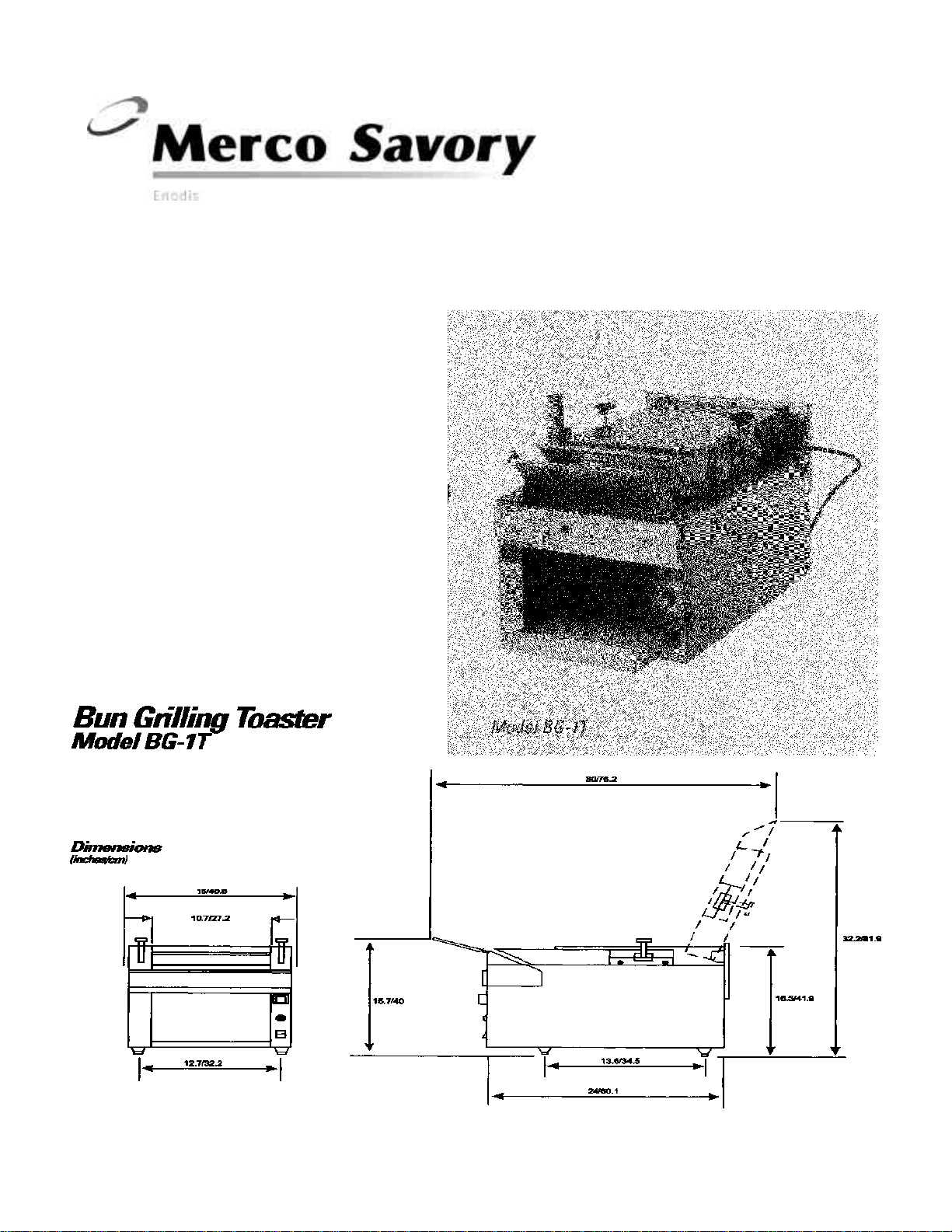

PARTS & SERVICE Manual for BG-1T Horizontal Grilling

Toaster

The BG-1T horizontal conveyer grilling

toasters are engineered for efficient,

dependable service throughout the

years. Like any piece of equipment

with moving parts, physical wear takes

its toll. When this happens, the

information in this manual will prove

helpful. Although the instructions are

easy to follow, the work should be

handled by a qualified Savory Certified

Service Technician.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE USE

1200-JDM 07011

PARTS LISTING for BG-1T

DESCRIPTION PART #

Bearing retainer, front (Pk/4) 12381

1” plastic leg (Pk/4) 12668

90 Deg strain relief bushing Metal 12682

Speed control 12464

Conveyor drive sprocket 14T 13733

Front spacers 14606

Bearings 22754

Terminal block 21858

Thermostat knob 22566

1” metal legs (Pk/4) 41087

Power indicator light 51052

Handle shield, black 68258

Strain relief bushing 69523

Strain relief lock nut 69524

Speed control decal 69526

Front adjustment pins 69527

Thermostat 69528

Hi-limit control 69529

Motor Fan 12946

Belleville washers 69532

Conveyor wire belt 5”-69 links 69538

Rear spacers 69542

6’ cordset 120V NEMA 5-15P 69549

On/off rocker switch 15A 69550

Master link 5” conveyor wire belt 69754

Coated platen sheets (Pk/10) 69556

Heater platen 120V 1500W 69571

DESCRIPTION PART#

Platen power cord 69574

Platen cover 69576

Platen back cover 69578

Teflon strip, heat barrier 69580

Thermostat insulator 69581

