

SBE Data Processing.

• Route cabling as cleanly as possible, avoiding sources of noise. Electric

motors are a particular problem. Avoid routing the cable next to

generators and air conditioners. Cables longer than 3 meters should be

installed inside an earthed metal conduit by a qualified electrician. This

minimizes the potential for external signals to disrupt communication and

ensures that high voltage lines (such as the sea cable) are sufficiently

protected. Cables shorter than 3 meters can be used without shielding

when installing or bench testing the instrument.

• If practical, mount the optional SBE 38 remote temperature sensor outside

the hull. However, the remote temperature sensor is usually mounted in

the remote sensor mount kit, which has 1-inch pipe threads on each end;

plumb the mount kit into your seawater system. Install the SBE 38 as

close to the seawater intake as possible (before the pump), near the bow of

the ship. Since the installation is below the water line, consult with your

ship’s engineer / naval architect / shipyard regarding the actual

installation. Sea-Bird cannot offer advice in this matter as each ship is

different and plumbing regulations vary.

• The SBE 21 can record a maximum of four auxiliary voltages from

auxiliary sensors. However, Sea-Bird has not developed methods for the

mechanical integration of these auxiliary sensors with the SBE 21.

When integrating auxiliary sensors with the SBE 21, consider the

following issues:

Install the sensors in a flow-through chamber that receives the

outflow from the SBE 21.

Design the flow-through chamber so sensors can be removed and

replaced for service and calibration.

Protect auxiliary sensors from bio-fouling.

15

Page 16

Manual revision 027 Section 3: Installing System SBE 21

Fresh

Flushing

Storage, Cleaning, or

Sensor/Electronics Module

Out

Open

Open

Closed

Fresh Water In

Closed

Open

Closed

Salt Water In

Open

Closed

Closed

Drain

Closed

Closed

Closed

Valves shown in Normal Use position

Base

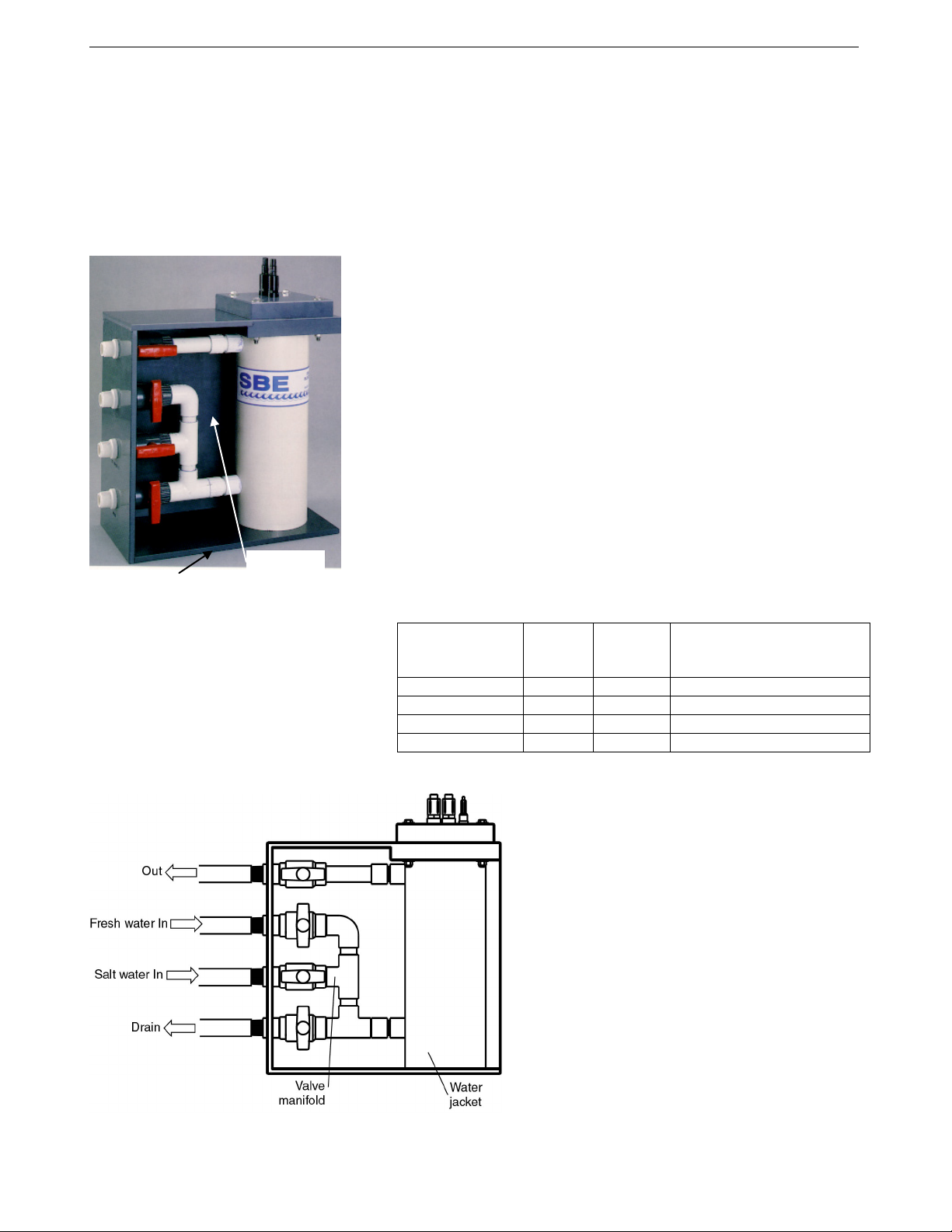

Mechanical Installation

1. A new SBE 21 is shipped with AF24173 Anti-Foulant Devices

pre-installed. Verify that the Devices are installed (see Removing

Sensor/Electronics Module from SBE 21 Water Jacket in Section 7:

Routine Maintenance and Calibration and Appendix IV: AF24173

Anti-Foulant Device).

2. Mount the SBE 21 at the desired location:

• Orient the SBE 21 with the bulkhead connectors at the top.

• Provide minimum top clearance of 559 mm (22 inches) for removal

of the sensor/electronics module from the water jacket.

• Drill the PVC base or back plate, and mount to the ship using

machine bolts.

3. Install the piping connections to the SBE 21. The connectors are

1-inch (25.4 mm) National (USA) threads. Female mating fittings suitable

for connecting to PVC plastic pipe with glue are provided; they may be

modified for use with existing piping.

A. Connect the Out fitting to the shipboard drain or to the low pressure

side of salt water supply.

B. Connect the Fresh Water In fitting to the shipboard fresh

water supply.

C. Connect the Salt Water In fitting to the shipboard sea surface water

intake line.

D. Connect the Drain fitting to shipboard drain.

Backplate

4. Set the valves, as described in the following table. The valve is open when

the handle is horizontal and closed when the handle is vertical.

