Page 1

6. REMARKS

Operation Notes

General Cautions

• While printing, do not turn off the main switch.

• While printing, do not open the door or covers.

• While printing, do not unplug the power cord.

• While printing, do not move the machine.

• Keep corrosive liquids, such as acid, off the machine.

• Open and close the door and covers softly.

• Do not put anything except originals on the machine.

• Do not spill liquid on the machine.

• When opening or closing the door or covers, keep hold of them so they don't

fall.

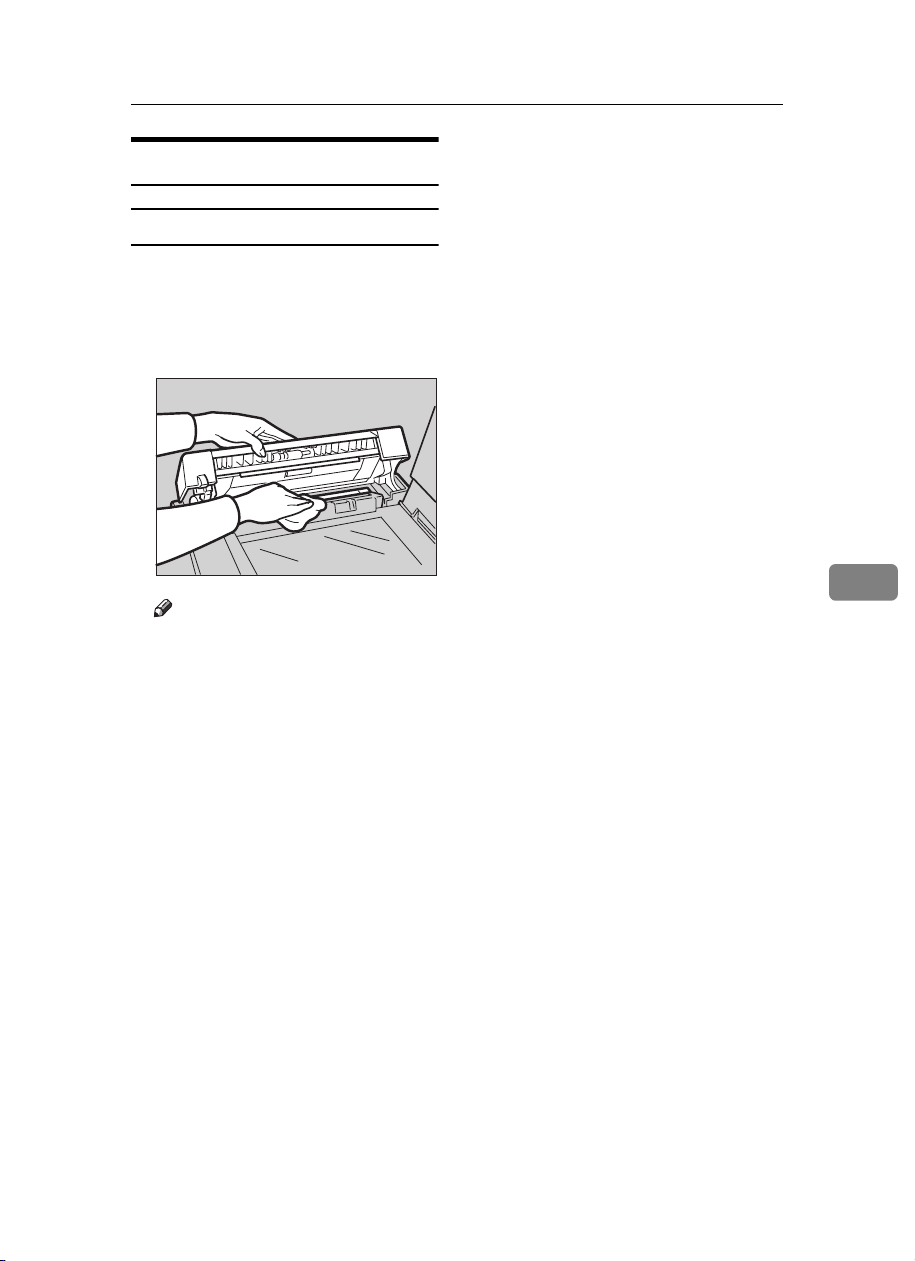

• When removing the drum unit from the machine, be careful not to let the

drum unit fall.

• Do not modify or replace any parts other than the ones specified in this manual.

• Do not operate the machine without covers. You might get your fingers

caught in the machine, or the machine might be damaged because, for example, dust or the like might get inside.

• Since some parts of the machine are sharp and might cause injury, touch only

the parts specified in this manual.

• If you clean rubber parts with benzine, wipe them with a dry cloth afterwards.

• Always turn the machine off when you have finished printing for the day.

• If the machine must be transported by vehicle, please contact your service

representative.

• Make sure to make a few trial prints to check the image position because the

image position of the trial print might not correspond with that of the original.

• If the image registration is not consistent, slow the printing speed down to

Setting 0.

• When performing duplex or multicolored printing, leave the printed paper

for a while before the next printing in order to let the ink dry on the printed

paper. If this is not done, feed roller marks will appear on the print image.

105

Page 2

REMARKS

• If the machine is not used for a long period, the image density might decrease

because the ink on the drum might dry. Make extra prints until the image

density recovers.

• When the machine is used in low temperature conditions, the image density

might decrease. In this case, slow the printing speed down to step 1 or 2.

• When making duplex prints, misdetection of paper wrapping might occur if

the paper delivery sensor detects a black area at the leading edge of the back

side. Keep at least an 5 mm, 0.2" margin at the leading edge of the back side

of the printing paper.

• Press the {

light.

• The top sheet might remain between the feed rollers when you press the {

per Feed Table Down

• When making duplex prints or when using non-white printing paper, the paper end sensor might malfunction and fail to detect the paper. In this case,

place a blank sheet under the printing paper on the paper feed table.

• The outer portion of the image might not be printed under low temperature.

In this case, slow the printing speed down to step 1 or 2, or increase the room

temperature.

6

• The paper exit pawl might contact the printing paper and cause black lines on

the prints. In this case, increase the printing speed or make a new master with

lighter image density mode.

• If you cannot pull out the drum, close the front cover again to rotate the drum.

Pull out the drum after it stopped at the position.

• The leading edge of the prints might become stained if the edge touches the

image of prints on the paper delivery table.

• The ink of the print on the paper delivery table might stick to the back side of

the next print.

• When the machine is on and the power source is less than 90 % of the specified amount, printing quality will decrease. Therefore, make sure the supply

from your electrical outlet is at least 90 % of the required amount.

• As various kinds and qualities of paper exist, some paper might be wrapped

around the drum or cause misfeeds.

• If your hands are stained with ink:

• Avoid prolonged or repeated contact with skin.

• Cleanse skin thoroughly after contact, before breaks and meals, and at the

end of the work period.

• Ink is readily removed from skin by waterless hand cleaners followed by

washing with soap and water.

• Also, be careful not to get any ink on your clothing while emptying the master

eject box or while loading a new ink cartridge.

} key to perform a test print as the first few prints might be

Proof

} key. In this case, remove the top sheet.

Pa-

106

Page 3

Operation Notes

• The image density varies according to the printing speed and the room temperature. So, adjust the printing speed or increase the room temperature.

• When you make a lot of prints from a small image, ink might ooze out from

the edges of the master, especially under high temperature and when printing in two or more colors. In this case, make a new master.

• Use ink made within one year. Ink stored for a long period tends to dry slowly and yield lower image density.

• While making a master, do not leave the platen cover or optional document

feeder open.

• In Letter/Photo mode, moire patterns might occur when screened originals

are printed. In this case, make prints in Letter or Photo mode.

• When you use originals with light lettering, edges of the letters might be

printed clearly and the inside of the letters might be light. In this case, increase the image density.

Print Paper

• When the paper is curled, stack the paper with the curl face down, otherwise

the paper might wrap around the drum or stains might appear.

• Postcards and the like do not absorb ink well. Offset images might appear on

the rear side of subsequent prints. Solid image originals will cause offset image prints.

6

Originals

• If there is no margin or if there is a solid image area near the leading edge of

the original, make at least a 5 mm, 0.2", margin at the leading edge; otherwise,

the paper might wrap around the drum or the paper exit pawl might become

dirty and cause black lines on prints.

• If you use originals that have bold letters or solid images at the leading edges,

you might get prints with dirty edges. In this case, insert the widest margin

first, or raise the printing speed.

• If you use paste-up originals, select Paste Shadow Erase mode (see ⇒ P.21

“Paste Shadow Erase—Erasing The Shadow Of Pasted Originals”) make sure that

the pasted parts hold firmly to the base sheet. If the thickness of the paste-up

originals is more than 0.1 mm and the space between the pasted parts is less

than 2 mm, 0.08", a shadow might appear on the print.

• Under the following conditions, the machine might not detect the original on

the exposure glass. If you press the {

making a master anyway:

• When you set a dark original on the exposure glass.

• When the original is not centered according to the size marks on the right

scale.

} key again, the machine will start

Start

107

Page 4

REMARKS

• If you do not open the platen cover at an angle of more than 25 degrees

with the exposure glass when you replace originals.

• If the machine is installed under a strong light.

6

108

Page 5

Where To Put Your Machine

R

R

Where To Put Your Machine

Your machine's location should be carefully chosen because environmental conditions greatly affect its performance.

Environmental Conditions

Optimum environmental conditions

CAUTION:

Keep the machine away from humidity and dust. A fire or an elec-

•

tric shock might occur.

•

Do not place the machine on an unstable or tilted surface. If it topples over, it could cause injury.

CAUTION:

•

If you use the machine in a confined space, make sure there is a

continuous air turnover.

• Temperature: 10 – 30°C, 50 – 86°F

•Humidity:

• Main Frame: 20 – 90 % RH

• Document feeder (option): 20 – 70 % RH

• A strong and level base (a sturdy desk and cabinet etc.).

• The machine must be level within 5 mm, 0.2" both front to rear and left to

right.

• Make sure to locate this machine in a large well ventilated room that has an

air turnover of more than 30 m

3

/hr/person.

6

Environments to avoid

• Locations exposed to direct sunlight or strong light (more than 1500 lux).

• Locations directly exposed to cool air from an air conditioner or heated air

from a heater. (Sudden temperature changes might cause condensation within the machine.)

• Places where the machine might be subjected to frequent strong vibration.

•Dusty areas.

• Areas with corrosive gases.

109

Page 6

REMARKS

R

R

R

R

Power connection

WARNING:

Only connect the machine to the power source described on

•

the inside front cover of this manual.

Avoid multi-wiring.

•

Do not damage, break or make any modifications to the pow-

•

er cord. Do not place heavy objects on it, pull it hard or bend

it more than necessary. These actions could cau se an electric shock or fire.

Do not plug or unplug the power cord with your hands wet.

•

Otherwise, an electric shock might occur.

WARNING:

Make sure the wall outlet is near the machine and freely ac-

•

cessible so that in event of an emergency it can be unplugged easily.

CAUTION:

6

•

When you move the machine, unplug the power cord from the

wall outlet to avoid fire or electric shock.

•

When the machine will not be used for a long time, unplug the

power cord.

❖❖❖❖ Main Frame

110

CAUTION:

•

When you pull out the plug from the socket, grip the plug to avoid

damaging the cord and causing fire or electric shock.

• Make sure the plug is firmly inserted in the outlet.

