sauter EQJW145,Equitherm Operating Manual

EQJW145: Heating

controller

Operating manual

7010015003 A

R

7010015003 A

Printed in Switzerland

Subject to changes

© Fr. Sauter AG

Im Surinam 55

CH - 4016 Basel

www.sauter-controls.com

2 7010015003 A

© Fr. Sauter AG

EQJW145:

Table

Heating controller

of contents

Table of contents

Table of contents ........................................................................................................3

Symbols used in this manual

....................................................................................7

1 General information ............................................................................................9

1.1 Introduction................................................................................................9

1.2 Safety information .....................................................................................9

2 Description of the operating controls .............................................................11

2.1 Front view of the EQJW 145 ...................................................................11

2.2 Top Rotary switches (heating) ................................................................12

2.3 Bottom rotary switch (hot water/pilot timer).............................................12

2.4 Input knob................................................................................................13

2.5 ESC key ..................................................................................................13

2.6 Display.....................................................................................................13

3 Commissioning..................................................................................................15

3.1 Operating the device for the first time ..................................................... 15

3.1.1 Setting the time .......................................................................................15

3.1.2 Setting the date .......................................................................................16

3.2 Commissioning level ...............................................................................16

3.2.1 List of SERVice parameters ....................................................................17

3.2.2 Access to commissioning level ...............................................................18

3.2.3 View SERVice parameters......................................................................18

3.2.4 Change SERVice parameters .................................................................18

3.3 SERVice level ......................................................................................... 19

3.3.1 Access to SERVice level.........................................................................19

3.3.2 View SERVice parameters......................................................................20

3.3.3 Change SERVice parameters .................................................................20

3.3.4 List of SERVice parameters ....................................................................21

3.3.5 Explanations for individual SERVice parameters....................................25

3.4 Communication level...............................................................................38

3.4.1 Access to communication level ...............................................................39

3.4.2 Viewing the communication parameters ................................................. 39

3.4.3 Changing communication parameters ....................................................39

3.4.4 List of communication parameters ..........................................................40

3.4.5 Explanations of individual communication parameters...........................42

7010015003 A

© Fr. Sauter AG

4 Operation............................................................................................................47

4.1 Operating modes.....................................................................................47

4.1.1 Displays when automatic mode is set .....................................................48

3

EQJW145:

of contents

Table

Heating controller

4.1.2 Displays when back-up mode, reduced mode and normal mode are set50

4.2 Entering the setpoint temperature in normal mode................................. 51

4.3 Enter setpoint temperature in reduced mode..........................................52

4.4 Weekly switching programme for heating ............................................... 52

4.4.1 Calling up the weekly switching programme........................................... 53

4.4.2 View switching commands ......................................................................53

4.4.3 Enter a switching command ....................................................................54

4.4.4 Changing and deleting a switching command ........................................54

4.5 Calendar switching programme ..............................................................55

4.5.1 Calling up the calendar switching programme ........................................ 55

4.5.2 View switching commands ......................................................................55

4.5.3 Enter a switching command ....................................................................56

4.5.4 Changing and deleting a switching command ........................................56

4.6 Temporary temperature change for the heating circuit...........................57

4.7 Entering DHW temperatures ...................................................................58

4.7.1 Notes on the boosted DHW temperature ................................................ 59

4.8 Weekly switching programme for domestic hot water ............................59

4.8.1 Calling up the weekly switching programme........................................... 60

4.8.2 View switching commands ......................................................................60

4.8.3 Enter a switching command ....................................................................61

4.8.4 Changing and deleting a switching command ........................................61

4.9 Weekly switching programme for pilot timer/circulating pump................ 62

4.10 Calling up the weekly switching programme...........................................63

4.10.1 View switching command........................................................................63

4.10.2 Enter switching command .......................................................................63

4.10.3 Change/delete switching command ........................................................ 64

4.11 Once-only tank charge............................................................................64

5 Manual mode......................................................................................................65

5.1 Access to manual mode (heating) ..........................................................65

5.2 Access to manual mode (domestic hot water, configurable output and

second final control element) ..................................................................65

5.3 Set valve position ....................................................................................65

5.4 Set status of other outputs (pumps, configurable output) for manual

mode .......................................................................................................66

5.5 Exit manual mode ...................................................................................66

5.6 Check measured values in manual mode ............................................... 66

6 Communication functions ................................................................................67

6.1 Bus wiring................................................................................................67

6.2 Device bus............................................................................................... 67

4 7010015003 A

© Fr. Sauter AG

EQJW145:

of contents

Table

Heating controller

6.2.1 Assigning addresses ...............................................................................67

6.2.2 Room operating unit EDB 100 ................................................................ 68

6.2.3 Sending and receiving outdoor temperatures ......................................... 68

6.2.4 Requesting and processing a heat requirement .....................................68

6.2.5 Requesting and processing a return temperature ..................................68

6.2.6 Synchronising the time............................................................................68

6.3 Modbus communication ..........................................................................69

6.3.1 Modbus data points (holding register).....................................................70

6.3.2 Modbus data points (coils) ......................................................................74

6.4 Modem operation ....................................................................................75

6.4.1 Connection with the modem....................................................................75

6.4.2 Modbus operation via modem.................................................................75

6.4.3 Sending SMS if there is a fault on the installation ..................................76

6.4.4 Displays for modem operation ................................................................76

6.5 Setting parameters using the PC ............................................................77

7 Faults ..................................................................................................................79

7.1 Displaying faults ......................................................................................79

7.1.1 Error list...................................................................................................79

7.1.2 Device status...........................................................................................79

7.2 Logbook...................................................................................................80

7.3 Reset functions ....................................................................................... 81

7.4 Actions to deal with faulty temperature value measurements ................81

8 Using the controller...........................................................................................83

8.1 General information.................................................................................83

8.2 Examples of use......................................................................................83

8.2.1 Control model 1.......................................................................................84

8.2.2 Control model 2.......................................................................................87

8.2.3 Control model 3.......................................................................................88

9 Economy tips .....................................................................................................89

10 Resistance values for the Ni1000 sensors .....................................................91

7010015003 A

© Fr. Sauter AG

11 Accessories .......................................................................................................93

Wiring diagram ..................................................................................................93

12

13 Dimension drawing ...........................................................................................93

14 Technical data....................................................................................................95

14.1 Overview of technical data......................................................................95

14.2 Overview of main functions.....................................................................97

15 Overview of controller settings......................................................................101

15.1 List of SERVice parameters..................................................................101

5

EQJW145:

of contents

Table

Heating controller

15.2 List of communication parameters ........................................................102

15.3 Weekly switching programme: heating .................................................103

15.4 Calendar switching programme: heating ..............................................103

15.5 Weekly switching programme: domestic hot water...............................104

15.6 Weekly switching programme: pilot timer/circulating pump .................. 104

Table of Figures ......................................................................................................105

List of tables............................................................................................................106

Abbreviations..........................................................................................................107

Index ........................................................................................................................108

6 7010015003 A

© Fr. Sauter AG

EQJW145:

Symbols

Heating controller

used in this manual

Symbols used in this manual

Information

Information concerning the use of the product.

Warnings

Factory setting of the EQJW 145 (e.g. manufacturer's specified control

values, switching times, etc.)

....

The operating instructions explain the various functions of the device, step by

step, using the following symbols:

'PROG' is shown on the display, flashing

'09:00' is shown on the display, not flashing

Press key ...

7010015003 A

© Fr. Sauter AG

7

EQJW145:

Symbols

Heating controller

used in this manual

8 7010015003 A

© Fr. Sauter AG

EQJW145:

General information

Heating controller

1 General information

1.1 Introduction

Congratulations! You have chosen a Sauter heating controller. The

equitherm

EQJW 145 is a quality product from one of the leading

manufacturers of control technology products for the heating, ventilation and

air conditioning industry.

The EQJW 145 is a compact, weather-compensated heating controller used

to regulate flow temperatures and domestic hot water preparation. In

automatic mode, the EQJW 145 reduces the room temperature during the

night (reduced mode) by means of switching commands from the weekly time

switch (weekly switching programme), and during the day it switches to the

normal temperature. Domestic hot water preparation is switched on or off via

another switching programme. There is a choice of two adjustable

temperatures for domestic hot water. The EQJW 145 is suitable for buildings

of all types. A fixed basic programme (factory setting) ensures that

commissioning is simple. Any adaptations to the heating system which might

be needed are implemented using SERVice parameters. Automatic

summertime/wintertime change-over eliminates the need for residents to

adjust the time twice a year. The equitherm

EQJW 145 incorporates a

variety of protective functions such as the anti-frost function and the pump

anti-jamming facility. Additional functions such as automatic switch-off are

also implemented. For every installation, these features ensure optimal

comfort with the minimum use of energy.

Analogue or digital room operating units can be connected to the EQJW 145,

enabling convenient remote control of the controller from the living room.

A programmable output is provided for additional tasks. For example, it may

be used as a pilot timer output, as a signal for a collective fault alarm, and to

activate a circulating pump for domestic hot water. The communication

interface makes it possible to network several controllers, to connect to a

control station and to send alarms to a mobile telephone via SMS.

1.2 Safety information

Special care is required in order to prevent injuries, damage by fire or

damage to equipment. After the device has been installed by a specialist in

accordance with the Installation Instructions enclosed with it (MV506103),

please read these instructions on operating it. Local regulations must be

followed during installation. The controller is not a safety-relevant component.

The anti-frost, overheating protection and flow temperature limitation

functions do not replace the relevant safety equipment.

7010015003 A

© Fr. Sauter AG

9

EQJW145:

General informatio

Heating controller

n

10 7010015003 A

© Fr. Sauter AG

EQJW145:

234

°C

sec1h

123

4

Description

Heating controller

of the operating controls

2 Description of the operating controls

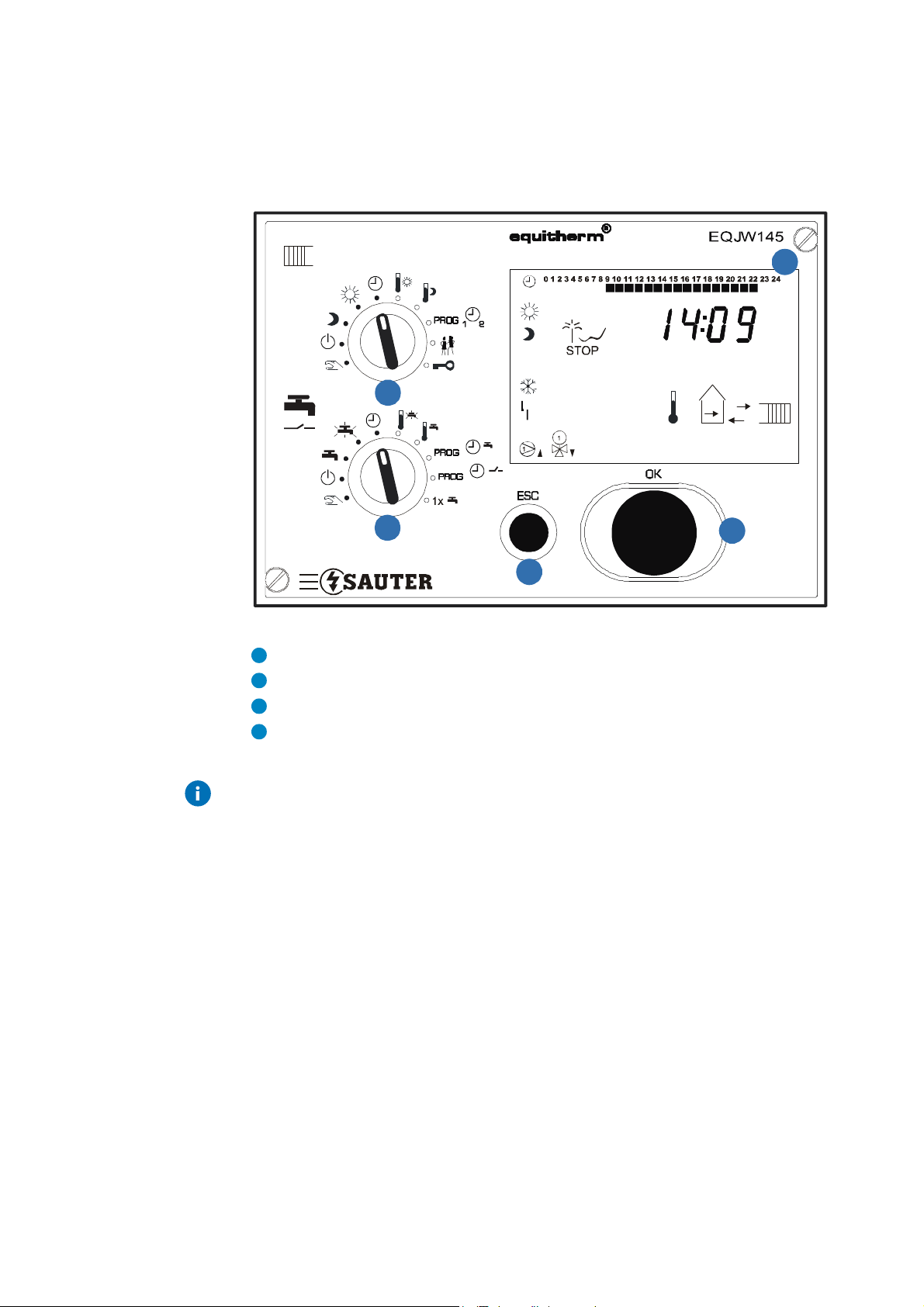

2.1 Front view of the EQJW 145

1

Fig. 1: EQJW 145 - Front view

Rotary switch

Display

ESC button

Input knob

The device has a rotary switch with 10 positions, an input knob and a button.

7010015003 A

© Fr. Sauter AG

11

EQJW145:

Operatingmodes:

Inputs:

Limited (unlimited)

l

Operatingmodes:

Inputs:

domestic hot water temperature

1

2

Description

Heating controller

of the operating controls

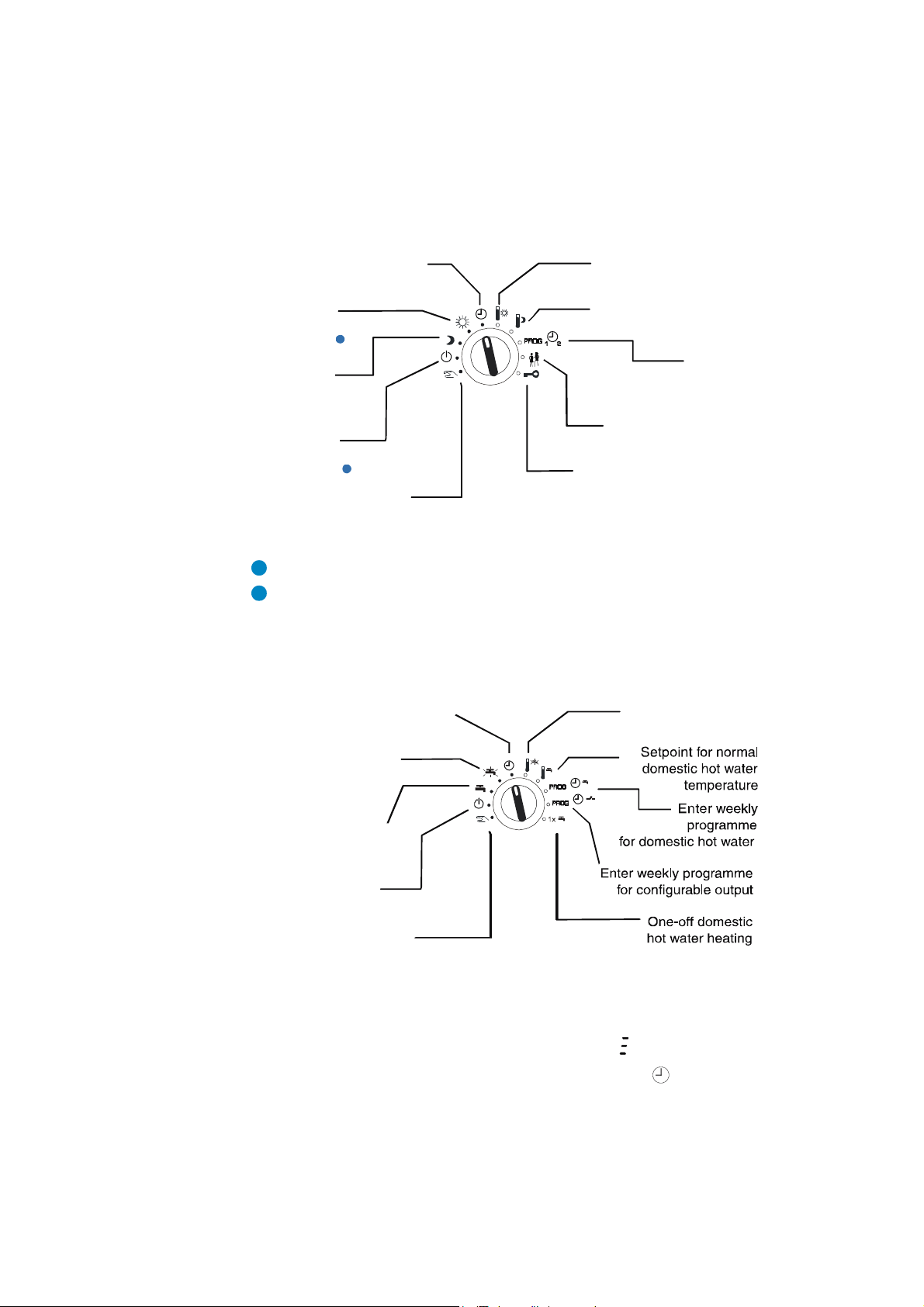

2.2 Top Rotary switches (heating)

The switch positions have these meanings:

Automatic mode according

to switching programme

Regulator is

continuously in

normal mode

1

Regulator is

continuously in

reduced mode

Regulator is

continuously in

back-up mode

2

Access to manual mode

for heating

Fig. 2: EQJW 145 - Top Rotary Switches

Normal mode corresponds to nominal mode as per EN 12098-1.

Back-up mode means that the heating is switched off and the anti-frost function is active.

2.3 Bottom rotary switch (hot water/pilot timer)

Automatic mode for domestic hot

water according to switching

programme

Continuous heating to

increased domestic hot

water temperature

Setpoint adjustment

Normal mode

Setpoint adjustment

Reduced mode

Enter

weekly and

yearly programme for

heating

temperature change

Access to SERVice and

communication leve

Setpoint for increased

12 7010015003 A

Continuous heating

to normal domestic hot

water temperature

Domestic hot water

heating switched off

Access to manual mode

Fig. 3: EQJW 145 - Bottom Rotary Switches

If the rotary switches are used to select a prohibited combination of positions,

e.g. simultaneous entry of setpoints for heating and domestic hot water

preparation, the controller will show this symbol:

In this case, one of the switches should be set to the symbol or to another

mode.

© Fr. Sauter AG

EQJW145:

0 1 2 3 4 5 6 7 8..........21 22 23 24

Description

Heating controller

of the operating controls

2.4 Input knob

2.5 ESC key

You can use the input knob to scroll through menus, and

to select or change values. Unless explicitly described

otherwise, you can scroll through or change

menus/values in a ring structure. There is no 'limit stop'

for adjusting values or scrolling.

The input knob has a key function, i.e. you can press it.

This is used to select the parameter just shown for

changing, or to confirm a flashing value, or to access a

lower menu level.

Press the ESC key to cancel operations, or to return from

a lower menu item to the next level up.

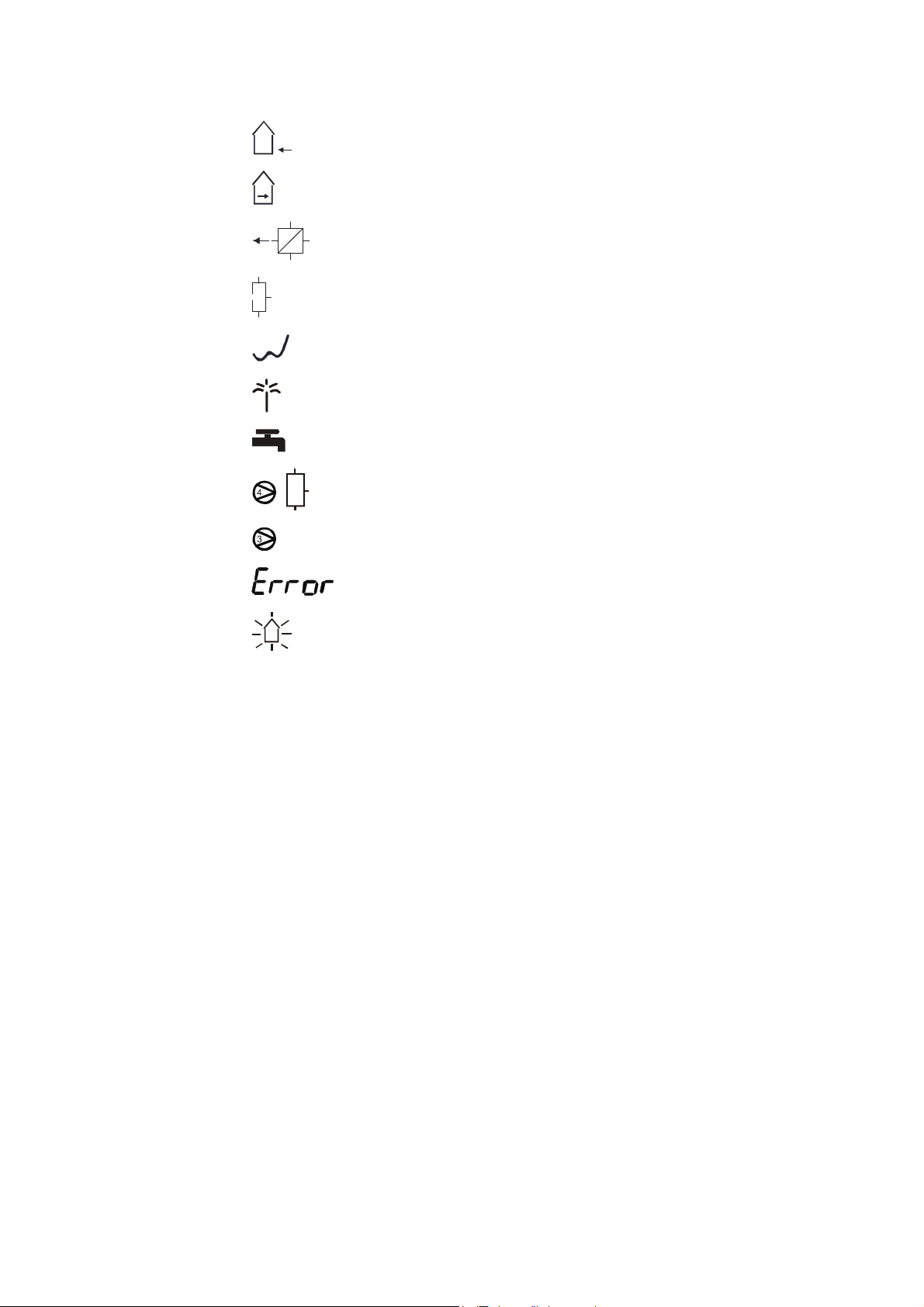

2.6 Display

The device has an LC display (see 2.1), which can show various items of

information at the same time. The next illustration shows what the symbols

mean:

Times for normal mode on the current day

Time, date, setpoints, actual values, etc.

