Page 1

SBE 38 Digit al Oceanographic Thermometer

With RS-232 or optional RS-485 Interface

User’s Manual

Sea-Bird Electronics, Inc.

1808 136

Bellevue, Washington 98005 USA

Telephone: 425/643-9866

Fax: 425/643-9954

E-mail: seabird@seabird.com Manual Version #006, 03-14-03

Website: www.seabird.com Firmware Version 1.2 and later

th

Place NE

Page 2

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

2

Page 3

Table of Contents

Table of Contents

Section 1: Introduction....................................................................................4

About this Manual .............................................................................................4

How to Contact Sea-Bird...................................................................................4

Quick Start.........................................................................................................4

Unpacking SBE 38.............................................................................................5

Section 2: Description of SBE 38....................................................................6

System Description............................................................................................6

Specifications.....................................................................................................7

Dimensions and End Cap Connector.................................................................8

Baud Rate and Cable Length .............................................................................8

Section 3: Preparing SBE 38 for Deployment ...............................................9

Installing Software.............................................................................................9

Power and Communications Test ......................................................................9

Test Setup...................................................................................................9

Test...........................................................................................................10

Section 4: Deploying and Operating RS-232 SBE 38..................................13

Sampling Modes..............................................................................................13

Polled Sampling........................................................................................13

Continuous Sampling................................................................................14

Command Descriptions....................................................................................15

Data Output Formats........................................................................................17

Deployment......................................................................................................17

Recovery..........................................................................................................17

Section 5: Routine Maintenance and Calibration.......................................18

Corrosion Precautions......................................................................................18

Connector Mating and Maintenance................................................................18

Sensor Calibration............................................................................................19

Glossary..........................................................................................................20

Appendix I: Functional Description.............................................................21

Sensor Interface...............................................................................................21

Settings ............................................................................................................21

Appendix II: Electronics Disassembly/Reassembly....................................22

Appendix III: RS-485 Interface....................................................................23

Operation Description......................................................................................23

Command Descriptions....................................................................................24

RS-485 Commands...................................................................................24

All Other Commands................................................................................25

Data Output Formats........................................................................................25

Wiring..............................................................................................................26

Conversion of RS-232 to RS-485 or RS-485 to RS-232..................................26

Appendix IV: Command Summary.............................................................27

Appendix V: Replacement Parts ..................................................................28

Index................................................................................................................29

3

Page 4

Section 1: Introduction

Section 1: Introduction

This section includes contact information, Quick Start procedure, and photos

of a standard SBE 38 shipment.

About this Manual

This manual is to be used with the SBE 38 Digital Oceanographic

Thermometer.

It is organized to guide the user from installation through operation and data

collection. We’ve included detailed specifications, command descriptions,

maintenance and calibration information, and helpful notes throughout

the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Pl ease e-mail any comments or suggestions to

seabird@seabird.com.

How to Contact Sea-Bird

Quick Start

Sea-Bird Electronics, Inc.

1808 136

Bellevue, Washington 98005 USA

Telephone: 425-643-9866 Fax: 425-643-9954

E-mail: seabird@seabird.com Website: http://www.seabird.com

Business hours:

Monday-Friday, 0800 to 1700 Pacific Standard Time

Except from April to October, when we are on summer time

Follow these steps to get a Quick Start using the SBE 38 with a standard

RS-232 interface. The manual provides step-by-step details for performing

each task:

1. Test Power and Communications (see Section 3: Preparing SBE 38

2. Deploy the SBE 38 (see Section 4: Deploying an d Operating RS-232 SBE 38):

For an SBE 38 with optional RS-485 interface , see Appendix III: RS-485

Interface for details.

th

Place Northeast

(1600 to 0100 Universal Time)

(1500 to 0000 Universal Time)

for Deployment).

A. Establish setup parameters.

B. Use one of the following sequences to start sampling:

• If AUTORUN=N: GO to start sampling continuously now, or

TS or TH to take a single sample.

• If AUTORUN=Y: Apply power to start sampling

continuously now.

C. Deploy SBE 38.

4

Page 5

Section 1: Introduction

Unpacking SBE 38

Shown below is a typical SBE 38 shipment.

I/O Cable with 9V battery snap

connector and 9V battery

User Manual

SBE 38 Digital

Oceanographic

Thermome ter

SBE 38

25-pin to 9-pin adapter

Software, and Electronic Copies of

Software Manuals and User Manual

5

Page 6

Section 2: Description of SBE 38

Section 2: Description of SBE 38

This section describes the functions and features of the SBE 38, including

specifications and dimensions.

System Description

Sophisticated A/D acquisition electronics, ultra-stable thermistor, and state-ofthe-art calibration provide the standards-level performance of an expensive

AC bridge and platinum thermometer at a small fraction of the cost. The

SBE 38 is unaffected by shock and vibration, has high accuracy and stability,

and is easy to use. It has a rugged, corrosion-proof, 10,500 meter (34,400 foot)

titanium pressure housing. Real-time temperature data is transmitted in ASCII

characters (in °C or raw counts) via an RS-232 or optional RS-485 serial

interface for display or logging by PC or data logger.

The standard measurement range is -5 to +35 °C. An optional range of -5 to

+50 °C is available at slightly reduced accuracy and resolution. For the

standard range, absolute accuracy is better than 0.001 °C (1 mK) and

resolution is approximately 0.00025 °C (0.25 mK). Each sensor includes

certification that demonstrates drift of less than 0.001 °C (1 mK) during a

six-month period.

Applications include calibration baths, oceanographic/aquatic research, and

environmental monitoring.

The SBE 38 operates in one of three ways:

• RS-232 (full duplex) with one SBE 38 connected to the interface

• RS-485 (half duplex) with one SBE 38 connected to the interface

• RS-485 (half duplex) with several RS-485 sensors sharing one pair

of wires

On power-up, the SBE 38 reads its EEPROM, which includes calibration

coefficients and other setup information. As programmed, the SBE 38 samples

and transmits temperature continuously, or waits for a command to begin

sampling. Note that for RS-485 applications with several sensors sharing one

pair of wires, the SBE 38 cannot sample continuously.

