PARTS & SERVICE Manual for CG-30 Gas Conveyor Toaster

The CG-30 Gas Toaster brings to commercial

toasting all the advancements and versatility

usually associated only with electric toasters.

Speed is combined with the known economy of

operation and service free characteristics in this

new approach to the oldest way of toasting.

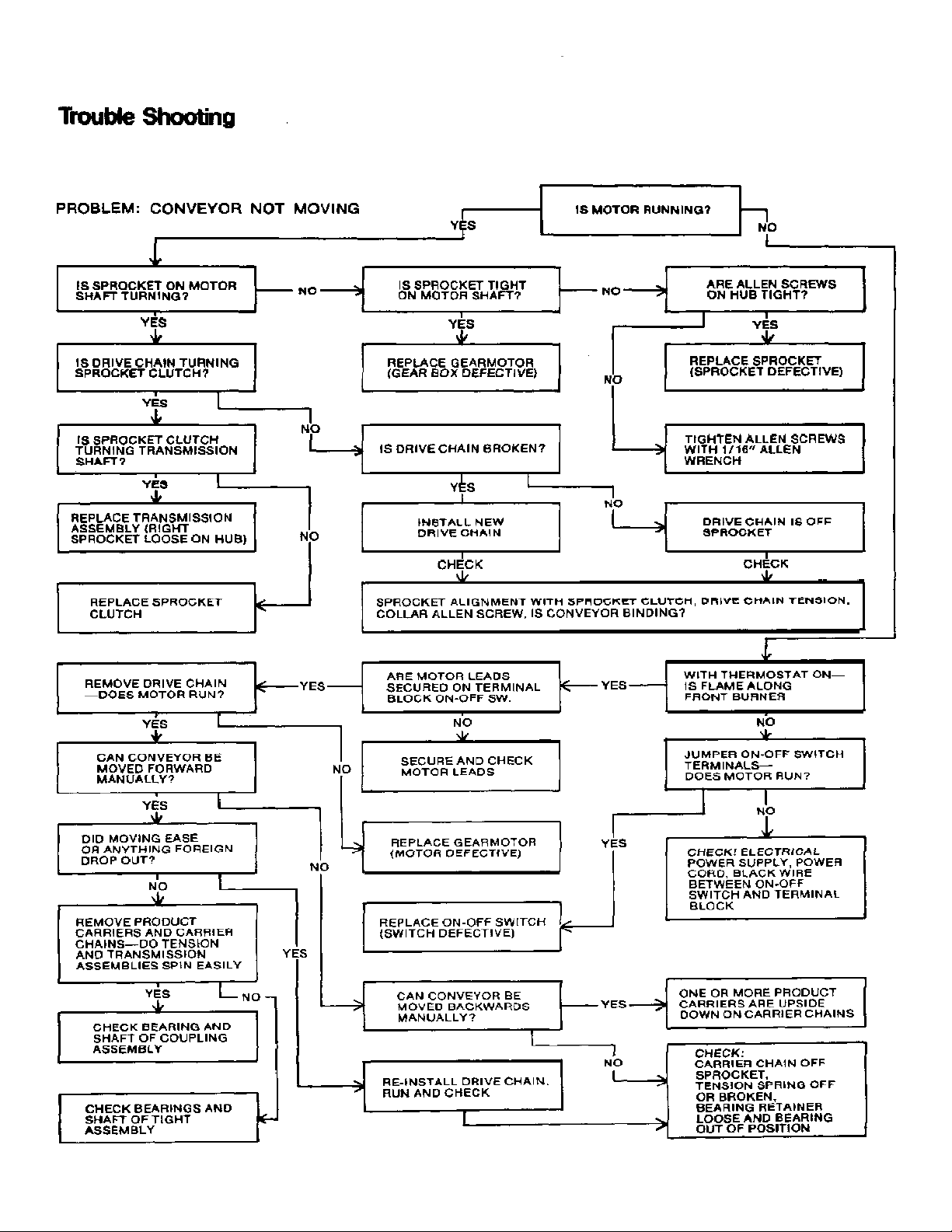

The CG-30 is engineered for efficient, dependable service throughout the years. Like any

other piece of fine equipment with moving parts

and broad temperature ranges, physical wear

and tear takes its toll. When this happens, the

following information will prove most helpful.

Although the instructions are easy to follow, the

work should be done by a qualified Savory

Certified Service Representative.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

1200-JDM 07019

WARNING

REMOVE PLUG FROM WALL RECEPTACLE

AND SHUT OFF GAS SUPPLY BEFORE

ATTEMPTING ANY SERVICE ON THIS UNIT.

Servicing: To gain access to the drive components,

switches and wire guard plate, remove the right side

panel. To gain access to the gas burners, associated

components and burner controls remove the left side

panel. Each side panel is easily removed by removing the

two screws located on the underside of the unit.

