PARTS & SERVICE MANUAL for RB-33VS Conveyor Bun Toaster

The RB-33VS Conveyor Bun Toaster is engineered for efficient,

dependable service throughout the years. Like any piece of fine

equipment with moving parts and broad temperatures ranges,

physical wear takes it toll. When this happens, the information

found in this Manual will prove very helpful.

NOTICE

Although the instructions are easy to follow, all

repair procedures, should be carried out by a

1200-JDM 07105

Savory Certified Service Technician.

RB-33VS PARTS REPLACEMENT INSTRUCTIONS

WARNING

DISCONNECT TOASTER FROM POWER SOURCE

BEFORE ATTEMPTING ANY SERVICE PROCEDURES

General information

The information on the following pages will describe

how to replace the most common components of the

RB-33VS Toaster. Though the instructions are easy

to follow, the work should be handled by a qualified

Service Technician.

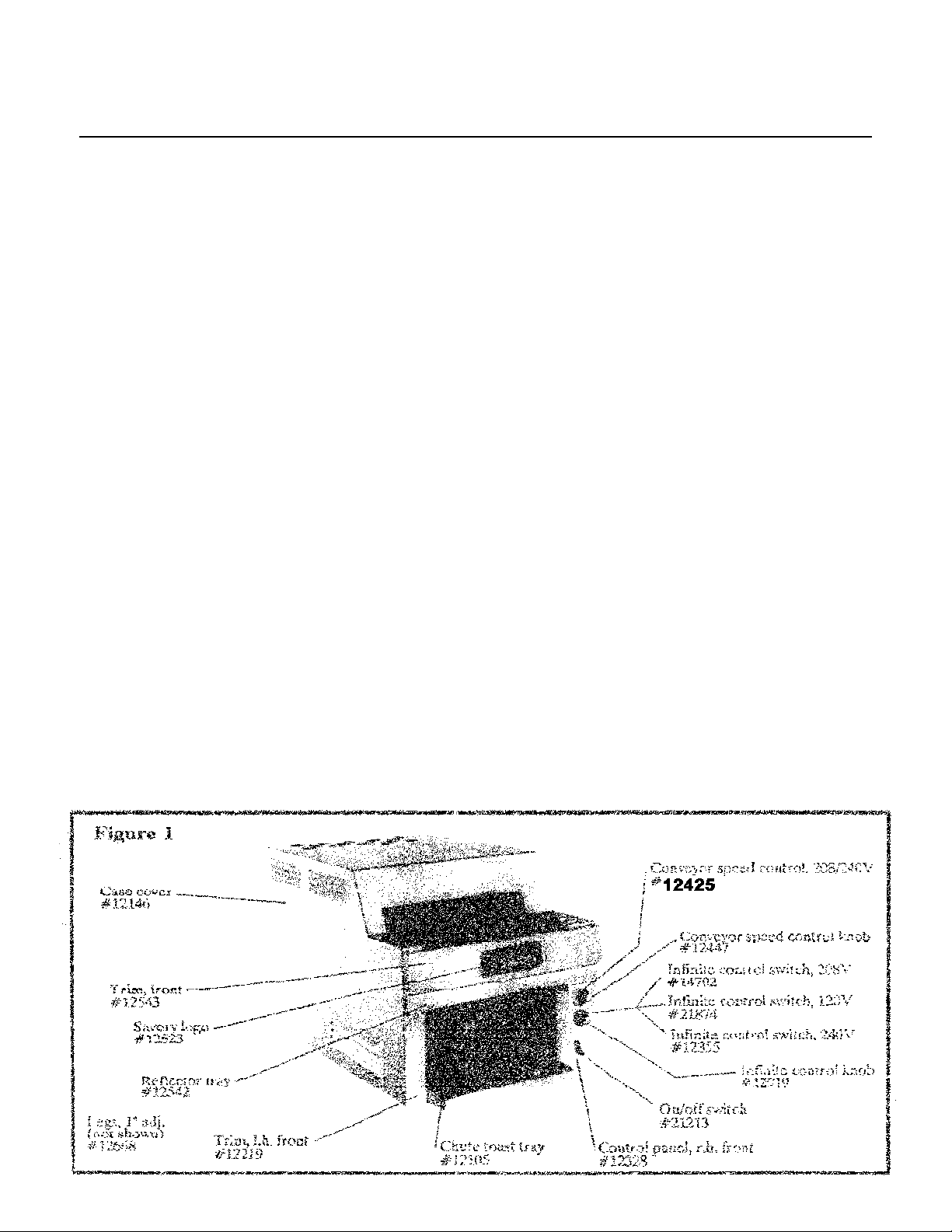

A Case Cover Removal:

1. Remove reflector tray and chute toast tray.

2. Remove the screws securing front trim panel and

remove panel.

