Page 1

Heating and hot water for the professionals

Installation and Servicing Instructions

THEMA F

IN WARRANTY

THIS IS A CAT II2H3+ APPLIANCE

TECHNICAL HELPLINE

01773 828400

01773 828100

1

Page 2

INSTALLATION AND SERVICING INSTRUCTIONS

THEMA F 23 E - THEMA F SB 18 E - THEMA F SB 23 E

Note!

The boiler serial number is marked on the label attached to the inside of the boiler. Refer to the

'Introduction' section page 3 for a description of the basic functions of the boiler. To safely operate

the boiler, refer to the Users Instructions.

INSTALLATION SECTION

Introduction.................................................. Page 3

Dimensions ............................................................. 3

Technical data ................................................. 4 - 5

Boiler schematic .................................................... 6

Fixing jig .................................................................. 7

Domestic hot water system design..................... 7

Heating system design ......................................... 8

Piping system installation...................................... 8

Boiler location ........................................................ 9

Boiler installation .................................................. 10

Rear outlet flue installation ......................... 11 - 12

Top outlet flue installation .................................. 13

Electrical connection ......................................... 14

Commissioning ............................................. 15 - 16

Safety devices ..................................................... 16

Settings.................................................................. 17

Changing gas type ............................................. 17

SERVICING SECTION

Routine cleaning and inspection .... Page 18 - 19

Replacement of parts ................................. 19 - 24

Microswitch assembly ......................................... 19

Fan ......................................................................... 19

Air pressure switch ............................................... 19

Spark generator................................................... 19

Main printed circuit board ................................. 19

Ignition printed circuit board............................. 20

Pump ..................................................................... 20

Temperature/Pressure gauge............................ 20

Reversing valve assembly .................................. 20

Reversing valve front section ............................ 21

Loss of water switch ............................................ 21

Water valve or diaphragm ................................ 21

Gas valve ............................................................. 22

Modulating coil ................................................... 22

Central heating safety valve ............................. 23

Heat exchanger .................................................. 23

Expansion vessel .................................................. 23

Boiler thermistor ................................................... 23

Overheat thermostat .......................................... 24

Combustion chamber insulation....................... 24

Ignition electrode ................................................ 24

Flame sense electrode ....................................... 24

Burner .................................................................... 24

Burner injectors .................................................... 24

Timeclock ............................................................. 24

Schematic wiring diagram ................................ 25

Fault finding................................................... 26 - 27

Spare parts ........................................................... 27

Mandatory warning notice for CEE countries

UK

WARNING, this appliance is designed, approved and inspected to meet the requirements of the

English market. The identification plate located on the inside of the appliance certifies the origin where the

product was manufactured and the country for which it is intended.

If you see any exception to this rule, please contact your nearest Saunier Duval dealer.

Thank you in advance for you assistance.

2

Page 3

INTRODUCTION

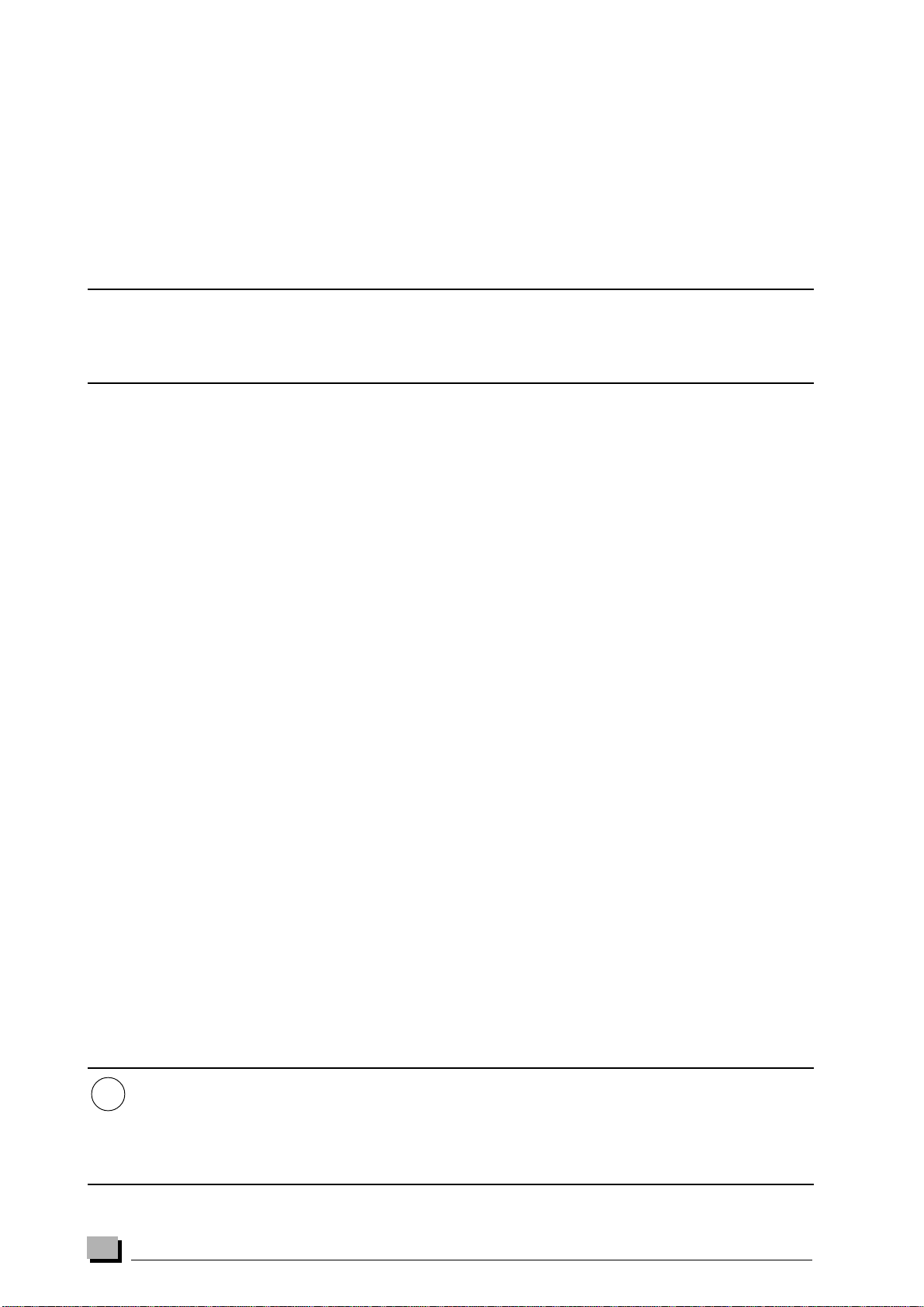

The THEMA F 23 E boiler is a wall mounted modulating combination boiler with electronic ignition providing central heating and instantaneous domestic hot water.

Both the central heating and domestic hot water

temperature are user adjustable from the boiler

control panel.

Domestic hot water demand always has priority

over heating demand.

The

THEMA F SB 18 E and SB 23 E

mounted modulating boilers with electronic ignition providing central heating only.

The central heating temperature is user adjustable

from the boiler control panel.

The boilers are of the II2H3+ category for use with

Natural Gas (G20) as distributed in the United Kingdom, or with Butane or Propane gas (G30/G31) with

the appropriate conversion kit.

Conversion kits:

Conversion Part No.

Natural Gas (G20) to G30/G31 86161

Boilers burning LPG or similar gases MUST NOT be

fitted in basements or below ground level.

The boiler has a fan assisted balanced flue which

both discharges the products of combustion to and

draws the combustion air from the outside air.

boilers are wall

The boiler is supplied for rear outlet flue connection. Alternatively, the boiler is designed to allow

the flue system to be connected to the top of the

boiler, top outlet flue connection. Refer to the flue

fitting instructions.

Electrical components have been tested to meet

the equivalent requirements of BEAB.

The boiler is designed for use as part of a sealed

water central heating system with fully pumped

circulation. The pump, expansion vessel and associated safety devices are all fitted within the boiler.

The boiler can be installed against either an external wall or on an adjacent inside wall, that is, the

flue system will pass directly to the rear or to either

side to the terminal fitted on the outside wall face.

The installation must be carried out by a competent person in accordance with the relevant requirements of The Building Regulations, The Water

Byelaws, The Building Standards (Scotland) Regulations and any applicable local regulations.

Ancillary equipment

A range of flue accessories are available including vertical flues, twin-pipe flues, bends etc.

For further information contact your supplier.

Diagram 1

THEMA F 23 E

DIMENSIONS

Diagram 2

The boiler is delivered in three

separate packages:

- The boiler

- The fixing jig

- The flue system

Net weight: 41 kg

Gross weight : 43 kg

THEMA SB 18 E and SB 23 E

234

802

623

857

410

378

Hab 271a

3

Page 4

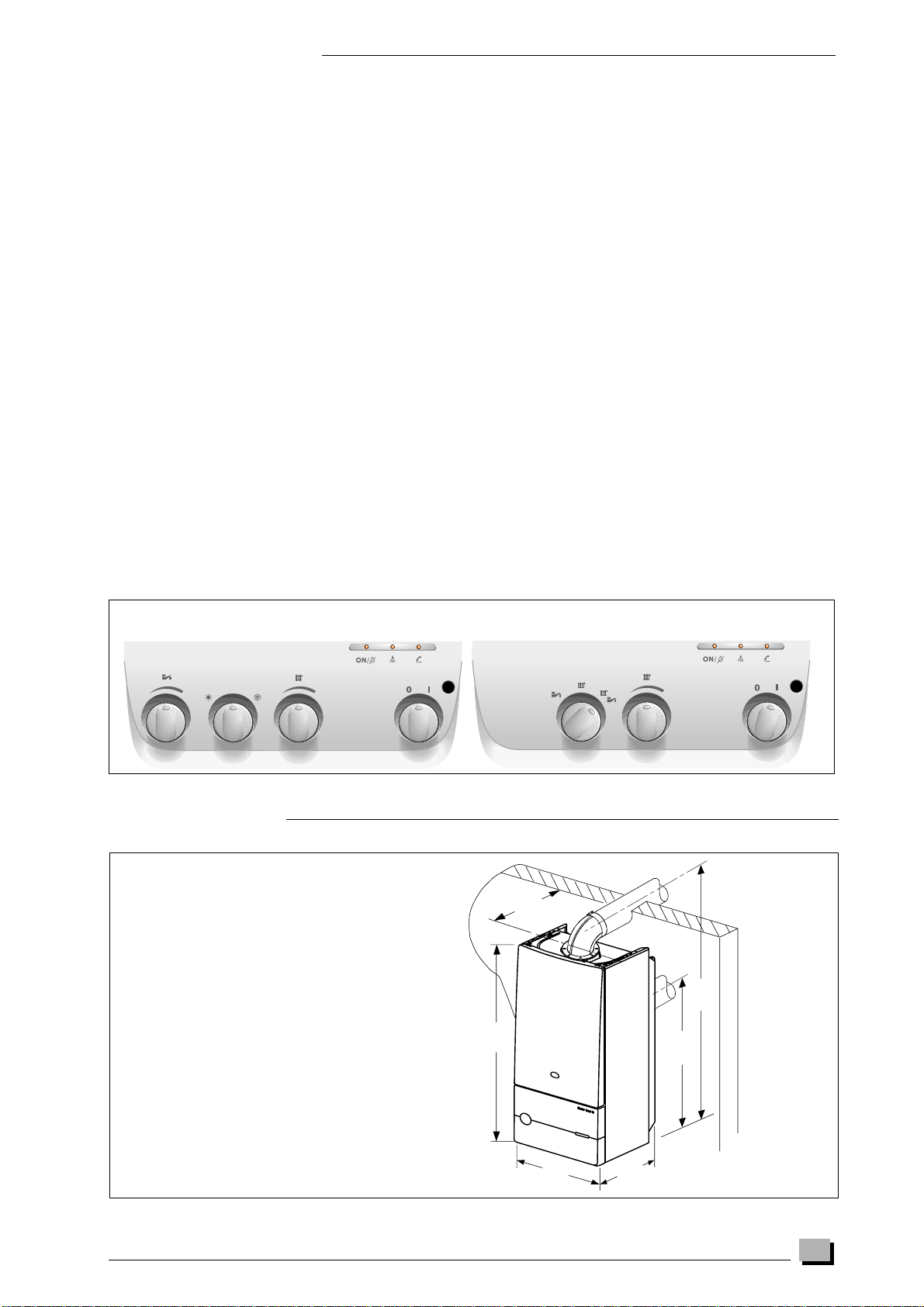

TECHNICAL DATA

THEMA F 23 E

THEMA F SB 18 E

Heating output automatically variable from (kW) 8,9 8,9 8,9

Efficiency (%) 91,5 90,5 91,5

Heating adjustment 38°C to 90°C

Expansion vessel effective capacity (l) 6,5 6,5 6,5

Expansion vessel charge pressure (bar) 0,5 0,5 0,5

Maximum system capacity at 75°C (l) 160 160 160

Safety valve, maximum service pressure (bar) 3 3 3

Products outlet diameter ( mm) 60 60 60

Fresh air inlet diameter (mm) 100 100 100

Hot water output automatically variable from (kW) 8,9 — —

Maximum hot water temperature (°C) 65 — —

Specific flow rate (for 30°C temp rise) ( l/min) 9,6 — —

Threshold flow rate (l/min) 3 — —

Nominal water flow rate (l/min) 12 — —

Maximum supply pressure (bar) 10 — —

Minimum operating pressure (bar) 0,5 — —

Electrical supply (V) 230 230 230

Maximum absorbed power (W 150 150 150

(BTU/H) 30,000 30,000 30,000

to (kW) 23,3 18,5 23,3

(BTU/H) 80,000 63,000 80,000

(BTU/H) 30,000 — —

to (kW) 23,3 — —

(BTU/H) 80,000 — —

THEMA F SB 23 E

Burner injector mm 1,20 1,20 1,20

Inlet pressure mbar 20 20 20

Diaphragme mm — — —

(G20)

Gas rate (maximum) m3/h 2,70 2,17 2,70

Natural Gas

Butane

Propane

Town gas

Gas rate (minimum) m3/h 1,13 1,13 1,13

Burner injector mm 0,73 0,73 0,73

Inlet pressure mbar 29 29 29

Diaphragme mm 4,8 3,2 4,8

(G30)

Gas rate (maximum) kg/h 2,01 1,62 2,01

Gas rate (minimum) kg/h 1,13 1,13 1,13

Burner injector mm 0,73 0,73 0,73

Inlet pressure mbar 37 37 37

Diaphragme mm 4,8 3,2 4,8

(G31)

Gas rate (maximum) kg/h 1,98 1,60 1,98

Gas rate (minimum) kg/h 0,97 0,97 0,97

Burner injector mm 2,4 2,4 2,4

Inlet pressure mbar 8 8 8

Diaphragme mm — — —

(G130)

Gas rate (maximum) m3/h 3,88 3,88

Gas rate (minimum) m3/h 1,63 1,63 1,63

4

Page 5

TECHNICAL DATA

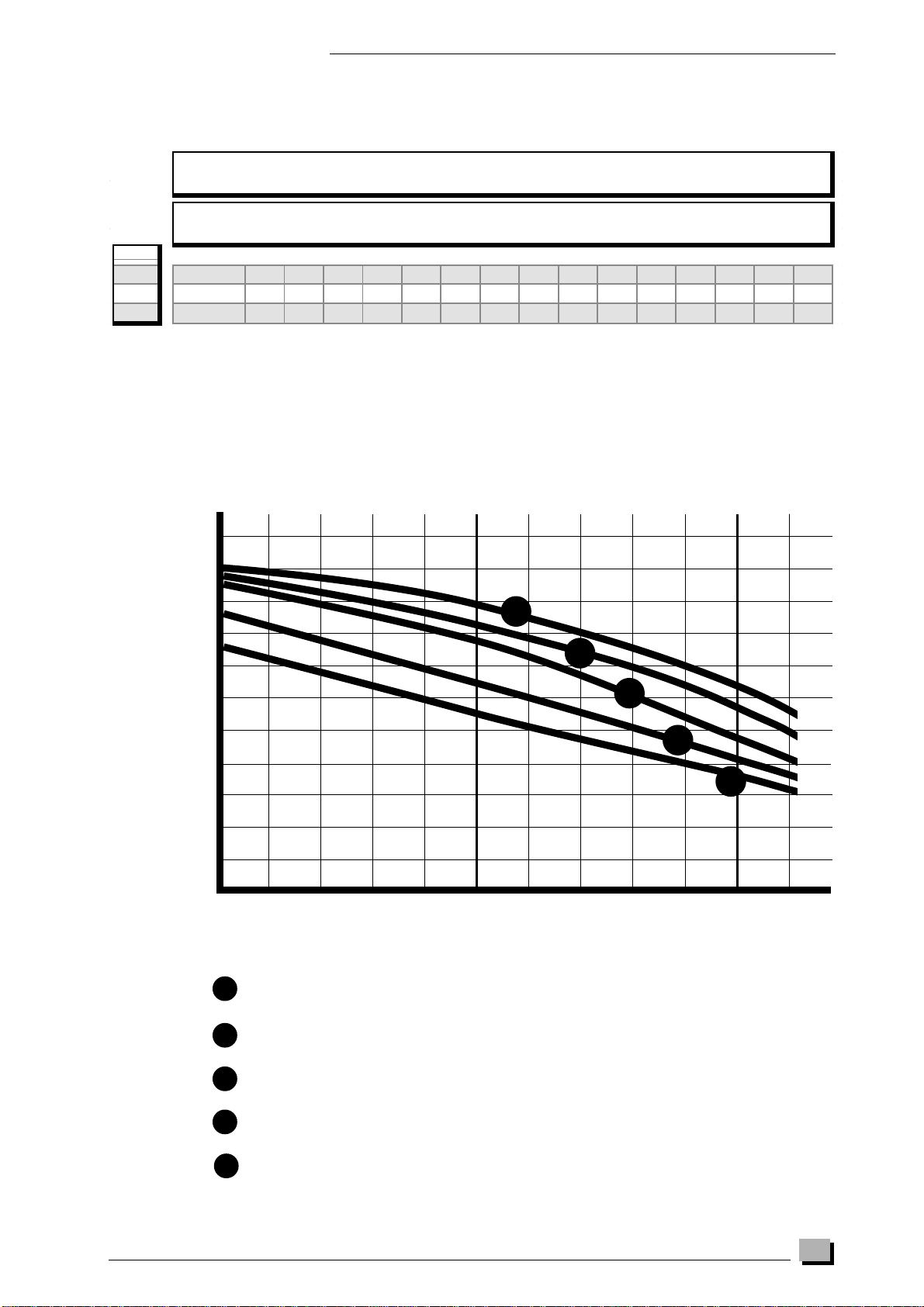

Pressure table :

(kW) 8,9 10 11 12 13 14 15 16 17 18 19 20 21 22 23,3

(Btu/h) 30387 34142 37557 40971 44385 47799 51214 54628 58042 61456 64871 68285 71699 75113 79552

(kW) 11,9 13,2 14,4 15,7 16,9 18,1 19,2 20,4 21,5 22,7 23,8 24,9 26,0 26,9 28,3

(Btu/h) 40678 45130 49332 53481 57579 61627 65626 69575 73477 77333 81142 84906 88913 91713 96602

GAS

G 20 (mbar) 1,3 2,1 2,6 3,0 3,5 4,0 4,5 5,1 5,7 6,3 6,9 7,6 8,3 8,8 9,8

G 30 (mbar) 3,7 5,3 6,3 7,4 8,6 9,8 11,1 12,5 13,9 15,5 17,0 18,6 20,4 21,7 24,1

G 31 (mbar) 4,0 6,3 7,5 8,8 10,2 11,7 13,3 14,9 17,2 20,1 20,3 22,2 24,4 26,0 28,8

Pump :

The performance of the pump varies according to the pump bypass setting, see diagram 3.

Heat output

Heat input

50

40

30

flow and return

20

10

Available pressure (kPa) between heating

0

(10 kPa = 1 m WG)

Diagram 3

Bypass fully shut

1

Open 1/4 turn

2

1

2

3

4

5

Pom 052

500 1000

Flow rate through heating system (I/h)

