Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

Mobile Leeb Hardness Tester

SAUTER HK-D/ HK-DB

Version 1.3

07/2017

GB

HK-D_HK-DB-BA-e-1713

PROFESSIONAL MEASURING

2 HK-D_HK-DB-BA-e-1713

GB

SAUTER HK-D/ HK-DB

Version 1.3 07/2017

Instruction Manual Mobil e Le e b Hardness Te s t e r

Thank you for buying a digital SAUTER Leeb hardness tester. We hope you are

pleased with your high quality instrument and with its big functional range. If you

have any queries, wishes or helpful suggestions, do not hesitate to call our service

number.

Summarize:

1 General Description ....................................................................................... 4

1.1 Features ..................................................................................................................................... 4

1.2 Main Application and Testing Range ..................................................................................... 4

1.2.1 Main Application ......................................................................................................................... 4

1.2.2 Testing Range ............................................................................................................................ 5

1.3 Types and specification ........................................................................................................... 6

1.4 Operating conditions ............................................................................................................... 9

2 Structure features and testing principle ...................................................... 9

2.1 Structure Features .................................................................................................................... 9

2.1.1 Hardness Tester ......................................................................................................................... 9

2.1.2 Main unit ..................................................................................................................................... 9

2.1.3 D type impact device .................................................................................................................. 9

2.1.4 Non-conventional types of impact devices ............................................................................... 10

2.2 Testing principle ..................................................................................................................... 10

3 Technical capabilities .................................................................................. 10

3.1 Specifications ......................................................................................................................... 10

3.2 Dimension, size and weight .................................................................................................. 11

3.2.1 Dimensions: .............................................................................................................................. 11

3.2.2 Weight: ..................................................................................................................................... 11

4 Testing .......................................................................................................... 11

4.1 Preparation and Inspection prior to testing......................................................................... 11

4.1.1 The preparation of work piece surface ..................................................................................... 11

4.1.2 System setting of tester ............................................................................................................ 12

4.1.3 Measuring condition setting of tester ........................................................................................ 12

4.2 Testing ..................................................................................................................................... 12

4.2.1 Start-up ..................................................................................................................................... 12

4.2.2 Loading ..................................................................................................................................... 12

4.2.3 Testing ...................................................................................................................................... 13

4.2.4 Read measured value .............................................................................................................. 13

4.2.5 Print out the measuring result .................................................................................................. 13

4.2.6 Press key to turn off ............................................................................................................ 13

4.2.7 The processing of testing results .............................................................................................. 13

4.2.8 Expression of testing results .................................................................................................... 13

5 Special prompts ........................................................................................... 14

6 Detail Testing procedures ........................................................................... 14

6.1 Start-up .................................................................................................................................... 14

6.2 Turn On or turn off ................................................................................................................. 14

6.3 Testing ..................................................................................................................................... 14

6.3.1 Explanation of the main display interface ................................................................................. 15

6.3.2 Testing procedures ................................................................................................................... 15

HK-D_HK-DB-BA-e-1713 3

6.3.3 Key operation ........................................................................................................................... 15

6.4 Menu structure diagram......................................................................................................... 16

6.5 Measuring condition setting ................................................................................................. 17

6.5.1 Impact direction setting............................................................................................................. 18

6.5.2 Mean times setting ................................................................................................................... 18

6.5.3 Material setting ......................................................................................................................... 18

6.5.4 Hardness scale setting ............................................................................................................. 19

6.5.5 Tolerance limit setting............................................................................................................... 19

6.5.6 Hardness/σb setting .................................................................................................................. 20

6.6 Print function .......................................................................................................................... 20

6.6.1 Printing current value ................................................................................................................ 20

6.6.2 Print memory value ................................................................................................................... 21

6.6.3 Print all memory ........................................................................................................................ 22

6.7 Memory manager .................................................................................................................... 22

6.7.1 Viewing from the No.1 group/ Viewing from the end group...................................................... 22

6.7.2 Viewing from selected group .................................................................................................... 22

6.7.3 Transferring data ...................................................................................................................... 22

6.7.4 Deleting selected group ............................................................................................................ 23

6.7.5 Delete all ................................................................................................................................... 23

6.7.6 Confirm deletion ....................................................................................................................... 23

6.8 Viewing interface .................................................................................................................... 23

6.9 System Set .............................................................................................................................. 24

6.9.1 LCD brightness Set .................................................................................................................. 25

6.9.2 Time and Date Set .................................................................................................................... 25

6.10 About software ....................................................................................................................... 25

6.11 Calibration of the Tester ........................................................................................................ 26

6.12 Back light ................................................................................................................................ 26

6.13 Turn off Power automatically ................................................................................................ 26

6.14 Battery replacement ............................................................................................................... 27

6.15 The connection of data communication cable .................................................................... 27

7 Trouble shooting.......................................................................................... 27

8 Maintenance ................................................................................................. 27

8.1 Impact device .......................................................................................................................... 27

8.2 Standard maintenance procedures ...................................................................................... 27

9 Transportation and Storage ........................................................................ 28

10 Non-warranty parts ...................................................................................... 28

4 HK-D_HK-DB-BA-e-1713

Safety Precautions

1. The complete instruments may not be immerged into water either be exposed to

rain. This could lead to unpredictable damages. The accumulator or display could be

destroyed.

2. If the instrument is not used for a longer period of time, it should be stored cool

and dry, the best in its original package. The environmental temperature should be

from -30°C up to +80°C and relative humidity at (RH) 5% up to 95%.

1 General Description

1.1 Features

LCD display of 128×64 matrix is used.

Converts to all common hardness s cales (HV, HB, HRC, HRB, HRA, HS).

English displaying and menu operating, the operation is easy and convenient.

With RS232 interface, multiple communication modes are adopted to meet cus-

tomized requirements of various users.

Equipped with 7 types of impact devices which need not to be recalibrated when

changing them, the system can identify the type of impact device automatically.

Max 600 groups(imp act times: 32~1)of data can be stored at internal non-

volatile data storage.

Upper and lower limit of hardness can be pre-set; If the tested value exceeds the

limits, alarm will be sent out automatically to make convenient for the requirements of batch measurements.

Back light display has been used to make convenient for the use in poor light.

Test values software calibration function.

Material of “cast steel” is added; HB values can be read out directly when D/DC

impact device is used to measure “cast steel” work piece.

Printer be separated from main unit and copies of testing results can be printed

as required.