A On/Off Switch Replacement

1. Remove right side panel.

2. Remove two retaining screws from front panel.

3. Disconnect wiring harness from switch terminals.

4. Connect wiring harness to new switch and install

switch in panel. (Refer to wiring diagram)

B Bun/Toast Switch Replacement

1. Remove right panel.

2. Disconnect wiring harness from switch terminals.

3. Depress two spring clips on top of switch and tilt

switch forward.

4. Insert the new switch into the panel opening, snapping

snugly into place.

5. Reconnect the wiring harness to the terminals. (Refer

to wiring diagram)

3. Remove the two nuts at the bottom of the motor

mounting plate and slide plate to the left. Disengage drive chain from sprocket and remove from

weld bolts.

4. From the back of the plate, remove the four

screws holding the gearmotor.

5. Using a 1/16” Allen wrench, loosen sprocket

locking Allen screws and remove sprocket from

shaft.

6. Fasten new gearmotor to motor mounting plate.

7. Place motor mounting plate on weld bolts,

replace nuts. Do NOT tighten.

8. Slip sprocket on gearmotor shaft with hub facing

outward, mesh with drive chain, align with

sprocket clutch and tighten Allen screws.

9. Remove drive chain slack by sliding the mounting

plate to the right. Tighten nuts on motor mounting plate.

10. Connect motor leads to terminal block and on/off

switch.

11. Replace side panel.

C Gearmotor Replacement

(Refer to illustrations 3 & 5)

1. Remove right side panel.

2. Disconnect motor lead wires from the terminal block

and on/off switch.

2

D Drive Chain Adjustment

1. Tension is correct when chain can be

depressed about 1/8” on each side with

slight pressure. Shifting the motor mounting

plate to the right will tighten the drive chain

tension. Sliding it to the left will loosen the

tension (Illustration 3).

2. An overtight chain tension will result in

premature wear of the chain and sprocket

and may cause a bind. Too loose pressure

will create excessive noise, with the possibility of jumping off the sprocket teeth.

E Drive Chain Replacement

(Refer to illustration 3 & 5)

1. Remove right side panel.

2. Loosen motor mounting bolts and slide

motor to left to loosen chain.