Open 1/2 turn

3

4

Open 1 turn

5

Open 2 turns

5

Page 6

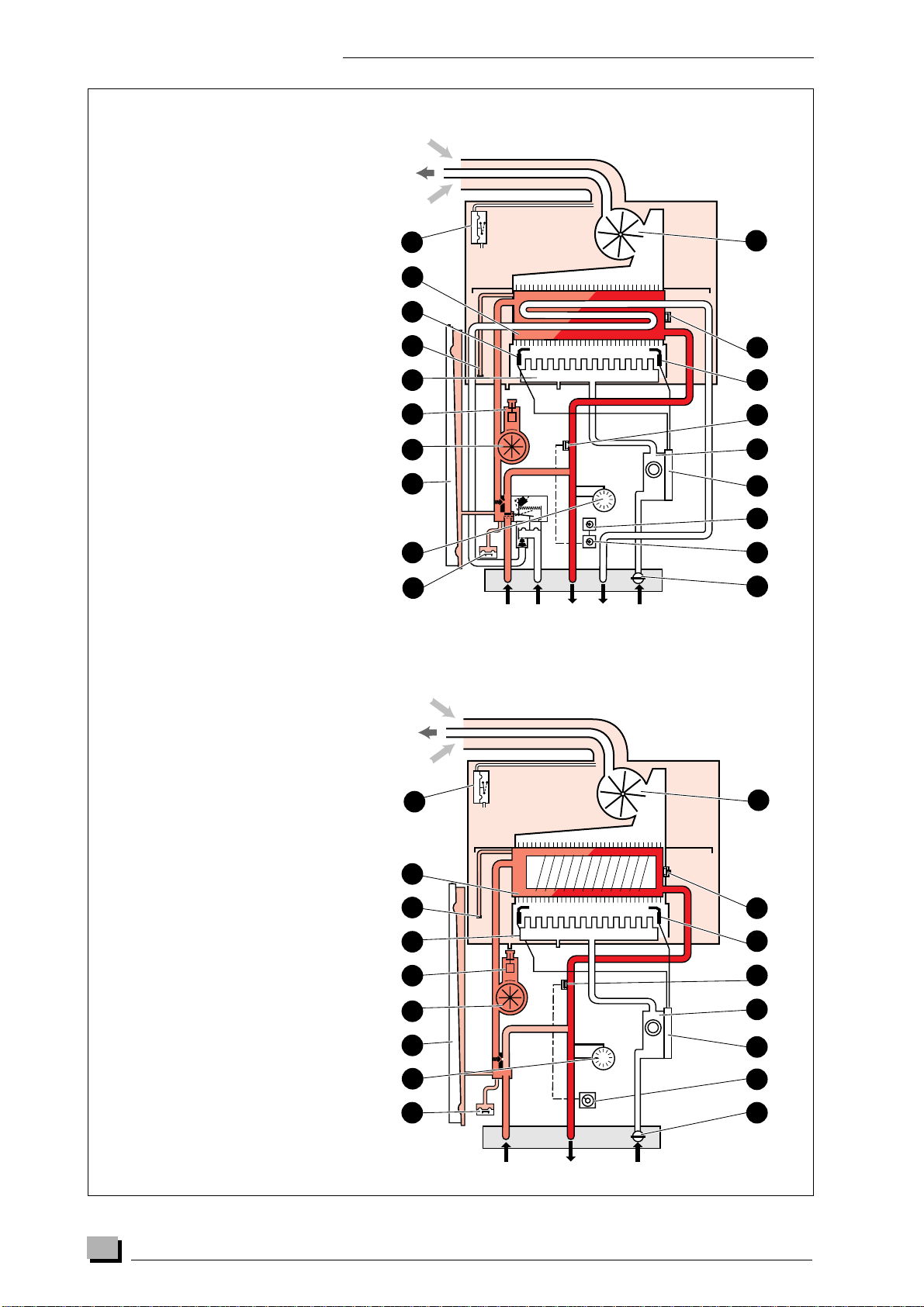

BOILER SCHEMATIC

3-Ignition module

4-Heating temperature adjuster

5-Hot water temperature adjuster

6-Temperature/ressure gauge

8-Expansion vessel

9-Pump

10 - Automatic air vent

11 - Burner

12 - Heat exchanger bleed pipe

13 - Heatexchanger

14 - Gas valve

16 - Heating and hot water thermistor

17 - Ignition electrode

19 - Overheat thermostat

20 - Flame sense electrode

21 - Loss of water pressure switch

22 - Fan

23 - Air pressure switch

24 - Gas cock

THEMA F 23 E

23

13

20

12

11

10

9

22

19

17

16

14

A - Heating return

B - Cold water inlet

C - Heating flow

D - Domestic hot water flow

E - Gas supply

THEMA F SB 18 E - THEMA F SB 23 E

3-Ignition module

4-Heating temperature adjuster

6-Temperature/pressure gauge

8-Expansion vessel

9-Pump

10 - Automatic air vent

11 - Burner

12 - Heat exchanger bleed pipe

13 - Heatexchanger

14 - Gas valve

16 - Heating and hot water thermistor

17 - Ignition electrode

19 - Overheat thermostat

20 - Flame sense electrode

21 - Loss of water pressure switch

22 - Fan

23 - Air pressure switch

24 - Gas cock

21

23

13

12

11

10

8

6

AB C

D

E

3

5

4

24

22

19

17

16

A - Heating return

B - Cold water inlet

C - Heating flow

D - Domestic hot water flow

E - Gas supply

Diagram 4

6

21

9

8

6

ACE

14

3

4

24

Shy 131

Page 7

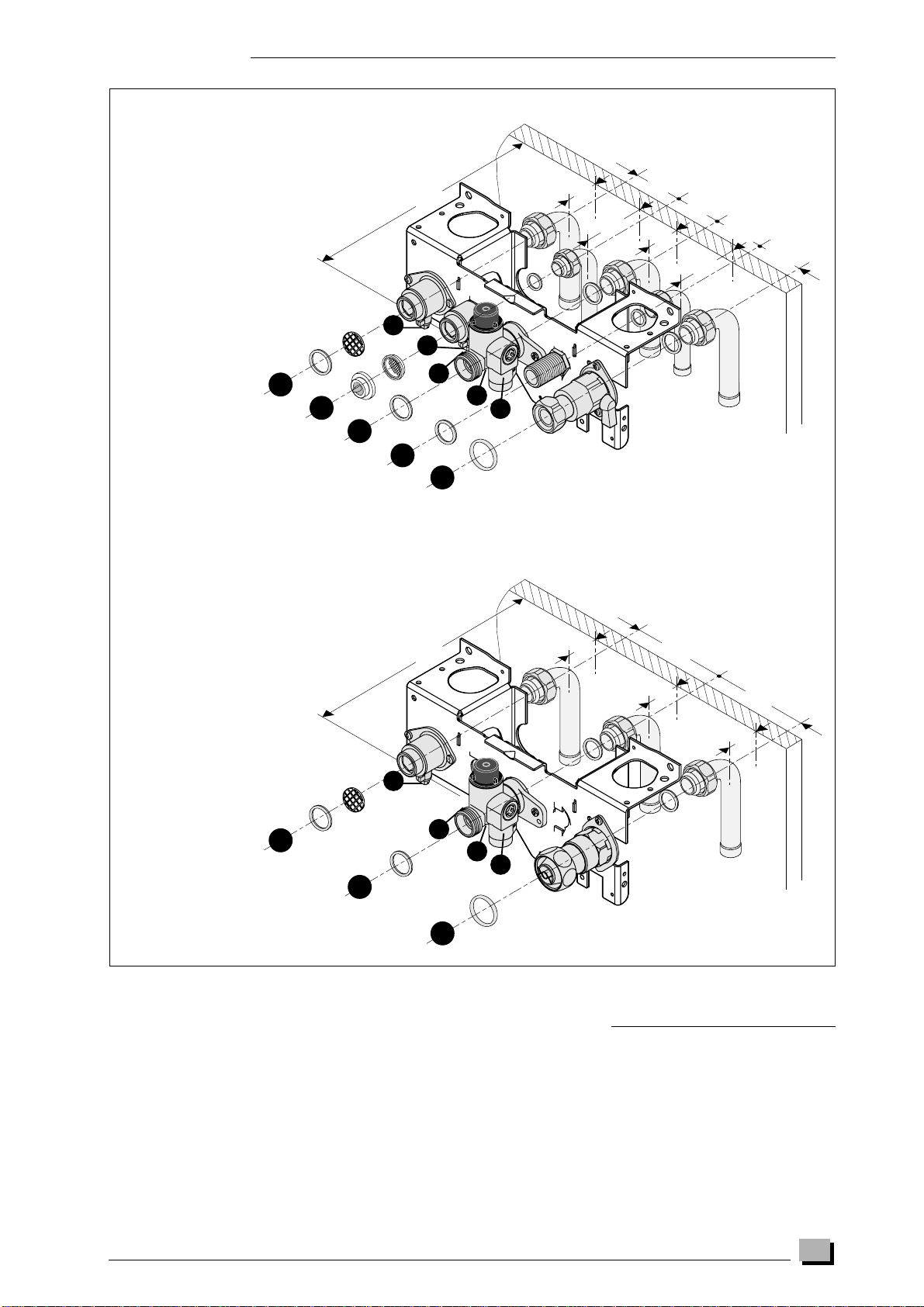

FIXING JIG

THEMA F 23 E

From left to right, the fixing jig comprises:

A - Heating return with isolating valve (m).

B - Cold water inlet with isolating valve (p).

C - Heating flow with isolating valve (q),

drain screw (r) and safety valve (s).

D - Domestic hot water out.

E - Gas service cock.

m

2

1

A

B

THEMA F SB 18

THEMA F SB 23 E

From left to right, the fixing jig comprises:

A - Heating return with isolating valve (m).

C - Heating flow with isolating valve (q),

drain screw (r) and safety valve (s).

E - Gas service cock.

4

3

C

D

55

113

p

r

5

113

q

6

E

s

7

23

34

23

55

57,5

25

33

Filters and washers :

1 - Washer

2 - Metal filter

3 - Flow regulator

4 - Plastic filter

5, 6 & 7 - Washers

57,5

110

Pla 105c

m

2

1

A

C

Diagram 5

p

r

5

q

s

7

E

DOMESTIC HOT WATER SYSTEM DESIGN

• Copper tubing or plastic Hep2 O may be used

for the domestic hot water system. Unnecessary

pressure losses should be avoided.

• The boiler may operate with a minimum supply

pressure of 0,3 bar but under a reduced flow rate.

Optimum performance will be obtained from a

supply pressure of 1 bar.

• The flow restrictor must be fitted in the cold water inlet during installation. This limits the flow through

the boiler to a maximum of 12 l/min.

25

115

23

Pla 116b

7

Page 8

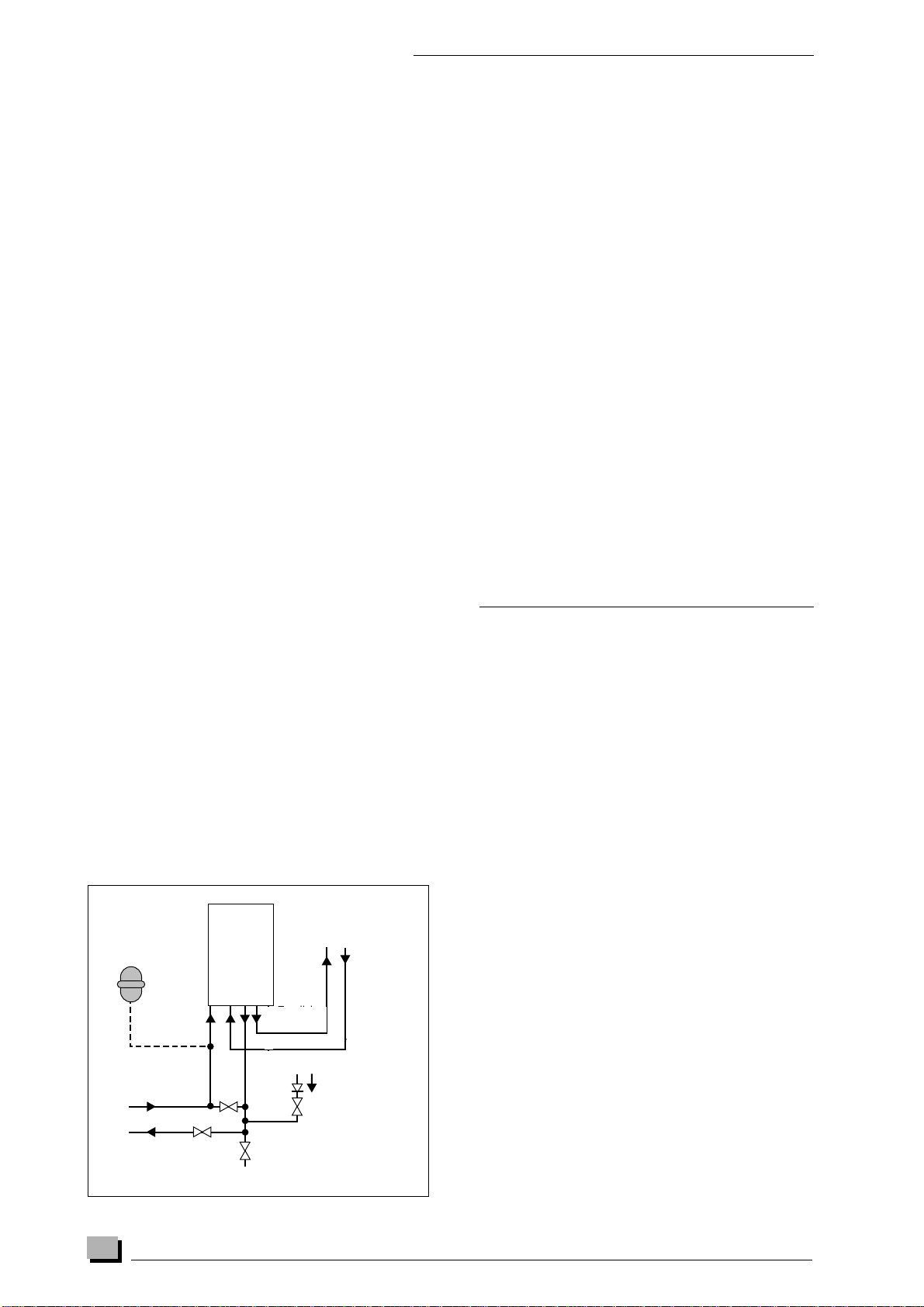

HEATING SYSTEM DESIGN

• The THEMA F boiler is compatible with any type of

installation.