3. Remove left front panel.

4. Remove the screws securing control panel to unit and

carefully pull control panel outward and towards

center of toaster.

5. When replacing cover, be sure tabs on sides and top

of cover fit into grooves on back of toaster.

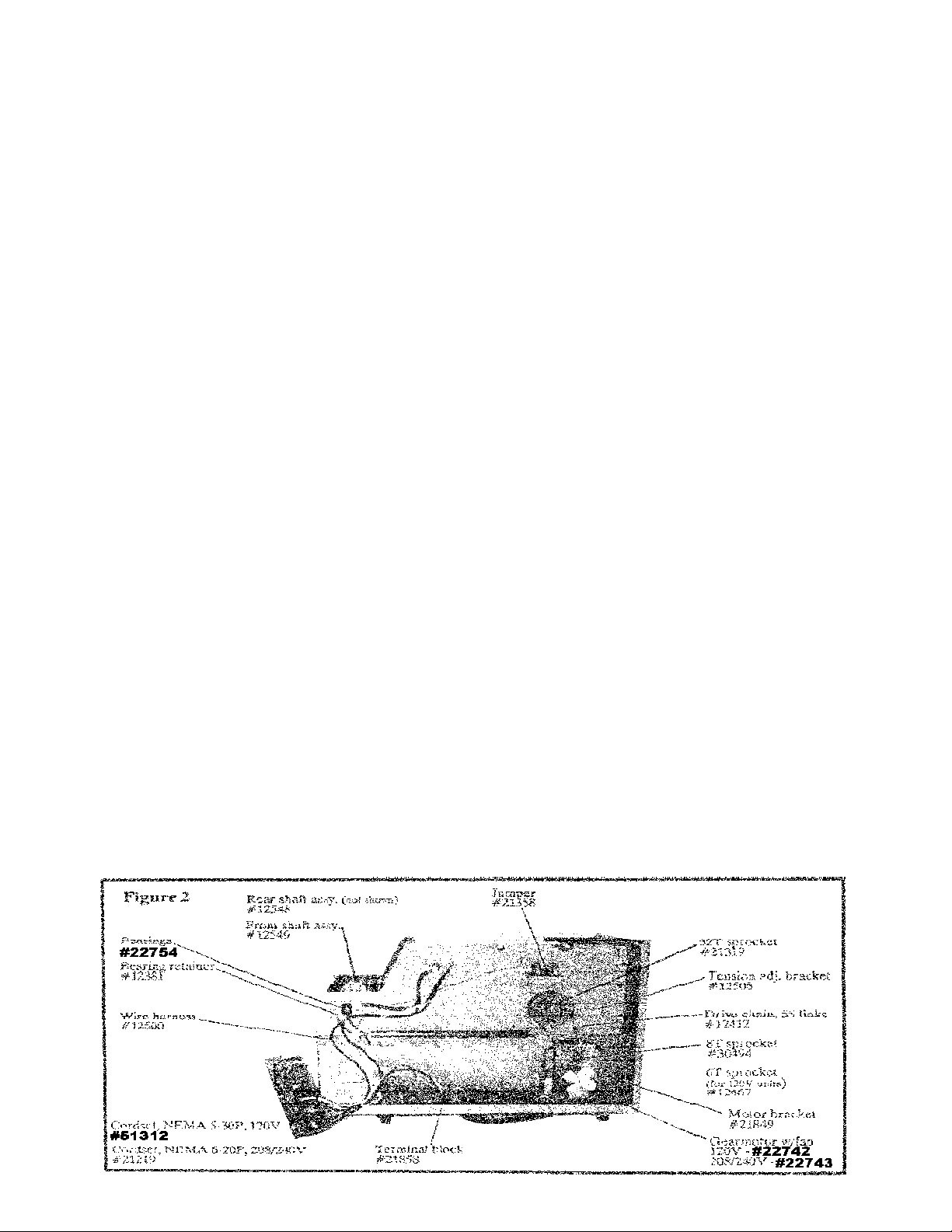

C Conveyor Speed Control/P.C. Board

(Figure 1 & 2)

1. Remove case cover. (Section A)

2. Pull off speed control knob and remove the nut

securing the control to the panel. Pull out

control from back of control panel.

