Page 1

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

S&B Part # 75-5017

Yamaha Rhino 660cc

***WARNING***

Re-jetting of the carburetor is

necessary to compensate for the

increased air flow. Our R&D facility

tuned a stock engine using a # 177

main jet, and 2 full turns out on

the mixture screw. Your specific

engine stock or modified, along with

other factors such as operating altitude may require a different setting

and jet #. So adjust accordingly, or

have a qualified service center determine your carburetor settings.

Do not operate your vehicle until the

carburetor has been properly

re-jetted. Failure to do so may

cause severe engine damage.

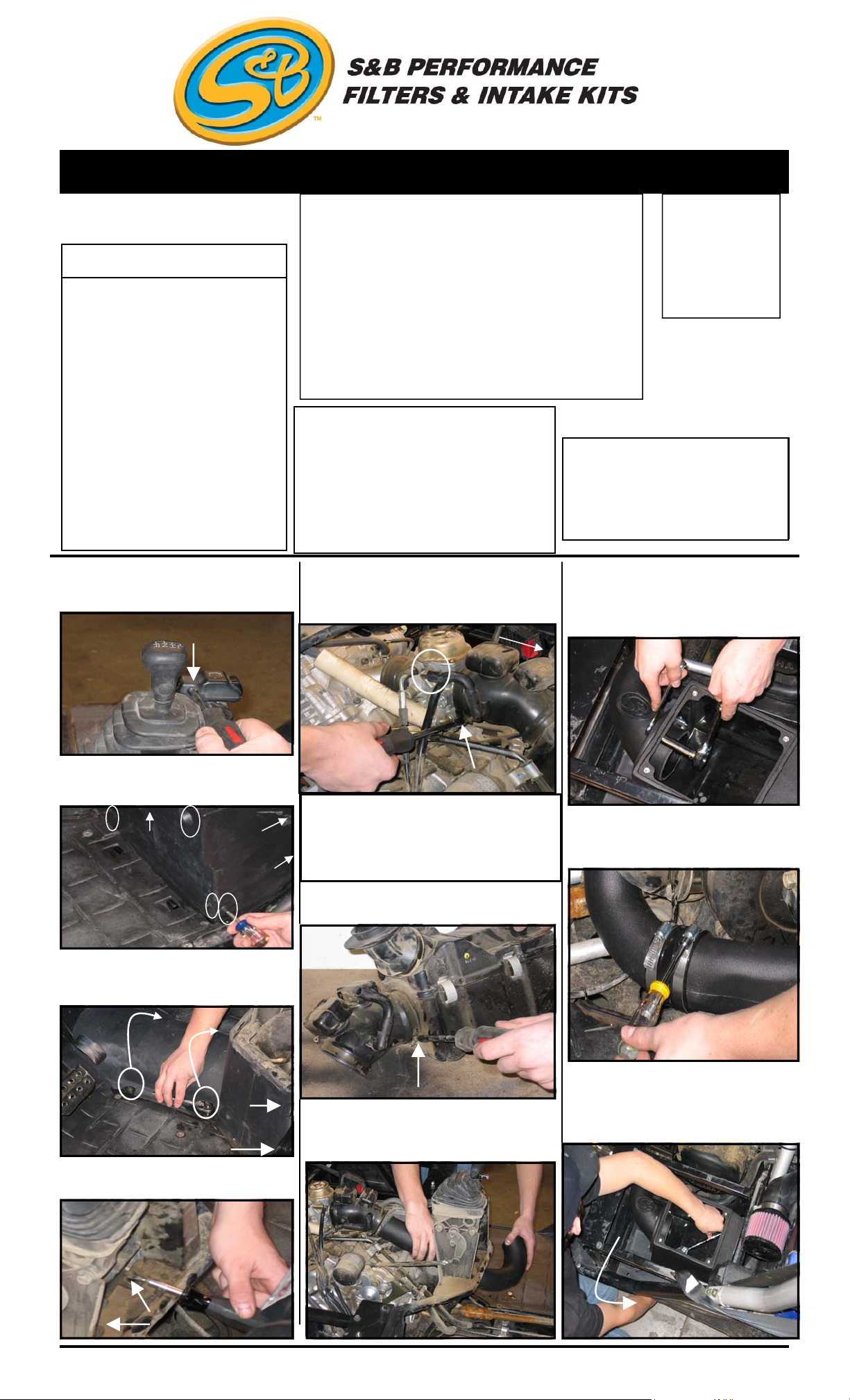

1. With the ignition switched off, remove the

parking brake lever, use a Phillips screw

driver. Then remove driver and passenger

seats, then remove the engine cover.

