Page 1

HIGH EFFICIENCY CONDENSING COMBINATION BOILER

Instructions for use

Installation and servicing

Semia Condens F24 E G.C. 47-920-51

Semia Condens F30 E G.C. 47-920-52

Page 2

Page 3

Instructions for use

Index

1 Important information ...........................................................2

2 Guarantee registration ..........................................................3

3 Appliance use ........................................................................4

4 Servicing ................................................................................4

5 Recycling ...............................................................................4

6 Operating the boiler (user instructions) .............................5

6.1 Control panel ................................................................................5

6.2 Commissioning and lighting .........................................................5

6.3 To program daily timeclock ...........................................................5

6.4 Temperature adjustment ...............................................................6

7 Turn the boiler off ..................................................................6

8 Fault finding ...........................................................................6

9 Frost protection .....................................................................9

9.1 Boiler frost protection ...................................................................9

9.2 Frost protection activation ............................................................9

Instructions for Use

10 Maintenance/After Sales Service .........................................9

1

Page 4

1 Important information

WARNINGS

Gas Leak or Fault

Turn off the gas emergency control valve immediately. Eliminate all sources of ignition, i.e. smoking, blowlamps, hot air

guns, etc. Do not operate electrical lights or switches either on or off. Open all doors and windows, ventilate the area.

Sheet Metal Parts

This boiler contains metal parts (components) and care should be taken when handling and cleaning, with particular

regard to edges.

Sealed Components

Under no circumstances must the User interfere with or adjust sealed parts.

Gas Category

This boiler is for use only on G20 natural gas, but the 30cxi may be

converted for use on G31 gas (Propane L.P.G.).

Gas Safety (Installation and Use) Regulations

In your own interests and that of safety, it is the Law that ALL gas

appliances are installed by a competent person in accordance with

the current issue of the above regulations.

Testing and Certifi cation

This boiler is tested and certifi cated for safety and performance.

It is, therefore, important that no alteration is made to the boiler,

without permission, in writing, by Saunier Duval.

Any alteration not approved by Saunier Duval, could invalidate the

certifi cation, boiler warranty and may also infringe the current issue

of the statutory requirements.

CE Mark

This boiler meets the requirements of Statutory Instrument, No.

3083 The Boiler (Effi ciency) Regulations, and therefore is deemed

to meet the requirements of Directive 92/42/EEC on the effi ciency

requirements for new hot water boilers fi red with liquid or gaseous

fuels.

Type test for purposes of Regulation 5 certifi ed by: Notifi ed body

0087.

Product/production certifi ed by: Notifi ed body 0086.

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the laws of the

Member States relating to appliances burning gaseous fuels.

2. Directive 73/23/EEC on the harmonisation of the Laws of the

Member States relating to electrical equipment designed for use

within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of the

Member States relating to electromagnetic compatibility.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act 1974, we are

required to provide information on substances hazardous to health.

The adhesives and sealants used in this appliance are cured and

give no known hazard in this state.

Insulation Pads / Ceramic Fibre

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible to

irritation. High dust levels are usual only if the material is broken.

Normal handling should not cause discomfort, but follow normal

good hygiene and wash your hands before eating, drinking or going

to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin

seek medical attention.

Electrical Supply

The boiler must be earthed.

All system components shall be of an approved type and all wiring

to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in accor-

dance with the relevant standards.

In GB this is BS 6891.

In IE this is the current edition of I.S.813 “Domestic Gas Installa-

tions”.

The boiler must be connected to a permanent 230V ac, 50Hz sup-

ply.

Connection of the whole electrical system of the boiler, including

any heating controls, to the electrical supply must be through one

common isolator and must be fused 3 Amp maximum.

Isolation should be by a double pole switched fused spur box, with

a minimum gap of 3mm for both poles. The fused spur box should

be readily accessible and preferably adjacent to the appliance. It

should be identifi ed as to its use.

Alternatively connection can be made through an unswitched shuttered socket and 3A fused 3-pin plug both to the current issue of BS

1363 may be used, provided they are not used in a room containing

a bath or shower.

Wiring to the boiler must be PVC 85°C insulated cable, not less than

0.75mm2 (24/0.20mm).

2

Page 5

2 Guarantee registration

Thank you for installing a new Saunier Duval appliance in your home.

Saunier Duval appliances’ are manufactured to the very highest standard so we are pleased to offer our customers’ a

Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date of manufacture,

whichever is the shorter, for parts. In addition this product is guaranteed for 12 months from the date of installation

or 18 months from the date of manufacture, whichever is the shorter, for labour.

The second year of the parts guarantee, from the beginning of the 13th month onwards after installation, is conditional

upon the boiler having been serviced by a CORGI registered gas installer, in accordance with the manufacturer’s

recommendations. We strongly recommend regular servicing of your gas appliance, but where the condition is not met, any

chargeable spare parts of components issued within the applicable guarantee period still benefi t from a 12 month warranty

from the date of issue by the manufacturer.

We recommend you complete and return as soon as possible your guarantee registration return literature, supplied in

the document envelope.

If your guarantee certifi cation return literature is missing you can obtain a copy by telephoning

the Saunier Duval Customer Service number 00 44 (0)1773 525914.

REGISTER YOUR SAUNIER DUVAL APPLIANCE DIRECTLY BY CALLING

00 44 (0)870 240 3413

Instructions for Use

Customer service:

Saunier Duval GB Great Britain:

Tel. 00 44 (0)1773 525914

Fax. 00 44 (0)1773 828070

Saunier Duval,

Nottingham Road, Belper, Derbyshire. DE56 1JT

Saunier Duval IE Ireland:

Tel. 00 3531 4508120

Taney Distribution

Unit 4, Riverside Industrial Estate

Bluebell Avenue

Dublin 12

Technical Advice Line:

Tel. 00 44 (0)1773 828400

General and Sales enquires:

Tel. 00 44 (0)870 606 4351

Fax. 00 44 (0)1773 820569

3

The code of practice for the installation,

commissioning & servicing of gas central heating

Page 6

3 Appliance use

4 Servicing

Saunier Duval’s appliances are

manufactured according to the latest

technical evolutions and current safety

regulations.

This appliance is used to produce

hot water using gas. Any other use is

considered inappropriate and is forbidden.

The manufacturer shall not be responsible

for any damage caused by another use. In

that case the user shall be the responsible

party.

•

Clean the case of the appliance with

wet soapy cloth.

•

Do not use any abrasive cleaning

product as they could damage the

housing or plastic parts.

•

Also see section 12 & 35.

5 Recycling

The appliance comprises many recyclable

parts. The packaging, the appliance and

the content of the package shall not be

thrown together with domestic waste

but eliminated according to the current

regulations.