The SBE 38 is frequently integrated as a remote temperature sensor with one

of our thermosalinograph instruments (SBE 21 Thermosalinograph or SBE 45

MicroTSG), to provide accurate sea surface temperature. See the manuals for

Notes:

• Sea-Bird also supplies a DOS

software package, SEASOFT-DOS,

which can be used with the SBE 38.

However, this manual only details

use of the Windows software with

the SBE 38.

• Help files provide detailed

information on the use of

SEATERM, SEASAVE, and SBE

Data Processing.

• Separate software manuals on

CD-ROM contain detailed

information on the setup and use of

SEASAVE, SBE Data Processing,

and SEASOFT-DOS.

those instruments for integration information.

The SBE 38 is supplied with a powerful Win 95/98/NT/2000/XP software

package, SEASOFT-Win32, which includes:

• SEATERM terminal program for easy communication.

• SEASAVE real-time data acquisition and SBE Data Processing

post-processing programs – When the SBE 38 is integrated with the

SBE 21 or 45 thermosalinograph, SEASAVE and SBE Data Processing

can be used to view and process the entire data stream, including data

from the SBE 38.

6

Page 7

Section 2: Description of SBE 38

Specifications

Measurement

Range

Standard: -5 to +35 °C

Optional: -5 to +50 °C

Note:

If the SBE 38 is sampling data

and the voltage is less than

6.5 volts for 10 consecutive

scans, the SBE 38 halts sampling

and displays a low battery

indication in the data.

Initial Accuracy 1

Typical Stability

Resolution

Calibration

Response Time 2

Self-Heating

Error

RMS Noise

(at temperature

equivalent of 8.5 °C)

External Power

Materials

0.001 °C (1 mK)

0.001 °C (1 mK) in 6 months, certified

0.00025 °C (0.25 mK)

Standard: -1 to +32 °C

Optional: -1 to +50 °C (accuracy above

standard range is degraded to 0.003 degrees)

500 milliseconds

less than 200 µK

NAVG Noise (°C)

1 0.000673

2 0.000408

4 0.000191

8 0.000133

16 0.000081

32 0.000052

Note:

NAVG = number of A/D cycles per sample.

Interval between samples (seconds)

= (0.133 * NAVG) + 0.339

RS-232 (standard):

8 – 15 VDC at 10 milliamps average

RS-485 half-duplex (optional):

8 – 15 VDC at 6 milliamps average

Titanium pressure case rated at

10,500 meters (34,400 feet)

Weight

Notes:

1

NIST-traceable calibration applying over the entire range.

2

Time to reach 63% of final value following a step change in temperature.

In water: 0.5 kg (1.2 lbs)

In air: 0.9 kg (2.0 lbs)

7

Page 8

Section 2: Description of SBE 38

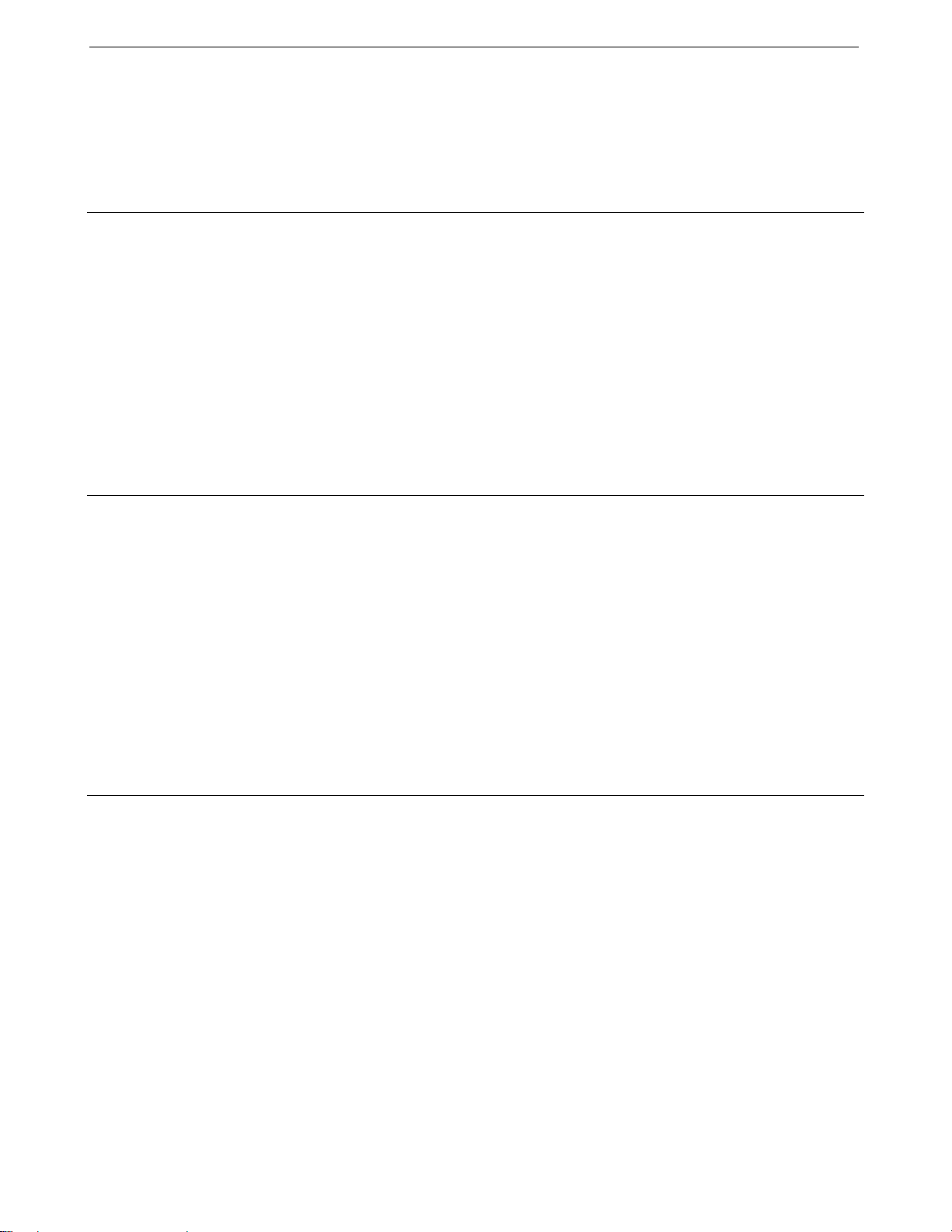

Dimensions and End Cap Connector

The SBE 38 is available with a 4-pin XSG or optional MCBH (wet-pluggable)

external connector.

