Page 1

SAUTER equitherm®

Heating and District Heating Controller

EQJW146F001

Short Instruction Manual

Firmwareversion 2.33,

April 2017

Page 2

2

KA_EQJW146F001_EN011

Short Instruction Manual

Warranty

We are constantly developing our products further and therefore reserve the right to make changes to the products at any time without

prior notice.

We assume no liability for the correctness or completeness of these operating instructions. No liability is assumed for the fact that the

buyer can use the products for a certain purpose. Claims of the buyer, in particular claims for damages including loss of profit or other

financial losses are excluded. This does not apply if the cause of damage is based on intent or gross negligence. If an essential contractual

obligation is negligently breached, our liability shall be limited to the foreseeable damage.

Safety Information

The device may only be mounted, started up or operated by trained and experienced personnel familiar with

this product. Proper transport and storage are assumed.

Table of Contents

Installation .........................................................................................................................................................................3

Assembly...........................................................................................................................................................................3

Electrical connection ..........................................................................................................................................................3

Operating controls .............................................................................................................................................................4

Display ..............................................................................................................................................................................5

Information level ................................................................................................................................................................5

Operating modes ...............................................................................................................................................................6

Set operating mode ...........................................................................................................................................................6

Setting the time and date ...................................................................................................................................................6

Check and change times-of-use ........................................................................................................................................7

Check and set party mode .................................................................................................................................................8

Commissioning ..................................................................................................................................................................8

Set system code number ...................................................................................................................................................8

Hydraulic systems .............................................................................................................................................................9

Activating and deactivating functions ............................................................................................................................... 13

Change parameter .......................................................................................................................................................... 14

Setting the factory settings .............................................................................................................................................. 14

Key figures ...................................................................................................................................................................... 14

Manual operation ............................................................................................................................................................. 15

Malfunction - Error list

Function block list ............................................................................................................................................................16

CO1: Heating circuit (HK1) (not system 1.9)* ...................................................................................................................16

CO2: Heating circuit (HK2) (systems 3.x, 4.x and 10.0, 16.6)* .........................................................................................17

CO4: DHW circuit (systems 1.1–1.3, 1.5, 1.6, 1.9, 2.x, 4.1, 4.5, 11.x )* ............................................................................18

CO5: System-wide functions (all systems) .......................................................................................................................19

CO6: Modbus ..................................................................................................................................................................20

CO7: Device bus (all systems, F02, F03, ... only with CO7 -> F01 - 1) 21 ........................................................................21

Parameter list ..................................................................................................................................................................22

PA1: Parameter HK1 (Heating circuit 1) ...........................................................................................................................22

PA2: Parameter HK2 (Heating circuit 2) ...........................................................................................................................22

PA4: DHW circuit parameter ............................................................................................................................................22

PA5: System-wide parameters (all systems) ....................................................................................................................23

PA6: Modbus ...................................................................................................................................................................23

Technical data .................................................................................................................................................................23

Article list ......................................................................................................................................................................... 24

Notes ............................................................................................................................................................................... 24

The device is intended for use in power installations. The relevant safety regulations must be observed during

connection and maintenance.

...................................................................................................................................................... 15

Page 3

3

KA_EQJW146F001_EN011

Short Instruction Manual

The EQJW146F001 controller is used to control a maximum of two control circuits:

•

Control of a primary heat exchanger or boiler. Max. one mixed and one unmixed heating circuit (each weather controlled) as

well as the control of the DHW heating on the secondary side.

•

Control of a weather-compensated heating circuit and DHW heating with two valves on the primary side.

•

Control of two weather-compensated heating circuits with two valves on the primary side.

It has eight temperature sensor inputs, two binary inputs, one 0-10V control output and seven switching outputs.

The controller is ready for operation with the factory-set temperatures and time programs. During commissioning, the current

time and date must be entered on the controller and system-dependent parameters must be defined.

These short instruction manual is intended to provide necessary information during installation and commissioning of the controller.

Further information can be found at http://www.sauter-cumulus.de.

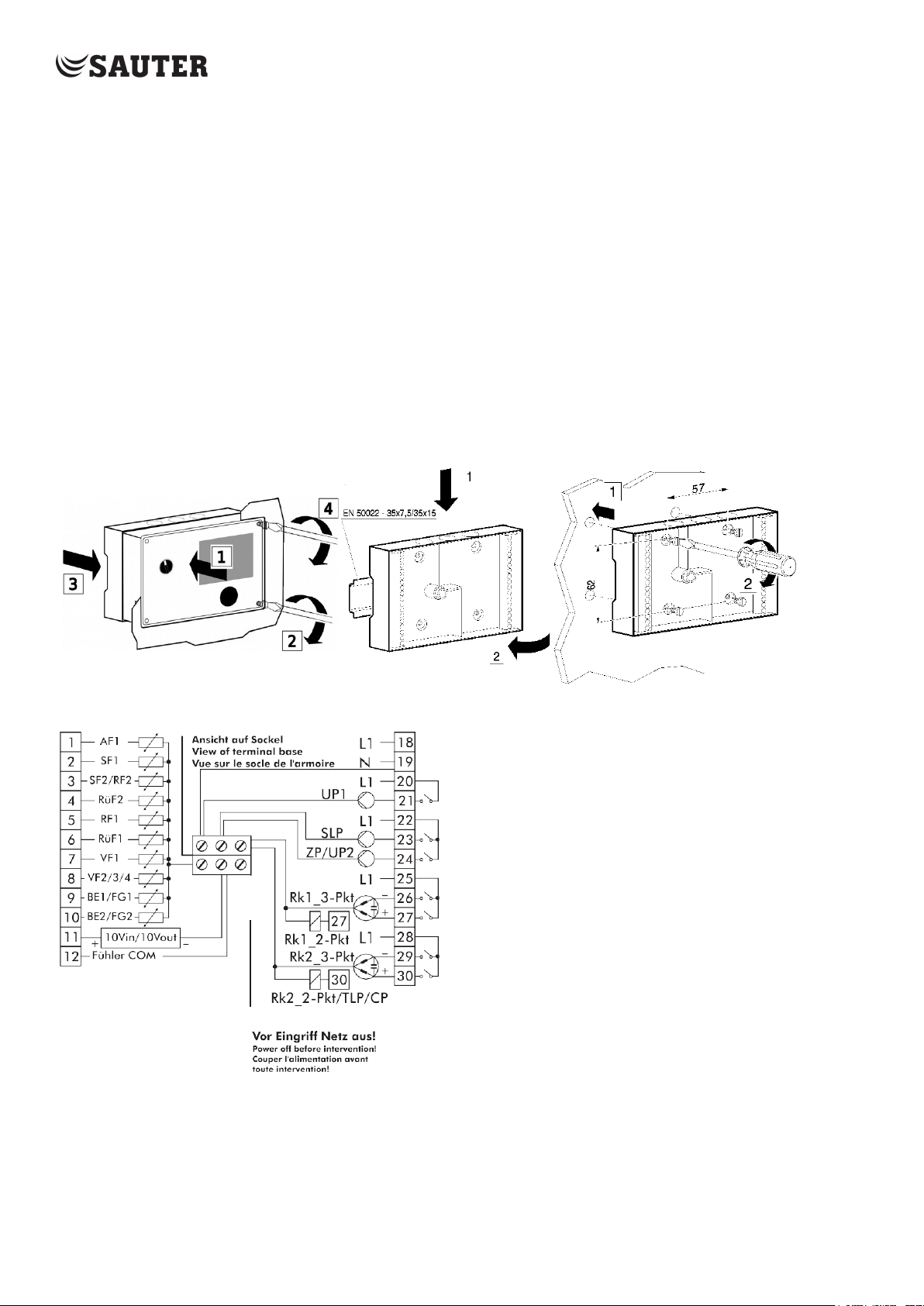

Installation

Assembly

Front panel mounting DIN rail Wall mounting

Electrical connection

This connection diagram is shown on the back of the

controller.

The housing must be opened for the cable connection. For

the cable entry, the marked openings at the top, bottom or rear of the rear

part of the housing must be broken through and provided with the enclosed

choke nipples or suitable cable glands.

Connection of sensors and 0-10V drives

Terminal strips with a cross-section of at least 2 x 0.5 mm² can be

connected to the terminal strips on the rear of the housing.

Connection of 3-point/2-point drives and pumps

Connect cables as damp-proof cables with at least 1.5 mm² to the terminals

of the controller output. It is recommended to check the running direction

of the valve during commissioning

.