3. Lift off old chain and position new chain over

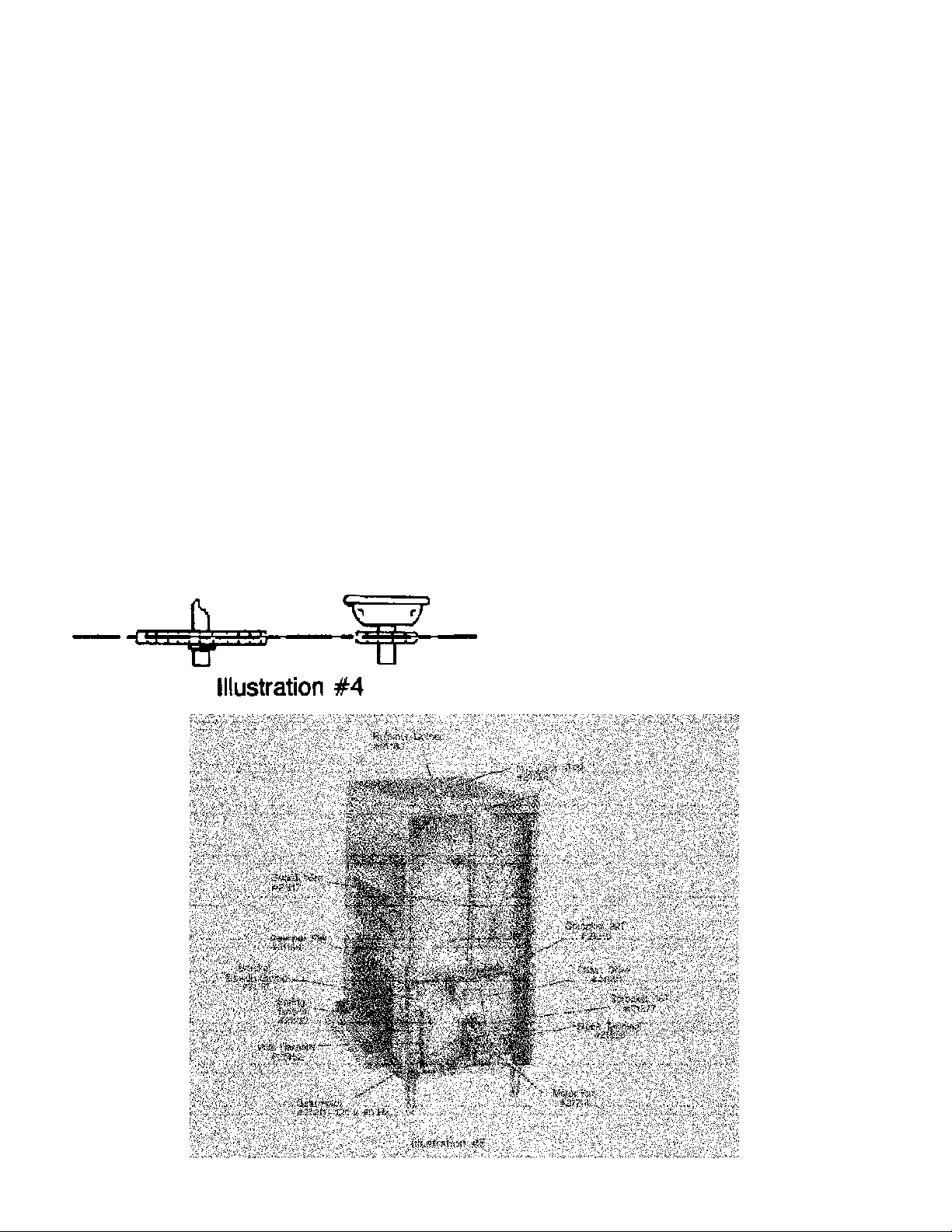

sprockets. Check orientation. (Illustration 4)

4. Slide motor to right to remove chain slack

and tighten motor mounting bolts.

5. Check chain tension. (Illustration 3) Too

tight will result in premature wear of chain,

sprocket and bearing and may bind drive

components. Too loose will result in chain

slipping or falling off sprockets.

F Clutch Replacement

(Refer to illustration 4 & 5)

1. Remove right side panel.

2. Loosen motor mounting bolts and slide motor to

left and remove drive chain.

3. Loosen Allen screws on clutch sprocket and

remove sprocket from motor shaft.

4. Install new sprocket on motor shaft and tighten

screws. Check sprocket alignment. (Illustration

4)

5. Position chain on sprocket and slide motor to

right to remove slack. Tighten mounting bolts.

Check chain orientation.

6. Check chain tension (Illustration 3) and adjust if

necessary. (See Section D)

7. Replace side panel.

G Hubbed Sprocket Replacement

(Refer to illustration 4 & 5)

1. Remove right side panel.

2. Loosen motor mounting bolts and slide motor left.

3. Remove drive chain and loosen Allen screws on

hub of sprocket and slide off shaft.

4. Install new sprocket and align set screws with

indents in transmission shaft.

5. Replace drive chain and slide motor to right to

tighten. (Illustration 3)

6. Replace side panel.

3

H Bearing Replacement

Coupling Bearing (Right Side)

1. Remove right side panel and insulation.

2. Remove the two lock nuts holding bearing

retainer and remove retainer.

3. Remove old bearing.

4. Install new bearing and seat in opening.

5. Replace retainer, nuts, insulation and side

panel.

Coupling Bearing (Left Side)

1. Remove left side panel and insulation.

2. Remove the two lock nuts holding bearing

retainer and remove retainer.

3. Remove old bearing.

4. Install new bearing and seat in opening.

5. Replace retainer, lock nuts, insulation and side

panel.

Transmission Bearing (Right Side)

1. See Section G; follow steps 1, 2 and 3.

2. Remove the two lock nuts holding bearing

retainer and remove retainer.

3. Remove old bearing.

4. Install new bearing and seat in opening.

5. Replace retainer and lock nuts.

6. See Section G; follow steps 4, 5 and 6.

Transmission Bearing (Left Side)

1. Remove left side panel.

2. Remove the two lock nuts holding bearing

retainer and remove retainer.

3. Remove old bearing.

4. Install new bearing and seat in opening.

5. Replace retainer, nuts and side panel.

I Conveyor Chain Replace-

Tension Assembly Bearing (Right or Left Side)

1. Remove side panel.

2. Remove one end of tension spring from

tension bracket.

3. Remove the two lock nuts holding bearing

retainer and remove retainer.

4. Remove tension bracket and old bearing.

5. Install new bearing and seat in opening.

(Refer to illustration 6)

6. Replace tension bracket, retainer, lock nuts

and spring. NOTE: If tension bracket has

two anchor holes for spring, use hole

closest to the front of machine.

