Contents

CONTENTS

Chapter 1 Introduction………………………………………………………1-5

Chapter 2 Safty ………………………………………………………………2-1

Chapter 3 Equipment Description and Component Identification…3-1

Chapter 4 Installation ………………………………………………………4-1

Chapter 5 Ink Jet Printer Operation ………………………………………5-1

Chapter 6 Maintenance ……………………………………………………6-1

Chapter 7 Troubleshooting …………………………………………………7-1

Appendix:

1. Hydraulic System Connecting Figure …………………………8-1

2. Electric System ……………………………………………………8-2

3. Hydraulic System …………………………………………………8-3

4. Printing Speed List ………………………………………………8-4

5. User-defined Font…………………………………………………8-5

6. S400 Series Upgrade Introduction……………………………8-11

Version: 20100420

Introduction

1

In this chapter you will find:

Introduction

z a brief description of the intended use of the machine

z who this manual is intended for, how it is organized, and the

writing conventions that are used to present information

z an introduction to each of the chapters in this manual

WARNING: Read chapter 2, Safety, before attempting to

service operate the equipment.

Turn to page 1-2 for a chapter-level Table of Contents.

1-1

Introduction

Chapter 1 Contents

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

References to the S400 serials printer - - - - - - - 1-3

Printers Supplies - - - - - - - - - - - - - - - - - - - - - -1-3

Who Should Use this Manual? - - - - - - - - - - - - - - - - - 1-4

Writing Conventions Used In this Manual - - - - - - - - - - - - 1-5

1-2

Introduction

Introduction

The S400 Serials Printer is a non-contact ink jet printer designed to print small character messages

onto a product. This equipment is typically used for industrial marking, coding and overprinting. The

technical specialties are listed as followed.

For ease of reading, the S400 Series Printer will be referred to as

References to the

S300/400 Printer

Due to the large variety of SATURN Inks available for use with this

Printer Supplies

the “S480 Printer” or “Printer” throughout the remainder of this

Manual.

product, this printer can print on virtually any surface, texture,

contour or shape.

Contact your SATURN sales representative or distributor if you

have any question regarding supplies selection (inks, make-up

fluids and cleaning solutions) or product application.

1-3

Introduction

Who Should Use this Manual?

Introduction

This Manual is intended for use by SATURN service personnel

and those customers who are qualified to perform their own

printer service and maintenance.

WARNING: Customers who intended to service and maintain the

printer themselves must be qualified personnel,

which are considered those persons who have the

proper technical training (successful completion of a

training course covering this printer), have

experience to work on this equipment, and are aware

of the hazards to which they will be exposed. The

Service Manual is intended to be supplement (and

not a replacement) to training.

The Manual contains information on operating, installing, setting

up, maintaining, troubleshooting, and servicing the printer.

Keep this Manual in a safe location where it can be easily

accessed for reference.

1-4

Introduction

Service Manual Overview

Chapter 2, Safety

This chapter contains important equipment and safety guidelines, as well as the safety writing

conventions used throughout the manual.

Chapter 3, Equipment Description and Component Identification

This chapter shows the location and provides a brief description of each of the main

components in the printhead, the hydraulic and electronic co mpartments of the printer.

Chapter 4, Installation

This chapter includes the necessary procedures when installing the printer and setup the

technical data.

Chapter 5, Printer Operation

This chapter includes an overview of the fluid system, a description of how ink drops are

created and controlled, and detailed functional sequences of operation for electrical, and

hydraulic functions.

Chapter 6, Maintenance

The maintenance chapter lists all recommended scheduled maintenance procedures, ink

maintenance procedures, and procedures to follow to attain th e finest print quality.

Chapter 7. Troubleshooting

This chapter includes the cause, judge, and solutions of printer common fault s.

1-5

Safety

2

Safety

In this chapter you will find:

important safety guidelines to follow when operating the

equipment

important safety guidelines to follow when working with

inks, make-up fluids, and cleaning solutions

important safety guidelines to follow when long-term

shutdown

printhead cleaning

shutdown without cleaning

recovery tube cleaning

WARNING: Read this chapter thoroughly before attempting

Refer to page 2-2 for a chapter-level Table of Contents.

to operate this product.

2-1

Safety

Chapter 2 Contents

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Safety Terms - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

Fire Prevention Statements- - - - - - - - - - - - - - - - -2-4

Danger Statements - - - - - - - - - - - - - - - - - - - -2-4

Warning Statements - - - - - - - - - - - - - - - - - - - 2-4

Caution Statements - - - - - - - - - - - - - - - - - - - 2-4

Equipment Safety Guidelines - - - - - - - - - - - - - - - - - - 2-5

Comply with Electrical Codes - - - - - - - - - - - - - - - 2-5

Avoid Breathing Exhaust Vapors - - - - - - - - - - - - - 2-5

Do Not Remove Warning Labels - - - - - - - - - - - - - 2-5

Ink Safety Guidelines - - - - - - - - - - - - - - - - - - - - - 2-6

No Smoking - - - - - - - - - - - - - - - - - - - - - - - 2-6

Wear Safety Glasses - - - - - - - - - - - - - - - - - - -2-6

Avoid Skin Contact - - - - - - - - - - - - - - - - - - - 2-6

Dispose of Ink Properly - - - - - - - - - - - - - - - - - 2-6

Store Inks Properly - - - - - - - - - - - - - - - - - - - -2-6

Ground the Service Tray - - - - - - - - - - - - - - - - - 2-6

Ink and make-up fluid caution items- - - - - - - - - - - - - - - - - - - - 2-7

Long-term Shutdown- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

Printhead Cleaning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-8

Shutdown without Auto Flush - - - - - - - - - - - - - - - - - - - - - 2-9

Recovery Tube Cleaning - - - - - - - - - - - - - - - - - - - - - - - - -2-10

2-2

Safety

Introduction

z The policy of Saturn Technologies Ltd. is to manufacture non-contact printing/coding systems

and ink supplies which meet high standards of performance and reliability. We enforce strict

quality control techniques to eliminate the potential defects and haza rds in our products.

z The intended use of the S480 printer is to print information directly onto a product. Use of this

equipment in any other fashion may lead to serious personal injury.

z The safety guidelines provided in this chapter are intended to educate the operator on all safety

issues in order to operate the printer in a safe manner.

z The safety guidelines provided in this chapter are intended to educate the operator on all safety

issues in order to install, service, and maintain the printer in a safe manner.

z Before using this printer, thoroughly read this chapter and follow the guidelines strictly.

z You must use Saturn’s ink、make-up, or the warranty period will stop automatically.

z Please find technical support from distributor directly. Do not use untrained staff in the warranty

period, or the warranty period will stop automatically.

z Filter and O ring are consumables, which are not included in warranty, please replace on time.

2-3

Safety

Safety Conventions Used in this Manual

Fire prevention statement The ink and make-up fluid are both flammable and may cause fire.

Danger Statements Danger statements:

Please keep any fire five meters away from the printer, and set up

the printer in dry environment

are used to indicate immediate hazards which WILL result in

severe personal injury or death

have a triangular symbol with an

immediate left

are always found before the step or piece of information to

Warning Statements Warning statements:

are used to indicate hazards or unsafe practices which could

have a triangular symbol with an exclamation point to the

are always found before the step or piece of information to

Caution Statements Caution statements:

are used to indicate hazards or unsafe practices which could

is preceded by the word "DANGER"

which they refer

result in severe personal injury or death

immediate left

is preceded by the word “WARNING”

which they refer

result in minor personal injury or product or

property damage

exclamation point to the

have a triangular symbol with an

immediate left

is always preceded by the word CAUTION

2-4

exclamation point to the

Safety

Equipment Safety Guidelines

WARNING: Always observe the following safety guidelines when

Comply with Electrical Codes

Shutdown the power before opening printer door;

Do not insert tweezers, screw driver or any steel material into ink

ejection hole at the end of printhead. When the printer is ready to

print, a high voltage (approximately 6 kV) is applied to the

deflection electrode section in the printhead.

Exercise caution to avoid electric shock, injury, and fire.

Avoid Breathing Exhaust Vapors

During operation, the printer exhausts vapors through the muffler.

These vapors may be flammable and present a healthy hazard. For

these reasons, do not allow the exhaust to be confined to an area

that does not have proper ventilation or near a source of ignition.

Printer exhaust fumes are generally heavier than air, so keep all

sources of ignition away from low areas where fumes may travel or

accumulate. Ensure that no welding operations are performed

within 5 m of the printer.

Do Not Remove Warning Labels

Do not, under any circumstances, remove or obstruct any warning

or instruction labels in the printer.

WARNING: Do not place the printer in an explosive atmosphere.

If emergency occurs, press the power switch to turn off the power.

Use the printer at the temperature with 0—40°C and relative

humidity of 30-90%, or will cause fault to printer.

Do not mix different types of ink together, or will cause printer fault

Printer should link to ground well, or will affect printing.

installing, operating, servicing, or maintaining the

printer and associated equipment.

2-5

Safety

Ink Safety Guidelines

WARNING: Always observe the following safety guidelines when

No Smoking

Do not smoke when near the printer or printhead. Explosion or fire

Ground the Service Tray Ground the Saturn service tray to the printer, and install the

may result if the printer exhaust fumes are subjected to an ignition

source.