4

Page 7

6 Operating the boiler (user instructions)

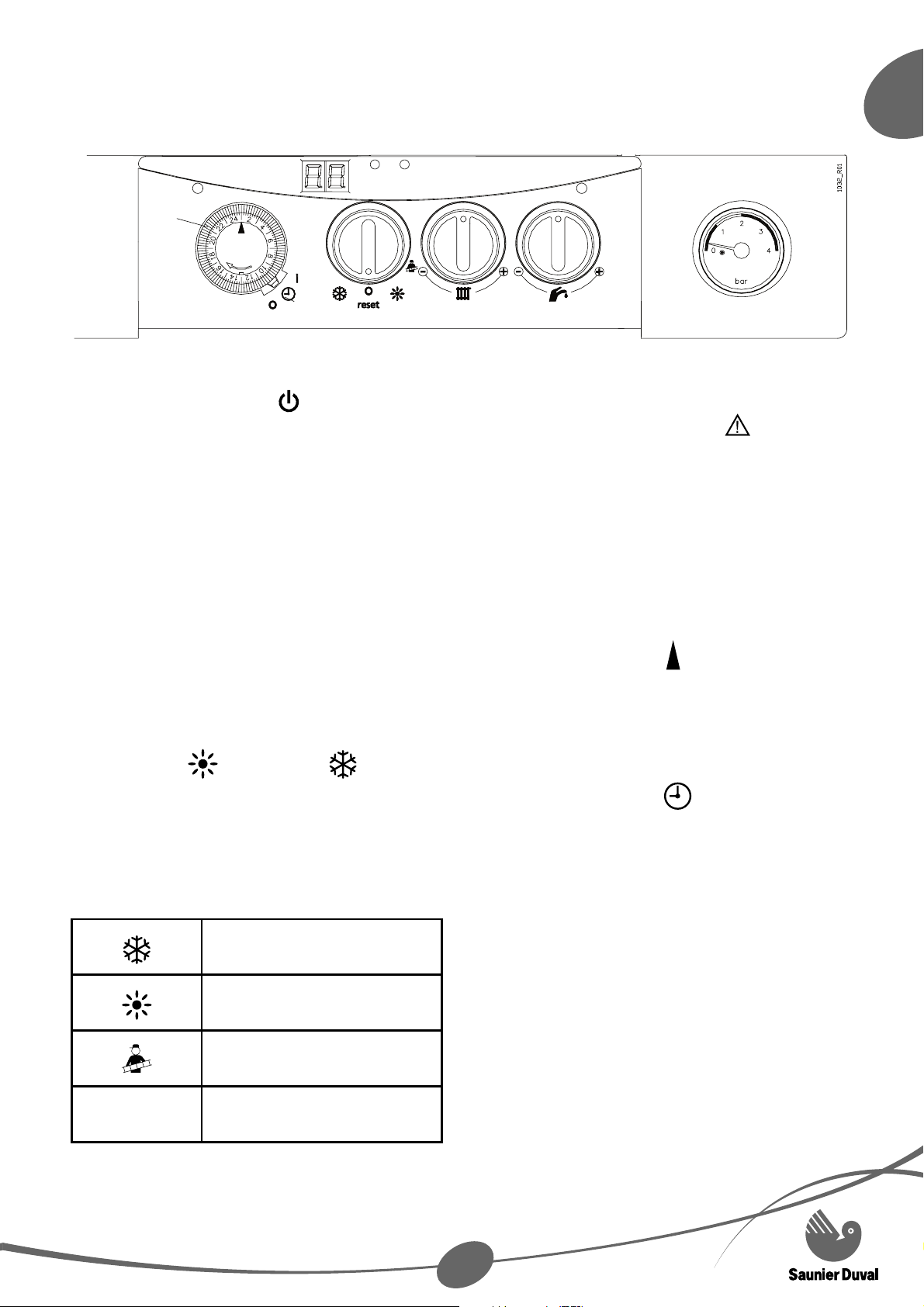

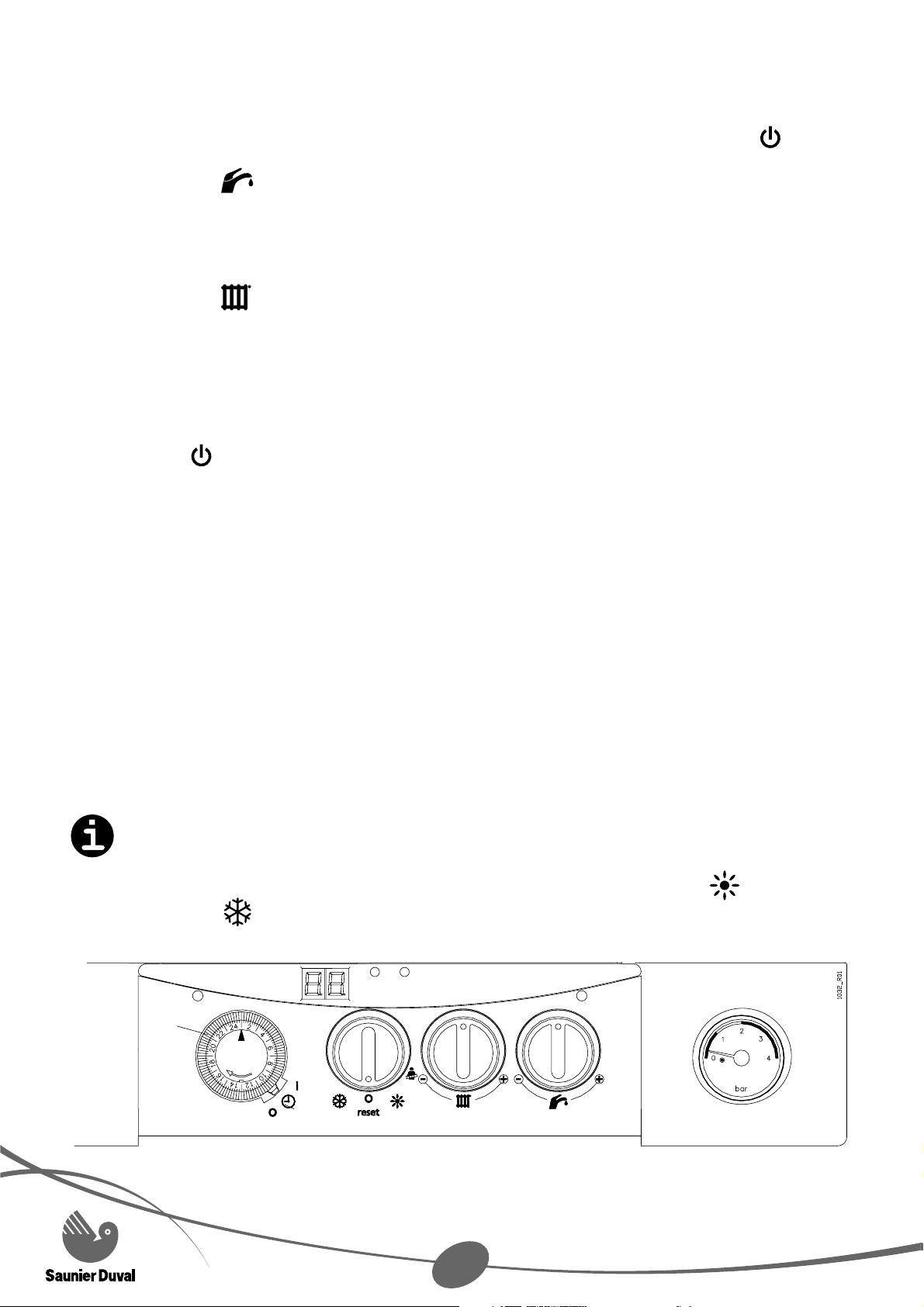

6.1 Control panel

5

1

9

8

234

10

Legend

1 Operating indicator

2 Operating mode selection

3 Heating temperature adjustment

4 DHW temperature adjustment

5 Display of the temperature /

error codes

6.2 Commissioning and lighting

Make sure that:

•

the boiler is connected to the electrical

supply (the green indicator [1] blinks).

7

6

6 Pressure gauge

7 Safety lockout indicator

8 Timeclock

9 Timeclock toggles

10 Timeclock mode selector

6.3 To program daily timeclock

Set the current time, by turning the dial [8]

clockwise until the current time is shown

against the indicator ‘

’.

Instructions for Use

the gas service cock is open.

Turn the selector [2] bringing it in the

•

SUMMER

The operating indicator [1] on the

control panel turns on: the boiler is

ready to run.

Turn the selector [2] to modify the

•

operating mode of the boiler:

0

reset

or WINTER position.

Central heating and

domestic hot water

Domestic hot water only

Installer mode

Stand-by and appliance

frost protection

Push in plastic toggles [9] against the time

you wish the heating to be off.

The timeclock can operate in three

positions: automatic ‘ ’, heating

permanently off ‘0’, and heating

permanently on ‘1’.

To select, move the lever [10] to the

desired position.

NOTE: In case the electrical supply fails

the timeclock will not operate as

it has no back-up battery backup.

Therefore, it will be necessary

to reset the current time once

electrical supply is restored.

5

Page 8

6.4 Temperature adjustment

6.4.1 Domestic hot water temperature

adjustment

Turn the knob

•

domestic hot water max temperature.

6.4.2 Heating temperature adjustment

[4] to adjust the

7 Turn the boiler off

Turn the selector [2] on the 0 / reset

•

position

blinks).

We advise you to turn off the appliance

gas supply if you leave home for a long

period.

(the green indicator [1]

Turn the knob

•

heating system temperature.

[3] to change the

8 Fault finding

GREEN LED [1]

The green led can be off, fl ashing (slowly or rapidly) or on.

OFF: the boiler is electrically disconnected. In these conditions the boiler obviously

doesn’t work. The Automatic Anti Freezing and Anti Blocking functions can’t be activated (prevents damage to boiler during long period of inactivity). The external general

switch could be off.

FLASHING (slowly): the boiler has power but the SUMMER/WINTER Selector is in central

position (0). The boiler will not provide heating or hot water but the boiler protection

systems are operating (Anti Freezing and Anti Blocking functions may ignite the boiler

and as such require the gas supply to be open).

FLASHING (rapidly): the Chimneysweep Function (which is reserved for the installer)

is on by mistake.

Turn it off bringing the SUMMER/WINTER selector on the central position (0) until

the green led fl ashes slowly.

ON: the boiler is on and the SUMMER/WINTER selector is in the SUMMER

the WINTER

Position. The boiler will provide heating and hot water on demand.

5

1

7

Position or in

6

9

8

234

10

6

Page 9

RED LED [7] - FAULT CODES AND LOCKOUTS

The red led [7] can be off, fl ashing or on.

Led OFF: the boiler is functioninging correctly.

Led FLASHING: signals a boiler fault. The display [5] will show a fault code:

Fault code “06” - the heating system temperature sensor (inside the boiler) is

damaged. Call a Qualifi ed Technician to repair.

Led ON - The display [5] shows a fl ashing code. Things to try:

Code “01” - If the boiler has just been installed, or adjustments have been made

to the gas pipes.

