Page 1

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

MOBILE LEEB HARDNESS TESTER

Model: HMM

Table of contents

Caution

1. Summarize

1.1 Measuring Principle Scope

1.2 Hardness Value „L“

1.3 Main Features

1.4 Application Range

1.5 Technical Information

1.5.1 Display Unit

1.5.2 Impact Unit D

1.6 Overview Display Unit

1.7 Impact Device Assembling

2. Checking Supplied Accessories

3. Quick Start Guide

3.1 Cable Connection

3.2 Calibration

4. Operation Instructions

4.1 Display Unit

4.1.1 Keys

4.1.2 Measurement Mode

4.1.3 Setup

4.1.3.1 Material Group

4.1.3.2 Impact Direction

4.1.3.3 Scale

4.1.3.4 Browse

4.1.3.5 Adjusting Clock and Calendar

4.1.3.6 Calibration

4.2 The Format of Memory Data

4.3 Backlight

4.4 System Reset

4.5 Automatic Shutdown

5. Printing Data

5.1 Printer Link

5.2 Test Report Format

6. Hardness Test

6.1 Test Preparation

6.2 Sample Preparation

6.3 Test Steps

7. Troubles and Solutions

8. Maintenance and Service

8.1 Impact device Maintenance

8.2 Storage of Report

8.3 Normal Maintenance Procedures

APPENDIX 1 Daily Checking

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

HMM

APPENDIX 2 Factors affecting the Accuracy

APPENDIX 3 Measuring and Conversion Range

APPENDIX 4 Material Code

9. Declaration of Conformity

Caution

Please read this carefully first:

1. Only the special battery offered by our Company may be

used in the main body of the hardness tester. Improper

batteries might cause damages to the instrument, battery

leakage, even fire or explosion.

2. Any components of the instrument may not get

submerged in water or get exposed to rain, which could

cause a battery explosion and damage the main body.

3. Electrical shocks have to be avoided; the cabinet may

not be opened.

4. If the instrument hasn’t been used for a longer period, it

has to be stored in a cool and dry place.