Platen brace 69584

Platen insulation holder 69605

Platen sheet holder bracket 69607

Platen safety latch 69609

Front platen adjustment bracket 69622

Bearing retainer, rear 69654

Conveyor tension adjust. Bracket 69655

Loading ramp insert 69666

Delivery chute 69670

Toast tray 69671

Front shelf 69693

Rear adjustment cover 69703

Left side panel 69707

Right side panel 69708

Platen handle 69714

Motor assy., w/fan 120V 69716

Drive chain 60 links 69719

Platen mounting bracket 69747

Front shaft assy., 5” 69751

Rear shaft assy., 5” 69752

Loading ramp 69773

Motor sprocket 12T 69787

PARTS REPLACEMENT INSTRUCTIONS

WARNING:

DISCONNECT UNIT FROM POWER SOURCE

BEFORE ATTEMPTING AND SERVICE PROCEDURES.

General instructions:

The BG-1T has two 5” wide conveyor belt systems.

The parts replacement information contained in this

manual will pertain to the BG-1T model only.

A Panel Removal

1. All parts replacement procedures will require the

removal of one or both toaster side panels and/or

the bottom panel. Parts replacement procedures

on the platen assembly will require the removal of

the platen cover and the platen back panel.

2

2. To remove either the right or left side toaster panel,

remove all 5 sheet metal screws and pull downward

on the panel to remove.

3. To remove the bottom toaster panel, remove the 2

sheet metal screws.

4. To remove the platen cover, remove the 4 sheet

metal screws and lift upward.

5. To remove the platen back panel, remove the 6 sheet

metal screws.