Power is two of AA battery. Continuous working period: approx. 200 h (no back

light on).

Software of PC can be installed according to the requirements of user, the fun c-

tion will be more powerful to satisfy the more strict demands of quality control and

management.

1.2 Main Application and Testing Range

1.2.1 Main Application

The assembled machinery and permanently installed parts

Die cavity of molds

Heavy work piece

Failure analysis of pressure vessel, steam turbo-generator set and other equip-

ment

Narrow testing space where work piece installed

Bearings and other parts

Cases which require the test result with normalized original recording

Material identification of the metal material warehouse

Quick tests of large range and multipoint measuring positions for heavy work

piece

HK-D_HK-DB-BA-e-1713 5

1.2.2 Testing Range

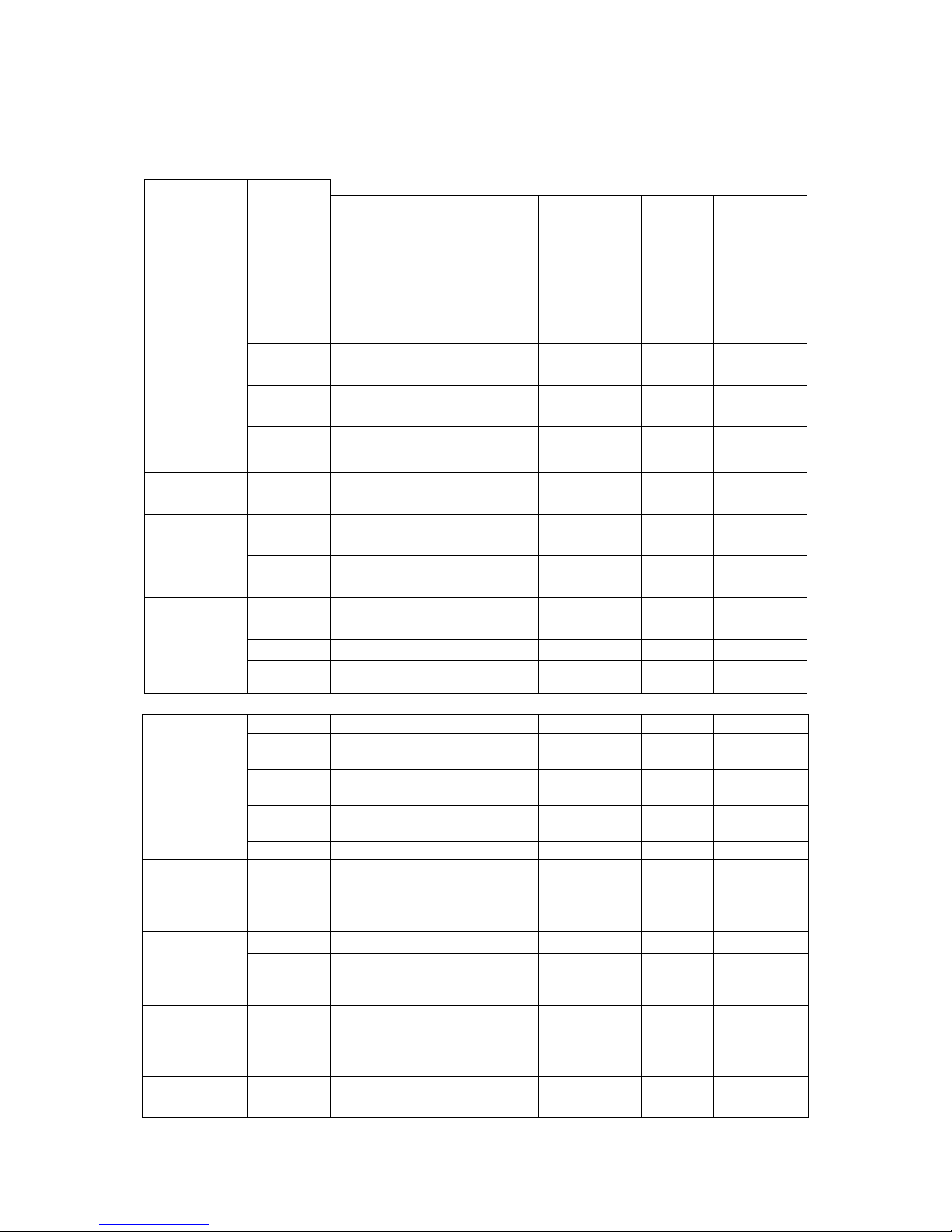

Testing range see table 1 and table 2.

Table 1

Material

Hardness

method

D/DC

D+15

C G DL

Steel and

cast steel

HRC

17.9~

68.5

19.3~

67.9

20.0~

69.5

20.6~68.

2

HRB

59.6~

99.6

47.7~

99.9

37.0~99.

9

HRA

59.1~

85.8

HB

127~

651

80~

638

80~

683

90~

646

81~646

HV 83~976

80~

937

80~

996

80~950

HS

32.2~

99.5

33.3~

99.3

31.8~

102.1

30.6~

96.8

Hammered

steel

HB

143~

650

Cold work

tool steel

HRC

20.4~

67.1

19.8~

68.2

20.7~

68.2

HV 80~898

80~

935

100~

941

Stainless

steel

HRB

46.5~

101.7

HB

85~655

HV 85~802

Gray cast

iron

HRC

HB 93~334

92~32

6 HV

Nodular

cast iron

HRC

HB 131~387

127~3

64 HV

Cast

aluminum

alloys

HB 19~164 23~210

32~16

8

HRB 23.8~84.6 22.7~85.0

23.8~

85.5

Brass(copp

er-zinc

alloys)

HB

40~173

HRB 13.5~95.3

Bronze (copper

Aluminum/copper-

tin alloys)

HB

60~

290

Wrought

copper

alloys

HB 45~315

6 HK-D_HK-DB-BA-e-1713

Table 2

No.

Material

HLD

Strength σ

b

(MPa)

1

Mild steel

350~522 374~780

2

High-carbon steel

500~710 737~1670

3

Cr steel

500~730 707~1829

4

Cr-V steel

500~750

704~1980

5

Cr-Ni steel

500~750

763~2007

6

Cr-Mo steel

500~738 721~1875

7

Cr-Ni-Mo steel

540~738 844~1933

8

Cr-Mn-Si steel

500~750 755~1993

9

Super strength

steel

630~800 1180~2652

10

Stainless steel

500~710 703~1676

1.3 Types and specification

No.

