Page 1

Installation Instructions

P/N: 75-5040 / 75-5040D

Vehicle Application

Year: 2003-08

Make: DODGE/ RAM

Model: 1500

Engine: 5.7L Hemi

Notes

Kit may not fit with the following

Aftermarket Parts installed:

Body Lift or Lowering Kit

•

Custom Hood

•

Throttle body upgrades

•

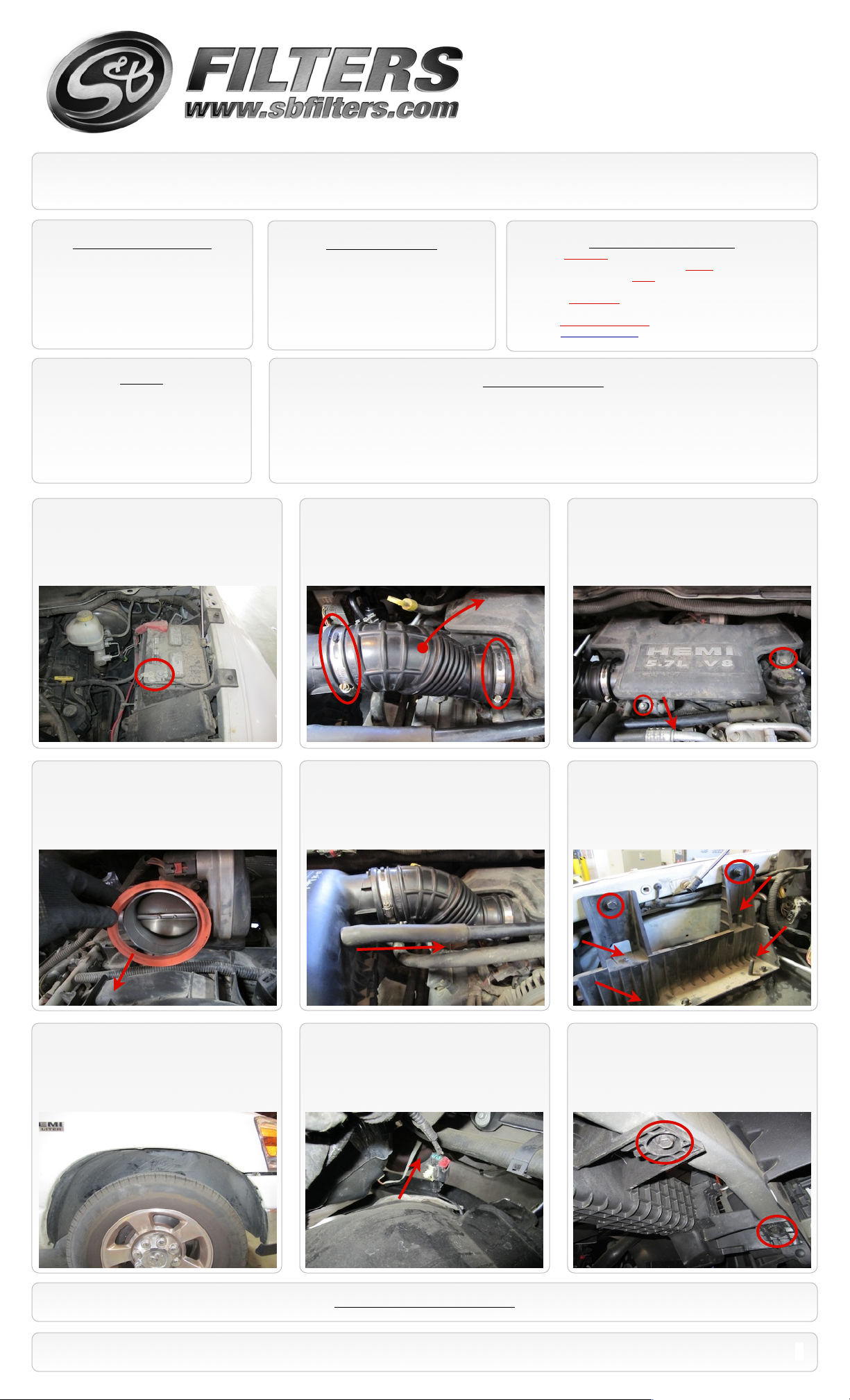

1. With the ignition switched off and the

parking brake set, disconnect the negative

battery cable on the driver’s side.

Tools Required

8mm, 10mm, 13mm Wrench & Socket

•

7/16” Wrench and Socket

•

5/16” Nut Driver or Flat Blade Screwdriver

•

Phillips Screwdriver

•

Cleanable (KF-1056). If the enclosed filter is Red, it came pre-oiled

from the factory. When serviced, apply (110g) of S&B oil to the

main body of the filter and (20g) to the Power Stack (Top).