Page 4

4

KA_EQJW146F001_EN011

Short Instruction Manual

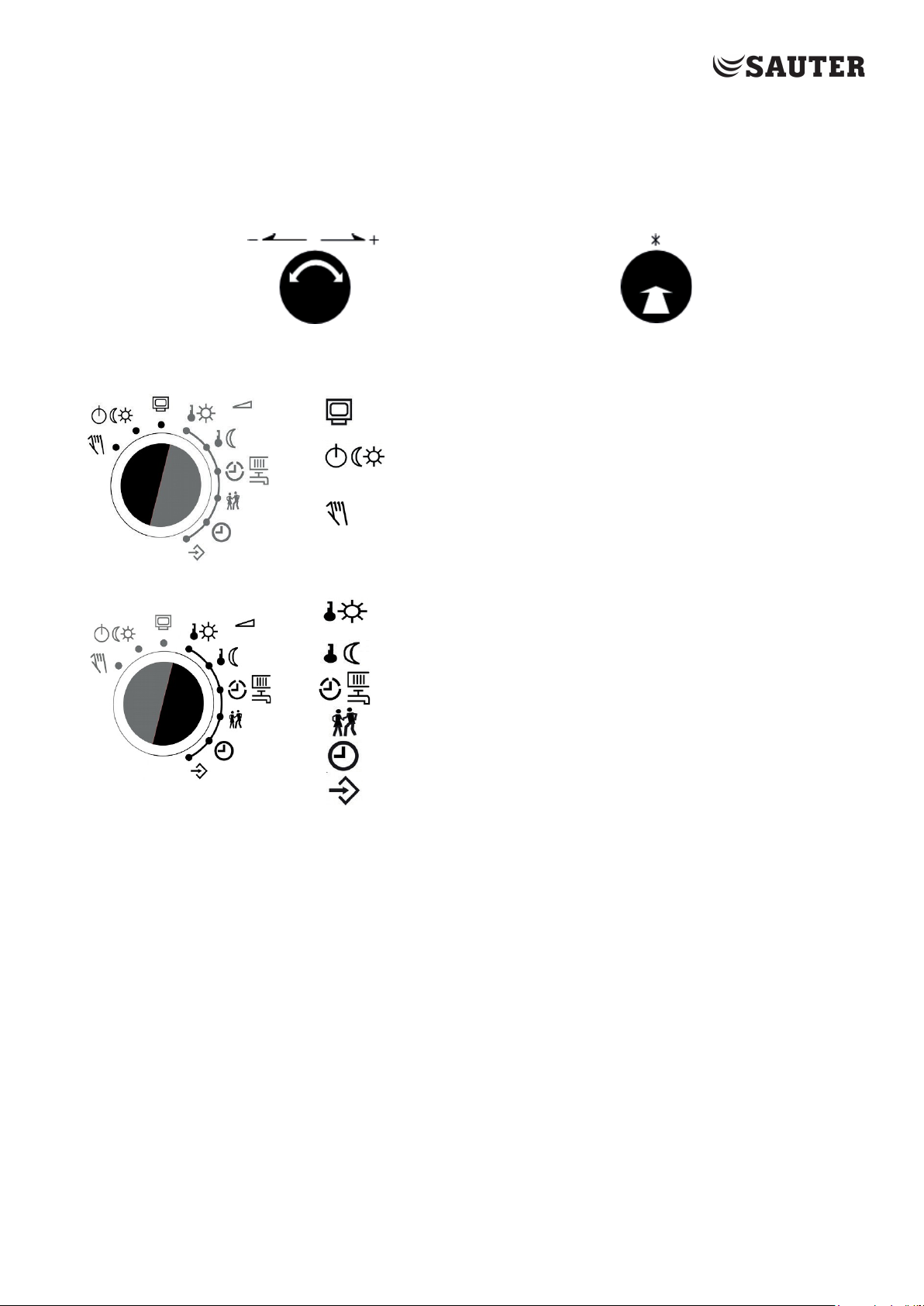

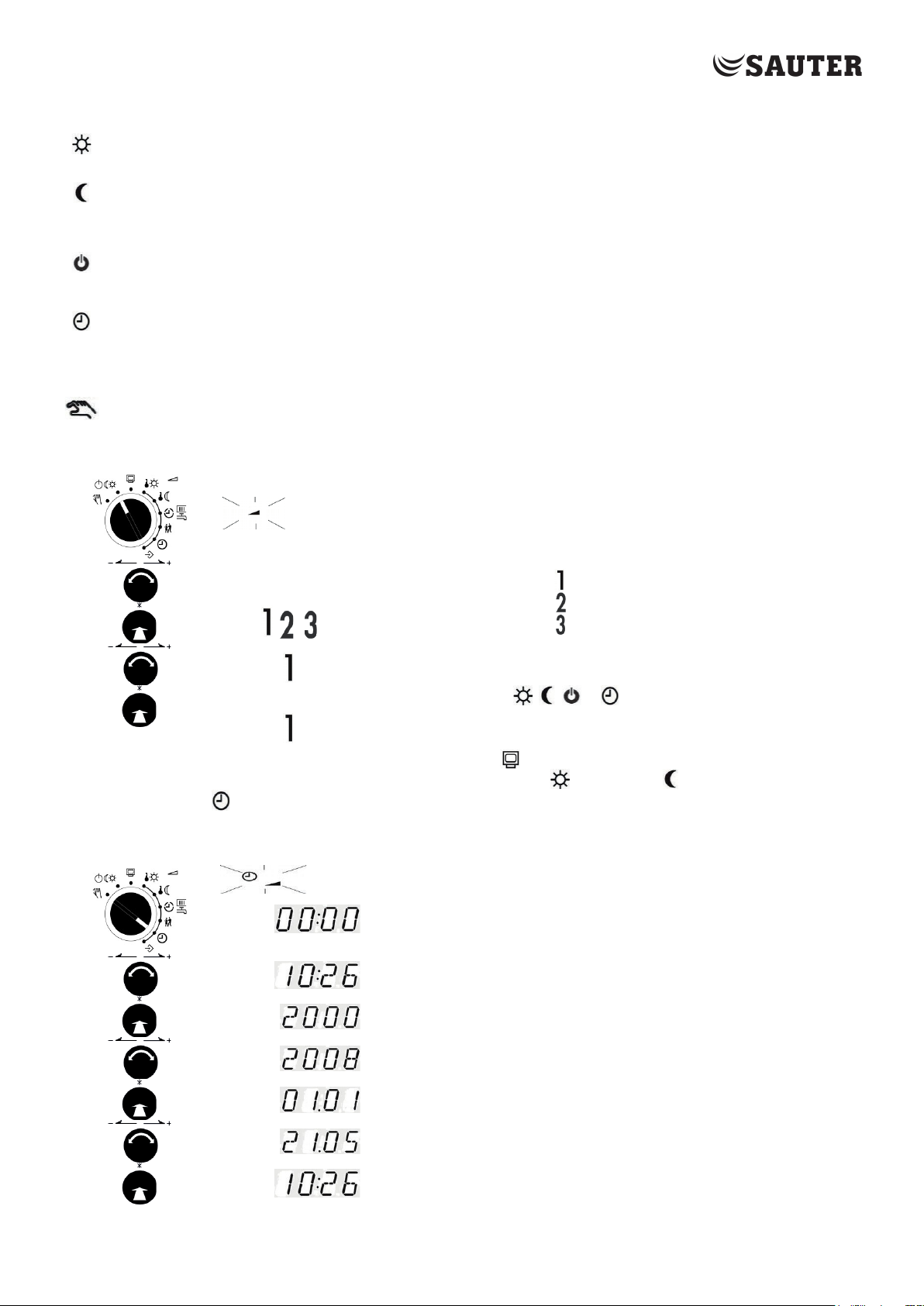

Operating controls

The operating controls are located on the front of the controller.