Remarks

Standard

Delivery

1

Main unit

1 2

D type impact device

1 3

Small supporting ring

1

Additional

Optional

Delivery

1

Communication cable with

DataView Software ATC 01

2

Printer

3+4 Nylon brush1 and 2

2. in case of choosing

G type impact device

5

Various non-conventional

types of impact devices

See table 3

6

Various non-conventional

types of impact supporting

rings

See table 4

Table 3

Non conventional

impact devices

DC(D)/DL D+15 C G

Impacting energy

Mass of impact

body

11Mj

5.5g/7.2g

11mJ

7.8g

2.7mJ

3.0g

90mJ

20.0g

Test tip Hardness Diame-

ter of test tip

Material of test tip

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten

carbide

1600HV

5mm

Tungsten

carbide

HK-D_HK-DB-BA-e-1713 7

Impact device Diameter

Impact device

Length

Impact device

Weight

20mm

86(147)/

75mm

50g

20mm

162mm

80g

20mm

141mm

75g

30mm

254mm

250g

Max. hardness of

workpiece

940HV 940HV 1000HV 650HB

Mean roughness of

workpiece surface of the

Ra

1.6μm 1.6μm 0.4μm 6.3μm

Min. weight of sample

Measure directly Need

support firmly

Need coupling tightly

>5kg

2~5kg

0.05~2kg

>5kg

2~5kg

0.05~2kg

>1.5kg

0.5~1.5kg

0.02~0.5k

g

>15kg

5~15kg

0.5~5kg

Min. thickness of sample

coupling tightly

Min.layer thickness for

surface harden

5mm

≥0.8mm

5mm

≥0.8mm

1mm

≥0.2mm

10mm

≥1.2mm

Hardn

ess

300HV

Indentation

diameter

0.54mm 0.54mm 0.38mm 1.03mm

Indentation

depth

24μm 24μm 12μm 53μm

Hardn

ess

600HV

Indentation

diameter

0.54mm 0.54mm 0.32mm 0.90mm

Indentation

depth

17μm 17μm 8μm 41μm

Hardn

ess

800HV

Indentation

diameter

0.35mm 0.35mm 0.35mm --

Indentation

depth

10μm 10μm 7μm --

Available type of impact

device

D:

General test

DC:

Hole or hollowcylindrical

test

DL:

Slender nar-

row groove

or hole test

D+15:

groove or

re-entrant

surface

C:

small, light,

thin parts

or surface

of hardened layer

G:

large, thick,

heavy or

rough surface steel

8 HK-D_HK-DB-BA-e-1713

Hardn

ess

800HV

Indentation

diameter

0.35mm 0.35mm 0.35mm --

Indentation

depth

10μm 10μm 7μm --

Available type of impact

device

D:

General test

DC:

Hole or hollowcylindrical

test

DL:

Slender nar-

row groove

or hole test

D+15:

groove or

re-entrant

surface

C:

small, light,

thin parts

or surface

of hardened layer

G:

large, thick,

heavy or

rough surface steel

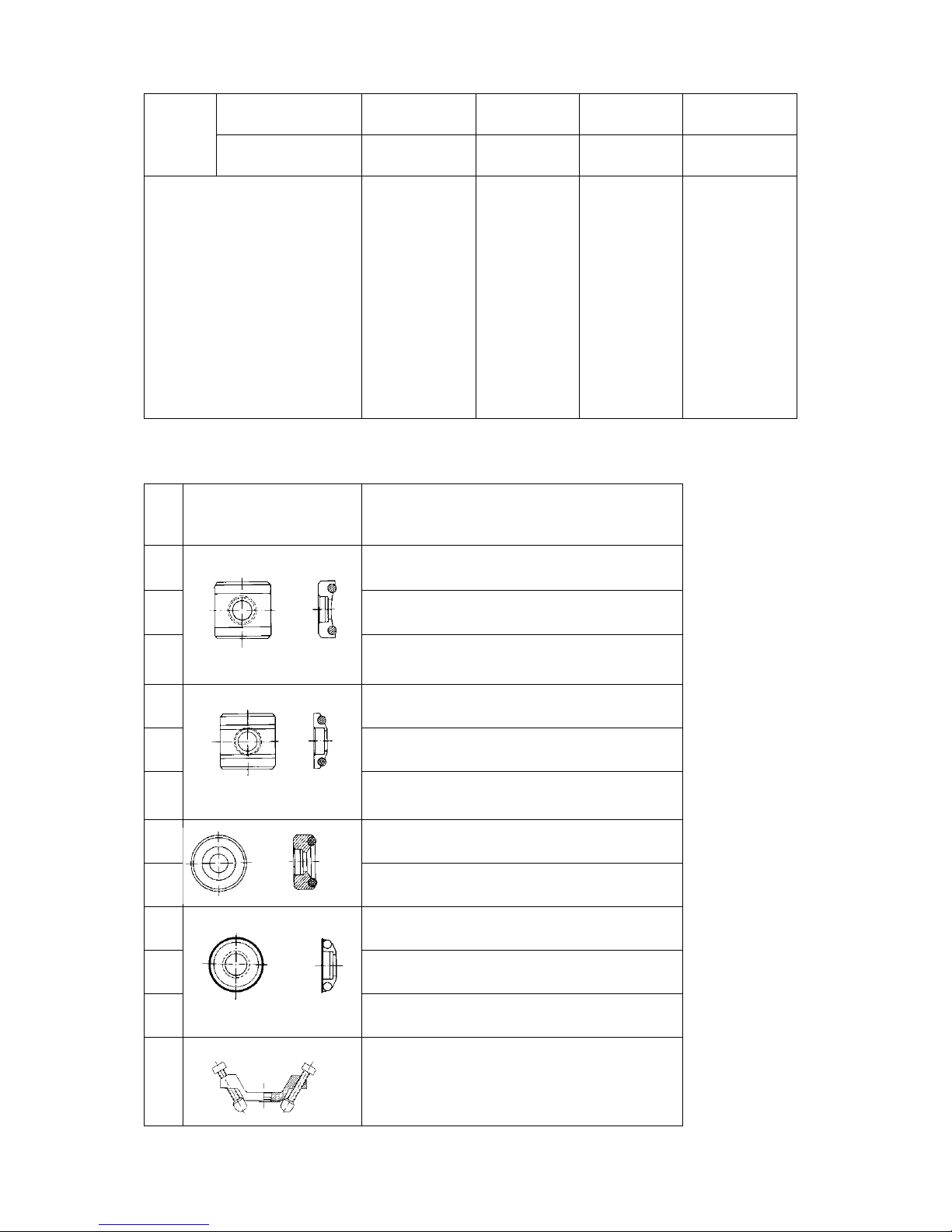

Table 4

N

o.