Automatic mode according to the weekly and calendar switching

programme. flashing: temperature change for limited (unlimited) period

Heating circuit is in normal mode flashing. Optimisation takes place on

changing to normal mode.

Heating circuit is in reduced mode flashing. Optimisation takes place on

changing to reduced or off mode.

Heating circuit is in back-up mode. flashing: anti-frost function is active

At least one sensor is faulty (or not connected)

7010015003 A

© Fr. Sauter AG

Heating medium pump is switched on

Final control element 1 is opened ( ) or closed ( )

Final control element 2 is opened ( ) or closed ( )

Display of setpoint temperature. flashing: display of actual temperature

Display of flow temperature

13

EQJW145

Description

: Heating controller

of the operating controls

Display of outdoor temperature

Display of room temperature

Display of return temperature

Display of tank temperature

Controller is in summer mode

Calendar switching programme mode is currently active

Domestic hot water. flashing: with increased temperature

Charge pump switched on

2nd charge pump switched on

An error has occurred (see 7)

Floor drying function (heating function) is active

14 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

3 Commissioning

3.1 Operating the device for the first time

When you operate the equitherm

the date and time. Essentially, once this is done, the controller is ready for

use. However, depending on the application, it may be necessary to change

further settings after this.

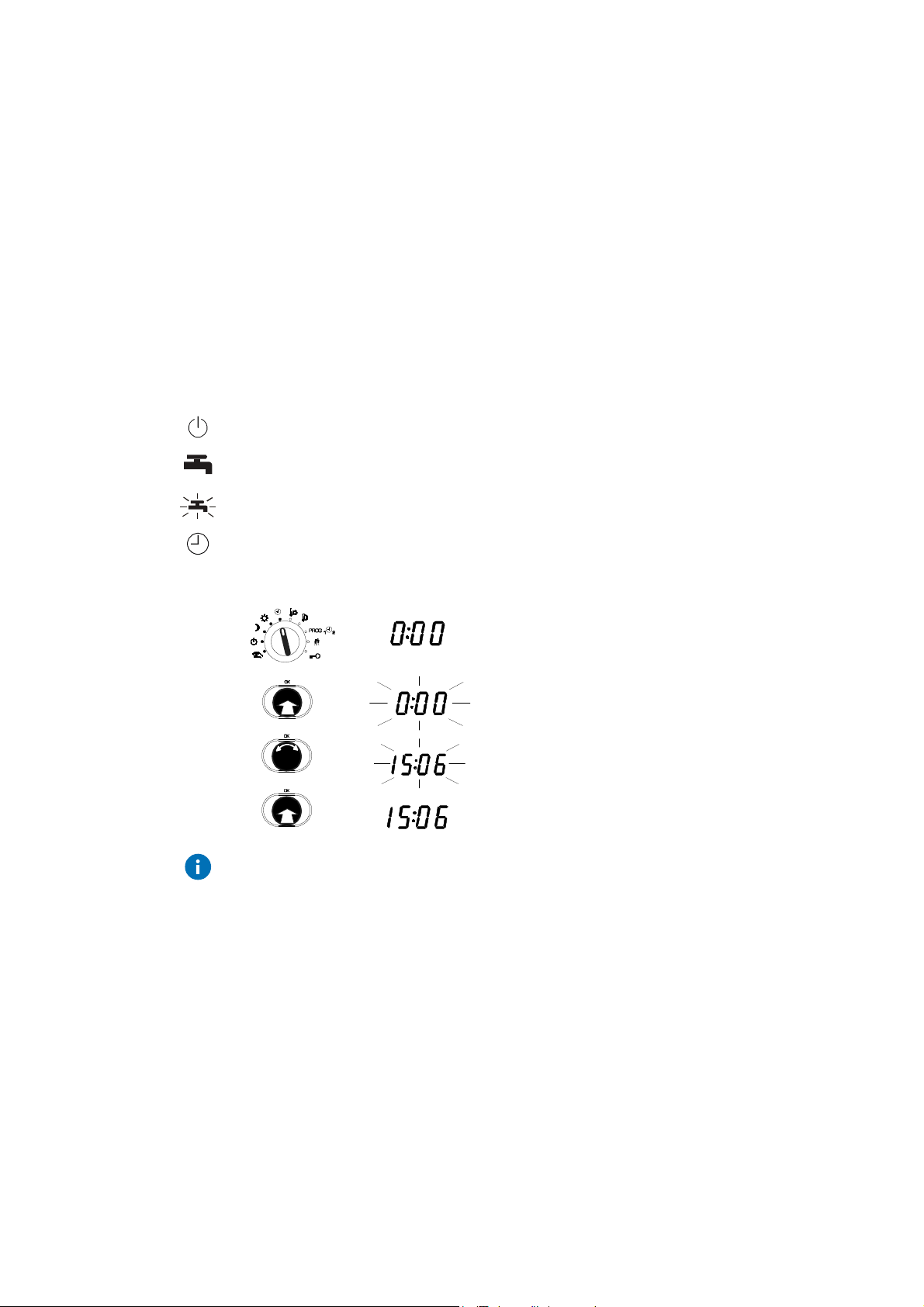

3.1.1 Setting the time

To enable you to set the time, you must first move the bottom rotary switch

into one of the following positions (see 4.1):

Off mode

Continuous heating to normal DHW temperature

Continuous heating to increased DHW temperature

Automatic mode

Procedure

EQJW 145 for the first time, you must set

1. Set the top rotary switch to automatic mode.

•

The time is shown.

2. Press the input knob.

•

the time flashes ...

3. Turn the input knob.

•

The time is set.

4. Press the input knob again.

•

The new time is confirmed.

If several devices are connected to each other via a device bus (see 3.4.4)

and you set the clock on one device, the time and date are also set on all the

other devices.

7010015003 A

© Fr. Sauter AG

15

EQJW145:

CAUTION!

Commissioning

Heating controller

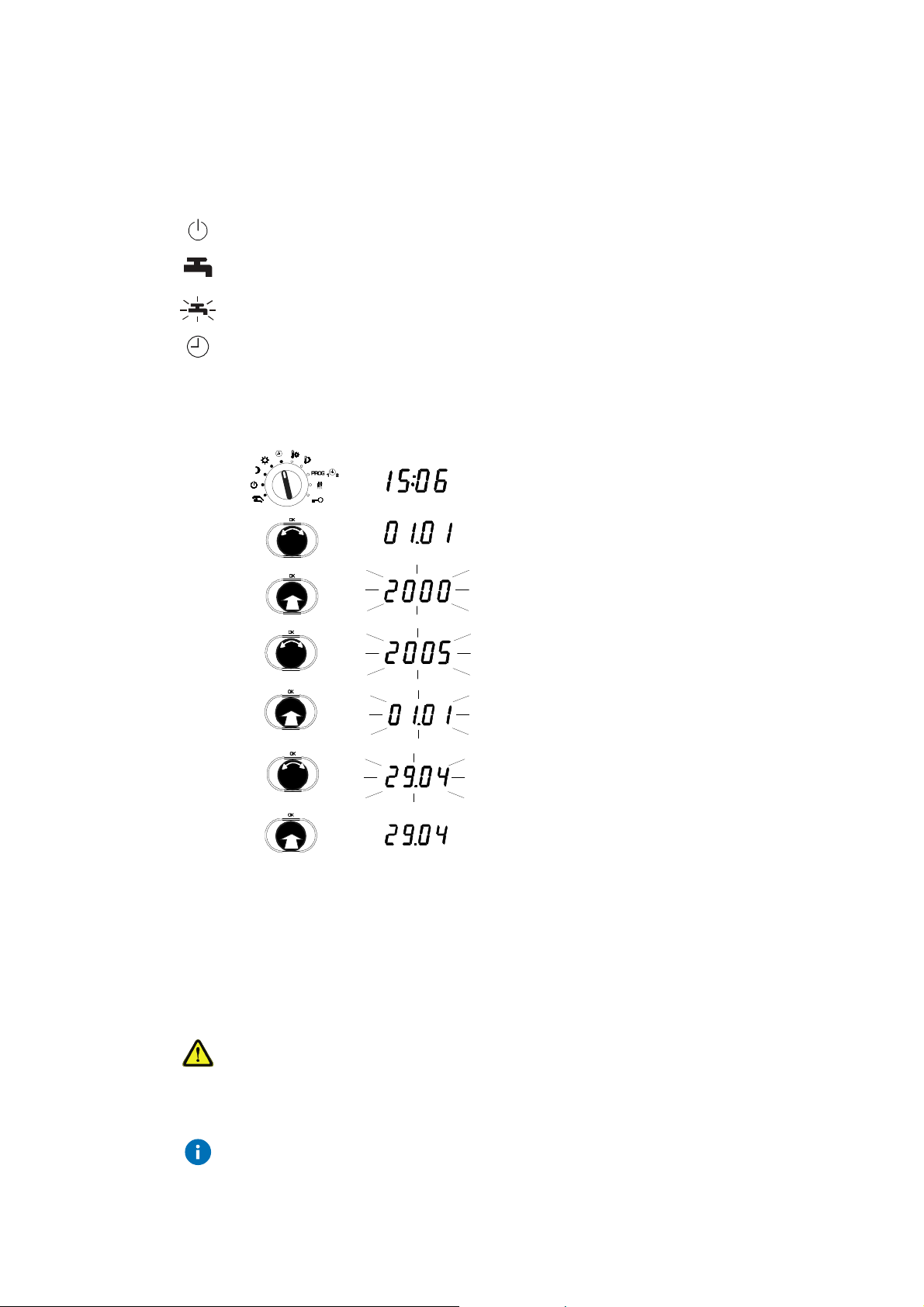

3.1.2 Setting the date

To enable you to set the date, you must first move the bottom rotary switch

into one of the following positions (see 4.1):

Off mode

Continuous heating to normal DHW temperature

Continuous heating to increased DHW temperature

Automatic mode

Procedure

1. Set the top rotary switch to automatic mode.

•

The time is shown.

2. Turn the input knob until the date is displayed

(day/month and year are shown alternately).

3. Press the input knob.

•

The number of the year flashes...

4. Turn the input knob.

•

The year is changed.

5. Press the input knob.

•

The year is confirmed and the day/month

is shown.

6. Turn the input knob.

•

The date is changed.

7. Press the input knob,

•

The new date is confirmed.

3.2 Commissioning level

In commissioning level, a specialist can perform the basic settings on the

GZP which are important for commissioning. Direct access to specified

service parameters is enabled.

Incorrect parameterisation (setting) of the heating controller

It can cause major faults or damage to the installation.

The commissioning level must only be enabled by a specialist.

Some of the parameters cannot be changed. They can only be viewed

(version number, status information).