Pin Signal

1 Common

2 RS-232 Receive or RS-485 A

3 RS-232 Transmit or RS-485 B

4 Power

Baud Rate and Cable Length

Note:

Baud rate is set with the BAUD=

command. See Command

Descriptions in Section 4:

Deploying and Operating RS-232

SBE 38 for command details.

For RS-232, the length of cable that the SBE 38 can drive for transmitting

real-time data is dependent on the baud rate. The allowable combinations are:

Maximum Cable Length (meters) Maximum Baud Rate

800 1200

400 2400

200 4800

100 9600

8

Page 9

Section 3: Preparing SBE 38 for Deployment

Section 3: Preparing SBE 38 for Deployment

This section describes the software installation and the pre-check procedure

for preparing the SBE 38 for deployment.

Installing Software

If not already installed, install SEATERM and other Sea-Bird software

programs on your computer using the supplied software CD:

1. Insert the CD in your CD drive.

2. Double click on Seasoft-Win32.exe.

Note:

It is possible to use the SBE 38

without SEATERM by sending

direct commands from a dumb

terminal or terminal emulator,

such as Windows HyperTerminal.

3. Follow the dialog box directions to install the software.

The default location for the software is c:/Program Files/Sea-Bird. Within that

folder is a sub-directory for each program.

Power and Communications Test

Locking

sleeve

Dummy plug or cable

Test Setup

1. If applicable, remove locking sleeve and dummy plug from bulkhead

2. Install the Sea-Bird I/O cable on the SBE 38:

3. Connect the I/O cable connector to your computer’s serial port.

4. Connect the I/O cable battery terminal clip to a 9-volt battery. Note that

connector:

A. By hand, unscrew the locking sleeve from the SBE 38’s bulkhead

connector. If you must use a wrench or pliers, be careful not to

loosen the bulkhead connector instead of the locking sleeve.

B. Remove the dummy plug from the SBE 38’s bulkhead connector by

pulling the plug firmly away from the connector.

• XSG Connector (shown in photos) - Align the raised bump on the

side of the connector with the large pin (pin 1 - ground) on the

SBE 38.

• MCBH Connector (optional) – Align the pins.

A 25-to-9 pin adapter is supplied for use if your computer has a 9-pin

serial port.

the 9-volt battery supplied with the SBE 38 will provide approximately

50 hours of operation.

9

Page 10

Section 3: Preparing SBE 38 for Deployment

Test

Note:

See SEATERM’s help files for

detailed information on the use

of the program.

1. Double click on SeaTerm.exe. If this is the first time the program is used,

the setup dialog box appears:

Select the instrument type (SBE 38) and the computer COM port for

communication with the SBE 38. Click OK.

2. The main screen looks like this:

Note:

There is at least one way, and as

many as three ways, to enter

a command:

• Manually type a command in

Command/Data Echo Area

• Use a menu to automatically

generate a command

• Use a Toolbar button to

automatically generate

a command

Note:

Once the system is configured and

connected (Steps 3 and 4 below),

to update the Status bar:

• on the Toolbar, click Status; or

• from the Utilities menu, select

Instrument Status.

SEATERM sends the status

command, which displays in the

Command/Data Echo Area, and

updates the Status bar.

Menus

Toolbar

Command/Data Echo Area

Capture

Status bar

Computer

Instrument

Instrument

EPROM version

• Menus – Contains tasks and frequently executed instrument

commands.

• Toolbar – Contains buttons for frequently executed tasks and

instrument commands. All tasks and commands accessed through the

Toolbar are also available in the Menus. To display or hide the

Toolbar, select View Toolbar in the View menu. Grayed out Toolbar

buttons are not applicable.

• Command/Data Echo Area – Echoes a command executed using a

Menu or Toolbar button, as well as the instrument’s response.

Additionally, a command can be manually typed in this area, from the

available commands for the instrument. Note that the instrument must

be awake for it to respond to a command (use the Connect button on

the Toolbar to wake up the instrument).

• Status bar – Provides status information. To display or hide the Status

bar, select View Status bar in the View menu.

COM port

Baud rate, data bits,

stop bits, and parity

10

to file

status –

grayed

out if not

capturing

Page 11

Section 3: Preparing SBE 38 for Deployment

Following are the Toolbar buttons applicable to the SBE 38:

Toolbar

Button

Connect

Status

Re-establish communications with SBE 38.

Computer responds with S> prompt.

Display instrument setup and status (number of

A/D cycles per sample, sampling status, etc.).

Description

Coefficients Display calibration coefficients.

Equivalent

Command*

(press Enter

key)

DS

DC

Capture instrument responses on screen to file.

Capture

File has .cap extension. Press Capture again to

turn off capture. Capture status displays in

—

Status bar.

Free computer COM port used to communicate

Disconnect

with SBE 38. COM port can then be used by

—

another program.

*See Command Descriptions in Section 4: Deploying a nd Oper at i n g

RS-232 SBE 38.

3. In the Configure menu, select SBE 38. The dialog box looks

like this:

Computer COM port, baud rate,

data bits, and parity for

communication between computer

and SBE 38

Note:

SEATERM’s baud rate must be the

same as the SBE 38’s baud rate

(set with BAUD=). BAUD= is factory-

set to 9600, but can be changed by

the user. See Command Descriptions

in Section 4: Deploying and

Operating RS-232 SBE 38 for details.

Interface for communication

between computer and

SBE 38

Make the selections in the Configuration Options dialog box:

• COMM Port: COM 1 through COM 10, as applicable

• Baud Rate: 9600 (documented on front cover of this manual)

• Data Bits: 8

• Parity: None

• Mode: RS-232 (Full Duplex) or RS-485 (Half Duplex)

Click OK to overwrite an existing configuration file, or click Save As to

save the configuration as a new filename.

11

Page 12

Section 3: Preparing SBE 38 for Deployment

4. Click the Connect button on the Toolbar. The display looks like this:

SBE 38 V 1.2 S/N 0090 (this line may not appear)

S>

This shows that correct communications between the computer and the

SBE 38 has been established.