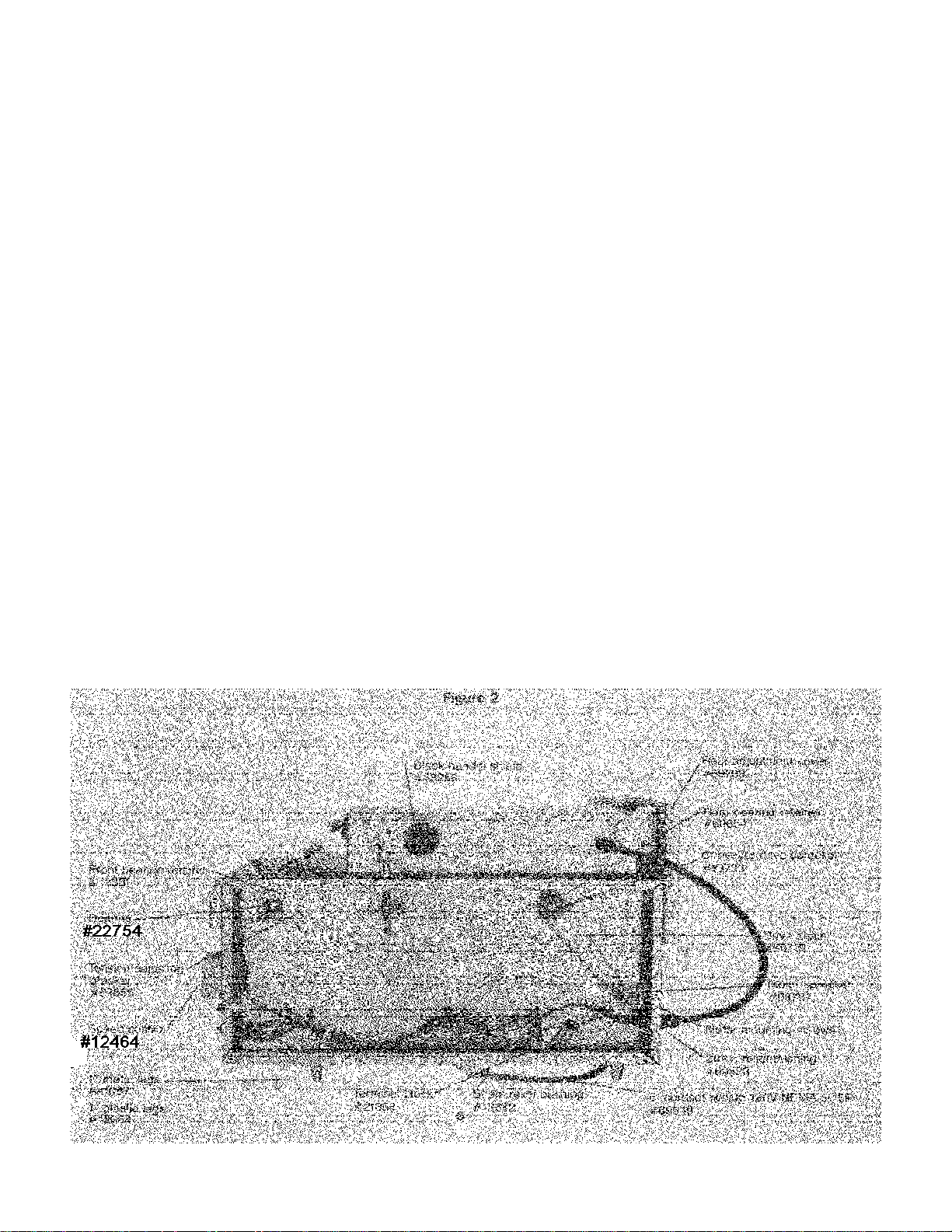

B Conveyor Speed Control Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Pull off speed control knob.

3. Disconnect the 2 wire leads, one at the on/off switch

and the other at the wire connector.

4. Remove the nut securing the control to the

front toaster panel and pull control out from

back side of panel.

5. Reverse this procedure to install new

control. (Refer to wiring diagram)

C Power Indicator Light

Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Disconnect the 2 wires from back of light.

3. Press spring loaded tabs on back of light

and push light through front of panel.

4. Insert new light from front of panel and snap

into place.

5. Re-attach wires to light terminals. (Refer to

wiring diagram)

D On/Off Switch Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Disconnect all wires from back switch noting

proper orientation.

3. Press spring loaded tabs on back of switch

and push through front of panel.

4. Install new switch from front of panel and

snap into place.

5. Re-attach wires to switch terminals. (Refer

to wiring diagram)

E Terminal Block Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Disconnect all wires from terminal block noting proper

orientation.

3. Remove the 2 nuts and screws securing the terminal

block to the toaster floor and remove terminal block.

4. Reverse this procedure to install new terminal block.

(Refer to wiring diagram)

F Main Power Cord Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Disconnect wire at on/off switch, terminal block and

ground wire.

3. Remove retaining nut securing the 90 deg., elbow to the

toaster floor and remove power cord along with the 90

deg., elbow.

4. Remove the power cord from the 90 deg., elbow by

loosing the two screws on the 90 deg., elbow.

5. Reverse this procedure to install a new power cord.

(Refer to wiring diagram)

G Drive Chain Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Loosen, but do NOT remove, the 4 motor mounting

screws.

3. Slide motor slightly to loosen drive chain tension and

remove drive chain from around the motor and conveyor

sprockets.

3

4. Install new drive chain over sprockets with

open looped side of chain facing upward.

5. Slide motor to remove excess slack from

drive chain and tighten the 4 motor mounting

screws.

H Conveyor Chain Sprocket

Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Remove the drive chain. (Section G)

3. Loosen the set screw on hub of sprocket and

slide sprocket off shaft.

4. When installing new sprocket, make sure set

screw rests in hole on the shaft.

5. Replace the ddrive chain. (Section G)

I Motor Sprocket Replacement

(Figure 2)

1. Remove the right side panel. (Section A)

2. Remove the drive chain. (Section G)

3. Loosen the 2 set screws on hub of sprocket

and slide sprocket off shaft.