Page 7

Where To Put Your Machine

Access to machine

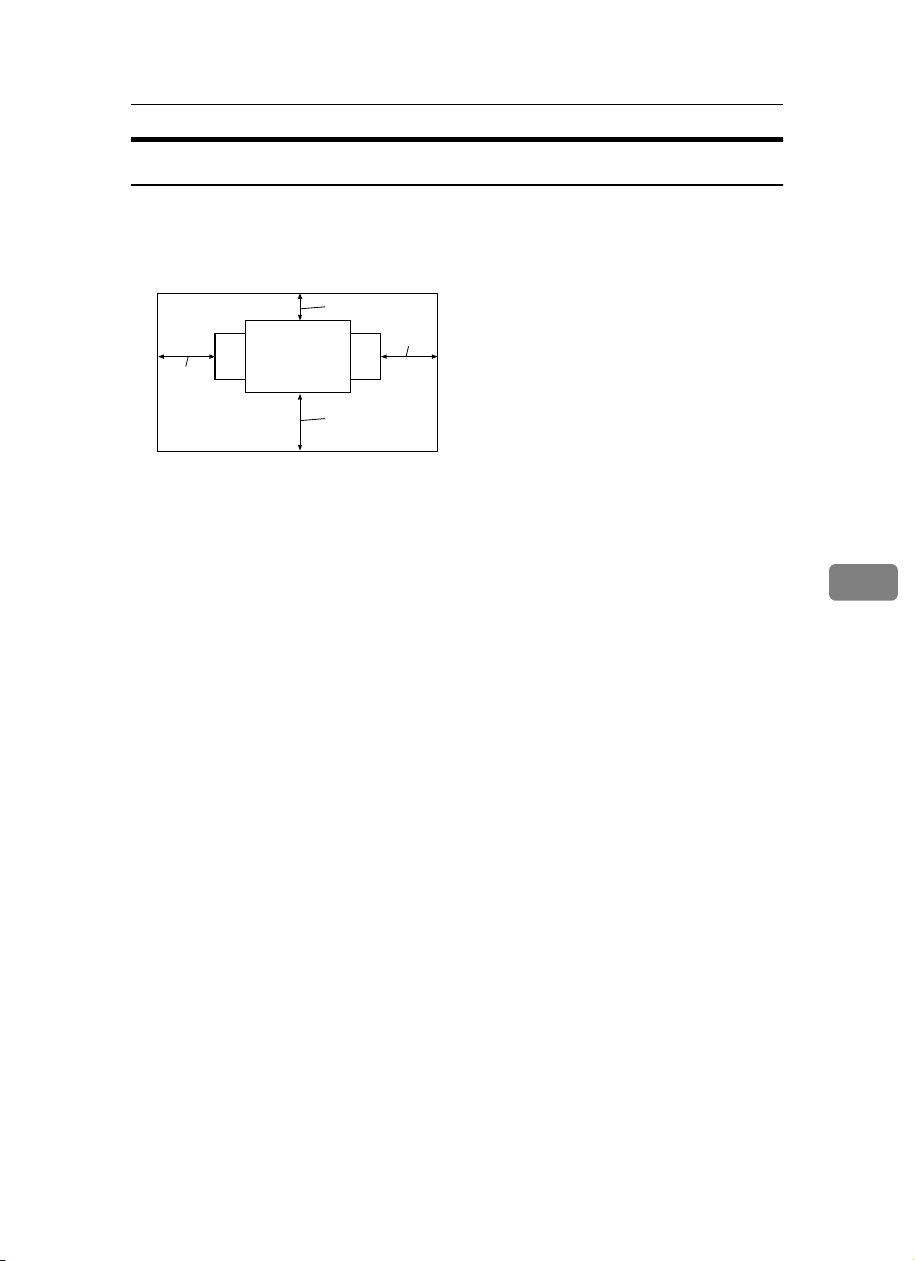

Place the machine near the power source, providing clearance as shown.

❖❖❖❖ Main Frame

1

2

4

3

GRINST0E

1. More than 20 cm, 8.0"

2. More than 60 cm, 23.7"

3. More than 60 cm, 23.7"

4. More than 60 cm, 23.7"

6

111

Page 8

REMARKS

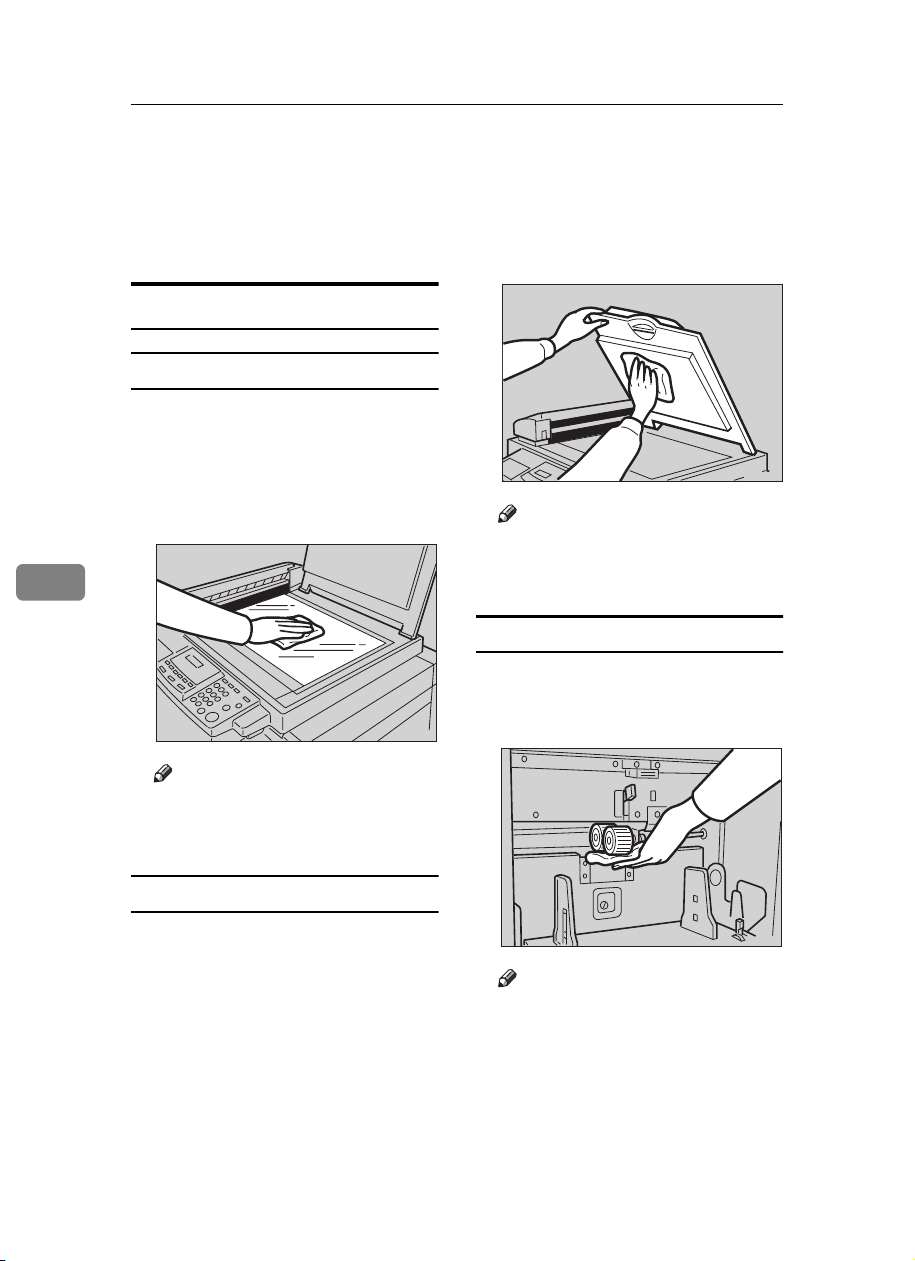

Maintaining Your Machine

To maintain high print quality, clean

the following parts and units regularly.

Clean the platen cover with a

B

damp cloth and wipe it with a dry

cloth.

Main Frame

Exposure Glass

Lift the platen cover or document

A

feeder.

Clean the exposure glass with a

B

damp cloth and wipe it with a dry

cloth.

6

TSLH019E

Note

❒ If you do not clean the exposure

glass, marks on the glass will be

printed.

Note

❒ If you do not clean the platen

cover, marks on the cover will

be printed.

Paper Feed Roller (paper feed table)

Wipe off the paper dust on the pa-

A

per feed roller with a damp cloth,

then wipe it with a dry cloth.

TSLH015E

112

Platen Cover

Lift the platen cover.

A

TSLH017E

Note

❒ If you do not clean the paper

feed roller, paper misfeeds tend

to occur.

Page 9

Optional Document Feeder

Separation Roller

Open the ADF unit.

A

Clean the separation roller with a

B

damp cloth and wipe it with a dry

cloth.

Note

❒ If you do not clean the separa-

tion roller, original misfeeds

tend to occur.