16 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

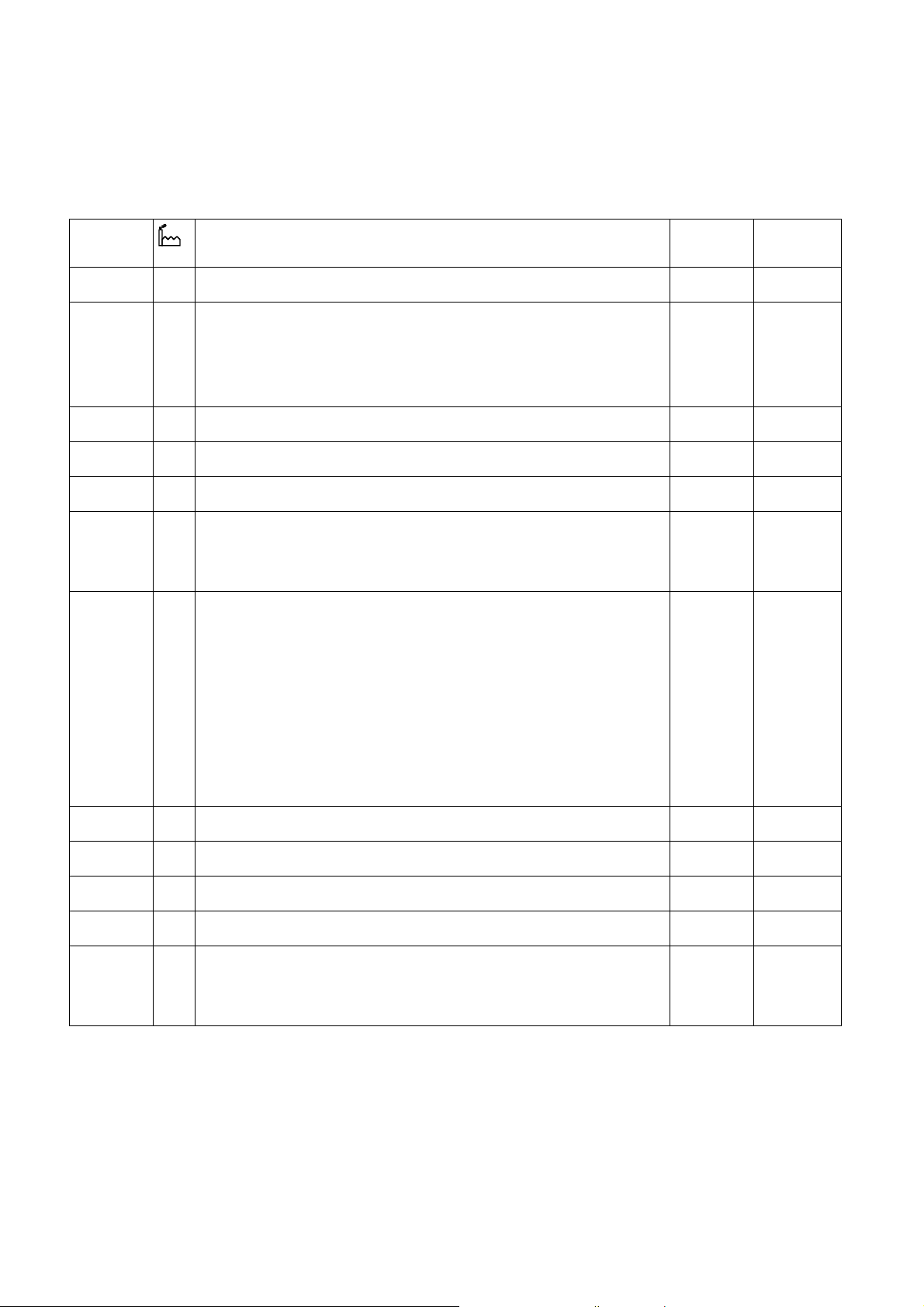

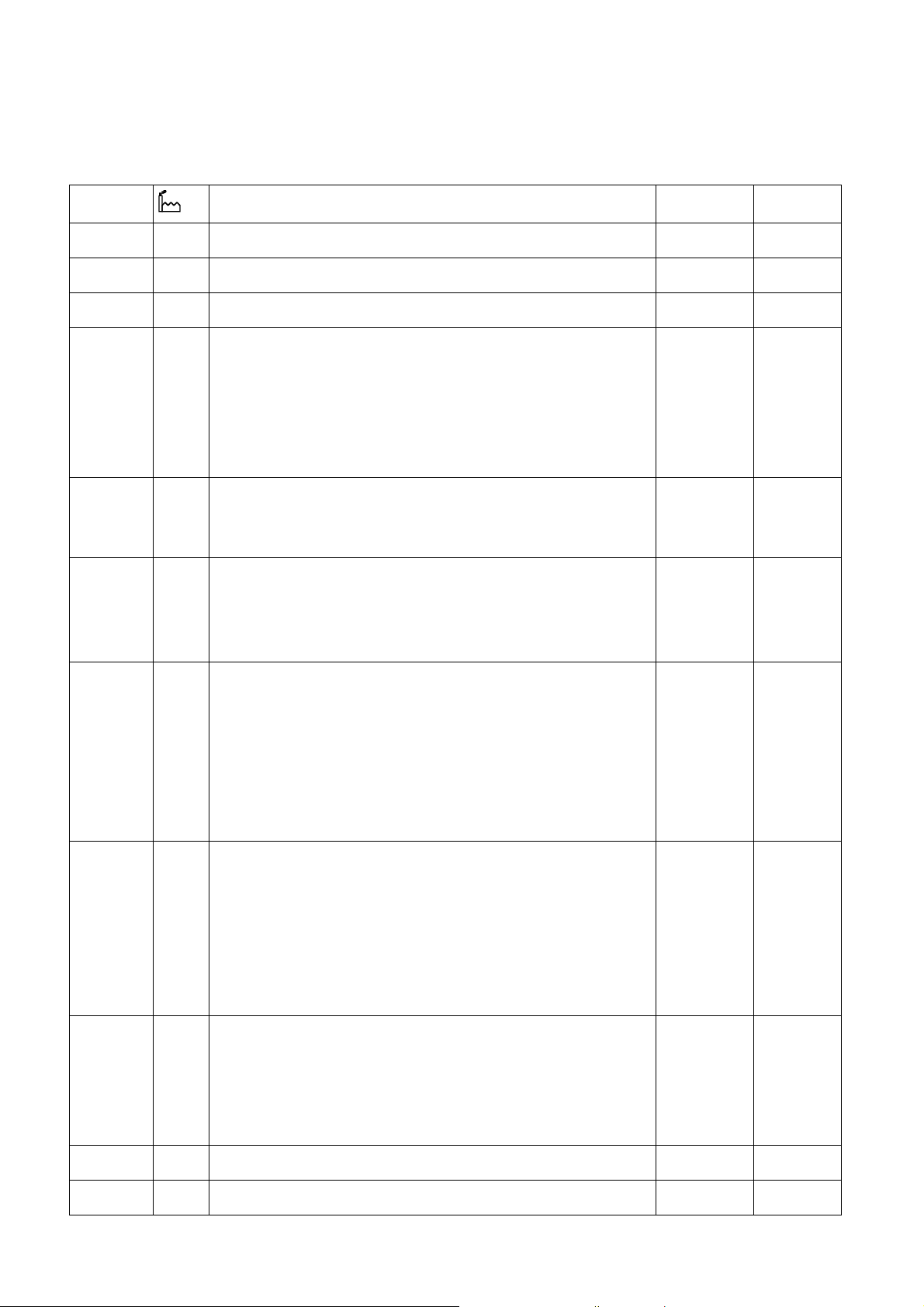

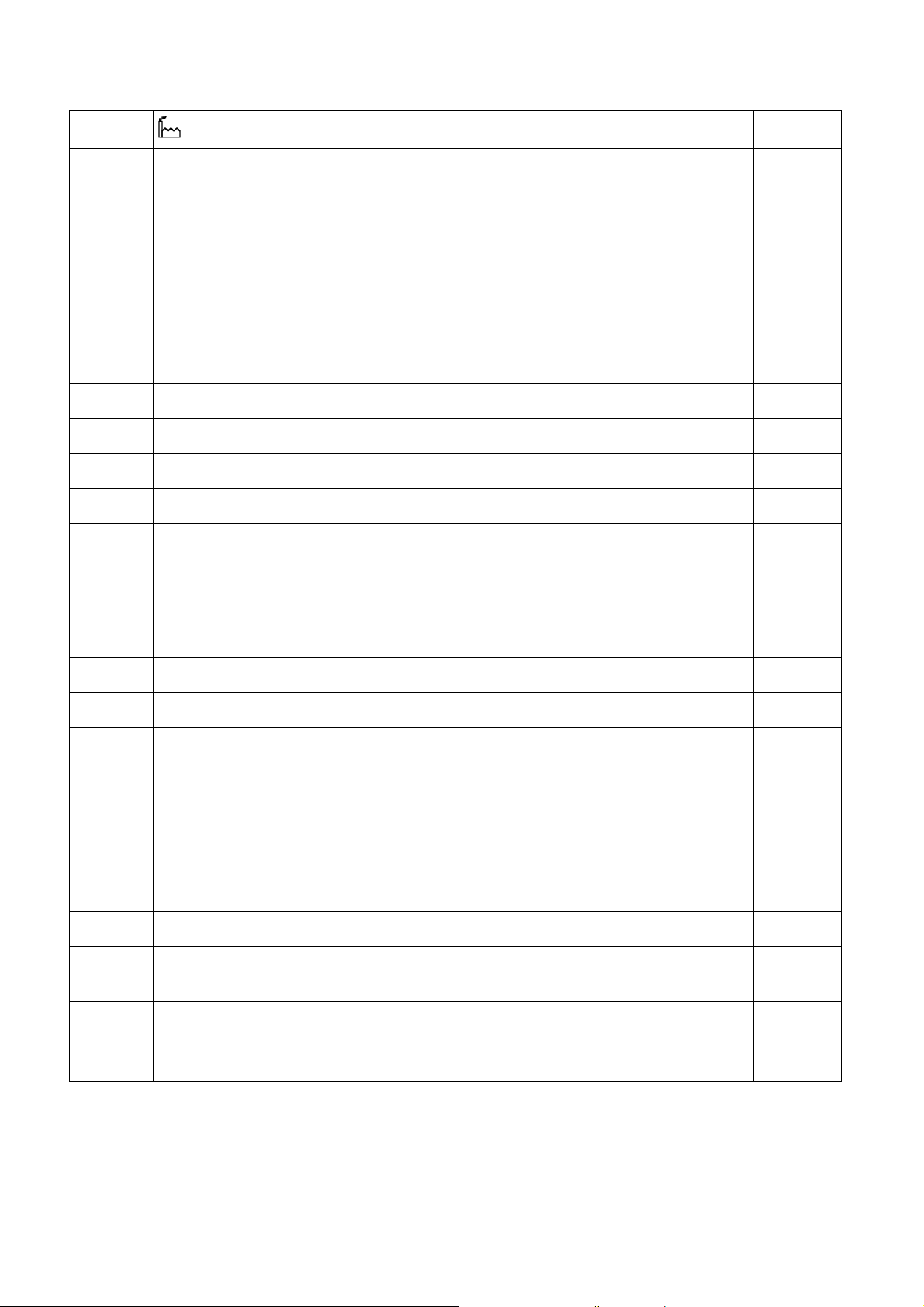

3.2.1 List of SERVice parameters

The following SERVice parameters can be reached on commissioning level.