Wear Safety Glasses

Wear safety glasses with side shields (or equivalent eye protection)

when handling any ink, make-up fluid or cleaning solution. If

splashed into your eyes, flush eyes with water for 15 minutes and

see a doctor immediately.

Avoid Skin Contact

Wear butyl rubber gloves when handling any ink, make-up fluid or

cleaning solution. Avoid contact with skin and mucous membranes

(nasal passage, throat). Upon contact with skin, remove any

contaminated clothing and wash area with soap and water. See a

doctor if irritation persists.

Dispose of Ink Properly

Do not pour any ink, make-up fluid, or cleaning solution into sinks,

sewers, or drains. Waste disposal must comply with local

regulations; contact the appropriate regulatory agency for further

information.

Store Consumables Properly

The ink and make-up fluid are both flammable and may cause fire,

and must be stored properly. Consult the appropriate regulatory

agency for further information

printhead into the service tray when test printing or dumping ink

from the printhead. This is necessary to avoid the possibility of

electrostatic discharge which may result in fire.

working with any ink, make-up fluid, or cleaning

solution.

2-6

Safety

Ink and Make-up Fluid Caution Items

1. Ink and make-up replenishment

While the printer is operated, the ink and make-up are automatically transferred at fixed intervals

from the ink or make-up tank to the main ink supply pipe for replenishment purposes. If the ink or

make-up sufficiency alarm is issued, add ink or make-up to the tank within 60 minutes. If such

replenishment procedure is not completed within 60 minutes, the printer comes to a stop.

2. Ink replacement

Refer to “System Maintainence ”.

During printer operated, ink will polluted by dust. Long-term running will cause to badly charge

of ink. Replace the ink refer to the table as below;

Replacement periods Type Numbers

Operating hours Period

Normal black ink R1182 800-1200 hours 8 month

Low viscosity ink R1180 800-1200 hours 8 month

Invisible blue ink R1360 600-1000 hours 6 month

Alcohol endurable ink R1582 600-1200 hours 8 month

High adhesive ink R1782 600-1200 hours 6 month

White pigment ink R1000 600-1000 hours 6 month

Edible ink R1960 300-600 hours 3 month

3. Store requirement

1) The ink and make-up must be hermetically sealed and stored in a cool dark place(0 to 20 ℃)

2) Using the ink and make-up before “Unseal period”.

3) Once the ink unsealed, please use it as soon as possible, if the ink in the printer over the

time which in above table, that means the ink can not be used any more.

4) Once the make-up unsealed, please add into the ink jet printer within one year. Do not need

to change the make-up.

Caution

: Waste ink and make-up can not be poured into sewer or public places.

2-7

Safety

Long-term Shutdown Guidelines

Please refer to the procedure of "auto flush" in the system maintenance. Long-term shutdown

requires that you drain out the ink from the printer and flush the ink system. This is necessary, as left

ink in the system will dry/solidify, causing problems when re-commissioning the printer.

Cleaning of Print Head

Most of ink used in printer is fast dry ink. This type of ink will come to dry and solidify immediately.

The "auto flush" function ensures that the nozzle and gutter will be cleaned when the printer is

starting up and shutting down.

Some ink sprayed out of the nozzle over time will accumulate on the charge deflection plate/nozzle

plate, causing the ink stream unable to spray out. It is necessary to clean the printhead manually.

(1) Take off nozzle cover, spray out make-up on nozzle plate, charge deflection, H.V. deflection

electrode and gutter, clean out printhead.

Screw for Printhead Cover

Do not clean this area with

cleanings.

Use wet paper with cleanings

to clean this area.

Charge Electrode

Cleaning

Range

(2) Clean out the nozzle as the picture shows. Can not spray out make-up to other area.

(3) Dry the printhead using the rubber pipette bulb.

z Ensure the nozzle, charge electrode, H.V. deflection electrode, gutter and surrounding area

are clean enough.

z Do not force make-up to flow inside the nozzle.

Nozzle

Nozzle Plate

H.V. Deflection Electrode

Gutter

2-8

Safety

Shutdown without Auto Flush

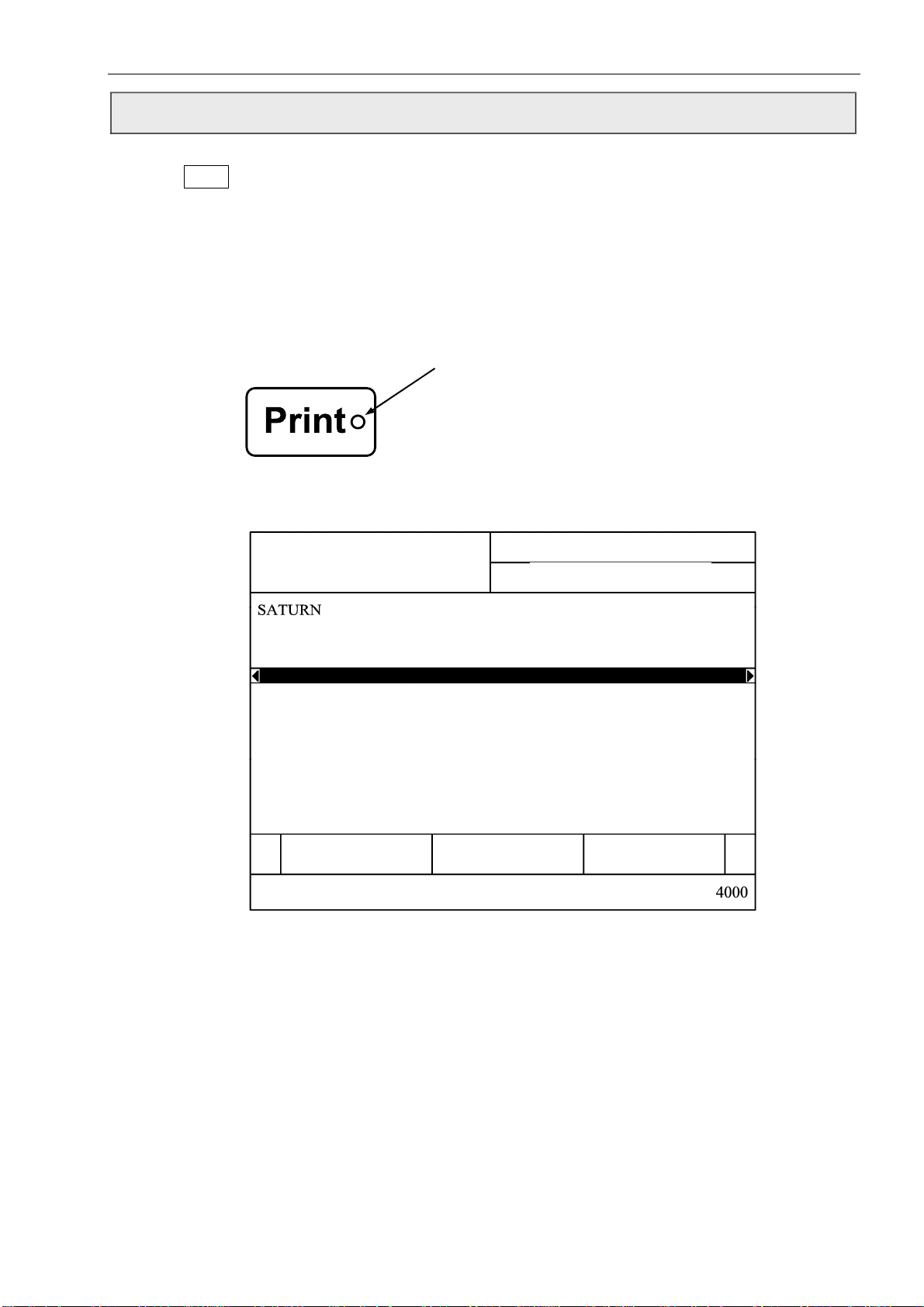

Press the

this shutdown frequently in a short period of time will cause surplus adding of make-up to the

system. If the shutdown time is less than 30 seconds, you should perform the quick shutdown

procedure.

Quick shutdown: If the shutdown time is less than 30 seconds you may perform the quick

Print Status

Print Key for 2 seconds, the printer will start to shutdown with a "system cleaning”. Using

shutdown procedure to avoid surplus adding of make-up. This procedure will

shorten shutdown time. Shutdown without auto flush is used normally for

maintenance purposes only.

(Green LED)

z Press “Print Key”, green LED will off, and status area will indicate “Printer is

ready”;

System St atus:

Printer is ready

System Maintainence-1

2007/12/26 12:00

Ink On/Off Print Test

H.V. On/Off

Current Flow Time:

z Enter “System Maintainence-1”, select “Ink On/Off”, status area will display

“Printer is Shutting down H.V.”, “Printer is Shutting down”. When the ink in

recovery tube is drain out, you can turn off the switch to maintain the printer.

Caution

① After finishing maintenance on the printer using "shutdown without auto flush"

it is important to note that if you intend not to use the printer for some time you

must perform the normal shutdown procedure to make sure that the ink recovery

tube is perfectly clean.

② After finish the maintenance, if need to start up again, manually cleaning the

nozzle procedure is needed to perform to make sure the ink stream perfectly

recover to the gutter.