Rotary pushbutton

Turn: Press:

Display, select parameters and function blocks Confirm adjusted selection or setting

Rotary switch - Operating mode

Information level, rotary switch in normal position

Operating modes

Manual mode:

manual switching of pumps and valves, percentage setting

of the output value

Rotary switch – Parameter

Day set point (rated room temperature)

Night set point (reduced room temperature)

Times-of-use for heating/drinking water heating

Special use/party function

Controller time: Setting the time, date and year

Configuration and parameter level

Page 5

5

KA_EQJW146F001_EN011

Short Instruction Manual

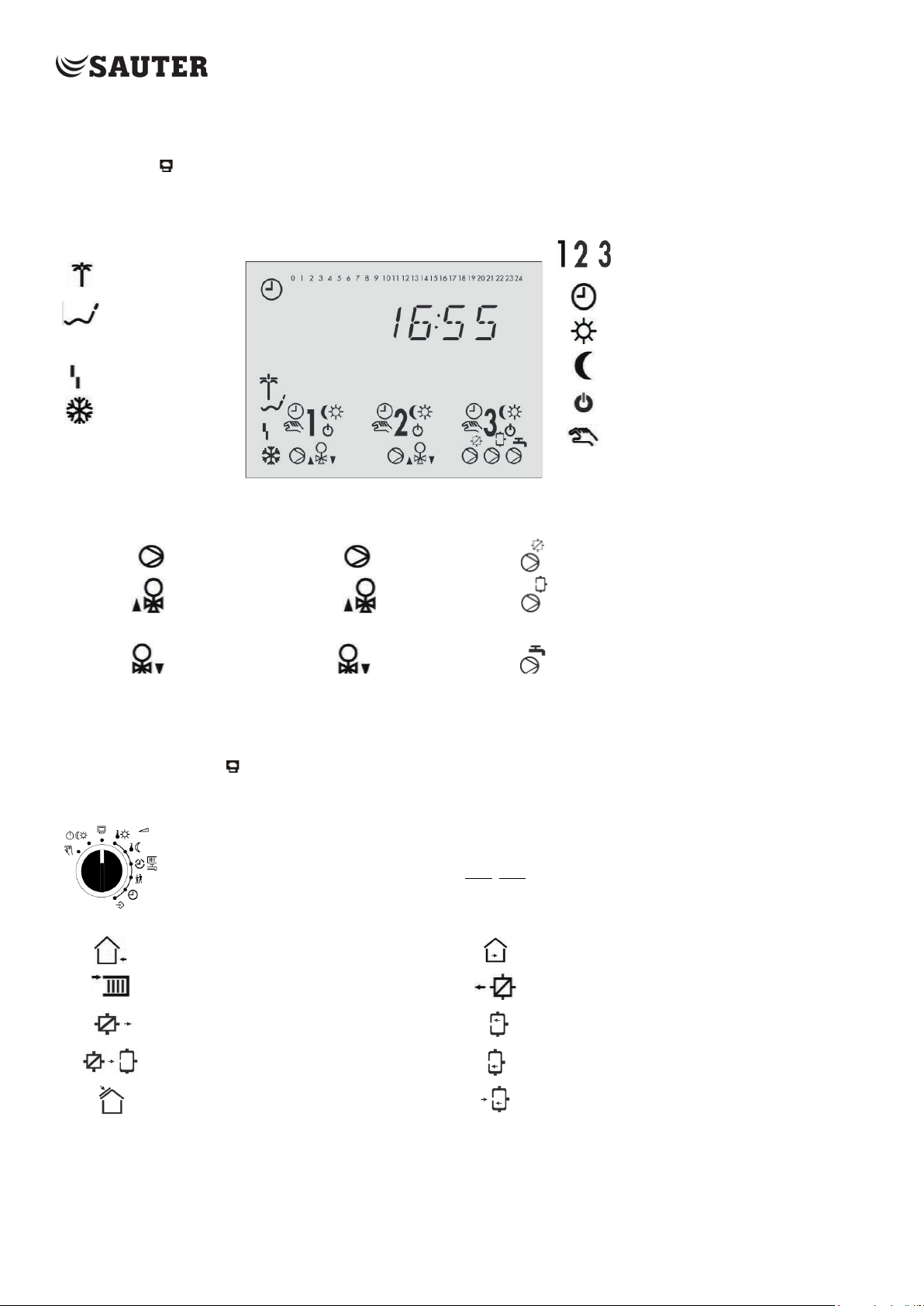

Display

The display indicates the time as well as information about the operation of the controller when the rotary switch is at the

normal position (information level). The times-of-use together with temperatures of the various control circuits can be

viewed on the display by turning the rotary pushbutton. The times-of-use are represented by black squares below the row of

numbers at the top of the display. Icons indicate the operating status of the controller.

Heating circuits

Vacation mode

Automatic mode

Public holiday

Day mode

Operational fault

Frost protection

Heating circuit 1 Heating circuit 2 DHW circuit (3)

Circulation pump UP1 Circulation pump UP2

Valve HK1 opening Valve HK2 opening Storage loading pump

SLP*

Valve HK1 closing Valve HK2 closing Circulation pump ZP*

* UP1, UP2, TLP, CP, SLP and ZP represent the selection display for the pumps in manual mode.

Night mode

Stand-by mode

Pump output TLP/CP*

Manual mode

Information level

At the normal switch position (information level), the time, date, public holidays and vacation periods as well as the

temperatures measured by the connected sensors and their set points can be retrieved and displayed.

Depending on the configuration of the controller, the current values of the following data points are displayed one after the other:

Set the rotary switch to information:

the time is displayed.

:

Time

Outside temperature Room temperature heating circuit 1, 2

Temperature at flow sensor VF,

Heating circuit 1, 2

Temperature at flow sensor VF1,

primary exchanger circuit

Temperature at flow sensor VF2, VF4,

DHW

Temperature at solar sensor VF3

Temperature at return sensor RüF

Temperature at storage sensor SF1

Temperature at storage sensor SF2

Temperature at the storage tank

Page 6

6

KA_EQJW146F001_EN011

Short Instruction Manual

Operating modes

Day mode (rated operation)

Night mode

(reduced

operation)

Regardless of the programmed times-of-use and summer mode, the set points relevant for

rated operation are used by the controller.

Regardless of the programmed times-of-use, the set points relevant for reduced operation

are used by the controller.

Stand-by

mode

Automatic mode During the programmed times-of-use, the controller works in rated operation. Outside

Manual mode

Setting the operating modes

Turn back the rotary switch on normal position (Information level)

Remark: In automatic mode, the current phase of the time program for day mode or night mode is displayed

together with the symbol in the information level.

Regardless of the programmed times-of-use, control operation is deactivated. Only the frost

protection is activated, if need be.

these times-of-use, the controller is in reduced operation, un- less control operation is

deactivated depending on the outdoor temperature. The controller switches automatically

between both operating modes.

Valves and pumps can be controlled manually

Turn the rotary switch to operating

modes. Parameter symbol flashes

In systems with only one control loop (e.g. Anl 1.0), the steps for

selecting the control loop are not required..

Turn the button;

Select the circuit:

Push the button;

Confirm the circuit

Turn the button;

Select operating mode:

Push the button;

Confirm operating mode

Heating circuit 1

Heating circuit 2

DHW/Circulation pump

, ,

or

Setting time and date

Turn the rotary switch to time;

Time and parameter symbol

flashing, time is displayed

Turn the button; Edit

the controller time

Push button;

Confirm the adjusted time, year is displayed

Turn button;

Edit year

Push button;

Confirm year, date is displayed

Turn button;