Parameter

SP01 Software version Y.XX (read only)

SP06 1 Control model

SP15 40 Proportional band, PI controller in K 2...100 1

SP16 40 MOD3: Proportional band, PI controller in K (2nd control circuit) 2...100 1

SP19 120 Runtime for final control element in sec 30...960 15

SP20 180 Runtime for second final control element in sec

SP34 1 Functions for domestic hot water

Description Range Step value

0...3 1

1 = one control valve on the primary side

2 = one control valve on the secondary side

3 = two control valves on the primary side

30...960 15

MOD1, 2: for diverter valve (SP34 = 3 or 4)

MOD3: for second control valve

0…4 1

0 = not enabled.

1 = MOD 1, 2: with sep. charge pump using one DHW

sensor

2 = MOD 1, 2: with sep. charge pump using two DHW

sensors

3 = MOD 1, 2: with diverter valve using one DHW sensor

4 = MOD 1, 2: with diverter valve using two DHW

sensors

SP36 5 MOD 1, 2: Switching difference for domestic hot water in K 1...30 1

SP37 70 Maximum setpoint for increased DHW temperature/[°C] 10…90 1

SP38 10 Setpoint boost for domestic hot water in K 0…30 1

SP41 1.4 Slope of heating characteristic 0.2...5.0 0.1

SP60 0 Floor drying

Tab. 1: SERVice parameter

0 = not enabled. 7d = enabled. 8 = malfunction

9 = successfully completed

0.7d.8.9 0.7d. 8.9

An overview of the SERVice parameters and explanations for individual

SERVice parameters is given in these sections: 'List of SERVice parameters'

and 'Explanations for individual SERVice parameters'.

7010015003 A

© Fr. Sauter AG

17

EQJW145:

Commissioning

Heating controller

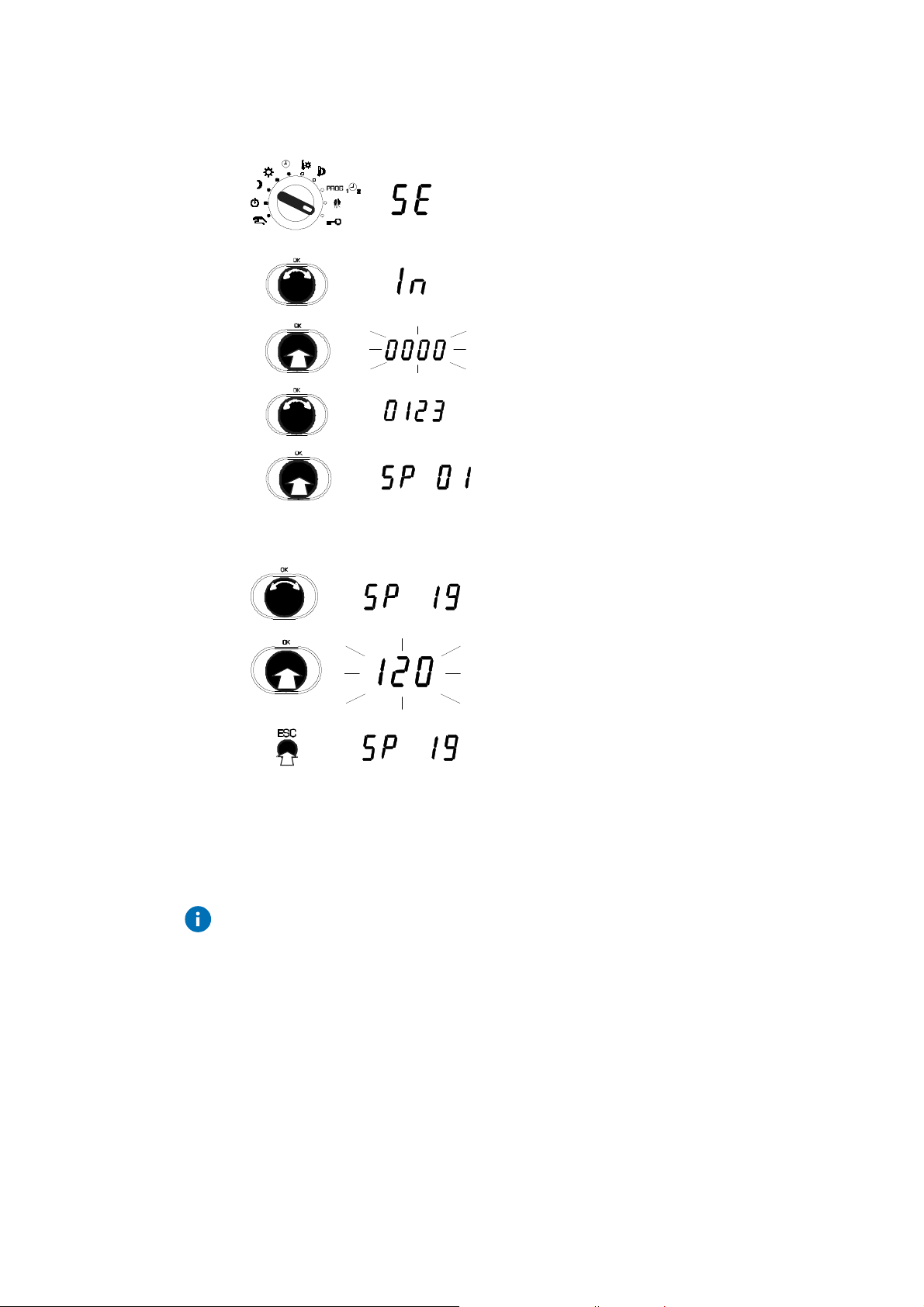

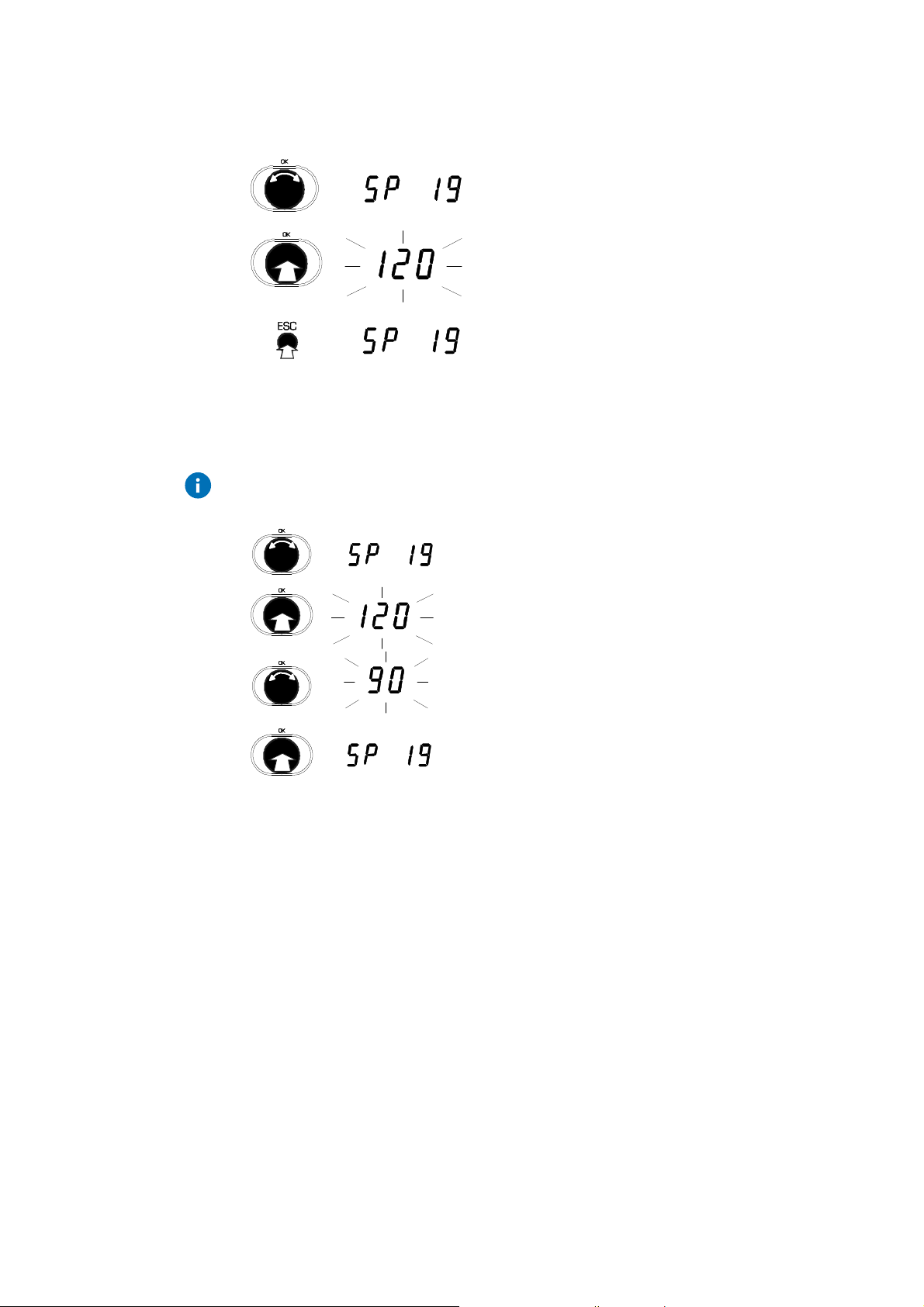

3.2.2 Access to commissioning level

1. Set the upper rotary switch to the Service

position.

2. Press the input knob, select 'In' (=

commissioning)

.

3. Press the input knob.

4. Turn the input knob,

show the code.

5. Press the input knob.

•

The first SERVice parameter is displayed.