Maintaining Your Machine

TSLH016E

6

113

Page 10

REMARKS

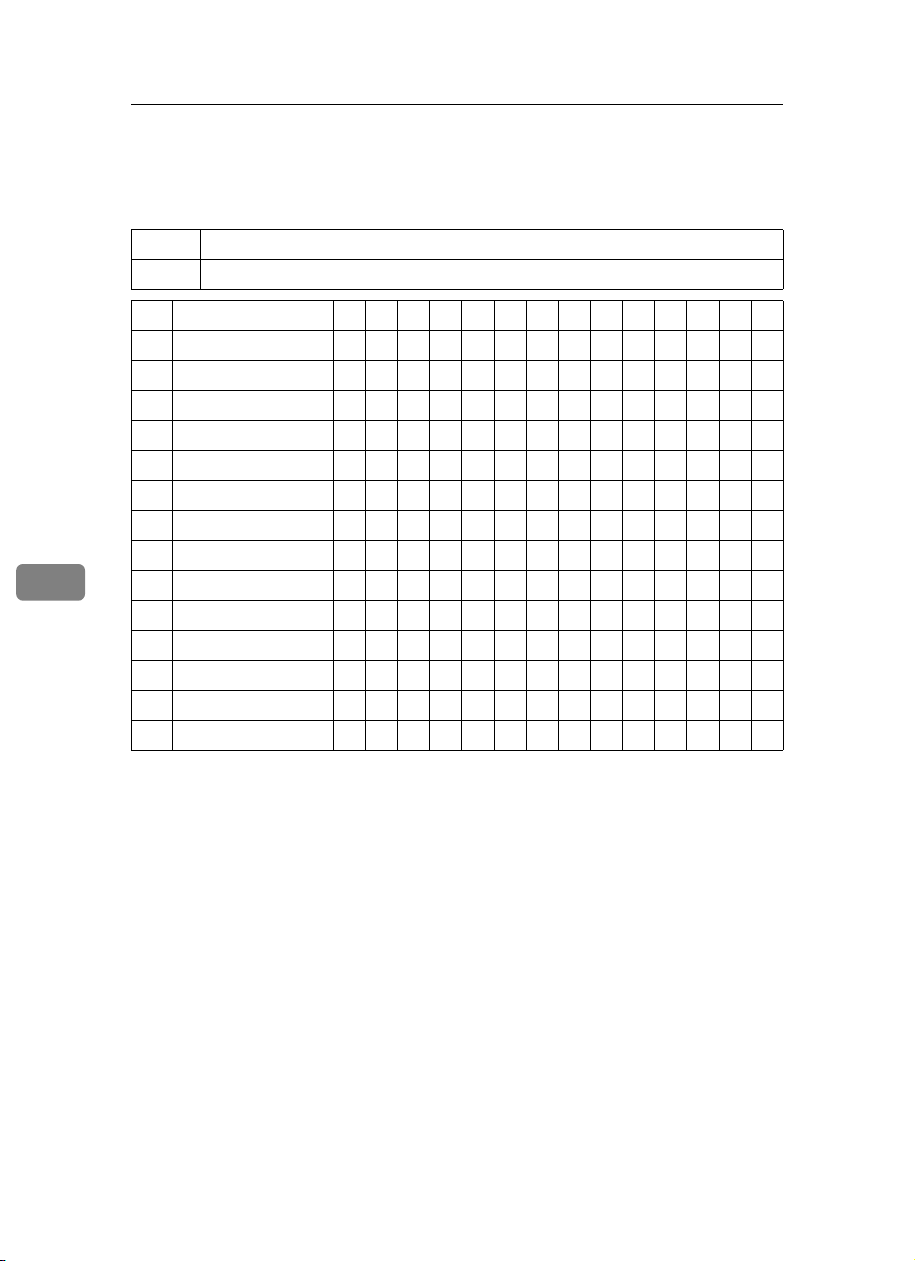

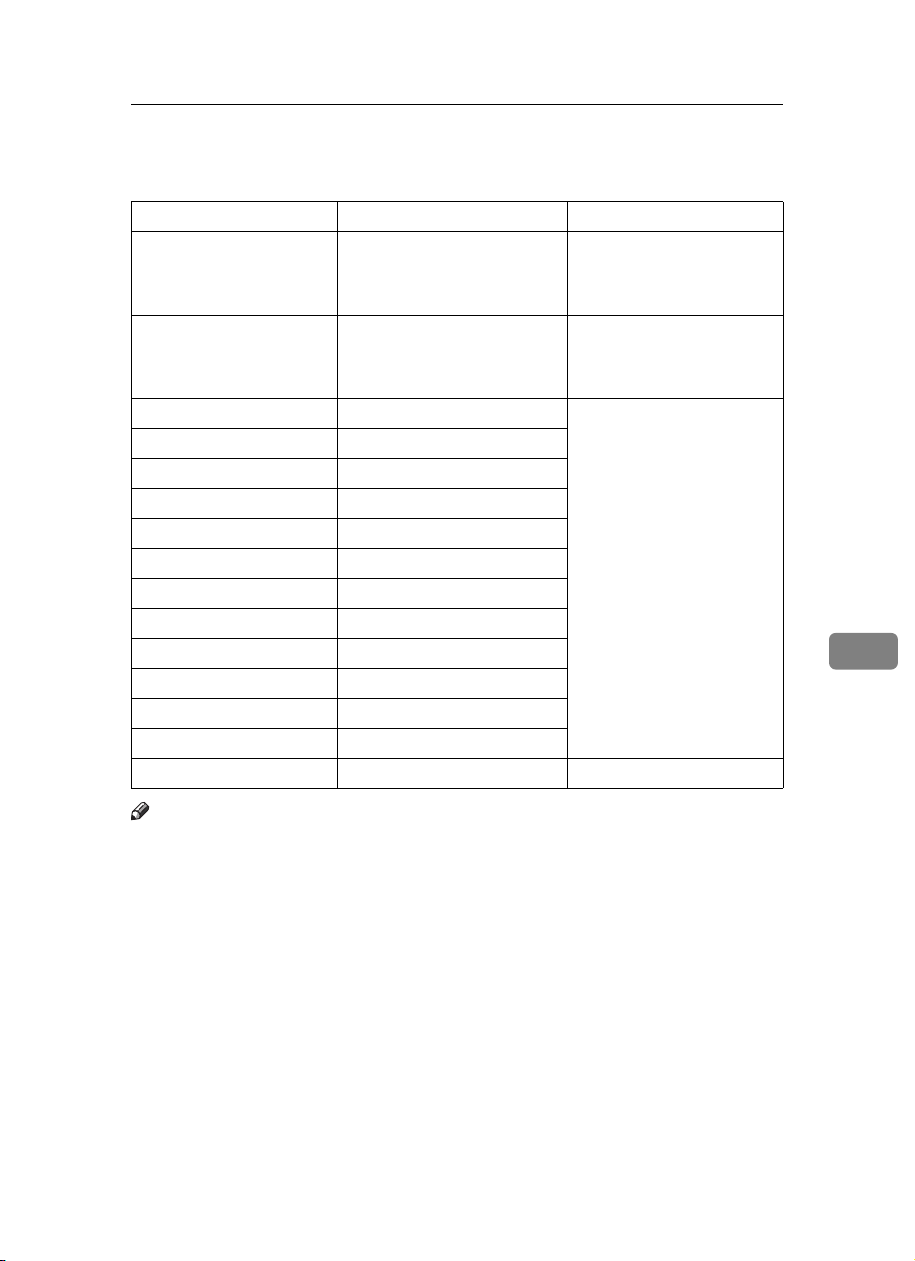

Combination Chart

This combination chart shows which modes can be used together.

❍

×

1 Reduction

2 Enlargement ×

3Auto Cycle ❍❍--❍❍❍❍❍❍❍❍❍❍❍

4 Memory mode ❍❍❍--× ❍❍❍❍××❍❍❍

5Class mode ❍❍❍×

6 Combine Copies ❍❍❍❍❍--❍❍❍××❍❍❍

7 Center/Edge Erase ❍❍❍❍❍❍--❍❍× ❍❍❍❍

8 Type of Original ❍❍❍❍❍❍❍--❍ × ❍❍❍❍

6

9 Image Density ❍❍❍❍❍❍❍❍--× ❍❍❍❍

10 On-Line ××❍ ЧЧЧЧЧЧ--❍❍××

11 Overlay ❍❍❍×××❍❍❍❍--❍ ××

12 Economy mode ❍❍❍❍❍❍❍❍❍❍❍--❍❍

13 Tint mode ❍❍❍❍❍❍❍❍❍××❍

14 Fine mode ❍❍❍❍❍❍❍❍❍××❍❍

means that these modes can be used together.

means that these modes cannot be used together.

1234567 8 91011121314

--

× ❍❍❍❍❍❍❍× ❍❍❍❍

--

❍❍❍❍❍❍❍× ❍❍❍❍

--

❍❍❍❍××❍❍❍

--

❍

--

114

Page 11

7. SPECIFICATION

Main Frame

❖❖❖❖ Configuration:

Desk top

❖❖❖❖ Printing Process:

Full automatic one drum system

❖❖❖❖ Original Type:

Sheet/Book

❖❖❖❖ Original Size:

Maximum 257 mm × 364 mm, 10.2" × 14.4"

❖❖❖❖ Pixel Density:

300 dpi (in Fine mode 400dpi)

❖❖❖❖ Image Mode:

Photo mode (Sand pattern)

Letter mode (Standard mode)

Letter/Photo mode

❖❖❖❖ Reduction Ratios:

• Inch version:

93 %, 77 %, 74 %, 65 %

• Metric version:

93 %, 87 %, 82 %, 71 %

❖❖❖❖ Enlargement Ratios:

• Inch version:

155 %, 129 %, 121 %

• Metric version:

141 %, 122 %, 115 %

❖❖❖❖ Printing Area:

•LG drum:

More than 210 mm × 355 mm, 8.2" × 14.0"

•B4 drum:

More than 250 mm × 355 mm, 9.8" × 14.0"

❖❖❖❖ Print Paper Size:

Maximum 268 mm × 388 mm, 10.5" × 15.2"

Minimum 90 mm × 148 mm, 3.6" × 5.9"

115

Page 12

SPECIFICATION

❖❖❖❖ Leading Edge Margin:

5 mm ± 3 mm, 0.2" ± 0.12"

❖❖❖❖ Print Paper Weight:

47.1 g/m2 to 157.0 g/m2, 12.5 lb to 41.7 lb

❖❖❖❖ Print Speed:

80 – 120 rpm (3 steps)

❖❖❖❖ First Copy Time (Master Process Time):

Less than 27.0 seconds (A4L, 81/

" × 11"L)

2

(When setting an original on the exposure glass)

❖❖❖❖ Second Copy Time (First Print Time):

Less than 29.0 seconds (A4L, 81/

" × 11"L)

2

(When setting an original on the exposure glass)

❖❖❖❖ Color Printing:

Drum unit replacement system (black, red, blue, green, brown, yellow, purple, navy, maroon, orange, teal and gray)

❖❖❖❖ Image Position Adjustment:

•Vertical:

More than +10 mm, –10 mm, +0.39", –0.39"

7

•Side:

10 mm, 0.39" (for either side)

❖❖❖❖ Paper Feed Table Capacity:

1,000 sheets (80 g/m2, 20 lb)

❖❖❖❖ Paper Delivery Table Capacity:

1,000 sheets (80 g/m2, 20 lb)

❖❖❖❖ Master Eject Box Capacity:

More than 30 masters under low temperature

More than 40 masters under high temperature

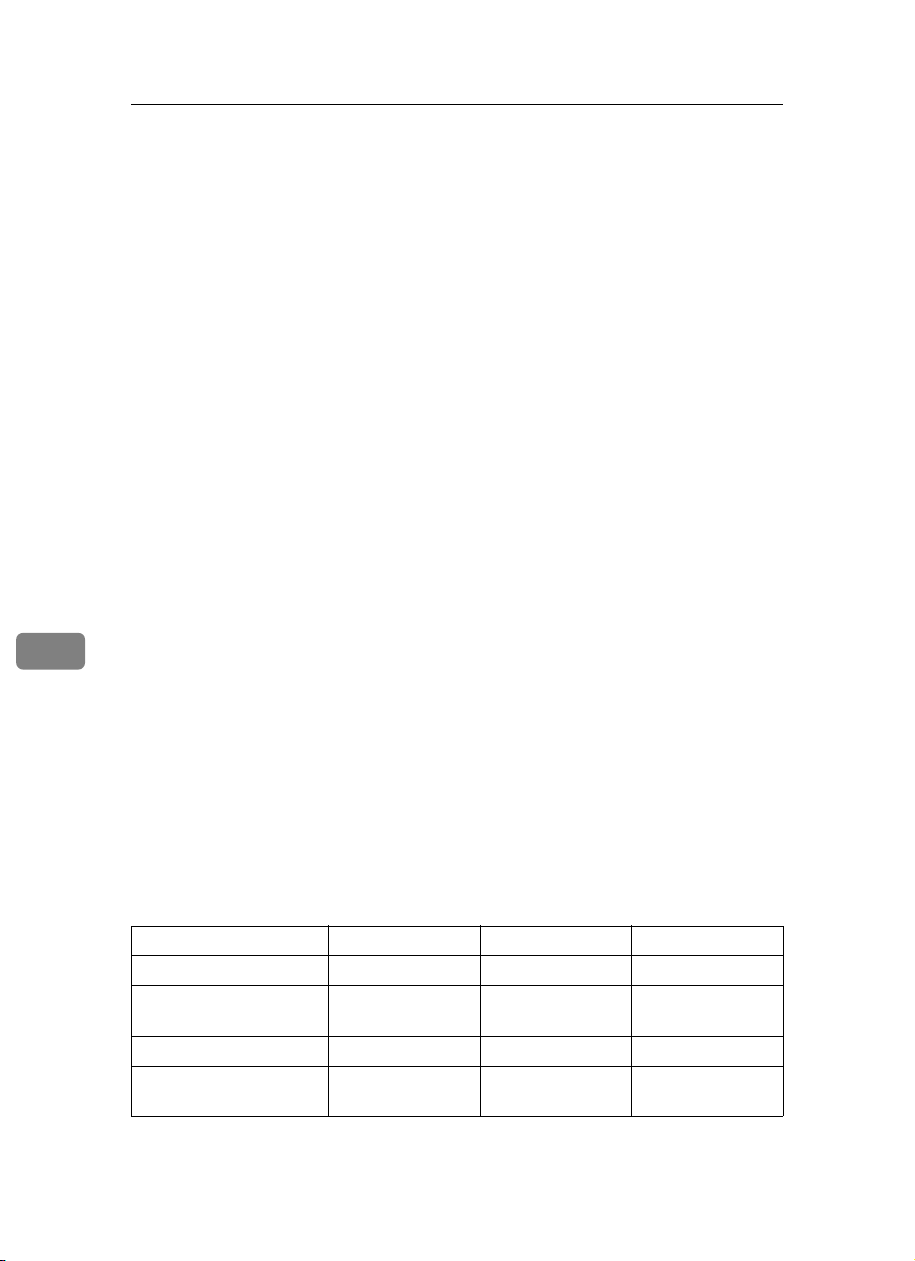

❖❖❖❖ Dimensions (W ×××× D ×××× H):

Width Depth Height

Stored 594 mm, 23.4" 601 mm, 23.1" 567 mm, 22.4"

Stored with document

feeder

Set up 1,187 mm, 46.8" 601 mm, 23.1" 567 mm, 22.4"

Set up with document

feeder

594 mm, 23.4" 601 mm, 23.1" 617 mm, 24.3"

1,187 mm, 46.8" 601 mm, 23.1" 617 mm, 24.3"

116

Page 13

Main Frame

❖❖❖❖ Weight:

• Main Frame: 65 kg, 143.3 lb

• Main Frame with optional document feeder: 68 kg, 150.0 lb

❖❖❖❖ Noise Emission:

Sound Power level (The measurements are made according to ISO 7779.)

Printing Speed

80 rpm 81 dB (A)

100 rpm 82 dB (A)

120 rpm 83 dB (A)

❖❖❖❖ Noise Emission:

• Sound Pressure level (The measurements are made according to ISO 7779

at the operation position.)

Printing Speed

80 rpm 71 dB (A)

100 rpm 72 dB (A)

120 rpm 72 dB (A)

❖❖❖❖ Power Source:

See the inside front cover of this manual.

❖❖❖❖ Power Consumption:

Stand-by Less than 0.04 kW

Master Making Less than 0.25 kW

Printing: Speed 1 Less than 0.14 kW

Printing: Speed 2 Less than 0.16 kW

Printing: Speed 3 Less than 0.18 kW

❖❖❖❖ Optional Equipment:

• Color Drum

LG Drum

B4 Drum

• Key Counter

• Tape Dispenser

• 30 Originals Document Feeder

7

117

Page 14

SPECIFICATION

30 Originals Document Feeder

❖❖❖❖ Original Type:

Sheet

❖❖❖❖ Original Weight:

• When setting a stack of originals:

50 – 90 g/m

• When setting one sheet at a time:

40 – 120 g/m

❖❖❖❖ Original Size:

Max. 257 mm × 364 mm, 10.2" × 14.4"

Min. 148 mm × 105 mm, 5.8" × 4.1"

❖❖❖❖ First Copy Time (Master Process Time):

Less than 29.0 seconds (A4L, 81/

❖❖❖❖ Second Copy Time (First Print Time):

Less than 32.0 seconds (A4L, 81/

❖❖❖❖ Original Capacity:

30 sheets (80 g/m2, 20 lb)

7

Note

❒

Specifications are subject to change without notice.