Adjust date

Push button; confirm

date, time is displayed

Page 7

7

KA_EQJW146F001_EN011

Short Instruction Manual

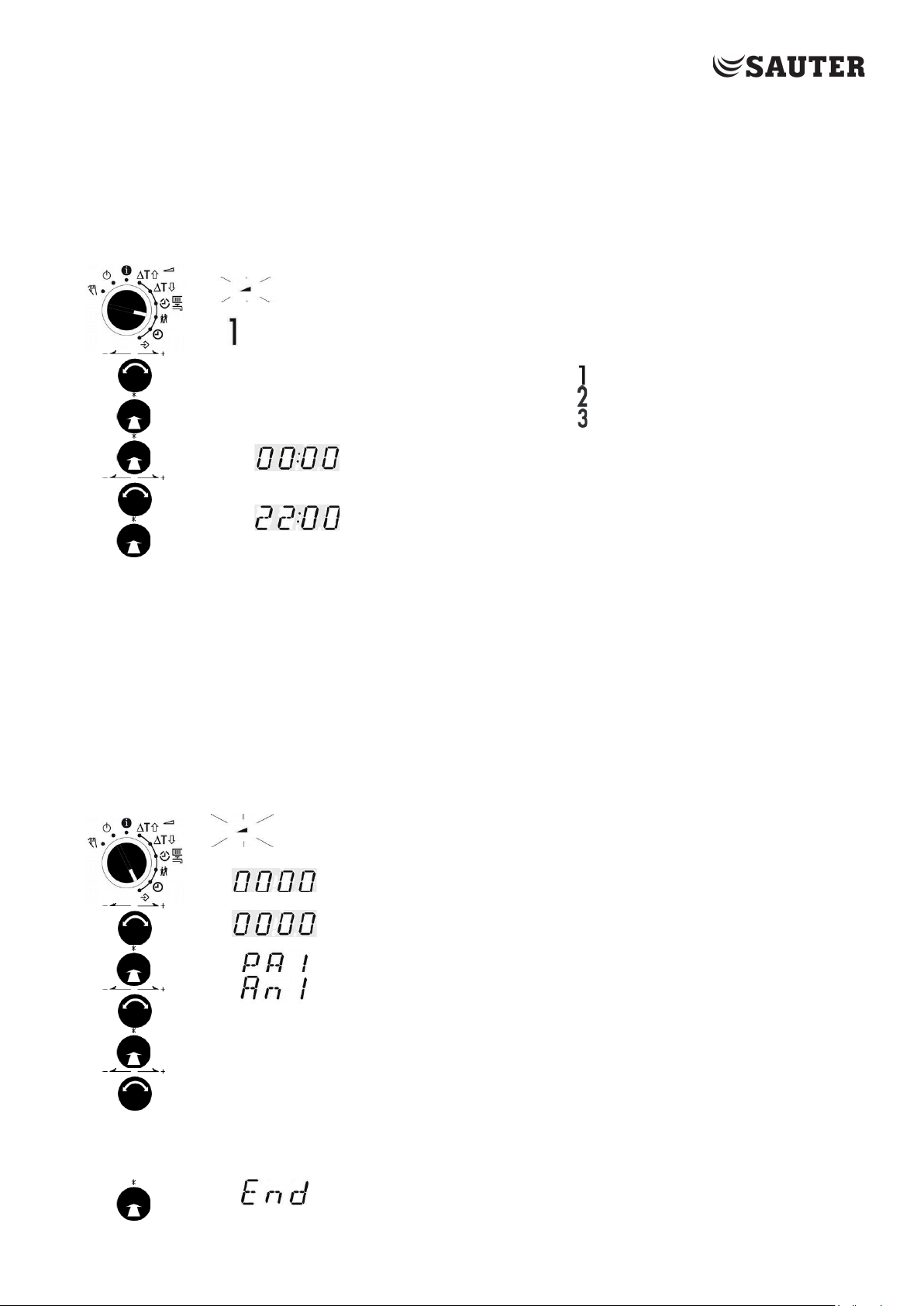

Check and setting the times-of-use

Three times-of-use can be programmed for each day of the week. If only one time-of-use is required, the start and end times

of the second time-of-use must be identical. The third time-of-use is then no longer displayed. If two time-of-use periods are

required, the start and end times of the third time-of-use must be identical.

Set rotary switch to times-of-use;

Time and parameter symbol flashing, heating (1) is displayed

In systems with only one control circuit (e.g. Anl 1.0), the steps for

selecting the control circuit and specifying the DHW circuit are not

required. In systems 1.5 and 1.9, only the DHW circuit is controlled, so the

steps for selecting the control circuit are omitted.

Turn the button;

Select the circuit:

Heating circuit 1

Heating circuit 2

Push the button;

Confirm the circuit

DHW/Circulation pump

Turn the button;

Specify DHW:

Push button;

Confirm specification

DHW

Circulation pump

Push button; Symbol for heating and daily digits are

displayed

Turn button; select day of week (1 = Monday,

2 = Tuesday, ..., 1-7 = daily)

Times-of-use for weekdays are displayed for checking purposes

Press rotary pushbutton; start time for time-of-use is displayed.

Turn button; change start time for time-of-use

Press button; start time is confirmed

S

top time for times-of-uses is displayed

Turn button; Changing the stop time for the time-of-use

Push button; the stop time is confirmed; the times-of-use for the

following day of the week are displayed for checking purposes.

Turn button; 'End' is displayed

Push button

The time-of-use level for the control circuit is exited

Page 8

8

KA_EQJW146F001_EN011

Short Instruction Manual

I.0

I. I

Check and setting party mode

With the Party mode function, the rated operation of the controller (day) - deviating from the set times-of-use - is continued or initiated for

the duration of the set party timer. The party timer starts to run when the rotary switch is turned back to one of the operating mode

positions. After the party timer has expired, the party function resets to 00:00.

Party mode is set for up to 48 hours in 15-minute increments.

Set rotary switch to party mode;

Parameter symbol flashes, heating (1) is displayed

the remaining time of the set party timer. The steps for selecting the control

For systems 1.0, 1.9 and 3.5, the display shows 00:00 or

loop are omitted.

Turn button;

Select control circuit:

Push button;

Confirm control circuit

.

Heating circuit 1

Heating circuit 2

DHW/Circulation pump

Push button

Party timer for control circuit is displayed

Turn button;

Party timer for control circuit is adjusted

Push button; party timer for control circuit is confirmed, control

circuit is displayed

Start-Up

The controller is ready for operation with the factory-set temperatures and time programs. During start-up, the current time

and date must be entered on the controller, the system selected and system-dependent parameters defined.

The changes to the controller configuration and parameterization described in this chapter can only be made after entering

the valid code number for general parameterization and configuration (page 14).

Setting the system code number

A distinction is made between various hydraulic circuit variants. Each system is represented by a system code number. The

systems are shown in the manual. Changing the system code number resets previously set function blocks to the factory

setting (FS). Function block parameters and parameter level settings are retained..

Set rotary switch to parameter and functions;

Symbol Parameter flashes,

Key number is displayed

Turn button

Set valid key number (page 14)

Push button

Parameter level 1

(control circuit 1) is

displayed

Push button

Select display 'Anl

Push button

System code number is displayed

Turn button

Adjust system code

Push button; system code number is confirmed

Factory settings for the selected system are set automatically 'End' is displayed - system

parameters can be modified as follows

Page 9

9

KA_EQJW146F001_EN011

Systems

System 1.0

Short Instruction Manual

Systems 1.1 bis 1.3

System 1.5

System 1.9

System 2.0

System 1.6

Systems 2.1 bis 2.3

Selection of types for DHW heating for systems 1.x and 2.x: Page 12

Page 10

10

KA_EQJW146F001_EN011

Short Instruction Manual

System 11.1

System 3.0

System 3.5

System 4.0

System 4.5

System 4.1

System 10.0

System 11.0

Page 11

11

KA_EQJW146F001_EN011

System 11.2

Short Instruction Manual

System 11.1/11.2 buffer storage

System 11.5

System 11.9

System 11.6

System 16.0

System 16.1

System 16.2

Page 12

12

KA_EQJW146F001_EN011

Short Instruction Manual

System 16.6

System 16.3

System 16.4

Types for DHW heating (systems 1.x and 2.x)

Type 1

Type 2

Type 3

Page 13

13

KA_EQJW146F001_EN011

2.1

Activating and deactivating functions

A function is activated via the corresponding function block. The number sequence 0 to 24 at the top of the

display represents the function block number. When a configuration level is called, the activated function

blocks are identified by a black square on the right below the function block number.

The function blocks are explained in the manual. This document contains a list of functions. The functions are

arranged according to topics:

CO1: Heating circuit 1 CO2: Heating circuit 2 CO4: DHW circuit (3)

CO5: cross-system CO6: Communication Modbus

Set rotary switch to parameter and functions; Parameter

symbol flashes

Key number is displayed

,

Push the button;

Set valid key number (page 14)

Press the button;

Parameter level 1 (control loop 1) is displayed

Turn control knob ;

Select configuration level, activated function blocks are

displayed

Press button;

Function block 5 (ON) is displayed

Turn the button; change function block 5 to OFF

Press the button; function block 5 (ON) is confirmed; if the

function block is not closed, function block parameters can be

entered..

Turn the button;

Select another function block for setting or 'End' for leaving the

level.

Short Instruction Manual

Page 14

14

KA_EQJW146F001_EN011

Short Instruction Manual

Change parameter

The parameters are arranged according to subject areas:

PA1: Heating circuit 1 PA2: Heating circuit 2 PA4: DHW

PA5: cross-system PA6: Communication Modbus

Resetting to default values

Set rotary switch to parameter and functions;

Parameter symbol flashes

Key number is displayed

Turn the button;

Set valid key number (page 14)

Push the button; Parameter level 1 (control circuit 1) is displayed; turn the

button and select the required parameter level.

