Page 1

Installation Instructions

P/N: 75-5068 / 75-5068D

Approx. Install Time 3Hrs 00Min

Vehicle Application

Year: 2013 - 2014

Make: Ram

Model: 2500/3500 Diesel

Engine: 6.7L Cummins

Notes

Kit may not fit with the following

Aftermarket Parts installed:

Body Lift or Lowering Kit

•

Custom Hood

•

Intercooler or Turbo upgrades

•

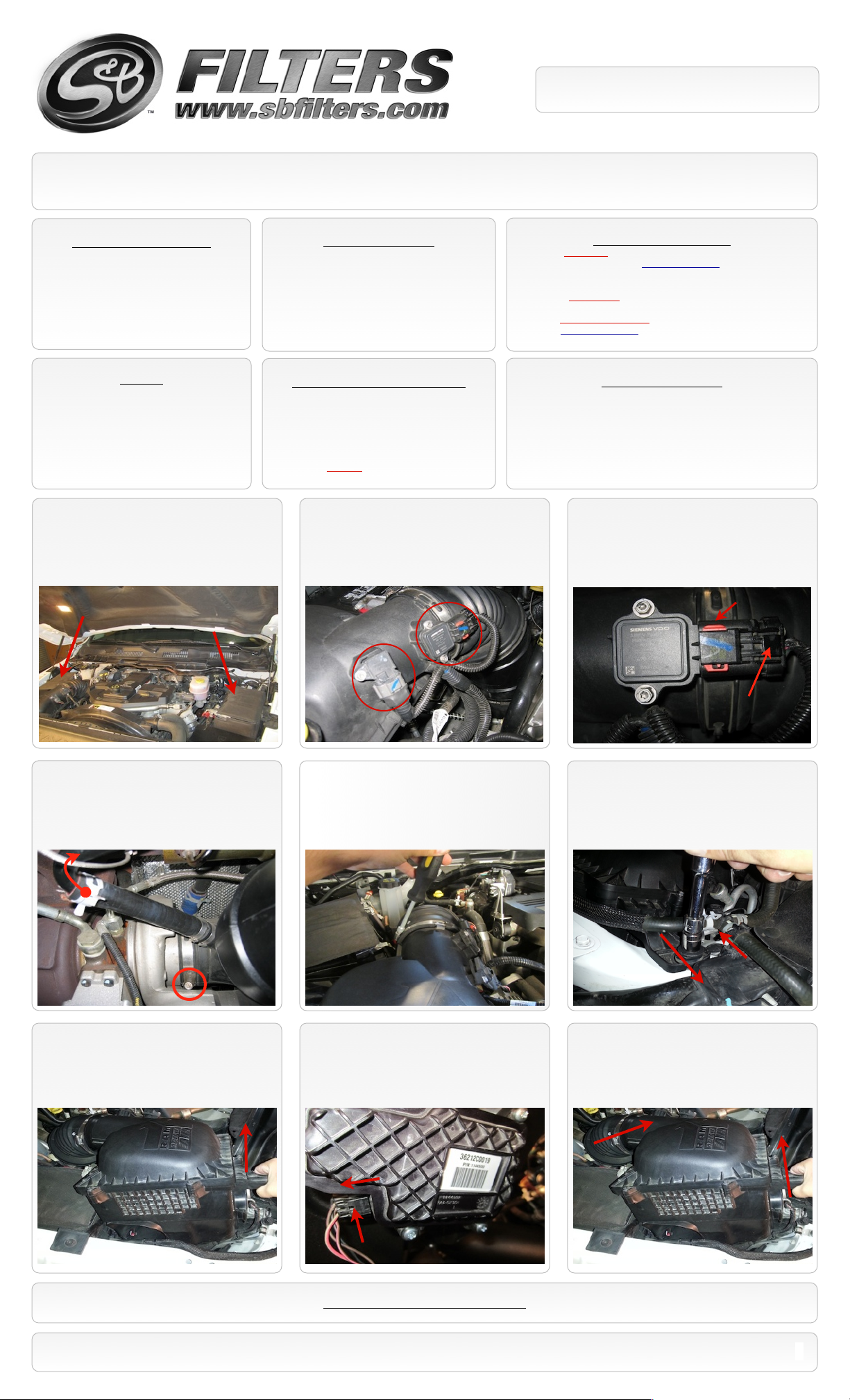

1. With the ignition switched off and the

parking brake set, disconnect the negative

battery cables on both batteries.