If the air-gas mix ratio is incorrect then this will prevent combustion and can

force the boiler into a state of lockout. In order to correct the mix you should

repeat the ignition process several times with the SUMMER/WINTER Selec-

tor on the 0 /

reset position until the red led turns off.

Code “01” - Ignition problems if no work has been carried out.

Ensure that the SUMMER/WINTER selector is on the 0 / reset position until the

red led turns off. If this does not happen or the boiler goes back into lockout please

ask your installer to check the following points:

• Check the CO

levels of the boiler are correct. Please refer to Technical Data

2

table in the section reserved for installers (in this manual);

• Check the fl ue outlet for leaks and inspect general condition clearliness.

Please refer to “Flue connection” in the section reserved for installers (in

this manual).

Instructions for Use

Technical Note for the TECHNICIAN: if the Flame Control Unit is not detecting a fl ame

it could be due to one of the following reasons:

• the fl ame has not ignited;

• the fl ame control unit has become disconnected from the burner.

7

Page 10

Code “05” - The boiler is overheating and the Safety Thermostat has triggered.

Move the SUMMER/WINTER Selector on the 0 /

led turns off (this may take a while to allow the boiler to cool). Once the led

is off move the selector to the desired position (Summer

If the boiler locks out again please call the group service for assistance.

Code “05” - The boiler fl ue is overheating and the Flue Safety Thermostat has

triggered;

The thermostat must be replaced by the installer. Please try the following

process, if it does not work then call group service for assistance.

Move the SUMMER/WINTER Selector on the 0 /

led turns off (this may take a while to allow the boiler to cool). Once the led

is off move the selector to the desired position (Summer

If the boiler locks out again please call the group service for assistance.

Code “21” - You have insuffi cient water pressure (0.5 bar or lower).

Repressurise the system to the optimum pressure of between 1-1,5 bar

(cold) by following the procedure outlined in the paragraph “Commissioning”

in the section reserved for installers (in this manual).

If a system continues to lose pressure it would suggest a system leak and

the system should be inspected for water loss. Also check that all radiators

bleed points are closed or have not been recently opened before checking

the system.

reset position until the red

or Winter ).

reset position until the red

or Winter ).

8

Page 11

9 Frost protection

9.1 Boiler frost protection

In case of frost risk, do as follows:

•

Make sure the boiler is supplied with

electrical power and gas.

•

Turn the selector [2] on the 0 /

position (the green indicator

blinks).

The frost protection system operates the

boiler as soon as the temperature in the

heating circuit is under 5°C. The boiler

stops as soon as the water temperature in

the heating circuit reaches 30°C.

9.2 Frost protection activation

If you leave home for a few days, select

•

the minimum heating temperature on

the control panel of the boiler and just

decrease the setpoint temperature on

your room thermostat.

reset

[1]

10 Maintenance/After Sales Service

Please note that an incorrectly serviced

appliance can affect the safety of the

appliance and can lead to injury.

To ensure the continued effi cient and

safe operation of the appliance it is

recommended that it is checked and

serviced as necessary at regular intervals.

The frequency of servicing will depend

upon the particular installation conditions

and usage, refer to guarantee registration.

If this appliance is installed in a rented

property there is a duty of care imposed

on the owner of the property by the current

issue of the Gas Safety (Installation and

Use) Regulations, Section 35. Servicing/

maintenance should be carried out by

a competent person in accordance with

the rules in force in the countries of

destination. To obtain service, please call

your installer or Saunier Duval service

team.

Instructions for Use

If you leave home for a long period, see

•

chapter “Draining of the appliance” in

the section reserved for installers (in

this manual).

9

Page 12

Installation and servicing

Index

1 Comments on the instructions ..........................................12

2 Appliance description .........................................................12

2.1 Data label ...................................................................................12

2.2 Mandatory WARNING for EEC countries ...................................12

2.3 Block diagram .............................................................................13

3 Appliance location ..............................................................13

4 Safety instructions and regulations ..................................14

4.1 Safety instructions ......................................................................14

4.2 Regulations ................................................................................15

5 Appliance installation .........................................................16

5.1 Recommendations before mounting ..........................................16

5.2 Dimensions .................................................................................17

5.3 List of delivered equipment ........................................................18

5.4 Fixing to the wall .........................................................................18

5.5 Gas and water connection ..........................................................19

5.6 Connection to the condensate trap ............................................20

5.7 Flue connection ..........................................................................22

5.7.1 Flue restrictor .............................................................................22

5.7.2 Horizontal concentric flue Ø 60/100 (C13 type installation) ......24

5.7.3 Vertical concentric flue Ø 60/100 (C33 type installation) ...........24

5.7.4 Twin flue 2 x Ø 80 (C53 type installation) ...................................25

5.8 Electrical connection ..................................................................25

5.8.1 External controls .........................................................................26

5.9 Wiring diagram ...........................................................................28

6 Commissioning ...................................................................29

7 Specific adjustments ..........................................................29

7.1 Pump speed ...............................................................................29

7.2 Personalizing the boiler’s functioning .........................................31

8 Draining of the appliance ...................................................32

8.1 Heating circuit .............................................................................32

10

Page 13

9 Gas valve / Output power settings ....................................33

9.1 Gas valve setting ........................................................................33

9.2 Central heating output setting ....................................................34

9.3 Domestic hot water flow rate setting ..........................................34

9.4 Slow opening setting ..................................................................35

9.5 Changing gas type .....................................................................35

10 Fault finding .........................................................................35

11 Control / Commissioning ...................................................38

12 User information .................................................................38

13 Spare parts ..........................................................................38

14 Maintenance ........................................................................39

14.1 Casing ........................................................................................39

14.2 Combustion chamber .................................................................39

14.3 Burner .........................................................................................39

14.4 Heat exchanger ..........................................................................39

14.5 Reassembly of parts removed for servicing ...............................40

14.6 Flue system ................................................................................40

14.7 Operation of fan ..........................................................................40

15 Replacement of parts ..........................................................40

15.1 To replace fan .............................................................................40

15.2 To replace air pressure switch ....................................................40

15.3 To replace pump .........................................................................41

15.4 To replace gas valve ...................................................................41

15.5 To replace domestic heat exchanger ..........................................42

15.6 To replace thermistor ..................................................................42

15.7 To replace overheat thermostat ..................................................42

16 Technical data .....................................................................43

16.1 Burner pressure tables ...............................................................44

17 Boiler schematic .................................................................45

Installation and servicing instructions strictly reserved for qualifi ed gas installers

11

Page 14

1 Comments on the instructions

Please give all of the instructions to

•

the user. The user shall keep them for

future reference.

We accept no liability in case of damage

due to the non-compliance of the

instruction manual.

2 Appliance description

2.1 Data label

The data label certifi es the origin where

the product was manufactured and the

country for which it is intended.

Warning! The appliance shall only be used

with the gas types indicated on the data

label.

Member States relating to appliances

burning gaseous fuels.

Directive 73/23/EEC on the

harmonisation of the Laws of the

Member States relating to electrical

equipment designed for use within

certain voltage limits.

Directive 89/336/EEC on the

approximation of the Laws of

the Member States relating to

electromagnetic compatibility.

IMPORTANT. With regards to the

Manual Handling Operations, 1992

Regulations, the following lift operations

are recommended as the appliance weight

exceeds a one-man lift.

Clear the route before attempting the

•

lift.

2.2 Mandatory WARNING for EEC

countries

This appliance is designed, approved and

inspected to meet the requirements of the

intended market. The data label indicates

where the product was manufactured and

the country for which it is intended.

This appliance meets the requirements

of Statutory Instrument, No. 3083 The

Appliance (Effi ciency) Regulations,

and therefore is deemed to meet the

requirements of Directive 92/42/EEC

on the effi ciency requirements for new

hot water appliances fi red with liquid or

gaseous fuels.

Type test for purposes of Regulation 5

certifi ed by: Notifi ed body 0063. Product/

production certifi ed by: Notifi ed body

0086.

The CE mark on this appliance shows

compliance with:

Directive 90/396/EEC on the

approximation of the laws of the

Ensure safe lifting techniques are used

•

- keep back straight - bend using legs.

Keep load as close to body as possible.

•

Do not twist - reposition feet instead.

•

If two persons performing lift, ensure

•

co-ordinated movements during lift.

Always use assistance if required.

•

Manufacturer’s instructions must not be

taken as overriding statutory requirements.

Reference in these instructions to British

standards and statutory regulations/

requirements apply only to the United

Kingdom. For Ireland the current edition of

I.S.813 «Domestic Gas Installations» must

be used.

This appliance certifi cated to the

current issue of EN 483: 2000 for

performance and safety. It is important

that no alteration is made to the appliance,

without permission, in writing, from

Saunier Duval. Any alteration that is

not approved by Saunier Duval could

invalidate the warranty and could also

infringe the current issue of the Statutory

Requirements.