ment

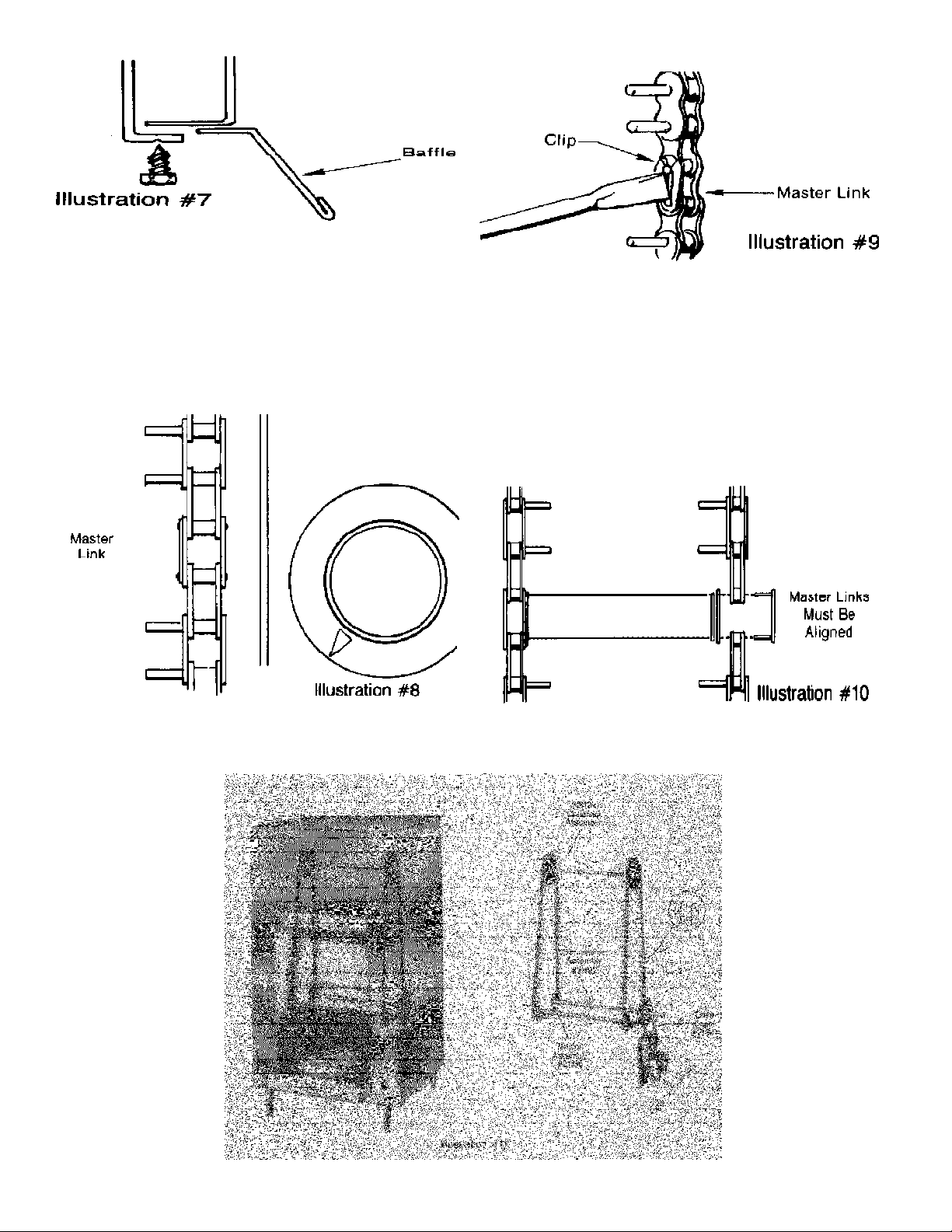

(Refer to illustration 11)

1. Remove toast receiving tray, delivery

chute, left and right side panels.

2. Remove the two screws in upper edge of

front opening that holds the front baffle.

Slide baffle toward back of machine to

remove. (Illustration 7)

4

3. Remove baskets by slightly spreading chains, sliding

basket to one side and lifting out.

4. Release the tension spring from spring bracket on both

sides of tension bracket on both sides of tension

assembly.

5. Locate the master link (link without extended pinsillustration 8). Remove clip on master link (Illustration

9) and remove. Pull chain out from bottom.

6. With extended pins facing inward, drape new

chain over the top of the coupling assembly. Make

certain links of chain are meshed over sprocket

teeth. Drop remainder of chain behind sprocket and

from bottom opening, lift it across transmission

assembly and tension assembly sprockets. Visually

check for fit over sprocket teeth and bring two ends

of chain together. Install master link and clip.

Repeat procedure for other chain. IMPORTANT!

Align right and left side master links to insure

proper alignment of baskets. (Illustration 10)

7. Replace baskets, spring on tension brackets, front

baffle, receiving tray, delivery chute and left and

right side panels.

5

J Transmission Assembly Replacement

(Refer to illustration 11)

1. Follow steps 1 thru 5 in Section I.

2. Remove drive chain, hubbed sprocket, bearing retainers and bearings. (Refer to Sections G & H)

3. Slide assembly shaft to right side and lift left end of

shaft out of bearing hole and remove shaft.

4. Inspect shaft bearing for wear or binding. Replace with

new if necessary.

5. Replace new assembly in reverse order.

6. Check conveyor chain line-up. (Refer to Section I Step

6)

7. Check drive chain tension. (Refer to Section E Step 5)

K Tension Assembly Replacement

(Refer to illustration 11)

1. Remove receiving tray, delivery chute, left and right

side panels.

2. Remove all baskets and both conveyor chains. (Refer

to Section I steps 2 thru 5)

3. Unhook tension springs from brackets. (Illustration 6)

4. Remove bearing retainers and bearings.

5. Lift one end of assembly shaft and remove carrier chain

from sprocket. Move chain to one side; repeat for

opposite end of shaft.