Tools Required

7mm, 8mm, 10mm,& 13mm Wrench & Socket

•

1/8” Allen Key (Supplied w/ Kit), 3/16” Allen Key

•

T27 Security Torx Wrench

•

5/16” Nut Driver or Flat Blade Screwdriver

•

Phillips Screwdriver, Pliers or Channel locks

•

5/16” Drill bit and Drill

•

Electrical Tape

•

Razorblade

•

CARB Status - Pending

Product will be submitted to Air Resources

Board for approval shortly.

Not legal for use in CA or other states

adopting CA emissions standards See

Page 6 for more info.

2. Disconnect the electrical connection for the

Intake Air Temp. (IAT) Sensor and the Mass Air

Flow (MAF) Sensor then unsnap the wire loom

from the tube. (See the next step for removal)

Cleanable (KF-1037). If the enclosed filter is Red, it came pre-oiled

from the factory. Please visit www.sbfilters.com for exact oil

amount required after cleaning.

Disposable (KF-1037D). If the enclosed filter is White, it is a

disposable filter and should be discarded once it reaches capacity.

This filter (does not require oil). For more info on S&Bʼs disposable

filter, visit www.sbfilters.com.

Before You Start

S&B Filter Maintnance

Please read the entire product guide before proceeding.

•

Ensure all components listed on page 4 are present.

•

If you are missing any of the components, call customer support

•

at (909) 947-0015.

Do not work on your vehicle while engine is hot.

•

Make sure the engine is turned off and the vehicle is in Park or

•

the Parking Brake is set.

3. For the MAF sensor, slide the red locking

tab up then depress the black lever while

disengaging the connector. For the IAT

sensor just depress the grey lever while

disengaging the connector.

Locking Tab

4. Loosen the hose clamp at the turbo inlet,

next pinch the spring clamp and slide it up the

steel piping. Then disconnect the silicone

hose from the steel piping and remove spring

clamp.

7. Lift up on factory air box, be careful not to

remove the whole box because the swing gate

motor harness is still connected on the side of the air

box. Remember to move the hose forward from Step

6 when pulling out the box.

5. Loosen the hose clamp on the intake

tube to assist with the removal of the air box.

8. Disconnect the factory swing gate motor

connector that is located on the side of the

factory air box. Press in the locking button on

the connector and pull out.

Lever

6. Remove factory retaining bolt on the front of

the factory air box. Once retaining bolt is

removed disconnect hose clip by pulling up and

then move hose forward to help remove air box.

(See Below)

9. Once the swing gate motor is

disconnected completely remove the factory

air box and intake tube by lifting up and out.

SEE EXPLODED VIEW ON PAGE 7

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

1

Page 2

Installation Instructions (continued)