12

Page 15

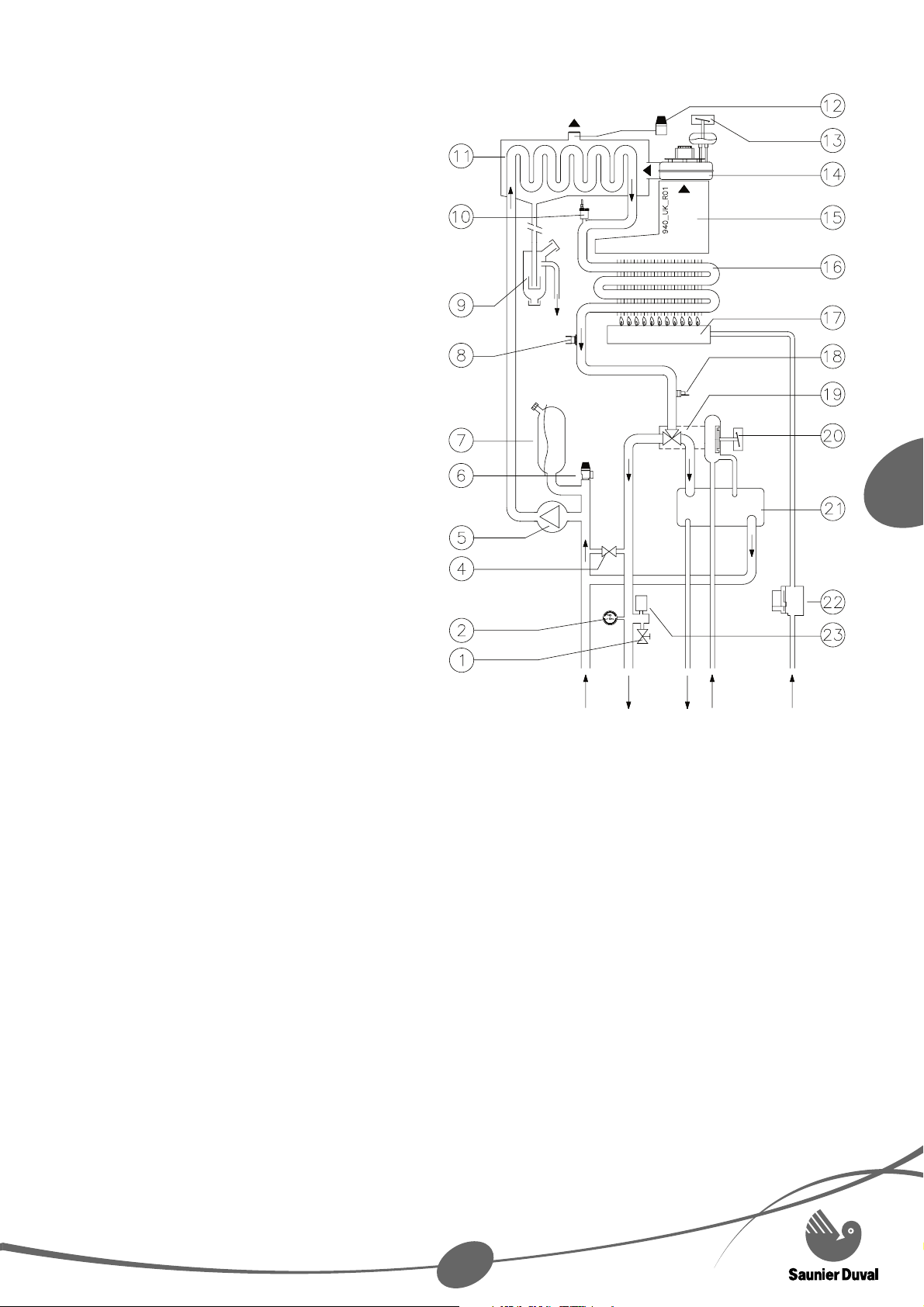

2.3 Block diagram

1 Drain valve

2 Pressure gauge / thermometer

4 By-pass

5 Pump

6 Heating system safety valve 3 bar

7 Expansion vessel

8 Overheat thermostat

9 Condense syphonic trap

10 Automatic air vent

11 Recuperator

12 Flue overheat safety thermostat

13 Air pressure switch

14 Fan

15 Flue hood

16 Primary heat exchanger

17 Burner

18 Thermistor

19 Hydraulic 3-way valve

20 Water valve

21 Domestic plate to plate

heat exchanger

22 Gas valve

23 low pressure sensor

CONDENSE

(orange)

FLUE

WARNING: This

schematic is for

information only.

3 Appliance location

This appliance is not suitable for

•

outdoor installation.

This appliance may be installed in any

•

room, although particular attention is

drawn to the installation of an appliance

in a room containing a bath or shower

where reference must be made to the

relevant requirements. In GB this is the

current I.E.E. WIRING REGULATIONS

and BUILDING REGULATIONS.

GAS

FLOW

(green)

RETURN

HEATING

In IE reference should be made to the

•

(green)

INLET

(black)

OUTLET

DOMESTIC

WATER

(white)

(white)

current edition of I.S.813 «Domestic

Gas Installations» and the current ETCI

rules.

•

Make sure you keep the minimum

clearances to ensure total accessibility

for servicing. Top: 150 mm; bottom: 200

mm; side: 5 mm.

The appliance must be mounted on a

•

fl at wall, which is suffi ciently robust to

take its weight.

Installation and servicing instructions strictly reserved for qualifi ed gas installers

13

Page 16

The appliance is room sealed, so when

•

it is installed in a room or space, a

permanent air vent is not required.

Do not install the appliance above

•

another appliance that could damage

it (for example, above a cooker that

might emit steam or grease) or in a

room, which has a lot of dust in the

atmosphere which is corrosive.

to provide information on substances

hazardous to health.

The adhesives and sealants used in this

appliance are cured and give no known

hazard in this state.

In the event of the appliance overheating

the safety devices will cause a safety

shutdown. If this happens, call your

installation/servicing company.

4 Safety instructions and

regulations

This appliance is tested and certifi cated

for safety and performance. It is, therefore,

important that no alteration is made to the

appliance, without permission, in writing,

from Saunier Duval.

Any alteration not approved by Saunier

Duval, could invalidate the certifi cation,

appliance warranty and may also

infringe the current issue of the statutory

requirements.

4.1 Safety instructions

If the gas pressure at the input of the

appliance is outside the range specifi ed,

you shall not start the appliance. If the

cause of the problem cannot be found

nor solved, please contact the Gas Utility

company.

Warning! This appliance must be

earthed. This appliance must be wired in

accordance with these instructions. Any

fault arising from incorrect wiring cannot

be put right under the terms of the Saunier

Duval guarantee.

The following safety instructions must

be imperatively followed during the

maintenance and the replacement of

spare parts.

Stop the appliance (see chapter “Turn

•

the boiler off” in the “Instructions for

use” section, in this manual).

Deactivate the appliance from the

•

mains power supply with the socket or

the double-pole switch (with a minimum

gap of 3mm for both poles).

Turn off the gas control valve.

•

Warning! Incorrect installation can cause

electric shock or appliance damage.

When making the connections, locate

the sealing washers properly so as to

avoid any gas or water leakage.

Never use a wire brush or stiff-bristle

scrubbing brush to clean the heat

exchanger as this could damage the

appliance.

Under no circumstances must the User

interfere with or adjust sealed parts.

Under Section 6 of The Health and

Safety at Work Act 1974, we are required

14

Close the shut off valves located on the

•

connection sockets.

Drain the appliance when you want

•

to change the hydraulic parts of the

appliance.

Let the appliance cool down before

•

undertaking any maintenance

operation.

Protect all the electrical components

•

from water when you achieve any

operations.

Use only new O-rings and gaskets.

•

Page 17

After having carried out work on the

•

gas carrying components check that

they are correctly fi tted and sealed by

checking for leaks.

When the work is complete check the

•

boiler operates correctly.

4.2 Regulations

When installing and commissioning the

appliance, the regulations below shall be

observed in their current version:

In your own interests and that of safety, it

is the Law that ALL gas appliances must

be installed by a competent person only,

in accordance with the current issue of the

above regulations.

In GB the installation of the appliance

must be carried out by a competent

person as described in the following

regulations:

The manufacturer’s instructions

supplied.

The Gas Safety (Installation and Use)

Regulations.

The appropriate Buildings Regulations

either The Building Regulations, The

Building Regulations (Scotland), The

Building Regulations (Northern Ireland).

The Water Fittings Regulations or

Water byelaws in Scotland.

reference should be made to the current

ETCI rules for Electrical Installation.

In GB the following Codes of Practice

apply: BS4814, BS6798, BS5440 Part 1

and 2, BS5546 Part 1, BS5449, BS6891,

BS6700, BS7074 Part 1 and 2, BS7593,

BS7671.

In IE: I.S.813, BS5546, BS 5449, BS

7074, BS 7593.