If the system does not provide the S> prompt:

• Click the Connect button again.

• Verify the correct instrument was selected in the Configure menu and

the settings were entered correctly in the Configuration Options

dialog box. Note that the baud rate’s factory setting is documented on

the front cover of this manual.

• Check cabling between the computer and the SBE 38.

5. Display SBE 38 status information by clicking the Status button on the

Note:

See Appendix III: RS-485

Interface for details on sending

commands to an SBE 38 with

optional RS-485 interface.

Toolbar. The display looks like this:

SBE 38 V 1.2 S/N = 0090

NAVG=1

Not sampling data

Automatically start sampling on power up

Default interface is RS-232

6. Command the SBE 38 to take a sample by typing TS and pressing the

Enter key. The display looks like this if the output format was set to

converted data (FORMAT=C) with 4 digits to the right of the decimal

place (DIGITS=4):

23.7658

where 23.7658 = temperature in degrees Celsius

This number should be reasonable; i.e., room temperature.

The SBE 38 is ready for programming and depl oy ment.

12

Page 13

Section 4: Deploying and Operating RS-232 SBE 38

Section 4:

Deploying and Operating RS-232 SBE 38

Note:

See Appendix III: RS-485

Interface for details on deploying

and operating an SBE 38 with

optional RS-485 interface.

Sampling Modes

This section includes a discussion of system operation, example sets of

operation commands, and detailed command descriptions. It also provides

instructions for deploying and recovering the SBE 38.

The SBE 38 has two sampling modes:

• Polled Sampling – take a single sample on command

• Continuous Sampling – sample continuously; start when power is applied

or on command, depending on the setup

Descriptions and examples follow for an SBE 38 with RS-232 Interface. Note

that the SBE 38’s response to each command is not shown in the examples.

Review the sampling modes and the commands described in C ommand

Descriptions before setting up your system.

Polled Sampling

The SBE 38 takes one sample of data on command. Transmission of data to

the computer is dependent on the particular command used.

Example: (user input in bold)

Apply power and establish communications. Set up SBE 38 to average 4 measurements per sample and output

converted data with 3 digits after decimal place. Command SBE 38 to take a sample and send data to computer.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>DS (to verify setup)

S>TS

13

Page 14

Section 4: Deploying and Operating RS-232 SBE 38

Continuous Sampling

The SBE 38 continuously samples and transmits real-time data.

Sampling is started by:

• Sending the GO command, or

• Setting AUTORUN=Y. If AUTORUN=Y, sampling automatically starts

when power is applied.

Sampling is stopped by:

• Sending the STOP command, or

• Removing power.

Example: Continuous Sampling (user input in bold)

Example 1 AUTORUN=N: Apply power and establish communications. Set up SBE 38 to average 4 measurements

per sample and output converted data with 3 digits after decimal place. Set up to wait for a command when power is

applied. Remove power.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>AUTORUN=N

S>DS (to verify setup)

(Remove power.)

When ready to start sampling, apply power and establish communications. Send command to start sampling

continuously, outputting real-time data. When ready to stop sampling, send command.

(Apply power and then click Connect on Toolbar.)

S>GO

S>STOP (You may need to send command several times to interrupt SBE 38 sampling.)

Example 2 AUTORUN=Y: Apply power and establish communication. Set up SBE 38 to average 4 measurements

per sample and output converted data with 3 digits after decimal place. Set up to automatically begin sampling when

power is applied. Remove power.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>AUTORUN=Y

S>DS (to verify setup)

(Remove power.)

To start sampling, apply power. SBE 38 begins sampling continuously, outputting real-time data.

To stop sampling, remove power.

To change setup: apply power, and then stop sampling by command.

(Apply power)

(Press Enter key to get S> prompt)

S>STOP (You may need to send command several times to interrupt SBE 38 sampling.)

(Enter commands as desired to change setup.)

14

Page 15

Section 4: Deploying and Operating RS-232 SBE 38

Command Descriptions

This section describes commands and provides sample outputs.

See Appendix IV: Command Summary for a summarized command list.

When entering commands:

• Input commands to the SBE 38 in upper or lower case letters and register

commands by pressing the Enter key.

• The SBE 38 sends ? CMD if an invalid command is entered.

• If the system does not return an S> prompt after executing a command,

press the Enter key to get the S> prompt.

Note:

If the voltage is below 6.5 volts,

the following displays in

response to the DS command:

WARNING: LOW BATTERY

VOLTAGE!!

Status Command

DS Display status and setup parameters.

Example: (user input in bold).

S>DS

SBE 38 V 1.2 S/N = 0090 (firmware version, serial number)

NAVG=1 (number of A/D cycles to average for each sample [NAVG=])

Not sampling data (sampling status)

Automatically start sampling on power up (sampling start-up mode [AUTORUN=])

Default interface is RS-232 (RS-232 or RS-485 interface [INTERFACE=])

Equivalent to Status button on Toolbar.

Description in example includes, where applicable,

command used to modify parameter.

Note:

The SBE 38’s baud rate (set with

BAUD=) must be the same as

SEATERM’s baud rate (set in

Configure menu).

Note:

After you send AUTORUN=Y, to start

sampling immediately:

• Turn power off and then on again,

or

• Send the GO command.

Setup Commands

INTERFACE=x x=232: Set interface to RS-232.

x=485: Set interface to RS-485. See Appendix III:

RS-485 Interface for all details.

BAUD=x x= baud rate (1200, 2400, 4800, 9600).

Default 9600.

FORMAT=x x=C: Output converted data (°C).

x=R: Output raw data (counts).

DIGITS=x x= number of digits (0 – 6) to rig ht of decimal point

for converted temperature (°C). Applicable only if

FORMAT=C.

NAVG=x x= number of A/D cycles to average per sample

(1 – 127).

Time between samples (seconds)

= (0.133 * NAVG) + 0.339

(Time between samples for continuous sampling;

minimum time required for each polled sample.)

AUTORUN=x x=N: Wait for a command when power is applied.

x=Y: Start continuous sampling automatically when

power is applied.