Sketch of

non-conventional

supporting rings

Remarks

1

For testing cylindrical outside surface

R10~R15

2

For testing cylindrical outside surface

R14.5~R30

3

For testing cylindrical outside surface

R25~R50

4

For testing cylindrical inside surface

R11~R13

5

For testing cylindrical inside surface

R12.5~R17

6

For testing cylindrical inside surface

R16.5~R30

7

For testing spherical outside surface

SR10~SR15

8

For testing spherical outside surface

SR14.5~SR30

9

For testing spherical inside surface

SR11~SR13

10

For testing spherical inside surface

SR12.5~SR17

11

For testing spherical inside surface

SR16.5~SR30

12

For testing cylindrical

outside surface, radius adjustable

R10~∞

HK-D_HK-DB-BA-e-1713 9

1.4 Operating conditions

Ambient temperature: -10℃~40℃

Relative humidity: ≤90%

No vibration, no strong magnetic field and no corrosive medium and heavy dust in

ambient environment.

2 Structure features and testing principle

2.1 Structure Features

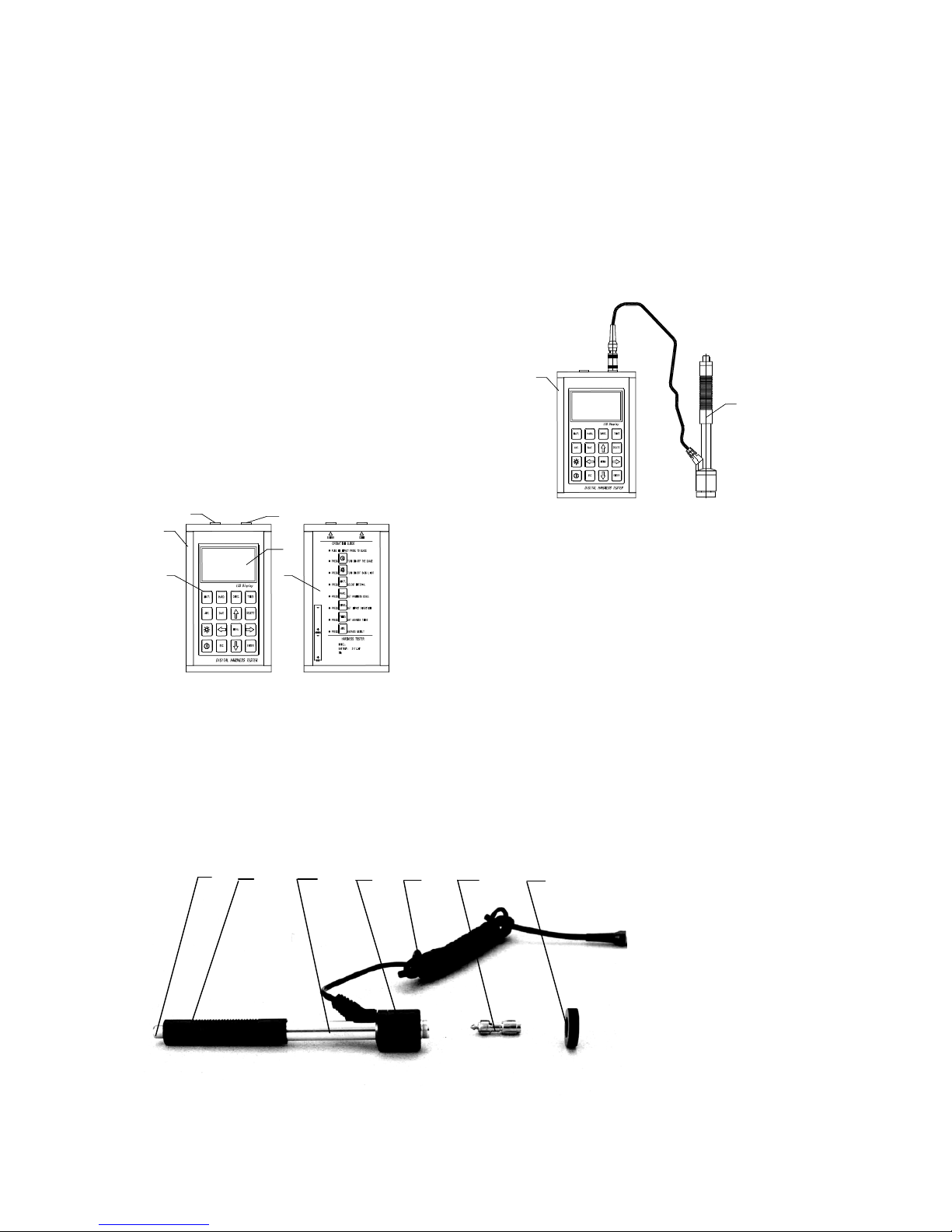

2.1.1 Hardness Tester

1: Main unit

2: Impact device

2.1.2 Main unit

1: Shell 2: Communication socket 3: Impact device socket 4: Keypad 5:

LCD screen 6: Name plate

2.1.3 D type impact device

1 2 3 4 5 6 7

1

2

4

2

1

6

3

5

10 HK-D_HK-DB-BA-e-1713

1: Release button 2: Loading sheath 3: Guide tube 4: Coil part

5: Connection cable 6: Impact body 7: Support ring

2.1.4 Non-conventional types of impact devices

DC DL C D+15 E G

2.2 Testing principle

Let an impact body whose weight is definite rush into the surface of sample, the

hardness value comes from the rate of rebound velocity and rush velocity at 1mm

distance from testing surface. The calculation formula is following:

Fehler! Textmarke nicht definiert.HL=1000×VB/ VA

In which: HL——Leeb hardness value

VB——Rebounding velocity of the impact body

VA——Impacting velocity of the impact body

Output signal diagram of the impact device is as following.

3 Technical capabilities

3.1 Specifications

Measuring range: HLD(170~960)HLD

Measuring direction: 360°

Hardness scale: HL, HB, HRB, HRC, HRA, HV, HS

Display: LCD, 128×64 matrix LCD

Data memory: 48~600 groups (impact times: 32~1)

Range of upper and lower limit: the same as measuring range

Working voltage: 2*1.5V

Continuous working period: approx. 200 h (no back light on)

Communication interface: RS232

Accuracy and repeatability of displayed value, see table 5.