6. Slide shaft to one side and lift opposite end out of

bearing hole. Lift assembly out and under to clear

carrier chains.

7. Reverse above procedure to install new assembly.

8. Inspect bearing for wear or binding. Replace with new

if necessary.

9. Install bearing, spring brackets and retainers. Attach

springs to bracket.

10. Check conveyor chain line up. (Illustration 10)

11. Install baskets, left and right side panels.

L Coupling Assembly Replacement

(Refer to illustration 11)

1. Follow steps 1 thru 5, Section I)

2. Remove insulation.

3. Remove wire guard. (Refer to Section M)

4. Locate the four screws on the upper inside corners of

the toaster that hold case top in place. Loosen screws

and lift off top. A rubber mallet or similar “soft” tool

maybe helpful in lifting a tight fitting top. (Illustration 12)

5. Remove insulation.

6. Remove the twelve screws holding the inner top panel

assembly in place and lift it off.

7. Remove coupling assembly bearing from both sides.

(Refer to Section H)

8. Remove the three screws from the left inside panel that

attach to front reflector.

9. Standing at right side of machine gently push on left

inner wall to expand toasting chamber. (Illustration 13)

This will allow enough clearance for coupling assembly

to be lifted from toaster.

6

10. To install new assembly spread inner walls as in

Step 9 for clearance.

11. Check bearing for wear or binding. Replace with

new if necessary.

12. Install bearings, retainers and lock nuts.

13. Replace three screws into front reflector.

14. Replace conveyor chains, springs to tension

brackets, front baffle, inner top assembly, insulation

and case top. Be certain case top is seated properly

in retaining channels.

15. Replace side insulation, wiring, side panels and

baskets.

M Wire Guard Replacement

(Refer to illustration 6)

1. Remove left side panel and insulation.

2. Remove the three nuts holding end plate and

remove plate.

3. Slide out wire guard

4. Insert new wire guard into track. NOTE: Use

rear track for toasting buns or bread. Use

forward track for toasting bread only.

5. Replace end plate, nuts, insulation and side

panel.

N Burner Component Adjustments

1. Air Shutter Adjustments - May be required due to

local gas supply conditions. Loosen air shutter locking

screw on burner. Move shutter until burner flame is

without yellow.

2. Pilot Flame Adjustment - Remove thermostat knob.

With a thin bladed screwdriver, reach through bottom

of opening and turn pilot adjustor screw clockwise until

pilot flame starts to reduce. Then, turn pilot adjuster

screw clockwise until pilot flame starts to reduce.

Then, turn pilot adjustor screw counterclockwise until

pilot flame envelopes and is just above flame switch

sensing tube. Replace thermostat knob. NOTE:

Changing to propane gas will require reducing the

pilot flame to the above condition.

3. Thermostat By-Pass Adjustment - Allow toaster to

reach normal toasting heat. Place bun-toast switch to

the Toast position. Turn thermostat to #1 position (set

on Low with knobs so marked). Carefully remove

thermostat knob without disturbing setting. With a thinbladed screwdriver, reach through upper right of

opening and turn by-pass adjustment screw until

burner flame is steady across length of burner. Replace knob and reset thermostat and bun-toast switch

to original position.