4. When installing new motor sprocket, make

sure that one of the two set screws rests on

the flat of the motor shaft.

5. Replace drive chain. (Section G)

J Motor Replacement

(Figure 3)

1. Remove the right side panel and the panel

from underside of unit. (Section A)

2. Remove the drive chain (Section G), and the

motor sprocket. (Section I)

3. Disconnect the wire leads at the terminal

block and at the wire connector.

4. Remove the 4 motor mounting screws and

lock washers and remove motor.

5. Install new motor and secure with the 4 motor

mounting screws and lock washers.

6. Re-attach wire leads at the wire connector

and at the terminal block. (Refer to wiring

diagram)

K Conveyor Belt Replacement

(Figure 2 & 5)

1. Remove both the right and left side panels.

(Section A)

2. Loosen, but do NOT remove, the bearing

retainer brackets on both sides of toaster.

3. Loosen, but do NOT remove, the tension

adjusting brackets on both sides of toaster.

4. Push front conveyor shaft towards the back

of toaster to loosen belt tension.

5. Separate the conveyor belt at any link and

slide out of toaster.

6. When installing new conveyor belt, check for

proper link orientation. (Figure 5)

7. Starting at front of toaster, slide belt under

front shaft and push towards rear of unit.

Bring belt up and over rear shaft and pull

towards front of unit. Make sure belt is

resting on top of all belt support guides. Reconnect links. CAUTION: MAKE SURE

BELT IS NOT INSTALLED AT AN ANGLE.

8. Pull forward on front conveyor shaft until

excess slack is removed from the belt.

9. Tighten tension adjusting brackets and

bearing brackets on both sides of toaster.

L Front And Rear Shafts

And Bearing Replacement

(Figure 2, 4 & 5)

1. Remove both right and left side panels.

(Section A)

2. To remove front shaft and front shaft

bearings: Remove bearing retainers on

both sides of toaster.

3. Loosen conveyor belt tension adjusting

brackets on both sides of toaster.

4. Bearings (with shaft) will now slide out. Note

proper orientation of spacers.

5. To remove rear shaft and rear shaft

bearings: Remove drive chain (Section G),

and conveyor shaft sprocket. (Section H)

6. Remove rear bearing retainer brackets

from both sides of toaster.

7. Bearings (with shaft) will not slide out. Note

proper orientation of spacers.

8. Replace bearings, spacers and shaft.

Replace conveyor belt tension adjusting

brackets (on front shaft) and bearing retainer

brackets on both front and rear shafts.

9. Replace conveyor shaft sprocket and drive

chain on rear shaft.

10. On front shaft, adjust tension of conveyor

belt to remove excess slack from belt.

4

5

PLATEN ASSEMBLY COMPONENTS PARTS REPLACEMENT

INSTRUCTIONS:

General Instructions: The following instructions

will describe how to replace components of the platen

assembly. To gain access to the internal parts of the

platen you must first remove the platen cover by

removing the 4 sheet metal screws securing the cover

to the platen assembly. For some parts replacement

procedures you will be required to remove the entire

platen assembly from the toaster body. Instructions on

platen assembly removal will be found in Section P.

M Platen Handle Replacement

(Figure 1 & 6)

1. The platen handle screws onto the threaded weld

stud. Be sure black handle shield is properly

located between the handle and the platen side.

N Hi-limit Control Replacement

(Figure 6)

1. Disconnect the 2 wires at the control.

2. Remove the 2 screws and washers securing the

control to platen.

3. Reverse this procedure to install new control.

(Refer to wiring diagram)

4. Before installing new hi-limit control, coat entire

bottom of control with Thermal Mastic compound.

P Platen Power Cord Replacement

(Figure 6 & 7)

1. Disconnect the wire leads at the thermostat,

platen and the ground wire.

2. Remove the lock nut from inner wall and

carefully pull out power cord with wires intact.

3. Reverse this procedure to install new power

cord. (Refer to wiring diagram)

Q Platen Assembly Removal

(Figure 6 & 7)

1. To replace the following components, the

entire platen assembly must first be removed

from the toaster body.

2. Remove platen cover and platen cord. (Section P)

3. Remove the acorn nut from the platen pivot

rod and slide out rod. Note proper orientation

of washers on both platen assembly.