HK-D_HK-DB-BA-e-1713 11

3.2 Dimension, size and weight

3.2.1 Dimensions:

132×82×33mm (main unit)

3.2.2 Weight:

approx. 0.6kg (main unit);

Table 5

No.

Type of

impact

device

hardness value of

standard Leeb

hardness block

Error of

displayed

value

Repeatability of

displayed value

1 D

760±30HLD

530±40HLD

±6 HLD

±10 HLD

6 HLD

10 HLD

2 DC

760±30HLDC

530±40HLDC

±6 HLDC

±10 HLDC

6 HLD

10 HLD

3 DL

878±30HLDL

736±40HLDL

±12 HLDL 12 HLDL

4 D+15

766±30HLD+15

544±40HLD+15

±12 HLD+15 12 HLD+15

5 G

590±40HLG

500±40HLG

±12 HLG 12 HLG

6 E

725±30HLE

508±40HLE

±12 HLE 12 HLE

7 C

822±30HLC

590±40HLC

±12 HLC 12 HLC

4 Testing

4.1 Preparation and Inspection prior to tes ting

4.1.1 The preparation of work piece surface

The preparation for work piece surface should comply with the relevant requirements

specified in table 3

During the preparation for sample, the affect to surface hardness of sample caused

by overheating, cold processing and etc. should be avoided as far as possible.

If the surface to be tested is too rough, measuring error will appear. So the surface of

the sample must have metallic luster and the surface must be flat, smooth and have

no oil dirt.

Curved surface: it is better that the testing surface of work piece is plane. W hen the

curvature radius R of the curved surface to be tested is less than 30mm (for D, DC, D

+ 15, C, E and DL type impact device) and less than 50mm (for G type impact device), a small support ring or non-conventional support ring should be used

12 HK-D_HK-DB-BA-e-1713

Work piece supporting

—— Support is not necessary for heavy test work pieces

—— Work pieces with medium weight must be placed on flat and solid plane, and

they must be placed stably without any shaking.

Enough thickness of work pieces is necessary, and the min. thickness should comply

with the specification in table 3.

As for test piece with hardened surface layer, the depth of hardened layer should

comply with table 3.

Coupling

——Work work pieces with lightweight must be firmly coupled with the support; both

coupled surfaces must be flat, smooth and the coupling agent should not be too

much. The measuring direction must be vertical to the coupled surface.

——When the work piece is a large area plate, long rod or bending piece, it can be

deformed and become unstable even the weight and the thickness is heavy and the

test value may not be accurate. So it should be reinforced or supported at the back of

the work piece.

Self-magnetism of work piece should be less than 30 Gauß.

4.1.2 System setting of tester

Specific procedures for setting, refers to 6.9.

4.1.3 Measuring condition setting of tester

Specific procedures for setting, refers to 6.5.

4.2 Testing

A standard hardness block should be used to check the tester prior to the testing;

and the reading value error and repeatability should not be more than the specification in table 5.

Note: the hardness value of standard hardness test block can be measured

via a Leeb hardness tester which

had been calibrated; five measurements

should be carried out in direction of vertical down and the arithmetic mean of

these five values should be used as the hardness value of standard hardness

test block. If the value exceeds the standard range, it can be

calibrated via

user calibration function.

4.2.1 Start-up

Insert the impact device plug into the socket of impact device located on the right of

the tester.

Press key to turn on the power, then the tester enters into the measuring state.

4.2.2 Loading

Push down the loading sheath to lock the impact body; for DC type impact device,

the loading bar can be attracted on testing surface and insert DC type impact device

into loading bar until the stop position, then loading has been finished.

Press tightly the support ring of impact device on the surface of test sample, the direction of impact should be vertical with testing surface.

HK-D_HK-DB-BA-e-1713 13

4.2.3 Testing

Press down the release button on the top of the impact device to make a test. At this

point, the test sample, impact device and the operator are all required to be stable;

and the force direction shoul d compl y w i th the axis of the impact device.

Five measurements should be carried out per measuring position of test sample. The

divergence of data should be not exceeds ±15HL of mean value.

Distance between any two indentations, or the distance between any indentation

centre and the edge of test sample should be in accordance with the specification of

table 6.

For any special material, a comparative test must be performed to obtain relevant

conversion relation if Leeb hardness value accurately conversing to other type of

hardness value is required. Procedures are as following: tests are made on the same

test sample via Leeb hardness tester which recalibrated well and relevant hardness

meter respectively; for each hardness value, five points which uniformly distributed

around hardness indentation should be chosen to make tests, and tests for three (at

least) indentations should be made; the mean value of Leeb hardness and the mean

value of relevant hardness will be act as relevant values respectively to make a comparative hardness curve. Three groups corresponding data should be included at

least in comparative curve.

Table 6

Type of impact

device

The distance of two indentations center

The distance between indentation

center and edge of test piece

No less than

No less than

D、DC

3

5

DL 3 5

D+15

3 5 G 4 8 C 2

4

4.2.4 Read measured value

4.2.5 Print out the measuring result

For specific setting method, see 6.3.3 and 6.6.

4.2.6 Press key to turn off

4.2.7 The processing of testing results

The mean value of five valid testing points can be served as a testing data of Leeb

hardness.

4.2.8 Expression of testing results

Hardness value will be displayed ahead of HL (the symbol of Leeb Hardness), and

type of impact device will be displayed back of HL. For example, 700HLD expresses

that the Leeb hardness is 700 by means of the measurement made by D type impact

device.

For other type hardness which changed from Leeb Hardness value, corresponding

hardness symbol should be added ahead of Leeb hardness symbol. For example,

14 HK-D_HK-DB-BA-e-1713

400HVHLD expresses that the Vickers hardness value is 400, which changed from

Leeb hardness value measured by D type impact device.

Note: HL values which measured by various impact devices are various. For

example: 700HLD≠700HLC.

5 Special prompts

Replacing impact device must be performed under the condition of turn off, otherwise

the impact device type cannot be identified automatically, and even it is possible to

cause the damage of circuit board o f the tester.

In normal conditions, the current measured value can be printed or stored if the

【Impact times】 value which had been set is not satisfying. If the printing and stor-

ing are required at this point, 【Average】 key can be pressed to finish measurement, and then printing can be carried out.