3.2.3 View SERVice parameters

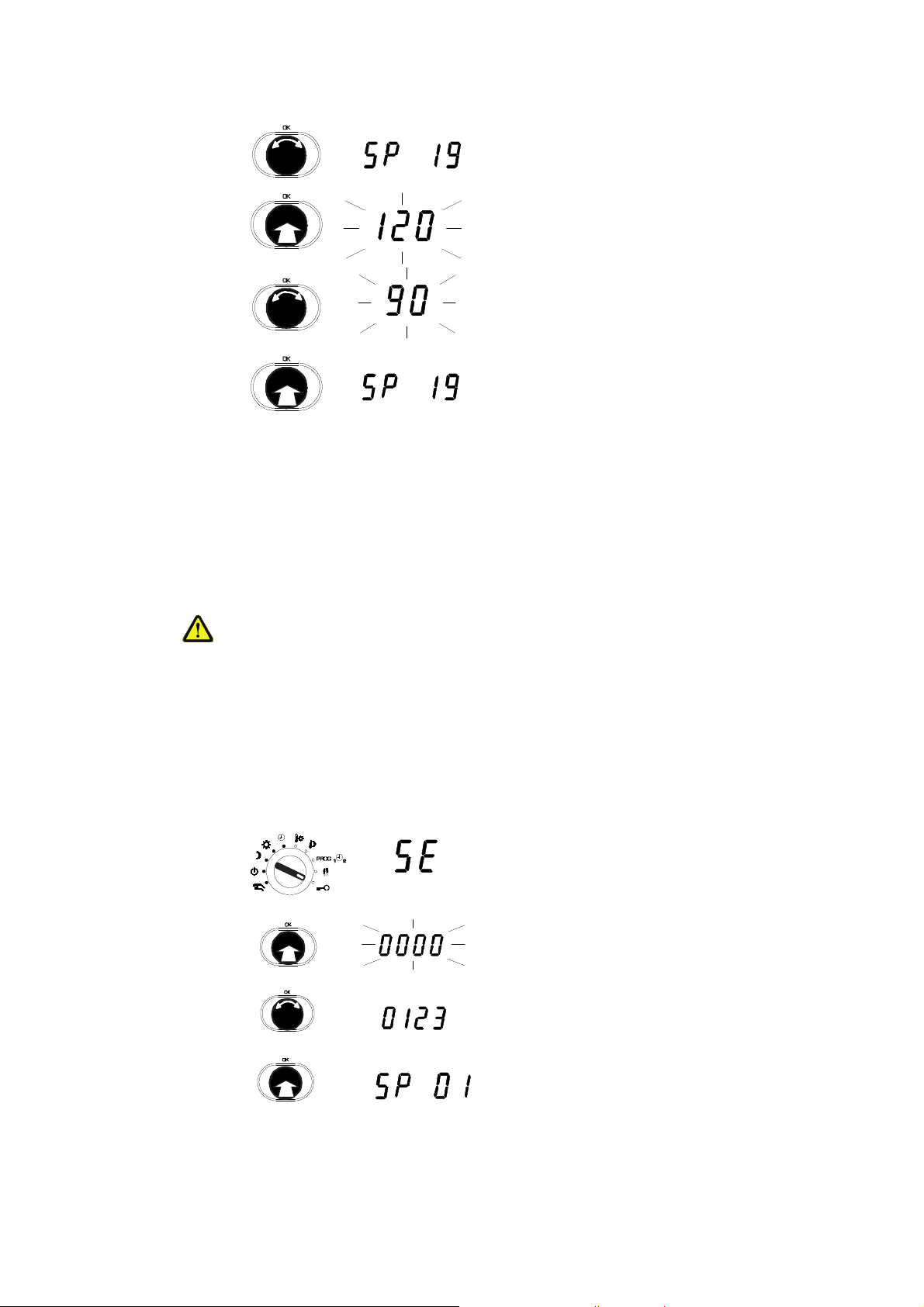

3.2.4 Change SERVice parameters

Press the ESC key to cancel the operation. The value is not accepted unless

it has already been confirmed.

1. Turn the input knob.

2. Select the SERVice parameter you want.

3. Press the input knob.

sec

•

The value of the parameter is shown.

4. To leave the value unchanged.

5. Press ESC to exit the display.

18 7010015003 A

© Fr. Sauter AG

EQJW145:

CAUTION!

Commissioning

Heating controller

3.3 SERVice level

1. Turn the input knob.

2. Select the SERVice parameter you want.

3. Press the input knob.

sec

•

The value of the parameter is shown.

Turn the input knob.

4.

•

sec

The value of the parameter is changed.

5. Press the input knob.

•

The new value is confirmed.

In SERVice level, a specialist can adapt the basic setting of the EQJW 145 to

the installation so as to meet specific requirements. For this purpose, also

please note the installation instructions enclosed with the EQJW 145

(MV506103).

Incorrect parameterisation (setting) of the heating controller

It can cause major faults on the installation, injuries to people or damage to

the installation.

SERVice mode must only be enabled by a specialist.

Some of the parameters cannot be changed - they can only be viewed

(version number, status information).

3.3.1 Access to SERVice level

1. Set the upper rotary switch to the Service

position.

2. Press the input knob.

7010015003 A

© Fr. Sauter AG

3. Turn the input knob.

4. Show the code.

5. Press the input knob.

6. The first SERVice parameter is displayed.

19

EQJW145:

Commissioning

Heating controller

3.3.2 View SERVice parameters

3.3.3 Change SERVice parameters

Press the ESC key to cancel the operation. The value is not accepted unless

it has already been confirmed.

1. Turn the input knob.

2. Select the SERVice parameter you want.

3. Press the input knob.

sec

•

The value of the parameter is shown.

4. To leave the value unchanged, press ESC to

exit the display.

sec

sec

1. Turn the input knob.

2. Select the SERVice parameter you want.

3. Press the input knob.

•

The value of the parameter is shown.

4. Turn the input knob.

•

The value of the parameter is changed.

5. Press the input knob.

•

The new value is confirmed.

20 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

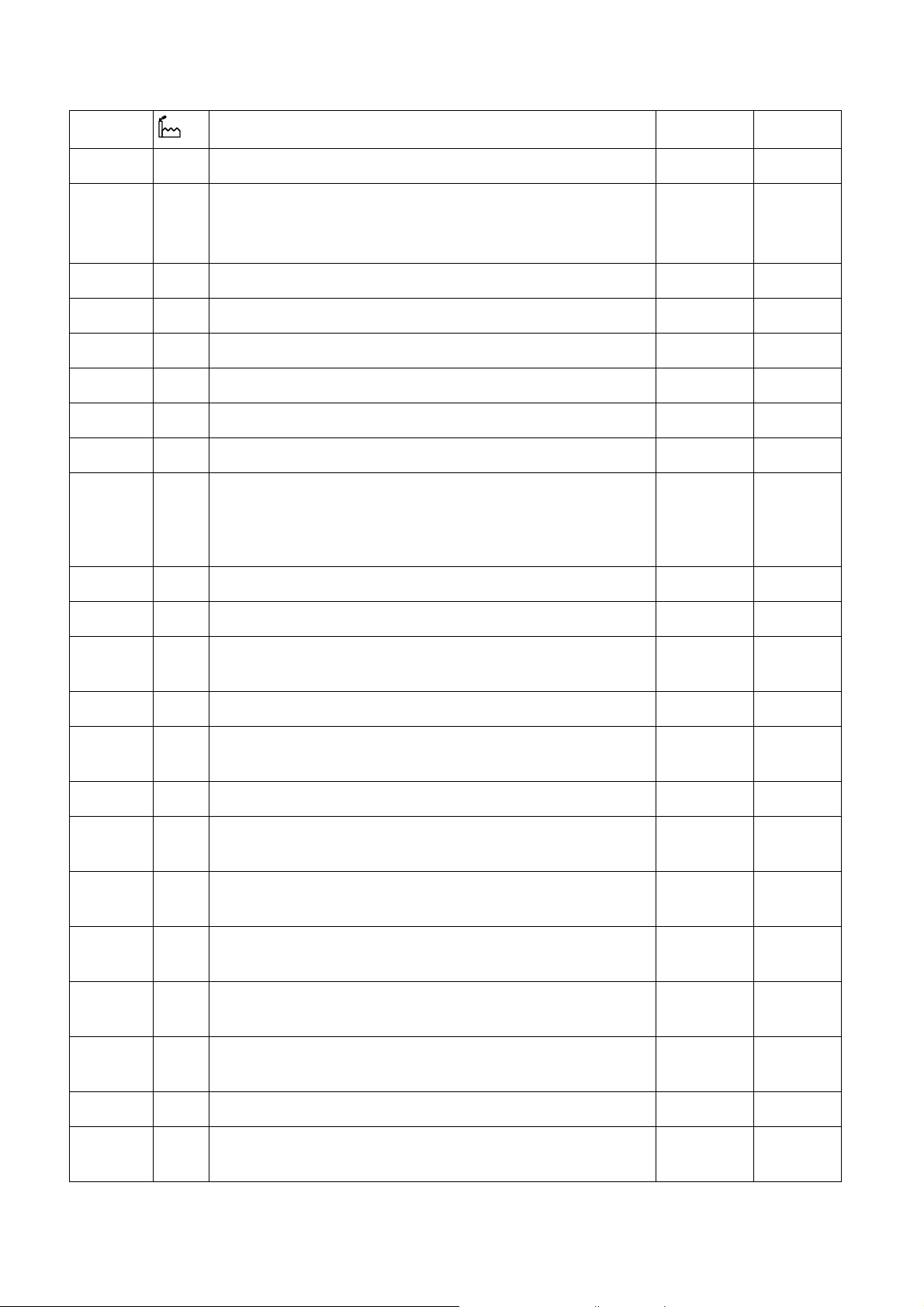

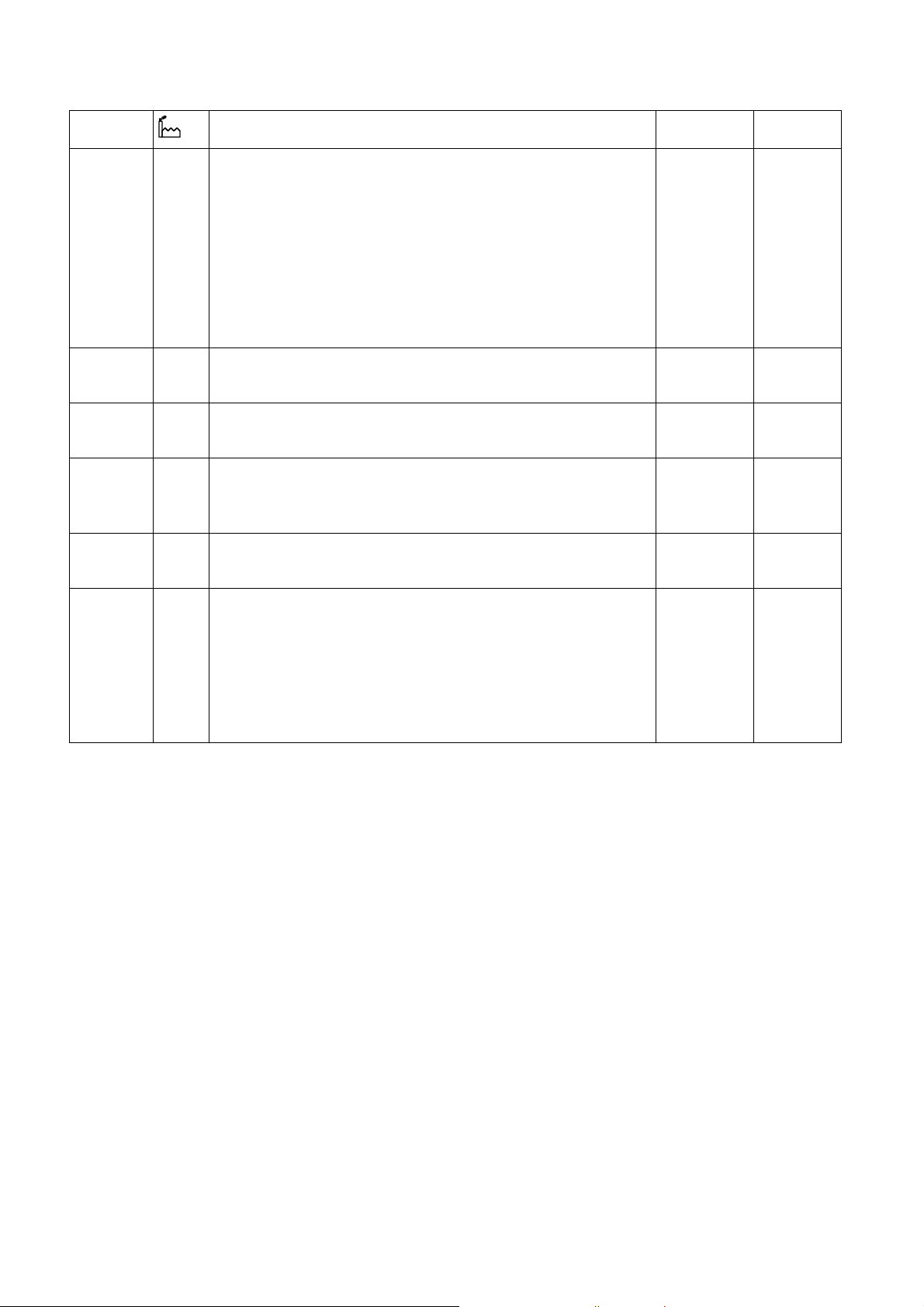

3.3.4 List of SERVice parameters

Parameter Description Range Step value

SP01 Software version Y.XX (read only)

SP02 0 Device status (error coding) (read only)

SP03 View logbook -

1

SP04 0 Software reset

0 = no Reset

1 = factory setting for SE + CO parameters

2 = factory setting for switching commands

3 = factory setting for SE- + CO parameters +

switching commands

SP05 0 Manual mode

0 = manual mode not enabled

1 = manual mode enabled

SP06 1 Control model

1 = one control valve on the primary side

2 = one control valve on the secondary side

3 = two control valves on the primary side

SP07 0 Effect of binary / pulse input (terminals 21, 22)

0 = HK in back-up mode if contact is closed.