Where no British Standard exists,

materials and equipment should be fi t

for their purpose and of suitable quality

and workmanship. The installation of

this appliance must be carried out by

a competent person in accordance

the rules in force in the countries of

destination. Manufacturer’s instructions

must not be taken as overriding statutory

requirements.

If the appliance is to be installed in a

timber frame building it should be fi tted

in accordance with the Institute of Gas

Engineers document IGE/UP/7/1998. If

in doubt seek advice from the local gas

undertaking or Saunier Duval.

The installation is subject to building

regulation approval, notify the Local

Authority of intention to install.

The Health and Safety at Work Act,

Control of Substances Hazardous to

Health (COSHH).

The Current I.E.E. Wiring Regulations.

-

Where no specifi c instructions are given,

reference should be made to the relevant

British Standard Code of Practice.

In IE, the installation must be carried out

by a competent person and installed in

accordance with the current edition of

I.S.813 «Domestic Gas Installations»,

the current Building Regulations and

Installation and servicing instructions strictly reserved for qualifi ed gas installers

15

Page 18

5 Appliance installation

All the dimensions in this chapter are

expressed in mm.

5.1 Recommendations before

mounting

5.1.1 Domestic hot water circuit design

The circuit should be designed to avoid

any unnecessary fl ow losses (decrease

the number of elbows).

The boiler will operate with a minimum

supply pressure but with a low fl ow.

Optimum performance will be achieved

with a pressure of 1 bar (cold).

5.1.2 Heating circuit design

SEMIA CONDENS boilers can be used for

any kind of installation: serial or derivated

double tube, single tube, under fl oor

heating, etc...

Heating surfaces can be made up with

heaters, convectors or unit heaters.

Warning: If the materials used are of

a different type, some corrosion can

occur. In that case, we advise you to

add an inhibitor to the heating circuit

water (according to the manufacturer’s

recommendations) that could avoid gas

production and oxide formation.

The pipework sections should be fi xed by

using the following fl ow/pressure curve

(see chapter “Heating circuit adjustment”).

The system will be calculated according

to the fl ow corresponding to the power

that is really required without taking into

account the maximum power that the

boiler can supply. Nevertheless, we advise

you to have a fl ow big enough so that the

temperature difference between outgoing

and return is under or equal to 20°C. The

minimum fl ow rate is indicated in the

chapter “Technical Data” at the end of this

instruction manual.

The piping route should be designed in

such a way that it avoids any air locks

and make purging of gas from the system

easier. Bleeders should be placed at each

high point of the system as well as on any

radiators.

Total water volume accepted by the

heating circuit depends, amongst

other things, on the cold static load.

The expansion tank fi tted in the boiler

is delivered set in plant (see chapter

“Technical Data” at the end of this

instruction manual). At commissioning, it

is possible to change this pressure in case

of a larger static load. We advise you to

provide a drain valve at the lowest point of

the system.

If thermostatic radiator valves are used,

we advise you not to fi t in a room where a

room thermostat is fi tted.

In case of an old installation, the

•

system should be fl ushed. See section

5.1.4.

If the boiler is not immediately set,

•

protect all the pipe fi ttings so as to

avoid that any plaster element or paint

could impede the connection.

16

Page 19

5.1.3 Water treatment

In the case of an existing installation, it is Essential that prior to installing the new boiler

the system is thoroughly fl ushed. For optimum performance after

installation of a new system, the boiler and its associated central heating system

should also be fl ushed.

Flushing should be carried out in accordance with BS7593: 1992 using a

cleanser such as Sentinel X300 or X400, Fernox Superfl oc or Salamander corrosion

guard cleaner.

For long-term corrosion protection, after fl ushing, an inhibitor suitable for stainless

steel heat exchangers should be used, refer to the current issue of BS 5449 and BS 7593

on the use of inhibitors in central heating systems. Examples are Sentinel X100 Fernox or

Salamander corrosion guard inhibitor.

5.2 Dimensions

F Cold water inlet (white)

T Room thermostat

L Electrical power supply

G Gas (white)

400 347

116

284

223

R Heating return (green)

M Heating fl ow (green)

SC Condense outlet

(orange) (fl exible pipe)

C Hot water outlet (black)

RM

SC

52 52 88 39

TLFCG

403046 53

CONNECTIONS FOR FLUE

116

750

735

2

1

13

941_2

1 Flue products outlet

2 Air inlet for concentric system

223

942_1

17

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 20

5.3 List of delivered equipment

The boiler is delivered in two packages:

The boiler

-

One isolating valve pack:

-

- 2 heating isolating valves

- 1 domestic cold water isolating valves

- 1 gas isolating valves

One safety discharge pipe pack:

-

- 1 safety discharge pipe

- 1 1/2 in. gasket

One installation and documentation

-

pack:

- 1 user and installation manual

- 1 guarantee envelope

- 1 gas conversion instructions sheet

- 1 log book

- 1 condense drain pipe

- a set of 1/2 in. gaskets

- a set of 3/4 in. gaskets

One pipe pack:

-

- 2 central heating pipes

- 2 gas/cold water pipes

- 1 hot water pipe

- a set of 1/2 in. gaskets

- a set of 3/4 in. gaskets

- 1 wall template

- 1 hanging bracket

The fl ue is supplied separatly and will

depend upon the confi guration of the

installation.

5.4 Fixing to the wall

Make sure the material you use fi ts

•

those of the appliance.

Chose the location of the appliance.

•

See chapter “Appliance location”.

18

1033_R01

GREEN

GREEN

BLACK

ORANGE

WHITE

WHITE

Page 21

The hanging bracket will be adapted to

•

the features of the bearing wall and will

have to take into account the weight

of the boiler (please refer to Technical

Data table in this manual);.

Drill the holes for the fi xing screws

•

in accordance to the diagram below

and to the size of the wall template

delivered with the appliance.

The heating safety discharge valve

must be connected, using not less than

15mm o.d. pipe, to discharge, in a visible

position, outside the building, facing

downwards, preferably over a drain.

The pipe from the safety discharge valve

must not discharge above an entrance,

window or any type of public access area.

Place the boiler above the hanging

•

bracket.

Slowly lower the boiler.

•

Set the seals on the different pipe

•

fi ttings.

Make connections to boiler, gas,

•

water and heating cocks with the tube

assemblies supplied in piping pack.

5.5 Gas and water connection

Before undertaking any operation,

•

carefully clean the pipes with an

appropriate product in order to remove

impurities such as fi lings, welds,

different oils and greases that may

be present. These foreign bodies

may enter the boiler and disrupt the

operation.

The pipe must have a continuous fall

and be routed to a position so that any

discharge of water, possibly boiling,

or steam cannot create any danger to

persons, damage to property or external

electrical components and wiring.

To ease future servicing it is advisable to

use a compression type fi tting to extend

the safety discharge valve tube.

Warning! Relief valve connections should

not be used for any other purpose.

Do not use any solvents that could

•

damage the heating circuit.

Do not brase the nozzles set on place:

•

this operation could damage the seals

and the taps tightness.

Only use the genuine seals delivered

•

with the appliance.

Check that there is no leakage. Repair

•

if need be.

Installation and servicing instructions strictly reserved for qualifi ed gas installers

19

Page 22

5.6 Connection to the condensate

trap

Connect the fl exible pipe to a discharge

•

system leading to the sewer in

compliance with the instructions below:

Use the condensate drain fl exible

•

connection pipe supplied.

Ensure there is a conbinual fall of 2.5°

•

(44 mm/m).

Do not let the condensate drain fl exible

•

connection fall into the trap.

Do not use copper pipes.

•

Important notice:

The fl oat in the condensate trap also

ensures fume tightness. Therefore, it

is not necessary to add water in the

condensate trap.

OK

OK

20

Page 23

1041_R00

Installation and servicing instructions strictly reserved for qualifi ed gas installers

21

Page 24

5.7 Flue connection

Different fl ue outlet confi gurations can be

carried out.

•

Consult your supplier for more

information about the other possibilities

and associated accessories.

Warning! You can only use fl ue

accessories approved for the SEMIA

CONDENS.

Saunier Duval’s horizontal fl ue

automatically provides a 3° angle that

enables the return of the condensates to

the appliance.

Whatever the kind of fl ue system

•

chosen, observe the minimum

distances indicated in the chart on the

next page to position the fl ue terminals.

5.7.1 Flue restrictor

Depending on the length of the fl ue

system, it may be necessary to install the

fl ue restrictor “D”. The length of the system

is specifi ed for each fl ue confi guration.

Then, install the plastic adaptor “A”.