Press the button;

Parameter is displayed for checking;

Press the button; Parameter symbol flashes,

parameter is displayed for changing;

Turn the button;

parameter is set

Press the button; parameter is confirmed. The following parameters are displayed and set

as described above

Turn the button;

Select further parameters for setting or 'End' for leaving the level.

,

All parameters set over the rotary switch as well as parameters in PA and CO can be reset to their default settings (WE).

Set rotary switch to parameter and functions;

Key numbers

I732

I999

I995

I99 I

0010, 25

0073

0002

Parameter symbol flashes

Key number is displayed

Turn the button;

Set key number '1991'

Push the button; Factory settings are saved;

all display elements become active for 2 seconds; Key number is displayed for

further operation

General parameterization and configuration

Enable / disable extended information level

Change key number for parameterization and configuration

Load factory settings

reserved

Activation/deactivation of cable converter 0440210012

Restart

,

Page 15

15

KA_EQJW146F001_EN011

Manual operation

Switch to manual mode to configure all outputs, refer to wiring diagram

Select the display taking the control circuit into account.:

POS1, POS2: Percentage setting of output value (HK1, HK2)

UP1, UP2: Switching the circulation pump UP1, UP2

SLP: Switching the storage charging pump

TLP Switching the exchanger charging pump

CP Switching the solar circuit pump

ZP Switching the circulation pump ZP

Set rotary switch to manual mode;

display of the setpoint of POS1

Push the button;

Presetting of the output value is

displayed; Turn the button;

Presetting of the output value is set

Push the button;

Presetting of the output value is

confirmed

Short Instruction Manual

To quit manual operation, set the rotary switch to the 'Information'

position. The manual positions lose their validity, all outputs are set to

the value defined by the control function.

Time display

Note:

Simply setting a rotary switch to the "Manual operation" position does not affect the outputs of the controller. Only the

specific setting of the output value or switching state has an effect on the outputs..

The frost protection function is not guaranteed in manual mode..

Malfunction - Error list

A sensor failure is indicated on the display by a flashing symbol. The message "Error" is displayed immediately. Press the

button to open the error level. By turning the button, several faults can be queried under certain circumstances. As long as

there is an acute operating fault, the error message remains in the display loop, even if it is not opened by pressing the button.

Note: After changing the system code number or restarting the controller, any error messages are suppressed for approx. 3 minutes. Error list:

Err 1 = Sensor failure Err 4 = Maximum charging temperature reached

Err 2 = Factory settings read in Err 6 = Temperature monitoring alarm

Err 3 = Disinfection temperature not reached Err 7 = Unauthorized access of BMS has taken place

With the exception of "Err 1", all error messages can be acknowledged in the error level. If an error message is displayed,

proceed as follows to acknowledge an error message:

Turn the button; select display "Clr" (Clear)

Press button; error message is confirmed

Page 16

16

KA_EQJW146F001_EN011

Short Instruction Manual

F Function

WE

Comment

Function block parameters / Range of values

01

Room sensor RF1

0

CO1 -> F01 - 1: Room sensor RF1 active

not systems 1.5, 1.6, 3.x

02

Outdoor sensor AF1

1 CO1 -> F02 - 1: Waether-compensated control active

WE=0 for systems 1.5, 1.6

03

Return flow sensor

RüF1

1 CO1 -> F03 - 1: Sensor and limiting functions active (WE=0 for system 1.2)

Function block parameter:

1,0

KP(limiting factor) / 0,1 to 10,0

04

Cooling control

0

CO1 -> F04 - 1: Cooling control, only with CO1 -> F11 – 1

the return flow temperature in HK1. (not systems 1.5, 1.6, 3.x)

05

Underfloor heating

0

CO1 -> F05 - 1: Limitation of the adjustment ranges (not systems .5, 1.6, 3.x)

SToP, ■ STArT,

STArT,

STArT

07

Optimization

0 CO1 -> F07 - 1: only with • CO1 -> F01 - 1

• CO1 -> F02 - 1 (not 1.5, 1.6, 3.x)

08

Adaptation

0

CO1 -> F08 - 1: only with • CO1 -> F01 - 1

• CO1 -> F11 - 0 (not 1.5, 1.6, 3.x)

09

Flash adaptation

0 CO1 -> F09 - 1 only with CO1 -> F01 - 1 (not 1.5, 1.6, 3.x)

Function block parameters:

20 min

Cycle time / 0 or 1 to 100 min (20 min)

0,0

KP (gain) / 0.0 to 25.0 (0.0)

11

Four-point

characteristic

0

CO1 -> F11 - 1: 4-Point characteristic, only with CO1 -> F08 - 0 (not 1.5, 1.6)

CO1 -> F11 - 0: Gradient characteristic

12

Control mode

1

CO1 -> F12 - 1: three-step control

Min. OFF time / 0 to 10 min

13

Limitation of deviation

0

2,0 °C

CO1 -> F13 - 1 only with CO1 -> F12 - 1

Max. deviation / 2.0 to 10.0 °C

14

Release HK1 at BE1

0

With CO1 -> F14 - 1, FG1 has no function;

1

Options: HK1 activ at bE= 1or bE=0

15

Processing an external

demand in HK1

0

How the external demand is processed in Rk1 depends on CO1 -> F16,

CO1 -> F17 and CO7 -> F15.

Function block list

CO1: Heating circuit 1 (HK1) (not system 1.9)*

The cooling control causes the reversal of the operating direction and a minimum limitation of

Screed drying

25 °C

5,0 °C

45 °C

4 days

0,0 °C

2,0

120 s

0 s

45 s

5,0 °C

2 min

2 min

Function block parameters:

Start temperature / 20 to 60 °C

Temperature rise per day / 0.0 to 10.0 °C

Maximum temperature / 25.0 to 60.0 °C

Maintaining time of max. temp. / 0 to 10 days

Temperature reduction per day / 0.0 to 10.0 °C

■■

■■■

• CO1 -> F02 - 1

Function block parameters:

KP (proportional gain) / 0.1 to 50.0

Tn (reset time) / 1 to 999 s

TV (derivative-action time) / 0 to 999 s

TY (valve transit time) / 5, 10, 15, …, 240 s

CO1 -> F12 - 0: On/off control

Function block parameters:

Hysteresis / 1.0 to 30.0 °C

Min. ON time / 0 to 10 min

for OPEN signal

Function block parameter:

Page 17

17

KA_EQJW146F001_EN011

Short Instruction Manual

F

Function

WE Comment

16

Processing an

external demand, 0 to

0

CO1 -> F16 - 1: only with • CO1 -> F15 - 1

The standard signal output (terminals 11/12) is not available anymore as a control output..

17

Processing an

Input term. 03/12

0

CO1 -> F17 - 1: Only with • CO1 -> F15 - 1

not in systems with

18

Request max. flow set

point by issuing a 0 to

0

0,0 °C

CO1 -> F18 - 1: The standard signal output (terminals 11/12) is not available anymore as a

Boost of flow temperature demand: 0 to 30 °C

20

External demand for

supply

0

CO1 -> F20 - 1: Demand for an external heat source

21

Speed reduction of

the charging pump as

a function of charging

0

CO1 -> F21 - 1: Activation of speed reduction (only 16.x) Function block parameters:

F

Function

WE Comment

01 Room sensor RF2

0

CO2 -> F01 - 1: Room sensor RF2 active

03 Return flow sensor

RüF1

0

CO2 -> F03 - 1: Sensor and limiting function active (WE=1 for system 10.x)

Function block parameter:

1,0 KP (limiting factor) / 0,1 to 10,0

04 Cooling control

0

CO2 -> F04 - 1: Cooling control, only with CO2 -> F11 - 1

The cooling control causes the reversal of the operating direction and a minimum

limitation of the return flow temperature in HK2

05

Underfloor heating

0

CO2-> F05 - 1: Limitation of the adjustment ranges (not .5, .6, 3.x)

SToP, ■ STArT, ■■ STArT, ■■■ STArT

07

Optimization

0

CO2 -> F07 - 1: only with • CO2 -> F01 - 1

• CO1 -> F02 - 1

08

Adaptation

0

CO2 -> F08 - 1: only with • CO2 -> F01 - 1

• CO2 -> F11 - 0

09

Flash adaptation

0

0,0

CO2 -> F09 - 1 only with CO2 -> F01 - 1

KP (gain) / 0,0 to 25,0

11

Four-point

characteristic

0

CO2 -> F11 - 1: 4-point characteristic, only with CO2 -> F08 - 0

CO2 -> F11 - 0: Gradient characteristic

10 V

Input term. 11/12

external demand,

binary

10 V signal

heat due to

insufficient heat

progress

0 °C

120 °C

0,0 °C

120 °C

40 °C

50 °C

2 V

• CO1 -> F17 - 0

Function block parameters:

Lower transmission range: 0.0 to 130.0 °C

Upper transmission range: 0.0 to 130.0 °C

CO1 -> F16 - 0

Options bE= 1, bE=0 (bE=1)

SF2/RF2

control output. The maximum flow set point (with boost, if applicable) is demanded by issuing

the signal output (0 to 10 V).