• Heating surfaces may consist of radiators, convectors or fan assisted convectors.

• Pipe sectional areas shall be determined in accordance with normal practices, using the output/pressure curve (diagram 3). The distribution system shall

be calculated in accordance with the output requirements of the actual system, not the maximum output

of the boiler. However, provision shall be made to

ensure sufficient flow so that the temperature difference between the flow and return pipes be less than

or equal to 20°C. The minimum flow is 500 l/h.

• The piping system shall be routed so as to avoid

any air pockets and facilitate permanent venting of

the installation. Bleed fittings shall be provided at

every high point of the system and on all radiators.

• The total volume of water permitted for the heating system depends, amongst other things, on the

static head in the cold condition.

The expansion vessel on the boiler is pressurised at 1

bar (corresponding to a static head of 5 m w.g.) and

allows a maximum system volume of 140 litres for an

average temperature of 75°C and a maximum service pressure of 3 bar. This pressure setting can be modified at commissioning stage if the static head differs.

An additional expansion vessel can be fitted to the

system if required, see diagram 6.

• Provision shall be made for a drain valve at the

lowest point of the system.

• Where thermostatic radiator valves are fitted, not

all radiators must be fitted with this type of valve, and

in particular, where the room thermostat is installed.

• In the case of an existing installation, it is ESSENTIAL

that the system is thoroughly flushed prior to installing

the new boiler using a proprietary product such as

Fernox or Sentinel. Contact the product manufacturers for specific details.

Filling the system

Provision must be made for filling the system at low

level. The use of a WRC approved filling loop is strongly

recommended, connected as shown in diagram 6.

PIPING SYSTEM INSTALLATION

• Heating system connections - Pipe diam 22 mm

• Hot water system connections - Pipe diam 15 mm

• Gas connection - Pipe diam 22 mm

• Safety valve discharge - Pipe diam 15 mm

Water connection

Connect the water pipes to the fixing jig using the

copper tails supplied, see diagram 5.

Warning: To prevent damage to the isolating cocks,

do not solder joints or fittings with the copper tails

connected.

Connect the system pipework to the boiler observing the correct flow and return format as shown in

diagram 6.

Additional

expansion

vessel

(if required)

Return

Heating

circuit

Diagram 6

Flow

control valve

Boiler

Minimum 22 mm diameter

Bypass

valve

Drain point

Tundish

(supplied)

Filling point

Domestic

water

Hot

Cold supply

Pressure

reducing

valve

(supplied)

Sch 173

Safety valve discharge

WARNING. It must not discharge above an en-

trance or window or any type of public access

area.

Connect the safety valve discharge pipe to the

boiler, the discharge must be extended using not

less than 15 m o.d. pipe, to discharge in a visible

position outside the building, facing downward

preferably over a drain. The pipe must have a continuous fall and be routed to a position so that any

discharge of water, possibly boiling or steam, cannot create any danger to persons, damage to

property or external electrical components and

wiring. Tighten all pipe connection joints.

Gas connection

• The supply from the governed gas meter must

be of adequate size to provide a constant inlet

working pressure of 20 mbar (8 in w.g.).

To avoid low gas pressure problems, it is recommended that the gas supply is connected using 22

mm pipe.

• On completion, the gas installation must be

tested using the pressure drop method and purged

in accordance with the current issue of BS6891.

Gas Safety (Installation and Use) Regulations

In your interests and that of gas safety, it is the law

that ALL gas appliances are installed and serviced

by a competent person in accordance with the

above regulations.

8

Page 9

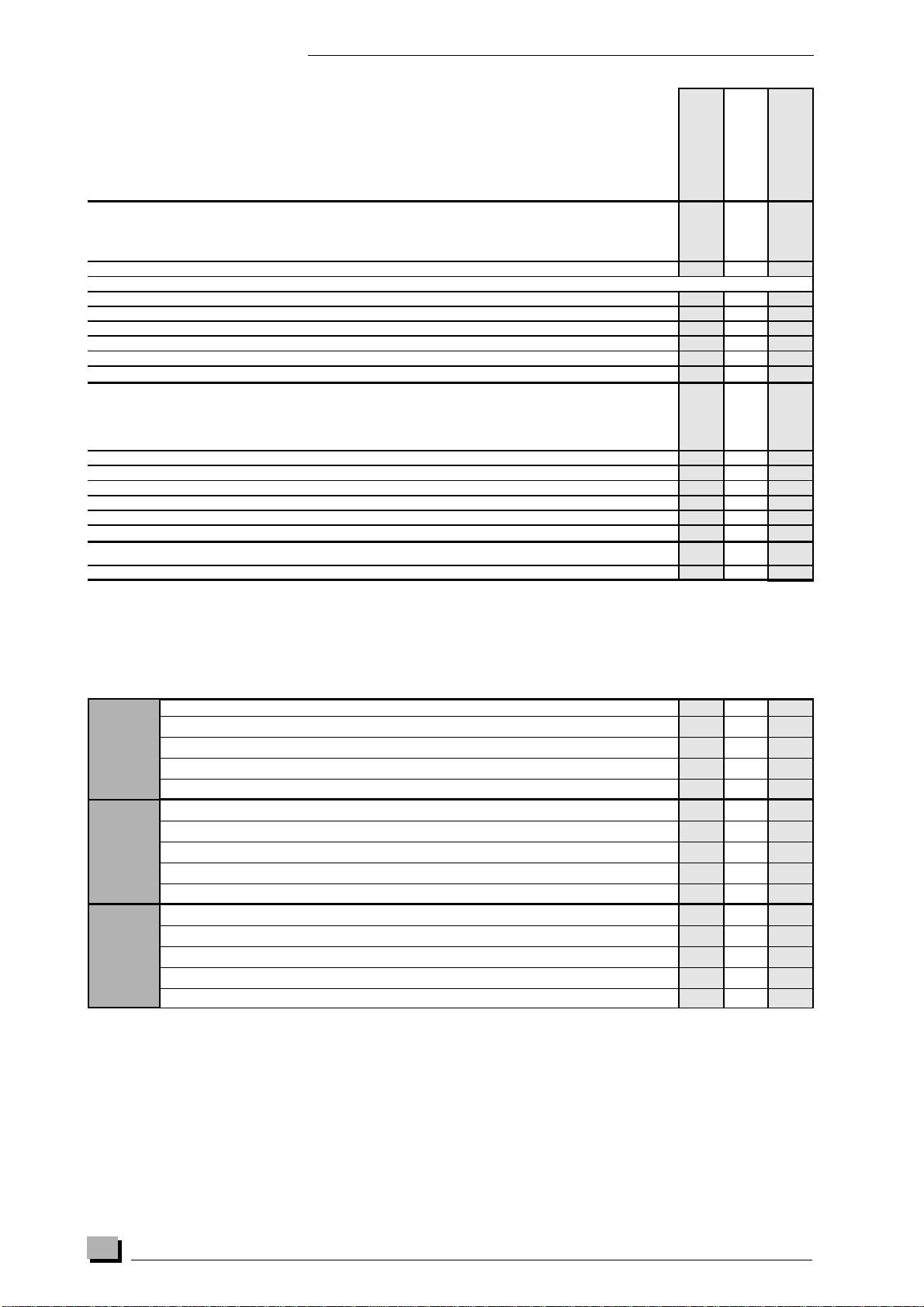

BOILER LOCATION

Clearances

The position of the boiler must be such that there is

adequate space for servicing.

The recommended clearances are:

40 mm either side of the boiler.

600 mm at the front of the boiler.

300 mm below the boiler.

Fixing jig

The fixing jig comprises three parts:

1) The connecting plate which allows the connection and soundness testing of all the pipework before the boiler is fitted and helps support the weight

of the boiler.

2) The hook which supports the weight of the boiler.

3) The template which ensures the hook and con-

necting plate are correctly fitted relative to one

another.

• Place template on wall in required position, making allowances for the necessary clearances etc.,

see diagram 7.

Note: It is permissible to install the boiler with re-

duced clearances at the bottom and sides of the

boiler PROVIDING that adequate consideration is

given for Servicing/Repairs at a later date. If any

doubt exists, contact the Saunier Duval Technical

Helpline 01773 828400.

• Mark the position of the holes for the hook and

connecting plate.

• Drill, plug and fix the connecting plate and hook

to the wall using suitable screws.

• Check that both the hook and connecting plate

are level.

If the boiler is not installed immediately, protect the

various couplings to prevent any ingress of foreign

materials e.g. plaster, paint etc.

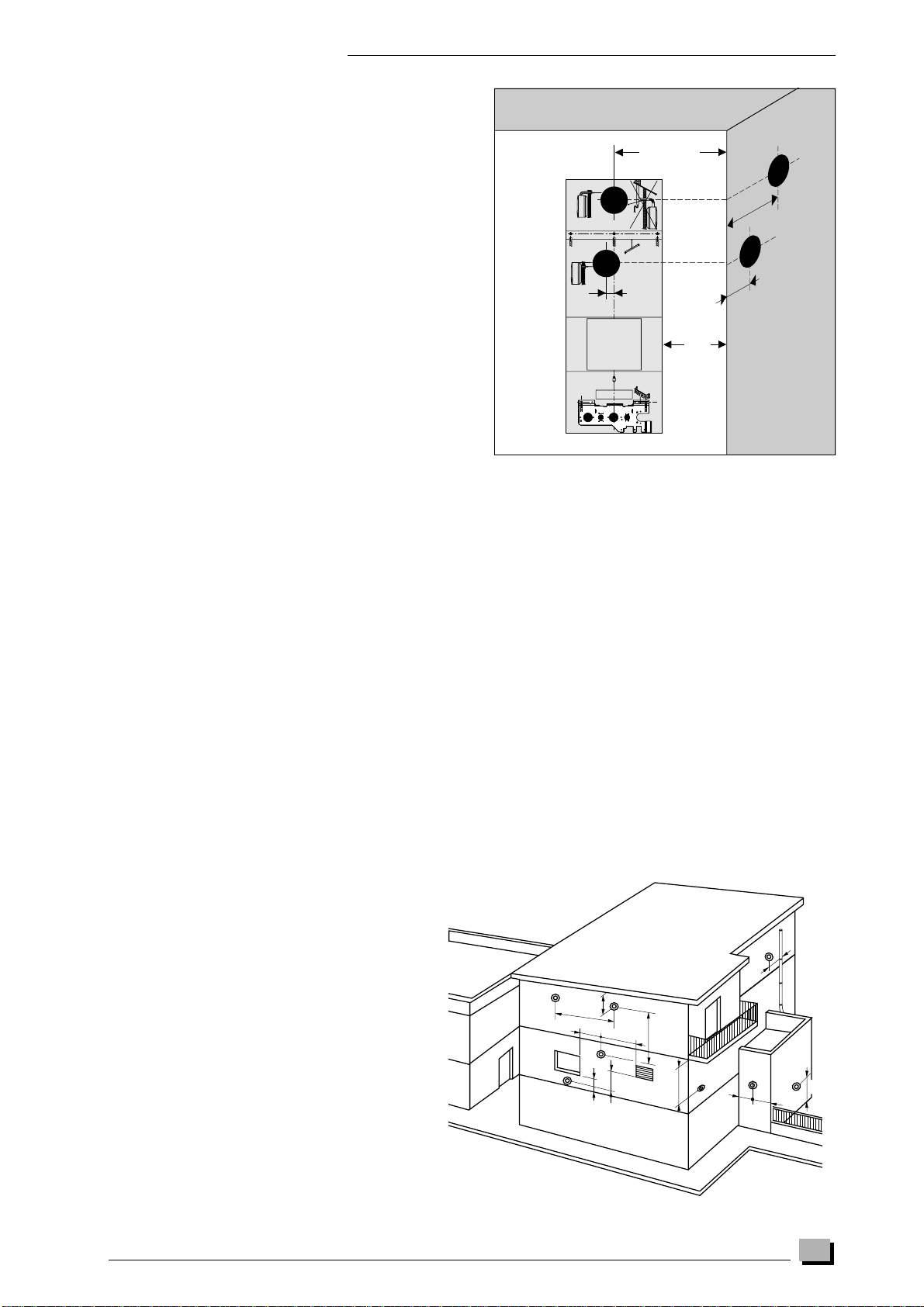

Terminal position

The minimum acceptable spacings from the terminal to obstructions and ventilation openings are

shown in diagram 8.