:

2-9

Safety

Recovery Tube Cleaning

If the printer is running for a long time without auto flush, the recovery tube may accumulate some

ink and will need to be cleaned.

Caution

: Do not perform recovery tube cleaning more than twice.

2-10

Equipment Description and Component Identification

3

Equipment Description and

Component Identification

In this chapter you will find:

a brief description of the two main printer assemblies --- the

control unit and the printhead

the location and a brief description of the function of the main

components in the hydraulic, and electronic compartments of

the printer, as well as the printhead

Turn to page 3-2 for a chapter-level Table of Contents.

3-1

Equipment Description and Component Identification

Chapter 3 Contents

Equipment Description- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Control Unit- - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Hydraulic Compartments - - - - - - - - - - - - - - - - - - - - - 3-4

Electronic Compartments- - - - - - - - - - - - - - - - - - - - - 3-5

Keyboard - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

The Printhead- - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Component Identification - - - - - - - - - - - - - - - - - - - - 3-7

Introduction- - - - - - - - - - - - - - - - - - - - - - - - - 3-7

The Location and Description of a Main Component- - - - 3-7

Hydraulic Components - - - - - - - - - - - - - - - - 3-7

Electronic Components - - - - - - - - - - - - - - - 3-14

Printhead Components - - - - - - - - - - - - - - - 3-16

3-2

Equipment Description and Component Identification

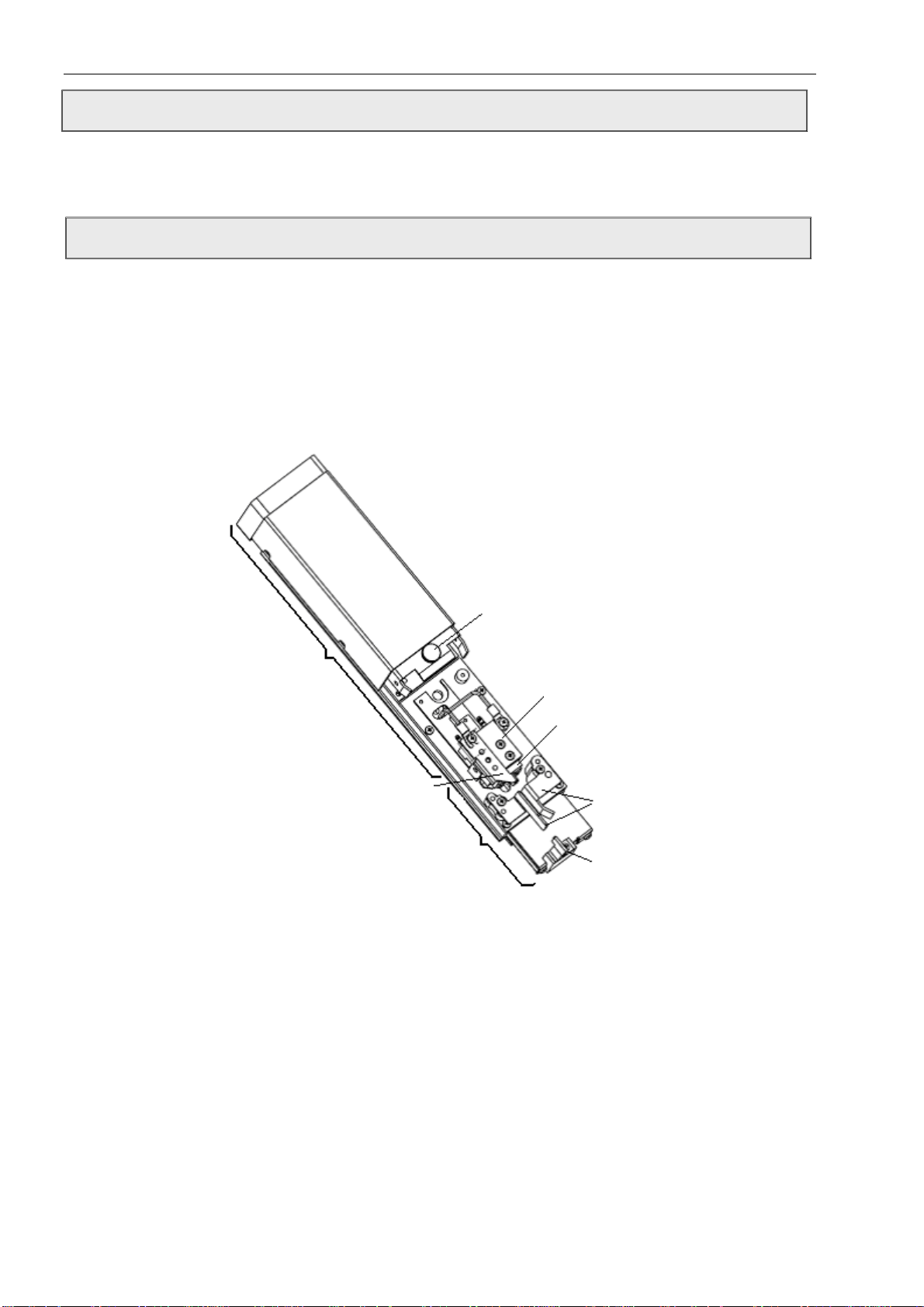

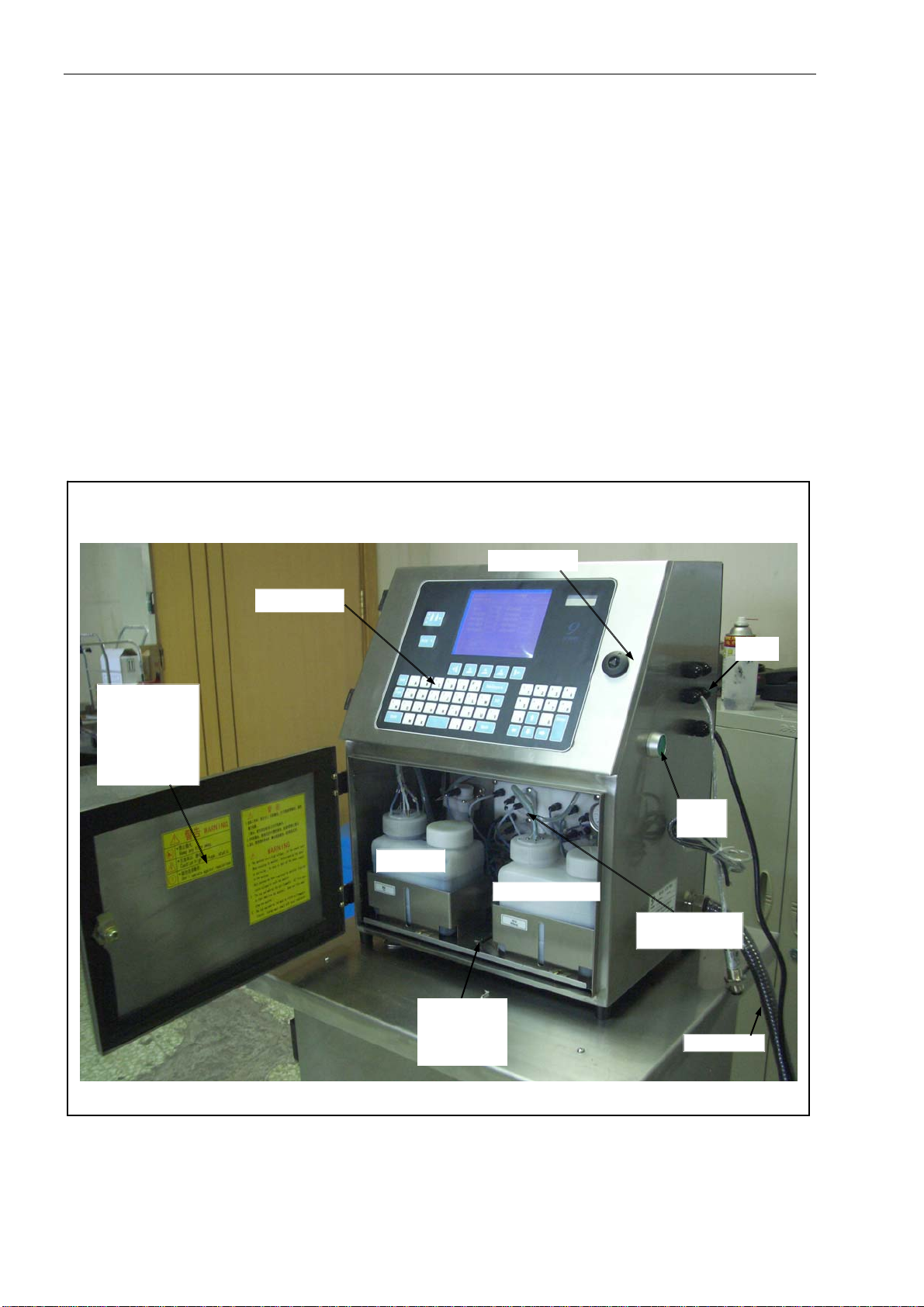

Introduction The S400 Series printer is comprised of two basic assemblies

-- the control unit and the printhead -- connected by an umbilical

assembly (a flexible conduit containing electrical and fluid lines).