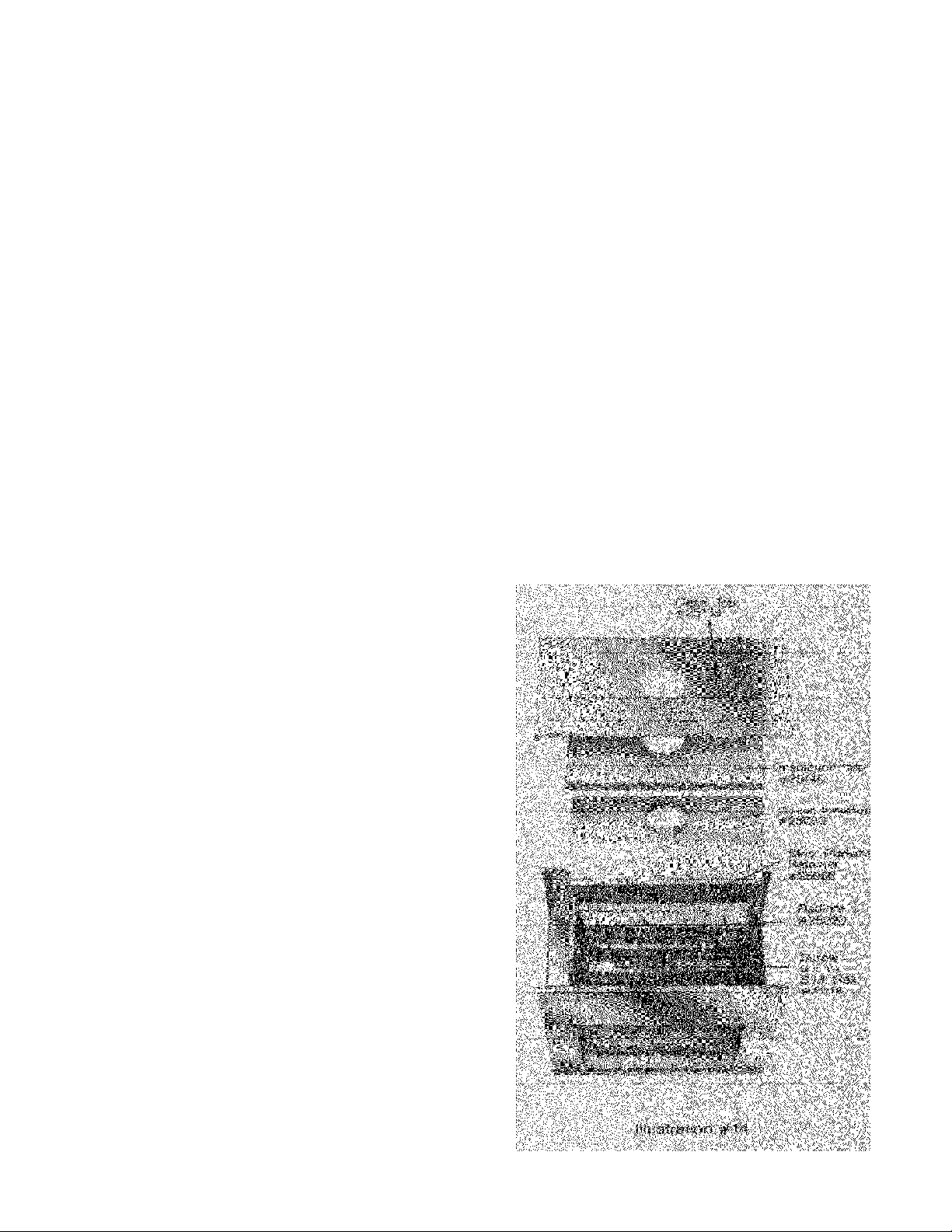

P Radiant Replacement

(Refer to illustration 14)

1. Remove both sides panels.

2. Loosen the inside screws on each corner holding

the case top to the front and rear panels.

3. Lift off top and remove insulation.

4. Remove the three screws from top rear, three

screws from top front, and five screws from each

side and remove inner top cover.

5. Reach through top opening, remove the three

screws holding the radiant retainer strip.

6. Radiants lean inward and can be removed.

7. Place new radiants into the channel retainer with

bosses toward the top and cones facing inward.

8. Place radiant retainer strip over bosses, push

retainer into position and fasten with the three

screws.

9. Place inner top corner in position, fasten with the

five screws from under side of each side, and the

three screws at top rear and top front.

10. Place insulation over inner top cover.

11. Position case top over the four screws and push

to fit toaster.

12. Tighten the four screws to fasten case top of front

and rear panels.

13. Replace side panels.

0 Control Functions

Safety Solenoid Valve - Operates when both flame

switches close, to complete electrical circuit to coil,

which pulls plunger to open gas flow path to front burner

and control solenoid valve.

Pilot Flame Switches - Bulbs, positioned over the

pilots, are heated. Heat is transferred through sensing

tubes to close the series wired switches to complete

circuit and energize the safety solenoid valve coil.

Control Solenoid Valve - Coil is energized by bun-toast

switch placed in TOAST position which pulls plunger to

open gas flow path to the rear burner. In BUN position

coil is not energized, plunger shuts off gas flow.

On/Off Switch -The “ON” position closes the circuit to

the gearmotor, flame switches and bun-toast switch.

Bun-Toast Switch - Completes the electrical circuit to

the control solenoid valve coil when placed in the

TOAST position.

Shut-Off Valve - Manually opens or shuts off gas supply

line. When open, the gas flows through the pilot tubes.

Pressure Regulator - Maintains a 4” water column

pressure when natural gas supply exceeds that pressure.

Thermostat – Regulates the gas flow to the burners.

Gas flow through the thermostat is controlled by the

temperature at the bulb. “Off” position shuts off all gas

flow except through the pilot tubes.