2

, 13.3 – 23.9 lb

2

, 10.6 – 31.9 lb

" × 11"L)

2

" × 11"L)

2

118

Page 15

Consumables

Consumables

Name Size Remarks

Master for LG drum Length: 125 m, 410 ft/roll

Width: 240 mm, 9.5"

2 Rolls/case

Master for B4 drum Length: 125 m, 410 ft/roll

Width: 280 mm, 11.0"

2 Rolls/case

Ink-Black 600 ml/pack, 5 packs/case Environmental conditions:

Ink-Red 600 ml/pack, 5 packs/case

Ink-Blue 600 ml/pack, 5 packs/case

Ink-Green 600 ml/pack, 5 packs/case

Ink-Brown 600 ml/pack, 5 packs/case

Ink-Yellow 600 ml/pack, 5 packs/case

Ink-Purple 600 ml/pack, 5 packs/case

Ink-Navy 600 ml/pack, 5 packs/case

Ink-Maroon 600 ml/pack, 5 packs/case

Ink-Orange 600 ml/pack, 5 packs/case

Ink-Teal 600 ml/pack, 5 packs/case

Ink-Gray 600 ml/pack, 5 packs/case

Tape for Tape dispenser 35 m (114.8 ft)/roll

260 masters can be made

per roll

260 masters can be made

per roll

– 5 to 40°C, 10 to 95 % RH

7

Note

❒ Specifications are subject to change without notice.

119

Page 16

INDEX

Symbols

,

{#} key

{W} and {V} keys (Speed keys)

xiii

,

xiii

,

Drum Unit

Drum Unit Lock Lever

x

E

,

x

A

111

,

,

,

53

41

,

,

82

Accessing Service Programs

,

41

,

25

,

xiii, 25

Access to machine

ADF Unit

ADF Unit Open Lever

Adjusting The Print Image Density

Adjusting The Print Image Position

After clearing misfeeds

Auto Cycle

{Auto Cycle} key

,

B

Behind Cover

,

x

C

,

54

,

27

,

,

,

,

49

,

119

,

17

xii

,

82

xiii

xiii, 14

,

114

32

,

,

xii, 17, 19

,

34

70

,

,

13

49

Center/Edge Erase

{Center/Edge Erase} key

Changing The Color Drum Unit

Changing The Paper Size

Changing The Printing Speed

Changing The Settings Of Service

Programs

Check Indicator

Class Mode

Clearing Misfeeds

{Clear Modes} key

{Clear/Stop} key

Color Printing

Combination Chart

Combine Copies

{Combine Copies} key

Combine Copies With The Document

Feeder

Consumables

Counter

,

,

,

44

xiv

D

,

,

100

41

Dirt On The Back Side Of Paper

Dirt On The Front Side Of Paper (Black

Line/Stain)

Document Feeder

Document Feeder Exterior

,

102

, x,

41

10

,

81

,

19

,

,

,

xii, 24

,

xii, 16

15

,

,

24

xiv

112

,

109

{Economy} key

Economy Mode

Edge Erase

{Enlarge} key

Enlargement

Environments to avoid

8

Error Indicators

Exposure Glass

(E-XX)

F

Feed Roller Pressure Lever

{Fine} key

Fine Mode

Front Door

{Full Size} key

,

,

,

xiii, 12

12

ix

,

xii

,

ix

G

Guidance Display

,

xiv

H

How To Check The Total Number Of Masters

,

,

62

63

,

,

,

65

63

64

And Prints Made Under All User Codes

How To Check The User Code Counter

How To Clear The User Code Counter

How To Clear The User Code Total

,

Counter

How To Set User Code Mode

How To Use User Code Mode

66

I

,

,

xii, 10

,

xiii, 8

x

{Image Density} key

{Image Position} key

Ink Holder

L

Loading Paper

Loading Paper On The Paper Feed Table

,

3

,

69

M

Machine Exterior

,

ix

120

Page 17

,

112, 115

,

x

,

,

29

,

x

,

79

,

,

49

,

97

,

74

,

xiv

xiii, 27, 29

112

Machine Interior

Main Frame

Main Switch

Maintaining Your Machine

Making Color Prints

Master Eject Indicator

Master Roll Replacement

Memory/Class Indicator

{Memory/Class} key

Memory Mode

misfeed indicator

N

{Number} keys

,

xiii

O

105

41

xii

,

79

,

,

ix

open cover/unit indicator

xi

, 2,

41

,

,

, ix,

,

41

Operation Notes

Operation Panel

Optimum environmental conditions

,

Options

Original Guides

Originals

Original Table Release Lever

Original Tray

P

Paper Delivery End Plate

Paper Delivery Side Plates

Paper Delivery Table

Paper Feed Roller

Paper Feed Side Plates

Paper Feed Table

Paper Feed Table Down key

Paste Shadow Erase

{Paste Shadow Erase} key

,

,

,

36

,

23

76

, ix,

,

,

xiii

100

Photo mode

Placing A New Roll Of Tape In The Tape

Dispenser

Platen Cover

Poor Printing

Power connection

Preparation For Printing

Preset Reduce/Enlarge

Printing In Two Colors

Printing On Thick Paper

Printing On Thin Paper

Printing Paper

{Print} key

Program

,

x

,

x

,

x

,

112

,

ix

,

ix

,

ix

,

21

,

xii, 21

112

,

110

,

3

,

15

,

51

,

22

,

22

1

109

,

,

xiii

xiii, 36

,

38

{Program} key

{Proof} key

Protecting A Program

R

15

,

,

16

xii

,

,

37

,

39

69

Recalling A Program

{Reduce } key

{Reduce} key

,

,

7

Reduction

Removing Program Protection

Replenishing Paper

Restoring Paper Feed And Paper Delivery

Tables

S

,

,

,

,

8

xiii

xii

,

,

13

xii, 40

40

,

,

xii, 35

,

,

,

,

,

xiv

113

5

14

i

,

55

,

,

8

,

,

8

,

ix

35

,

36

,

79

Safety Information

{Scroll} key

{Security} key

Security Mode

Separation Roller

Service Program Menu

Setting Up The Paper Delivery Table

Shifting The Image Position Forward Or

Backward

Shifting the image to the left

Shifting the print image to the right

side plate fine adjusting dial

Side Table Fine Adjusting Dial

{Skip Feed} key

Skip Feed Printing

Speed Indicators

{Speed} key

Standard Printing

{Start} key

Stop The Machine

Storing Your Settings

supply/exchange indicators

T

,

,

,

,

,

22

22

xii, 11

11

76

,

xiii, 23

tape dispenser

Thick paper

Thin paper

{Tint} key

Tint Mode

{Type of Original}

{Type of Original} key

U

User Codes

,

62

4

8

121

Page 18

W

When The Add Ink Indicator Blinks

Where To Put Your Machine

White Prints Or Incomplete Prints

,

109

,

,

71

102

122

UE USA AE AE C231

Page 19

SilverV-EN.book Page 1 Monday, May 15, 2000 3:23 PM

JP1230

Operating Instructions

Read this manual carefully before you use this product a nd k eep it hand y f or fut ure

reference.

For safety, please follow the instructions in this manual.

Page 20

SilverV-EN.book Page 1 Monday, May 15, 2000 3:23 PM

RICOH COMPANY, LTD.

15-5, 1 chome, Minami-Aoyama, Minato-ku, Tokyo

Telephone: Tokyo 3479-3111

JP1230 Operating Instructions

Overseas Affiliates

U.S.A.

RICOH CORPORATION

5 Dedrick Place

West Caldwell, New Jersey 07006

Phone: +1-973-882-2000

The Netherlands

RICOH EUROPE B.V.

Groenelaan 3, 1186 AA, Amstelveen

Phone: +31-(0)20-5474111

United Kingdom

RICOH UK LTD.

Ricoh House,

1 Plane Tree Crescent, Feltham,

Middlesex, TW13 7HG

Phone: +44-(0)181-261-4000

Germany

RICOH DEUTSCHLAND GmbH

Mergenthalerallee 38-40,

65760 Eschborn

Phone: +49-(0)6196-9060

France

RICOH FRANCE S.A.

383, Avenue du Général de Gaulle

BP 307-92143 Clamart Cedex

Phone: +33-(0)1-40-94-38-38

Printed in Korea

UE USA C237-8607

Spain

RICOH ESPAÑA S.A.

Avda. Litoral Mar, 12-14,

08005 Barcelona

Phone: +34-(0)93-295-7600

Italy

RICOH ITALIA SpA

Via della Metallurgia 12,

37139 Verona

Phone: +39-045-8181500

Hong Kong

RICOH HONG KONG LTD.

23/F., China Overseas Building,

139, Hennessy Road,

Wan Chai, Hong Kong

Phone: +852-2862-2888

Singapore

RICOH ASIA PACIFIC PTE.LTD.

260 Orchard Road,

#15-01/02 The Heeren,

Singapore 238855

Phone: +65-830-5888

Page 21

SilverV-EN.book Page 1 Monday, May 15, 2000 3:23 PM

Introduction

This manual contains detailed instructions on th e operation a nd maintena nce of this mach ine. To get

maximum versatility from this machine all operators sho uld carefu lly read and fo llow the inst ruction s in

this manual. Please keep this manual in a handy place near the machine.

Please read the Safety Information before u sing this machin e. It contain s important info rmation relate d

to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

Notes:

Some illustrations might be slightly different from your machine.

Certain options might not be available in some countr ies. Fo r det ails, pleas e conta ct your lo cal deal er.

Notes:

The model names of the machines do not appear in the following page s. Check the type of your machine before reading this manual.

• LG drum: JP1230

• A4 drum: Not Available

• B4 drum: Not Available

Certain types might not be available in some countries. For details, please contact your local dealer.

Two kinds of size notation are employed in this manual. With this machine refer to the inch v ers ion.

For good print quality, Ricoh recommends that you use genuine Ricoh master and ink.

Ricoh shall not be responsible for any damage or expense that might result from the use of parts other

than genuine Ricoh parts in your Ricoh office product.

Power Source

120V, 60Hz, 2.3A or more

Please be sure to connect the power cord to a power source as above. For details about power source,

see ⇒ P.112

“Power Connection”

.

Page 22

SilverV-EN.book Page 1 Monday, May 15, 2000 3:23 PM

Note to users in the United States of America

Notice:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio /TV technician for help.

Warning

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

Warning:

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

Properly shielded and grounded cables and connectors must be used for connections to host computer (and/or peripheral) in order to meet FCC emission limits.

This device complies with Part 15 of FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired operation.

Ricoh Corporation, 5 Dedrick Place, West Caldwell, NJ 07006

973-882-2000

Note to users in Canada

Note:

This Class B digital apparatus complies with Canadian ICES-003.

Remarque concernant les utilisateurs au Canada

Avertissement:

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

In accordance with IEC 60417, this machine uses the following symbols for the main switch:

aaaa means POWER ON.

bbbb means POWER OFF.

Copyright © 2000 Ricoh Co., Ltd.

Page 23

R

R

SilverV-EN.book Page i Monday, May 15, 2000 3:23 PM

Safety Information

When using your equipment, the following safety precautions should always be

followed.

Safety During Operation

In this manual, the following important symbols are used:

WARNING:

CAUTION:

R

WARNING:

•

Connect the power cord directly into a wall outlet and never use an extension cord.

•

Disconnect the power plug (by pulling the plug, not the cable) if the

power cable or plug becomes frayed or otherwise damaged.

•

To avoid hazardous electric shock, do not remove any covers or

screws other than those specified in this manual.

•

Turn off the power and disconnect the power plug (by pulling the plug,

not the cable) if any of the following conditions exists:

•

•

•

Indicates a potentially hazardous situation which, if instructions

are not followed, could result in death or serious injury.

Indicates a potentially hazardous situation which, if instructions are not

followed, may result in minor or moderate injury or damage to property.

You spill something into the equipment.

You suspect that your equipment needs service or repair.

Your equipment's cover has been damaged.

i

Page 24

SilverV-EN.book Page ii Monday, May 15, 2000 3:23 PM

R

CAUTION:

Protect the equipment from dampness or wet weather, such as rain, snow,

•

and so on.

•

Unplug the power cord from the wall outlet before you move the equipment.

While moving the equipment, you should take care that the power cord will

not be damaged under the equipment.

•

When you disconnect the power plug from the wall outlet, always pull the

plug (not the cable).

•

Do not allow paper clips, staples, or other small metallic objects to fall inside

the equipment.

•

For environmental reasons, do not dispose of the equipment or expended

supply waste at household waste collection points. Disposal can take place

at an authorized dealer or at appropriate collection sites.