The functions of 【Auto Save】, 【Auto Print】, and 【Auto Trans.】 will be ina ctive

in case of pressing【Average】 key to finish measurement in advance.

Only D and DC type impact device have strength measuring function so that

【Hard/σb】 setting cannot be changed if other types of impact devices are used; if

the setting has been changed into 【σb】 via D/DC type impact devices, the

【Hard/σb】 setting will be changed into 【Hard】 when other impact devices had

been installed instead of D/DC type impact device.

When 【σb】 has been set, hardness scale will not been set (cursor will skip off

【Hardness Scale】).

Not all materials can be changed into every hardness scale, hardness scale will return to Leed hardness (HL) automatically after material has been changed. So

【Material】 will be set firstly when setting measurement parameters, and

【Hardness Scale】 should be set subsequently.

6 Detail Testing procedures

6.1 Start-up

Press key to turn on the equipment, following interface will be displayed.

Tester will check and display the type of impact device. At this point carefully observe

whether the type is right or not, then enter the main measuring display interface.

6.2 Turn On or turn off

Tester can be turn on or turn off by press key in any display status.

6.3 Testing

The tester will enter the main display interface after turn on, as the following figure

HK-D_HK-DB-BA-e-1713 15

The measured values are displayed with big font in this interface, and multiple shortcut key operation functions supplied.

6.3.1 Explanation of the main display interface

Battery information: displaying rest capacity when no charging, and displaying

charging degree when charging.

Impact direction: current impact direction.

Average value indicator: average value will be displayed when impact times setting

has been achieved.

Hardness scale: the hardnes s sc al e o f curre nt meas ur i ng val ue.

Measured value: current single measured value (without average value indicator),

current average value (with average value indicator). It expresses the value is more

than conversion or measuring range when is displayed; and it expresses the value

is lower than conversion or measuring rang e when is displayed.

Material: material that has been set currently.

Impact times: impact times that has been finished will be displayed when measur-

ing; Impact times that has been set will be displayed when impact times is been set

by shortcut key, and the times which corresponding to single measured value will be

displayed when viewing single measured value.

6.3.2 Testing procedures

Testing can be carried out under this interface status, and the current measured

value will be displayed whenever one measurement is finished. The counting of impact times will add 1 per measurement is performed. The buzzer will send out a long

sound provided that the value exceeds tolerance limit; and the buzzer will send out

two short sounds if the impact times which has been set is achieved. After 2 seconds

waiting, average value will be displayed with a short sound given out by buzzer.

6.3.3 Key operation

Press 【SAVE】 key to save current group data. The key can only be active after

average value has been displayed; furthermore the save can be done only once.

Press 【DELETE】 key, the latest single measured value can be deleted, but the

deletion should be confirmed in the following interface.

16 HK-D_HK-DB-BA-e-1713

Press the or key to move the cursor to 【YES . Then press the

【ENTER】key to confirm the deletion of the latest single measured value.

Press the or key to move the cursor to【NO】.

Then press the 【ENTER】key to cancel the deletion.

Deletion can be also cancelled by pressing the 【ESC】key wherever the cursor is

located.

Single measured value can be viewed by press 【 】 or 【 】 key, and the average value or latest measured value can be showed again by press 【ESC】 key.

The viewing sequence is different by press【 】 or 【 】 key.

Measurement can be finished by press 【Average】 key in case of impact times set-

ting has not been achieved, and the average value will be displayed.

LCD back light can be turn on or off by press 【】 key.

Press 【MENU】 or 【ENTER】 key to return to main interface.

Press 【MENU】 key to enter main menu interface.

Shortcut key setting:

Impact direction setting can be changed by press 【DIREC.】 key.

Impact times setting can be changed by press 【TIMES】 key, the current impact

times can be showed by press 【TIMES】 at the first time; the counting will add 1

when press 【TIMES】 once, and it will return to 1 if times of 32 is achieved.

Hardness scale setting can be changed by press 【HARD】 key. Whenever press

the key once, a circulating conversion among all hardness scales that available to

current material and impact device will be performed. The hardness scale will be

changed into Leeb hardness if the current setting is strength measurement.

Material setting can be changed by press 【MAT’L】 key. Whenever press the key

once, the circulating conversion among all material setting will be performed and

hardness scale will be changed into Leeb hardness, therefore, material should be set

firstly when measuring, then hardness scale should be set.

Note: what is called “conversion” refers to the corresponding relationship of

Leeb Hardness and other hardness for a certain material, which established on

basis of abundant tests. According to the conversion relationship, the Leeb

hardness value which measured will be changed into other hardness scale

value automatically via calculating by hardness tester.

6.4 Menu structure diagram

HK-D_HK-DB-BA-e-1713 17

The parameter setting and additional function of equipment can both realized by

menu operating. At the main display interface, pressing 【MENU】 key to enter the

main menu.

6.5 Measuring condition setting

When being in main display interface, press 【MENU】 key to enter the main menu.

Press 【ENTER】 key to enter 【TEST Set】menu. Press 【 】【 】 key to move

cursor to the item which will be set, then press 【ENTER】 key.

Note: 1. If the 【Hard/σ

b

】

is set to 【Hard】, hardness scale could not be selected obviously. Therefore, the cursor will skip over the item 【Hardness】

while moving.

2. Only D/DC type impact device is provided with the function of strength

measuring, therefore, cursor cannot be moved to item【Hard/σ

b

】

when other

type of impact device is used.

18 HK-D_HK-DB-BA-e-1713

3. The symbol ↓ on the left bottom of menu s hows the menu is not end, which

can be paged down by press 【 】 key; The symbol ↑ on the top of menu

shows the menu is not end, which can be paged up by press 【 】.

6.5.1 Impact direction setting

Press or key to move cursor to the direction which will be set.

Press 【ENTER】 key to finish the change.

Press 【ESC】 key to cancel the change.

6.5.2 Mean times setting

The mean times can be modified in the range of 1~32.

Press number key to input the value, and the cursor can move in circles to right

automatically.

Press 【ENTER】key to finish the change. Press 【ESC】key to cancel the change.

6.5.3 Material setting

6.5.3.1 Following available materials will be displayed in case of 【Hard/σb】 is

set to【Hard】:

Press 【 】or 【 】 key to move cursor to the material which will be set.

Press 【ENTER】 key to finish the change.

Press 【ESC】 key to cancel the change.