Valve

Normal

Use

Water

Removal of

16

Page 17

Manual revision 027 Section 3: Installing System SBE 21

Note:

CAUTION:

Note:

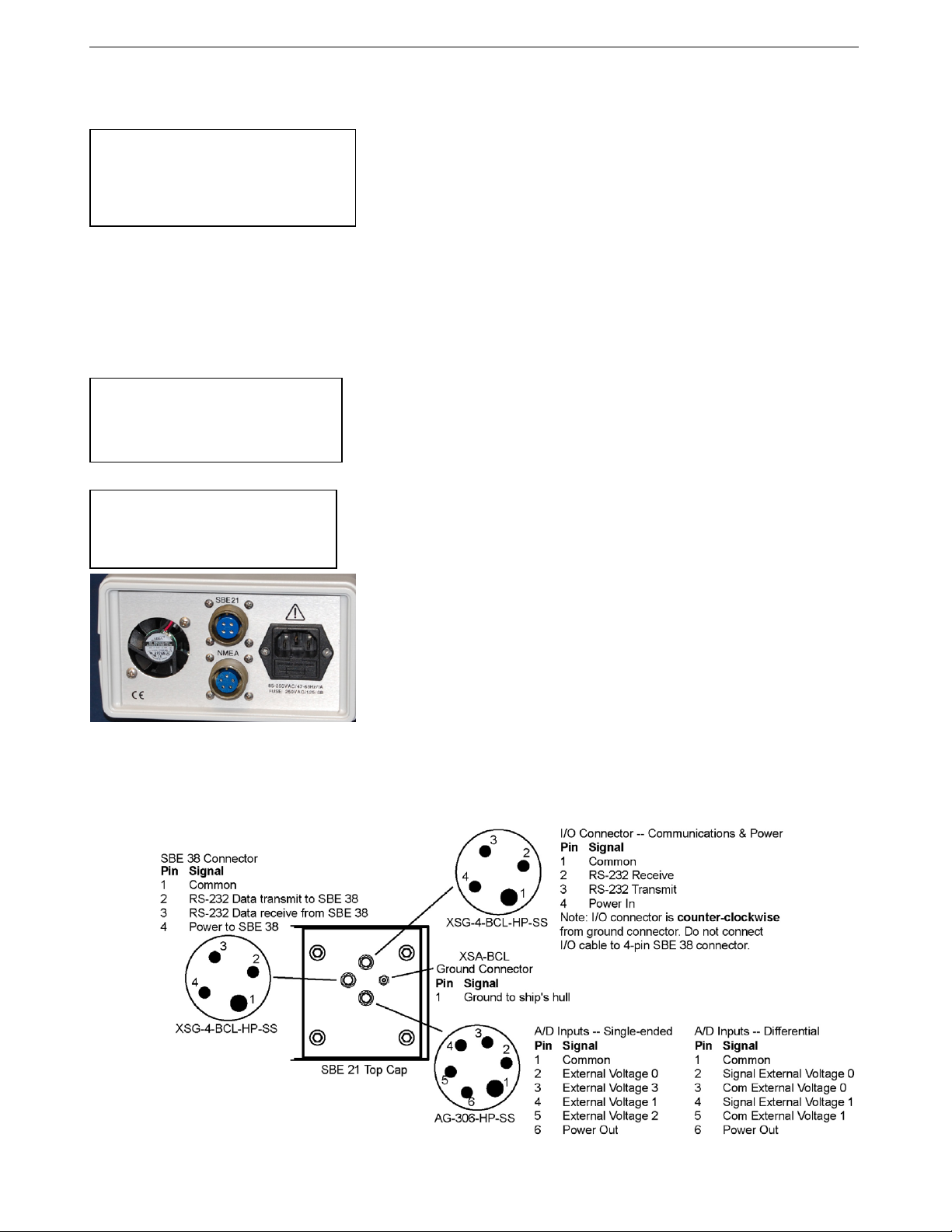

Electrical Installation

Connecting SBE 21 to Interface Box

The Interface Box is included with a

standard SBE 21 order. If testing the

SBE 21 without the Interface Box,

provide 9-14 VDC power.

Do not use WD-40 or other

petroleum-based lubricants, as they

will damage the connector.

Follow the procedure in Steps 2A

through 2E for proper installation of

all cables with similar connectors.

1. Locate the Interface Box near the computer.

• If the distance between the SBE 21 and Interface Box is longer than

the provided 10 meter I/O cable, cut the cable and splice it into the

ship’s cable. The ship’s cable should have 3 conductors, preferably

with at least 2 of the conductors shielded (RS-232 TX and RX) if

engine ignition noise or other EM interference might be encountered.

See drawing number 31063 for cable wiring details.

2. Connect the I/O cable to the SBE 21:

A. By hand, unscrew the locking sleeve from the SBE 21’s I/O

(4-pin) connector. If you must use a wrench or pliers, be careful not

to loosen the I/O connector instead of the locking sleeve.

B. Remove the dummy plug from the SBE 21’s I/O connector by pulling

the plug firmly away from the connector.

C. Lightly lubricate the inside of the 4-pin cable connector with silicone

grease (DC-4 or equivalent).

D. Install the 4-pin cable connector on the SBE 21, aligning the raised

bump on the side of the connector with the large pin on the SBE 21’s

bulkhead connector. Remove any trapped air by burping or gently

squeezing the connector near the top and moving your fingers toward

the end cap.

E. Place the locking sleeve over the cable connector. Tighten the locking

sleeve finger tight only. Do not overtighten the locking sleeve, and

do not use a wrench or pliers.

3. Connect the MS-style metal shell connector on the I/O cable to SBE 21 on

the Interface Box.

Connecting SBE 21 to Ground and to Auxiliary Sensors

1. Connect the SBE 21’s 1-pin ground connector to ship’s ground.

2. (optional) Install the cable between the SBE 21 and optional SBE 38

Remote Temperature Sensor.

3. (optional) Install the cable(s) for optional auxiliary voltage sensors.

17

Page 18

Manual revision 027 Section 3: Installing System SBE 21

Interface Box

Function

Pin A

Optional power return

Pin B

NMEA A (signal)

Pin C

NMEA B (signal return)

Pin D

No connection

Pin E

Optional +12 DC power out, up to 2 amps

Connecting Interface Box

1. Connect Serial on the Interface Box to the computer using the DB-9S to

DB-9P cable.

2. Connect the Interface Box AC Input to a standard, 3-prong, grounded,

AC outlet, using the UL/IEC-approved power cord (AC voltage between

85-270 VAC).

3. (optional) Connect a NMEA device to NMEA on the Interface Box with

the 5-pin MS connector (MS3106A14S-5P). The connector pin

designations are:

18

Page 19

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Notes:

SBE21

Notes:

Section 4: Setting Up SBE 21

This section describes:

• Setting communications parameters in the Interface Box

• Testing power and communications and setting up the SBE 21 in Seaterm

• Command descriptions

• Setting up the configuration (.xmlcon or .con) file in Seasave

• Data format

Setting Communications Parameters in Interface Box

The PN 90488 Interface Box is shipped with default communication settings

• Although baud rates may be set

higher than the factory defaults,

some users experience dropped

characters with higher baud rates.

• The baud rate between the

Interface Box and computer must

be equal to or higher than the baud

rate between the SBE 21 and

Interface Box.

that are compatible with operation with the SBE 21:

• 9600 baud for Interface box to computer

• 4800 baud for SBE 21 to Interface Box

• 7 data bits, even parity (SBE 21 to Interface Box and Interface Box

to computer)

• 4800 baud for NMEA device to Interface Box

If you want to change these settings, or you are using an Interface Box that

was set up for use with a different CTD, see the Interface Box manual for

details on changing communication settings.

Power and Communications Test and SBE 21 Setup in Seaterm

1. Wire the SBE 21 to the Interface Box, wire the Interface Box to the

computer, and provide power to the Interface Box, as described in

Electrical Installation in Section 3: Installing System.

• See Seaterm’s help files.

• It is possible to use the SBE 21

without Seaterm by sending direct

commands from a dumb terminal

or terminal emulator, such as

Windows HyperTerminal.