7

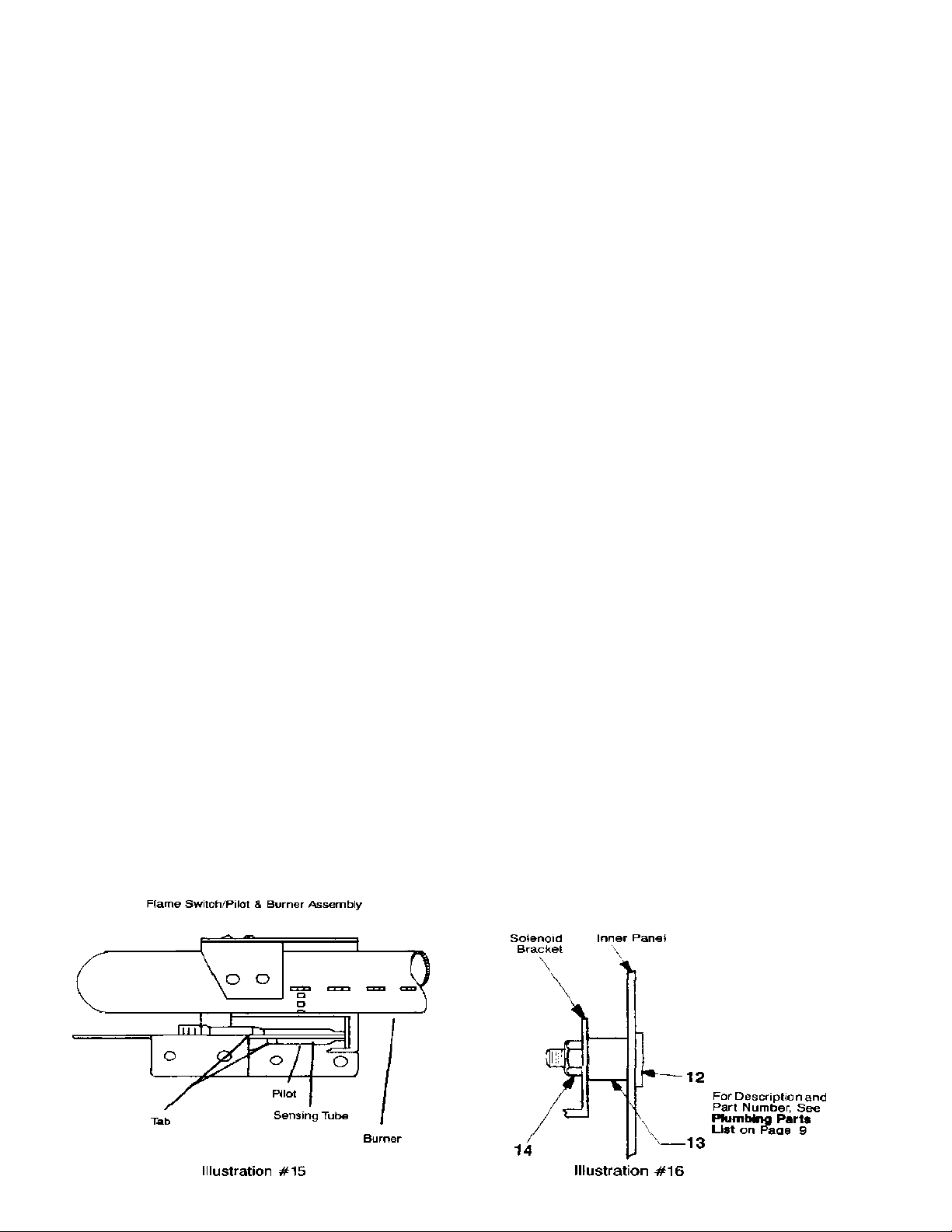

Q Burner Replacement

(Refer to illustration 15 & 17)

1. Loosen nut holding burner lock plate.

2. Remove wires from underside of pilot flame switch.

3. Using a screwdriver, press spring catch on side of

flame switch, snap ceramic base up and out of

bracket.

4. Using a 7/16” open end wrench, loosen pilot tube

compression nut at the burner. CAUTION: Pilot

orifice is loose in end of pilot.

5. Move pilot tube to the side and out of the way.

6. Lift burner to clear orifice and slide burner out.

7. Remove pilot bracket, containing pilot flame switch

assembly by removing screws fastening pilot bracket

to burner.

8. To install new burner, first place pilot bracket,

containing pilot flame switch assembly, on burner

and fasten with retaining screw.

9. Check that pilot flame switch assembly is parallel to

the burner in both the horizontal and vertical plane

and that sensing tube is locked even with the end of

pilot. (Illustration 15)

10. Insert burner into opening, slide along channel until

flat end of burner is fully seated in slot of right interior

wall.

11. Seat burner over orifice.

12. Drop burner lock plate to seat firmly over burner,

tighten nut to secure in place.

13. Place pilot tube in pilot and join by tightening compression nut. CAUTION: Be sure pilot orifice is

positioned in end of pilot.

14. Snap flame switch ceramic into bracket and place

wires on terminals.

R Burner Replacement

(Follow procedures in Section Q)

Sub Assembly Components

(Refer to illustrations 15, 16 & 17)

NOTE: The sub assembly contains the components that

direct and control gas flow to the burners. All threaded

fittings, with the exception of compression fittings and

orifices, should be coated with rectorseal #5 thread

sealing compound during installation.