1. Summarize

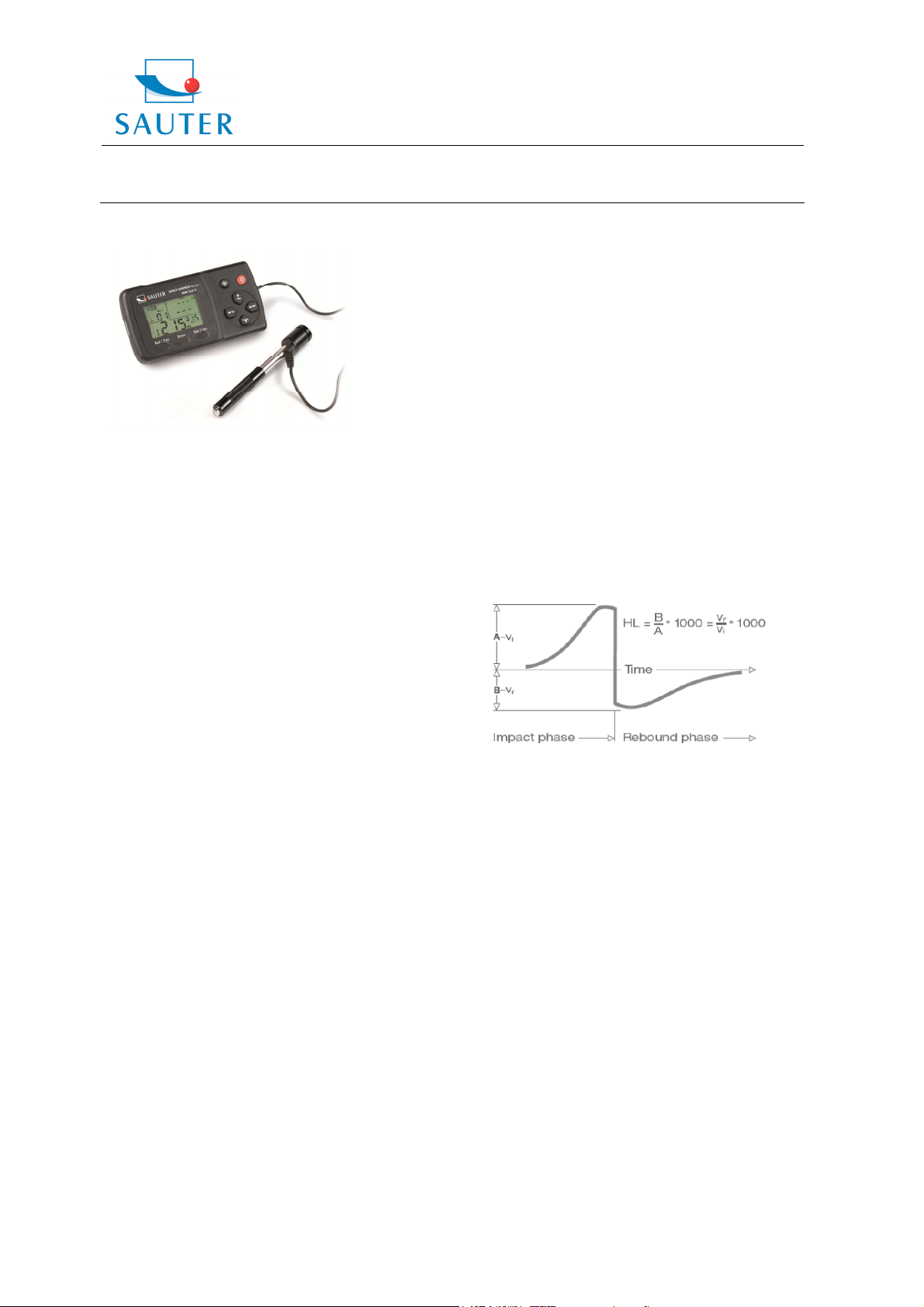

1.1 Measuring Principle Scope

The measuring principle of HMO Hardness Tester is

physically a rather simple dynamic hardness test:

An impact body with a hard metal test tip is propelled by

spring force against the surface of the test piece. Surface

deformation takes place when the impact body hits the test

surface, which results in a loss of kinetic energy. This

energy loss is calculated by velocity measurements when

the impact body is at a precise distance from the surface

for both, the impact phase and the rebound phase, of the

test. The permanent magnet in the impact body generates

an induction voltage in the single coil of the impact device.

The voltage of the signal is proportional to the velocity of

the impact body. A signal processing by the electronics

provides the hardness reading for display and storage.

Simply said, harder materials produce higher rebound

velocities than less harder ones (higher L- value).

HMM Hardness Tester provides a direct hardness

measurement within any particular material group (i.e.

steel, aluminium etc.). It can be used as a final test result

without conversion. However, there are established

conversions to other hardness scales in this Hardness

Tester as a comfort for our customers. These conversions

to other scales (HRC, HRB, HB, HV, HSD etc.) are

programmed into the electronics and they can be shown

directly on the display as a test result. All data is stored in

the native L scale to prevent any possible errors with

multiple conversions.

HMM-BA-e-1111 1

Page 2

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

1.2. The Hardness value “L”

This term was introduced 1978 into measuring technology

by Dr. Dietmar Leeb. It contains the quotient for the impact

body’s rebound and impact velocity, multiplied by 1000.

Harder materials produce higher rebound velocity than

less harder ones. With reference to a particular material

group (i.e. steel, aluminium etc.), the L value represents a

direct hardness measurement and is used as such.

Comparison curves with other standard statistic hardness

values have been established (Brinell, Vickers, Rockwell

C, B) for the most prevalent materials, enabling the

L values to be converted into the relevant values by these

procedures. With this hardness tester, such hardness

values can directly be displayed in the hardness scales

HRC, HRB, HB, HV, HSD and tensile strength (MPa).

1.3 Main features

- Highly accurate, ± 6 HL

- Automatic correction for impact direction

- Large, easy to read display with backlight

- User profiles for fast change of all settings

- Conversion to all common hardness scales

HRC, HRB, HB, HV, HSD and tensile strength

(MPa).

