Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

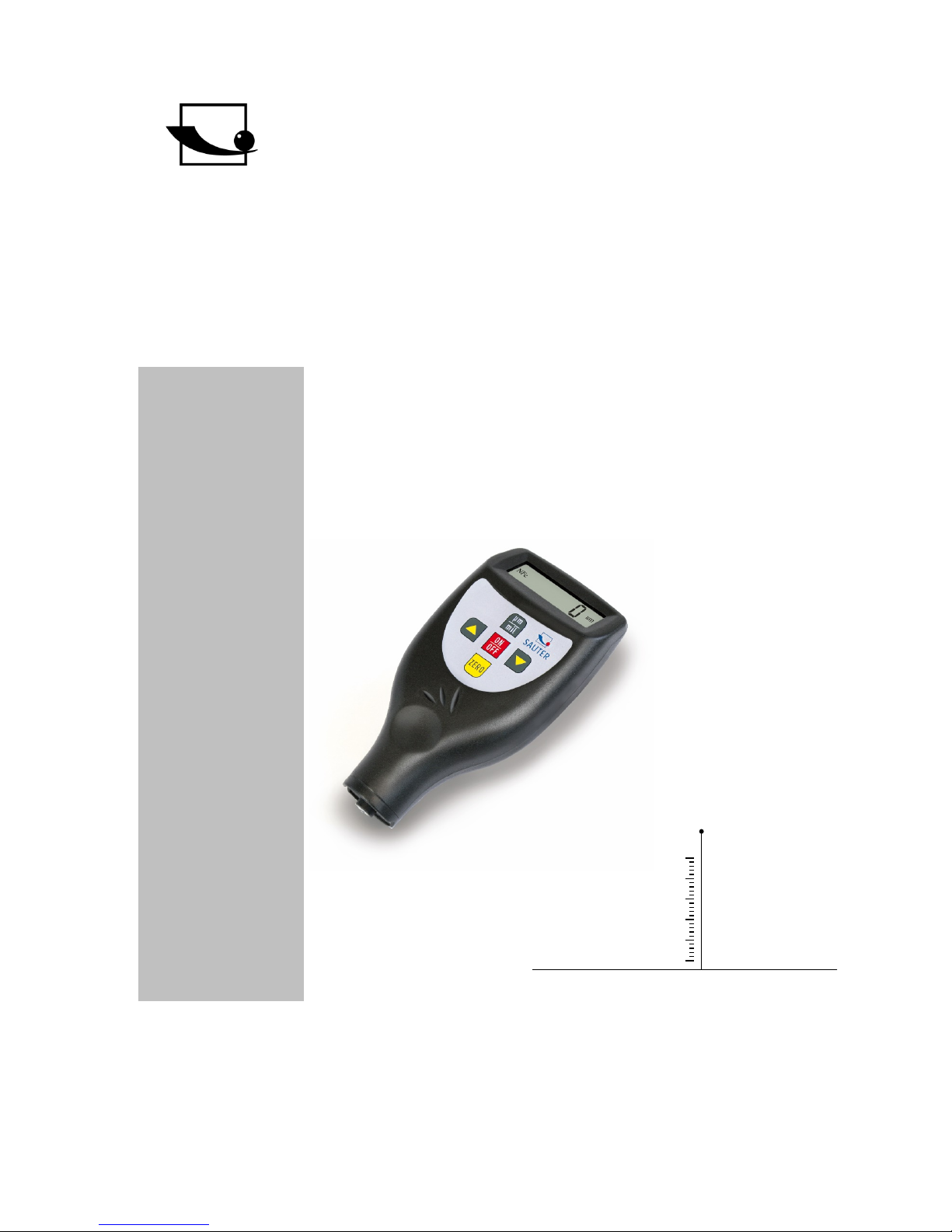

Digital Coating Thickness Gauge

SAUTER TC

Version 1.2

08/2017

GB

Illustration: TC 1250-0.1FN

TC -BA-e-1712

PROFESSIONAL MEASURING

2 TC-BA-e-1712

GB

SAUTER TC

Version 1.2 08/2017

Instruction Manual

Digital Coating Thickness Gauge

Thank you for buying a SAUTER digital Coating Thickness Gauge. We hope you are

pleased with your high quality Thickness Gauge with its big functional range.

If you have any queries, wishes or helpful suggestions, do not hesitate to call our

service number.

Models available:

- TC 1250-0.1 F

- TC 1250-0.1 N

- TC 1250-0.1 FN

- TC_car 1250-0.1FN (separate instruction manual available)

Summarize:

1 Features .......................................................................................................... 3

2 Specifications ................................................................................................ 3

3 Front Panel description ................................................................................. 5

4 Measuring procedure .................................................................................... 5

5 Zero- Adjustment (Calibration) ..................................................................... 6

6 Battery replacement ...................................................................................... 7

7 Adjustment foils ............................................................................................. 7

8 General advise ............................................................................................... 7

9 How to restore Factory Settings ................................................................... 7

10 Notes ............................................................................................................... 8

TC-BA-e-1712 3

This coating thickness gauge is small in size, light in weight and easy to carry. Although it is complex and advanced, it is convenient to operate. Its ruggedness will

allow many years of use if all the instructions are followed carefully.

Please keep this instruction manual always within reach!

Annotation: It is strongly recommended to adjust the new instrument before

the first use, as described in paragraph 5. By doing this, you will achieve a

much better measurement result right from the start.

1 Features

» This instrument meets the standards of both, ISO 2360 and DIN as well as ASTM

and BS. It is suitable for the laboratory and for use under “harsh field” conditions.

» The F- sensor measures the thicknes s of non-magnetic coatings, e.g. paint, plastics, enameled porcelain, galvanic coatings, phosphorescent layers chrome, lacquer

layers, copper plates, aluminum plates, alloys, paper etc.

These layers are located on magnetic metals, e.g. steel, iron, nickel etc.

» The N- sensor measures the thickness of non-magnetic coatings on non-magnetic

metals. It is used on anodizing, varnish, paint, enamel, plastic coatings, powder et c.

It can be applied on non-magnetic materials like aluminium, bras s, stainless st eel et c .

»The N- sensor measures the thickness of non-magnetic coatings on non-magnetic

metals. It is used on anodization, varnish, paint, enamel, plastic coatings, powder

coatings etc. These can be applied on non-magnetic materials like aluminium, br ass,

non-magnetic stainless steel and others.

»Die FN-sensor is a combination of both sensors and this way, it is applicable for

both application ranges.

» automatic base material recognition.

» manual or automatic Auto-Power off to conserve batteries

» metric /imperial conversion from µm / mil

»Two measurement modes: single and continuous (S= single/ C= cont inuous)

» Large measurement range and high resolution

» Data transfer to PC possible by RS232 interface

Cable and software can be obtained as optional accessory ATC-01.

2 Specifications

Display: 4 digits, 10mm LCD

Measurement range: 0- 1250 µm/ 0- 50 mil (default)

Loading...

Loading...