Function block parameters:

Lower transmission range: 0.0 to 130.0 °C

Upper transmission range: 0.0 to 130.0 °C

Start speed reduction: 5 to 90 °C

Stop speed reduction. 5 to 90 °C

Min. speed signal: 0 to 10 V

F Function block number, WE Default settings

CO2: Heating circuit 2 (HK2)

Screed drying

(Systems 3.x, 4.x and 10.0, 16.6)*

25 °C

5,0 °C

45 °C

4 days

0,0 °C

Function block parameters:

Start temperature / 20 to 60 °C

Temperature rise per day / 0.0 to 10.0 °C

Maximum temperature / 25.0 to 60.0 °C

Maintaining time of max. temp. / 0 to 10 days

Temperature reduction per day / 0.0 to 10.0 °C

• CO1 -> F02 - 1

Function block parameter:

20 min

Cycle time / 0 or 1 to 100 min

Page 18

18

KA_EQJW146F001_EN011

Short Instruction Manual

F Funktion

WE

Bemerkung

12

Control mode

1

2 min

CO2 -> F12 - 1: three-step control

Min. OFF time / 0 to 10 min

13

Limitation of deviation

0

CO2 -> F13 - 1 only with CO2 -> F12 - 1

maximale Regelabweichung / 2,0 bis 10,0 °C

14

Release HK2 at BE2

0

With CO2 -> F14 - 1, FG2 has no function;

F Function

WE

Comment

01

Storage tank sensor

SF1

1

CO4 -> F01 - 0 (not 11.0): Storage tank thermostat, only with CO4 -> F02 - 0

(WE=0 for 1.9, 11.9)

02

Storage tank sensor

stop loading

0

CO4 -> F02 - 1 (not in 1.3, 1.9, 2.3, 11.0 and 11.9): Only with CO4 -> F01 - 1

03

Return flow sensor

0

CO4 -> F03 - 1: Sensor and limitation function active

KP(limitation factor) / 0.1 to 10.0

05

Flow sensor VF4

0 CO4 -> F05 - 1: Flow sensor VF4 for measuring the storage tank charging temperature

active (only 1.1, 1.2, 1.6, 2.2)

06

parallel pump

0

CO4 -> F06 - 1: (only 2.1-2.3, 4.1, 4.5)

CO4 -> F06 - 0: UP1 deactivated for DHW

07

intermediate heating

1

CO4 -> F07 - 1: after 20 minutes DHW heating 10 minutes heating operation in UP1

(only. 2.x, 4.1, 4.5)

08

Priority by inverse

0

1,0

CO4 -> F08 - 1 only with CO4 -> F09 - 0; (only 1.1-1.3, 4.1, 4.5, 11.x)

KP (influencing factor) / 0.1 to 10.0

09

Priority through

0

2 min

CO4 -> F09 - 1 only with CO4 -> F08 - 0 (only 1.1-1.3, 4.1, 4.5, 11.x)

Activation of priority in case of control deviation / 0 to 10 min

10

Circulation pump

exchanger

0

CO4 -> F10 - 1: DHW circuit control active when the circulation pump ZP in is in

11

Circulation pump

storage tank charging

0

CO4 -> F11 - 1: Circulation pump runs during storage tank charging according to time

Function block parameters:

2,0

120 s

0 s

45 s

5,0 °C

2 min

KP (proportional gain) / 0.1 to 50.0

Tn (reset time) / 1 to 999 s

TV (derivative-action time) / 0 to 999 s

TY (valve transit time) / 5, 10, 15, …, 240 s

CO2 -> F12 - 0: On/off control

Function block parameters:

Hysteresis / 1.0 to 30.0 °C

Min. ON time / 0 to 10 min

for OPEN signal

F Function block number, WE

2,0 °C

1

Default settings

Function block parameters:

Options: HK2 activ at bE= 1 or bE=0

CO4: DHW circuit (systems 1.1–1.3, 1.5, 1.6, 1.9, 2.x, 4.1, 4.5, 11.x )*

SF2 with the function

RüF2

operation

1,0

10 min

40 °C

(WE=1 for 1.2, 1.6, 2.2, 11.2)

(not assigned to the solar circuit)

Function block parameters:

Function block parameters:

Termination of parallel operation in case of system deviation / 0 to 10 min

Flow limit temperature for parallel operation / 20.0 to 90.0°C

circuit

CO4 -> F07 - 0: Storage tank charging unlimited in time in priority to UP1 circuit

control

2 min

lowering operation

integrated in

operation during

Function block parameters:

Activate priority in case of control deviation / 0 to 10 min

Function block parameters:

operation (WE=0 for 1.6, 11.2; WE=1 for 11.6)

program CO4 -> F11 - 0: Circulation pump (ZP) switched off during storage tank charging

(onlyl 1.1-1.3, 1.5, 1.6, 2.x, 11.1, 11.2)

Page 19

19

KA_EQJW146F001_EN011

Short Instruction Manual

F Funktion

WE

Bemerkung

12

Control mode

1

CO24-> F12 - 1: three-step control (only 1.9, 11.x)

Min. OFF time / 0 to 10 min

13

Limitation of control

signal

0

CO4 -> F13 - 1 only with CO4 -> F12 – 1 (only 1.9, 11.x)

14

Thermal disinfection

0

CO4 -> F14 - 1 only with CO4 -> F01 - 1 Function block parameter:

15

SLP ON depending on

return temperature

0 For systems 1.5, 1.6, 2.0, 2.1, 2.3, 4.1: CO4 -> F15 - 1. only with CO1 -> F03 - 1

16

External demand has

0

with CO4 -> F16 - 1 leads to correspondingly high external demand to excessive

4.1)

19

Time program

controlled storage tank

sensor switching

0 CO4 -> F19 - 1 only with CO4 -> F02 - 1

20

DHW circuit

valve

0

CO4 -> F20 - 1: Return flow temperature limitation by means of globe valve mt VF2 in the

21

Speed reduction of the

0

2 V

CO4 -> F21 - 1: Activation of speed reduction and memory sensor SF2 (only1.1-

Min. speed signal: 0 to 10 V

F Funktion

WE

Bemerkung

01

Sensor initialization

1 CO5 -> F01 – 1, F02 – 0, F03 – 0 Pt 1000

1 CO5 -> F01 – 1, F02 – 1, F03 – 0 Ni 1000-DIN

02

0 CO5 -> F01 – 1, F02 – 1, F03 – 0, CO9 -> F01 – 0 Ni 1000-5k

03

04

Summer mode

0

CO5 -> F04 - 1: Activation of time-controlled summer mode

Function block parameters:

01.06

Start summer mode / 01.01 to 31.12

2

No. of days until activation / 1 to 3

30.09

Stop summer mode / 01.01 to 31.12

1

No. of days until deactivation / 1 to 3

18°C

Outdoor temperature limit for summer mode / 0.0 to 30.0 °C

Function block parameters:

2,0

120 s

KP (proportional gain) / 0.1 to 50.0 (system. x.9: WE=0,6)

Tn (reset time) / 1 to 999 s (system. x.9: WE=12 s)

TV (derivative action time) / 0 s; do not change value!