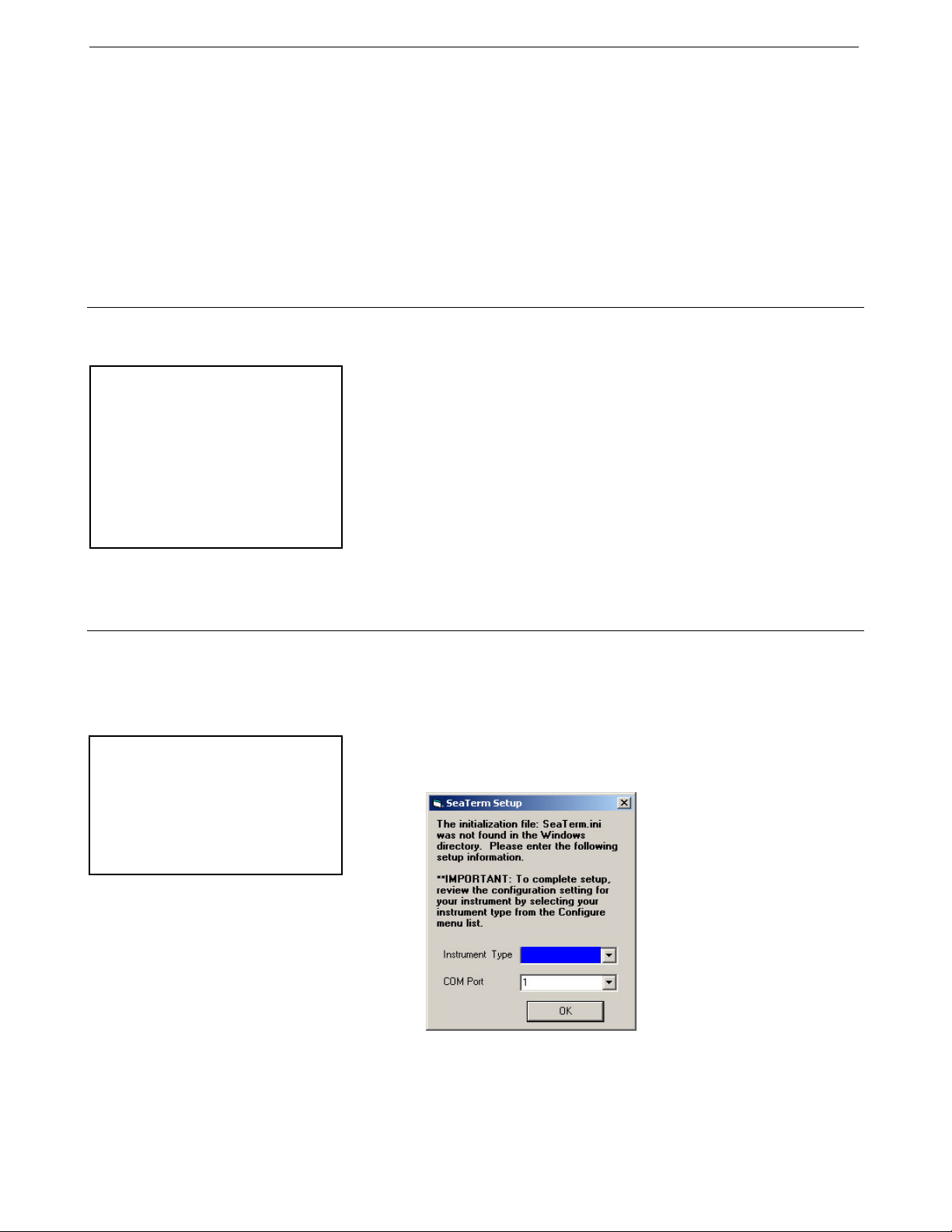

2. Double click on SeaTerm.exe. If this is the first time the program is used,

the setup dialog box may appear:

Select the instrument type (SBE 21) and the computer COM port for

communication with the SBE 21. Click OK.

19

Page 20

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Equivalent

Command*

Status

Display instrument setup and status (logging, samples in memory, etc.).

DS

View data headers (header number, date and time, first and last sample, and sample interval).

Reset data pointers and cast numbers. This should be performed after existing data has been

uploaded from SBE 21 and prior to recording new data.

Capture instrument responses on screen to file; may be useful for diagnostics. File has .cap

extension. Press Capture again to turn off capture. Capture status displays in Status bar.

Upload data stored in memory, in format Sea-Bird’s post-processing software can use.

Stop logging by sending QL.

DD (use Upload key if

Perform one or more diagnostic tests on SBE 21. Test(s) accessed in this manner are

Stop

Interrupt and end current activity, such as uploading or diagnostic test.

(press Esc key or Ctrl C)

Free computer COM port used to communicate with SBE 21. COM port can then be used by

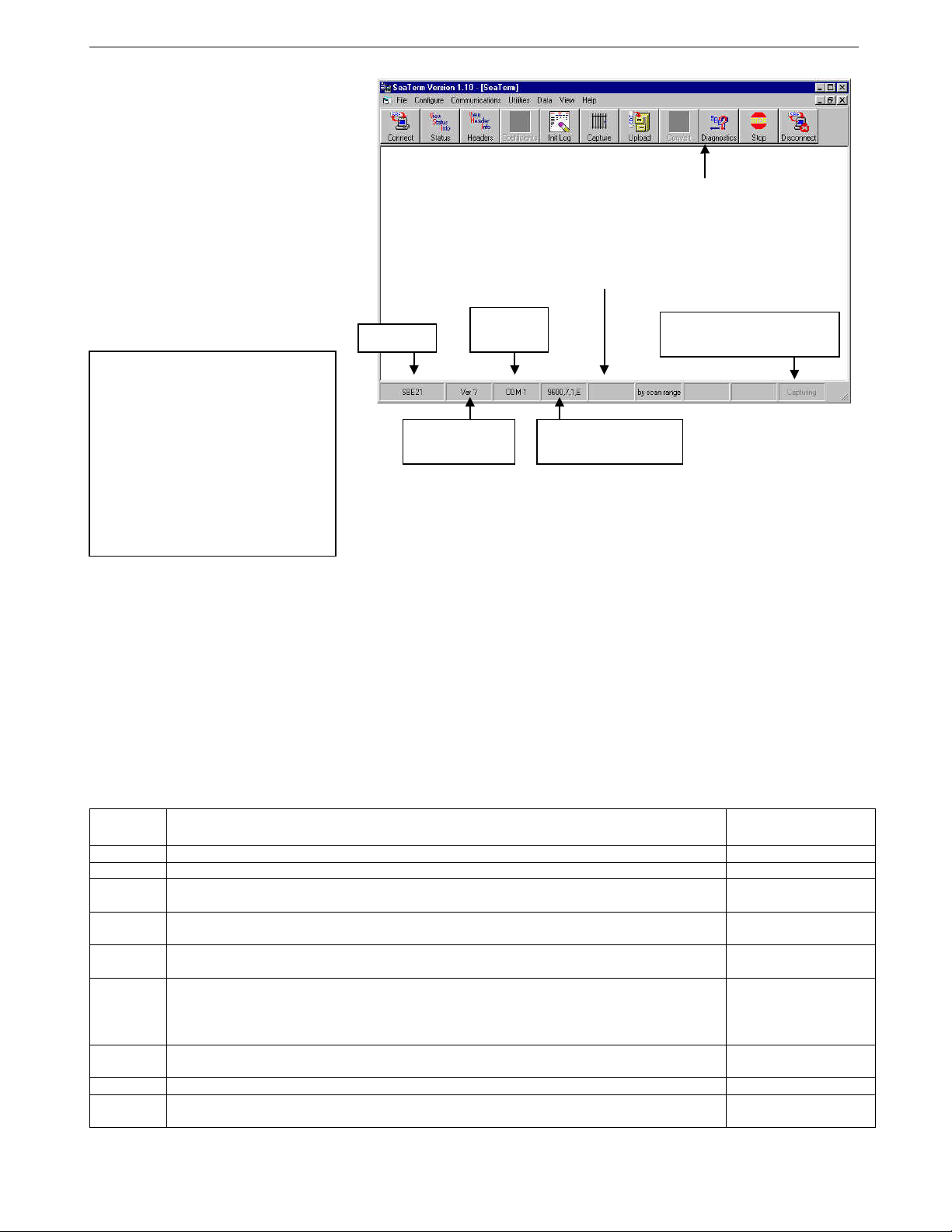

Note:

Status bar

Menus

Toolbar

Instrument

Capture to file status –

3. The main screen looks like this:

Command/Data Echo Area

Computer

There is at least one way, and as

many as three ways, to enter

a command:

• Manually type a command in

Command/Data Echo Area

• Use a menu to automatically

generate a command

• Use a Toolbar button to

automatically generate

a command

COM port

Instrument

EPROM version

Baud rate, data bits,

stop bits, and parity

• Menus – Contains tasks and frequently executed instrument

commands.