Refer to Figure 3-1.

Figure 3-1. S400 Series Printer

3-3

Equipment Description and Component Identification

Control Unit

Hydraulics Compartment

(Fluid pan)

For more information

The control unit consists of the hydraulic and electronic

compartments of the printer, as well as the keyboard

(Refer to Figure 3-2).

The hydraulics compartment is located behind the front

door of the control unit (refer to Figure 3-2). This is where

ink and makeup fluid are stored, monitored, and

maintained to ensure proper fluid viscosity. This is also

where pressure is applied to the ink to ensure proper

velocity of the ink drops at the printhead.

Caution

commonly referred to as the “fluid pan”.

Refer to Hydraulic Components on page 3-7 for

information on the main components found in the

hydraulics compartment.

Keyboard

Lower Door

(Open before

maintaining or

filling ink and

makeup in)

Ink Tank

Figure 3-2. The Control Unit

: The hydraulics compartment is also

Upper Door

Makeup Tank

Support Tray

(loosen the

screw to pull

out the tray)

Power

Supply

Hydraulics

Compartment

Umbilicals

Ports

3-4

Equipment Description and Component Identification

n

Electronic Compartments

For more inf ormatio

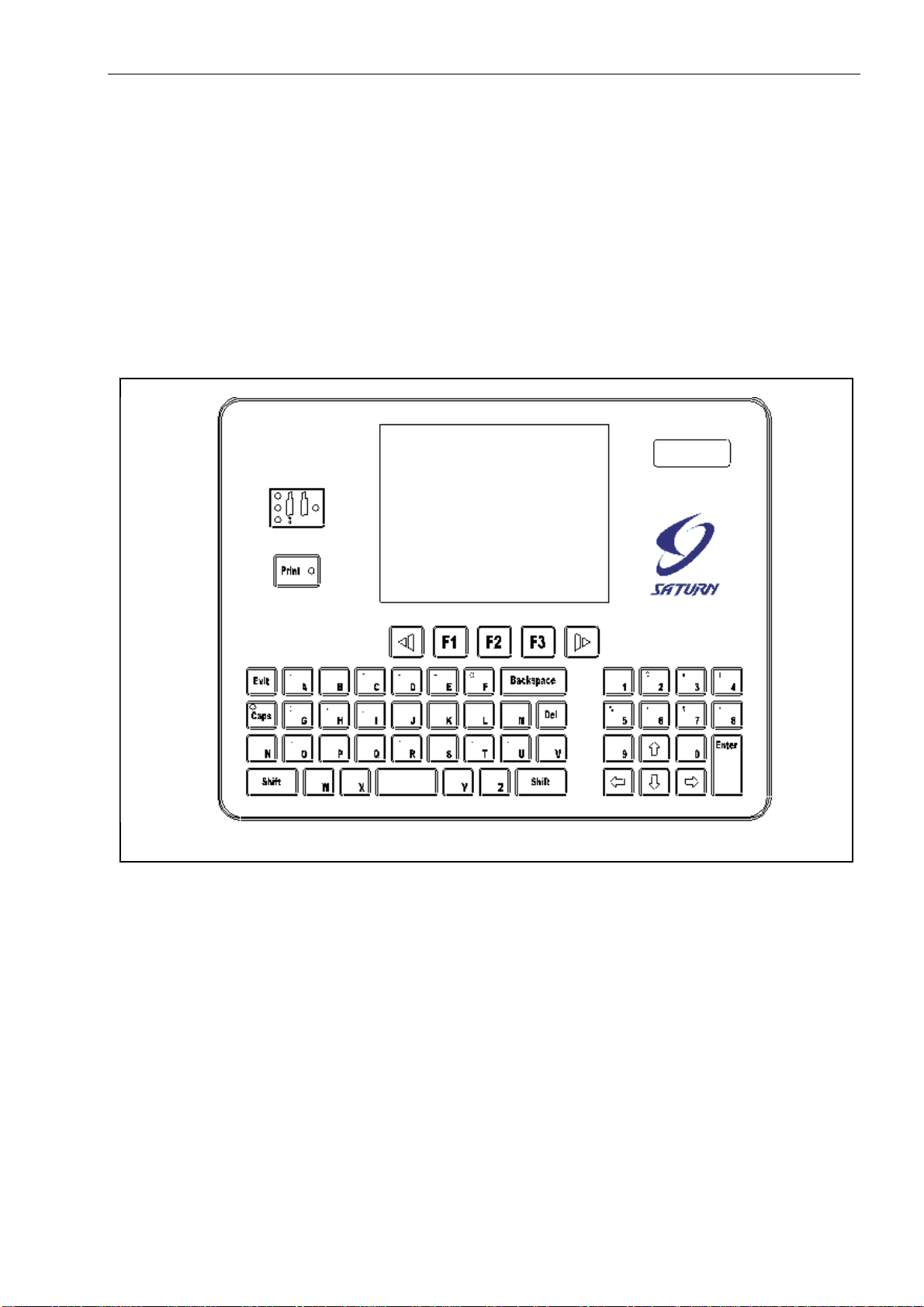

Keyboard

Figure 3-3. Keyboard

Electronic compartments are set in the upper door (refer to

Figure 3-2). The main function is to control all the electronic

signal.

Refer to Electronic Components on page 3-16 for

information on the main components found in the

electronic compartment.

The keyboard is located on the front of the control unit (refer

to Figure 3-2). The keyboard consists of control keys, an alpha

keypad, and a display screen (refer to Figure 3-3). Use the

keyboard to operate the printer.

3-5

Equipment Description and Component Identification

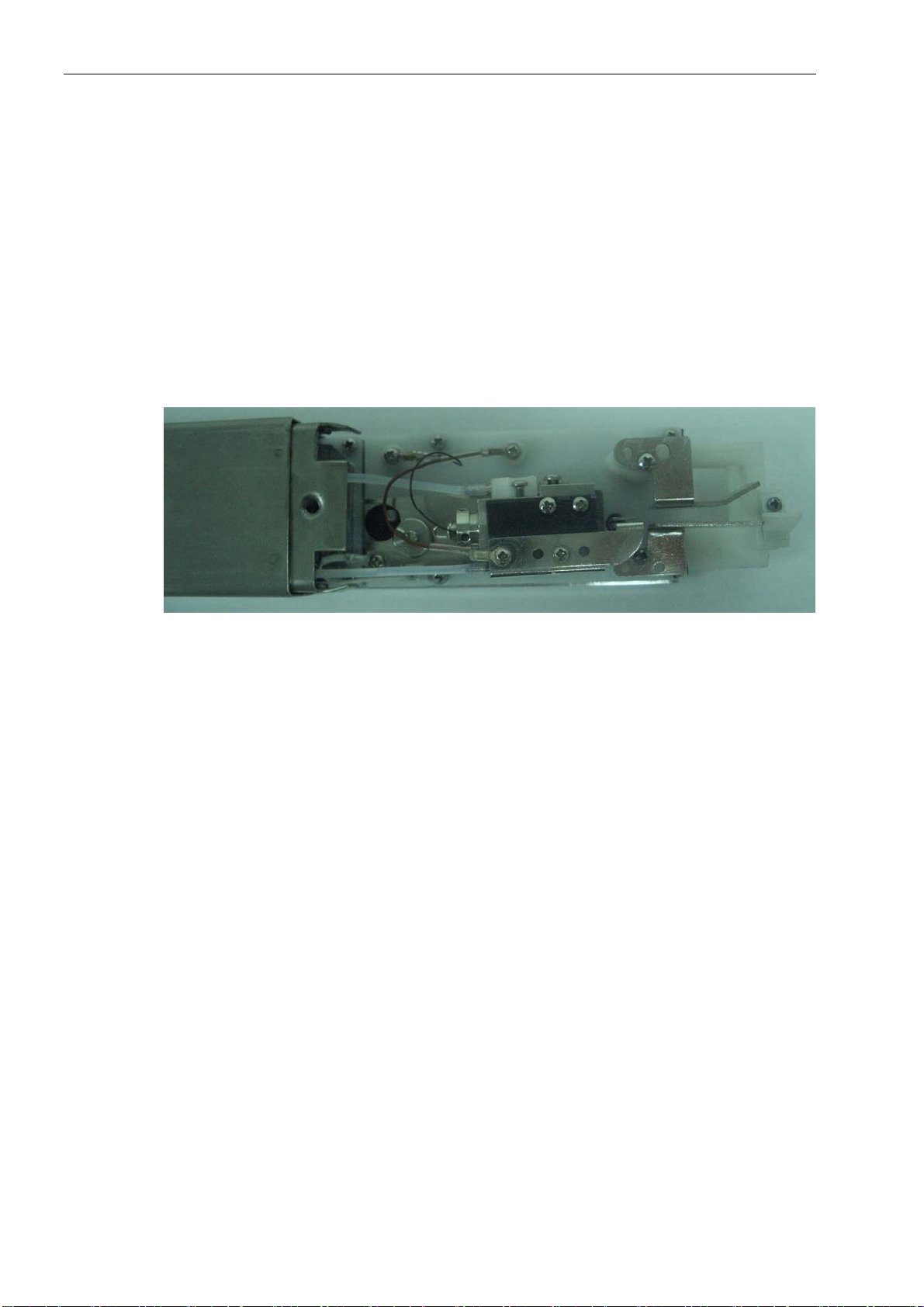

The Printhead The printhead is connected to the control unit by the umbilical

assembly. The printhead receives pressurized ink through the

umbilical, and turns the ink stream into tiny electrically

charged ink droplets which are deflected onto a substrate to

form a printed code.