4. Carefully lift off platen assembly.

R Thermostat Replacement

(Figure 6 & 7)

1. Remove entire platen assembly from toaster

body. (Section Q)

2. Remove the 6 sheet metal screws on back

panel of platen assembly and remove the

panel.

3. Disconnect wires going to the hi-limit control

and the power cord.

4. Remove the temperature control knob.

5. Remove the 2 screws (located behind the

temperature control knob) securing the

thermostat to the retaining bracket.

6. Remove the insulation from the platen

insulation holder.

7. Remove the thermostat bulb retainer bracket

which slips over the capillary tube, and

carefully pull thermostat and bulb from inside

the platen.

8. IMPORTANT: Before installing new thermostat, coat entire capillary bulb with a thin layer

of Thermal Mastic compound.

9. Set thermostat to desired platen temperature.

(Section U)

S Platen Replacement

(Figure 6 & 7)

1. Remove platen power cord. (Section P)

2. Remove entire platen assembly from toaster

body. (Section Q)

3. Remove thermostat. (Section R)

4. Remove the 2 sheet metal screws securing

platen strip to platen insulation holder.

5. Disconnect all wires from platen and hi-limit

control.

6. Remove the 4 large nuts and Belleville

washers securing the platen. IMPORTANT:

Note proper orientation of Belleville washers.

7. Remove the 4 screws and nuts securing the

platen brace and remove the brace. Note

proper orientation of brackets and platen

brace.

8. Remove platen.

9. IMPORTANT: When replacing platen, be

sure that teflon strip is properly located

between the rear edge of the platen and the

platen insulation holder.

10. Before installing new platen, coat entire

bottom surface with Thermal Mastic compound.

11. Reverse this procedure to install new platen.

6

T Platen Height Adjustment

Instructions

(Figure 3 & 10)

It is recommended that the amount of space between

the conveyor belt surface and the platen surface be ¼”

less than the thickness of the product being toasted.

1. Remove both side panels and the rear adjustment

cover.

2. Loosen the lock nut on the two front adjustment

pins. (Figure 3)

3. Loosen, but do NOT remove, the 4 #10 nuts on the

rear adjustment brackets (2 on each bracket), and

the lock nut on each bracket.

4. CAREFULLY lift the loosened platen and rest on the

safety latch. (Figure 3). Position height adjustment

device over conveyor belt making sure the slots fall

over the two front adjustment pins.

5. Slide adjustment device to the desired “step” height.

6. CAREFULLY lower loosened platen making sure

platen making sure platen comes into contact with

the same “step” in all four corners,

IMPORTANT

BEFORE TIGHTENING ADJUSTMENT HARDWARE,

BE SURE PLATEN IS RESTING SQUARELY ON THE

SAME “STEP” IN ALL FOUR CORNERS. PLATEN

SHOULD NOT WOBBLE.

7. Adjust the two front adjustment pins until they just

touch the bottom surface of the front adjustment

brackets. Tighten lock nut on each.

8. Tighten the four #10 nuts on the rear adjustment

brackets. Adjust the two rear adjustment nuts until

they just touch the lower edge and tighten the lock

nut on each.

9. Remove platen height adjustment device. Retain

for future use.

10. Replace side panels and rear adjustment cover.

U Platen Temperature Adjustment Instructions

(Figure 6)

1. Remove platen cover. (Section A)

2. To increase platen temperature; turn temperature

control knob clockwise. To decrease platen

temperature; turn temperature control knob counterclockwise.

3. IMPORTANT: Allow at least a 30 minute warm-up

or cool-down period. It is recommended that

temperature should be noted at the center point of

the platen surface. There will be a 10 deg., to 20

deg., drop in temperature between the actual

platen casting and the platen cooking surface.

Platen will reach set temperature after 4 to 5

complete temperature control cycles.

4. Replace platen cover.

7891011

WIRING DIAGRAM

BG-1T

208V SYSTEM PARTS LIST

CORDSET #69940

DRIVE CHAIN #69538

PLATEN HEATER #69870

MOTOR ASSY. #69935

SPEED CONTROL #69880

CONVEYOR SPROCKET 14T #13300 1111 N. Hadley Rd.

Fort Wayne, In 46804

Tel. 800-701-2992

12

Fax (260) 436-0735

www.mercosavory.com

Loading...

Loading...