255 mini

234

29

Diagram 7

60

50

mini

The boiler must be installed so that the terminal is

exposed to the external air.

Note: Under certain weather conditions the flue

may produce a plume of condensation, this is quite

normal.

If the terminal is fitted within 850mm of a plastic or

painted gutter or 450m of painted eaves, an aluminium shield of a minimum length of 750mm

should be fitted to the underside of the gutter or

painted surface.

Should any doubt exist as to the permissible position of the terminal, contact the Saunier Duval

Technical Helpline 01773 828400.

Cupboard or compartment ventilation

The boiler can be fitted in a cupboard or compartment without need for permanent ventilation.

Ins 012a

Minimum dimensions (in mm) for the positioning of flue terminals

A-Under a window ................................................. 300

B-Under an air vent ................................................ 300

C-Under a gutter ....................................................... 75

D-Under a balcony.................................................300

E-From an adjacent window ................................300

F-From an adjacent air vent.................................300

G-From vertical drain pipes or soil pipes ..................75

H-From an external corner of the building .......... 300

I-From an internal corner of the building ........... 300

L-From the ground or from another floor ............ 300

M-Between two terminals vertically ....................1500

N-Between two terminals horizontally .................. 300

Diagram. 8

G

C

N

E

F

M

A

B

D

I

H

L

Ven 060b

9

Page 10

BOILER INSTALLATION

Statutory requirements

The installation of this boiler must be carried out by

a competent person in accordance with the relevant requirements of the current issue of:

The Gas Safety (Installation and Use) Regulations

The Building Regulations

The local water company Byelaws

The Building Standards Regulations (Scotland)

The Health and Safety at Work Act

Sheet metal parts

WARNING. When installing or servicing this boiler,

care should be taken when handling the edges of

sheet metal parts to avoid the possibility of personal

injury.

Diagram. 9

Installing the boiler

Prior to starting work, the system must be thoroughly

flushed so as to eliminate any foreign bodies and

contaminants such as filings, solder particles, oil,

grease etc.

Note. Solvent products could cause damage to the

system.

Note. If using a rear outlet flue system, follow the

instructions in 'Rear outlet flue installation' section

prior to hanging the boiler.

• Engage boiler upper part onto the hook, see dia-

gram 9.

• Allow the boiler to seat down onto support plate,

see diagram 10.

• Fit filter and washers, strictly adhering to the sequential order and directions shown on diagram 5.

• Connect the various couplings between the

boiler and the connection plate.

Diagram. 10

➞

Ins 020

REAR OUTLET FLUE INSTALLATION

The boiler is supplied for rear outlet flue connection.

Alternatively, the boiler is designed to allow the flue

system to be connected to the top of the boiler,

top outlet flue connection.

For top outlet flue connection, refer to 'Top outlet

flue installation'

Rear outlet flue - kit 86151

The rear outlet flue system consists of two parts, a

white painted outer pipe and an aluminium inner,

they are positively locked together when assembled.

The flue kit 86151, see diagram 11, is 1000 mm long

and comprises:

- Outer pipe ........................................................... A

- Inner pipe ............................................................. B

- External rubber sealing collar ........................... C

- Flue elbow............................................................ D

- Internal flange ......................................................E

- 'O' rings ..................................................................F

- Screws ................................................................... G

- Rubber collar ....................................................... H

- Clamp and seal ....................................................I

- Gasket ................................................................... J

➞

A - Direct rear outlet flue

Mark correct position of hole from template using

hole between hook and connecting plate.

Diagram 11

A

B

G

I

C

H

E

D F

J

Ins 021

Pho 422

10

Page 11

REAR OUTLET FLUE INSTALLATION

e

a

X

B - Rear outlet side flue

Mark the horizontal centre line on the rear wall.

Extend the horizontal centre line to the side wall

and mark the vertical centre line of the flue hole

as shown in diagram 12.

255 mini

Important: When cutting the flue hole and when

extending the flue centre line to a side wall, remember that the flue system must have a fall of about

35 mm per metre of flue DOWNWARD AWAY FROM

the boiler. There must NEVER be a downward incline towards the boiler.

Cutting the flue hole

• Making allowance for the slope of the flue, cut

hole in external wall, preferably using a core drill.

For installations with internal and external access Use a 105 mm diameter core drill.

For installations with internal access only - Use a

125 mm diameter core drill.

Important: Before cutting the hole for flues to the

rear of boiler, always cover fixing jig to make sure it

is not damaged.

Calculation of flue cutting lengths

• Measure wall thickness e (mm).

• For side flues, measure distance from inside face

of side wall to centre line of flue and subtract 176

mm for right hand flue or subtract 234

for left hand flue to get dimension a (mm), see

diagram 13 or 14.

• Refer to table 1 for cutting lengths of both inner

and outer flue pipes for each of the various flue

options available.

Important: All flue cutting lengths must be measured from the terminal end of the flue pipes, see

diagram 15.

When the dimension X measured on site is greater

than that given in table 1, a flue extension kit will

be required, refer to table 2 for details.

Refer to table 1 for the cutting lengths of both the

inner and outer pipes for each of the flue options

available.

Diagram 12

e

Diagram 13

234

29

mini

a

60

50

Ins 012a

X

Hab 208

Table 1

Flue cutting lengths

Cutting length (mm)

Flue option outer pipe inner pipe Comments

Rear outlet e + a + 96 e + a + 173 maximum

Side flue to distance 'X'

left without

(Diagram 13) extension

Rear outlet e + a + 154 e + a +231 maximum

Side flue to distance 'x'

right without

(Diagram 14) extension

1080 mm

1080 mm

Diagram 14

Hab 209

11

Page 12

REAR OUTLET FLUE INSTALLATION

Extended flue

The horizontal flue is extended by using one or more

of the 1000 mm extension pipes, Saunier Duval part

number 85091. These are connected together by

push fit type joints, clamps and seals.

Calculation of flue cutting lengths for extended flue

• Using the correct number of extension kits as table 2, measure dimensions a and e, see diagram

13 or 14. Cut both the inner and outer pipe to the

dimensions given in table 3.

Important: All cutting lengths should be measured

from the push fit end of the extension pipe. Do not

leave any burrs or sharp edges on the cut ends of

the pipes.

Outer pipe

Cutting length

Inner pipe

Cutting length

Installation of flue assembly-direct rear flue

• Fit rubber sealing collar (C) into groove at the

outer end of pipe (A), see diagram 16.

• Fit outer pipe (A) into wall with groove to the

outside.

• Pull pipe inwards to bring rubber sealing collar

hard up against external wall, see diagram16.

• Fit internal plastic flange (F) onto outer pipe. Push

along the pipe until engaged against internal wall.

• From inside, insert inner pipe (B) into outer pipe

turning anti-clockwise to allow inner to fully enter

outer pipe.

• Fit rubber sleeve (H) onto outer pipe.

• Take hold of inner flue,twist clockwise and push

gently onto fan outlet.

• Pull rubber sleeve onto boiler spigot ensuring a

good seal.

Installation of flue assembly-side flue

• Fit rubber sealing collar (C) into groove at the

outer end of pipe (A), see diagram 16.

• Fit outer pipe (A) into wall with groove to the

outside.

• Pull pipe inwards to bring rubber sealing collar

hard up against external wall, see diagram16.

• Fit internal plastic flange (F) onto outer pipe. Push

along the pipe until engaged against internal wall.

• From inside, push inner pipe (B) into outer pipe

turning anti-clockwise to allow inner to fully enter

outer pipe.

• Fit rubber sleeve (H) onto outer pipe.

• Fit both 'O' rings (F) into flue elbow (D), one at

the inlet, one at the outlet. By necessity, they are a

loose fit, apply a small amount of silicone grease

to each 'O' ring when fitting.

Diagram 15

Table 2

Number of extension kits required

Flue option Dimension 'X' No. of

extension kits

Side flue 1081 to 1811mm 1

(left or right) 1812 to 2542 mm 2

Table 3

Extended flue cutting lengths

Cutting length (mm)

Flue option outer pipe inner pipe Comments

Rear outlet e + a - 906 e + a + 829 maximum

Side flue to distance 'X'

left without

(Diagram 13) extension

1080 mm

Rear outlet e + a - 848 e + a + 771 maximum

Side flue to distance 'x'

right without

(Diagram 14) extension

1080 mm

Ven 089

Important: If the flue has been cut, ensure that there

are no burrs that could damage the 'O' ring.

• Remove the backing from the self adhesive gasket (J) and carefully fit gasket to base of flue elbow.

• Fit elbow onto boiler and secure with the four

screws (G).

• Take hold of inner flue, twist clockwise and push

gently onto the elbow outlet taking care not to tear

the 'O' ring.

• Pull rubber sleeve onto elbow ensuring a good

seal.

12

Diagram 16

Pho 087

Page 13

TOP OUTLET FLUE INSTALLATION

Top outlet flue - kit 86151 see diagram 18, is 1000 mm long

and comprises:

- Outer pipe ....................................................................... A

- Inner pipe ........................................................................ B

- External rubber sealing collar ........................................ C

- Flue elbow .......................................................................D

- Internal flange ................................................................ E

- 'O' rings ............................................................................. F

- Screws ............................................................................ G

- Rubber collar .................................................................. H

- Clamp and seal ............................................................... I

- Gasket .............................................................................. J

A - Flue to rear of boiler

• Mark correct position of hole from template.

B - Flue to side of boiler

• Mark horizontal centre line for hole on rear wall. Extend

horizontal centre line to side wall and mark vertical centre

line of flue hole as shown in diag. 12.

Under normal circumstances, it will be possible to gain access to the outside of the building to fit the flue terminal

assembly. Where outside access is not possible e.g. high

rise buildings, the flue terminal can be fitted from inside the

building only if required.

Note : When cutting flue hole and when extending flue

centre line to a side wall, remember that the flue system

must have a fall of about 35 mm per metre of flue DOWNWARD AWAY FROM the boiler. There must NEVER be a downward incline towards the boiler.

Cutting the flue hole

• Making allowance for the slope of the flue, cut hole in

external wall, preferably using a core drill.

For installations with internal and external access - Use a

105 mm diameter core drill.

For installations with internal access only - Use a 125 mm

diameter core drill.

Important: Before cutting hole for flues to rear of boiler, always cover fixing jig to make sure it is not damaged.

Table 1 :

Flue Cutting length (mm)

Flue option outer pipe inner pipe Comments

Top outlet e + a + 125 e + a + 202 maximum

Side flue to distance 'X' without

(left or right) extension 1080 mm

Calculation of flue cutting lengths

• Measure wall thickness e (mm), see diagram 17.