P/N: 75-5068 / 75-5068D

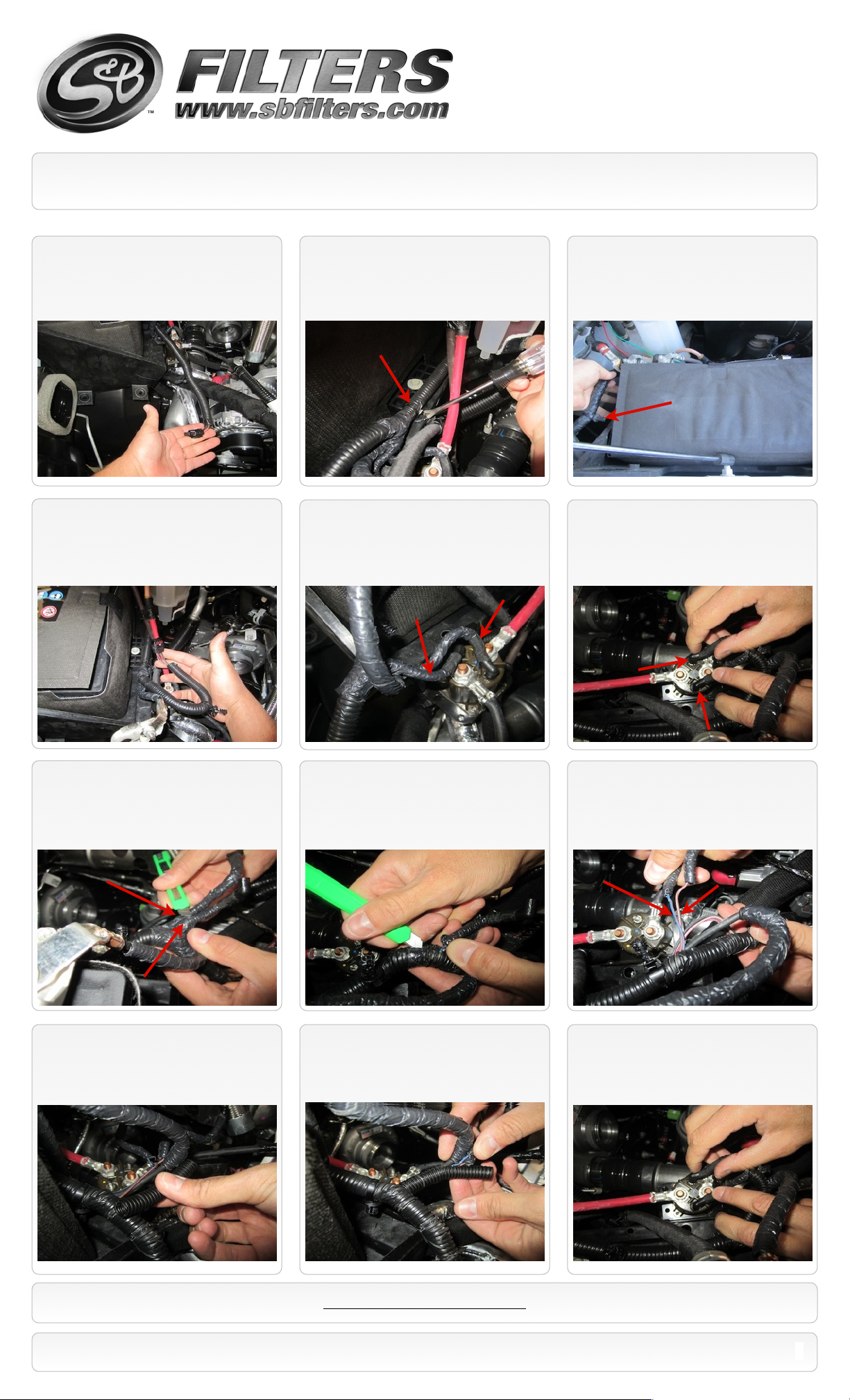

10. Once the factory air box and intake tube

are removed the swing gate motor harness

must be modified for the harness to reach the

S&B air box.

13. Once the push pins are pulled out the

harness can be pulled out further.

11. First remove the harness push pins that

hold the harness down to the battery tray

using a pry tool or flat head screw driver.

14. Pull the harness until it is stopped by

these wires hooked up to the relay

component.

12. Remove the push pins on the harness

that are located on the side and back of the

battery tray.

15. Disconnect the wires from the relay component by

pulling them off. Please take note on which wire was

connected to which terminal because these wires will be

reconnected after modification. Please mark each wire

or take a photo to help remember the wire connections.