- Supplied by dry-cell, Ultra-low-power

- Easy calibration

- Conforms to the Standard ASTM A956-02

1.4 Application range

- Appropriate for all metals

- Ideal for production level testing

- Best suited for on- site testing of heavy, big or

already installed parts

- Handy for difficult to access or confined test

locations

- Automatic compensation for impact direction

- Excellent for material selection and acceptance

tests

- Easy to handle and accurate on curved test

surfaces (R> 10mm)

- Metal production & processing

- Automotive & transportation

- Aerospace & shipyard

- Testing services & laboratories

1.5 Technical information

1.5.1 Display unit

* HL Display range: 0 to 999 HLD

* Accuracy: ± 6 HL

* LCD: large LCD with backlight

* Resolution: 1 HL; 1 HV; 1 HB; 0,1 HRC;

0,1HRB; 1 HSD; 1 MPa

* Power: dry cell (3 x 1.5V AAA)

* Operating temperature: 0°C up to + 50°C

(32°F up to 122°F)

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

HMM

* Storage Temperature: -10°C up to + 60°C

(14°F up to 140°F)

* Humidity: 90 % max.

* Dimensions: 150mm x 80mm x 24mm

(5.9 x 3.1 x 0.9 inches)

* Weight: Approx. 200g (main body)

1.5.2 Impact unit D

Impact energy: 11 Nmm

Mass of the impact body: 5.5 g

Test tip diameter: 3 mm

Test tip material: tungsten carbide

Test tip hardness: ≥ 1600 HV

Impact length: 147 mm

Impact maximum diameter: 20 mm

Impact weight: 75 g

1.6 Overview Display Unit

Picture 1-1

1.7 Impact Device Assembling

1. Impact body

2. Support ring

3. Coil

4. Cable

5. Catch chuck

6. Loading tube

7. Release button

2. Checking supplied accessories

It should be checked that the following accessories are

supplied with your instrument

Picture 2-1

HMM-BA-e-1111 2

Page 3

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

The items are supplied with the hardness tester. The

accessories available may vary from retailer to retailer,

depending on the country or service provider.

The purchased accessories only have to be used with

Polygon-authorised devices. The use with other devices

could cause problems and any repair costs wouldn’t be

covered by warranty.

3. Quick start guide

3.1 Connection

The signal cable has to be connected to the impact device

and the display unit.

Picture 3-1

HMM

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

b) In other mode, the “Back/Print” button has to be

pressed to complete setup and to save the parameters set.

Then it is returned to measurement mode.

4. “Browse” button: browse the memory data.

5. “Date/Time” button: adjustment of clock and calendar

6.

button: This button has to be pressed to delete

current data in measurement mode or browse mode.

7. button: It has to be pressed to setup the conversion

scale in measurement mode. In Date/Time setup mode

and in calibration mode, this button has to be pressed to

decrease the flickering bit. In browse mode,

to be pressed to display the next data.

8. button: It has to be pressed to setup the impact

direction in measurement mode. In Date/Time setup mode

and in calibration mode, this button has to be pressed to

button has

3.2 Calibration

The test block has been calibrated in accordance with the

dynamic hardness value L. The HMM Impact Hardness

Tester has to be calibrated by the test block before the first

use (APPENDIX 1)

4. Operating instructions

4.1 Display unit

4.1.1 Keys

Picture 4-1

2

increase the flickering bit. In browse mode,

to be pressed to display the previous data.

button: In measurement mode, it has to be pressed

9.

to select the material that will be impacted. In Date/Time

setup mode and in calibration mode, this button has to be

pressed to select the next bit.

4.1.2 Measurement Mode

HMM Hardness Tester has got a large LCD and an

abundance of information.

Picture 4-2

4.1.3 Setup

4.1.3.1 Material Group

In measurement mode,

select the material that will be impacted. Following material

list is shown on the back of the instrument:

button has to be pressed to

button has

“On/Off“ button: The instrument is turned on and

1.

off by pressing and holding the button.

2. Backlight button: The button has to be

pressed to turn on and off the LCD backlight.

3. “Back/Print” button:

a) In measurement mode, the “Back/Print” button has to

be pressed to erase the measured data. At the same time,

if the mini-printer is linked with the display unit, those data

will be printed out.