15

Page 16

Section 4: Deploying and Operating RS-232 SBE 38

Notes:

• To capture real-time data to a file,

do this before starting sampling:

1. Click Toolbar’s Capture button.

2. Enter desired file name in

dialog box. Capture status

displays in status bar at bottom

of screen.

• If the SBE 38 is sampling data and

the voltage is less than 6.5 volts for

ten consecutive scans, the

SBE 38 halts sampling and sets

the status to low battery.

Note:

You may need to send the STOP

command several times to get the

SBE 38 to respond.

Notes:

• Date shown is when calibration

was performed. Calibration

coefficients are initially factory-set

and should agree with Calibration

Certificate shipped with SBE 38.

• See individual Coefficient

Commands below for definitions of

the data in the example.

Sampling Commands

These commands are used to request data from the SBE 38.

For all sampling commands:

• Output format is determined by FORMAT= and DIGITS=.

• Number of A/D cycles per sample is defined by NAVG.

GO Start sampling data continuously, and transmit data

real-time.

Time between samples (seconds)

= (0.133 * NAVG) + 0.339

STOP Stop continuous sampling. Press Enter key to get

S> prompt before entering command.

TS Take 1 sample and transmit data.

TH Take 1 sample and hold data in SBE 38 buffer.

SH Transmit data that was held in SBE 38 buffer.

SL Transmit data from last sample from

SBE 38 buffer.

SLT Transmit data from last sample from SBE 38

buffer, and then take 1 new sample and hold data

in buffer.

Calibration Coefficients Commands

DC Display calibration coefficients. Equivalent to

Coefficients button on Toolbar.

Example: Display coefficients for SBE 38 (user input in bold).

S>DC

SBE 38 V 1.2 S/N = 0090

Cal Date: 08-apr-96

A0 = -9.420702e-05

A1 = 2.937924e-04

A2 = -3.739471e-06

A3 = 1.909551e-07

Note:

F = floating point number

S = string with no spaces

The individual Coefficient Commands listed below modify a particular

coefficient or date:

TCALDATE=S

A0=F

A1=F

S=Temperature calibration date

F=Temperature A0

F=Temperature A1

A2=F F=Temperature A2

A3=F

F=Temperature A3

16

Page 17

Section 4: Deploying and Operating RS-232 SBE 38

Data Output Formats

Notes:

• Each line of output is followed by

a carriage return and line feed.

• For converted data, leading zeros

for temperature output are

suppressed, except for one zero

to the left of the decimal point

(for example, 0.1034).

• See Appendix III: RS-485

Interface for data output format

for an SBE 38 with optional

RS-485 interface.

Converted Data (FORMAT=C)

ttt.ttt

where:

t = temperature (degrees Celsius, ITS-90)

Number of digits to right of decimal point is defined by DIGITS=.

Raw Data (FORMAT=R)

nnnnnn.n

where:

n= counts

Deployment

CAUTION:

Do not use WD-40 or other

petroleum-based lubricants, as

they will damage the connector.

I/O cable

Locking sleeve

1. Install the I/O cable:

A. Lightly lubricate the inside of the cable connector with silicone

grease (DC-4 or equivalent).

B. XSG Connector (shown in photo) - Install the cable connector,

aligning the raised bump on the side of the connector with the large

pin (pin 1 - ground) on the SBE 38. Remove any trapped air by

burping or gently squeezing the connector near the top and moving

your fingers toward the end cap. OR

MCBH Connector (optional) – Install the cable connector,

aligning the pins.

C. Place the locking sleeve over the connector. Tighten the locking

sleeve finger tight only. Do not overtighten the locking sleeve and

do not use a wrench or pliers.

2. Mount the SBE 38.

3. Verify that the hardware and external fittings are secure.

4. Use one of the following sequences to start sampling:

• If AUTORUN=N: Send GO command to start sampling

continuously now, or TS or TH command to take a single sample.

• If AUTORUN=Y: Apply power to start sampling continuously now.

5. Deploy the SBE 38.

Recovery

WARNING!

Pressure housings may flood under

pressure due to dirty or damaged

o-rings or other failed seals, causing

highly compressed air to be trapped

inside. If this happens, a potentially

life-threatening explosion can occur

when SBE 38 is brought to surface.

If the SBE 38 is unresponsive to

commands or shows other signs of

flooding or damage, carefully secure

the SBE 38 in a location away from

people until it has been determined

that abnormal internal pressure

does not exist. Contact Sea-Bird for

assistance with procedures for

safely relieving internal pressure.

1. Use one of the following sequences to stop sampling:

• Press Enter key to get S> prompt, and then send STOP command to

stop sampling continuously. OR

• Remove power.

2. Rinse the SBE 38 with fresh water, and dry thoroughly.

17

Page 18

Section 5: Routine Maintenance and Calibration

Section 5: Routine Maintenance

and Calibration

This section reviews corrosion precautions, connector mating and

maintenance, and sensor calibration. The SBE 38’s accuracy is sustained

by the care and calibration of the sensor and by establishing proper

handling practices.

Corrosion Precautions

All exposed materials are titanium or plastic. No corrosion precautions are

required, but direct electrical connection of the SBE 38 housing to mooring or

other dissimilar metal hardware should be avoided. Rinse the SBE 38 with

fresh water after use and prior to storage.

Connector Mating and Maintenance

Mated connectors do not require periodic disassembly or other attention.

Inspect the connector when it is unmated for signs of corrosion product around

the pins. When remating:

1. Lightly lubricate the inside of the cable connector with silicone grease

CAUTION:

Do not use WD-40 or other

petroleum-based lubricants, as

they will damage the connector.

(DC-4 or equivalent).

2. XSG Connector - Install the cable connector, aligning the raised bump on

the side of the plug/cable connector with the large pin (pin 1 - ground) on

the SBE 38. Remove any trapped air by burping or gently squeezing the

connector near the top and moving your fingers toward the end cap. OR

MCBH Connector (optional) - Install the cable connector, aligning

the pins.

3. Place the locking sleeve over the cable connector. Tighten the locking

sleeve finger tight only. Do not overtighten the locking sleeve and do

not use a wrench or pliers.

Verify that a cable is installed on the SBE 38 before deployment.