45 s

TY(valve running time) / 5, 10, 15, ..., 240 s (system x.9: WE=20 s)

CO4 -> F12 - 0 On/off control (only in 11.0, 11.1):

Function block parameters:

5,0 °C

2 min

Hysteresis / 1.0 to 30.0 °C

Min. ON time / 0 to 10 min

2 min

deviation for OPEN

priority

readjusted with globe

charging pump as a

function of charging

progress

2,0 °C

3

00:00

04:00

70,0 °C

10 °C

0 min

40,0 °C

50,0 °C

Function block parameter: Maximum control deviation / 2.0 to 10.0 °C

Weekday / 1, 2, ..., 7, 1-7

Start time / 00:00 to 23:45

Stop time / 00:00 to 23:45

Disinfection temperature / 60.0 to 90.0 °C

Set point boost / 0 to 50 °C

Hold time Disinfection temperature / 0 to 255 min

with setting start time = stop time Select: bE= 1, bE=0

(bE= 1), input terminal 03/12 (only possible without SF2/RF2)

For systems 11.1 and 11.2: CO4 -> F15 - 1 only with CO4 ->F03 - 1

Charging temperatures in DHW circuits without control valve (only 1.5, 1.6, 2.x,

In day mode SF1 is important, in night mode SF2.

(only 1.1-1.3, 1.5, 1.6, 2.x, 4.1, 4.5, 11.1, 11.2)

Heating coil return of the storage tank (only 11.1)

1.3, 1.5, 1.6, 2.x, 4.1, 11.1, 11.2); function block parameters:

Start speed reduction: 5.0 to 90.0 °C

Stop speed reduction: 5.0 to 90.0 °C

F Function block number, WE

Default settings

CO5: System-wide functions (all systems)

Signalisiert der Regler CO5 -> F00 - 1, sind alle Zugriffe auf die Rücklauf-, Volumenstrom- und Leistungseinstellungen gesperrt.

Page 20

20

KA_EQJW146F001_EN011

Short Instruction Manual

F Funktion

WE

Bemerkung

05

Delayed outdoor

decreases

0

CO5 -> F05, 06 - 1:

06

Delayed outdoor

increases

08

Automatic summer

changeover

1 Automatic summer/winter time changeover (last Sunday in March and October)

09

Frost protection

1

CO5 -> F09 - 0: Frost protection program I (limited frost protection - only active if all HK in

protection limit value / -15 to 3 °C

16

Release controller at

BE1

0

CO5 -> F16 - 0: Return flow temperature limitation only with PI action

19

Return flow temperature

limitation with P

algorithm

0 CO5 -> F19 - 1: Temperature monitoring active

20

Sensor calibration

1

CO5 -> F20 - 1: Setting all sensor calibration values CO5 > F20 - 0: Deleting set sensor calibration values

21

Locking manual level

0 CO5 -> F21 - 1: In switch position automatic mode is operated

22

Locking the rotary

switch

0 CO5 -> F22 - 1: all rotary switches without function

23

Outdoor temperature

0

CO5 -> F23 - 1:Outdoor temperature receive/transmit via 0 to 10 V (terminals 11/12)

End: -30.0 to 100.0 °C

F Function

WE

Comment

01

Modbus

1 CO6 -> F01 - 1: Modbus active

02

Modbus 16-bitaddressing

0

CO6 -> F02 - 1: 16-bit-addressing, only with CO6 -> F01 – 1

CO6 -> F02 - 0: 8-bit addressing

03

Modem function

0

CO6 -> F03 - 1 only with CO6 -> F01 – 1, CO6 -> F08 - 1

04

Automatic

modem configuration

0 CO6 -> F04 - 1 only with CO6 -> F03 – 1, CO6 -> F08 - 1

05

Lock dial-up

0 CO6 -> F05 - 1: No dial-up to BMS in case of error, only with CO6 -> F03 - 1

06

Dial-up also upon

0 CO6 -> F06 - 1: Dial-up to BMS also to indicate that an error has been

07

Control system

monitoring

0 CO6 -> F07 - 1: Resetting all level bits to “autonomous“ when there is no

communication, only with CO6 -> F03 - 1

08

Text message

0 CO6 -> F08 - 1: Sending of Text message active

10

Meter bus (only with

0

CO6 -> F10 - 1: Meter bus active

For WMZ1 with “1434” and “CONT”, select: tAr-A, tAr-E with time schedule

temperature adaptation

when temperature

temperature adaptation

when temperature

time/winter time

program II

3,0 °C

3 °C

3 °C

Function block parameter:

Delay per hour/ 1.0 to 6.0 °C

OFF mode)

Frost protection limit value / -15 to 3 °C

CO5 -> F09 - 1: Frost protection program II (all UP switched on when frost occurs) Frost

CO5 -> F16 - 1: Return flow temperature limitation only with P action

received over 0 to 10

V input

F Function block number, WE

CO6: Modbus (all systems)

Input

-20,0 °C

50,0 °C

Default settings

corrected error

optional, meter

bus/Modbus gateway)

255

1434

24h

Function block parameters:

Operating direction: Input, output

Start: -30.0 to 100.0 °C

corrected, only with CO6 -> F03 - 1

Function block parameters: (for WMZ1 to WMZ3)

Meter bus address / 0 to 255

Model code / 1434, CAL3, APAtO, SLS

Reading mode / 24h, CONT, CoiL

Page 21

21

KA_EQJW146F001_EN011

Short Instruction Manual

F Funktion

WE

Bemerkung

11

Flow rate limitation in HK1

0

CO6 -> F11 - 1: Only with • CO6 -> F10 - 1

Limiting factor / 0.1 to 10

1,5 m³/h

1,5 m³/h

1,5 m³/h

12

Capacity limitation in

0

CO6 -> F12 – 1 Only with • CO6 -> F10 - 1

Limiting factor / 0.1 to 10

1,5 kW

F Function

WE

Comment

01

Device bus

1

CO7 -> F01 - 1: Device bus active; function block parameters: Device bus address

*Auto = automatic search for free device bus address in the system

02

Time synchronization

0 CO7 -> F02 - 1: Controller sends its system time to all device bus participants

every 24 hours.

03

Reserved

0

04

Reserved

0

06

Send value AF1

0 CO7 -> F06 - 1: (not 1.9); Function block parameter:

1

Register No. / 1 to 4

07

Receive value AF1

0 CO7 -> F07 - 1:(not 1.9); Function block parameter:

1

Register No. / 1 to 4

08

Send value AF2

0 CO7 -> F08 - 1: (not 1.9); Function block parameter:

2

Register No. / 1 to 4

09

Receive value AF2

0 CO7 -> F09 - 1: (not 1.9); Function block parameter:

2 Register No. / 1 to 4

10

Send flow set point

HK1

0 CO7 -> F10 - 1: In systems 1.5-1.8, 2.x, 3.1-3.4, 4.1-4.3, 7.x, 8.x the storage

tank charging set point is transmitted during DHW heating.

5 Function block parameter: Register No. / 5 to 64

11 Send flow set point

HK2

0 CO7 -> F11 - 1: Function block parameter:

5 Register No. / 5 to 64

13 Send flow set point

DHW

0 CO7 -> F13 - 1: The Charging temperature boost parameter is generated in PA4

level.

5 Function block parameter: Register No. / 5 to 64

14 Send maximum flow

0 CO7 -> F14 - 1: The controller already determines the maximum flow set

controller; Function block parameter:

5 Register No. / 5 to 64

15 Receive demand in

HK1

0 CO7 -> F15 - 1: external demand processing in HK1 via device bus (not 1.9);

5 Function block parameter: Register No. / 5 to 64

16

Display error

device bus

0 CO7 -> F16 -1: Controller generates the message "Err 5" as long as faults are

17 Receive demand in

HK2

0

5

CO7 -> F17 - 1: external demand processing in HK2 via device bus (not 1.x, 2.x);

Function block parameter: Register No. / 5 to 64

19

Increase in return flow

temperature limit value

0 CO7 -> F19 - 1: Increase of return flow temperature limit HK1 with message

"DHW-heating active” from the device bus;

using meter bus

CO5 -> F11 - 0

Function block parameters:

Maximum limit value /At, 0.01 to 650 m³/h

Maximum limit for heating operation* /At, 0.01 to 650 m³/h

Maximum limit for drinking water* / 0.01 to 650 m³/h

1

HK1 using meter bus

CO5 -> F10 - 0

Function block parameters:

Maximum limit /At, 0.1 to 6500 kW

1,5 kW

1,5 kW

1

F Function block number, WE

CO7: Device bus (all systems, F02, F03, … only with CO7 -> F01 - 1)

Default settings

32

Maximum limit for heating operation* /At, 0.1 to 6500 kW

Maximum limit for drinking water* / 0.1 to 6500 kW

/Auto*, 1 to 32

set point

messages from the

point of its circuits internally and sends this one value to the primary

present in other device bus stations.