HMM-BA-e-1111 3

Page 4

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

If button is pressed continuously, material changes

according to following sequence:

Note:

1. It is necessary to select the material classification. If

the type of material isn’t known, the related material

handbook will help.

2. If the material group is changed, the impact times

counter will be set to “0”.

3. Default setting: steel and cast steel.

4.1.3.2 Impact Direction

Ideal Leeb Hardness Testing is a downward straight

testing method. As a result of gravity, the test should be

amended when measuring other directions in order to

measure correct hardness values of materials. As long as

the impact direction is chosen correctly, impact direction is

automatically amended by the hardness tester.

There are five impact directions to chose:

In measurement mode, the

select the impact direction. It changes to following

sequence:

Note: Default setting is

4.1.3.3 Scale

HLD values can be automatically converted by HMM

Hardness Tester to other scales HRC,HRB, HB, HV, HSD

or tensile strength (MPa) according to a particular material

group (e.g. steel, aluminium etc.)

In measurement mode, the

convert all common hardness scales or tensile strength

(MPa). button has to be pressed continuously and the

scale changes according to following sequence:

Notes:

1. If the conversion is out of range, the conversion

value is indicated by “---“.

2. If the conversion is set from hardness scale to

tensile strength or the other way round, the material

group has to be reset.

2. Conversion value only supplies a general reference,

which results in some offset. Generally, comparative

tests are necessary to achieve precise conversion.

3. If the hardness scales are changed, the current

impact times counter will be cleared to “0”.

4. Standard setting for the conversion is “HRC”.

4.1.3.4 Browse

“Browse” button has to be pressed to browse stored data

and to display the first data group of the last nine test data,

button has to be pressed to

.

button has to be pressed to

HMM

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

including hardness value HLD, material, conversion

values, impact direction, date and time etc.

The

button has to be pressed to browse the next data

group.

previous data group. “Back/Print” button has to be

pressed to get back to measurement mode.

4.1.3.5 Adjusting Clock and Calendar

HMM Hardness Tester has got an inbuilt real-time clocksystem. Clock and calendar have to be adjusted if, i.e. the

dry cell has been reinstalled. The procedure is as follows:

The “Date/Time” button has to be pressed to enter clock

and calendar adjustment mode. If the “month” bit starts

flickering, the

and

The

flickering, the

and

The

flickering, the

and

The

flickering, the

and

The

starts flickering, the

increase and

to 59.

“Back/Print” button can be pressed every time if the

adjustment is completed and to return to measurement

mode.

4.1.3.6 Calibration

Calibration is used to calibrate the measured value (HLD)

of the hardness tester to decrease the measuring error as

far as possible. The procedure is as follows:

1) “Back/Print” button has to be pressed to clear the

testing times to “0”. It has to be impacted 5 times on the

test block to get an average value (some previous error

data can be deleted).

button has to be pressed to browse the

button has to be pressed to increase

button to decrease. Valid numbers are 1 to 12.

button has to be pressed and the “day” bit starts

button has to be pressed to increase

button to decrease. Valid numbers are 1 to 31.

button has to be pressed and the “year” bit starts

button has to be pressed to increase

button to decrease. Valid numbers are 00 to 99.

button has to be pressed and the “hour” bit starts

button has to be pressed to increase

button to decrease. Valid numbers are 00 to 23.

button has to be pressed and the “minute” bit

button has to be pressed to

button to decrease. Valid numbers are 00

HMM-BA-e-1111 4

Page 5

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

2) “Date/Time” button has to be pressed about two

seconds to display the calibration mode. The HLD value

which is remarked on the test block has to be input by the

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

HMM

5.1 Printer Link

Picture 5-1

buttons

button again, the calibration is finished.

Note:

The hardness tester must be calibrated on the test

block before use.

The default impact direction is

4.2 The Format of Memory Data

The data group (such as test result, material and impact

direction) are automatically saved in memory after each

individual measurement. HMM Hardness Tester can store

9 sets of data. When measuring more than 9 times, the

last group of data will be stored in 9

one will be erased. The second group will be moved into

the 2nd position. Simultaneously, the position of other

groups of data will be moved into one lower position.