16. Cut into the base of the insulation on

each line being careful not the cut or damage

the wires inside.

19. Use the provided insulated sleeve (AC)

to insulate both wires together. The insulated

sleeve gives the wires added protection.

17. Once the insulation is cut at the base of

each line carefully cut into the main harness

and again be careful not to cut or damage the

wires inside.

20. Install the insulated sleeve (AC) over both

wires, this extra length will let the harness extend

and reach the S&B air box. Re-apply electrical tape

to any exposed wires and sleeve to avoid corrosion.

18. Once the insulation is cut pull a length

of about 3 inches for each line.

21. Once both lines are insulated with the

provided insulation sleeve reconnect each

wire to the correct terminal on the relay

component.

SEE EXPLODED VIEW ON PAGE 7

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

2

Page 3

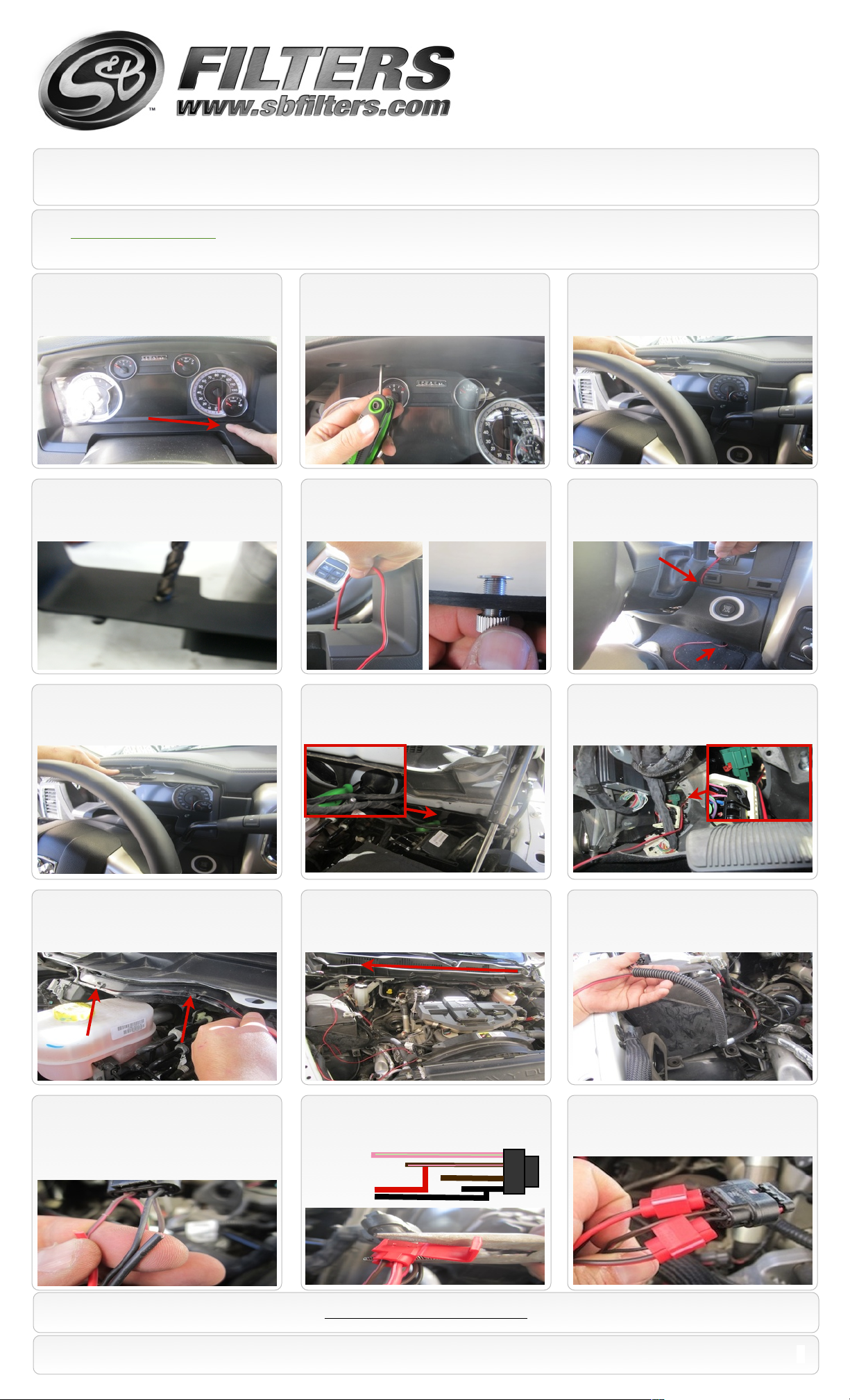

Installation Instructions (continued) (Optional Step)

P/N: 75-5068 / 75-5068D

LIGHT WIRE

Swing Gate Motor Harness

22. Active Monitoring Light Install Light may be installed if desired, we recommend on the trim of the instrumentation panel inside the cab (Warning:

drilling of the instrument panel will be required)

A. Choose a location to drill a hole to install

the monitoring light.

D. Carefully drill a hole using a 5/16” drill bit, use

lower rpm speeds and start hole with smaller bits

like a 1/8” or 3/16” to avoid damage to panel.

B. Remove panel by first removing the 4 Torx

screws under top part of instrument panel.

E. Install monitoring light (AD) into the drilled out

hole, screw the locking nut onto the back of the

panel by running the wire through the nut.

C. Once Torx are removed pull down and out

to remove panel. (lowering of shifter and

steering wheel may be required).

F. Before re-installing the panel run the

indicator light wire down through the steering

column to the bottom of the dash.

G. Reinstall panel, again steering column and

gear shifter may need to be lowered to install

panel.

J. Pull wire through fire wall and run wire

through the vehicles wire/cable guard. A