•

Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

•

Our products are engineered to meet high standards of quality and functionality, and we recommend that you only use the expendable supplies available at an authorized dealer.

ii

Page 25

R

R

SilverV-EN.book Page iii Monday, May 15, 2000 3:23 PM

How to Read this Manual

Symbols

In this manual, the following symbols are used:

WARNING:

This symbol indicates a potentially hazardous situation that might result in

death or serious injury when you misuse the machine without following the instructions under this symbol. Be sure to read the instructions, all of which are described in the Safety Information section.

CAUTION:

This symbol indicates a potentially hazardous situation that might result in minor or moderate injury or property damage that does not involve personal injury

when you misuse the machine without following the instructions under this

symbol. Be sure to read the instructions, all of which are described in the Safety

Information section.

* The statements above are notes for your safety.

Important

If this instruction is not followed, paper might be misfed, originals might be

damaged, or data might be lost. Be sure to read this.

Preparation

This symbol indicates the prior knowledge or preparations required before operating the machine.

Note

This symbol indicates precautions for operation, or actions to take after misoperation.

Limitation

This symbol indicates numerical limits, functions that cannot be used together,

or conditions in which a particular function cannot be used.

Reference

This symbol indicates a reference.

[]

Keys that appear on the machine's display panel.

{}

Keys built into the machine's operation panel.

iii

Page 26

SilverV-EN.book Page iv Monday, May 15, 2000 3:23 PM

What You Can Do with this Machine

Below is a quick summary of this machine's features and where to look in this

manual for more information

❖❖❖❖

Standard Printing

See ⇒ P.5 “Standard Printing”.

❖❖❖❖

Adjusting the Print Image Position

See ⇒ P.9 “Adjusting the Print Image Position”.

❖❖❖❖

Adjusting the Print Image Density

See ⇒ P.11 “Adjusting the Print Image Density”.

❖❖❖❖

Halftone Printing

See ⇒ P.12 “Tint Mode—Halftone Printing”.

❖❖❖❖

Making Clear Prints

See ⇒ P.13 “Use the

❖❖❖❖

Changing the Print Speed

See ⇒ P.14 “Changing the Printing Speed”.

❖❖❖❖

Reducing and Enlarging Using Preset Ratios

See ⇒ P.16 “Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios”.

{Fine}

key to make clear prints.”.

GRREDU0E

GRENLA0E

iv

Page 27

SilverV-EN.book Page v Monday, May 15, 2000 3:23 PM

❖❖❖❖

Erasing Center and Edge Margins

See ⇒ P.18 “Center/Edge Erase—Erasing center and Edge Margins”.

❖❖❖❖

Erasing Edge Margins

See ⇒ P.20 “Edge Erase—Erasing Edge Margins”.

❖❖❖❖

Erasing the Shadow of Pasted Originals

See ⇒ P.22 “Paste Shadow Erase—Erasing the Shadow of Pasted Originals”.

❖❖❖❖

Printing on Thick or Thin Paper

See ⇒ P.23 “Printing on Thick or Thin Paper”.

❖❖❖❖

Selecting Original Type

See ⇒ P.24 “Selecting Original Type”.

❖❖❖❖

Saving Ink

See ⇒ P.25 “Economy Mode—Saving Ink”.

GRMARG0E

❖❖❖❖

Printing from Several Originals at Once

See ⇒ P.26 “Auto Cycle—Printing from Several Originals at Once”.

❖❖❖❖

Group Printing from the Same Original

See ⇒ P.28 “Class Mode—Group Printing from the Same Original”.

R

R R

R

R R R

GRCLAS0E

v

Page 28

SilverV-EN.book Page vi Monday, May 15, 2000 3:23 PM

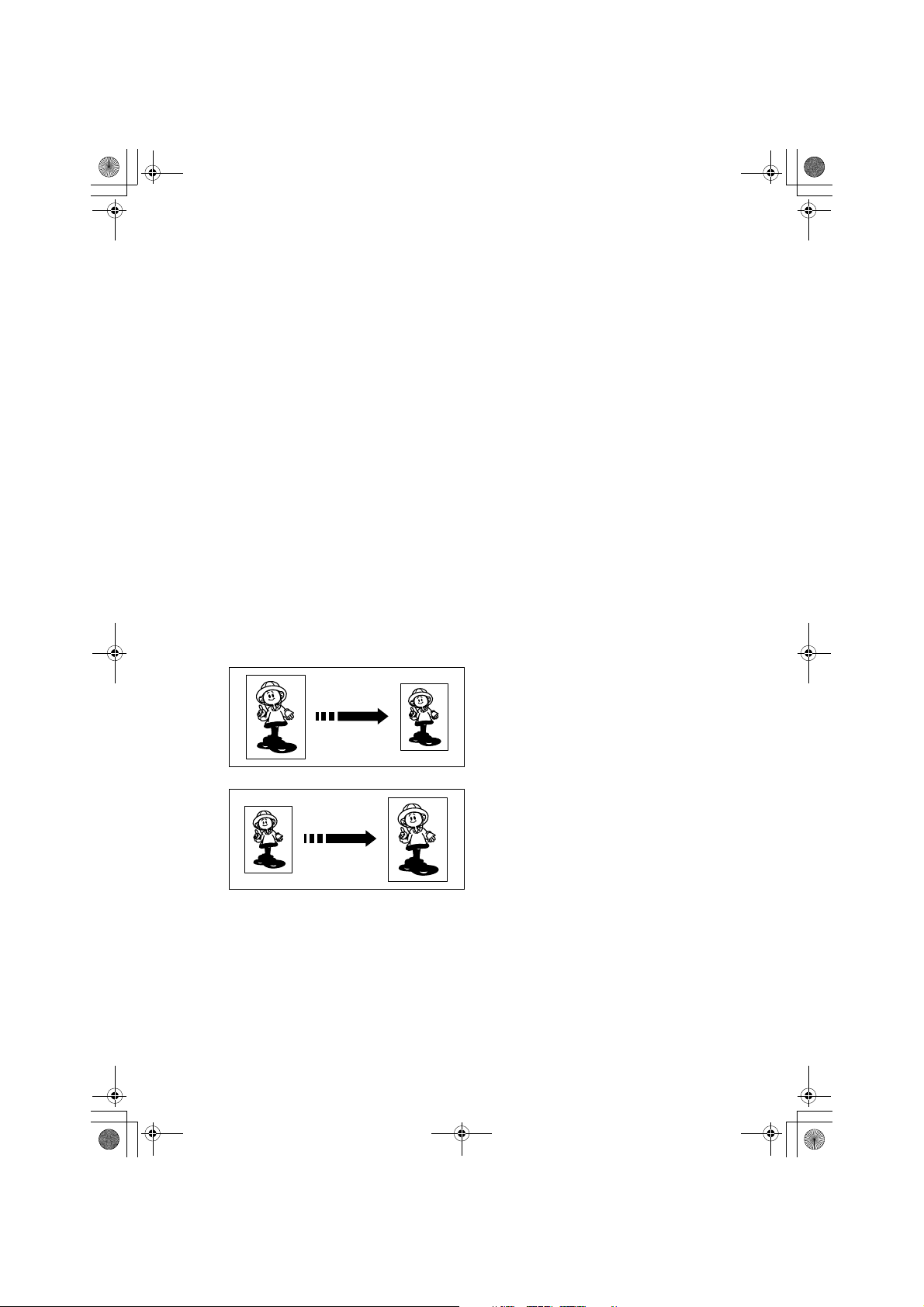

❖❖❖❖

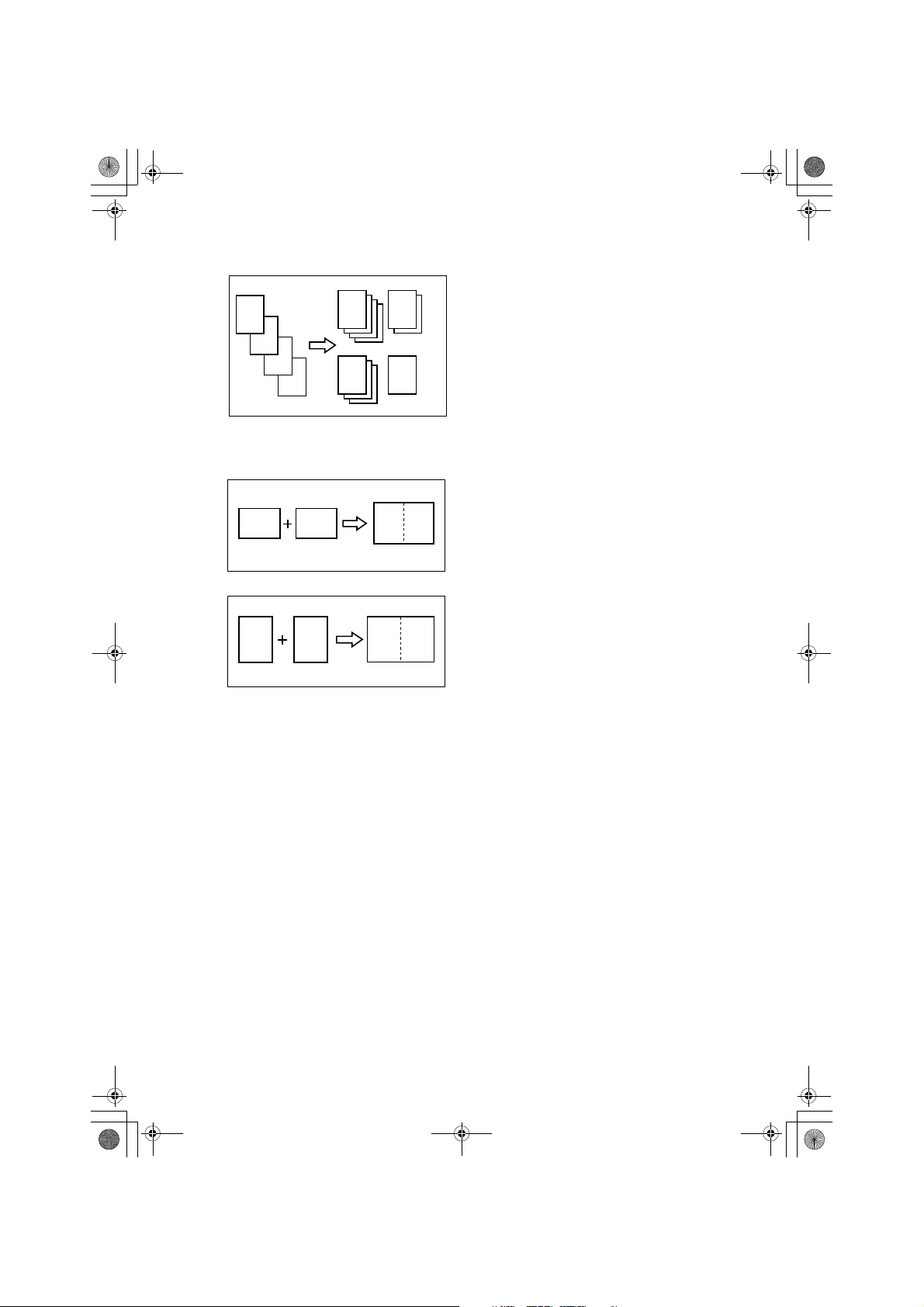

Group Printing from Different Originals

See ⇒ P.30 “Memory Mode—Group Printing from Different Originals”.

A

A

B

B

C

D

❖❖❖❖

Combining Originals onto One Print

See ⇒ P.33 “Combine—Combining 2 Originals onto One Print”.

A

C D

B

GRCLAS1E

AB

ZCTX050E

BA AB

ZCTX040E

❖❖❖❖

Skip Feed Printing

See ⇒ P.37 “Skip Feed Printing”.

❖❖❖❖

Storing Your Print Settings in Memory

See ⇒ P.38 “Program—Storing Your Print Settings in Memory”.

❖❖❖❖

Printing Secret Documents

See ⇒ P.42 “Security Mode—Printing Secret Documents”.

❖❖❖❖

Making Color Prints

See ⇒ P.52 “Making Color Prints”.