For more information

Refer to Printhead Components on page 3-15 for information

on the main components found in the printhead.

Refer to Chapter 5, Inkjet Printer Operation,for more

information on how the printhead works.

Figure 3-4. Printhead

3-6

Equipment Description and Component Identification

Component Identification

Introduction This section identifies the location and describes the function

of the main components included in the hydraulic, pneumatic,

and electronic compartments of the control unit, as well as the

main components in the printhead.

Only main printer components are covered in this section.

This section is divided into the following subsections:

Hydraulic Components - - - - - - - - turn to page 3-7

Electronic Components - - - - - - - turn to page 3-13

Printhead Components - - - - - - -- turn to page 3-15

Hydraulic Components Refer to Figure 3-5 and Figure 3-6 for the location of the main

hydraulic components, and refer to the following pages to find

a brief description of the function of the components.

Caution

components.

: Open the lower door to check the hydraulic

3-7

Equipment Description and Component Identification

Viscosimeter

Ink Pouring Orifice

Ink Pressure

Regulator

Ink Tank

Support Tray

Figure 3-5. Hydraulics Compartment-1 (with support tray pulled out)

1. Ink Pressure Gauge

The ink pressure gauge indicates the amount of air pressure (in

psi and bar) applied to the ink supply cylinder. This pressure is

commonly referred to as "ink pressure”. The ink pressure is

controlled by adjusting the ink pressure regulator (refer to page

3-10).

2. Ink Pressure Regulator

The ink pressure regulator is used to adjust the ink pressure, and

accordingly to change the speed of the ink steam. According to

the style of ink and the measure of print head, ink pressure is

usually set at 2.8- 3.5 bar(40- 50 psi).

WARNING: Do not adjust the ink pressure regulator unless

you are performing the “Viscosity Calibrate”

procedure. (Refer to page 6-26)

3-8

Ink Pressure

Gauge

Makeup Pouring

Orifice

Makeup Tank

Equipment Description and Component Identification

3. Ink Tank

The ink tank stores fresh ink for printer.

4. Makeup Tank

The Makeup tank stores Makeup and adds Makeup to the ink when

ink becomes too dense.

5. Support Tray

The support tray carries the whole hydraulic system, ink and

Makeup tank, which can be pulled out in order to check the

hydraulic system.

Note: Please loose the support tray lock before pulling out the

tray.

6. Viscosimeter

The viscosimeter includes a metal float and a sensor to monitor

the viscosity coefficient of the ink.

7. Main Ink Filter

The main ink filter is installed at the right side of the bracket

(Figure 3-6). It filtrates and cushions the ink going to hydraulic

system.

8. Makeup Filter

The Makeup filter filtrates the Makeup ink going to flush pipe in

the printhead (Figure 3-6), and prevents dust into printhead.

9. Churn Filter

The churn filter filtrates the ink going to the viscosimeter (Figure

3-6), and prevents dust into viscosimeter.

10. Recovery Filter

The recovery filter filtrates un-used ink from gutter (Figure 3-6),

and prevents dust into ink tank.

3-9

Equipment Description and Component Identification

Makeup

Filter

Valves Board

Churn Filter

11

12

Figure 3-6. Hydraulics Compartment-2

11. Ink Supply Pump

The ink supply pump transfers ink to printhead and generates a

pressure to spurt out the ink through printhead.

12. Makeup Pump

The makeup pump transfers the makeup ink to the printhead and

generates a pressure to spurt out the Makeup ink to clean the

printhead.

13. Circulation Pump

The circulation pump absorbs ink from viscosimeter and also

absorbs ink from printhead and returns ink to ink tank.

14. Recovery Pump

The recovery pump returns un-used ink from printhead to ink

tank.