18

Page 19

Section 5: Routine Maintenance and Calibration

Sensor Calibration

Sea-Bird sensors are calibrated by subjecting them to known physical

conditions and measuring the sensor responses. Coefficients are then

computed, which may be used with appropriate algorithms to obtain

engineering units. The temperature sensor on the SBE 38 is supplied fully

calibrated, with coefficients printed on the Calibration Certificate (see back of

manual). These coefficients have been stored in the SBE 38’s EEPROM.

We recommend that the SBE 38 be returned to Sea-Bird for calibration.

The primary source of temperature sensor calibration drift is the aging of the

thermistor element. Sensor drift is not substantially dependent upon the

environmental conditions of use, and — unlike platinum or copper elements

— the thermistor is insensitive to shock.

Sea-Bird’s Calibration Methodology

The SBE 38 is calibrated in Sea-Bird’s state-of-the-art calibration laboratory,

which maintains primary temperature standards (water triple point [TPW] and

gallium melting point [GaMP] cells), ITS-90 certified and standards-grade

platinum resistance thermometers, and a low-gradient temperature bath.

Temperature is computed using the Steinhart-Hart polynomial for thermistors

(Steinhart and Hart, 1968; Bennett, 1972), which is based on thermistor

physics. The equation characterizes the non-linear temperature versus

resistance response of the sensor. Note that thermistors require individualized

coefficients to the Steinhart-Hart equation, because the thermistor material is

an individualized mix of dopants:

t90 = 1.0

a0 + a1 * [ln(n)] + a2 * [ln

2

(n)] + a3 * [ln

where

n = SBE 38 raw output (counts).

3

(n)]

- 273.15 [°C]

19

Page 20

Glossary

Glossary

PCB – Printed Circuit Board.

SBE 38 – High-accuracy digital oceanographic thermometer.

SBE Data Processing – Sea-Bird’s Win 95/98/NT/2000/XP data

processing software, which calculates and plots measured and

derived variables. SBE Data Processing can be used to view and process the

entire data stream, including data from the SBE 38, when the SBE 38 is

integrated with the SBE 21 or 45 thermosalinograph.

Scan – One data sample.

SEASAVE – Sea-Bird’s Win 95/98/NT/2000/XP software used to acquire,

convert, and display real-time or archived raw data. SEASAVE can be used to

view and process the entire data stream, including data from the SBE 38, when

the SBE 38 is integrated with the SBE 21 or 45 thermosalinograph.

SEASOFT-DOS – Sea-Bird’s complete DOS software package, which

includes software for communication, real-time data acquisition, and data

analysis and display.

SEASOFT-Win32 – Sea-Bird’s complete Win 95/98/NT/2000/XP software

package, which includes software for communication, real-time data

acquisition, and data analysis and display. SEASOFT-Win32 includes

SEATERM, SeatermAF, SEASAVE, SBE Data Processing, and Plot39.

SEATERM – Sea-Bird’s Win 95/98/NT/2000/XP terminal program used to

communicate with the SBE 38.

20

Page 21

Appendix I: Functional Description

Appendix I: Functional Description

Sensor Interface

Temperature is acquired by applying an AC excitation to a hermetically sealed

VISHAY reference resistor and an ultra-stable aged thermistor with a drift rate

of less than 0.002°C per year. A 24-bit A/D converter digitizes the outputs of

the reference resistor and thermistor. AC excitation and ratiometric

comparison using a common processing channel avoids errors caused by

parasitic thermocouples, offset voltages, leakage currents, and reference errors.

Maximum power dissipated in the thermistor is 0.5 microwatts, and

contributes less than 200 µK of overheat error.

A raw count (ratio) is related to resistance measurements:

raw counts = 1048576 * (NT) / (NR)

where

NR = output from reference resistor

NT = thermistor output

The SBE 38’s output is computed from the raw count and the calibration

coefficients that are stored in EEPROM.

The number of acquisition cycles (raw counts) averaged per measurement is

user-programmable (NAVG= command; see Section 4: Deploying and

Operating RS-232 SBE 38). Increasing the number of cycles per measurement

increases the time to acquire the measurement and the interval between

measurements, while reducing the RMS temperature noise from the sensor.

The interval between measurements is:

interval [seconds] = (0.133 * NAVG) + 0.339

where

NAVG = number of acquisition cycles per measurement

Settings

Calibration coefficients and setup parameters (BAUD=, NAVG=,

INTERFACE=, etc.) are written to EEPROM and are non-volatile. These

settings do not change if power is removed.

21

Page 22

Appendix II: ?

Appendix II: Electronics Disassembly/Reassembly

1. Remove the titanium end cap and electronics from the housing as follows:

A. Wipe the outside of the end cap and housing dry, being careful to

remove any water at the seam between them.

B. Unscrew the end cap.

C. Pull the end cap and attached electronics out of the housing. Note that

the PCB is electrically connected to the I/O connector.

Note:

Before delivery, a desiccant bag is

placed in the housing, and the

electronics chamber is filled with dry

Argon gas. These measures help

prevent condensation.

To ensure proper functioning:

1. Install a new desiccant bag

each time you open the

housing. If a new bag is not

available, see Application

Note 71: Desiccant Use and

Regeneration (drying).

2. If possible, dry gas backfill each

time you open the housing. If you

cannot, wait at least 24 hours

before redeploying, to allow the

desiccant to remove any moisture

from the chamber.

D. Remove any water from the end cap O-ring and mating surfaces

inside the housing with a lint-free cloth or tissue.

E. Be careful to protect the O-ring from damage or contamination.

2. Reinstall the end cap and electronics in the housing as follows:

A. Remove any water from the O-ring and mating surfaces in the

housing with a lint-free cloth or tissue. Inspect the O-ring and mating

surfaces for dirt, nicks, and cuts. Clean as necessary. Apply a light

coat of O-ring lubricant (Parker Super O Lube) to O-ring and

mating surfaces.

B. Carefully fit the electronics into the housing.

C. Screw the end cap into the housing.

End cap

O-ring

22

Page 23

Appendix III: RS-485 Interface

Appendix III: RS-485 Interface

Operation Description

Commands can be directed to one SBE 38 or globally to all SBE 38s. If

IDREQ=Y, a command prefix (#ii) is used to direct commands to an SBE 38

with the same ID (ii = ID). Global commands do not use a prefix, regardless of

the setting for IDREQ=, and are recognized by all SBE 38s attached to the

RS-485 interface.