Disposable (KF-1056D). If the enclosed filter is White, it is a

disposable filter and should be discarded once it reaches capacity.

This filter (does not require oil). For more info on S&Bʼs disposable

filter, visit www.sbfilters.com.

S&B Filter Maintanence

Before You Start

Please read the entire product guide before proceeding.

•

Ensure all components listed on page 4 are present.

•

If you are missing any of the components, call our customer support at (909) 947-0015.

•

Do not work on your vehicle while engine is hot.

•

Make sure the engine is turned off and the vehicle is in Park or the Parking Brake is set.

•

2. Loosen the hose clamp connecting the

tube to the air box and the clamp attaching

the tube to the resonator body. Then remove

intake tube from the truck.

3. Loosen the two screws on the resonator

assembly using a 10mm socket.

Disconnect the Temp. Sensor wiring harness

from the sensor.

4. Remove the OE throttle body gasket.

7. Remove the eight screws securing the

wheel liner using 8mm socket.

5. 2004-08 Models: Remove the breather

hose from the lid of the air box only.

2003 Models: Remove the breather hose

from the oil fill reservoir.

8. From inside the engine compartment,

carefully pull the wiring harness connector out

from the wheel liner. Then remove the wheel

liner from the truck.

6. Remove air box by carefully pulling the air

box straight up out of the four pins of the air

box tray. Then remove the two bolts

mounting the tray to the frame using 13mm

socket.

9. Using 13mm socket, remove the other 2

bolts securing the air box tray. Then remove

the tray from the truck

SEE EXPLODED VIEW ON PAGE 4

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

1

Page 2

Installation Instructions (continued)