❖❖❖❖

Printing in Two Colors

See ⇒ P.54 “Printing in Two colors”.

vi

Page 29

SilverV-EN.book Page vii Monday, May 15, 2000 3:23 PM

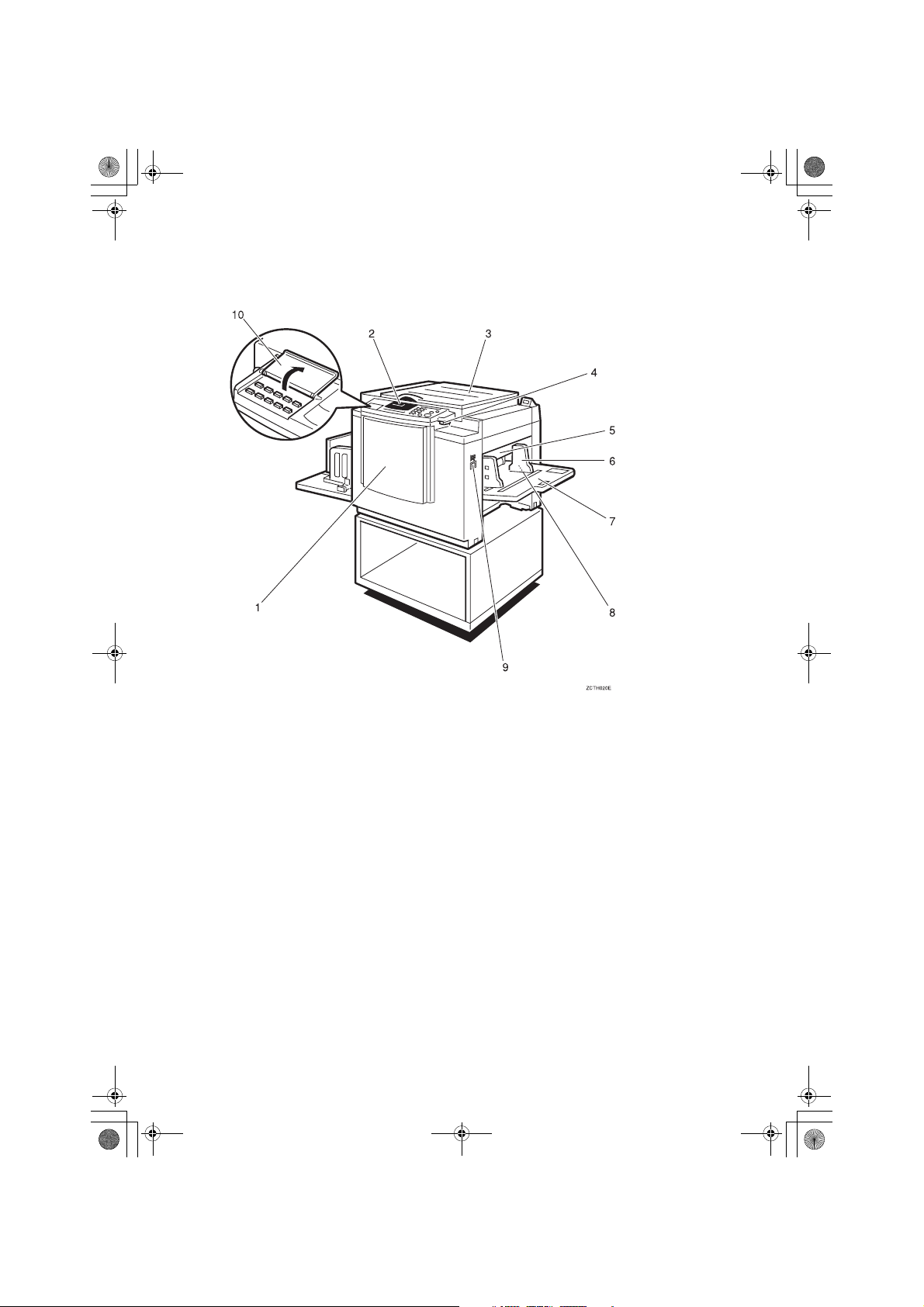

Machine Exterior

1. Front door

Open for access to the inside of the machine.

2. Operation panel

Operator controls and indicators are located here. See ⇒ P.x “Operation Panel”.

3. Platen cover

Lower this cover over an original before

printing.

4. Original tray release lever

Use to open the original tray unit when

installing the master.

5. Feed roller pressure lever

Use to adjust the contact pressure of the

paper feed roller according to paper

thickness.

6. Paper feed side plates

Use to prevent paper skew.

7. Paper feed tray

Set paper on this tray for printing.

8. Side tray fine adjusting dial

Use to shift the paper feed tray sideways.

9. Paper feed tray down key

Press to lower the paper feed tray.

10. Behind cover

Flip up when you use the keys underneath.

vii

Page 30

SilverV-EN.book Page viii Monday, May 15, 2000 3:23 PM

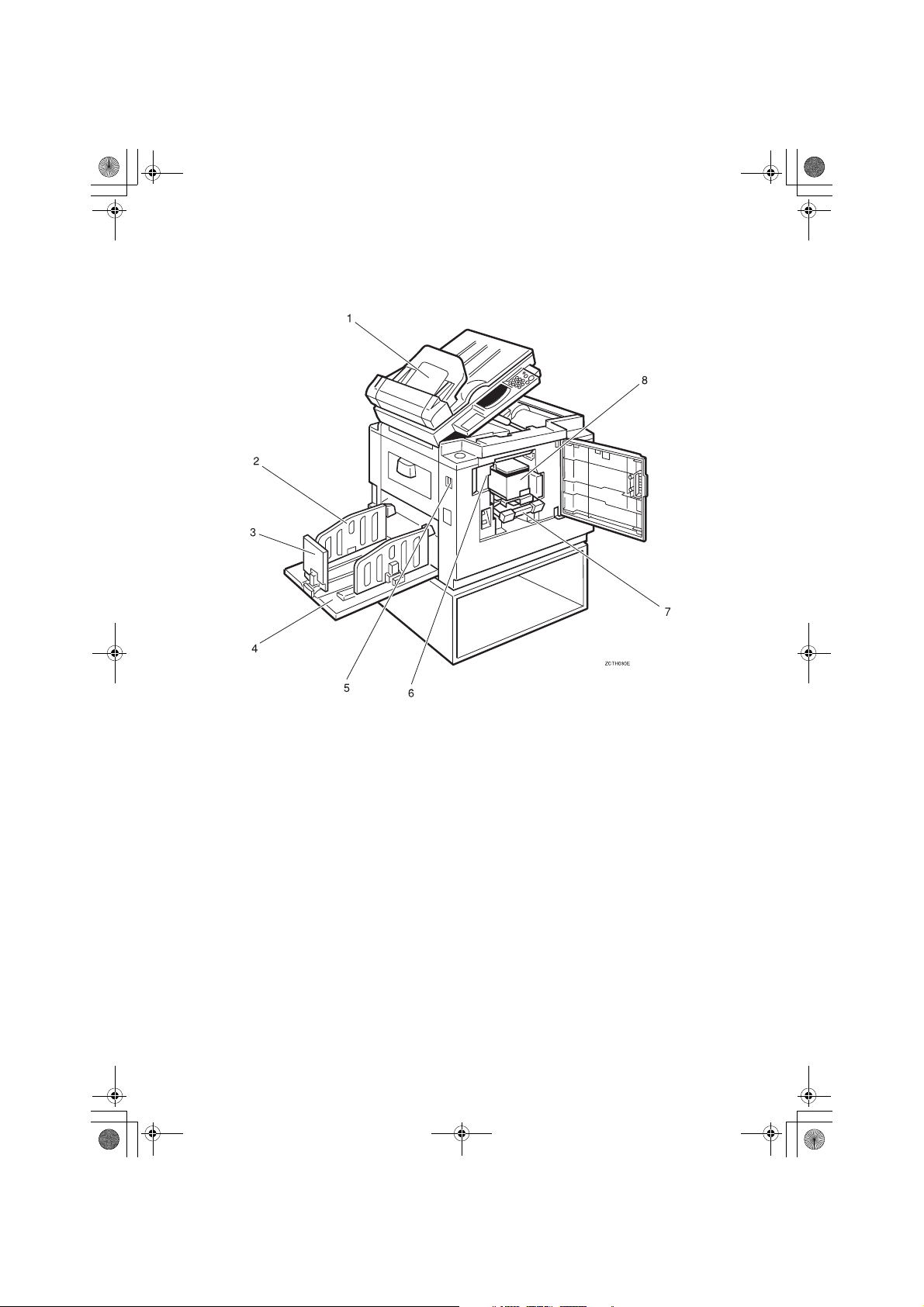

Machine Interior

1. Document feeder (Option)

Original inserted into the document feeder are individually and automatically fed

onto and removed from the exposure

glass. See ⇒ P.43 “Printing Using the Op-

tional 30 Originals Document Feeder”.

2. Paper delivery side plates

Use to align the prints on the paper delivery tray.

3. Paper delivery end plate

Use to align the leading edge of prints.

4. Paper delivery tray

Completed prints are delivered here.

viii

5. Main switch

Use to turn the power on or off.

6. Drum unit

The master is wrapped around this unit.

7. Drum unit lock lever

Lift to unlock and pull out the drum unit.

8. Ink holder

Set the ink cartridge in this holder.

Page 31

SilverV-EN.book Page ix Monday, May 15, 2000 3:23 PM

Options

❖❖❖❖

30 Originals document feeder

Note

❒ Other options:

• Color Drum: LG drum

• Color Drum: A4 drum

• Color Drum: B4 drum

• Tape Dispenser

•Key Counter

TSLP015E

ix

Page 32

SilverV-EN.book Page x Monday, May 15, 2000 3:23 PM

Operation Panel

Keys

1. {

{

{{

Press to make prints of secret documents.

See ⇒ P.42 “Security Mode—Printing Secret

Documents”.

2. {

{

{{

Press to erase the shadow of pasted originals. See ⇒ P.22 “Paste Shadow Erase—Eras-

ing the Shadow of Pasted Originals”.

3. {

{

{{

Press to make halftone prints. See ⇒ P.12

“Tint Mode—Halftone Printing”.

Press to save ink. See ⇒ P.25 “Economy

Mode—Saving Ink”.

4. {

{

{{

Press to make prints darker or lighter. See

⇒ P.11 “Adjusting the Print Image Density”.

5. Check Indicator

This indicator lights when you have selected one or more of the functions accessed by

lifting the behind cover and pressing the

keys underneath (e. g. {Security

Shadow Erase

This lets you know whether one or more of

these functions is selected, even if the cover

is lowered.

6. {

{

{{

Press to select skip feed printing. See ⇒

P.37 “Skip Feed Printing”.

x

}}}} key

Security

Paste Shadow Erase

Tint/Economy

Image Density

Skip Feed

}}}} key

}}}} key

}

key etc.).

}}}} key

}}}} key

}

key,

{

Paste

7. {

{

Center/Edge Erase

{{

Press to print book originals that have a solid image on the center or edges. See ⇒ P.18

“Center/Edge Erase—Erasing center and Edge

Margins”.

8. {

{}}}} and {{{{}}}} keys (Scroll keys)

{{

Press to select size and direction of paper or

original in Center/Edge Erase.

9. {

{

{{

Press to reduce the image. See ⇒ P.16 “Pre-

set Reduce/Enlarge—Reducing and Enlarging

Using Preset Ratios”.

10. {

Press to make full size prints.

11. {

Press to enlarge the image. See ⇒ P.16 “Pre-

set Reduce/Enlarge—Reducing and Enlarging

Using Preset Ratios”.

12. {

Press to combine originals onto 1 print. See

⇒ P.33 “Combine—Combining 2 Originals

onto One Print”.

13. {

Press to select Letter, Photo, or Letter/Photo mode. See ⇒ P.24 “Selecting Original

Type”.

}}}} key

Reduce

{

{{

{

{{

{

{{

{

{{

}}}} key

Full Size

}}}} key

Enlarge

Combine

Type of Original

}}}} key

}}}} key

}}}} key

Page 33

SilverV-EN.book Page xi Monday, May 15, 2000 3:23 PM

14. {

{

Fine

}}}} key

{{

Press to select the fine image. See ⇒ P.13

“Fine Mode—Making Clear Prints”.

15. {

{

Image Position

{{

Press to shift the image forwards or backwards. See ⇒ P.9 “Adjusting the Print Image

Position”.

16. {

{

Program

{{

Press to input or recall user programs. See

⇒ P.38 “Program—Storing Your Print Settings in Memory”.

17. {

{

Clear Modes/Energy Saver

{{

•Clear Modes

Press to clear the previously entered job

settings.

• Energy Saver

Press to switch to and from Energy Saver Mode ⇒ P.8 “Energy Saver Mode —

Saving Energy”.

18. {

{

Auto Cycle

{{

Use to process the master and make prints

automatically. See ⇒ P.26 “Auto Cycle—

Printing from Several Originals at Once”.

19. {

{

Proof

}}}} key

{{

Press to make proof prints.

}}}} key

}}}} key

}}}} key

}}}} key

20. {

} and {{{{VVVV}}}} keys (Speed keys)

{{{WWWW}}}

Press to adjust the printing speed. See ⇒

P.14 “Changing the Printing Speed”.