QTY PARTS LIST QTY PARTS LIST

1 (A) Upper Intake Tube 1 (G) 1/4”-20 Lock Nut

1 (J) Air Box 1 (I) 1/4”-20 SS Socket Head Screw

1 (Z) Clear Lid 2 (D) #52 Hose Clamp

1 (B) 3” x 2” Round Adapter 4 (X) 10/24 SS Concave Rubber

2 (H) 1/4” Fender Washer 1 (M) 1/2” x 9” rubber hose

4 (E) 5/16-18 Bolt 1 (W) S&B Air Filter

4 (V) 5/16-18 Lock Nut 1 (U) # 64 Hose Clamp

4 (F) 5/16 Washer 1 (K) Oil Catch

1 (L) 1/2” hose barb

Washer

*** TOP SPEED ***

This intake kit will greatly increase the

Bottom to Mid range torque of your

engine. If you have an after market CDI

installed and want to improve the Top

speed of your Rhino, enlarge the

opening of the air inlet on the air box.

5. Loosen the hose clamp at the carburetor (# 4

hex) disconnect the crank case vent line at the air

box and the carburetor vacuum line at the carburetor. Remove the air box and adapter from the

vehicle.

***WATER CROSSING***

This intake kit will lower the engine air

intake inlet approximately 18”.

It is not recommended for any type of

water crossings or deep muddy situations.

9. Place the S&B air box (J) in the space

under the drivers seat. Assemble the lower

half of the S&B tube (C) with the S&B air

box (J), using the 5/16 bolts (E) and lock

nuts (V). Place a washer (F) under each nut.

Use 7/16 socket and wrench.

TOOLS REQUIRED

3 & 4 mm, 5/32 Hex Head

Wrench

Phillips & Flat Head

Screwdriver

8mm, 7/16”, 1/2” Wrench

1/2” Socket & Ratchet

Your S&B Air Filter is

factory oiled and ready

to use. Air Filter P/N

KF-1033 will require 29g

of oil for main body and

4g of oil for the top

when serviced.

2. Remove the 7 push locks that secure the

kick panel under the drivers seat, use a Phillips

head screw driver. Then remove the panel.

3. Remove the 4 bolts that secure the

driveshaft cover use an 8 mm socket. Unhook

the 4 clips, 2 on each side. Then remove the

cover.

CLIPS

4. Use a flat head screw driver to pry up

the 2 push locks that secure the OE air box to

the frame.

6. Note: Re-jetting of the carburetor is

recommended at this step as you will need to

carefully drill out the factory plug that is covering

the mixture screw so that it can be adjusted. Refer

to Yamaha Service Manual.

7. Remove the OE air box adapter from the air

box and reinstall onto the carburetor , secure the

factory clamp. Use # 3 hex.

8. Slide the S&B 3” adapter (B) half way on the

upper intake tube (A), secure with # 52 hose clamp

(D). Place the upper half of the S&B tube (A) in the

OE adapter and secure the OE clamp (#4 hex).

10. Insert the lower S&B intake tube (C)

into the S&B 3” adapter (B) already on the

upper intake tube (B). Secure the #52 hose

clamp (D).

11. Align the mounting hole in the bottom

of the S&B air box (J) with the hole in the

floor of the vehicle. Secure with the 1/4-20

hex bolt (I), 2 fender washers (H) and lock

nut (G) provided. Insert bolt from outside

bottom. Use 5/32 Hex and 7/16 socket.

1/18/2008

(909) 947–0015 PHONE • (909) 947- 0603 FAX

(OVER)

Page 2

INSTALLATION INSTRUCTIONS (continued)