Page 22

21

KA_EQJW146F001_EN011

32

Function block parameter: Register No. / 5 to 64

20

"DHW heating

0 CO7 -> F20 - 1: Sending of "DHW-heating active”

active“ sending

32

Function block parameter: Register No./ 5 bis 64

21

Receive release HK1

0

32

CO7 -> F21 - 1:

Function block parameter: Register No. / 5 to 64

22

Receive release HK2

0

32

CO7 -> F22 - 1: (not 1.x, 2.x);

Function block parameter: Register No. / 5 to 64

F Function block number, WE Default settings

Page 23

22

KA_EQJW146F001_EN011

Short Instruction Manual

Parameter designation

Range of values

WE

Comment

Gradient, flow

0,2 to 3,2

1,8

Level (parallel shift)

–30,0 to 30,0 °C

0,0 °C

Minimum flow temperature

–5,0 to 150,0 °C

20 °C

Maximum flow temperature

5,0 to 150,0 °C

90 °C

4-point characteristic

Press the rotary pushbutton () to set the parameters..

Point 1: Outdoor temperature

–50 to 50 °C

1: -15 °C

4: 15 °C

Outside temperatures of points 2, 3, 4 are marked by squares below

(point 1: 5.0 °C, point 2: 15.0 °C, point 3: 25.0 °C, point 4: 30.0 °C)

Range of valuesPoint 1: Flow

temperature

5 to 130 °C

1: 70 °C

4: 25 °C

Flow temperatures of points 2, 3, 4 are marked by squares below the

(point 1: 20.0 °C, point 2: 15.0 °C, point 3: 10.0 °C, point 4: 5.0 °C)

Point 1: Reduced flow temperature

5 to 130 °C

1: 60 °C

4: 20 °C

Reduced flow temperatures of points 2, 3, 4 are due to

Point 1: Return flow temperature

5 to 90 °C

1 to 4:

65 °C

Return temperatures of the points 2, 3, 4 are indicated by squares

below the numbers 2, 3, 4.

Point 1: Flow rate

At,

0,01 to 650 m³/h

1 to 4: At

Flow rate values of points 2, 3, 4 are indicated by squares below the

numbers 2, 3, 4 (only in parameter level PA1)

Point 1: Power

At,

0,1 to 6500 kW

1 to 4: At

Flow values of points 2, 3, 4 are indicated by squares below the

numbers 2, 3, 4 (only in parameter level PA1)

OT deactivation value Rated operation

0,0 to 50,0 °C

22,0 °C

OT deactivation value Reduced mode

–50,0 to 50,0 °C

15,0 °C

OT switch-on value Rated operation

–50,0 to 5,0 °C

–15,0 °C

Gradient, return flow

0,2 to 3,2

1,2

Level, Return

–30,0 to 30,0 °C

0,0 °C

Return flow temperature foot point

5,0 to 90,0 °C

65 °C

maximum return temperature

5,0 to 90,0 °C

65 °C

Set point boost primary exchanger

control

0,0 to 90,0 °C

5,0 °C

Only in parameter level PA1

Setpoint for binary demand processing

0,0 to 150,0 °C

40,0 °C

Only in parameter level PA1

Flow set point day

–5,0 to 150,0 °C

50,0 °C

only for short-term adaptation without outdoor sensor

Flow set point night

–5,0 to 150,0 °C

30,0 °C

only for short-term adaptation without outdoor sensor

Parameter designation

Range of values

WE

Comment

Minimum DHW temperature

5,0 to 90,0 °C

40,0 °C

maximum DHW temperature

5,0 to 90,0 °C

60,0 °C

switching difference

1,0 to 30,0 °C

5,0 °C

Charging temperature boost

0,0 to 50,0 °C

10,0 °C

maximum charging temperature

20,0 to 150,0 °C

80,0 °C

Only with VF4

After-run storage tank charging pump

0,0 to 10,0

1,0

maximum return temperature

20,0 to 90,0 °C

65,0 °C

Solar circuit pump on

1,0 to 30,0 °C

10,0 °C

Solar circuit pump off

0,0 to 30,0 °C

3,0 °C

maximum storage temperature

20,0 to 90,0 °C

80,0 °C

DHW control signal for storage tank

charging

5 to 100 %

100 %

Parameter lists

PA1: Parameters HK1 (heating circuit 1)

PA2: Parameters HK2 (heating circuit 2)

2: -5 °C

3: 5 °C

2: 55 °C

3: 40 °C

2: 40 °C

3: 20 °C

the numbers 2, 3, 4.

Changed WE with CO1, 2 -> F04 - 1:

numbers 2, 3, 4.

Modified WE with CO1, 2 -> F04 - 1:

squares below the digits 2, 3, 4. Changed WE with CO1, 2 -> F04 - 1:

(point 1: 30.0 °C, point 2: 25.0 °C, point 3: 20.0 °C, point 4: 15.0 °C)

PA4: Parameter DHW

Page 24

23

KA_EQJW146F001_EN011

Short Instruction Manual

Parameter designation

Range of values

WE

Comment

Boiler pump on

20 to 90 °C

60 °C

only 16.x

switching difference

0 to 30 °C

5 °C

only 16.x

holidays

01.01 to 31.12

holiday periods

01.01 to 31.12

Parameter designation

Range of values

WE

Comment

Station address

1 to 247

255 with CO6 -> F02 - 1: 1 to 32000

Modem dialing pause (P)

0 to 255 min

5 min

Modem timeout (T)

0 to 255 min

5 min

Number of dial attempts for GLT calls

1 to 255

15

Call number to control station (TELnr)

maximum 22 characters; 1, 2, 3, ..., 9, 0;

Access number (TAPnr)

Subscriber number (mobile phone)

Inputs

8 inputs for temperature sensor (Pt 1000, Ni1000-DIN or Ni1000-5k) and 2

Outputs

2 x three-step signal: load max. 250 V AC, 2A*, alternatively 2 x two-point signal:

Optional interfaces

1 x Modbus interface (option: USB, RS232, RS485, LAN, modem)

RJ45 female connector on side

1 x connection for data logging module DataMem

1 x connection for memory module ParaMem

Operating voltage

85 to 250 V, 48 to 62 Hz, max. 1.5 VA

Ambient temperature

0 to 40 °C (operation),

-10 °C to 60 °C (storage and transport)

Degree of protection

IP 40 according to EN60529

Class of protection

II according to EN61140

Degree of contamination

2 according to EN60730

Overvoltage category

II according to EN60730

Interference immunity

according to EN 61000-6-1

Emitted interference

according to EN 61000-6-3

Assembly

Front panel mounting, wall mounting or on top hat rail

Housing L x W x H (mm)

144 x 98 x 60

Weight

ca. 0,5 kg

PA5: system-wide parameters (all systems)

PA6: Modbus

(C)

Technical data

"-" = end of a character string

"P" = Pause

* Inrush current max. 16 A

binary inputs, terminal 11 as input 0 to 10V for a demand or outdoor

temperature signal

load max. 250 V AC, 2 A*

3 x pump output: load max. 250 V AC, 2A*; all outputs relay outputs with varistor

suppression

Terminal 11 as output 0 to 10 V for continuous control HK1 or demand request,

load > 5 kΩ

Protocol: Modbus RTU; 19200 baud, data format 8N1;

Page 25

24

KA_EQJW146F001_EN011

Short Instruction Manual

Description

Item no.

Item list

Notes

EQJW146F001

0440210001

0440210002

0440210003

0440210004

0440210006

0440210007

0440210008

0440210010

0440210011

0440210005

Heating and district heating controller

Adapter for connecting EQJW126/146 controllers to RS232 (PC)

Adapter for connecting the EQJW126/146 controllers to modem

Adapter for connecting EQJW126/146 controllers to RS485 bus

Adapter for connecting EQJW126/146 controllers to RS485 bus (device bus master)

ModBus-MBus Gateway

Converter / repeater CoRe02 for RS232 or RS485 interfaces RS485

Overvoltage protection SA5000

Parameter memory module for transfer of controller parameters

Modbus GPRS Gateway

Modbus-TCP-Gateway

SAUTER Deutschland

Sauter-Cumulus GmbH

Hans-Bunte-Str. 15

79108 Freiburg

http://www.sauter-cumulus.de

Telefon +49 (761) 5105-0

Telefax +49 (761) 5105-234

E-Mail: sauter-cumulus@de.sauter-bc.com

Loading...

Loading...