21. {

{

Memory/Class

{{

Press to select Memory or Class mode. See

⇒ P.28 “Class Mode—Group Printing from

the Same Original”or ⇒ P.30 “Memory

Mode—Group Printing from Different Originals”.

}}}} key

22. Number keys

Press to enter the desired number of prints

and data for selected modes.

23. {

Use to enter data in selected modes.

24. {

While entering numbers, press to cancel a

number you have entered.

While copying, press to stop copying.

25. {

Press to make a master.

26. {

Press to start printing.

} key

{{{qqqq}}}

{

Clear/Stop

{{

{

Start

}}}} key

{{

{

Print

}}}} key

{{

}}}} key

xi

Page 34

SilverV-EN.book Page xii Monday, May 15, 2000 3:23 PM

Indicators

1. Error indicators

These indicators are lit when a non-standard condition occurs within the machine.

2. Memory/Class indicator

Shows the number entered in Memory or

Class mode.

3. Speed indicators

These indicators show the printing speed

that is selected.

4. Counter

Displays the number of prints entered.

While printing, it shows the number of

prints remaining.

5. Guidance display

Display the machine's condition.

xii

Page 35

SilverV-EN.book Page xiii Monday, May 15, 2000 3:23 PM

TABLE OF CONTENTS

1.Operation

Printing Paper............................................................................................ 1

Originals..................................................................................................... 2

Preparation for Printing............................................................................ 3

Loading Paper............................................................................................... 3

Setting Up the Paper Delivery Tray............................................................... 4

Standard Printing ...................................................................................... 5

Restoring Paper Feed and Paper Delivery Trays ................................... 7

Energy Saver Mode — Saving Energy..................................................... 8

Adjusting the Print Image Position.......................................................... 9

Shifting the Print Image Position Forward or Backward................................ 9

Shifting the Print Image Position to the Right or Left .................................. 10

Adjusting the Print Image Density......................................................... 11

Before Making a Master.............................................................................. 11

After Making a Master................................................................................. 11

Tint Mode—Halftone Printing................................................................. 12

Fine Mode—Making Clear Prints............................................................ 13

Changing the Printing Speed................................................................. 14

Stopping the Machine during the Multi-print Run................................ 15

When You Want to Stop the Machine during the Multi-print Run and

Print the Next Original ............................................................................... 15

When You Want to Change the Number of Prints Entered or Check the

Completed Prints....................................................................................... 15

Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios ... 16

Center/Edge Erase—Erasing center and Edge Margins...................... 18

Edge Erase—Erasing Edge Margins...................................................... 20

Paste Shadow Erase—Erasing the Shadow of Pasted Originals........ 22

Printing on Thick or Thin Paper............................................................. 23

Pressure Lever Position.............................................................................. 23

Selecting Original Type........................................................................... 24

Economy Mode—Saving Ink .................................................................. 25

Auto Cycle—Printing from Several Originals at Once......................... 26

Class Mode—Group Printing from the Same Original......................... 28

Memory Mode—Group Printing from Different Originals.................... 30

Combine—Combining 2 Originals onto One Print............................... 33

Skip Feed Printing................................................................................... 37

Program—Storing Your Print Settings in Memory............................... 38

xiii

Page 36

SilverV-EN.book Page xiv Monday, May 15, 2000 3:23 PM

Storing Your Settings .................................................................................. 38

Recalling a Program.................................................................................... 39

Protecting a Program .................................................................................. 40

Removing Program Protection.................................................................... 41

Security Mode—Printing Secret Documents........................................ 42

2.Optional Functions

Printing Using the Optional 30 Originals Document Feeder............... 43

Document Feeder Exterior.......................................................................... 43

Originals...................................................................................................... 44

Setting Originals in the Document Feeder .................................................. 45

Combine Copies with the Document Feeder .............................................. 46

Memory Mode with the Document Feeder.................................................. 48

Color Printing Using the Optional Color Drum..................................... 52

Making Color Prints..................................................................................... 52

Changing the color Drum Unit..................................................................... 52

Printing in Two colors.................................................................................. 54

3.Service Program Mode

Accessing Service Programs................................................................. 57

Changing the Settings of Service Programs ........................................ 58

Service Program Menu ............................................................................... 59

User Codes............................................................................................... 66

How to Set User Code Mode (# 120).......................................................... 66

How to Use User Code Mode ..................................................................... 67

How to Check the User Code Counter (# 121) ........................................... 68

How to Clear the User Code Counter (# 122)............................................. 69

How to Check the Total Number of Masters and Prints Made Under

All User Codes (# 123).............................................................................. 70

How to Clear the User Code Total Counter (# 124).................................... 71

4.Replenishing Supplies

Loading Paper on the Paper Feed Tray................................................. 73

Replenishing Paper..................................................................................... 73

Changing the Paper Size............................................................................ 74

When the Add Ink Indicator (j) Lights.......................... ....................... 75

Master Roll Replacement........................................................................ 77

Placing a New Roll of Tape in the Tape Dispenser (Option) ............... 79

5.What to do If Something Goes Wrong

If Your Machine does not Operate as You Want................................... 81

x Clearing Misfeeds............................................................................... 84

xiv

Page 37

SilverV-EN.book Page xv Monday, May 15, 2000 3:23 PM

“x” + “ORIGINAL JAM. REMOVE ORIGINAL”.......................................... 84

“x” + “PAPER FEED JAM. REMOVE JAMMED PAPER” ......................... 87

“x” + “MASTER FEED JAM. REMOVE JAMMED MASTER”.................... 90

“x” + “PAPER WRAP JAM. REMOVE JAMMED PAPER” ........................ 92

“x” + “MASTER EJECT JAM. REMOVE JAMMED MASTER”.................. 94

“x” + “DELIVERY JAM. REMOVE JAMMED PAPER” .............................. 96

When the Open Cover/Unit Indicator (M) Lights.................................. 97

When the Master Eject Indicator (k) Lights......................................... 99

When Other Indicators Light................................................................ 100

When the Prints are Thrown Over the Paper Delivery Tray............... 101

Poor Printing.......................................................................................... 102

Dirt on the Back Side of Paper.................................................................. 102

Dirt on the Front Side of Paper (Black Line/Stain) .................................... 104

White Prints or Incomplete Prints.............................................................. 105

6.Remarks

Operation Notes..................................................................................... 107

General Cautions ...................................................................................... 107

Print Paper................................................................................................ 109

Originals.................................................................................................... 109

Where to Put Your Machine.................................................................. 111

Environmental Conditions......................................................................... 111

Power Connection..................................................................................... 112

Access to Machine.................................................................................... 112

Maintaining Your Machine.................................................................... 113

Main Frame..... ........ ........ .......................................................................... 113

Optional Document Feeder....................................................................... 114

Combination Chart................................................................................ 115

7.Specification

Main Frame............................................................................................. 117

30 Originals Document Feeder............................................................. 121

Consumables......................................................................................... 122

INDEX...................................................................................................... 123

xv

Page 38

SilverV-EN.book Page xvi Monday, May 15, 2000 3:23 PM

xvi

Page 39

SilverV-EN.book Page 1 Monday, May 15, 2000 3:23 PM

1. Operation

Printing Paper

The following types of print paper are not recommended for this machine.

• Paper smaller than 90mm × 148mm, 3.6" × 5.9"

• Paper larger than 268mm × 388mm, 10.5" ×15.2"

2

• Paper heavier than 209.3g/m

• Paper lighter than 47.1g/m

• Roughly-cut paper

• Paper of different thickness in the same stack

• Buckled or curled paper

• Low stiffness paper

Correct curls in the paper before setting it in the machine. When you cannot correct the paper curl, stack the paper with the curl face down. Otherwise the paper

might wrap around the drum or stains might appear.

Store paper where it will not curl or absorb moisture. Use paper soon after it is

unpacked.

Only use paper where the leading edge has two right angle corners, as shown

below.

, 55.6 lb

2

, 12.5 lb

GRPRIN0E

1

Page 40

SilverV-EN.book Page 2 Monday, May 15, 2000 3:23 PM

Operation

Originals

Note

1

❒ Originals that can be set on the exposure glass are as follows:

• Maximum size: 257 × 364mm, 10.2" × 14.4"

• Maximum total thickness: 30mm, 1.1"

• Maximum total weight: 5kg, 11.0 lb

❒ If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet and press the {

up original is more than 0.1mm and the space between the pasted parts is less

than 2mm, 0.08", a shadow might appear on the prints.

❒ If you use originals that have bold letters or solid images at the leading edges,

you might get prints with dirty edges. In this case, insert the widest margin

first, or raise the printing speed.

❒ The first 5mm, 0.2" of the leading edge cannot be printed. Make sure the lead-

ing edge margin is at least 5mm, 0.2".

Original Print

Paste Shadow Erase

} key. If the thickness of the paste-

❒ a: 5mm, 0.2"

2

a

Page 41

SilverV-EN.book Page 3 Monday, May 15, 2000 3:23 PM

Preparation for Printing

Preparation for Printing

Loading Paper

Carefully open the paper feed

A

tray.

Put the paper feed side plates lock

B

lever. Adjust the side plates to

match the paper size.

TSLH026E

1

Note

❒ Correct the paper curl before

setting the paper. If you cannot

do so, stack the paper with the

curl face down as shown.

Make sure that the paper feed

D

side plates touch the paper lightly. Put back the lock lever.

1

GRMARU0E

GRBATS0E

1: Paper Feed Side Plates Lock Lever

Place the paper on the paper feed

C

tray.

TSLH01AE

TSLY015E

TSLY013E

3

Page 42

SilverV-EN.book Page 4 Monday, May 15, 2000 3:23 PM

Operation

Setting Up the Paper Delivery

Tray

Lift the paper delivery end plate

C

and move it to match the print paper size.

1

Open the paper delivery tray.

A

Reference

When the prints are not delivered in a neat stack, see ⇒ P.101

“When the Prints are Thrown

Over the Paper Delivery Tray”.

Lift the paper delivery side plates

B

and adjust them to the paper size.

2

1

2

1

TSLH01YE

22

1

Turn on the main switch.

D

TSLH01ZE

TSLH030E

4

Page 43

SilverV-EN.book Page 5 Monday, May 15, 2000 3:23 PM

Standard Printing

----

Printing

In this manual, the word, “Printing”

is used as opposed to “Copying” in

order to distinguish between the process that your machine uses to make

prints, and the process used by a standard copier machine.

A standard copier scans in the original for each copy set made. This machine, however, scans in your original

once and makes multiple prints from

this master.

This chapter describes the basic

pointing operations that your machine is capable of.

Standard Printing

Set the original face down on the

B

exposure glass. The original

should be centered according to

the size marks on the right scale.

Lower the platen cover.

C

1

TSLH010E

Lift the platen cover.

A

{{{{

Press the

D

A trial print is delivered to the paper delivery tray.

Start

}}}}

key.

TSLS012N

5

Page 44

SilverV-EN.book Page 6 Monday, May 15, 2000 3:23 PM

Operation

1

Press the {{{{

E

}}}} key and check

Proof

the image density and the image

position of the proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {

Position

} keys or the fine adjust-

ment dial. See ⇒ P.9 “Adjusting

the Print Image Position”.

❒ If the image density is slightly

dark or light, adjust the image

density using the {WWWW} or {VVVV}

key. See ⇒ P.11 “Adjusting the

Print Image Density”.

Enter the number of prints re-

F

quired with the number keys.

TSLS013N

Image

Press the {{{{

G

Note

Print

}}}} key.

❒ After printing is completed, the

same number of prints is automatically set for the next job.

❒ To stop the machine during the

multi-print run, press the {

} key.

Stop

❒ To return the machine to the ini-

tial condition after printing,

press the {

} key.

Saver

Clear Modes/Energy

TSLS014N

Clear/

TSLS011N

Note

❒ Up to 9999 prints can be entered

at one time.

❒ To change the number entered,

press the {

Clear/Stop

} key and

enter the new number.

6

Page 45

SilverV-EN.book Page 7 Monday, May 15, 2000 3:23 PM

Restoring Paper Feed and Paper Delivery Trays

Restoring Paper Feed and Paper Delivery

Trays

Remove the paper from the paper

A

feed tray.

The paper feed tray will lower.

Turn off the main switch.

B

Close the paper feed tray.

C

TSLY016E

ZCTH140E

Move the end plate until the plate

D

handle is flush with the end of

the tray.

Lower the end plate.

E

Move the side plates to the sides,

F

then lower them.

1

TSLH021E

TSLH01VE

TSLH020E

1

Close the tray.