A

D

22

Page 25

R

S

Position

Horizontal flues

A

B

C

D below gutter, drain/soil pipe 25

E below eaves 25

F below a balcony or car port

G

H

Position of the flue

terminal

directly below an opening,

air brick,

opening windows

above an opening, air brick,

opening windows

horizontally to an opening,

air brick,

opening windows

from vertical drain pipes

and soil pipes

from internal/external

corners

mm

300

300

300

25

25

25

H*

I

J

K facing terminals 1200

L

M vertical from a terminal 1500

N horizontally from a terminal 300

Vertical flues

P from another terminal 600

Q above roof level 300

R

S from adjacent wall to flue 300

to a boundary alongside

the terminal

above adjacent ground or

balcony level

from surface or a boundary

facing the terminal

from opening (door/

window) in car port

into dwelling

from adjacent opening

window

300

300

600

1200

1000

Installation and servicing instructions strictly reserved for qualifi ed gas installers

23

Page 26

H*: This dimension comply with the

building regulations, but it may need to

be increased to avoid wall staining and

nusance from pluming depending on site

conditions.

5.7.2 Horizontal concentric fl ue

Ø 60/100

(C13 type installation)

IMPORTANT: turn the coaxial socket 45°

(as shown in the picture) when horizontal

concentric fl ue Ø 60/100 is used.

45°

1035_R01

A Plume mangement kit can be installed at

the extremity of the duct.

Every time a 90° elbow is used (or 2 off

45°), the length (L) should be reduced by

1 m.

5.7.3 Vertical concentric fl ue

Ø 60/100

(C33 type installation)

L

L

1

72

1034_R00

Legend

1 Gasket

Maximum fl ue index: 150 Pa

This value is reached with the length of

the maximum duct (L) + 1 90° elbow.

Flue model

Ø 60/100

horizontal

Boiler

model

F24 E 4 m < 2 m

F30 E 3 m < 1 m

Max.

length L

Restrictor

if length

Maximum fl ue index: 150 Pa

This value is reached with the length of

the maximum duct (L) + 1 90° elbow.

Flue model

Ø 60/100

vertical

Boiler

model

F24 E 5 m < 2 m

F30 E 4 m < 1 m

Max.

length L

Restrictor

if length

Every time an extra 90° elbow is used (or

2 off 45°), the length (L) should be reduced at by 1 m.

24

Page 27

5.7.4 Twin fl ue 2 x Ø 80

(C53 type installation)

Warning!

-

Any duct that goes through a wall

and whose temperature is over 60°C

from the room temperature will be

thermally insulated at this passage.

The insulation will be composed of an

appropriate insulating material whose

thickness is ≥ 10 mm and thermal

conductibility λ ≤ 0.04 W/m.K.

For separator correct and wrong positions,

refer to the following diagram:

1043_R00

L2

L1

L1

188

Maximum fl ue index: 150 Pa

This value is reached with 2 elbows, the

separator and the maximum duct length

(L1+L2).

Flue model

Ø 80

twin

Boiler

model

F24 E 10 (9) m always

F30 E 10 (9) m always

Max.

length

L1+L2 (L2)

Restrictor

if length

L1+L2

5.8 Electrical connection

Warning! Incorrect installation can cause

electric shock or appliance damage.

Connect the power cable of the boiler to

•

the 230 V single-phase + earth network.

Observe the phase and neutral

•

connection on the boiler.

Important: A skilled professional should

achieve the electrical connection of the

appliance.

Isolation should be by a double pole

switched fused spur box, with a minimum

gap of 3mm for both poles.

The fuse of the PCB must be connected to

the neutral.

Every time an extra 90° elbow is used (or

2 off 45°), the length (L) should be reduced by 0.5 m.

Installation and servicing instructions strictly reserved for qualifi ed gas installers

25

Page 28

5.8.1 External controls

The boiler will work for heating AS DELIVERED without a room thermostat fi tted provided

the two wires on the integral external controls lead REMAIN LINKED TOGETHER.

ANY EXTERNAL HEATING CONTROL MUST BE POTENTIAL FREE (see Figure 1).

ON NO ACCOUNT MUST ANY ELECTRICAL VOLTAGE BE APPLIED TO EITHER OF

THE TERMINALS OF THE WHITE EXTERNAL CONTROLS LEAD

WARNING: This boiler must be wired in accordance with these instructions. Any

fault arising from incorrect wiring may invalidate the terms of the guarantee.

1) INTERNAL TIME CLOCK WITH EXTERNAL ROOM THERMOSTAT

If a room thermostat is required it must be connected to the external controls lead as

shown in fi gure 1, using a suitable electrical connection.

POTENTIAL

FREE ROOM

THERMOSTAT

617R01

Figure 1

FUSED MAINS

SPUR OR

FUSED 3 PIN

PLUG

BLACK MAINS LEAD WHITE EXTERNAL CONTROL LEAD

BOILER

Internal time clock (factory fitted)

External potential-free room thermostat

2) CONNECTION WITH EXTERNAL PROGRAMMER

Any eventual external programmer must be connected in series with the room thermostat

(see fi gure 2)

IMPORTANT: the boiler time clock must be linked across (see the REMARK below)

FUSED MAINS

SPUR OR

FUSED 3 PIN

PLUG

PROGRAMMER

BOILER

ROOM

THERMOSTAT

Figure 2

BLACK MAINS LEAD WHITE EXTERNAL CONTROL LEAD

Internal time clock (factory fitted) disconnected

External potential-free room thermostat

External potential-free programmer

26

617A

Page 29

3) CONNECTION WITH EXTERNAL CHRONOTHERMOSTAT

As an alternative solution it is possible to connect a single external chrono-thermostat

which makes the double function of a room thermostat and a programmer (see fi gure 3)

IMPORTANT: the boiler time clock must be linked across (see the REMARK below)

FUSED MAINS

SPUR OR

FUSED 3 PIN

PLUG

BOILER

BLACK MAINS LEAD WHITE EXTERNAL CONTROL LEAD

CHRONOTHERMOSTAT

Figure 3

Internal time clock (factory fitted) disconnected

External potential-free chrono-thermostat

617B

REMARK: In case of installation of an external programmer (see fi gure 2 and 3) the

internal time clock (factory fi tted) must be excluded acting in the following way:

1. Remove the front panel of the boiler;

2. Gain access to the PCB;

3. Disconnect the two low voltage wires connected to the clock and make a link by using

the “wiring link” supplied in the Documentation Pack as shown in fi gure 4.

Figure 4

220 Vac

from PCB

(M1 2-4)

Time clock

low voltage

terminals

from PCB

(M6 18-19)

220 Vac

from PCB

(M1 2-4)

Time clock

low voltage

terminals

from PCB

(M6 18-19)

to link across

27

“wiring link”

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 30

5.9 Wiring diagram

C Pump

PSA Loss of water pressure switch

(“NO” contact closed = in pressure)

MOD Modulating coil

S Thermistor

MP Water valve microswitch

CA Ignition and fl ame control unit

EA Ignition electrodes

ER Flame sense electrode

F1 Fuse (2 A)

TA Voltage-free contact for room Thermo-

stat or Cronothermostat

Colour

abbreviations:

BK Black

BN Brown

BU Blue

GN Green

GNYE Green-Yellow

GY Grey

OG Orange

RD Red

VT Violet

WH White

TC Syphonic condensate trap

with overfl ow sensor

TF Flue Overheat thermostat

TS Overheat thermostat

MV Fan

MPV Air pressure switch

AO Timeclock power supply

CO Timeclock microswitch

SD Display board

(SE) External temperature sensor (optional)

28

Page 31

6 Commissioning

Turn the mode selector to the WINTER

•

position.

The green operating indicator on the

control panel turns on: the boiler is

ready to operate.

Open the isolating valves located on

•

the pipes: they will be placed in the

direction of the fl ow.

Open the automatic bleeders of the

•

system.

Open the fi lling loop valve situated

•

under the boiler until you obtain a 1 bar

pressure on the indicator (cold).

Bleed each radiator to remove the air,

•

re-tighten bleed screws.

7 Specific adjustments

7.1 Pump speed

1

2

3

4

Legend

1 Speed III

2 Speed II

3 Speed I

4 Speed selector of pump

Leave the cap on the pump auto air

•

vent open.

Flush the domestic hot water system by

•

opening the hot water taps for several

minutes.

Make sure the display indicates a

•

system pressure of between 1 and 2

bars. Re-fi ll system as necessary.

Make sure the condense syphon works

•

properly. It ensures the seal only when

it’s fi lled with condense (or water).

Turn the selector (4) to choose pump

•

speed I, II or III in relation to the output/

pressure curve (see next page).

29

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 32

Output/pressure curve

6

O

2

5,5

5

4,5

Pressure m. H

4

3,5

3

2,5

2

1,5

1

0,5

0

0 200 400 1000 1200600 800 1400

Semia Condens F24 E

977

R00

Water fl ow l/h

Semia Condens F30 E

7

O

2

6,5

6

5,5

Pressure m. H

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

0 200 400 1000 1200600 800 1400

1038

R00

Water fl ow l/h

30

Page 33

7.2 Personalizing the boiler’s functioning

(for professional and After Sales Service use only)

The SEMIA CONDENS models are equipped with a Microprocessor P.C.B., with an array

of 8 microswitches (SW3 / 1-8) which allow to make personalizing actions for the boiler’s

functioning. The fi rm arrangements are underlined.