An example follows for a system with two SBE 38s (IDs 01 and 02)

online. Note that the SBE 38’s response to each command is not shown

in the example. Review the commands described in Command Descriptions

and the example below before setting up your system.

Example: Wake up all SBE 38s. Set up all SBE 38s to average 4 measurements per sample and output converted

data with 3 digits to the right of the decimal place. Command all SBE 38s to take a sample and hold data in

buffer, and then command each SBE 38 to transmit data from buffer. Repeat sampling sequence a number of

times. (user input in bold)

(Apply power and click Connect on Toolbar to wake up all SBE 38s.)

S>IDREQ=Y (global command to require ID prefix)

S>#01NAVG=4 (set number of measurements per sample to 4 for SBE 38 with ID=01)

S>#02NAVG=4 (set number of measurements per sample to 4 for SBE 38 with ID=02)

S>#01FORMAT=C (set output format to converted data for SBE 38 with ID=01)

S>#02FORMAT=C (set output format to converted data for SBE 38 with ID=02)

S>#01DIGITS=3 (set number of digits to right of decimal point to 3 for SBE 38 with ID=01)

S>#02DIGITS=3 (set number of digits to right of decimal point to 3 for SBE 38 with ID=02)

S>#01DS (verify setup with status command for SBE 38 with ID=01)

S>#02DS (verify setup with status command for SBE 38 with ID=02)

S>GDATA (global command to all SBE 38s to take sample and hold data in buffer)

S>DATA01 (get data from buffer of SBE 38 with ID=01)

S>DATA02 (get data from buffer of SBE 38 with ID=02)

(Repeat GDATA through DATA02 commands as desired)

23

Page 24

Appendix III: RS-485 Interface

Command Descriptions

RS-485 Commands

Note:

For reliable operation, all commands

may need to be preceded with two @

characters to clear the buffers.

Example (status command for

SBE 38 with ID=01):

S>@@#01DS

Example 1: Multiple RS-485 instruments on 1 pair of wires (user input in bold)

S>IDREQ=Y (global command to require ID prefix)

S>#01NAVG=4 (set number of A/D cycles to average for SBE 38 with ID=01)

S>#02NAVG=4 (set number of A/D cycles to average for SBE 38 with ID=02)

S>#01DS (verify setup with status command for SBE 38 with ID=01)

S>#02DS (verify setup with status command for SBE 38 with ID=02)

Example 2: Only 1 SBE 38 on 1 pair of wires (user input in bold)

S>IDREQ=N (global command to require ID prefix)

S>NAVG=4 (set number of A/D cycles to average for SBE 38, no ID required as part of command)

S>DS (verify setup with status command for SBE 38, no ID required as part of command)

Global Commands

Global commands are recognized by all SBE 38s attached to the

RS-485 interface.

IDREQ=x x=Y: Precede commands to individual SBE 38s

with #ii, where ii= ID (ii = 0 -99). Use this setting

for systems with multiple RS-485 instruments on

1 pair of wires. Note that the use of a prefix does

not apply to Global, Get Data, or ID commands.

x=N: Do not precede commands to individual

SBE 38s with #ii. Use this setting for systems with

only 1 SBE 38.

Note:

GDATA and ADATA perform the

same function in the SBE 38.

Both are included here to provide

compatibility with RS-485 MicroCATs.

TXDELAY=x x= delay after SBE 38 transmits a reply until

SBE 38 transmitter is disabled

(1 – 500 milliseconds). Default 25 milliseconds.

RXDELAY=x x= delay after SBE 38 receives a command

until SBE 38 transmitter is enabled

(1 – 500 milliseconds). Default 25 milliseconds.

GDATA Command all SBE 38s to take 1 sample and hold

data in SBE 38 buffer until receiving:

DATAii;

SH, SL, or SLT (if IDREQ=N); or

#iiSH, #iiSL, or #iiSLT (if IDREQ=Y).

ADATA Command all SBE 38s to take 1 sample and hold

data in SBE 38 buffer until receiving:

DATAii;

SH, SL, or SLT (if IDREQ=N); or

#iiSH, #iiSL, or #iiSLT (if IDREQ=Y).

Get Data Command

DATAii Get data obtained with GDATA or ADATA

command from SBE 38 with ID = ii (ii = 0 -99).

24

Page 25

Appendix III: RS-485 Interface

ID Commands

Only one SBE 38 can be online when sending these commands.

ID? Display SBE 38 ID (ID = ii, where ii= 0-99) and

whether ID is required as a prefix for commands to

individual SBE 38s (see IDREQ= command).

*ID=ii Set SBE 38 ID to ii, where ii= 0-99. This command

must be sent twice, because the computer requests

verification. If more than one RS-485 instrument

is online when sending this command, all

instruments online will be set to same ID.

All Other Commands

All other commands (status, setup, sampling, and coefficients) are listed

in Section 4: Deploying and Operating RS - 23 2 SBE 38 and in

Appendix IV: Command Summary.

Notes on use of these commands for an SBE 38 with RS-485 interface:

• Effect of IDREQ= command:

If IDREQ=Y, precede these commands with #ii (ii = 0 – 99) to direct a

command to a particular SBE 38.

If IDREQ=N, do not precede these commands with #ii. This setting

works only for a system with one SBE 38.

• The RS-485 interface cannot accommodate multiple instruments

transmitting real-time data at the same time. Therefore, do not set

AUTORUN=Y (start sampling continuously when power is applied) for a

system with more than one RS-485 instrument on a pair of wires.

Similarly, do not attempt to send the GO command to multiple SBE 38s

on a pair of wires, as the system cannot transmit a command to one

instrument while another instrument is transmitting real-time data.

• If AUTORUN=Y (sample continuously when power is applied), set

NAVG= (A/D cycles to average per sample) to a value greater than 30.

Data Output Formats

Notes:

• Each line of output is followed by

a carriage return and line feed.

• For converted data, leading zeros

for temperature output are

suppressed, except for one zero

to the left of the decimal point

(for example, 0.1034).