• Toolbar – Contains buttons for frequently executed tasks and

instrument commands. All tasks and commands accessed through the

Toolbar are also available in the Menus. To display or hide the

Toolbar, select View Toolbar in the View menu. Grayed out Toolbar

buttons are not applicable.

• Command/Data Echo Area – Echoes a command executed using a

Menu or Toolbar button, as well as the instrument’s response.

Additionally, a command can be manually typed in this area, from the

available commands for the instrument. Note that the instrument must

be awake for it to respond to a command (use Connect on the Toolbar

to wake up the instrument).

• Status bar – Provides status information. To display or hide the Status

bar, select View Status bar in the View menu.

Following are the Toolbar buttons applicable to the SBE 21:

grayed out if not capturing

Toolbar Description

Connect Re-establish communications with SBE 21. (press Enter key)

Headers

Init Log

Capture

Upload

Diagnostics

Disconnect

New header is generated at start of logging and every subsequent 10,000 scans.

Uploaded data has .hex extension. Before using Upload:

• Configure upload and header parameters in Configure menu.

•

non-destructive –they do not write over any existing instrument settings.

another program.

*See Command Descriptions.

20

DH

IL

—

will be data processing

with SBE Data

Processing)

DS, FR, and VR

—

Page 21

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

9600

Computer COM port (1 through 10 as

Interface Box.

Interface for

(RS-232).

Notes:

Note:

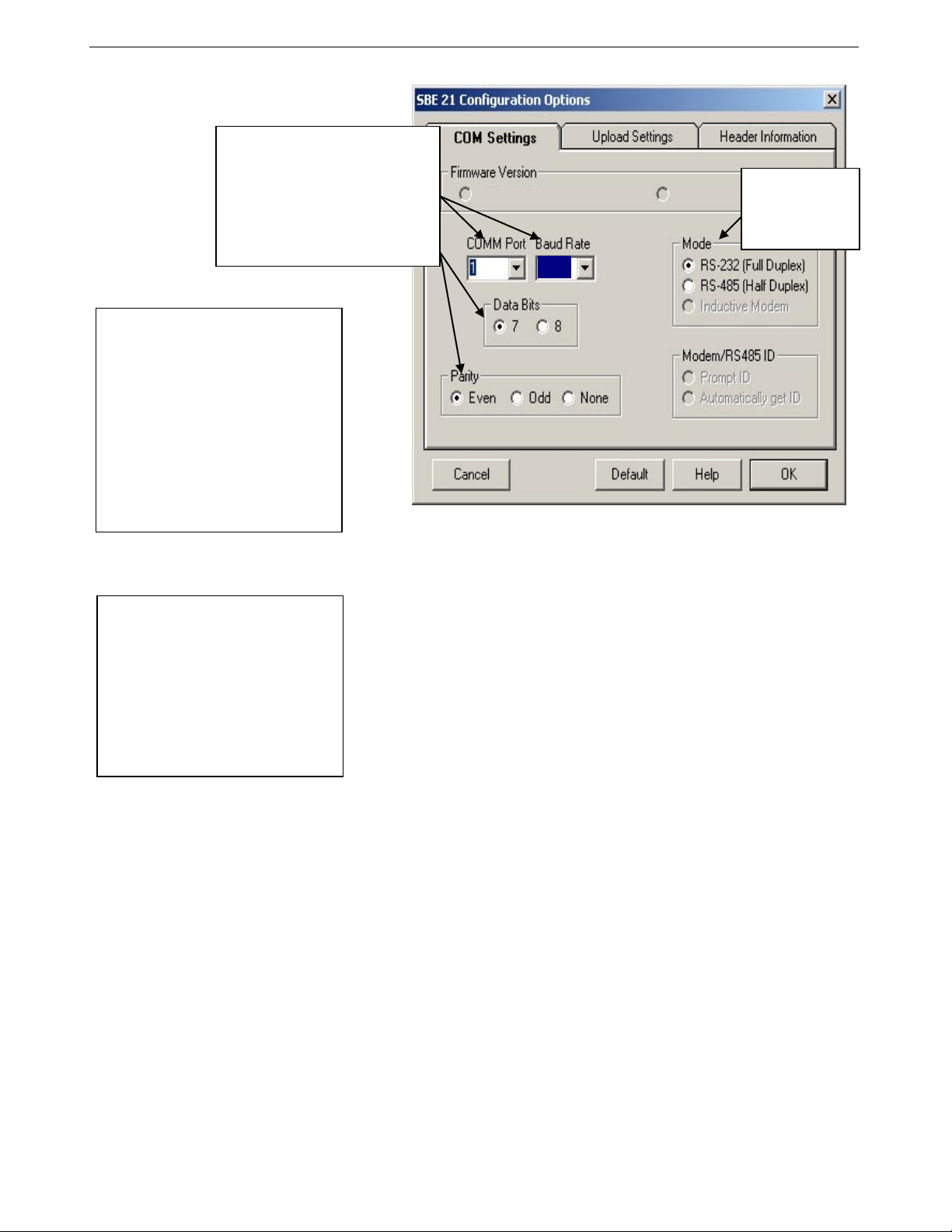

4. In the Configure menu, select SBE 21. The dialog box looks like this:

applicable), baud rate between

Interface Box and computer (9600,

documented on Configuration Sheet),

data bits (7), and parity (even) for

communication between computer

and Interface Box. Baud rate, data

bits, and parity must match settings in

communication

between computer

and Interface Box

When you click OK, Seaterm saves

the Configuration Options settings

to the SeaTerm.ini file in your

Windows directory. SeaTerm.ini

contains the last saved settings for

each instrument. When you open

Seaterm and select the desired

instrument (SBE 19, 21, 25, etc.) in

the Configure menu, the

Configuration Options dialog box

shows the last saved settings for

that instrument.

Make the selections in the Configuration Options dialog box. Click OK to

save the settings.

5. Turn on power to the Interface Box. The red PWR LED should light. The

display in Seaterm looks like this:

Interface box V 3.1b setup:

• See Section 5: Setting Up

NMEA Interface for details on

the setup menu.

• If the SBE 21 is set up to

automatically start sampling

when power is applied

(AutoRun=Y), the Interface Box

setup is followed by hex data

output from the SBE 21.

PC baud rate = 9600

SEACAT baud rate = 4800

7 data bits, even parity

NMEA baud rate = 4800

start mode = Echo characters to and from the instrument

NMEA message to decode = GGA, GLL, RMA, RMC, TRF, DBT, DPT

Press @ to change the interface box setup

This shows that correct communications between the computer and

Interface Box has been established. If the system does not respond

as shown:

• Verify the SBE 21 was selected in the Configure menu and the

settings were entered correctly in the dialog box.

• Check cabling between the computer and Interface Box.

21

Page 22

Note:

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

6. If the start mode is not echo characters to and from the instrument:

type @ to access the setup menu. The display looks like this:

• The Interface Box must be in

Mode 1 (echo characters to and

from the instrument) when sending

commands to the SBE 21.