“Back/Print” button has to be pressed and held to end the

measurement and print out the memory data (if connected

to a printer). If printing is completed, the original data will

be erased automatically.

4.3 Backlight

LED backlight is used for poor light conditions. It can be

turned on and off by pressing the button. The present

situation will be saved while the instrument is powered off.

If there is no measurement and no key operation within 10

seconds, the backlight will be turned off automatically and

the display unit will be shut off in 3 minutes.

4.4 System Reset

If the display unit isn’t working properly or halts, the

“Reset” button has to be pressed by inserting a slender

rod into the reset hole on the backside of the display unit.

Then the display will be shutdown. To reboot the system,

the

4.5 Automatic Shutdown

If there is no measurement and no key operation within 3

minutes, the display unit will automatically be switched off

in order to save battery power. All the parameters will be

stored before.

5. Printing Data

HMM Hardness Tester can be linked with a microcomputer on infrared base to print out the hardness test

result report.

or or . By pressing the “Back/Print”

(see Appendix 1)

th

position and the first

button has to be pressed and held.

The infrared connection is used for display unit and printer:

The printer has to be moved to the left side of the display

unit. The printer infrared window has to be opposite to the

infrared window of the display unit. The micro-printer and

the display unit has to be turned on. Then the

“Back/Print” button has to be pressed to print out the test

report.

5.2 Test Report Format

A complete test report format is shown in picture 5-2.

Picture 5-2

Note: The date and time printed are the actual time,

which means the report end date and time.

6. Hardness Test

6.1 Test preparation

1) It has to be assured that the system connection is safe

and reliable.

2) The

power. It has to be inspected if every setting of the

display unit is correct, particularly material type and

impact direction. It may cause a great error if the setting

is not in accordance with the actual conditions.

button has to be pressed to switch on the

HMM-BA-e-1111 5

Page 6

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

6.2 Sample Preparation

Inappropriate samples will cause great measurement

errors. Therefore, preparation and the necessary handling

should be done under original conditions of the sample.

Preparation of the sample and surface of test should be

coincident with the following basic requirements:

1) Cold processing and thermal processing of the impact

device during the process of sample surface preparation

should be avoided.

2) The surface of the sample should be plane, with a

metallic sheen, and not involve oxide layer or other stains.

3) Roughness of the test surface: Ra≤ 1.6

4) The sample has to be of sufficient quality and rigidity.

Otherwise displacements or shaking during the test might

happen. These could also lead to measurement errors.

A sample quality of ≥ 5 kg can be directly tested. If the

sample quality is 2~5 kg, it should be fixed before the test

by appropriate clamps. If the sample quality is 0.05~2 kg, it

should be coupled before the test; if it is < 0.05 kg, this

hardness tester is inappropriate to use.

Coupling method: The testing sample’s back should be

plane as well as the surface of the supporting object.

A little coupling substance (i.e. Industry Vaseline) has to

be filled between the two components. Then the two parts

have to be pressed together. If the weight of the supporting

object is more than 5 kg, it can be replaced by the test

block.

5) Samples should be thick enough with sufficient layered

surface. If the D-type of impact sensor is used, the

thickness of the sample should be less than 5 mm and the

surface absorption layer (surface- hardening layer) should

not be less than 0.8 mm. To perform accurate hardness

measurements, the best way is to remove this layer before

testing.

6) If the testing sample surface isn’t horizontal and flat, the

curvature radius of the testing and nearby surface should

be larger than 30 mm. An appropriate supporting ring has

to be selected and installed.

7) A sample should not be magnetic. The signal of the

impact sensor would be seriously affected, which might

cause inaccurate test results.

7. Test Steps

1) Loading:

The loading tube has to be slided forward to load the

impact device.

HMM

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

3) Measuring:

The trigger button has to be pressed to trigger the impact

device. The hardness value will be immediately displayed.

4) Reading the test result

The test result has to be read as shown in picture 6-4:

Sample Material: steel and cast iron

Impact direction: downwards

rd

Date: 3

Current hardness value: 786 HLD

The current measurement is the third point

Current mean value: 785 HLD

Conversions to HRC: 58.6 HRC

Mean value of HRC: 58.5 HRC

Repeating the above steps, tests in more points can be

carried out.