Converted Data (FORMAT=C)

Output from continuous sampling: ttt.ttt

Output from DATAii, #iiTS, TS, #iiSH, SH, #iiSL, SL, #iiSLT,

or SLT command: ii, sssss, ttt.ttt

where:

! t = temperature (°C, ITS-90)

(number of digits to right of decimal point is defined by DIGITS=)

! ii = ID (0 – 99)

! sssss = SBE 38 serial number

Raw Data (FORMAT=R)

nnnnnn.n

where:

n = counts

25

Page 26

Appendix III: RS-485 Interface

Wiring

The MAX1483 transceivers used in the SBE 38 are designed for bi-directional

data communications on multi-point bus transmission lines. To minimize

reflections, terminate the line at both ends in its characteristic impedance.

Also, keep stub lengths off the main line as short as possible (although the slewrate-limited MAX1483 is more tolerant of imperfect termination than standard

RS-485 ICs).

Optional

RS-485

terminating

resistor

solder

points

Conversion of RS-232 to RS-485 or RS-485 to RS-232

Sea-Bird supplies the SBE 38 with the correct wiring from the I/O connector

Notes:

• See Appendix II: Electronics

Disassembly / Reassembly to

access the PCB.

• Send the INTERFACE=232 or

INTERFACE=485 command to

program the SBE 38 to match the

wired configuration.

to the Printed Circuit Board (PCB) for your ordered configuration (standard

RS-232 or optional RS-485). If desired, you can modify the wiring to change

the configuration:

For RS-485 interface, connect:

• Pin 2 (black) to A

• Pin 3 (green) to B

For RS-232 interface, connect:

• Pin 2 (black) to RX

• Pin 3 (green) to TX

For RS-232 interface

For RS-485 interface

26

Page 27

Appendix IV: Command Summary

Appendix IV: Command Summary

CATEGORY COMMAND DESCRIPTION

Notes:

• See Command

Descriptions in Section 4:

Deploying and Operating

RS-232 SBE 38 for detailed

information and examples.

• See Appendix III:

RS-485 Interface for

RS-485 commands.

Status DS

INTERFACE=x

BAUD=x

FORMAT=x

Setup

DIGITS=x

NAVG=x

AUTORUN=x

GO

STOP

TS

Sampling

TH

SH

SL

SLT

Coefficients

(F=floating point

number; S=string

with no spaces)

Date shown is

when calibration

was performed.

Calibration

coefficients are

initially factory-set

and should agree

with Calibration

Certificate shipped

with SBE 38.

DC

CALDATE=S

A0=F

A1=F

A2=F

A3=F

Display status and setup parameters.

x=232: RS-232 interface.

x=485: RS-485 interface.

x= baud rate (1200, 2400, 4800, 9600,

19200, 38400). Default 9600.

x=C: Output converted data (°C).

x=R: Output raw data (counts).

x= number of digits (0 – 6) to right of

decimal point for converted

temperature (°C). Applicable only if

FORMAT=C

x= A/D cycles to average per sample

(1 – 127).

x=N: Wait for a command when

power applied.

x=Y: Start continuous sampling

automatically when power applied.

Start continuous sampling now.

Stop continuous sampling.

Press Enter key to get S> prompt

before entering command.

Take 1 sample and transmit data.

Take 1 sample and hold data in buffer.

Transmit data that was held in buffer.

Transmit data from last sample from

buffer.

Transmit data from last sample from

buffer, and then take 1 new sample and

hold data in buffer.

Display calibration coefficients; all

coefficients and dates listed below are

included. Use individual commands

below to modify a particular

coefficient or date.

S=Temperature calibration date.

F=Temperature A0.

F=Temperature A1.

F=Temperature A2.

F=Temperature A3.

27

Page 28

Appendix IV: Replacement Parts

Appendix V: Replacement Parts

Part

Number

231361

30931

801093

801206

17130 25-pin to 9-pin adapter

17046 4-pin dummy plug For SBE 38 (XSG) connector 1

17043

171398 4-pin dummy plug

171192

O-ring, Parker 2-214

25-pin DB-25S I/O cable

9-pin DB-9S I/O cable

I/O connector/dummy plug

I/O connector/dummy plug

Part Application Description

Plastic temperature

sensor guard

N674-70

4-pin RMG-4FS to

with battery snap,

2.4 m (8 ft) long

4-pin MCIL4FS to

with battery snap,

2.4 m (8 ft) long

locking sleeve

locking sleeve

Screws to end cap to protect

temperature sensor

Placed in end cap groove for

watertight seal

From SBE 38 (XSG) to computer 1

From SBE 38 (wet-pluggable) to

computer

Connects I/O cable to 9-pin COM

port on computer

For use with 17046 1

For SBE 38 (wet-pluggable)

connector

For use with 171398 1

Quantity in

SBE 38

1

1

1

1

1

28

Page 29

Index

Index

A

About Sea-Bird · 4

B

Baud rate · 8

C

Cable length · 8

Calibration · 19

Command summary · 27

Commands

coefficients · 16

descriptions · 15

get data · 24

global · 24

ID · 25

RS-485 · 24

sampling · 16

setup · 15

status · 15

Communication defaults · 11

Connector · 8, 18

Continuous sampling · 14

Corrosion precautions · 18

D

Data output formats · 17, 25

Deployment

installation · 17

preparing for · 9

Description · 6

Desiccant · 22

Dimensions · 8

Disassembly / reassembly · 22

E

Electronics · 22

F

Format

data output · 17, 25

Functional description · 21

M

Maintenance · 18

Modes · See Sampling modes

O

Operation description · 23

P

Parts

replacement · 28

Polled sampling · 13

Q

Quick start · 4

R

Recovery

physical handling · 17

Replacement parts · 28

RS-232 · 13

conversion to RS-485 · 26

RS-485 · 23

conversion to RS-232 · 26

wiring · 26

S

Sampling modes · 13

continuous · 14

polled · 13

SBE Data Processing · 6

SEASAVE · 6

SEASOFT-DOS · 6

SEASOFT-Win32 · 6, 9

SEATERM · 6, 9, 10

main screen · 10

toolbar buttons · 11

Sensor · 7

Settings · 21

Software · 6

installation · 9

Specifications · 7

System description · 6

G

Glossary · 20

L

Limited liability statement · 2

T

Testing · 9

U

Unpacking SBE 38 · 5

29

Loading...

Loading...