• If you select option 4 (you have a

NMEA depth device as well as a

NMEA position device), the mode 2

description changes to:

2. Add Lat/Lon/Depth to the

real-time HEX data from the

instrument

Interface Box set up menu:

Modes:

1. Echo characters to and from the instrument

2. Add Lat/Lon to the real-time HEX data from the instrument

3. Transmit Lat/Lon only

Options:

4. Add NMEA Depth to the real-time HEX/Lat/Lon data

5. Do not add NMEA Depth to the real-time HEX/Lat/Lon data

Communications:

6. Change communication settings and start mode

7. Display communication settings and start mode

Diagnostics:

8. enable diagnostic level 1

9. enable diagnostic level 2

the current mode = 1. Echo characters to and from the

instrument

enter 1, 2, 3, 4, 5, 6, 7, 8, or 9 followed by Enter, or press

@ to exit the set up menu

selection =

Type 1 and press the Enter key. The display then shows the current mode

as 1. Echo characters to and from the instrument, which is the mode

required for communicating with the SBE 21 to set it up. Type @ to exit

the setup menu.

7. Click Connect on the Toolbar or press the Enter key several times. If you

used Connect on the Toolbar, the display looks like this:

*ds

SC21, 4300, 5.0a, 0, 0, 6, N

This is a factory-diagnostic status command (*ds) and reply. The reply

indicates instrument serial number [4300], firmware version [5.0a],

number of samples in memory [0], number of headers in memory [0],

number of bytes in each scan [6], and whether the SBE 21 is logging [L]

or not logging [N].

If the system does not respond:

• Click Connect again or press the Enter key several times.

• Verify the correct instrument was selected in the Configure menu and

the settings were entered correctly in the Configuration Options

dialog box. The baud rate is documented on the instrument

Configuration Sheet.

• Check cabling between the computer, Interface Box, and

SBE 21.

8. Display SBE 21 status information by clicking Status on the Toolbar.

The display looks like this:

SEACAT THERMOSALINOGRAPH V5.0a SERIAL NO. 4300 12/15/2009 14:23:14

ioper = 50.7 ma, vmain = 11.4, vlith = 8.8

samples = 0, free = 10966357

sample interval = 5 seconds, no. of volts sampled = 0

output format = SBE21

start sampling when power on = no

average data during sample interval = yes

logging data = no

voltage cutoff = 7.5 volts

22

Page 23

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

9. If the status reply indicates that the SBE 21 is logging, command the

SBE 21 to stop logging by pressing the Enter key and sending QL. You

may need to send QL several times before the SBE 21 responds.

ql

logging stopped, stop command

10. Command the SBE 21 to take a sample by typing TS and pressing the

Enter key. The display looks like this (if output format=SBE 21, number

of volts sampled=0, and no external temperature sensor):

78610428

where 7861 = raw Hex temperature data

0428 = raw Hex conductivity data

See Data Formats to interpret the data and determine if they are

reasonable (i.e., room temperature and zero conductivity if running in air,

or expected temperature and conductivity for water).

11. Set up the SBE 21 as desired (see Command Descriptions).

12. Command the SBE 21 to go to sleep (quiescent state) by typing QS and

pressing the Enter key.

13. Turn off power to the Interface Box.

23

Page 24

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Command Descriptions

This section describes commands in detail and provides examples of their use.

See Appendix III: Command Summary for a summarized command list.

Commands are entered in Seaterm. When entering commands:

• Input commands in upper or lower case letters and register commands by

pressing the Enter key.

• The SBE 21 sends an error message if an invalid command is entered.

• (if OutputExecutedTag=N) If the SBE 21 does not return an S> prompt

after executing a command, press the Enter key to get the S> prompt.

• If a new command is not received within 2 minutes after

completion of a command, the SBE 21 sends a message

<ERRORType = 'TIMEOUT' msg = 'NO COMMAND RECEIVED'/>

and returns to the quiescent (sleep) state.

• If in quiescent state, re-establish communications by clicking Connect on

the Toolbar or pressing the Enter key.

• If the SBE 21 is logging and transmitting data and you want to send a

command, press the Esc key or click Stop on the Toolbar (or type Ctrl C)

and then press the Enter key. This temporarily stops logging that is in

progress, and allows you to enter a limited number of commands (GetCD,

GetSD, GetCC, GetEC, ResetEC, GetHD, DS, DCal, SS, TS, QL, and

QS can be entered while logging). After 30 seconds elapses without

transmission of a command, logging resumes.

• The SBE 21 cannot have samples with different scan lengths (more or

fewer data fields per sample) in memory. If the scan length is changed by

commanding it to add or subtract a data field (such as an external voltage),

the SBE 21 must initialize logging. Initializing logging sets the sample

number and header number to 0, so the entire memory is available for

recording data with the new scan length. Initializing logging should only

be performed after all previous data has been uploaded. Therefore,

commands that change the scan length (SV=x and SBE38=) prompt the

user for verification before executing, to prevent accidental overwriting of

existing data.

• The Interface Box must be in Mode 1 (Echo characters to and from the

instrument) when sending commands to the SBE 21.

Entries made with the commands are permanently stored in the SBE 21 and

remain in effect until you change them.

• The only exception occurs if J1 is removed from the Power PCB

(top board in PCB assembly) to replace the back-up lithium battery or to

do a reset of the instrument. Upon reassembly, set the date and time

(DateTime=) and initialize logging (IL). (See Appendix II: Electronics

Disassembly/Reassembly for details on accessing the PCBs.

See Section 8: Troubleshooting for details on performing a reset of

the instrument.)

24

Page 25

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: Send GetCD to SBE 21 (user input in bold, command used to modify parameter in parentheses)

Note:

Status Command

GetCD Get and display configuration data, which

The DS response contains similar

information as the combined

responses from GetSD and GetCD,

but in a different format.

includes all parameters related to setup of

SBE 21, including communication settings

and sampling settings. Most of these

parameters can be user-input/modified.

List below includes, where applicable,

command used to modify parameter:

• Device type, Serial number

• Sample interval [SI=]

• Start sampling automatically when power

on [AutoRun=]?

• Average data during sample interval

[Average=]?

• Sample external voltages 0, 1, 2, and 3

[SV= sets number of channels]?

• Sample SBE 38 remote temperature sensor

[SBE38=]?

• Output format [Fx]

• Output Executing and Executed tags

[OutputExecutedTag=]?

getcd

<ConfigurationData DeviceType='SBE21' SerialNumber='02106001'>

<SampleMode>

<SampleInterval>15</SampleInterval> [SI=]

<AutoRun>no</AutoRun> [AutoRun=]

<Average>no</Average> [Average=]

</SampleMode>

<DataChannels>

<ExtVolt0>yes</ExtVolt0> [SV= sets number of voltage channels]

<ExtVolt1>yes</ExtVolt1> [SV= sets number of voltage channels]

<ExtVolt2>no</ExtVolt2> [SV= sets number of voltage channels]

<ExtVolt3>no</ExtVolt3> [SV= sets number of voltage channels]

<SBE38>no</SBE38> [SBE38=]

</DataChannels>

<OutputFormat>SBE 21</OutputFormat> [Fx]

<OutputExecutedTag>no</OutputExecutedTag> [OutputExecutedTag=]

</ConfigurationData>

25

Page 26

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: (user input in bold, command used to modify parameter in parentheses)

Note:

Status Commands (continued)

GetSD Get and display status data, which contains

data that changes while deployed.

The DS response contains similar

information as the combined

responses from GetSD and GetCD,

but in a different format.