Recovery Filter

1413

Solenoid Electric Valves

Main Ink Filter

11 Ink Supply Pump

12 Makeup Pump

13 Circulation Pump

14 Recovery Pump

3-10

Equipment Description and Component Identification

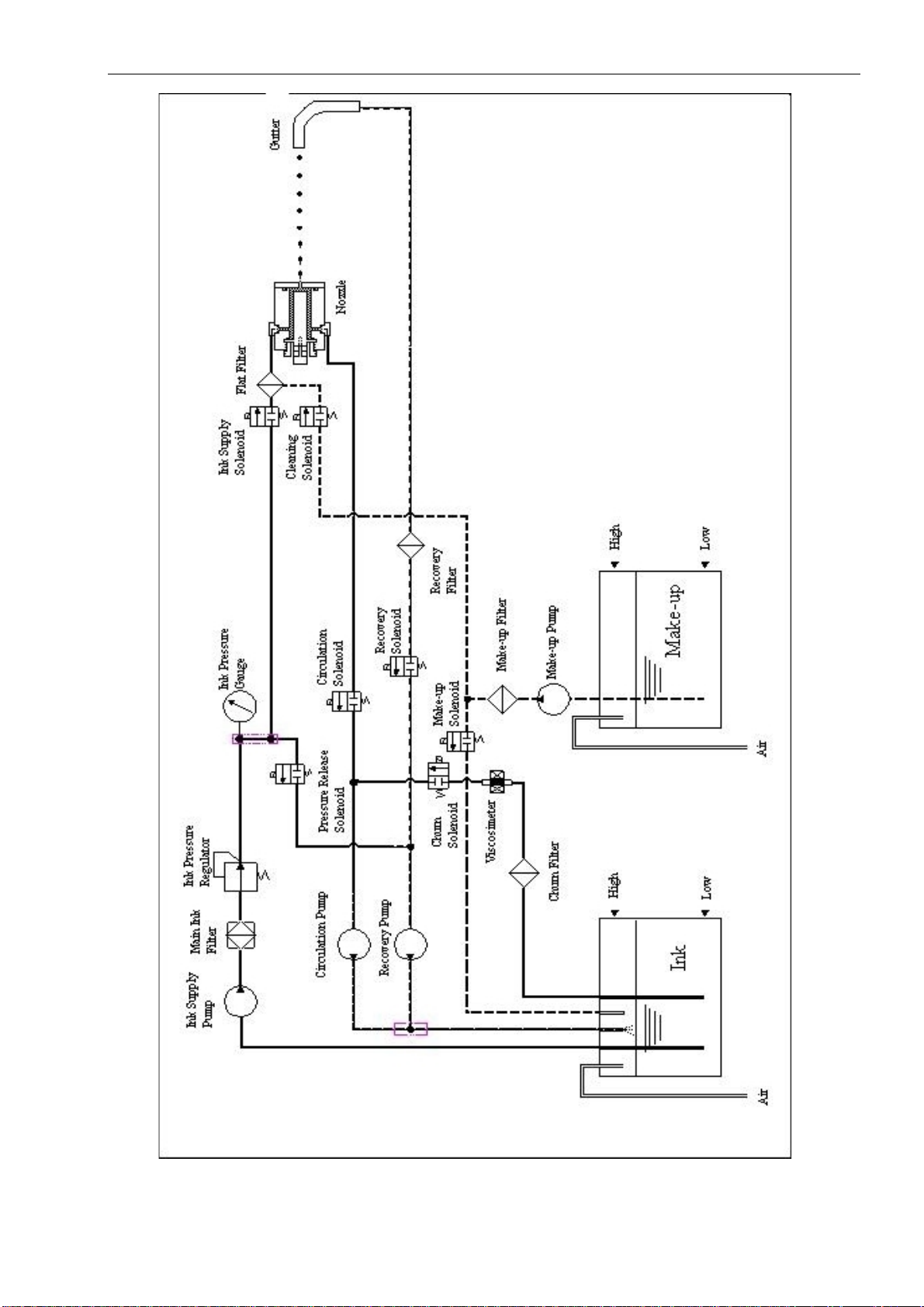

Figure 3-7 Hydraulic System

3-11

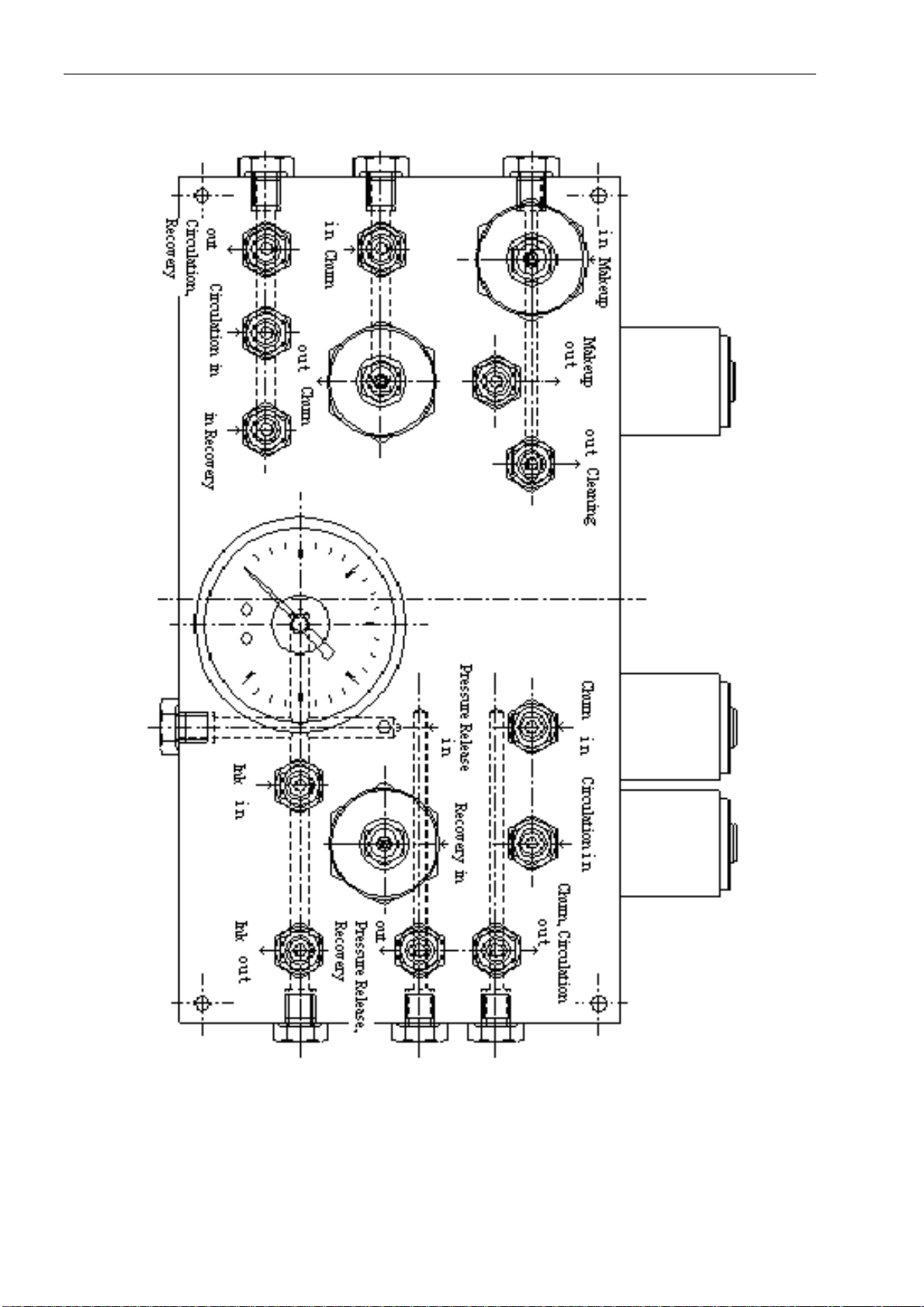

Equipment Description and Component Identification

Figure 3-8 Perspective Drawing for Valves Board

3-12

Equipment Description and Component Identification

15. Electric Solenoid Valve Assembly

The Electric Solenoid valve assembly distributes positive pressure

and vacuum to each connector and Electric Solenoid valve.

(Figure 3-8)

16. Ink Supply Electric Solenoid Valve

Turn on the ink supply Electric Solenoid valve and then the ink in

the ink supply pump and the main ink filter is able to reach ink

pressure gauge and printhead. (Figure 3-7 & 3-8)

17. Makeup Ink Electric Solenoid V alve

The Makeup ink Electric Solenoid valve controls flush pump to

add Makeup ink from Makeup ink tank when the viscosity

coefficient is above the initialization to adjust the viscosity to a

normal level. (Figure 3-7 & 3-8)

18. Cleaning Electric Solenoid V alve

Turn on the cleaning Electric Solenoid valve and then makeup ink

in the makeup pump will reach the printhead and complete clean

automatically. (Figure 3-7 & 3-8)

19. Churn Electric Solenoid V alve

After turning on the churn Electric Solenoid valve, the circulation

pump will absorb the ink in the ink tank to the viscosimeter, and

then from viscosimeter back to the ink tank to complete churning

the ink. (Figure 3-7 & 3-8)

20. Circulation Electric Solenoid Valve

Turn on the circulation Electric Solenoid valve, and then recycle

pump will absorb the ink in ink supply pipe back to ink tank to

complete the air release of ink supply pipe. (Figure 3-7 & 3-8)

21. Pressure Release Electric Solenoid Valve

After turning on the pressure release Electric Solenoid valve,

recycle pump will absorb the ink in the ink supply pump and main

ink filter back to ink tank to complete ink pressure release and

shut the ink stream quickly. (Figure 3-7 & 3-8)

22. Recovery Electric Solenoid Valve

Turn on the Recovery Electric Solenoid valve and then recovery

pump returns the un-used ink from printhead to the ink tank.

(Figure 3-7 & 3-8)

3-13

Equipment Description and Component Identification

Electronic Components Refer to Figure 3-10 for the location of the main electronic

components, and refer to the following pages to find a brief

description of the function of the components.

Caution

: To access this compartment, use the keys and/or

the hex key (supplied with the printer) to open the cabinet door.

27 Reverse Side

of Upper Door

23 Ink Control Unit

25 Print Drive Unit

24 Print Control Unit

23 Ink Control Unit(ICU)

24 Print Control Unit(PCU)

25 Print Drive Unit(PDU)

26 Input/Output Unit(IOU)

26 Input/Output Uint

28 Main Power

29 High Voltage

Power

Figure 3-10. Electronic Compartment

3-14

Equipment Description and Component Identification

23. Ink Control Unit(ICU)

ICU receives data from edit control unit and completes the control

of ink circulation, ink level and viscosity inspection.

24. Print Control Unit(PCU)

PCU receives data from edit control unit to control print signal

(step wave, sine wave, high voltage, etc.) and return data to edit

control unit.

25. Print Drive Unit(PDU)

PCU receives data from print control unit and output step wave,

sine wave, high voltage to the print head to realize printing.

26. Input/Output Unit(IOU)

IOU provides various connectors to synchronizer, magic eye and

U disc to enhance the reliability.

27. Edit Control Unit(ECU)

ECU realizes the communication between printer and human;

completes edit, store and download of message, setting of data

and control of printing.

28. Main Power

The main power supply transfers 110/220vac to low voltage direct

current power for PCB control and dual high voltage power.

29. High Voltage Power

The high voltage power supplies 900V to 6000V high voltage

power for printing.

3-15

Equipment Description and Component Identification

r

Printhead Components Refer to Figure 3-11 for the location of the main printhead components,

and refer to the following pages to find a brief description of the function

of the components.

45

42

41

48

46

43

40

49

40. Charging Electrode

41. Ground Electrode

42. Solenoid Cover

43. Nozzle

44. Gutte

45. High Voltage Deflection Electrode

46. Horizontal Locking Screw

47. Vertical Adjustment Screw

48. Horizontal Adjustment Screw

49. Recovery Tube (printhead)

Figure 3-11. Printhead Components

40. Charging Electrode

The charging electrode is an electrode that charges the ink drops

as they leave the nozzle.

41. Ground Electrode

Positioned directly opposite the high voltage deflection electrode,

the ground electrode acts as the lower electrode (where, the high

voltage deflection electrode is the upper electrode). Refer to High

voltage deflection electrode in 3-17 for further information.

3-16

Equipment Description and Component Identification

42. Solenoid (Ink Supply, Cleaning Solenoid)

Attached to the rear of the nozzle,the solenoid controls the flow of

pressurized ink to the nozzle. The Solenoid opens at40psi (2.8 bar)

of ink pressure.

43. Nozzle

The nozzle is an assembly which houses a jeweled orifice and a

piezo-electric crystal used to change the ink stream into ink

droplets. The nozzle is electrically-driven by an oscillator on the

print control board to produce ultrasonic vibrations that break the

ink stream into droplets.

44. Gutter

The gutter collects the ink drops that are not used for printing.

Vacuum draws all unused ink droplets back into the ink tank for

recirculation. The recovery block also contains a sensing

electrode used to detect charged ink drops to monitor the drop

chargeability when not printing.

45. High Voltage Deflection Electrode

Positioned directly opposite the ground electrode, the high

voltage deflection electrode provides the positive high voltage

(upper electrode). The ink drops pass through the electric field

created between the high voltage deflection electr ode and the

ground electrode. The high voltage deflection electrode causes

the negatively charged drops to be de flected over the gutter to

produce a printed code.

46. Horizontal Locking Screw

The horizontal locking screw enables you to adjust the nozzle

horizontally. When loosened (approximately one-half turn), you

can adjust the ink stream horizontally by turning the horizontal

adjustment screw. When tightened, you cannot move the nozzle

horizontally.

47. Vertical Adjustment Screw

The vertical adjustment screw adjusts the vertical position of the

ink stream in the gutter. Turning this screw will adjust the ink

stream up and down in the gutter.

48. Horizontal Adjustment Screw

The horizontal adjustment screw adjusts the horizontal position of

the ink stream in the gutter. Turning this screw will adjust the ink

stream to the left and right in the gutter.

Caution

screw, you must first loosen the horizontal locking screw.

49. Recovery Tube

The Recovery Tube is a tube leading from the gutter, through the

umbilical assembly, and to the ink tank in the fluid pan. The

Recovery Tube returns unprinted ink droplets to tank.