Note: 1. After the material setting had been changed, hardness scale setting

will return to HL automatically.

HK-D_HK-DB-BA-e-1713 19

2. Material should be chosen prior to the hardness scale.

3. The symbol ↓ on the left bottom of menu s hows the menu is not end, which

can be paged down by press 【 】key; The symbol ↑ on the top of menu

shows the menu is not end, which can be paged up by pressing 【 】.

6.5.3.2 Following available materials will be displayed in case of 【Hard/σb】 is

set to【σb】:

Press 【 】【 】 key to move cursor to the material which will be set.

Press 【ENTER】 key to finish the change.

Press 【ESC】 key to cancel the change.

Note 1: The symbol ↓ on the l eft bottom of menu shows the menu is not end,

which can be paged down by press 【 】 key; The symbol ↑ on the top of

menu shows the menu is not end, which can be paged up by press 【 】.

6.5.4 Hardness scale settin g

Press 【 】【 】 or【 】【 】 key to move cursor to the hardness scale

which will be set.

Press 【ENTER】 key to finish the change.

Press 【ESC】 key to cancel the change.

Note:

1. For the current selected impact device and material, only the hardness scale

which can be conversed will be displayed; hardness which can be conversed

will not be displayed.

2. Material should be chosen prior to the hardness scale.

3. After the material setting had been changed, hardness scale setting will return to HL.

6.5.5 Tolerance limit setting

Press number key to input the value, and the cursor can move in circles to right

automatically.

20 HK-D_HK-DB-BA-e-1713

Press 【ENTER】 key to finish the change.

Press 【ESC】 key to cancel the change.

Note: 1. If the setting exceeds the measuring range, the tester will ask operator

to reset.

2. Exchanging will be done automatically if the Min. tolerance limit is more than

Max. tolerance limit.

6.5.6 Hardness/σb setting

Press 【ENTER】 key to perform the selection between 【Hard/σb】, and the cursor

will exchange between hardness and strength.

Note: Only D/DC type impact dev ice is provided with the function of strength

measuring. Therefore, the item can only be set to 【Hard】 if the impact device

is not D or DC type.

6.6 Print function

If it is in main display interface, press 【MENU】 key to enter main menu.

Press【 】or【 】 key to move cursor to 【Print Function】.

Press 【ENTER】 key to enter 【Print Function】 menu.

Press 【 】or【 】key to move the cursor to the print

function required, then pr es s 【ENTER】 to print.

6.6.1 Printing current value

Note: Information about serial number and operator should be filled by manual.

HK-D_HK-DB-BA-e-1713 21

6.6.2 Print memory value

As for 【Print Memo ry】, the group range is necessary to be selected firstly, and the

group range which saved in memory will be displayed at the same time.

Press number key to input the value, and the cursor can move in circles to right

automatically.

Press 【ENTER】 key to confirm print.

Press 【ESC】 key to cancel print.

Information to be printed includes: tester name, date, type of impact device, impact

direction, average times, material, group No., single measured value and average

value.

If the information in the group is as the same as that in the previous group, such as

date, type of impact device, impact direction, average times, material and hardness

scale, only group No., single measured value and average value can be printed, otherwise date and measuring conditions can also be printed out.

Note: 1. Actual number of groups will be printed in case of the number which

had been set exceeds the actual range.

22 HK-D_HK-DB-BA-e-1713

2. No difference for the sequence to print the starting and endi ng group, that is

to say if 1~5 groups will be printed, the sequence can be set from 1 to 5 or from

5 to 1.

3. Wider the range of groups, shows the nearer the group from curre nt; on the

contrary, it will be further.

6.6.3 Print all memory

Press 【Print All Mem】key to print the values of all groups in the memory in the

same format.

6.7 Memory manager

When in the main display interface, press 【MENU】 key to enter the main menu.

Press 【 】or【 】key to move the cursor to 【Memory Manager】.

Press 【ENTER】 key to enter menu 【Memory Manager】.

If no data in the memory, “No Memory!” will be showed, and return subsequently.

Press 【 】or【 】key to move the cursor to the function required, then press

【ENTER】 key.

6.7.1 Viewing from the No.1 group/ Viewing from the end group

Press 【View from No.1】 key to display data in memory from the No.1 group.

Press 【View from End】 key to display data in memory from the end group.

6.7.2 Viewing from selected group

Press 【View from N o.】 key, selecting interface will be displayed

Press number key to input the value.

Press 【ENTER】 key to display data in memory from the starting group selected.

Press 【ESC】 key to cancel operation.

6.7.3 Transferring data

Press 【Transfer】 key to output the data in memory via RS232 interface in text format.

HK-D_HK-DB-BA-e-1713 23

6.7.4 Deleting selected group

Press 【Delete by No.】 key, an interface including group range to be deleted will be

shown.

Press number key to input digital value.

Press 【Enter】 key to cancel selected group.

Press 【Esc】 key to cancel the operation.

Note: 1. If the input group number exceeds the actual range, then deletes the

actual group among them.

2. No difference for the sequence to the starting and ending group, that is to

say if 1~5 groups will be deleted, the sequence can be set from 1 to 5 or from 5

to 1.

3. Data group No. saved in memory will be reordered after deletion.

4. When deleting data, especially small group data, because the following data

needs to be moved, max 30 seconds (approx.) may be required. Never to turn

off power at this time, or data confusion can be caused.

6.7.5 Delete all

Press 【Delete All】 to cancel all data in memory.

6.7.6 Confirm deletion

Confirming interface will be displayed when deleting data in memory.

Press 【 】【 】 key to move cursor to 【YES】, then press 【ENTER】 key

to delete the data.

Press 【 】【 】 key to move cursor to 【NO】, then press 【ENTER】 key to

cancel the operation.

6.8 Viewing interface

The No., dates and average values of 8 data groups can be displayed at most in the

same interface.

Press【 】or 【 】 key to turn over pages.

Press 【ESC】 key to exit view.

24 HK-D_HK-DB-BA-e-1713

By pressing 【ENTER】 key, cursor will be shown and furthermore details can be

viewed.

Press 【 】or 【 】 key to select the group in this interface.

Press 【ESC】 key to return to the previous viewing interface.

Press 【ENTER】 key to view detail information in this group.

Press 【 】or 【 】 key to turn over pages to view average value, measuring condition or single measured value.

Press 【ESC】 key to return to the previous viewing interface.

6.9 System Set

When in the main display interface, press 【ESC】 key to enter the main menu.