List below includes, where applicable,

command used to modify parameter:

• Device type, Serial number

• Date and time [DateTime=] in

ISO8601-2000 extended format

(yyyy – mm-ddThh:mm:ss)

• Logging status (not logging, logging, or

unknown status)

• Number of recorded events in event

counter [reset with ResetEC]

• Voltages and currents -

- External power

- Back-up lithium battery voltage

- Operating current

- External voltage sensor current –

displays only if 1 or more voltage

channels enabled

- RS-232 sensor current – displays only if

channel enabled

• Memory - [reset with IL]

- Number of bytes in memory

- Number of samples in memory

- Number of additional samples that can

be placed in memory

- Length (number of bytes) of each sample

getsd

<StatusData DeviceType = 'SBE21' SerialNumber = '02106001'>

<DateTime>2009-12-22T10:53:03</DateTime> [DateTime=]

<LoggingState>not logging</LoggingState>

<EventSummary numEvents = '0'/> [can clear with ResetEC]

<Power>

<vMain>11.5</vLith>

<vLith>8.9</vLith>

<iMain>61.9</iMain>

<iExt>67.2</iExt>

<iSerial>67.2</iSerial>

</Power>

<MemorySummary>

<Bytes>0</Bytes> [can clear with IL]

<Samples>0</Samples> [can clear with IL]

<SamplesFree>3870479</SamplesFree> [can clear with IL]

<SampleLength>17</SampleLength>

</MemorySummary>

</StatusData>

26

Page 27

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: SBE 21 (user input in bold, command used to modify coefficient in parentheses)

Note:

Status Commands (continued)

Calibration coefficients for the

conductivity and primary temperature

sensor, and for any auxiliary sensors,

are stored in the SBE 21’s

configuration (.xmlcon or .con) file.

View and/or modify the calibration

coefficients using the Configure menu

in SBE Data Processing or Seasave

(see Checking SBE 21 Configuration

(.xmlcon or .con) File in Seasave).

GetCC Get and display calibration coefficients:

• Voltage (0, 1, 2, and 3) channel offset and

slope, as determined at Sea-Bird:

Output voltage =

(slope * calculated V from sensor equation) + offset

• conductivity zero frequency: characteristic

frequency of conductivity sensor for

0 conductivity, as determined at Sea-Bird from

a cell thoroughly rinsed in distilled or deionized water, with all the water shaken out.

Zero frequency that has changed by a few

tenths of a Hz indicates a dirty cell. Zero

frequency that has changed by more may

indicate a cell that is damaged or considerably

out of calibration.

getcc

<CalibrationCoefficients DeviceType = 'SBE21' SerialNumber = '02106001'>

<Calibration format = 'VOLT0' id = 'Volt 0'>

<OFFSET>0.000000e+00</OFFSET> [VOffset0=]

<SLOPE>1.260977e+00</SLOPE> [VSlope0=]

</Calibration>

<Calibration format = 'VOLT0' id = 'Volt 1'>

<OFFSET>-4.728750e-02</OFFSET> [Voffset1=]

<SLOPE>1.259474e+00</SLOPE> [VSlope1=]

</Calibration>

<Calibration format = 'VOLT0' id = 'Volt 2'>

<OFFSET>-4.715313e-02</OFFSET> [Voffset2=]

<SLOPE>1.259946e+00</SLOPE> [VSlope2=]

</Calibration>

<Calibration format = 'VOLT0' id = 'Volt 3'>

<OFFSET>-4.772396e-02</OFFSET> [Voffset3=]

<SLOPE>1.260486e+00</SLOPE> [VSlope3=]

</Calibration>

<Calibration format = 'CF0' id = 'conductivity zero frequency'>

<CF0>2.689054e+03</CF0>

</Calibration>

</CalibrationCoefficients>

27

Page 28

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example (user input in bold, command used to modify parameter in parentheses)

</EventCounters>

Status Commands (continued)

GetEC Get and display event counter data, which

can help to identify root cause of a

malfunction. Event counter records

number of occurrences of common

timeouts, power-on resets, etc. Can be

cleared with ResetEC. Possible events that

may be logged include:

• Power fail – external power below voltage

cutoff

• EEPROM read or EEPROM write – all

power removed (external power removed,

and back-up lithium batteries are dead)

• AD7730 timeout – response from

temperature A/D converter delayed; typically

if woke up to send a command while logging

• AD7714 timeout – response from voltage

channel A/D converter delayed; typically if

woke up to send a command while logging

• FLASH out of memory – all available

memory space is used; autonomous sampling

continues, but no additional data written to

FLASH (does not overwrite)

• FLASH correctable error – single bit error in

a page, corrects itself, does not affect data

• FLASH ECC error – does not affect data

• FLASH timeout – problem with FLASH

• FLASH ready – problem with FLASH;

timeout error

• FLASH erase failed – problem with FLASH

• FLASH write failed – problem with FLASH

• FLASH uncorrectable – problem with

FLASH; 2 or more bits of errors in a page

• FLASH block overrun – problem with

FLASH

• New bad block – problem with FLASH;

FLASH write or erase failed, or a FLASH

uncorrectable error

getec

<EventCounters DeviceType = 'SBE21' SerialNumber = '02106001'>

<EventSummary numEvents = '1'/> [can clear with ResetEC]

<Event type='powerfail' count='1'/>

ResetEC Delete all events in event counter (number

28

of events displays in GetSD response, and

event details display in GetEC response).

Page 29

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: (user input in bold, command used to modify parameter in parentheses)

Note:

Status Commands (continued)

GetHD Get and display hardware data, which is

External sensor types and serial

numbers can be changed in the field,

to accommodate changes in auxiliary

sensors cabled to the SBE 21.

Other hardware data is typically not

changed by the user.

gethd

<HardwareData DeviceType = 'SBE21' SerialNumber = '02106001'>

<Manufacturer>Sea-Bird Electronics, Inc.</Manufacturer>

<FirmwareVersion>5.0a</FirmwareVersion>

<FirmwareDate>2 September 2009 09:00</FirmwareDate>

<PCBAssembly PCBSerialNum = 'not assigned' AssemblyNum = 'not assigned'/> [SetPcbSerialNum1=, SetPCBAssembly1=]

<PCBAssembly PCBSerialNum = 'not assigned' AssemblyNum = 'not assigned'/> [SetPcbSerialNum2=, SetPCBAssembly2=]

<PCBAssembly PCBSerialNum = 'not assigned' AssemblyNum = 'not assigned'/> [SetPcbSerialNum3=, SetPCBAssembly3=]

<PCBAssembly PCBSerialNum = 'not assigned' AssemblyNum = 'not assigned'/> [SetPcbSerialNum4=, SetPCBAssembly4=]

<MfgDate>03 february 2008</MfgDate> [SetMfgDate=]

<InternalSensors>

<Sensor id = 'Main Temperature'>

<type>temperature0</type>

<SerialNumber>01606001</SerialNumber>

</Sensor>

<Sensor id = 'Main Conductivity'>

<type>conductivity-0</type>

<SerialNumber>01606001</SerialNumber>

</Sensor>

</InternalSensors>

<ExternalSensors>

<Sensor id = 'volt 0'>

<type>not assigned</type> [SetVoltType0=]

<SerialNumber>not assigned</SerialNumber> [SetVoltSN0=]

</Sensor>

<Sensor id = 'volt 1'>

<type>not assigned</type> [SetVoltType1=]

<SerialNumber>not assigned</SerialNumber> [SetVoltSN1=]

</Sensor>

<Sensor id = 'volt 2'>

<type>not assigned</type> [SetVoltType2=]

<SerialNumber>not assigned</SerialNumber> [SetVoltSN2=]

</Sensor>

<Sensor id = 'volt 3'>

<type>not assigned</type> [SetVoltType3=]

<SerialNumber>not assigned</SerialNumber> [SetVoltSN3=]

</Sensor>

</ExternalSensors>

</HardwareData>

fixed data describing SBE 21:

• Device type, Serial number

• Manufacturer

• Firmware version

• Firmware date

• PCB serial number and assembly number

• Manufacture date

• Internal sensor types and serial numbers

• External voltage sensor types (for

example, dissolved oxygen, fluorometer,

etc.) and serial numbers

29

Page 30

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: Display status for SBE 21 that has SBE 38 remote temperature sensor enabled

voltage cutoff = 7.5 volts

Status Commands (continued)

DS Display operating status and setup

parameters. Equivalent to Status

on Toolbar.