screwdriver may be needed to unlock tabs.

H. From under the hood on the driver side firewall,

carefully insert a screw driver on the side of the

rubber boot to help run the indicator wire through.

K. Below is a photo of the wire being ran

through the wire/cable guard. Remember to

lock tabs when finished running wire through.

I. From under the dash run the wire through fire wall

to the outside were the screw driver enters the

firewall, use zip ties to fasten down the indicator wire

as needed.

L. Once done running the wire through the guard,

run wire down along the side of the battery. It is

recommended to run the wire through the swing

gate motor harness.

M. This is a photo of how the indicator wire

will be connected into the swing gate motor

harness wires. The Red will connect to the

Brown w/Pink and the Black will connect to

the Black wire. (See illustration on next step)

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

N. Use the provided tap connectors (AE) to tap both

wires together using pliers. Tap the RED wire into the

Brown w/Pink wire and tap the Black into the Black wire

on the harness.

INDICATOR

SEE EXPLODED VIEW ON PAGE 7

M. Photo of finished harness with the correct wire

taps. It is recommended to use zip ties on lose wires

and to also use electrical tape over the tap

connectors for added protection.

3

Page 4

Installation Instructions (continued)

P/N: 75-5068 / 75-5068D

23. Remove the MAF sensor and IAT

Sensor from the factory air box by removing

the three factory bolts.

26. A good amount of force may be required to

remove the motor from the factory air box. The motor

shaft may need to be rotated while removing from the

factory butterfly valve in the factory air box. Grab both

the butterfly valve and motor and twist while pulling out.

24. Place MAF sensor and IAT Sensor onto

the S&B intake tube (X) using the 8-32 pan

head screws (U) and gaskets (V&W).

27. Mount the swing gate motor onto the

bottom of the S&B intake air box (I) using

spacers (K) and screws (M) and washers

(BB).

25. Remove the swing gate motor (L) from

the side of the factory air box using a T-27

torx key.