P/N: 75-5040 / 75-5040D

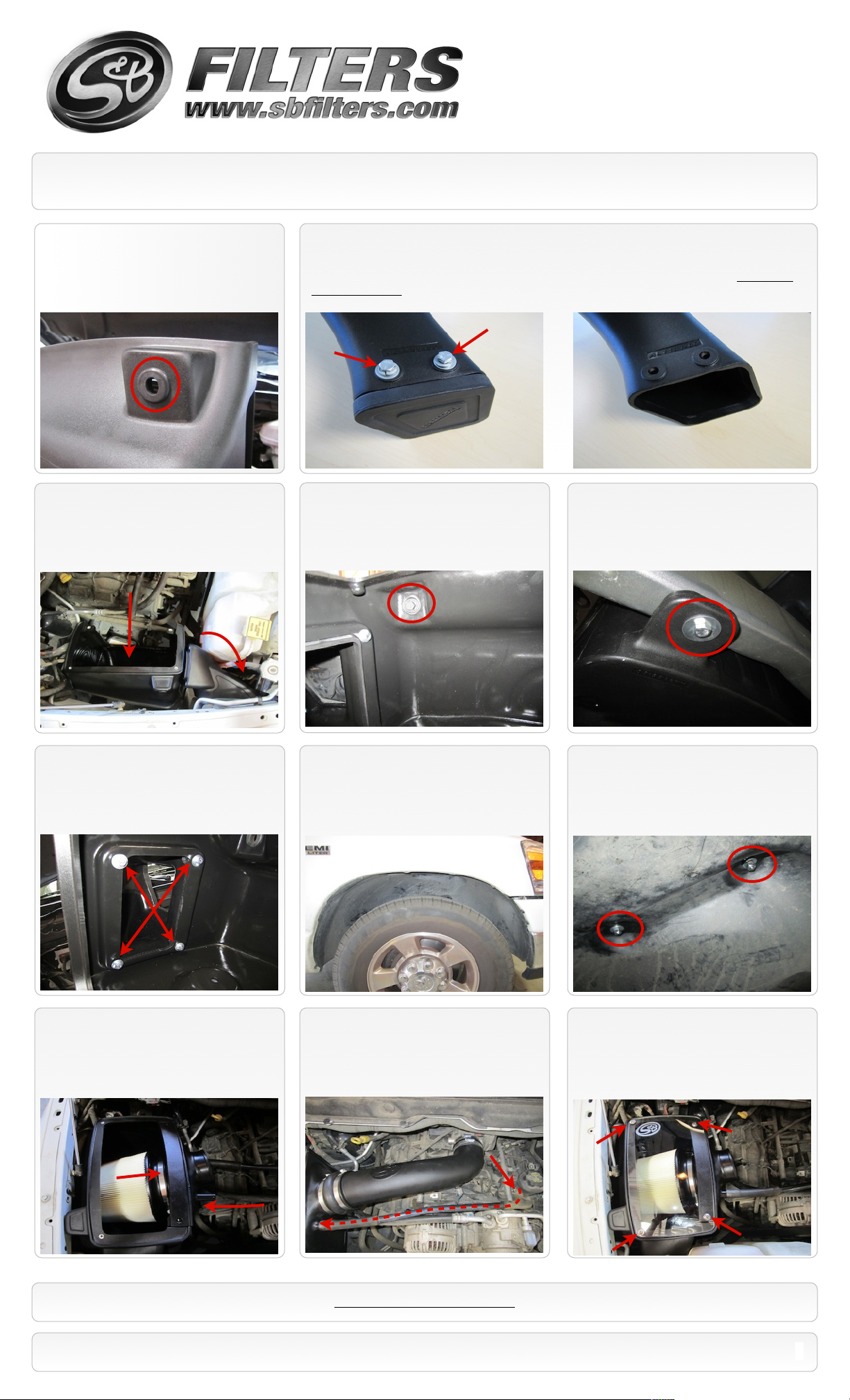

10. Insert the supplied Grommet (D) into

the Air Box (M).

12. Carefully place the Air box (M) and the

Air Inlet tube (S) in the general location. You

may have gently push some hoses aside to

drop both parts in at the same time.

11. For those concerned about minimal engine heat; insert the Air Inlet Plug (T) into the end of the

Air Inlet tube (S). Attach using the supplied 1/4”-20x3/4” screws (V), 1/4” Lock washers (U) and 1/4”

Flat washers (W). For those seeking additional air flow, set the Air Inlet Plug aside and save all the

supplied hardware. (See page 3 for more info and test results)

13. Using the OE bolt, secure the Air box

(M) to the frame. Leave loose for now.

14. From inside the wheel well, attach the

air box to frame using the supplied M8 x

40mm Hex bolt (K) and Fender Washer (L).

Then secure both bolts mounting the air box

to the frame.

15. Insert the Air Inlet tube (S) onto the Air

Box (M) and secure using the supplied

1/4”-20x3/4” screws (V), 1/4” Lock washers

(U) and 1/4” Flat washers (W).

18. Insert the S&B Filter (J) onto the Adapter

Tube (H) and secure the #104 Hose Clamp

(I). Install the assembly into the Air box.

2004-08 Models: Push the OE breather hose

onto the stem of the Adapter tube (H).

16. Reinstall the wheel liner using 6 of the

OE screws. Reinstall wiring harness

connector into wheel liner that was removed

in Step #8.

19. 2003 Models Only: Install the S&B

Breather Hose (Z) onto the oil fill reservoir

using the #8 Hose clamp (Y) and push the

other end onto the stem of the Adapter tube

(H). Secure using the supplied Cable ties (Z).

17. Secure the wheel liner to the air box

using two supplied 1/4”-20x3/4” screws (V)

and Flat washers (W) inside the air box. Use

the 1/4” Nylock nuts (X) and 1/4” Flat washers

(W) under the wheel liner.

20. Install the Clear Lid (N) using the supplied

5/16” S.S. Screws (Q) and Rubber Washers (R)

along with the 10-24 Screws (P) and SS Sealing

Washers (O). This will secure the Filter Adapter

to the Air Box as well. (Do not over tighten!)

SEE EXPLODED VIEW ON PAGE 4

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

2

Page 3

Installation Instructions (continued)

P/N: 75-5040 / 75-5040D

21. Note the OE Temp. Sensor orientation.

Then carefully turn it counter clockwise and

pull it out of the OE resonator.

Then remove the O-ring from the sensor.

24. Secure the Silicone Step Coupler (B) to

the throttle body using a #56 Hose Clamp (A).

Place the #60 Hose Clamp (C) around the top

of the Silicone coupler.

22. Insert the supplied Grommet (D) into

the Intake Tube (E). Carefully push the Temp.

sensor into the grommet using a twisting

motion. Be sure to match the OE orientation.

25. Insert the Intake tube assembly into the

Silicone Coupler, then slide the Hump Adapter

over the Adapter Tube. Tighten all hose

clamps when you are satisfied with the

positioning.

23. Place a #72 Hose clamp (F) over each

end of the Hump Coupler (G). Then slide the

hump coupler over the end of the Intake Tube

(E).

26. Reconnect the Temp. Sensor wiring

harness.

27. Reconnect the battery. Inspect your

installation, make sure the kit is properly

positioned and all fasteners are secure. Affix

the CARB sticker (if applicable) near the

intake kit. The installation is now complete.