List below includes, where applicable,

command used to modify parameter.

• firmware version, serial number, and date

and time [DateTime=]

• operating current (milliamps), external

power voltage, and lithium battery voltage

• number of samples and available sample

space in memory

• sample interval [SI=], number of external

voltages enabled [SV=]

• Enable sampling of SBE 38 remote

temperature sensor [SBE38=]?

(only appears in status if SBE 38 enabled)

• output format [Fx]

• start sampling automatically when power

on [AutoRun=]?

• average data during sample interval

[Average=]?

• logging status

• power cutoff voltage

(user input in bold).

DS

SEACAT THERMOSALINOGRAPH V5.0a SERIAL NO. 4300 12/15/2009 14:23:14 [DateTime=]

ioper = 50.7 ma, vmain = 11.4, vlith = 8.8

samples = 0, free = 3870479

sample interval = 5 seconds, no. of volts sampled = 4 [SI=, SV=]

sample external SBE 38 temperature sensor [SBE38=]

output format = SBE21 [Fx]

start sampling when power on = no [AutoRun=]

average data during sample interval = yes [Average=]

logging data = no

30

Page 31

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example: Display coefficients for SBE 21 (user input in bold).

Notes:

directly and using Seaterm.

Status Commands (continued)

• Calibration coefficients for the

conductivity and primary

temperature sensor, and for any

auxiliary voltage sensors, are stored

in the SBE 21’s configuration

(.xmlcon or .con) file. View and/or

modify the calibration coefficients

using the Configure menu in SBE

Data Processing or Seasave (see

Checking SBE 21 Configuration

(.xmlcon or .con) File in Seasave).

• If using an SBE 38 remote

temperature sensor, its calibration

coefficients are not stored in the

SBE 21 EEPROM or in the SBE 21’s

configuration (.xmlcon or .con) file.

View and/or modify the instrument’s

calibration coefficients by connecting

the instrument to the computer

DCal Display calibration coefficients.

• Voltage (0, 1, 2, and 3) channel offset and

slope, as determined at Sea-Bird:

Output voltage =

(slope * calculated V from sensor equation) + offset

• conductivity zero frequency: characteristic

frequency of conductivity sensor for

0 conductivity, as determined at Sea-Bird from

a cell thoroughly rinsed in distilled or deionized water, with all the water shaken out.

Zero frequency that has changed by a few

tenths of a Hz indicates a dirty cell. Zero

frequency that has changed by more may

indicate a cell that is damaged or considerably

out of calibration.

DCAL

SEACAT THERMOSALINOGRAPH V5.0a SERIAL NO. 3166 12/15/2009 14:30:14

volt 0: offset = -4.662333e-02, slope = 1.249281e+00

volt 1: offset = -4.658000e-02, slope = 1.249034e+00

volt 2: offset = -4.699667e-02, slope = 1.248704e+00

volt 3: offset = -4.707333e-02, slope = 1.249847e+00

Cfo = 2596.697

31

Page 32

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Note:

Notes:

Notes:

Example: Set current date and time to 05 February 2010 12:05:00 (user input in bold).

Example:

(Note: <Executed/> tag at end of command response takes place of S> prompt.)

Setup Commands

DateTime=mmddyyyyhhmmss Set real-time clock month, day, year, hour,

minute, and second.

datetime=02052010120500

The SBE 21 baud rate (set with

Baud=) must match the Interface

Box setup for baud rate between the

SBE 21 and Interface Box.

Baud=x x= baud rate (600, 1200, 2400, 4800,

9600, 19200, or 38400). Default 4800.

OutputExecutedTag=x x=Y: Display XML Executing and

Executed tags (default). Executed tag

displays at end of each command

response; Executing tag displays one or

more times if SBE 21 response to

command requires additional time.

x=N: Do not.

Set SBE 21 to output Executed and Executing tags (user input in bold).

outputexecutedtag=y

<Executed/>getcd

. . . (GetCD response)

<Executed/>

SBE38=x x= Y: Enable sampling of SBE 38 remote

• See Notes on SBE 38 Remote

Temperature Data Format for details

on how the SBE 38 data is handled.

• The SBE 21 configuration (.xmlcon

or .con) file must match the selection

of remote temperature sensor and

external voltages. View and edit the

configuration file in Seasave or SBE

Data Processing. These parameters

are factory-set to match the ordered

instrument configuration.

• The SBE 21 requires verification

when SBE38= or SV=x are sent. The

This command

Scan length has

SV=x x= number of external voltages to be

SBE 21 responds:

will change the scan length

and/or initialize logging.

Repeat the command to verify.

Type the command again and press

the Enter key to proceed. The

SBE 21 responds:

changed, initializing logging.

Fx x=1: Set data format to SBE 21. Outputs

x=2: Set data format to SBE 16 (custom

• Output format does not affect how

data is stored in memory.

• If you will be using Sea-Bird

software (Seasave and/or

SBE Data Processing), set the

format to SBE 21 (F1).

• See Data Formats for a complete

description of the data output.

QS Quit session and place SBE 21 in

32

temperature sensor.

Note: You must also set up SBE 38 to

interface with SBE 21. Connect SBE 38

directly to computer, and set:

- SBE 38 baud (Baud=) to same baud as

SBE 21;

- interface to RS-232 (Interface=232);

- sampling to begin when power applied

(AutoRun=Y); and

- format to converted data (Format=C).

See SBE 38 manual for command details.

x= N: Do not enable SBE 38.

acquired (0, 1, 2, 3, or 4). Maximum is 4 if

single-ended A/D channels are installed, or

2 if differential A/D channels are installed.

raw data (in Hex): primary temperature,

conductivity, remote temperature, voltages.

applications not using Sea-Bird software).

Outputs raw data (in Hex): # (attention

character), primary temperature,

conductivity, remote temperature,

voltages, linear count (starting at 0).

quiescent (sleep) state. Quiescent current

is only 30 microamps. Memory retention

is not affected.

Page 33

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

If Average=Y

If Average=N

1. Take samples continuously at

each sample interval [SI=],

2. Store averaged data in FLASH

real-time, and

2. Store data in FLASH

real-time, and

3. Write a header to memory, listing logging start date and time, sample

every 10,000 samples. A maximum of 1000 headers can be written.

Notes:

Example: Set sample interval to 5 seconds (user input in bold).

Logging Commands

Logging commands configure the SBE 21’s response upon waking up, and

direct the SBE 21 to sample data at pre-programmed intervals. When

• In SEATERM, to save real-time data

to a file, click Capture on the Toolbar

before beginning logging.

• If the FLASH memory is filled to

capacity, data sampling and

transmission of real-time data

continue, but excess data is not

saved in memory. The SBE 21 will

not overwrite data stored in

memory.

• If the maximum number of headers

is reached but there is still room for

samples in FLASH memory, data

sampling and transmission of realtime data continue without writing

additional headers.

• If the SBE 21 is logging data and the

external voltage is less than the cutoff voltage (7.5 volts), the SBE 21

halts logging and displays:

logging stopped, no power

commanded to start sampling with GL or RL, or upon powering up (if

AutoRun=Y), the SBE 21 responds as follows:

4 Hz (every 0.25 seconds) and

average the samples taken within

memory and transmit averaged data

1. Take 1 sample every sample

interval [SI=] seconds,

memory and transmit data

interval, and sample number range. A new header is also written after

The SBE 21 does not enter quiescent (sleep) state between samples.