3. Cut wire harness tie and remove speed control

wires.

4. Disconnect motor lead and on/off lead from P.C.

board terminals.

5. Remove 2 screws and nuts securing P.C. board

to floor of unit and remove P.C. board assembly.

6. Reverse this procedure to install new assembl;y.

(Refer to wiring diagram)

B Main Power On/Off Switch

(Figures 1 & 2)

1. Remove the case cover. (Section A)

2. Disconnect the 2 wires at the on/off switch terminal

ends. Note correct orientation of wires

3. Remove the 2 slotted screws securing switch to

control panel.

4. The on/off switch can now be removed from the back

of the control panel.

5. Reverse this procedure to install new switch.

(Refer to wiring diagram)

D Infinite Control Switch

(Figure 1 & 2)

1. Remove case cover. (Section A)

2. Pull off heater control knob to gain access to 2

slotted screws that secure control to control

panel. Remove these 2 screws.

3. Disconnect the wires from the control terminal

ends, noting proper orientation of wires.

4. Install new control from back of control panel

and secure with 2 slotted screws.

5. Re-attach wires to terminal ends. (Refer to

wiring diagram)

2

E Terminal Block

(Figure 2)

1. Remove case cover. (Section A)

2. Remove the wires at the terminal ends noting

proper wire orientation.

3. Remove the 2 nuts securing the terminal block to

the floor of the toaster.

4. Reverse this procedure to install new terminal

block. (Refer to wiring diagram)

F Gearmotor and Motor

Sprocket

(Figure 2, 6 & 7)

1. Remove case cover. (Section A)

2. Loosen the 4 motor mounting screws and slide

motor to achieve slack in the drive chain. Remove drive chain.

3. Loosen set screw on motor sprocket and remove

sprocket.

4. Remove the 4 motor mounting screws and lift out

motor.

5. Disconnect 2 wire leads from motor, one at wire

connector and the other at the terminal block.

6. Reverse this procedure to install new motor.

(Refer to wiring diagram)

G Resistor

Not shown

1. Remove case cover. (Section A)

2. Disconnect wires from resistor.

3. Remove hardware securing resistor bracket and

resistor.

4. Reverse this procedure to install new resistor.

(Refer to wiring diagram)

SPECIAL NOTE: The RB-33VS is no longer built

with the resistor installed.

H Drive Chain

(Figure 2 & 6)

1. Remove case panel. (Section A)

2. Loosed, but do NOT remove, the 4 motor

mounting screws. Slide motor to achieve slack in

drive chain and remove chain.

3. When installing new chain, check for proper chain

orientation and tension.

I Conveyor Shaft Sprocket

(Figure 2, 6 & 7)

1. Remove right side panel. (Section A)

2. Remove drive chain. (Section H)

3. Loosen set screw on hub of sprocket and slide sprocket

off shaft.

4. When installing new sprocket, make sure set screw rests

in hole on shaft.

5. Replace drive chain. (Section H)

J Conveyor Belt

(Figure 2 & 8)

1. Remove case cover. (Section A)

2. Loosen, but do NOT remove, the bearing retainer

brackets on both sides of toaster.

3. Loosen, but do NOT remove, the tension adjusting

brackets on both sides of toaster.

4. Push front conveyor shaft towards the back of the

toaster to loosen belt tension.

5. Separate the conveyor belt at any link and slide out of

toaster.

6. When installing new conveyor belt, check for proper

link orientation. (Figure 7)

7. Starting at front of toaster, slide belt under front shaft

and push towards rear of unit. Bring belt up and over

the rear shaft and pull towards front of toaster. Make

sure belt is resting on both belt support guides. Reconnect links. CAUTION: Make sure belt is not in-

stalled at an angle.

8. Pull forward on front conveyor shaft until excess slack

is removed.

9. Tighten tension adjusting brackets and bearing retainer

brackets on both sides of toaster.