1 = HK in reduced mode if contact is closed.

2 = HK in nominal mode if contact is closed.

3 = Pulse input for quantity metering

4 = Seepage limitation

5 = Input for fault signal

0...3 1

0...1 1

0...3 1

0…5 1

SP08 0 Room temperature recording

0 = no room temperature recording

1 = connect room sensor

2 = connect EGS52/15 or EGT 333 with room sensor

3 = connect EGS52/15 or EGT 333 without room

0...4 1

sensor

4 = MOD1,2: 2nd flow sensor for DHW (SP49 = 2)

SP09 0 Connect room temperature

0 = not enabled

1 = enabled if TRi> T

2 = enabled if T

3 = enabled if TRi <> T

Rs

Ri < TRs

Rs

0...3 1

SP10 20 Scanning time for room temperature if connected /[min] 1…100 1

SP11 0

7010015003 A

© Fr. Sauter AG

Correction to room temperature TRiin K

-6.0...+6.0 0.1

21

EQJW145:

Commissioning

Heating controller

Parameter Description Range Step value

SP12 0

SP13 0 Return temperature recording

SP14 0

Correction to outdoor temperature TAin K

0 = return temperature is not recorded

1 = return temperature is recorded

Correction to return temperature TRF (MOD3: TRF of heating circuit)

-10.0…+10.0 0.1

0…1 1

-10.0…+10.0 0.1

SP15 40 Proportional band, PI controller in K 2...100 1

SP16 40 MOD3: Proportional band, PI controller in K (2nd control circuit) 2...100 1

SP17 240 Reset time, PI controller in sec 5...1000 5

SP18 240 MOD3: Reset time, PI controller in sec (2nd control circuit) 5...1000 5

SP19 120 Runtime for final control element in sec 30...960 15

SP20 180 Runtime for second final control element in sec

30...960 15

MOD1, 2: for diverter valve (SP34 = 3 or 4)

MOD3: for second control valve

SP21 5

Minimum limitation for flow temperature TF (heating circuit) in °C

5 …100 1

SP22 75

SP23 90

Maximum limitation for flow temperature TF (heating circuit) in °C

Upper limit value for max. limitation of TRF during heating

20…150 1

5…150 1

in °C

SP24 90

SP25 0 Outdoor temperature at which the sliding part of the limit function for

Lower limit value for max. limitation of TRF during heating in °C

5…150 1

-30...+50 1

TRFbegins, in °C

SP26 1.0

SP27 90

Slope of limitation function for TRFin [K/K]

Maximum limitation for return temperature TRF during DHW

0.0…5.0 0.1

5…150 1

heating in °C

SP28 5 Intervention intensity if limit value for return temperature is violated in

0.1…10 0.1

[K/K]

SP29 no Limit value pulse/min for max. flow or power of heating and DHW no 0.1...16.0.

60...16000

SP30 no Limit value pulse/min for max. flow or power of heating only no 0.1...16.0.

60...16000

SP31 no Limit value pulse/min for max. flow or power of DHW only no 0.1...16.0.

60...16000

0.1/1/10

0.1/1/10

0.1/1/10

SP32 0.0 Intervention intensity in K/min if limit value for flow or power is violated 0.0…30.0 0.1

SP33 no Limit value pulse/min for min. flow or power no. 0.1...16.0.

0.1/1/10

60...16000

22 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

Parameter Description Range Step value

SP34 1 Functions for DHW

0 = not enabled.

1 = MOD 1, 2: with sep. charge pump using one

0…4 1

DHW sensor

2 = MOD 1, 2: with sep. charge pump using two

DHW sensors

3 = MOD 1, 2: with diverter valve using one DHW

sensor

4 = MOD 1, 2: with diverter valve using two DHW

sensors

SP35 60 Maximum setpoint for domestic hot water temp./[°C] 10…70 1

SP36 5 MOD 1, 2: switching difference for DHW in K 1...30 1

SP37 70 Maximum setpoint for increased DHW temperature/[°C] 10…90 1

SP38 10 Setpoint boost for domestic hot water in K 0…30 1

SP39 -30 Outdoor temperature limit value for operation of domestic hot water

-30…50 1

heating in °C

TA < limit value parallel operation

TA > limit value domestic hot water with priority

Note: only valid if value SP34 = 1 or 2

SP40 4 After-run time for charge pump for domestic hot water/[min] 0…20 1

SP41 1.4 Slope of heating characteristic 0.2...5.0 0.1

SP42 10 Setpoint boost for demand request via device bus/ [ K] 0…30 1

SP43 0.0 External heat portion/[K] 0.0...5.0 0.1

SP44 15 Heating limit/[°C] 0...39 1

SP45 1 Outdoor temperature recording for heating limit

0 = TA used unsmoothed for heating limit function

1 = smoothed TA is used for heating limit function

0…1 1

SP46 -16 Design temperature/[°C] -30...0 1

SP47 2 After-run factor for heating medium pump (after-run time = runtime for

1…10 1

final control element x after-run factor)

SP48 1 Anti-frost function

0 = not enabled

1 = enabled

0...1 1

7010015003 A

© Fr. Sauter AG

23

EQJW145:

Commissioning

Heating controller

Parameter Description Range Step value

SP49 0 Configurable output

0 = no function

1 = pilot timer function

2 = 2nd tank charge pump (MOD1, 2 only)

3 = forced control of heating medium pump at low

0…5 1

speed in reduced and back-up mode

4 = collective fault alarm

5 = circulating pump

SP50 0 Pump anti-jamming facility

0 = not enabled. 1 = enabled

0…1 1

SP51 25.10 Summer/winter time changeover 01.01 ...

31.12

SP52 25.03 Winter/summer time changeover

SP51 = SP52 means no summer/winter time

01.01 ...

31.12

changeover

SP53 0 Optimisation

SP60 0 Floor drying

0 = not enabled. 1 = enabled

0 = not enabled

7d = functional heating

25°C = ready-for-laying heating

8 = malfunction

9 = successfully completed

0…1 1

0.7d.25°C.8.9 0.7d.25°C.8

Tab. 2: SERVice parameter

.9

24 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

3.3.5 Explanations for individual SERVice parameters

SP01

SP02

SP03

SP04

View software version

The controller's software version number is shown.

View device status

SERVice parameter 2 allows you to read the device status of the EQJW 145.

Value 0 means that the EQJW 145 is operating without faults. The coding for

faults is shown in section7.1.2. Once the fault is rectified, the value for the

SERVice parameter is reset automatically.

Note: this coded error description is primarily used to signal faults via bus,

modem or SMS. Faults can be conveniently read directly from the ERROR

display on the controller (see7.1).

Logbook

This is not a parameter but an indicator for the logbook, in which the date,

time and type of fault is entered for every fault that occurs during operation.

Further information on this function can be found in section 7.2.

Software reset

Switching commands and/or SERVice or communication parameters are

returned to the factory setting. To do this, the value of the SERVice

parameter must be changed and confirmed. After this, the EQJW 145

performs the relevant reset and assigns value 0 to the parameter.

SP05

SP06

Manual mode

SERVice parameter SP05 is used to disable or enable manual mode. If the

value of the parameter is 0, manual mode is disabled.

Control model

Various control models are stored in the EQJW 145. Use this parameter to

specify the model that the EQJW 145 uses as the basis for control. The

following control models are available for selection.

MOD1: one control valve on the primary side

(SP06 =1)

MOD2: one control valve on the secondary side (SP06 = 2)

MOD3: two control valves on the primary side (SP06 = 3)

With MOD1 and MOD2, it is possible not only to control a heating circuit but

also to prepare DHW. SERVice parameter 33 can be used to configure the

DHW preparation.

With MOD3, the second control valve on the primary side is used for fixedvalue control (e.g. for DHW preparation). The assignment of TF2 or T

RF2

to

the appropriate terminal is done automatically (see wiring diagram). More

information about the control models and the most important applications is

given in the section on 'Information on applications'.

7010015003 A

© Fr. Sauter AG

25

EQJW145:

Commissioning

Heating controller

SP07

Effect of binary / pulse input (terminals 21, 22)

If the external switching contact is closed, this SERVice parameter can be set

appropriately (SP07 = 0, 1 or 2) to influence the heating programme, as long

as the controller is in automatic mode. If the contact is opened again, the

controller will operate according to the weekly / calendar switching

programme again and the following apply:

0 = HK in back-up mode if contact is closed

1 = HK in reduced mode if contact is closed

2 = HK in nominal mode if contact is closed

Alternatively, the input can be used for quantity metering (and therefore for

quantity limitation as well), to limit see page or to forward a fault signal (using

a modem via SMS or via the configurable relay output to another device). For

SP07, the values mean:

3 = input used as pulse input for quantity metering

4 = input used to limit seepage

The minimum flow can be limited. A signal from the auxiliary contacts of a

control unit can be used to do this. If the contact input is closed, the valve

on the primary side closes and is not opened again until the setpoint for

the flow temperature is 5K higher than the actual value.

5 = input is a fault signal input, used to forward fault signals from other

devices

SP08

Room temperature recording

Various types of room temperature sensor can be connected:

0 = no room temperature recording

1 = connect room sensor

2 = connect EGS52/15 or EGT333 with room sensor

3 = connect EGS52/15 or EGT333 without room sensor

4 = only for MOD1,2 with second tank charge pump (SP49 = 2): the

analogue input (terminal 28) is not used as a room sensor but as a second

flow sensor for DHW preparation (also see the section on 'Application

examples').

Room operating unit EGS52/15 allows you to switch over the controller's

mode remotely. Room operating unit EDB100 can also be connected via the

device bus and used to switch the mode over. The mode on the EQJW145

can also be changed using a control station via Modbus. In case of

contradictory commands, the following priority applies: direct settings on

EQJW145 have priority 1. A setting using room operating unit EDB100 via

device bus or a preset via Modbus have priority 2. The setting via the binary

input has priority 3. Settings on room operating unit EGS52/15 have the

lowest priority. If the setpoint for the room temperature is changed via the

setpoint transmitter of the EGS 52/15 or EGT 333 room operating units, it

also changes the actual value for the room temperature at the sensor input of

26 7010015003 A

© Fr. Sauter AG

EQJW145:

Commissioning

Heating controller

the EQJW 145. This, in turn, means that the flow temperature and, therefore,

the heating capacity, for the room are altered accordingly.

SP09

SP10

Connect room temperature

A room temperature sensor (resistance sensor or device bus) is required for

this function. The flow temperature setpoint is changed – in divergence from

the setpoint according to the heating characteristic – if the room temperature

in the reference room diverges from the room setpoint. The change in flow

temperature is limited to a maximum of ± 30K.