: Before you adjust the horizontal adjustment

3-17

Installation

4

Installation

In this chapter you will find:

Site preparation requirements

Procedures for unpacking and assembly

Encoder and Photocell set-up procedures

Turn to page 4-2 for a chapter-level Table of Contents.

4-1

Installation

Chapter 4 Contents

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

Site Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Determine Printer Location - - - - - - - - - - - - - - - - - - - - - - - -4-4

Electrical Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Unpack and Inspect the Printer - - - - - - - - - - - - - - - - - - - - - - - - 4-5

Remove the Printer from its Carton - - - - - - - - - - - - - - - - - 4-5

Connect Electrical Power - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

Assemble the Printhead Stand - - - - - - - - - - - - - - - - - - - - - - - - -4-6

Unpack and Assemble the Printhead Stand - - - - - - - - - - - 4-6

Bolt the Printhead Stand to the Floor - - - - - - - - - - - - - - - - 4-6

IOU Board Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-7

Connect the Photocell - - - - - - - - - - - - - - - - - - - - - 4-7

Connect the Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-7

Set up the Printer- - - - - - - - - - - - - - - - - - - - - -- - - - - - - -- - - - - -4-17

Final Installation Content - - - - - - - - - - - - - - - - -- - - - 4-17

Tools and Supplies Needed - - - - - - - - - - - - - - - - - - - 4-17

Flush the System and Load the Ink - - - - - - - - - - - - -4-17

4-2

Installation

Introduction

This chapter guides you through the recommended procedures

to install the printer.

Proceed through the sections in this chapter in the order shown

below:

Site Preparation - - - - - - - - - - - - - - - - - - turn to page 4-4

Unpack and Inspect the Printer - - - - - - turn to page 4-5

Assemble the Printhead Stand - - - - - - - turn to page 4-6

IOU Board Connections - - - - - - - - - turn to page 4-7

Set Up the Printer - - - - - - - - - - - - - - - - turn to page 4-16

4-3

Installation

Site Preparation

Determine Printer

Location

Electrical Requirements

Position the printer near the conveyor. Consider the following

guidelines:

The area selected should be free of vibration.

Make certain that the print head can reach the conveyor

and there is some space left for operator to disassembly

and clean the print head.

Make certain that the power supply and ground wire can

reach the printer.

There should be enough space left for opening the door to

maintain and service the printer.

Voltage / Frequency

The Microdot printer operates at 110/220 VAC±10%, 50-60 Hz.

Power Consumption

90 Watts maximum, 50 Watts typical.

4-4

Installation

Unpack and Inspect the Printer

Remove the Printer from

Remove the printer from its carton and visually inspect it for

its Carton

Connect Electrical

damage. Examine the control unit, umbilical, and printhead closely.

The printer is packed carefully at the SATURN manufacturing

facility. If any damage is noted, file damage claims with the carrier.

The printer is available at 110/220 VAC. Complete the follo wing

steps to connect AC power to the printer.

Prepare an electrical source of 110/220 ± 10% VAC, 50/60 HZ.

Plug the power cord plug into the appropriate electrical

source.

Push the switch of the AC power supply to turn on the printer.

Push the switch of the AC power supply again to turn off the

printer.

4-5

Installation

Assemble the Printhead Stand

Unpack and Assemble

the Printerhead Stand

Bolt the Printerhead

Stand to the Floor

Follow the installation instructions included with the printhead

stand.

Once you have determined the final location of the printhead

stand, bolt the stand to the floor.

Figure 4-1. Printhead stand

4-6

Installation

IOU Board Connector’s Definition and Encoder and Photocell

Installation

Connect the

Connect the Encoder

Procedure

Follow these steps to connect the Photocell:

WARNING: The printer must be power off when installing the

Photocell.

1. Route the photocell wires through one of the side ports on

the printer.

2. Attach the wires from the photocell to the photocell on the

IOU board. Pin identification for photocell hook-up is shown

in Figure 4-2 and Table 4-1.

A shaft encoder is used when the speed of the conveyor varies.

The frequency of the pulse which the shaft encoder generates

can be multiplied or divided by the FCU (optional). The printer

will print one stroke when received one pulse from FCU. So when

the frequency changed, the print speed changed synchronously.

The width of printed message will be the same all the time except

the speed of the conveyor goes beyond the speed limit of the

printer.

Enter <Print Setup-3>, set “Setup Encoder” as follow:

1. If the speed of the production line is steady, adjust message

“Width” to control the printing speed. You need to turn “Off”

the setup of “Encoder Select”.

2. If the speed of the production line is not steady, it is

suggested adjust the printing speed (“Width”) by encoder.

You need to turn “On” the setup of “Encoder Select”. When

adjusting the printing speed (“Width”), change the value of

Frequency Divide (1~15) and Frequency Multiple (1~15), to

control the frequency received, then adjust the message

width.

CAUTION: The higher the value of Frequency Divide is, the

wider the message; The higher the value of

Frequency Multiple is, the narrower the message.

Follow these steps to install the encoder wires in the printer:

WARNING: The printer must be power off when installing the

encoder.

1. Route the encoder wires through one of the side ports on the

printer.

2. Attach the wires from the encoder to the encoder connector

on the IOU board. Pin identification for encoder hook-up is

shown in Figure 4-2 and Table 4-1. (Follow the instructions

provided with your shaft encoder.)

4-7

Installation

X4 connector (Input)

X3 connector (Output)

Figure 4-2. Pin identification of IOU board

4-8

Installation

Port

Name

X3

(Output

X4

(Input)

Table 4-1. Pin description of IOU board

CAUTION:

Pin Name Signal Defined Purpose

N

L

SCM COM

R Red Lamp (NO)

Y Yellow Lamp (NO)

G Green Lamp (NO)

)

LCM COM

LNC NC

LNO NO

PCM COM

PNC NC

PNO NO

VDD

ENC Encoder signal

COM Encoder ground

VDD

PD Photocell signal

COM Photocell ground

IN0 Input signal

COM Common

IN1 Input signal

COM Common

IN2 Input signal

COM Common

IN3 Input signal

COM Common

IN4 Input signal

COM Common

PE Shield ground

B2 RS485A2 RS485+

GND Signal ground

220VAC

Encoder power

supply

Photocell power

supply

(1) Because most of the customers do not use X3 port, the X3 relay is selected spare parts,

ordered according to customer needs.

(2) The encoder must be used with FCU. Because most of the production line are moving at

the same speed, the encoder and FCU are selected spare parts, ordered from Saturn. For

standard S480 model, FCU has already been set inside.

Function

Description

Normal: Green lamp

lighting

Set on process: Green

Printer status alarm

beacon

Telecommunication

Control

Printing status

Encoder

Photocell De tect the product.

Reverse Printing

External message

Reset serials

number

Stop Printing

Not Used

RS-232/RS-485 port

lamp twinkling

Warning: Yellow lamp

lighting

Fault: Red lamp

lighting

Control other

equipment through

the status of printer.

Control other

equipment through

the printing status

Keep synchronization

with product line.

On or off: Reverse

printing automatically

On: Message 1

Off: Message 2

On or off: Reset

serials number

On or off: Stop

printing

External

Communication with

PC

Remarks

All the relays are

220VAC/5A or

30VDC/5A.

The 3 COMs

(SCM, LCM and

PCM) are

independent with

each other.

Open collector or

totem pole,

12VDC.

Open collector or

totem pole,

12VDC.

Note: All the

COMs are

connected.

Port of photo

electricity

seclusion.

4-9

Installation

1.Open the upper door, you will see: there is a blank area with the white letters of FCU in the centre

of IOU.

2.Turn off the power, and plug the FCU in the IOU, refer to the picture below about the plugging

direction.

CAUTION:The plugs under the FCU must be exactly against to the pins of IOU.

3.Choose Encoder: Output 2000 signals by a roll (24V). There is “Definition of wiring” on the encoder.

(The photo below).

4-10

Installation

+V (Positive of Supplied Power) is “red” wire; The color of OMRON encoder: 5

to 24VDC(Positive of Supplied Power) is “Brown” wire;

A(Signal A) is “Green” wire; ONT A(Signal A) is “Black” wire;

0V (Negative of Supplied Power) is “Black” wire. 0V(Negative of Supplied Power)

is “Blue” wire.

CAUTION:Printer can only use three of these wires. For the other wire of the encoder they must be

isolated with each other, or faults may happen.

For different brands of encoder, the definition of color wiring is different, and you can find these

three wires according to the examples. (Refer to the label when there is no encoder instruction

book)

4.Connect the wire of encoder to IOU by three hole on the right of X4 port (Refer to the photo below)

X4 Input Port

CAUTION:Wrong wiring method may burn down the encoder or IOU. Ensure it before turn on the

machine.

The definition of wiring from right to left is: +V (Positive of Supplied Power) connect to VDD; A(Signal

A) connect to ENC; 0V (Negative of Supplied Power) connect to COM.

5.Push the power button and adjust each parameter by the order below.

1. Message Width

It is used to adjust the width of the printed message on the products when the

encoder status is off (see “Encoder Setup”). The higher the setup value is, the

narrower the width of the message (the same product moving speed).