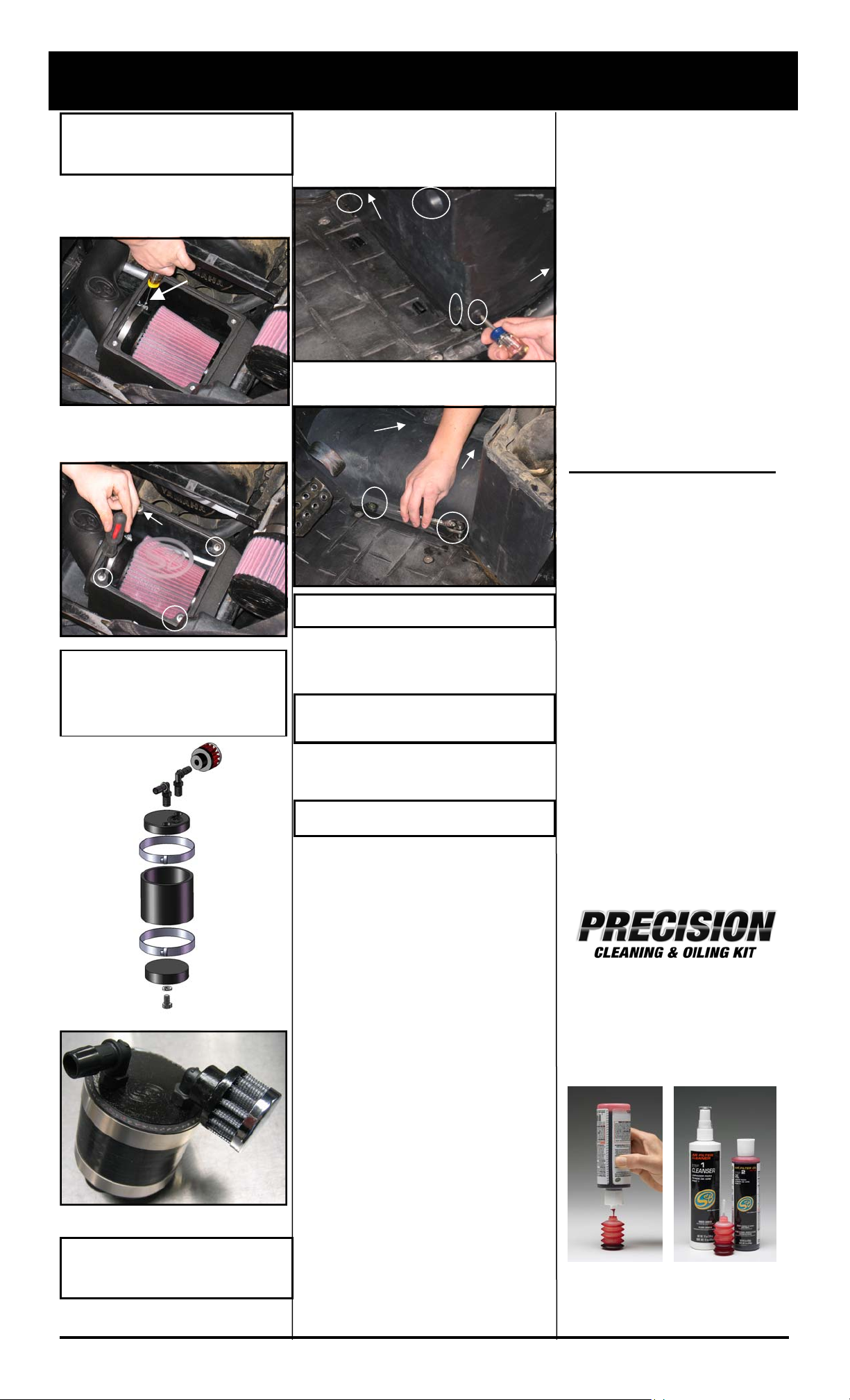

12. Note: It may be necessary to loosen all

hose clamps and reposition tubes for proper

fit and to locate mounting hole for the air

box. Retighten hose clamps.

13. Install S&B air filter (W) onto S&B

flange adapter tube (C) and secure with #64

hose clamp (U).

14. Place S&B clear lid (Z) on top of S&B

air box (J) and secure with 10-32 screws (Y)

and rubber washers (X).

Note: Do not over tighten.

15. Assemble the S&B Oil Catch (M), use

the 5/16 x 1/2” bolt and lock washer to

mount the oil catch on top of the frame

where the OE air box push locks were inserted. Use the hole on the drivers side.

Do not over tighten! See step # 4.

17. Install the OE Kick Plate.

18. Install the OE Drive Shaft Cover.

19. Install the OE Engine Cover.

20. Install the OE Parking Brake Lever and

reposition the shift boot so as to fit tightly

against the engine cover.

21. Install the Driver and Passenger seats. The

installation is now complete.

PERFORMANCE TESTING

∗

Engage parking brake and start

your engine. Listen for abnormal

noises. If an air leak is detected,

re-inspect hoses and connections

as they may need to be repositioned and tightened.

∗ S&B FILTERS RECOMMENDS

THAT YOU KEEP YOUR OEM

INTAKE SYSTEM IN THE

EVENT IT IS REQURIED IN THE

FUTURE.

∗ In order to maintain your war-

ranty, all connections and components must be checked periodically for alignment and for

proper tension on all connections. Failure to do so will void

your warranty.

∗ Use only S&B Filter cleaning and

oil products to service your filter.

Using any other brand oil and or

cleaners may void your warranty.

16. Connect the OE crank case hose to

the 90 degree 1/2” hose barb on the oil

catch assembly.

1/18/2008

S&B’S Precision Cleaning & Oiling

Kit allows vehicle owners to properly

maintain their high performance air

filters by precisely applying the correct amount of oil. The clearly

marked bottle and easy-to-use appli-

Part No. 88-0005

Order online today at www.sbfilters.com

or though your local S&B Distributor

(909) 947-0015 Phone • (909) 947-0603 Fax

www.sbfilters.net

Page 3

75-5017

1/18/2008

Loading...

Loading...