SP09 = 1 or 2 can be used to allow the room temperature connection to

influence the flow setpoint in one direction only. The meanings are:

0 = flow temperature is not changed, i.e. the room temperature connection

is not enabled

1 = flow setpoint can only be reduced, i.e. the room temperature

connection is only enabled if TRi> T

2 = flow setpoint can only be increased, i.e. the room temperature

connection is only enabled if TRi< T

3 = flow setpoint can be reduced and increased, i.e. the room temperature

connection is enabled if TRi<> T

Rs

Rs

Rs

Scanning time for room temperature if connected

If the room temperature connection is enabled, this SERVice parameter

determines the period within which a one-off adaptation of the flow setpoint

can occur. In "heavy" buildings with sluggish heating systems, a higher value

is more suitable than it would be for buildings of lightweight construction and

heating that reacts quickly. This time must not be too short, so as to prevent

control fluctuations. The algorithm prevents hunting by changing the flow

setpoint more quickly (at a rate of ±2 K within a scanning period) when the

deviation of the room temperature is diminishing than when it is increasing (at

a rate of ±1 K within a scanning period). If the deviation of the room

temperature is less than 0.25 K, the flow setpoint is not altered. In most

cases, the factory setting (20 minutes) provides satisfactory results for

residential buildings. As a general rule, the factory setting (20 minutes) leads

to satisfactory results in residential buildings.

SP11

SP12

7010015003 A

© Fr. Sauter AG

Open windows or other cooling or heating loads can influence control!

Sudden removal of these influences can lead to the value moving above or

below the room temperature in the opposite direction for short periods!

Correction to room temperature

The measured value for the room temperature is calibrated with the help of

this SERVice parameter. The value that was entered is added to the

measured value for the room temperature.

Correction to outdoor temperature

The measured value for the outdoor temperature is calibrated with the help of

this SERVice parameter. The value that was entered is added to the

measured value for the outdoor temperature.

27

EQJW145:

Commissioning

Heating controller

SP13

SP14

SP15

SP16

SP17

SP18

Return temperature recording

If a return temperature sensor is to be used, this parameter must be set to 1.

Correction to return temperature

The measured value for the return temperature is calibrated with the help of

this SERVice parameter. The value that was entered is added to the

measured value for the return temperature. If there are two return sensors

(MOD3), this parameter only affects the TRF of the heating circuit.

Proportional band

SERVice parameter 15 specifies the proportional band (XP) of PI control for

the flow temperature in K.

Proportional band – 2nd control circuit (only MOD3)

SERVice Parameter 16 specifies the proportional band (XP) of PI control for

the second control circuit in K.

Reset time

SERVice parameter 17 specifies the reset time (TN) of PI control for the flow

temperature in seconds.

Reset time – 2nd control circuit (only MOD3)

SERVice parameter 18 specifies the reset time (TN) of PI control for the

second control circuit in seconds.

SP19

SP20

SP21, 22

SP23 – SP27

Runtime for actuator of control valve

Valves with a motorised actuator need a specified time to open or close

completely. This is known as the valve runtime. This SERVice parameter is

used to set the equitherm

EQJW 145 to the runtime of the valve drive that is

used. Optimal control quality and various protective functions are only

ensured if the valve runtime is set correctly.

Runtime for second actuator

Depending on the control model, a second control valve is used on the

primary side, or a changeover valve is used on the secondary side. SERVice

parameter SP20 is used to set the valve runtime for the second actuator.

Minimum and maximum limits for flow temperature

The setpoint for the flow temperature can be limited. The value of SERVice

parameter SP21 sets the lower limit in this case, and the value of SERVice

parameter 22 sets the upper limit. Parameters SP21 and SP22 specify a

minimum and maximum flow temperature.

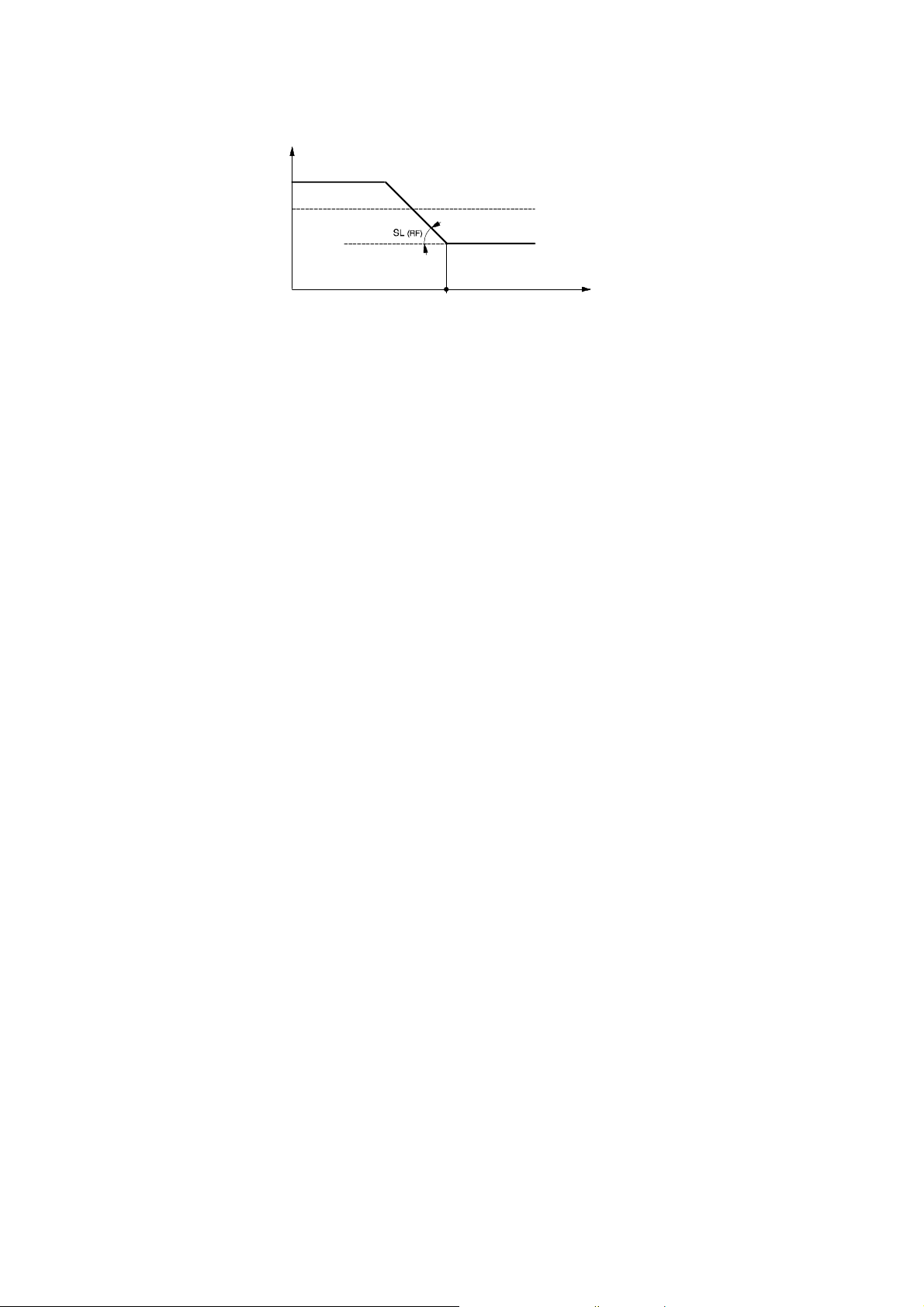

Limiting function for the return temperature

A limiting function can be set for the primary-side return temperature of the

converter. If the value falls below the limiting function, the flow temperature is

adjusted (also see SP28). The following illustration shows the limiting

function.

28 7010015003 A

© Fr. Sauter AG

EQJW145:

T

T

L 0BW (R F)

A

Commissioning

Heating controller

R F ma x.

T

L 0 ( RF )

T

L U ( R F)

T

A (R F)

Fig. 4: Limitation function

T

B 1 098 0

The following parameters are available to set the limiting function:

SP23

SP24

SP25

Upper value of maximum limit for primary return temperature

(T

) for heating.

LO(RF)

Lower value of maximum limit for primary return temperature

(T

Outdoor temperature (T

) for heating.

LU(RF)

) at which the sliding portion of

A(RF)

the limiting function for the primary return temperature starts

during heating.

SP26

Slope (S

) of the sliding portion of the limiting function for

L(RF)

the primary return temperature for heating.

SP27

Maximum limit (T

LOBW(RF)

) for the primary return temperature

during DHW heating.

In MOD1 or MOD2, if the heating is in reduced or normal mode and DHW

heating occurs at the same time, the maximum limit value for the primary

return temperature is checked with the outdoor-temperature-dependent value

for the heating circuit and the fixed value for the DHW during this time.

SP 28

7010015003 A

© Fr. Sauter AG

To make the return temperature limitation effective, return temperature

recording must be enabled (see SP13). In summer mode, or if the heating is

in back-up mode, the limitation on the return temperature for the heating is

not enabled.

Intervention intensity if return temperature is exceeded

If the limiting function for the return temperature set with SP23-SP27 is

exceeded, the setpoint for the flow temperature is reduced by the value

indicated in SP28 for each degree of the excess.

29

EQJW145:

Commissioning

Heating controller

SP29 - SP31

Maximum limit values for quantity metering

SP29, SP30 and SP31 specify maximum limit values for quantity metering

(i.e. usually for the flow or heat quantity/power). SP29 defines the maximum

limit value for heating and DHW, SP30 only defines this value for the heating

and SP31 only defines it for DHW. The value is always entered in units of

'pulses per minute'. See the following examples of converting the limit value

for the flow volume or power to the 'Pulses per minute' variable.

Example 1:

The flow volume should be limited to 1.6 m³ / hour.

The flow sensor transmits a signal of 50 pulses / litre.

The following conversion: 1.6 m³ / hour = 1,600 litres / hour and 1600 litres /

hour = 26.67 litres / minute, and the flow sensor variable of 50 pulses / litre,

give a limit value that must be entered on the EQJW145 (SP29, SP30 or

SP31) of 26.67 litres / min x 50 pulses / litre = 1333 pulses / min.

Example 2:

The power in heating mode should be limited to 35kW. With simultaneous

heating operation and DHW heating, 50 kW should be allowed. A heat

quantity meter is available which outputs 1200 pulses / kWh.

The following conversion: 35 kW = 35 kWh / h and the given variable for the

heat quantity meter provide 35 kWh / h x 1200 pulses / kWh = 42,000 pulses

/ h. This gives a value that must be entered on the EQJW145 of 42,000

pulses / h = 42,000 : 60 pulses / min = 700 pulses / min. The second limit

value is 50 kW. The same conversion: (50 kWh / h x 1200 pulses / kWh x 1h

/ 60 min = 1000 pulses / min) gives a value of 1000 pulses / min that must be

entered in the EQJW145. In the EQJW145, a value of 1000 should be

assigned to SP29 and a value of 700 to SP30.

The EQJW145 switches automatically between the following two measuring

methods.

measurement of time interval (time interval measurement) between two

pulses and calculation of the 'pulses per minute' variable

measurement of the number of pulses per minute (pulse measurement) .

If the three set limit values (SP29 to SP31) are in the range 0.1 - 16.0, the

EQJW145 automatically switches over to time interval measurement. If a

value between 60 and 16.000 is entered for one of SERVice parameters

SP29 to SP31, the controller switches over automatically to pulse

measurement.

30 7010015003 A

© Fr. Sauter AG