Press 【 】or 【 】 key to move cursor to【System Set】.

Press 【ENTER】 key to enter 【System Set】 menu. Press 【 】or 【 】 key to

move cursor to the item to be set.

Press 【ENTER】 key to directly change, or enter corresponding changing interface.

Press 【ESC】 key to return.

As for the items of 【Auto Save】, 【Auto Print】, 【Auto Delete】, 【Auto Trans.】,

【Key Sound】 and 【Warn. Sound】, 【ENTER】 key can be pressed to selected

【On】 or 【Off】.

If 【Auto Save】 is set to 【On】, the current group data can be saved automatically

after measurement is finished and the average value is displayed.

If 【Auto Print】 is set to 【On】, the current data can be printed out after measurement is finished and the average value is displayed.

If 【Auto Delete】 is set to 【On】, gross error can be deleted automatically when

average times had been achieved or measurement had been finished in advance by

pressing 【AVE.】key according to 3бrule. If some data had been cancelled, additional measurements should be carried out to satisfy the times set.

HK-D_HK-DB-BA-e-1713 25

If 【Auto Trans.】 is set to 【On】, the current group data can be output in text format via RS232 after measuring finished and average value displayed.

If 【Key Sound】 is set to 【On】, buzzer will send out a short sound with each

pressing.

If 【Warn. Sound】 is set to【On】, buzzer will send out a long sound in case of

measured value exceeds the tolerance limit, data deletion or other things.

If 【Auto Down】 is set to 【On】, Power will turn off if neither measurement nor any

key operation is performed within 5 minutes.

6.9.1 LCD brightness Set

Press 【 】key to increase brightness.

Press 【 】 key to reduce brightness.

Press 【ENTER】 key to finish change.

Press 【ESC】 key to cancel change.

The brighter of brightness, the deeper the colour; The darker of brightness, the lighter

the colour;

6.9.2 Time and Date Set

When in this interface, current time and date will be displayed on the screen, the format is “mm/dd/yy”.

Press 【 】or 【 】key to input the value, Press 【 】or【 】 key to move

cursor.

Press 【ENTER】 key to finish the change, which current time and date will be re-

placed by time and date set. Press 【ESC】 key to cancel the change.

6.10 About software

When in the main display interface, press 【MENU】 key to enter the main menu.

Press 【 】or 【 】key to move cursor to 【About Software】.

Press 【ENTER】 key to enter 【About Software】.

26 HK-D_HK-DB-BA-e-1713

Information about the tester and embedded software will be displayed on this interface.

The software version and embedded software identification are subjected to change

due to the upgrading of software without notifying in advance.

6.11 Calibration of the Tester

The tester and impact device must be calibrated with a standard Leeb hardness test

block (not included in delivery) prior to the first use, or reusing after a long term idle.

One time calibration is enough for each type of impact device which equipped with a

main unit; recalibration is not necessary after the replacement of impact device later.

Press 【ENTER】 key as well as key at the same time to enter the interface of

software calibration

Impact direction should be set to 【 】.

Five points should be measured vertically down on the Leeb hardness test block.

Average value will be shown after measur i ng .

Press 【 】or 【 】】 key to input nominal value.

Press 【ENTER】 key to finish calibration.

Press 【ESC】 key to cancel calibration.

Calibration range is ±15HL.

6.12 Back light

The LCD display is equipped with a Led Back Light, which supplied for easily use in

dark light conditions. The Back Light can be turned on or turned off by pressing

【】 at any time when the tester is in operation.

6.13 Turn off Power automatically

Auto turn off function is supplied to save the energy of battery.

If neither measurement nor any key operation is performed within 5 minutes, the

tester will turn off automatically, a flash showing for 20 seconds on the LCD screen

prior to switch off. At this time, any key except can be pressed to stop the flash of

LCD screen, and cancel the turn off oper ati o n.

HK-D_HK-DB-BA-e-1713 27

In case of too low battery voltage, “Battery Empty!” will be displayed and turn off

automatically.

6.14 Battery replacement

Battery symbol will flash if battery capacity runs out. At this point, User can replace the damaged battery according to the following procedures.

Turn off the Power of main unit.

Unscrew the screw. Remove the battery cover, take out used batteries.

Install the new batteries in their place (pay attention to orientation of batteries, take

caution not to connect the anode and cathode inversely).

Put back the battery cover, then turn on the power to check if the tester is in normal

operation or not.

6.15 The connection of data communication cable

The small 4-pin plug which located on the end of communication cable should be inserted in the RS232 socket on the left side of main unit, and D type 9-pin RS232 port

9-pin port should be inserted in PC communication or the serial port printer case.

7 Trouble shooting

Failure

Cause

Solution

Failure in starting Battery empty Replace battery

No measured value Sensor cable open circuit Replace Probe cable

Value is inaccurate Calibration data lose over again Calibration

8 Maintenance

8.1 Impact device

After using the impact device for 1000-2000 times, use the nylon brush, optional

available, to clean the guide tube and the impact body of the impact device. To clean

the guide tube, unscrew the support ring and then take out the impact body, spiral

the nylon brush in the counter-clock direction into the guide tube. When the brush

reaches the bottom, draw it out. Repeat this action for 5 times and mount the impact

body and the support ring.

Remember to release the impact body after use.

Any lubricating agent is absolutely banned to use inside the impact device.

8.2 Standard maintenance procedures

If the error is > 2HRC when using standard Rockwell hardness block to test, maybe

the test tip is disabled. Changing the test tip or impact body should be considered.

If other abnormal phenomena occur, user should not disassemble or adjust any part

which used for fixing. You can return the hardness tester to the service department of

our company.

28 HK-D_HK-DB-BA-e-1713

9 Transportation and Storage

The tester should be stored in room temperature, away from vibration, strong magnetic field, corrosive medium, dampness and dust.

10 Non-warranty parts

1 Sheath of Main unit

2 Panel

3 Impact body

4 Support ring

5 Sensor cable

6. Battery.

Leeb Hardness Tester

Packing List

No

Appellation

Num

1 Main unit

1 2

D type impact device

1 3

Small supporting ring

1 6

Instruction Manual

1 7

Carrying case

1 8

Screwdriver

1 9

Test block

1

Only HK-DB

10

Communication cable

Optional

11

DataView Software ATC 01

Optional

12

AA battery

Optional

13

Printer

Optional

14

Printer cable

Optional

Loading...

Loading...