G

22

1

22

TSLH01ME

7

Page 46

SilverV-EN.book Page 8 Monday, May 15, 2000 3:23 PM

Operation

Energy Saver Mode — Saving Energy

If you do not operate the machine for a certain period after printing, or when you

1

press and hold the {

display turns off and the machine enters Energy Saver mode. When you press

the {

Clear Modes/Energy Saver

dition. In Energy Saver mode, the machine uses less electricity.

See “Auto Energy Saving” ⇒ P.59 “Service Program Menu”.

Clear Modes/Energy Saver

} key for three seconds, the panel

} key again, the machine returns to the ready con-

8

Page 47

SilverV-EN.book Page 9 Monday, May 15, 2000 3:23 PM

Adjusting the Print Image Position

Adjusting the Print Image Position

After master making, you can adjust

the print image position to suit your

needs. There are two ways:

❖❖❖❖

Shifting the Image Position Forward

or Backward

Shift the image position using the

{

Image Position

❖❖❖❖

Shifting the Image Position to the

Right or Left

Shift the image position using the

side tray fine adjusting dial.

Shifting the Print Image

} keys.

B

Position Forward or Backward

GRFORW0E

* Paper feed direction

Note

❒ When you shift the image for-

wards, leave a margin (more

than 5mm, 0.2") at the leading

edge. If there is no margin, paper might wrap around the

drum and cause a misfeed.

❒ The right or left {

keys shift the image about

0.5mm, 0.02" each time they are

pressed. When the indicator

changes, the image position

shifts about 5mm, 0.2".

Press the {{{{

image position.

Proof

Image Position

}}}} key to check the

1

}

Press the left {{{{

A

to move the image forwards, the

right key to move it backwards.

Image Position

}}}} key

9

Page 48

SilverV-EN.book Page 10 Monday, May 15, 2000 3:23 PM

Operation

1

Shifting the Print Image

Position to the Right or Left

GRLEFT0E

* Paper feed direction

Turn the side tray fine adjusting

A

dial as shown in the illustrations.

❖❖❖❖

Shifting the image to the right

Note

❒ The image position can be shift-

ed up to about 10mm, 0.4" each

way. Each division on the scale

is 2mm, 0.08".

Adjust the paper delivery side

B

plates to the print paper position.

Press the {{{{

C

image position.

}}}} key to check the

Proof

10

❖❖❖❖

Shifting the image to the left

TSLH02IE

TSLH02JE

Page 49

SilverV-EN.book Page 11 Monday, May 15, 2000 3:23 PM

Adjusting the Print Image Density

You can adjust the print image density to suit your needs. There are two

ways:

❖❖❖❖

Before Making a Master

Adjust the image density using the

{

Image Density

❖❖❖❖

After Making a Master

Adjust the image density using the

{WWWW} or {VVVV} key.

} key.

Before Making a Master

After Making a Master

Press the {{{{WWWW}}}} or {{{{VVVV}}}} key. To in-

A

crease the speed, press the {{{{VVVV}}}}

key. To reduce the speed, press

the {{{{WWWW}}}} key.

Adjusting the Print Image Density

1

Use the {{{{

A

pressing the {{{{

Image Density

}}}} key.

Start

}}}} key before

Note

❒ The faster the printing speed be-

comes, the lighter the printing

density is. If you want darker

prints, decrease the printing

speed.

11

Page 50

SilverV-EN.book Page 12 Monday, May 15, 2000 3:23 PM

Operation

Tint Mode—Halftone Printing

1

Use the {

halftone prints.

A

Tint/Economy

Press the {{{{

lect Tint mode (Upper indicator).

Tint/Economy

GRTINT0E

} key to make

}}}} key to se-

Check the image position of the

D

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {

} keys (see ⇒ P.9 “Ad-

Position

justing the Print Image Position”)

or the side tray fine adjusting

dial (see ⇒ P.10 “Shifting the

Print Image Position to the Right

or Left”).

Enter the number of prints with

E

the number keys.

Image

Set your originals on the exposure

B

glass or in the optional document

feeder.

Press the {{{{

C

Start

}}}} key.

TSLS012N

Press the {{{{

F

Print

}}}} key.

12

Page 51

SilverV-EN.book Page 13 Monday, May 15, 2000 3:23 PM

Fine Mode—Making Clear Prints

Fine Mode—Making Clear Prints

Use the {

prints.

Press the {{{{

A

mode.

Set your originals on the exposure

B

glass or in the optional document

feeder.

Press the {{{{

C

image position of the trial or

proof print.

} key to make clear

Fine

}}}} key to select Fine

Fine

}}}} key. Check the

Start

Enter the number of prints with

D

the number keys.

Press the {{{{

E

Print

}}}} key.

1

TSLS012N

Note

❒ If the image position is not cor-

rect, adjust it using the {

Position

justing the Print Image Position”)

or the side tray fine adjusting

dial (see ⇒ P.10 “Shifting the

Print Image Position to the Right

or Left”).

} keys (see ⇒ P.9 “Ad-

Image

13

Page 52

SilverV-EN.book Page 14 Monday, May 15, 2000 3:23 PM

Operation

Changing the Printing Speed

Use the {WWWW} or {VVVV} key to adjust the

1

speed of the machine with the image

density and printing paper.

Press the {{{{VVVV}}}} key to increase the

A

speed and press the {{{{WWWW}}}} key to reduce the speed.

Note

❒ The following speeds are avail-

able:

• Setting 1:

80 sheets/minute

• Setting 2:

100 sheets/minute

• Setting 3:

130 sheets/minute

❒ As a default setting, setting 2 is

selected.

❒ The faster the printing speed be-

comes, the lighter the printing

density is, and vice versa.

14

Page 53

SilverV-EN.book Page 15 Monday, May 15, 2000 3:23 PM

Stopping the Machine during the Multi-print Run

Stopping the Machine during the Multiprint Run

When You Want to Stop the

Machine during the Multi-print

Run and Print the Next

Original

Press the {{{{

A

Set the new original.

B

Enter the number of prints and

C

press the {{{{

Clear/Stop

Start

}}}} key.

TSLS01AN

}}}} key.

When You Want to Change the

Number of Prints Entered or

Check the Completed Prints

Press the {{{{

A

Change the number of prints or

B

check the completed prints.

Note

❒ When you change the number

of prints, you can re-enter the

number with the number keys

after pressing the {

key.

Clear/Stop

}}}} key.

Clear/Stop

1

TSLS01AN

}

TSLS012N

Press the

C

{{{{

Print

key.

}}}}

15

Page 54

SilverV-EN.book Page 16 Monday, May 15, 2000 3:23 PM

Operation

Preset Reduce/Enlarge—Reducing and

Enlarging Using Preset Ratios

1

You can select a preset ratio for printing.

GRREDU0E

GRENLA0E

Note

❒ The center and the leading edge of

the print image do not shift when a

print image is made with this function.

a

b

GRFULLOE

a: Paper Feed Direction

b: Constant

❒ You can select one of 7 preset ratios

(3 enlargement ratios, 4 reduction

ratios).

❒ You can select a ratio regardless of

the size of an original or printing

paper. With some ratios, parts of

the image might not be printed or

margins will appear on prints.

❒ Prints can be reduced or enlarged

as follows:

Reduction (Metric version)

❖❖❖❖

Reduction Ratio

93 %

87 % A5 B6

82 % B4 A4

71 % A4 A5

*1

Select this ratio when you make

prints with a lot of edge margins.

Reduction (Inch version)

❖❖❖❖

Reduction Ratio

93 %

77 %

74 % 10" × 14"

65 %

*1

Select this ratio when you make

prints with a lot of edge margins.

Original

Size

*1

A4 B5

B5 A5

B4 B5

Original

Size

*1

1

8

/2" × 14" 81/2" × 11"

1

8

/2" × 11" 51/2" ×

Print Size

Print Size

1

8

/2" × 11"

1

/2"

8

16

Page 55

SilverV-EN.book Page 17 Monday, May 15, 2000 3:23 PM

❖❖❖❖

Enlargement (Metric version)

Enlargement Ratio

141 % B5 B4

122 % A4 B4

115 % B5 A4

❖❖❖❖

Enlargement (Inch version)

Enlargement Ratio

155 %

129 %

121 % — —

Select the desired reduction or en-

A

Original

Size

A5 A4

A5 B5

B6 A5

Original

Size

1

5

/2" ×

1

/2"

8

1

5

/2" ×

1

/2"

8

largement ratio using the {{{{

}}}} key or the {{{{

duce

Enlarge

Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios

Print Size

Press the {{{{

D

Check the image position of the

E

Start

}}}} key.

trial or proof print.

Print Size

Note

❒ If the image position is not cor-

1

8

/2" × 14"

1

8

/2" × 11"

rect, adjust it using the {

} keys (see ⇒ P.9 “Shift-

Position

ing the Print Image Position Forward or Backward”) or the side

tray fine adjusting dial (see ⇒

P.10 “Shifting the Print Image Po-

sition to the Right or Left”).

Make your prints.

F

Re-

}}}} key.

1

TSLS012N

Image

Make sure that the original and

B

the print paper are the correct

size.

Set your originals on the exposure

C

glass or in the optional document

feeder.

17

Page 56

SilverV-EN.book Page 18 Monday, May 15, 2000 3:23 PM

Operation

Center/Edge Erase—Erasing center and

Edge Margins

1

When printing from thick books, or

similar originals, the binding margin

at the center and the edges might appear on prints. To prevent this, follow

the steps below.

GRMARG0E

Note

❒ As a default setting, the paper sizes

and directions that can be used are

as follows:

Metric

version

Inch

version

B4L, A4L, A5K, A5L,

B5K, B5L

1

/2" × 14"L, 81/2" × 11"L,

8

1

/2" × 81/2"L, 51/2" ×

5

1

/2"K

8

❒ If you want to use other size origi-

nals, you can register the size using

Service Program mode (See ⇒ P.59

“Service Program Menu”).

❒ The margin width to be erased can

be adjusted with Service Program

mode (See ⇒ P.59 “Service Program

Menu”).

Press the {{{{

A

Center/Edge Erase

twice to select the Center/Edge

Erase mode.

Check Indicator is blinking and

is shown in the guidance dis-

play.

Note

❒ To cancel this mode, press the

{

Center/Edge Erase

Press the {{{{}}}} or {{{{}}}} key to se-

B

} key again.

lect the paper size and direction.

}}}} key

18

Page 57

SilverV-EN.book Page 19 Monday, May 15, 2000 3:23 PM

Center/Edge Erase—Erasing center and Edge Margins

When you reach the desired paper

C

size and direction, press the {{{{qqqq}}}}

key.

Set the book on the exposure

D

glass.

Press the {{{{

E

Start

}}}} key.

TSLS01TN

TSLH014E

Check the image position of the

F

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {

} keys (see ⇒ P.9 “Ad-

Position

justing the Print Image Position”)

or the side tray fine adjusting

dial (see ⇒ P.10 “Shifting the

Print Image Position to the Right

or Left”).

Enter the number of prints with

G

the number keys.

Press the {{{{

H

Print

}}}} key.

Image

1

TSLS012N

19

Page 58

SilverV-EN.book Page 20 Monday, May 15, 2000 3:23 PM

Operation

Edge Erase—Erasing Edge Margins

1

If you want to erase edge margins of a

book original, follow the steps below.

Note

❒ As a default setting, the paper sizes

and directions that can be used are

as follows:

Metric

version

Inch

version

B4L, A4L, A5K, A5L,

B5K, B5

8

5

8

L

1

/2" × 14"L, 81/2" × 11"L,

1

/2" × 81/2"L, 51/2" ×

1

K

/2"

❒ If you want to use other size origi-

nals, you can register the size using

Service Program mode (See ⇒ P.59

“Service Program Menu”).

❒ The margin width to be erased can

be adjusted with Service Program

mode (See ⇒ P.59 “Service Program

Menu”).

Press the {{{{

A

Center/Edge Erase

}}}} key

to select Edge Erase mode.

Check Indicator is blinking and

is shown in the guidance dis-

play.

Press the {{{{}}}} or {{{{}}}} key to se-

B

lect the paper size and direction.

When you reach the desired paper

C

size and direction, press the {{{{qqqq}}}}

key.

Set the book on the exposure

D

glass.

TSLS01TN

20

Note

❒ To cancel this mode, press the

{

Center/Edge Erase

} key twice.

TSLH014E

Page 59

SilverV-EN.book Page 21 Monday, May 15, 2000 3:23 PM

Edge Erase—Erasing Edge Margins

Press the {{{{

E

Check the image position of the

F

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {

Position

justing the Print Image Position”)

or the side tray fine adjusting

dial (see ⇒ P.10 “Shifting the

Print Image Position to the Right

or Left”).

Enter the number of prints with