Average=x x=Y: Set SBE 21 to sample continuously

at 4 Hz (every 0.25 seconds) and average

samples taken within each sample interval

[SI=] seconds, store averaged data in

memory, and transmit averaged data

real-time.

x=N: Set SBE 21 to take 1 sample every

sample interval [SI=] seconds, store data

in memory, and transmit data real-time.

SI=x x= interval (seconds) between samples or

sample averages. Minimum interval

3 seconds, maximum interval 600 seconds.

SI=5

If Average=Y: When logging starts, every 5 seconds SBE 21 takes

∼20 samples (1 sample every 0.25 seconds), averages data, stores averaged

data in FLASH memory, and transmits averaged data real-time.

If Average=N: When logging starts, every 5 seconds SBE 21 takes

1 sample, stores data in FLASH memory, and transmits data real-time.

33

Page 34

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Notes:

Example (user input in bold):

initialize logging. Repeat the command to

Example (user input in bold):

the scan length and/or

initialize logging. Repeat the command to

Logging Commands (continued)

IL Initialize logging - after all previous data

has been uploaded from SBE 21, initialize

logging before starting to log again to

• IL and SampleNumber=0 have

identical effects. Use either

command to initialize logging.

• Do not initialize logging until

all data has been uploaded.

These commands do not delete

data; they reset the data pointer.

If you accidentally initialize

logging before uploading,

recover data as follows:

1. Set SampleNumber=a and

HeaderNumber=b, where a and b

are your estimate of number of

samples and headers in memory.

2. Upload data. If a is more than

actual number of samples in

memory or b is more than actual

number of headers in memory,

data for non-existent

samples/headers will be bad,

random data. Review uploaded

data file carefully and delete any

bad data.

3. If desired, increase a and/or b and

upload data again, to see if there is

additional valid data in memory.

make entire memory available for

recording. IL sets sample number

(SampleNumber=) and header number

(HeaderNumber=) to 0 internally. Do not

send IL until all existing data has been

uploaded. SBE 21 requires verification

before it proceeds.

If AutoRun=Y: If IL is not sent,

when power is applied logging resumes,

storing data to memory without resetting

sample number (does not overwrite

recorded data).

If AutoRun=N: Overwriting of data is

controlled by which command is used to

start logging - GL (start logging, storing

data at beginning of memory) or RL

(resume logging, storing data without

resetting sample number).

IL

This command will change the scan length and/or

verify

IL

SampleNumber=x x= sample number for first sample when

logging begins. Typically used to recover

data if you accidentally initialize logging

(using IL) before uploading existing data.

HeaderNumber=x x= header number for first sample when

logging begins. Typically used to recover

data if you accidentally initialize logging

(using IL or SampleNumber=0) before

uploading existing data.

GL Start logging now. SBE 21 overwrites any

recorded data and headers in memory.

SBE 21 requires verification before it

proceeds. SBE 21 takes first sample

3 seconds after command is verified.

GL

This command will change

verify.

GL

(data begins appearing)

34

Page 35

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Example (user input in bold):

(data begins appearing)

Notes:

Example (user input in bold):

logging stopped, stop command

Note:

Logging Commands (continued)

RL Resume logging now. SBE 21 resumes

writing data and headers to memory

without resetting sample or header number

(it does not overwrite recorded data).

SBE 21 takes first sample

3 seconds after command is verified.

RL

AutoRun=x x=Y: Automatically start logging when

After sending AutoRun=Y, you

must turn power to the SBE 21 off

and then on again to start logging.

power is applied. When power is applied,

SBE 21 resumes writing data and headers

to memory without resetting sample

number or header number (does not

overwrite recorded data).

x= N: Do not automatically start logging

when power is applied.

QL Stop logging. Press Enter key before

• You may need to send QL

several times to get the SBE 21

to respond. If the SBE 21 does

not appear to respond to QL,

press Ctrl Z several times, and

then try QL again.

• If AutoRun=Y, remove power to

stop logging.

• You must stop logging before

uploading data.

QL

sending QL.

35

Page 36

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Note:

Example: Upload samples 0 through 199 to a file (user input in bold):

DD0,199

Example: Upload headers to a file (user input in bold).

hdr 2 10 Jul 2009 13:02:12 samples 5 to 10, int = 60 sec, stop = stop cmd

Data Upload Commands

Stop logging before uploading data.

Notes:

• To save data to a file, click

Capture on the Toolbar before

entering DD or DH.

• See Data Formats after these

Command Descriptions.

• To upload data in a form

that can be used by

SBE Data Processing:

1. Set the output format to

SBE 21 using F1 before

uploading.

2. Use Upload on the Toolbar or

Upload Data in the Data menu.

Manually entering DDb,e does

not produce data with the

required header information

for processing by SBE

Data Processing.

DDb,e Upload data in raw Hex form from scan b

to scan e. If b and e are omitted, all data is

uploaded. First sample is number 1.

(Click Capture on Toolbar and enter desired filename in dialog box.)

DH Upload all headers. First header is 1.

New header was written when logging

started or resumed and every 10,000

samples thereafter. Header includes:

• header number

• month, day, year, hour, minute, and

second when header was written

• first and last sample for header

• interval between samples (SI=)

• reason logging stopped

- stop cmd – sent QL to stop,

- no ext pwr – external power below

7.5 volt cutoff

(Click Capture on Toolbar and enter desired filename in dialog box.)

DH

hdr 1 10 Jul 2009 12:30:33 samples 0 to 4, int = 60 sec, stop = stop cmd

The SBE 21 has a buffer that

stores the most recent data

samples. Unlike data in the

FLASH memory, data in the

buffer is erased upon removal or

failure of power.

Sampling Commands

These commands request a single sample. The SBE 21 always stores data for

the most recent sample in its buffer.

SS Output last sample from buffer

(sample obtained with TS, or latest sample

from logging).

TS Sample for 1 second at 4 Hz (take

4 samples), average data, store averaged

data in buffer, and output averaged data.

Data is not stored in FLASH memory.

36

Page 37

Manual revision 027 Section 4: Setting Up SBE 21 SBE 21

Column

Output

2

Raw conductivity frequency

3

Temperature frequency converted to match older

4

Conductivity frequency converted to match older

SBE 21 (firmware version < 4.0)

Column

Output

1

External (auxiliary sensor) voltage 0

2

External (auxiliary sensor) voltage 1

3

External (auxiliary sensor) voltage 2

4

External (auxiliary sensor) voltage 3

5

External power voltage / 11

6

Back-up lithium battery voltage / 3.741

7

Operating current / 333.33

Notes:

Diagnostic Commands

The SBE 21 outputs 100 samples for each diagnostic test. Data is not stored in

FLASH memory. Press the Esc key or Stop button to stop the test.

FR Display frequencies:

1 Raw temperature A/D counts

SBE 21 (firmware version < 4.0)

VR Display voltages with offset and scale factors

applied.

• Calibration coefficients for the

conductivity and primary

temperature sensor, and for any

auxiliary voltage sensors, are stored

in the SBE 21’s configuration

(.xmlcon or .con) file. View and/or

modify the calibration coefficients

using the Configure menu in SBE

Data Processing or Seasave (see

Checking SBE 21 Configuration

(.xmlcon or .con) File in Seasave).

• If using an SBE 38 remote

temperature sensor (SBE38=Y), its

calibration coefficients are not stored

in the SBE 21 EEPROM or in the

SBE 21’s configuration (.xmlcon or

.con) file. View and/or modify the

instrument’s calibration coefficients

by connecting the instrument to the

computer directly and using

Seaterm.

T38 Display output from SBE 38 remote

temperature sensor.

Calibration Coefficients Commands

The following commands set voltage channel offsets and slopes at the