• For side flues, measure distance from inside face of side

wall to centre line of flue and subtract 205 mm for both

right and left hand flues to get dimension a (mm).

• Refer to table 1 for cutting lengths of both inner and outer

flue pipes for each of the various flue options available.

Important: All flue cutting lengths must be measured from

the terminal end of the flue pipes, see diag. 15.

When the dimension X measured on site is greater than that

given in table 1, a flue extension kit will be required, refer to

table 2 for details.

Extended flue

The horizontal flue is extended by using one or more of the

1000 mm extension pipes, Saunier Duval part number 85091.

These are connected together by push fit type joints, clamps

and seals.

Calculation of flue cutting lengths for extended flue

• Using the correct number of extension kits as table 3,

measure dimensions a and e, see diagram 17.

Important: All cutting lengths should be measured from the

push fit end of the extension pipe. Do not leave any burrs or

sharp edges on the cut ends of the pipes.

ee

a

X

Diagram 17

a

X

A

B

G

I

C

H

E

extension kits

D F

J

Diagram 18

Table 2 : Number of extension kits required

Flue option Dimension 'X' No. of

Side flue 1081 to 1811 mm 1

(left or right) 1812 to 2542 mm 2

Table 3 :

Extended Flue Cutting length (mm)

Flue option outer pipe inner pipe Comments

Top outlet e + a + 877 e + a + 800 maximum

Side flue to distance 'X' without

(left or right) extension 1080 mm

Installation of flue assembly

• Fit rubber sealing collar (C) into groove at the outer end

of pipe (A), see diagram 18.

• Fit outer pipe (A) into wall with the groove to the outside.

• Pull pipe inwards to bring rubber sealing collar hard up

against external wall, see diagram16.

• Fit internal plastic flange (E) onto outer pipe. Push along

the pipe until engaged against internal wall.

• From inside, insert inner pipe (B) into outer pipe.

• Fit both 'O' rings (F) into the flue elbow (D), one at the

inlet, one at the outlet. By necessity, they are a loose fit,

apply a small amount of silicone grease to each 'O' ring

when fitting.

Important: If the flue has been cut, ensure that there are no

burrs that could damage the 'O' ring.

• Remove the backing from the self adhesive gasket (J)

and carefully fit gasket to base of flue elbow.

• Fit elbow onto boiler and secure with the four screws

(G).

• Take hold of inner flue, twist clockwise and push gently

onto the elbow outlet taking care not to tear the 'O' ring.

• Fit clamp and seal (I) onto outer pipe ensuring a good

seal.

Hab 210b

Pho 422

13

Page 14

ELECTRICAL CONNECTION

Warning. This boiler must be earthed

All system components must be of an approved

type.

The mains electrical cable is supplied with the boiler.

It is coiled ans tucked inside the boiler

Connection of the whole electrical system and any

heating system controls to the electrical supply must

be through a common isolator.

Isolation should preferably be by a double pole

switched fused spur box having a minimum contact separation of 3 mm on each pole. The fused

spur box should be readily accessible and preferably adjacent to the boiler. It should be identified

as to its use.

A fused three pin plug and shuttered socket outlet

may be used instead of a fused spur box provided

that:

a) They are not used in a room containing a fixed

bath or shower.

b) Both the plug and socket comply with the current issue of BS1363.

The mains electrical supply must be maintained at

all times in order to provide domestic hot water.

Do not interrupt the mains supply with a time switch

or programmer.

WARNING: ON NO ACCOUNT MUST ANY EXTERNAL

VOLTAGE BE APPLIED TO ANY OF THE TERMINALS ON

THE HEATING CONTROLS CONNECTION PLUG.

Warning: This appliance must be wired in accord-

ance with these instructions. Any fault arising from

incorrect wiring cannot be put right under the terms

of the Saunier Duval guarantee.

Time clock

A mechanical or digital time clock is available as

an accessory, Saunier Duval part N° 86148 (mechanical) or 86149 (digital).

External controls

The THEMA boiler is designed to operate at maximum efficiency at all times. The of a programmable electronic room thermostat is recommended

for optimum performance, Saunier Duval part

number 40010. Please contact your supplier.

The boiler will work for heating without a room thermostat and/or timeswitch being connected provided that the wire link fitted between the two terminals of the connector (E) is left in place, see dia-

gram 19.

A 230V room thermostat can be used but do not

make any connection to the compensating resistor, see diagram 19.

ON NO ACCOUNT must any electrical voltage be

applied to any of the terminals of the external controls plug.

E

The mains electrical cable is supplied with the

boiler. It is coiled and tucked inside the boiler

THEMA F 23 E

For no external controls

leave wire link (E) in place

sch 228

Cylinder

When fitting room thermostat,

remove wire link (E) and connect

voltage free thermostat as shown

°C

sch 229

THEMA F SB 18 E

THEMA F SB 23 E

°C

Diagram 19

14

°C

sch 227

Page 15

COMMISSIONING

The commissioning and first firing of the boiler must

only be done by a competent person.

Gas installation

It is recommended that any air is purged from the

supply at the gas inlet test point on the left hand

side of the gas valve, see diagram 20.

Filling the system

1

Open shut off

valves (slot of

screw corresponds to flow

direction).

3

Open the tap on the system filling loop and fill the

system until the pressure

indicated on the display

is between 1 and 2 bar.

➜

➜

➜

Ins 017a

Sec 055

Diagram 20

2

Undo, but do not

remove, cap on

automatic air

vent on top of

pump. Do not retighten cap.

mec 117

Reg 008

Bleed air from the

4

heat exchanger by undoing the air bleed cap.

Do not remove this

cap. When

all the air

has been

removed,

tighten

cap.

Reg 007

Important:

- If this procedure is not carried out properly, the boiler

will go into safety lock-out until all of the air has been

purged.

- When venting air from boiler, do not touch the

schrader valve on the expansion vessel, it is NOT a

vent.

- Before starting the boiler, turn the pump impellor to

make sure it is free to move.

• Unscrew black cap on front of pump.

• Using screwdriver, push in pump spindle and turn

pump impellor 3 to 4 times. DO NOT HIT SPINDLE. Replace black cap.

Starting the boiler

Before starting the boiler check that:

- The gas meter tap is open. If using Butane or Propane, check that valve on storage cylinder or tank is

open.

- you have removed the two fan transist clips from fan.

Bleed each radia

5

tor until a continuous jet of water is obtained.

Open various

6

hot water taps to

bleed system.

Ins 061

- The boiler gas service cock is open.

- The boiler is connected to the electrical supply and

switched on.

- The front casing is fitted.

First starting up

• Following the instructions given in the 'User Instructions' set boiler to run in central heating mode.

• Set boiler thermostat for maximum temperature

and check that any external controls, if fitted, are

calling for heat.

• Allow the temperature to rise to the maximum

value, with all radiator valves open.

The temperature rise will cause release of the gases

contained in the water of central heating system.

- Gases driven towards the boiler will be automatically released through the automatic air vents.

- Gases trapped at the highest point of the system

must be released by bleeding the radiators.

Ins 062

Make sure that

7

pressure gauge

reads between 1 and

2 bar. Re-pressurise

system as necessary.

Sec 055

15

Page 16

COMMISSIONING

On reaching maximum temperature, the boiler

should be turned off and the system drained as

rapidly as possible whilst still hot.

• Refill system to a pressure of 1 bar and vent as

before.

• Restart boiler and operate until a maximum temperature is reached. Shut down boiler and vent

heating system. If necessary, top up heating system and make sure that a pressure of 1 bar

is indicated on the pressure gauge when system is

COLD.

Gas pressures

The main burner pressure should be checked during commissioning to make sure the correct input

is obtained. Proceed as follows:

• Shut down boiler.

• Undo screw on burner pressure test point below

sealed combustion chamber, see diagram 23.

• Connect a suitable pressure gauge.

• Gain access to the rear of the control panel and

locate the range rating adjuster screw, see dia-

gram 24.

• Start boiler as described in 'User Instructions'.

• Set boiler thermostat to maximum and check

that any external controls are calling for heat.

• Check that the reading on the gauge matches

that given in 'Technical Data' for the type of gas

being used.

• Adjust the range rating adjuster screw as necessary to obtain the desired input.

• Shut down boiler.

• Remove pressure gauge, tighten up test point

screws and check for gas soundness.

• Using a ball point pen, clearly indicate on the

data label the input the boiler is set to.

Note: This adjustment does not affect the domestic hot water output.

If measured burner pressure differs greatly from the

given figure, check the gas inlet pressure as follows:

• Shut down boiler.

Diagram 23

Diagram 24

• Remove screw from inlet test point on the side of

the gas valve, see diagram 23.

• Connect a suitable pressure gauge.

• Start boiler as described in 'User Instructions'.

• Check that the inlet pressure reading matches

that given in 'Technical Data' for the type of gas

being used.

• Shut down boiler.

• Remove pressure gauge, tighten up test point

screws and check for gas soundness.

• If the gas pressure is incorrect, refer to the Fault

Finding section in 'Servicing Instructions'.

• If the inlet pressure is below that given, the gas

supply pipework/meter must be checked and any

fault corrected.

• In the case of an LPG installation, check the storage tank or cylinder, regulator and pipework.

Des 044

Reg 056

SAFETY DEVICES

Air flow rate safety device

If an obstruction, even partial, of the flue occurs,

for any reason whatsoever, the built in safety system of the boiler will turn the boiler OFF and the

fan will continue to run.

The boiler will be ready to operate when the fault

has been cleared.

In case of power supply failure

The boiler no longer operates.

As soon as power supply is restored, the boiler will

be automatically restarted.

Overheat safety

In the event of a problem, the overheat thermostat causes safety shutdown of the boiler. Should this

occur, reset the thermostat by pressing in the red

button. The overheat thermostat is located on the

RHS of the heat exchanger.

16

Important notice: A central heating system cannot

operate satisfactorily unless it is properly filled with

water and unless the air initially contained in the

piping systems has been properly bled off. If these

conditions are not satisfied, air noise will occur

within the system.

The THEMA F 23 E boiler has a built in frost protec-

tion device that protects the boiler from freezing. If

the boiler is to be left and there is a risk of frost,

ensure that the gas and electrical supplies are left

connected and the summer/winter switch is in

the position. The frost protection device will light

the boiler when the temperature of the boiler water falls below 6°C. When the temperature reaches

16°C, the boiler stops.

Note: This device works irrespective of any room

thermostat setting and only protects the boiler.

Page 17

SETTINGS

Gas valve setting

All boilers are tested and factory set during manufacture. Should it be necessary to reset a gas valve,

for example after replacement, proceed as follows:

• Shut down boiler.

• Connect a suitable pressure gauge as described

in 'Commissioning'.

Maximum setting

• Remove one electrical connector from the

modulating gas valve coil.

• Turn the domestic hot water

temperature adjuster to maximum setting.

• Remove the protective cover

from the gas valve adjuster.

Using a 2 mm Ø rod, press in the

spindle in the middle of screw M,

see diagram 25.

• Turn nut 'B' to obtain the desired pressure, see technical

data.

Minimum setting

This must be done AFTER the maximum setting.

• Hold not B to prevent from turning, turn nut 'A' to

obtain the desired pressure, see technical data.

B

A

Mec 121

Diagram. 26

a

Reg 013

After adjustment, refit the cover to the gas valve

adjuster and refit electrical connector.