Disconnect the power supply before touching the microswitches. Restore the

power supply only after you have closed the back cover of the control panel.

Note: the changes to the microswitches have no effect until the boiler is electrically

connected.

SW3

OFF

ON

ON

12876543

706_SMC_R00

.

31

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 34

SW3 / 1 – Natural gas Functioning = OFF. LPG Functioning = ON. All the operations to

change the gas type are described on a separate document provided with the boiler.

SW3 / 2 – Heating Flow Temperature Range: OFF = normal (+30°C/+80°C); ON = reduced

(+25°C/+45°C). The reduced arrangement is used for low temperature systems, but

the best results with this type of system are gained with the normal arrangement, using

the suitable optional Low Temperature Kit.

SW3 / 3 – Gives a 3 minute delay (anti-cycling) preventing ignition after the heating set

temperature has been exceeded. OFF = Delay ON (for normal systems or radiators);

ON = Delay OFF (for fan coil systems).

SW3 / 4 – It determines the extinction and new ignition temperature for DHW: OFF = Burner

OFF at 75°C and burner ON at 70°C; ON = burner OFF at the arranged temperature

for DHW (T.SET) + 5°C, and burner ON at T.SET (this arrangement is suggested for

water with a high percentage of scale and not treated)

SW3 / 5 and 6 – Pump working mode (during heating):

5 OFF – 6 OFF: intermittent for normal applications (with or without delay, see

SW3/3)

5 OFF – 6 ON: always turned off (with outside circulators)

5 ON – 6 Unimportant (OFF or ON): always on (for high thermic inertia systems)

SW3 / 7 and 8 – In SEMIA CONDENS boilers they must be OFF.

8 Draining of the appliance

8.1 Heating circuit

Open the drain cock provided at the system low point.

•

Provide an air intake by opening a radiator bleed screw.

•

In order to drain only the water in the boiler, fi rst shut off the heating fl ow and return

•

isolating valves.

32

Page 35

9 Gas valve / Output power settings

9.1 Gas valve setting

— Check that the inlet pressure is correct for

G20 gas;

3 4

Move the Summer/Winter Selector to Chimney

Sweep

the selector return to the Summer

green led fl ashes rapidly and the burner ignites at

maximum rate for a defi ned period of time to allow

all of the checks to be made. The produced heat

is carried off by the heating system;

Wait for at least 10 seconds and check that the

pressure corresponds to the highest value indicated in the “Power Pressure” table of the specifi c

model. If it is necessary to correct the pressure,

use the following procedure:

position for at least 3 seconds, then let

position. The

• make sure that the modulation coil is

energised;

• remove protection cap “C”. Take off the

silicon tube from the “VENT” on the gas

valve (item 3 in the fi gure);

• adjust maximum pressure by turning

knob “B”, with a 10 mm. spanner. Clockwise to increase, counterclock wise to

decrease;

1

2

892_R00

1 = Pressure tapping point

for gas outlet

2 = Pressure tapping point

for gas inlet

3 = Vent (mod. SE)

C

B

A

• remove electrical connector on modulation coil;

• keeping knob “B” locked, adjust minimum pressure unscrewing screw “A” very

slowly, using a 4 mm screwdriver;

• refi t electrical connector on the modulator and check settings;

• turn off the burner by turning the Summer/Winter selector to the central position.

The green led fl ashes slowly.

• Refi t the silicon tube in the “VENT” on the gas valve (item 3 in the fi gure). ATTENTION: after this operation, the value indicated by pressure gauge could decrease due

to pressure compensation. This is normal and does not require any adjustment.

Important: lock the adjustment device after any setting operation.

Installation and servicing instructions strictly reserved for qualifi ed gas installers

33

Page 36

9.2 Central heating output setting

The central heating output can be set in accordance with the system requirements. To adjust

the burner pressure, proceed as follows, referring to “Burner pressure tables” paragraph (in

this manual):

- Gain access to the PCB, see diagram above.

- Set the ‘summer/winter’ switch to the ‘winter’ position

- Light the burner and check the gas pressure

- Adjust the pressure using potentiometer P1 MAX.R. on the PCB.

- Refi t cover to controls housing.

CONTROLS HOUSING

701_1_R00

9.3 Domestic hot water fl ow rate setting

The domestic hot water fl ow rate is factory set. However,

after installation, it may be necessary to adjust the domestic hot water fl ow rate, proceed as follows:

PCB

704_R01

- Fully open a domestic hot water tap.

- Using a suitable water fl ow gauge, adjust water fl ow

by turning the adjuster screw on the water valve (see

photo).

34

Page 37

9.4 Slow opening setting

To adjust the slow opening, proceed as follows:

- switch off the boiler;

- Gain access to the PCB as described on previous page

NOTE: you will have 8 seconds to regulate the slow opening pressure, and after this the

burner pressure increases to the highest value. To increase this period of time to 30

seconds, turn the trimmer P1 MAX.R. fully anticlockwise (it will be necessary to reset

the Max Heating output after this operation).

- turn on the boiler and open a cold water tap, the burner will light and the slow opening

setting pressures can be checked.

The setting pressure is: 7 mbar (71 mm w.g.)

Turn the trimmer P4 RLA (clockwise to increase the pressure and anticlockwise to

decrease the pressure)

CONTROLS HOUSING

701_1_R00

PCB

704_R01

9.5 Changing gas type

All the operations to change the gas type are described on a separate document provided

with the boiler.

10 Fault finding

You will fi nd the list of the fault codes in the User Instructions section. Fault fi nding must

be carried out by a skilled professional and if need be by SAUNIER DUVAL’s After Sales

Service.

Important: a central heating system cannot operate effi ciently if it is not fi lled with water

and if the air has not been completely removed. If those requirements are not fulfi lled, the

boiler could possibli generate unwanted noise.

35

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 38

- To carry out electrical continuity tests across the components make sure:

a) electrical supply is OFF and the multimeter is set to the :

position,

b) the connectors of the component to check are disconnected

- During checks, verify the integrity of the wirings and their correct electrical connections

TURN THE MAIN SELECTOR TO THE POSITION “STAND-BY”

a) Is the Has the main

green led

flashing?

NO

electrical supply

connector 230 V

NO

YES

- Check the 230 V electrical supply circuit

- PCB fuse blown

across L and N ? - PCB faulty

YES

TURN THE MAIN SELECTOR TO “SUMMER”, SET THE HOT WATER KNOB AT MAXIMUM, TURN OFF TAPS

b)Is the green led

permanently on?

YES

NO

- Replace PCB

c) Is the Is the

red led

off?

NO

red led

permanently - Insufficient water pressure (below 0,5 bar)

on ?

YES

d) Does

NO

Is there continuity on

NO

YES

- If the red led is flashing, NTC sensor faulty

- Low water pressure switch faulty

NO

- Replace PCB

the boiler DHW flow microswitch ? - Check, on the PCB, switches 7 and 8 are off

stay

off? terminals 16 and 20 )

YES

(PCB-M6 connector, across)

YES

- Domestic hot water flow switch faulty

TURN ON THE HOT WATER TAP AT THE MAXIMUM FLOW RATE

e) Does the water Is the main

come

through the tap?

YES

NO

NO

water supply

turned on?

YES

- Turn on valves or check the water supply feeding system

- Flow rate regulator turned off or boiler inlet filter dirty

f) - Clean or replace the diaphragm inside domestic water priority valve

- If not continuity on PCB-M6 across terminals 16-20, flow switch faulty

- PCB faulty

- Ignition unit faulty

NO

If the fan is not running:

- Air pressure switch faulty, if there is not continuity across C and NC

- Fan faulty, if there is 230 V across fan connectors

- Ignition unit faulty, if there is not 230 V across fan connectors

Does the boiler If the fan is running:

start working Does - Air pressure switch tubes disconnected or obstructed

and the burner boiler - Air pressure switch faulty, if there is not continuity across C and NO

ignite after

a few seconds?

NO

Lock- - Replace PCB if all the above checks did not produce successful result

out?

If the burner does not ignite:

- Insulating gas valves turned off

- Ignition electrode dirty or broken

YES

- Gas valve faulty, if the ignition unit has 230V across terminals 14 - N

during the ignition phase

- Overheat thermostat faulty or boiler temperature over 100°C

- Flue thermostat faulty or in open circuit

- Minimum gas pressure to be adjusted on the gas valve ( see manual )

If the burner ignites:

- Life and neutral reversed polarity

- Ionisation electrode dirty or broken.

- Condensate siphon is not draining or ionization wiring disconnected

- Ignition unit faulty ( no ionization )

YES

36

Page 39

YES

g) Does

the

NO

- Check if pump is blocked

- Pump faulty, if there is 230 V across pump terminals

pump run? - PCB faulty, if not power is supplied to the pump

YES

h) Does the flame

rise up

NO

- Check and adjust the gas pressures on the gas valve as indicated in the manual

- Gas valve modulator faulty, if there is nearly 5 v = across the modulator terminals

after 8 seconds? - PCB faulty, if there is not power to the modulator or the voltage is less than 3V =

YES

i) Is Is the domestic hot

the water

warming up

to the tap? indicated in the manual ?