28. Construct the S&B Swing Gate Dam to Arm (N&S)

using the provided hardware (O,P,&R) and using the provided

Allen key (AB). If you desire to have both inlets open in the

air box skip this step. Warning: The Dam (N) must be

installed during harsh weather including but not limited to

rain, ice, sleet or snow; or engine damage could result.

29. When placing the swing gate arm (S) onto

motor (L) please make sure the flat side of the swing

gate arm is placed correctly on the flat side of the

motor shaft. Push down on diverter base all the way

down till it snaps into place.

31. Install the provided inlets (G&J) and tube seal

(Q) into the S&B air box (I) by inserting and

snapping into place. A bit of force and effort may be

necessary to install inlets and seal. Line up each

part with the dot on the box.

30. Note: Do NOT remove Swing Gate Arm (S)

after installing it to the motor as this could

damage the snap in feature of the arm. If

removal of Dam (N) is desired, remove with Arm

(S) installed on motor (L).

32. Install the hose (T) with (Y) hose clamps. Next

install coupler (Z) and hose clamps (AA) onto the

S&B intake tube (X). Remember to only tighten hose

clamps (Y) and (AA) on the tube side.

Warning: Never operate the vehicle with

the Swing Gate Arm (S) removed or a

Active Air Box Error will result & require

the motor to be sent to S&B to be reset.

The Dam (N) can be removed during

good weather conditions. See #28

above.

33. Install S&B intake tube (X) into S&B air

box (I) by sliding the tube through the tube

seal (Q). This should be a snug fit. A perfect

seal is not required.

SEE EXPLODED VIEW ON PAGE 7

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

4

Page 5

Installation Instructions (continued)

P/N: 75-5068 / 75-5068D

34. Place the S&B air box with air tube

assembly into vehicle.

Read step 35 before continuing with #34

36.(b) Reach under the air box to feel if the

posts pushed through the holes (grommets).

Be careful not to push to hard or the tabs will

break off the battery tray.

35. Before installing the air box and tube

assembly attach the swing gate harness

connector to the swing gate motor (L) that is

located underneath the S&B air box.

37. After dropping in the box move hose

forward to let the box drop down completely.

Once box is dropped flush reconnect hose

clip to the vehicle.

36.(a) When fitting the S&B intake box into

the vehicle please make sure that the stand-off

post on the bottom of the air box fit properly into

the holes on the air box tray in the vehicle.

38. Push down on air box and tighten the

provided retaining bolt (H).

39. Connect hose (T) and tighten hose

clamp (Y).

42. Install the filter (E), please make sure to

install with flat side up and feed the filter onto

tube and push down. Once installed tighten

hose clamp.

40. Connect coupler (Z) to turbo and tighten

hose clamp (AA). Please make sure the

coupler is push all the way onto turbo before

tightening completely.

43. Install the provided edge trim (C) around

lid (D)

41. Reconnect the MAF and IAT sensor.

44. Once edge trim is installed roll the sides

of the lid on a flat surface to ensure a tight

seal.

SEE EXPLODED VIEW ON PAGE 7

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

5

Page 6

Installation Instructions (continued)

P/N: 75-5068 / 75-5068D

1/4” hardware (A&B).

Our active monitoring light

alerts you when the ram-air

gate is open.

46. Reconnect both batteries

Precision II

Filter Cleaning & Oiling

47. The Installation is now complete.45. Install the lid (C) using the provided

RELATED ITEMS FOR YOUR

PURCHASE

Replacement Air Filter (Oiled)

•

(S&B P/N: KF-1037)

Replacement Air Filter (Dry)

•

(S&B P/N: KF-1037D)

Air Filter Wrap (S&B P/N: WF-1037)

•

Order online today at www.sbfilters.com or

through your local S&B distributor.

Part #: 88-0008

Performance Testing

Engage parking brake and start your engine. Listen for abnormal noises. If an air leak is detected, re-inspect hoses and connections as they may need to be repositioned and

•

tightened.

S&B FILTERS recommends that you keep your OE intake system in the event it is required in the future.