Bypass

The THEMA F 23 E has a built-in bypass. This must be

adjusted according to the requirements of the system, refer to the flow rate pressure curve (diagram

3). The boiler is supplied with the built-in bypass

open a half a turn. It is adjusted by turning the bypass screw (a), see diagram 26. Turn the screw

clockwise to close the bypass.

When using thermostatic radiator valves (TRV's), it

is recommended that an additional, adjustable

bypass of 15 mm minimum diameter is fitted between the flow and return of the heating circuit,

see diagram 6. Any bypass must be fitted before

system controls.

PCB Settings

The PCB on the Thema F 23 E can be set to operate

in different ways to suit individual installations. The

dip switch SW1, see diagram 27, should be set as

follows:

1 - OFF 4 - OFF

2- ON 5- OFF

3 - OFF 6 - OFF

Diagram. 27

SW1

ON

123456

DIP

Reg 055

CHANGING GAS TYPE

Should it become necessary to change the gas type, a modification kit will be required.

This modification must only be carried out by a suitably qualified engineer.

Conversion: Natural Gas (G20) to G30/G31 Part No. 86161

17

Page 18

ROUTINE CLEANING AND INSPECTION

To ensure the continued efficient and safe operation of the boiler it is recommended that it is

checked and serviced at regular intervals. The frequency of servicing will depend upon the particular installation conditions and usage, but in general once a year should be enough.

It is the law that any servicing is carried out by a

competent person.

Service Check and Preparation.

• Operate boiler and check for any faults that

need to be put right.

• Isolate boiler from the gas and electrical supplies.

• On completion check all gas carrying parts for

soundness with leak detection fluid.

• The maximum domestic hot water flow rate is 12

litres/minute.

• Remove boiler casing as follows:

Upper front panel

• Hinge down control cover to gain access to control panel.

• Disengage the two 'quarter turn' fasteners by

turning the heads of the screws a quarter of a turn

towards the centre of the boiler.

• Carefully lower the panel down on its hinge until

it is horizontal.

• Turn both plastic catches to release upper front

panel.

• Remove upper front panel by pulling forward at

the bottom and lifting off.

Note: The upper front panel is retained by a plastic

safety strap, disengage this before removal.

Side panels

• From below boiler, unscrew and remove black

plastic screws securing side panels to the boiler.

• Prise out black plastic inserts and lift panel off

boiler.

Diagram 28

from boiler taking care to retain both fibre washers

and seal on gas supply for use on reassembly.

• Unscrew and remove two injector bar retaining

screws and separate injector bar from burner.

• Examine and clean injectors as necessary.

Note: Do not use a wire or sharp instrument on the

holes.

• Replace burner in reverse order to removal.

Heat exchanger

• After removal of burner, examine heat exchanger for any blockages or build up of deposits.

• Clean using soft brush or vacuum cleaner.

Important: Take care not to scratch or otherwise

damage painted surface of heat exchanger.

Reassembly of parts removed for servicing

• Replace all parts in reverse order to removal.

Des 047

Combustion chamber

• Loosen two wing nuts on combustion chamber

cover.

• Disengage retaining lugs from holes in either side

of combustion chamber and move rods away to

clear combustion chamber sides, see diagram 28.

• Unclip two toggle clips holding upper part of

combustion chamber in place.

• Holding both sides, pull chamber forward to release it from underside of heat exchanger and out

of boiler.

• Take care not to damage insulation material on

inside faces of combustion chamber.

Cleaning the burner

• Pull off leads to ignition electrode.

• Pull off lead to flame sense electrode.

• Unscrew and remove screw holding earth lead

to flame sense electrode.

• Undo main gas supply nut from main burner.

• Unscrew and remove locking nut from both main

gas connection and burner pressure tapping point.

• Lift front edge of burner until tapping point and

gas supply connection are free. Remove burner

Flue system

• Check externally to make sure flue is not blocked.

• Inspect flue system to make sure all fittings are

secure.

Operation of fan

• Switch on electrical supply and turn on gas.

• Switch boiler On/Off switch to 1 (On).

• Light burner by opening a hot tap.

• Without upper front panel in place, burner should

be prevented from lighting by air flow detection

system.

• Refit upper front panel.

• Check that fan runs when burner is lit and stops

when it goes out.

Cold water inlet filter (exept SB models)

• Drain down hot water circuit of boiler as follows:

• Close isolating valve on cold water inlet connection on fixing jig, see diagram 5.

• Open one or more hot water taps to drain boiler.

• Undo connecting nut from cold water inlet connection to gain access to filter.

• Remove white filter from inlet connection.

18

Page 19

ROUTINE CLEANING AND INSPECTION

Note: Connecting pipework is telescopic, it may be

necessary to slide sleeve back for easier access to

filter.

• Clean and inspect filter, replace if necessary.

• With both flow restrictor and filter in place, reconnect pipe to inlet connection and tighten.

• Fully open isolating cock on cold water inlet connection and check for leaks.

REPLACEMENT OF PARTS

To replace microswitch assembly exept SB models)

• Disconnect microswitch by pulling off plug.

• Unclip external controls connector from mounting bracket.

• Undo two screws securing microswitch assembly

to reversing valve assembly, see diagram 29.

• Remove microswitch assembly from reversing

valve.

• Fit replacement microswitch assembly in reverse

order to removal.

• Reconnect plug and refit external controls connection to bracket.

To replace fan

• Disconnect power supply and earth leads to fan.

• Unscrew and remove two fan retaining screws

located at front edge of fan mounting plate.

• Remove fan with mounting plate attached by

pulling forwards and out of boiler.

• Unscrew and remove three screws securing fan

to fan mounting plate.

• Fit replacement fan to mounting plate and secure with screws.

• Fit replacement fan to boiler in reverse order to

removal making sure that mounting plate retaining lugs are properly engaged into flue hood.

• Reconnect power supply and earth leads.

Important: Make sure that fan outlet is correctly fitted into either the flue elbow for top outlet flue, or

the rear connector for rear outlet flue.

Before commissioning boiler, remove the two plastic transit clips from replacement fan.

To replace air pressure switch

• Locate air pressure switch in upper left hand corner of sealed chamber.

• Pull off plastic tube from left hand connection.

• Grasp pressure switch and disengage it from

bracket clips by pulling from the top.

• Remove electrical connections from switch.

• Fit electrical connections to terminals 1 and 3 of

replacement switch.

• Fit replacement switch in reverse order to removal.

Important: Refit plastic tube to LEFT hand connector (marked P1).

To replace spark generator

• Locate spark generator on bracket to right hand

side of gas valve.

• Undo and remove screw securing lower terminal cover to bracket and remove bracket.

• Disconnect four leads from spark generator.

Operation of water valve (exept SB models)

• With the Summer/Winter control in the 'Summer'

position, slowly open a convenient tap until boiler

lights.

• Measure water flow, it should not be greater than

3,5 litres/minute.

• If necessary, replace diaphragm.

• Replace all outer panels.

microswitch on THEMA F 23 E

Diagram 29

Diagram 30

• Undo and remove screw securing spark generator to bracket and remove spark generator.

• Fit replacement spark generator in reverse order

to removal.

• Reconnect two grey power supply leads and two

clear ignition leads to spark generator, the polarity

is not important.

• Refit lower terminal cover.

To replace main printed circuit board (PCB)

• With lower front panel down as described previously, undo and remove screw holding pump connection cover to PCB cover, see diagram 30.

• Open cover and unclip plastic clip securing

pump cable to lower front panel.

• Pull off pump connector and earth lead.

• Undo and remove four screws securing PCB

cover to lower front panel.

• Lift off PCB cover.

• Pull off connectors CN6, CN7, CN8 and CN9 on

PCB.

• Undo and remove screw holding PCB to lower

front panel.

• Lifting PCB up slightly on LHS, pull PCB out of electrical connector on ignition PCB. Leave ignition PCB

in place.

Sch 228

Hab 286

19

Page 20

REPLACEMENT OF PARTS

• Fit replacement PCB in reverse order to removal.

Important: When fitting replacement PCB, ensure

that control knob spindles correctly locate into PCB

adjuster slots.

• Refit connectors and covers in reverse order to

removal.

To replace ignition PCB

• Gain access to PCB's as described in previous

section.

• Remove main PCB securing screw as described

in previous section.

• Pull off three electrical connectors on PCB.

• Lift up ignition PCB, separate from main PCB and

remove from boiler.

• Fit replacement PCB in reverse order to removal.

• Refit connectors and covers in reverse order to

removal.

To replace pump

• Drain down heating circuit of boiler only as follows:

• Close isolating valves on flow and return connections on fixing jig, see diagram 5.

Note: These valves are closed when slots are at right

angles to direction of flow.

It is not necessary to drain entire heating circuit to

carry out this work.

• Drain boiler by attaching a plastic tube to drain

outlet and opening drain valve knob anticlockwise,

see diagram 5.

• Gain access to pump connection as described

in 'To replace main PCB'.

• Pull off pump connector and earth lead.

• Pull out retaining clip from telescopic pump outlet connection and slide connection upwards to

release from pump.

• Undo and remove two fixing screws and remove

pump retaining bracket from front of pump.

• Grasp pump body, lift upward to disengage from

reversing valve and turn pump to right. Remove

pump by pulling forward and over reversing valve

assembly.

• Discard old pump inlet 'O' ring.

• Apply silicone grease to new 'O' ring supplied,

and fit onto inlet connection on replacement

pump.

• Fit replacement pump in reverse order to removal.

Note: Apply silicone grease to pump outlet connection 'O' ring before assembly.

• Refit pump electrical connection.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for leaks.

To replace temperature/pressure gauge

• Drain down heating circuit of boiler only as described in 'To replace pump'.

• Undo and remove screw securing pressure

gauge capillary to front section, see diagram 31.

• Carefully pull capillary from front section.

• Undo and remove two screws securing temperature/pressure gauge to lower front panel and remove gauge.

• Fit replacement gauge in reverse order to

removal.

Diagram 31

Diagram 32

• Fit capillary of new gauge to front section using

new 'O' ring supplied.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

To replace reversing valve assembly

• Remove temperature/pressure gauge capillary

as described previously.

• Remove pump as described previously.

• Remove microswitch assembly as described previously.

• Remove retaining clip from LHS pipe connection

on front section of valve and disengage pipe.

• Unscrew and disconnect heating flow (centre)

connection at fixing jig.

• Remove retaining clip from heating flow pipe

connection on right of front section.

• Remove flow pipe from boiler.

• Unscrew and disconnect heating return (left

hand) connection at fixing jig.

• Remove retaining clip from expansion vessel pipe

connection at rear of reversing valve assembly and

disengage pipe, pushing pipe back and out of reversing valve.

• Undo and remove large screw holding water

valve to back plate of reversing valve assembly,

see diagram 32.

Cla 007

Des 054

20

Page 21

REPLACEMENT OF PARTS

• Push water valve back to disengage it from reversing valve.

• Unclip and remove loss of water pressure switch

from left of reversing valve assembly, see diagram

33.

• From below boiler, undo and remove three

screws holding reversing valve to bottom plate of

boiler. Remove complete reversing valve assembly from boiler.

• Undo and remove heating return connecting

pipe and hose from rear of reversing valve assembly. Fit hose to replacement reversing valve assembly.

• Fit replacement reversing valve into boiler in reverse order to removal.

Note: Use new 'O' rings, retaining clip, filter and

washer provided.

• Unscrew and remove microswitch assembly from

top of replacement reversing valve assembly to

allow refitting of water valve.

Note: fit expansion vessel pipe and loss of water

switch to reversing valve assembly before pump,

to ensure that it is correctly located. Apply silicone

grease to all 'O' rings and hoses prior to assembly.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

Diagram 33

Sec 059

To replace reversing valve front section

• Remove pressure gauge capillary as described

previously.