YES

NO

NO

water flow rate - Check gas valve for correct gas regulation

greater than the one

YES

- Domestic hot water exchanger dirty

- Reduce the hot water flow rate to the tap

DECREASE THE HOT WATER FLOW RATE TO APPROXIMATELY 5 LITER PER MINUTE

j) Does Check resistance NTC values In case of difficulty:

the flame

modulate

a few seconds ?

YES

of the NTC sensor

and if necessary,

NO

replace

the NTC

0°C = 33 k:

20°C = 12,5 k:

60°C = 2,5 k:

80°C = 1,3 k:

- Check the gas valve for correct gas

pressure

- Check on the PCB the after

switches 7 and 8 are set to OFF

TURN OFF THE HOT WATER TAP

TURN THE MAIN SELECTOR TO “WINTER”, SET THE HEATING KNOB AT MAXIMUM, TIME-CLOCK TO “1”

k)

Does

the

NO

boiler calling for

Is the room

thermostat Make a link on the PCB-M10 across terminals 39 and 40:

NO

YES

- Set the temperature on the room thermostat

- Room thermostat faulty, if the boiler starts working

work? heating? - Faulty time-clock,if no continuity across switch terminals

- PCB faulty, if the boiler does not operate

YES

l) Does the pump

start ?

YES

m) Do

radiators

heat up? turned on ?

YES

n) Is the water

pressure

stable on the when temperature

NO

Are the switches 5 and 6

on the PCB

in position OFF ?

NO

NO

Are all the

valves of the system

Does the pressure

rise up over 2 bar

NO

YES

NO

YES

NO

YES

- Set switches 5 and 6 to the off position

- Replace PCB

- Turn on all the radiator valves and insulating valves

- Bleed air out of the radiators

- Verify the filling check valves are turned off

- Pressurize the expansion vessel. If leaks occurs from

pressure gauge? is above 50°C the valve, replace the expansion vessel

YES

END OF THE TEST

Guide for the correct electrical reading

37

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 40

11 Control / Commissioning

13 Spare parts

Once the appliance is installed, check

whether it operates correctly:

Start the appliance according to the

•

indications of the operating instructions

and check whether it operates correctly.

Check the appliance for leaks (gas

•

and water) and eliminate any leakage

found.

Check that the ignition is correct and

•

that the fl ames of the burner are

uniform.

•

Check that the fl ue exhausts properly.

•

Check the full control and safety

devices, their setting and their

operating states.

In order to guarantee the reliability and

quality of the individual components and

the correct functioning of the boiler, only

authentic spare parts from SAUNIER

DUVAL should be used when repairing

and servicing the appliance.

12 User information

It is your responsability to ensure that the

user knows how to use the appliance.

Points to explain:

•

Explain to the user the appliance

operating principles and demonstrate if

required.

•

Have a look at the operating

instructions together and answer any

questions if need be.

•

Give the user all of the manuals and

documents concerning the appliance

and tell the user to keep them near the

appliance.

•

Explain more precisely the safety

principles they should observe.

•

Remind the user to regularly service

the appliance (every 12 months

recommended).

38

Page 41

14 Maintenance

14.3 Burner

Warning!

•

Before performing the maintenance on

the appliance, read carefully the “Safety

instructions” chapter.

14.1 Casing

1. Unscrew the screws [1] and slide back

the catches [2] to release the front casing [3];

2. Push the front casing [3] upwards and

remove it;

3. Unscrew the two screws [4] and pull

down the control panel [5];

700_R01

3

- Undo main gas supply nut from burner.

- Pull main burner forward, pull off the

ignition and fl ame sense leads from

the electrodes and remove burner from

boiler.

Note: The washer between main burner and

main burner gas supply must be kept for

use on reassembly.

1

2

6

4

6

5

14.2 Combustion chamber

- Unscrew and remove 6 screws securing

sealed chamber cover to the boiler. Pull

cover forward and off boiler.

- Remove ignition and fl ame sense electrodes from burner.

- Unscrew and remove four injector bar

retaining screws and separate injector

bar from burner.

- Examine and clean injectors as necessary.

Note: DO NOT use a wire or sharp instru-

ment on the holes.

14.4 Heat exchanger

- Locate the heat exchanger inside the

sealed chamber.

- Gain acces to heat exchanger by removing fan and fl ue hood.

- Examine heat exchanger for any blockages or build up of deposits.

- Clean heat exchanger with soft brush

or vacuum cleaner.

39

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 42

14.5 Reassembly of parts removed

for servicing

- Slacken, but do not remove, two screws

securing fan to rear of fl ue hood.

All parts are replaced in reverse order to

removal.

14.6 Flue system

- Check externally to make sure that fl ue

is not blocked

- Inspect fl ue system to make sure that

all fi ttings are tight and secure.

14.7 Operation of fan

- Switch on electrical supply and turn on

gas.

- Set selector switch to ‘Winter’

tion.

- Light burner by operating external controls (if fi tted) to call for heat.

posi-

- Supporting fan, unscrew and remove

two screws securing fan to front of fl ue

hood.

- Lower fan from top of boiler then tilt

base of fan to right hand side. Gently

ease fan forwards and out of boiler.

- Transfer fl ue sensing probe assembly

onto replacement fan.

- Fit replacement fan in reverse order to

removal.

Note: Ensure white air sensing tube is con-

nected to upper probe and red tube to

lower probe.

15.2 To replace air pressure switch

- Locate air pressure switch in upper right

hand corner of sealed chamber.

- Do not light the boiler without the sealed

chamber cover fi tted

- Check that fan operates when burner lit

and stops when it goes out.

15 Replacement of parts

Warning!

•

Before starting the replacement of

parts, read the “Safety instructions”

chapter carefully.

15.1 To replace fan

- Slide fl ue sensing probe insulating boot

away from fan.

- Pull off both red and white sensing

probe tubes.

- Disconnect power supply and earth

leads to fan.

- Pull off plastic tubes from base of

switch.

- Remove electrical connections from

switch.

- Unscrew and remove two screws securing switch to upper panel and remove

switch.

- Fit electrical connections to replacement

switch as follows:

NO - BROWN

NC - BLACK

C - BLUE

- Fit replacement switch in reverse order

to removal.

Important: Refi t red tube to right hand

connector and white tube to left hand

connector.

40

Page 43

15.3 To replace pump

15.4 To replace gas valve

- Drain down boiler heating circuit as follows:

- From below boiler, close isolating valves

on fl ow and return connections.

- Open boiler drain valve to right of

pump.

Note: It is not necessary to drain down entire

heating circuit to carry out this work.

- Gain access to the pump by lowering

the controls panel.

- Pull off electrical connection to pump.

- Supporting pump, unscrew pump connection nuts at top and rear of pump.

Remove pump by lifting forward and

out of boiler.

- Fit replacement pump in reverse order

to removal.

1

- Isolate boiler from gas supply.

- Gain access to the gas valve by lowering the controls panel.

- Remove clear plastic sensing pipe from

gas valve.

- Unscrew and remove upper screw (1)

holding gas valve ignition box onto gas

valve body.

- Carefully pull off ignition box, leaving

electrical wiring connected, and move

clear of gas valve.

- Remove electrical connections to gas

valve modulating coil.

- Disconnect gas inlet cock from boiler.

- Open isolating valves on fl ow and return

connections,

- Refi ll, vent and pressurise boiler. Check

for leaks.

- Undo nuts on gas valve to burner supply pipe and swing pipe clear of gas

valve.

- Unscrew and remove two screws securing gas valve to boiler lower frame.

- Fit replacement gas valve in reverse

order to removal.

Note: When refi tting electrical connections

to gas valve modulating coil, the polarity

is not important.

41

Installation and servicing instructions strictly reserved for qualifi ed gas installers

Page 44

15.5 To replace domestic heat

exchanger

- Open isolating valves on fl ow and return

connections, refi ll, vent and pressurise

boiler. Check for leaks.

BC

F

- Drain down heating circuit of boiler as

described previously.

- Drain down hot water circuit of boiler as

follows:

- From below boiler, close cold water inlet

isolating valve.

- Open a hot tap to drain hot water circuit.

- Remove clip (A) and pull off microswitch

assembly

- Undo connections (B), (C), (D) and (F)

on 3 way valve

- Grasp 3 way valve and lift upwards

releasing ‘O’ ring joint (E)

- Remove 3 way valve and domestic heat

exchanger assembly (G) from boiler.

Important: Take care not to drip water

into PCB housing when removing

assembly.

EGD

H

A

- Open cold water isolating valve. Check

for leaks.

15.6 To replace thermistor

- Locate thermistor clipped onto fl ow pipe

behind and to the right of the pump.

- Pull off clip from fl ow pipe.

- Remove electrical connections from

thermistor.

- Fit replacement thermistor in reverse

order to removal.