3

K Front and Rear Shafts

M Individual Heating Ele-

and Bearings

(Figures 2 & 8)

1. Remove case cover. (Section A)

2. To remove front shaft and front shaft bearings: Remove bearing retainers on both sides of

toaster. Loosen conveyor belt tension adjusting

brackets on both sides of toaster. Bearings (with

shaft) will now slide out. Note proper orientation of spacers.

3. To remove rear shaft and rear shaft bearings:

Remove drive chain (Section H), and conveyor

shaft sprocket (Section I). Remove rear bearing

retainer brackets from both sides of toaster.

Bearings (with shaft) will now slide out. Note

proper orientation of spacers.

4. Replace bearings, spacers and shaft. Replace

conveyor belt tension adjusting brackets on front

and rear shafts.

5. Replace conveyor shaft sprocket and drive chain

on rear shaft.

6. Adjust tension of conveyor belt on front shaft to

remove excess slack.

L Heater Element Assembly

(Figure 3, 4 & 5)

1. Remove case cover. (Section A)

2. Remove the 6 sheet metal screws (3 on each side

securing the assembly to toaster sides.

3. Disconnect the 2 wires at the heating element

terminal ends.

4. Carefully lift out assembly.

5. Reverse this procedure to install new assembly.

(Refer to wiring diagram)

ment

(Figure 3, 4 & 5)

1. Remove case cover. (Section A)

2. Remove heating element assembly. (Section L)

3. Remove the 2 hex head screws securing element

to end plate. Note proper orientation of spacers,

nuts and retainer bars.

4. Bend the holding tabs to achieve clearance of

element. CAUTION: CHECK FOR PROPER

VOLTAGE AND WATTAGE STAMPED ON

EACH ELEMENT BEFORE INSTALLATION.

5. Reverse this procedure to install new element.

(Refer to wiring diagram)

N Power Cord

(Figure 2)

1. Remove case cover. (Section A)

2. Disconnect green ground wire and the 2 wires at

the large wire connectors.

3. Tilt toaster on back panel. Squeeze strain relief

bushing and pull out from toaster.

4. Reverse this procedure to install new power cord.

(Refer to wiring diagram)

456

NOTE: To wire or convert units with the old style Unit Assembly, which in-

cluded a Resistor and/or P.C. Board, do the following: Gearmotor, which has 2

black wires, one is plugged into white side of the terminal block, and the other is

spliced together with black wire off the Conveyor Speed Control POT. Then the

blue wire off the Conveyor Speed Control POT, is attached to the #1 position of

the on/off switch.

7

RB-33VS PARTS LISTING

DESCRIPTION #Req. Part #

Cordset –NEMA 6-20P 208/240V 1 21219

Cordset –NEMA 5-30P 120V 1 51312

Reflector tray 1 12542

Chute toast tray 1 12105

Chute, rear delivery only 1 12405

Leg, 1” adjustable 4 12668

Trim, front 1 12543

Savory logo 1 12523

Trim, left hand front 1 12219

Trim, right hand front 1 12328

Infinite control switch, 208V 1 14702

Infinite control switch, 120V 1 21874

Infinite control switch, 240V 1 12355

On/Off switch 1 21213

Infinite control knob 1 12919

Conveyor speed control knob 1 12425

Conveyor speed control 120V 1 12464

Conveyor speed control knob 1 12447

Wire harness kit (wires only) 1 12500

Terminal block 1 21858

Jumper 1 21358

Savory lubricant 1 30042

DESCRIPTION # Req. Part #

Drive chain, 55 links 1 12412

Tension adjusting bracket 2 12508

32T sprocket 1 21319

8T drive sprocket for 208/240V 1 30494

6T sprocket for 120V 1 12467

Motor bracket 1 21849

Gearmotor assembly 208/240V 1 22743

Gearmotor assembly 120V 1 22742

120V element 1100W 2 12463

208V element 1200W 2 12126

240V element 1185W 2 21103

120v heater assembly 1 12493

208V heater assembly 1 12494

240V heater assembly 1 12149

Bearings 4 22754

Bearing retainer 4 12381

Conveyor chain, coated 1 12552

Conveyor chain link, coated 45 12583

Front shaft assembly 1 12549

Rear shaft assembly 1 12548

Bushing, rear 2 12534

Bushing, front 2 12533

1111 N. Hadley Rd.

Fort Wayne, In. 46804

Tel. 800-701-2992

Fax (219) 436-0735 www.mercosavory.com

8

Loading...

Loading...