•

In order to maintain your warranty, all connections and components must be checked periodically for alignment and for proper tension on all connections. Failure to do so

•

may void your warranty.

Use only S&B FILTERS cleaning and oil products to service your filter. Using any other brand oil and or cleaners on your S&B air filter may void your warranty.

•

Warning!

If your vehicle has a Vehicle Emission Control Information decal affixed to the factory airbox, a new

replacement label must be obtained and installed in a readily visible position in the engine compartment in

order to remain CARB compliant. Failure to do so will prevent the vehicle from passing a smog check.

Replacement labels can be ordered from your local dealership. Regulations state that the VECI label shall

not be affixed to any equipment which is easily detached from the vehicle. Label placement, under the hood

on a painted surface is recommended.

Emissions Standard

The California Air Resource Board (CARB) requires that an E.O. identification label be applied to the vehicle in order to pass a smog check inspection when a Performance

Intake Kit has been installed. You must place the E.O. label provided on or near the intake kit after installation so that a smog check technician can easily verify the E.O. number.

As of April 2009, S&B has never had a product where CARB denied an exemption request; however, the exemption process with CARB can take as long as 18 months. Check

the status of the exemption process by looking up a specific part number at www.sbfilters.com. The CARB Exemption number and/or status is listed under the Product Details

section for each part number. If the status shows as “Pending,” CARB has yet to issue an exemption but the product has been submitted. Products that have not been issued an

EO number are street legal in most states, but may not be used on emission controlled vehicles in the state of California and are for off road use only. If you purchased your kit

from S&B Filters directly, we will automatically mail you your Exemption Sticker when it is issued to us. If you purchased your kit from an authorized S&B Filters Dealer, log onto

our web site and register to receive your Exemption Sticker.

SEE EXPLODED VIEW ON PAGE 7

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

6

Page 7

ITEM

QTY.

DESCRIPTION

P/N

A4S.S. Screw #10-24 x1/2”

AI1539-00

B4Sealing Washer #10

AI1540-00

C1Edge Trim

AI1620-01

D1Lid

AI1613-00

E1S&B Air Filter

KF-1037F1

Filter Hose Clamp #72

AG1009-00

G1Side Inlet Seal

AI1610-00

H1S.S. Allen Head M8

AI1369-00

I1Air Box

AL1218B-00

J1Front Inlet Seal

AI1610-00

K4Spacer

AI1621-00

L1Factory Swing Gate Motor

------------------

M4Screw #10-24 x 1.75”

AI1619-00

N1Swing Gate Dam

AI1623-00

O4Flat Washer #10

AI1226-00

P2Screw S.S. #10-24 x 3/4”

AI1624-00

Q1Tube Seal

AI1614-00

ITEM

QTY.

DESCRIPTION

P/N

R2Locknut 10-24

AI1047-00

S1Swing Gate Arm

AI1622-00

T1Hose 3/4” x 7”

AI1040-05

U3S.S. Pan Head Screw 8-32 x 1/2”

AI1479-00

V1Gasket MAF

AI1301-00

W1Temp Gasket

AI1302-00

X1Intake Tube

AL1218-00

Y2Hose Clamp #12

AG1030-00

Z1Silicone Adapter, 4.10”IDx2.00”

AI1029C-00

AA2Hose Clamp #64

AG1018-00

BB4Sealing Washer #10 S.S

AI1273-00

PARTS BELOW ARE NOT IN VIEW

AB1Hex Allen Key 1/8”

AI1634-00

AC1Insulation Sleeve 6.0”

AI1625-01

AD1Monitor Light 4M Red/Blk Wire

AI1627-00

AE23M Quick Splice

AI1628-00

AF5Zip Ties

AI1212-00

Exploded View

AM0174-00 Rev.C 12/23/13

P/N: 75-5068 / 75-5068D

Warranty

Visit www.sbfilters.com for complete warranty information.

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

7

Loading...

Loading...