S Sub Assembly Removal

(Refer to illustration 17)

1. Remove thermostat knob.

2. Remove union on intake pipe.

3. Remove pilot tube compression fittings at pilot flame filter

assembly.

4. Loosen burner lock plate nuts.

5. Bend capillary retainer clamp to achieve clearance and

slip tube from under clamp.

6. Remove wire connections from flame switches and

solenoid valves.

7. Carefully slide thermostat bulb from holder. CAUTION:

Avoid sharp bends or kinks in the capillary tube and

bulb that will create restriction, preventing proper

thermostat operation.

8. Remove the two nuts holding intake pipe to base plate.

9. Remove two nuts from each solenoid bracket, making

sure spacers remain in place. (Illustration 16)

10. Raise burners to clear orifices, tilt top of the sub assembly

to clear solenoid brackets from weld bolts, then move sub

assembly to rear until thermostat shaft clears front of

toaster.

11. Angle front of sub assembly outward and slide out of

toaster.

T Sub Assembly Installation

(Refer to illustration 17)

1. Slip intake pipe through rear opening far enough to allow

thermostat shaft to clear front of toaster and into front

opening.

2. Simultaneously, position solenoid brackets and intake pipe

over weld bolts. (Make sure spacers are in place on the

solenoid brackets). (Illustration 16) Install nuts and

tighten.

3. Carefully insert thermostat bulb into holder, dress capillary

tube and place under clamp. Bend clamp to secure tube.

4. Align burners over orifices, position burner lock plates and

tighten nuts.

5. Attach pilot tubes with compression fittings at pilot flame

filter assembly.

6. Slip wire connections on pilot flame switches and solenoid

valves. (Refer to wiring diagram)

7. Install union between intake pipe and pressure regulator.

8. Replace thermostat knob.

9. Turn on shut-off valve, light pilots and operate toaster.

CHECK ALL CONNECTIONS FOR LEAKS USING

SOAP SOLUTION.

8

9

U Thermostat Replacement

(Refer to illustration 17)

1. Remove sub assembly. (Refer to Section S)

2. Remove the two screws at the top of the thermostat

that go through to hold the intake pipe mounting

flange and remove the intake pipe.

3. Carefully coil the thermostat tube close to the thermostat and safety solenoid.

4. Holding the body of the safety solenoid with a wrench

or vise, unthread thermostat from nipple.

5. To install new thermostat, thread thermostat onto

nipple and tighten. NOTE: If nipple has been

removed with the old thermostat, replace nipple

into safety solenoid. Make sure intake pipe

mounting flange holes are aligned from top to

bottom.

6. Place intake pipe/mounting flange on bottom of

thermostat. Insert the two screws through the top

and secure.

7. Install sub assembly. (Refer to Section T)

V Control Solenoid Valve Replacement

(Refer to illustration 17)

1. Remove sub assembly (Section S), and intake pipe

(Section U Step #2).

2. Remove solenoid plug and retain for new installation.

3. Unthread street elbow assembly.

4. Unthread control solenoid valve from T-fitting, and

remove.

5. Thread new valve onto T-fitting, making sure the

valve is in vertical alignment with the safety solenoid

valve.

6. Thread street elbow assembly to control valve,

making sure street elbow assembly is in vertical

alignment with the other offset pipe.

7. Replace solenoid plug.

8. Replace intake pipe/mounting flange. (Refer to

Section U Step #6)

9. Replace sub assembly. (Refer to Section T)

W Safety Solenoid Valve

Replacement

(Refer to illustration 17)

1. Remove sub assembly (Section S), and

thermostat (Section U).

2. Remove solenoid plug and retain for new

installation.

3. Unthread safety solenoid valve from T-fitting

and remove.

4. To replace, thread safety solenoid valve onto

T-fitting making sure valve is in vertical

alignment with control solenoid valve.

5. Replace solenoid plug.

6. Replace thermostat (Section U), and sub

assembly (Section T).

X Intake Pipe Replacement

(Refer to illustration 17)

1. Remove sub assembly. (Refer to Section S)

2. Remove intake pipe from thermostat. (Refer

to Section U Step #2)

3. Unthreaded intake pipe mounting flange and

remove.

4. Remove pilot flame filter assembly.

5. To install new pipe, replace pilot flame filter

assembly checking for proper alignment.

6. Thread intake pipe mounting flange to intake

pipe, checking for proper orientation.

7. Attach pipe to thermostat. (Refer to Section

U Step #6)

8. Replace sub assembly. (Refer to Section T)

Y Pilot Flame Filter Assembly Replacement

(Refer to illustration 17)

1. Using a 7/16” wrench, remove both compression sleeves.

2. Unthread pilot flame filter assembly from

intake pipe.

3. Reverse this procedure to install new pilot

flame filter assembly.

10

11

1111 N. Hadley Rd.

Fort Wayne, In. 46804

Tel. 800-701-2992

Fax (260) 436-0735 www.mercosavory.com

12

Loading...

Loading...