Note: Generally, each measurement location of sample

is conducted for five tests. The X (difference of max.

value and the min. value) values must be less than 15

HL. The distance between any two impact positions

should be ≥ 3mm; the distance between impact

position and the edge of the sample should also be

≥ 3mm.

7. Troubles and solutions

, December

2) Placing:

The impact device has to be placed and held on the

surface of the test piece at the desired test point. Impact

direction should be vertical with the surface being tested.

HMM-BA-e-1111 6

Page 7

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

8. Maintenance and Service

8.1 Impact Device maintenance

After 1000- 2000 times use, the impact device and the

impact body should be cleaned with a nylon brush. The

screw of the supporting ring has to be turned off before the

catheter can be cleaned. Then the impact body has to be

taken out and it has to be rotated into the tube with the

nylon brush in anti-clockwise direction. The brush has to

be pulled out when touching the bottom. This procedure

has to be repeated several times. Then the impact body

has to be loaded and the supporting ring reinstalled. The

impact body should be released after use. The use of any

lubricant is banned.

9.2 Storage of the report

Printing paper is thermal paper and it should be preserved

to avoid heat and direct light. If the print records are

necessary to be kept in long-term conservation, they

should be copied and preserved in time.

8.3 Normal Maintenance procedures

If the error is larger than 12HLD by calibrating the

hardness tester, the steel ball or the impact body has to be

renewed. Those parts may be worn out and this may lead

to failure in operation.

In case if any other abnormal phenomena occur to the

Hardness Tester, it should not be either demolished or any

fixed assembly parts may not be adjusted. Instead, the

warranty card has to be completed and the Hardness

Tester has to be sent to our Maintenance department.

We will care for a prompt checking and if necessary, repair

of the device.

Appendix 1 Daily Checking

The test block is mainly used to calibrate the Hardness

Tester. The error and repeatability of it should be in the

scope defined in following table:

Note:

HLD is the mean value of 5 Leeb Hardness values

measured on the test block.

HLD is the value marked on the test block.

is the maximum value of 5 Leeb Hardness values

measured on the test block.

ist he minimum value of 5 Leeb Hardness values

measured on the test block.

HMM

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Appendix 2 Factors affecting the Accuracy

Incorrect operation or improper testing conditions can

seriously affect the accuracy. The following factors are the

main accounts in lack of accuracy:

1) Roughness of sample surface

When the impact body impacts on the sample, a small pit

will arise on the surface of it. The less roughness, the less

consumption of impact energy is needed. According to

this, the roughness of the surface should be Ra≤ 1.6.

2) The shape of the sample surface

Leeb testing principle demands that the velocity of rebound

and impact are on the same line, because the impact body

is moving in a metal tube. Of course, hardness can also be

shown if the velocity of rebound and impact are not on the

same line. In this case, the impact body would collide with

the tube wall when it rebounds, which will affect the

velocity of rebound. This will cause an error on test

accuracy. If the radius of curvature of the sample surface

is smaller, a suitable variant supporting circle has to be

used. We can contribute to design and release those

supporting circles, if needed.

3) The weight of the sample

If the weight of the sample is more than or equal to 5 kg,

testing can be directly started. If it is less than 5 kg, the

sample needs a special charge. The supporting piece has

to be coupled by a coupling medium and pressed onto the

surface of the test piece. By doing this, better test results

will be achieved.

The area of the testing points should be free of vibrations

or shaking. If the weight of the sample is not enough,

supporting, coupling and compressing must be increased

to avoid jitter and sloshing. Shocks should be avoided.

4) The sample stability

Any effective tests need to minimize possible interference

from outside. This is very important for dynamic

measurements, such as Leeb Hardness testing.

Therefore, measurements are only allowed in a stable

hardness testing system.

Appendix 3 Measuring and Conversion Range

HMM-BA-e-1111 7

Page 8

Appendix 4 Material Code

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

HMM

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

DESIGNED IN REGARD TO THESE STANDARDS:

• ASTM A956

• DIN 50156

9. Declaration of Conformity

HMM-BA-e-1111 8

Loading...

Loading...