• Remove pipe connections from either side of

reversing valve front section, refer to previous section.

• Move short selector lever on front of valve to left

hand position.

• From below boiler, undo and remove single screw

holding reversing valve front plate to bottom plate

of boiler.

• Undo and remove six screws holding front section to rear section of reversing valve, see diagram

34.

• Remove front plate complete with pump bracket

and then front section from reversing valve, along

with rubber sealing gasket.

• Assemble bypass valve provided and fit into hole

in underside of replacement front section. Fit 'U'

shaped retaining clip.

Note: Use bypass valve fitted to original front section for guidance.

• Fit replacement front section, with gasket, to rear

section.

• Locate front plate and replace six fixing screws.

Take care to evenly tighten screws ensuring they

are not cross threaded.

• Refit pipe connections to either side of front section using new 'O' rings provided. Apply silicone

grease to 'O' rings before fitting.

• Refit pressure gauge capillary in reverse order to

removal.

• Ensure short selector lever on front of valve is set

to right hand position.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

Diagram 34

Cla 007

To replace loss of water switch

• Drain down heating circuit of boiler only as described in 'To replace pump'.

Note: It is not necessary to drain entire heating circuit to carry out this work.

• Pinch plastic cover to release retaing clips and

remove cover from switch. Pull plug lead from

switch terminals.

• Remove clip holding switch into left side of reversing valve assembly.

• Pull switch out of reversing valve assembly, see

diagram 33.

• Fit replacement switch in reverse order to removal, using new 'O' ring provided and applying

silicone grease to 'O' ring before fitting.

• Reconnect plug to switch terminals.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

To replace water valve or diaphragm (except SB

models)

• Drain down hot water circuit of boiler only as

described in 'Routine Cleaning and Inspection'.

• Remove microswitch assembly as described previously.

• Unscrew connecting nut from cold water inlet

connection, second from left on fixing jig. Keep filter and flow regulator.

• Remove clip holding connecting pipe in rear of

water valve. From below boiler, grip clip with long

nosed pliers and pull down.

Note: This connecting pipe is telescopic, it may be

necessary to slide back brass sleeve to facilitate

removal.

21

Page 22

REPLACEMENT OF PARTS

• Remove clip holding pipe to heat exchanger in

rear of water valve. From front of boiler, grip clip

with long nosed pliers and pull upwards.

• Unscrew and remove large screw holding water

valve to back plate of reversing valve assembly,

see diagram 32.

• Disengage water valve from reversing valve and

remove from boiler.

Note: When disengaging water valve from heat

exchanger pipe, check that non-return valve is not

held on end of pipe. If so, carefully separate pipe

from valve to ensure that small spring and plunger

do not fly out and are lost.

• To replace diaphragm, undo five screws and

separate main components of water valve.

• If white diaphragm cover is to be replaced, separate original from water valve end casting and fit

replacement cover.

• Fit replacement diaphragm , making sure that

metal disc FACES diaphragm cover and beaded

edge of diaphragm is correctly fitted in corresponding groove in both cover and plastic housing, see

diagram 35.

• Reassemble water valve, evenly tightening five

screws.

• Fit water valve actuating pin into hole in diaphragm cover, through nose end of valve and and

push in until flush, or slightly below, nose end of

valve.

Note: Apply silicone grease to pin before fitting.

• Refit water valve to boiler, locating nose end into

rear of reversing valve assembly, 'springing' heat

exchanger pipe to gain clearance as necessary.

Fit large water valve retaining screw but do not

tighten fully at this stage.

• Apply silicone grease to 'O' ring and fit onto end

of heat exchanger pipe. Fit pipe into water valve

by pulling it forward. Make sure that 'O' ring is correctly located.

• Whilst holding pipe in rear of water valve, fit retaining clip. This should easily clip over pipe and

should NOT have to be forced. If resistance is experienced, either pipe is not correctly fitted in rear

of water valve or clip is not being fitted properly

through slot between back plate and plastic housing of water valve. When clip is fitted, check connection by pushing pipe back away from water

valve.

• Refit telescopic connecting pipe to inlet of water valve after applying silicone grease to 'O' ring.

Fit retaining clip into groove on connecting pipe,

through slot between back plate and water valve

plastic housing. Check connection by pulling pipe.

Make sure that clip is not loose and likely to fall out

at a later date. If in doubt, fit a new clip.

• With both flow regulator and and plastic filter

washer in place, refit connecting nut to inlet connection and tighten.

• Open isolating valve on cold water inlet connection and check for leaks.

• Replace microswitch assembly.

To replace gas valve

• Ensure gas supply is off.

• Disconnect two black electrical leads from gas

valve modulating coil.

Diagram 35

Diagram 36

• Disconnect two white and one red lead from gas

valve main solenoid.

• Pull off clear plastic tube from gas valve to sealed

chamber tapping point.

• Unscrew main gas supply pipe nut on top of gas

valve, releasing spark ignition unit bracket, see dia-

gram 36.

• From below boiler, unscrew gas valve connection between gas valve and fixing jig isolating cock.

• Unscrew and remove two screws securing gas

valve to bottom plate of boiler.

• Remove gas valve from boiler.

• Refit replacement gas valve in reverse order to

removal.

Note: Use new 'O' ring provided between gas valve

and burner supply pipe.

• Refit electrical connections to replacement gas

valve as follows:

- BLACK leads to modulating coil.

- WHITE leads to EV1 and EV2 terminals of main

solenoid

- RED lead to COM terminal of main solenoid.

To replace modulating coil

• Ensure gas supply is off.

• Disconnect two black electrical leads from gas

valve modulating coil.

• Unscrew and remove two screws holding modulating coil to gas valve and remove coil from gas

valve.

• Fit replacement modulating coil in recerse order

to removal.

• Reconnect electrical leads to replacement coil.

Note: All boilers are tested and factory set during

manufacture. Should it be necessary to reset a gas

valve, for example after replacement, refer to 'Set-

tings'.

Des 058

Mec 117

22

Page 23

REPLACEMENT OF PARTS

To replace safety valve

• Drain down entire heating system.

• From below boiler, disconnect heating flow pipe

from rear of fixing jig.

• Undo heating flow connection on front of fixing

jig. Remove clip from heating flow pipe connection on right of front section of reversing valve. Pull

pipe towards right and out of reversing valve. Remove pipe from boiler and keep.

• From below boiler, disconnect safety valve discharge pipe.

• Working through boiler from the front using a long

screwdriver, undo and remove screw holding safety

valve assembly to fixing jig.

• Remove complete safety valve assembly from

fixing jig and remove from boiler.

• Fit replacement safety valve in reverse order to

removal.

Note: Apply silicone grease to 'O' ring before fixing

pipe into right hand side of reversing valve.

• Refill heating system and boiler, vent and pressurise as described previously.

To replace heat exchanger

• Drain down both heating and hot water circuits

of boiler only as described previously.

Note: It is not necessary to drain entire heating system to carry out this work.

• Remove combustion chamber cover as described in 'Routine Cleaning and Inspection'.

• Remove two clips from heating connections to

left side of heat exchanger.

• Remove clip holding pump outlet connection

into pump and slide connection up pump outlet

pipe. Pull complete pipe down to disengage from

heat exchanger.

• Remove retaining clip from LHS pipe connection

on front section of valve and disengage pipe.

• Disengage pipe downwards from heat exchanger.

• Unscrew and disconnect two hot water connections to right side of heat exchanger.

• Grasp both sides of heat exchanger and slide

forwards and out of boiler.

• Fit replacement heat exchanger in reverse order to removal.

Note: Use new sealing washers and 'O' rings provided.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

To replace expansion vessel

1 Boiler in place

Note: The expansion vessel can be replaced with

the boiler in place provided that there is a minimum clearance of 400mm on one side of the boiler

and that no vertical pipework passes between

boiler and wall on that side.

• Drain down the heating circuit of the boiler only

as described in 'To replace pump'.

Note: It is not necessary to drain entire heating system to carry out this work.

• Remove pump from boiler as described previously.

• Unscrew pipe connection nut from expansion

vessel and disengage pipe from connection. Keep

sealing washer.

• Whilst supporting weight of vessel, push bottom

of vessel away from boiler, disengaging threaded

connection from hole in rear of boiler. Allow vessel

to drop out of its two upper retaining brackets.

• Remove vessel to side of boiler.

• Fit replacement expansion vessel in reverse order to removal ensuring that sealing washer is fitted to vessel pipe connection.

• Check that vessel charge pressure is 1bar. Correct if necessary.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

2 Boiler removed from wall

• Drain down the heating circuit of the boiler only

as described in 'To replace pump'.

Note: It is not necessary to drain entire heating system to carry out this work.

• Ensure that gas and electrical supplies to boiler

are turned off.

• Disconnect flue from either rear or top of boiler

as applicable.

• Disconnect external controls connections, if applicable.

• Unscrew and disconnect five connections between fixing jig and boiler.

• Disengage pipe connections. Lift boiler off hanging bracket and place on a convenient working

surface.

• Remove expansion vessel from boiler as described in previous section.

• Fit replacement vessel in reverse order to removal

and check charge pressure.

• Replace boiler on wall, tighten all connections,

gas connection first, ensuring that all sealing washers, filters and the cold water flow regulator are fitted before tightening.

• Reconnect flue system.

• Open isolating valves on flow and return connections, refill, vent and pressurise boiler. Check for

leaks.

• Reconnect external controls connections, if applicable.

• Reconnect gas and electrical supplies to boiler.

• Check for gas soundness.

To replace boiler thermistor

• Locate boiler thermistor on heating flow pipe on

left hand side of boiler, see diagram 37.

Diagram 37

23

Page 24

REPLACEMENT OF PARTS

• Unclip thermistor from pipe.

• Pull off electrical cennections from thermistor.

• Fit replacement thermistor in reverse order to removal.

Note: No heat sink compound is required. The polarity of the connections is not important.

To replace overheat thermostat

• Locate the overheat thermostat on the right

hand side of the heat exchanger.

• Pull off the electrical connections from the thermostat.

• Unscrew and remove two screws holding thermostat to heat exchanger.

• Fit replacement thermostat in reverse order to

removal, using heat sink compound on the contact surface of thermostat.

• Refit electrical leads, the polarity is not important.

To replace combustion chamber insulation

Front section

• Remove combustion chamber from boiler as

described in 'Routine Cleaning and Inspection'.

• Slide side panels out of combustion chamber

sides.

• Lift front insulation panel free from retaining lugs

and away from cover.

• Fit replacement panels in reverse order to removal.

Rear panel

• Remove burner from boiler as described in 'Routine Cleaning and Inspection'.

• Remove clip from base of insulation panel.

• Pull bottom edge of insulation panel forward,

downward and out from behind heat exchanger.

• Fit replacement panel in reverse order to removal.

• Replace burner into boiler in reverse order to removal.

To replace ignition electrode

• Remove combustion chamber from boiler as

described in 'Routine Cleaning and Inspection'.

• Pull off ignition leads from ignition electrode.

• Unscrew and remove two screws holding ignition electrode onto burner.

• Fit replacement ignition electrode in reverse order to removal.

• Refit ignition leads, the polarity is not important.

To replace burner

• Pull off ignition and flame sense leads from electrodes.

• Remove burner from boiler as described in 'Rou-

tine Cleaning and Inspection'.

• Remove ignition and flame sense electrodes as

described in previous sections.

• Unscrew and remove two screws holding burner

injector bar to burner and remove injector bar.

• Asemble replacement burner, supplied in parts,

as follows:

• Fit burner injectors to injector bar and tighten.