Available at www.sbfilters.com

Precision II Filter Cleaning & Oiling Kit

•

(S&B P/N: 88-0008)

Replacement Air Filter (Oiled)

•

(S&B P/N: KF-1056)

Replacement Air Filter (Dry)

•

(S&B P/N: KF-1056D)

Air Filter Wrap

•

(S&B P/N: WF-1034)

Air Scoop

•

(S&B P/N: AS-1005)

Related Items

Testing and Maintenance

Engage parking brake and start your engine.

•

Listen for abnormal noises. If an air leak is

detected, re-inspect hoses and connections as

they may need to be repositioned and tightened.

S&B FILTERS recommends that you keep your

•

OE intake system in the event it is required in the

future.

In order to maintain your warranty, all connections

•

and components must be checked periodically for

alignment and for proper tension on all

connections. Failure to do so may void your

warranty.

Use only S&B FILTERS cleaning and oil products

•

to service your filter. Using any other brand oil

and or cleaners on your S&B air filter will void

your warranty.

Air Box End Cap Testing

Stock air boxes are a significant contributor to poor air flow which is why S&B designs custom air boxes with secondary and/or enlarged openings. With

that said, S&B recognizes the benefits of cooler air, so we have included a plug to seal off the opening if so desired. For optimal performance, we

recommend that the intake be used without the end cap except in conditions of extreme heat.

ISO 5011 Test Data:

With the plug installed, the intake improves airflow by an average of 51.9% versus stock.

Without the plug installed, the improvement increases to an average of 54.2%.

The California Air Resource Board (CARB) requires that an E.O. identification label be applied to the vehicle in order to pass a smog check inspection when a Performance

Intake Kit has been installed. You must place the E.O. label provided on or near the intake kit after installation so that a smog check technician can easily verify the E.O. number.

As of April 2009, S&B has never had a product where CARB denied an exemption request; however, the exemption process with CARB can take as long as 18 months. Check

the status of the exemption process by looking up a specific part number at www.sbfilters.com. The CARB Exemption number and/or status is listed under the Product Details

section for each part number. If the status shows as “Pending,” CARB has yet to issue an exemption. Products that have not been issued an EO number are street legal in most

states, but may not be used on emission controlled vehicles in the state of California and are for off road use only. If you purchased your kit from S&B Filters directly, we will

automatically mail you your Exemption Sticker when it is issued to us. If you purchased your kit from an authorized S&B Filters Dealer, log onto our web site and register to

receive your Exemption Sticker.

SEE EXPLODED VIEW ON PAGE 4

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

Emissions Standard

3

Page 4

ITEM

QTY.

DESCRIPTION

P/NA1

Hose Clamp, #56

AG1019-0

B1Silicone Step Coupler

AI1306S-0

C1Hose Clamp, #60

AG1008-0

D2Grommet

AI1563-00

E1Intake Tube

AL1130-00

F2Hose Clamp, #72

AG1009-0

G1Urethane Hump Coupler

AI1286-00

H1Adapter Tube

AL1128-00

I1Hose Clamp, #104

AG1012-0

J1S&B Filter

KF-1056

K1Screw, Hex Head, M8x40mm

AI1163-00

L1Fender Washer, 1-1/4”OD

AI1080-00

M1Air Box

AL1126-00

N1Clear Lid

AI1561-00

ITEM

QTY.

DESCRIPTION

P/NO2

Washer, SS Sealing, #10

AI1272-00

P2Screw, Pan Head, #10-24

AI1287-00

Q2Screw, Truss, 5/16-18x1.0”

AI1297-00

R2Washer, Rubber

AI1435-00

S1Air Inlet/ Snorkel Tube

AL1131-00

T1Air Inlet Plug

AL1133-00

U6Washer, Split Lock

AI1309-00

V8Screw, Hex Head, 1/4-20x3/4”

AI1068-00

W10Washer, Flat, 1/4”

AI1073-00

X2Nut, Hex Nylock, 1/4-20

AI1074-00

Y1Hose Clamp, #8

AG1000-00

Z1Breather Hose (2003 Models only)

AI1576-00

AA3Cable Tie (2003 Models only)

AI1212-00

Exploded View

AM0186-00 Rev.A 07/25/12

P/N: 75-5040 / 75-5040D

Warranty

Visit www.sbfilters.com/Support/Why-S-B/Million-Mile-Limited-Warranty for S&B Filterʼs complete warranty.

15461 Slover Ave., Fontana, CA 92337 - Phone: (909) 947-0015 - Fax: (909) 947-0603 - www.sbfilters.com

4

Loading...

Loading...