It is used to adjust the print quality when the encoder status is on (see

“Encoder Setup”). The lower the setup value is, the better the print quality.

1. Enter <Print Setup-1>, select <Message Width>.

4-11

Installation

)

2. Enter the value directly or use right/left <Adjust Key> to adjust the value

as the “message width” to meet the production demand.

3. Press <Ok> to confirm it.

2. Setup Encoder The setting steps are listed as followed:

1. Enter <Print Setup-3>, select <Encoder Setup>. It displays as below:

Status:

Printer is enable to

Setup Encoder

2007/ 12 / 3 12:00

Saturn Technologies Co. Ltd

Encoder Status

Frequency Divide

Frequency Multiple

Ok (F1)

Cancel (F2

2. If the Frequency Divide and Frequency Multiple can not be selected,

please check if FCU frequency control unit has been installed correctly.

(See CAUTION of Chapter Four 4-7page)

3. You can setup the status of encoder to be on or off if an encoder has

been installed. “On” means that the print speed is controlled by the

encoder. You can divide or multiple the frequency of the encoder to adjust

the width of message. “Message Width” is only used to control the print

quality. “Encoder is Off” shows that the “Message Width” controls the

printing speed.

Off

1

(1~31)

1 (1~31)

Exit (F3)

Current Flow Time: 4200

3. Length Counter

4. Press <Ok> to confirm it.

Caution

:

z The higher the “Frequency Divide” is, the wider the printing message,

and the higher the “Frequency Multiple” is, the narrower the printing

message.

z If the “Encoder Select” is on, it only can control the print speed under the

print speed limit of the printer itself. It happens that the width of message

will be out of control (maybe wider than normal) if it is over the speed

limit available (The speed limit is according to the “Message Width” in

<Print Setup-1>). At that time, you must decrea se the product line spee d

or increase value of “Message Width” or adjust the width of printing

message through adjusting “Frequency Divide/Multiple”.

z If no encoder has been installed, you must not setup “Encoder Select” at

“On”, or else it cannot print anything because the printer can’t receive

any signal of the encoder.

If there is a need to print once in each interval of a certain length or certain

products, length counter becomes necessary. FCU (frequency control unit) is

necessary to control the print interval to ensure all the intervals are the same.

If there is a need to count meters by printer, length counter is also needed. The

operation is as follow:

4-12

Installation

y

1. Enter <Print Setup-3>, select <Length Counter>. If you can not select

Length Counter, please check the setup of FCU (Refer to the CAUTION of

figure 4-7 in Chapter 4)

2. If the FCU is set correctly, the screen will display like this:

System Status

Printer is off

EEEEEEEEEEE12345678902008/03/05

EEEEEEEEEEE123456789008:40:18

EEEEEEEEEEE1234567890000000205

Counter

Print Control

Length Par

Current length

Setup Encoder

2007/12/13 12:13

On

Print ke

5

0

(2~320000)

Ok (F1) Reset Counter (F2) Exit (F3)

Current Flow Time

3. When counter display “On”, it means the function is open.

4. “Print control”: controlled by photocell or “Print” button.

Length Par: set print space. It is used as followed:

Output 2000 pulse signal when rotating once. The rotating circumference

is the same as a wheel with the circumference of 1 meter. Therefore, when

the wheel is touching the product line, one rotating of the wheel equals to

1 meter of the product line moving. In a word, when printing every 1 meter,

set “Length Par” to 2000.

Caution

4.Print Setup by Length Counter

Insert “Serial number” in printing message, the printing effect of Length

counter can be realized.

Caution

numbers can be inserted into one message at most.

The procedures of “Insert Serial Number” as below:

1. Enter<Edit Message-1>, select <Select Font>, confirm the font size of the

:

z Under the status of “Printer is ready to print”, length counter’

setting is locked and cannot be changed. Press “Print” and exit the

status of “Printer is ready to print”, you may set up parameters of

length counter under any other status.

z When “Print Control” is controlled by “Print” to adjust the start or

stop of printing, enter Length Counter after start the printer, choose

“On” or “Off” of the Length counter once, Push “Print” twice to

enter into “Print is ready”, then the printer can print normally.

: According to the model of the printer there are 2 or 4 serial

serial number.

2. Enter<Edit Message-2>, select <Insert Serial Number>, it displays as

below:

4-13

Installation

r

f

Status:

Printer is of

2007 / 12/ 13

12 : 24 : 36

0013

Insert Serial Numbe

Name

Start

End

Current Value

Ok (F1)

1

0

9999

13

Leading Zeros

Step Size

Repeat Count

Cancel (F2)

Current Flow Time: 4200

Yes

1

1

Exit (F3)

3. There is a select box Illuminated in the “Parameter Setup Zone”. Using

<Direction Key> to move the select box to the position needed.

4. The value of “Start” and “End” represents that from which the serial

number starts to what number. When the serial number increases to

“End” value, the printer will print from “Start” value again. For example:

When printing a wire of 100 meters long, the Start value can be set at 1,

and the End value at 100. Then, the printer will print from 1 meter to 100

meters increasingly. When setting Start value at 100, and the End value at

1, the printer will print from 100 meters to 1 meter decreasingly. Then, it

will repeat printing from 100 meter again.

5. “Current Value” means the current serial number when setting it

(Normally set at 1). For example, when printing a wire of 100 meters long,

5 meters should be passed before printing everyday. So, we could set the

Current value at 95, then the printer will print from 95 meters to 100

meters(Pass 5 meters). When the Current value comes to 100, the printer

will print from 1 meter again.

CAUTION

: the value of “Current Value” should be within the rang

between Start value and End value.

6. “Leading Zeros” can be opened by right or left key. It displays that

whether the space of the serial number is filled in by zeros. For example,

when inserting a serial number circulate from 1 to 100, there is three bits.

When it displays “No”, the leading zeros will be displayed like 1, 2, 3~100;

when it displays “Yes”, the leading zeros will be displayed like 001, 002,

003~100.

7. “Step size” indicates how much the serial number increase or decrease

each time (Normally 1). If the Step size is 1, when the value increases 1 for

each time, the screen will displays as 1, 2, 3, 4~100. If the Step size is 2,

when the value increases 1 for each time, the screen will displays as 1, 3,

5, 7~100. If the Step size is 3, when the value increases 1 for each time,

the screen will displays as 1, 4, 7, 10~100.

8. “Repeat Count” shows how many times can each serial number print

repeatedly (Usually show as 1). If each serial number will be print once, it

will display as 1, 2, 3, 4~100. If the value is 2, each serial number will be

printed twice, and it will display as 1、1、2、2~100、100. For example, when

the customer require change (Increase or decrease) the serial number

after printing 10 product each time, this setup will be applied to, and the

value should be 10.

9. Select <Ok> to finish inserting serial number. And the serial number

information you setup will be displayed in the “Message Edit Zone”.

4-14

Installation

5. Reset Serial Number

CAUTION

:

z The name of the serial number is built up by the system, and it

cannot be changed by yourself.;

z If you enter wrong setting during parameter setup, press

<Cancel> to come back to the old value, and then enter the new

setting again.

z If you want to change the setting of the serial number inserted,

move the cursor to the “serial number” block, and this block

will reverse video in the “Message Edit Zone” of the screen,

then select <serial number>, set up the parameter of the serial

number again and the changed serial number information you

setup will be displayed in the “Message Edit Zone”.

z If you just want to change the current value of the serial number,

it is suggested to choose “Reset Serial Number”, which can be

used in the printing. The procedure will display as below:

This function is only to change the current value of serial number, but

cannot change other parameter of the serial number. The steps of

restoring serial number is as below;

1. Enter<Message Edit -2>, select <Reset Serial Number>, it displays as

below:

Status:

Printer is ready

2007 / 12/ 13

12 : 24 : 36

0070

Name

0

1

Ok (F1)

yes

no

Cancel (F2)

Reset Serial Number

Current Value

0070

076

Exit (F3)

Current Flow Time: 4200

2. Use <Direction Key> to move the Parameter Setup Zone to the

position of the serial number that needs to be changed, and the

serial number in the zone will be white.

3. Use <Adjust Key> to Change “Start” Value and choose “yes”, and

then use right <Direction Key> to move to the “Current Value” to

insert a new value you want.

4. Repeat the steps to change other current values of the serial

number.

5. After changing choose “Ok” to finish the operation.

CAUTION

: After “Reset Serial Number” changing, the times of

“repeat times” (when it is not 1) of this serial number, it will be counted

again.

4-15

Installation

Cable, wire, and construction material manufacturers usually require printing from the first meter at

any time, but this requirement is random and unpredictable. When deciding reset serial number to 1,

resetting serial number too many times may cause miss opportunity to reset.

Therefore, S420 Serial printer add a special function as “Quick Reset Serial Number”. When printing,

you just have to press Shift+Del together. Then, there come s out a quick reset dialogs. Press on

Enter, and current serial number will be reset to 1.

Other Concerning Points: (1) For 66 and 53 micro printer (Include S420P), the message height

should not be lower than 80, or the printing message will be missing.

Decrease the value of “Change SPEC” to further lower down the

message height.

(2) The value of “Change SEPC” for 53 micro should not be higher

than70, or the printing message will be missing.

(3) For 40 micro printer, the ink pressure is set at 46Psi, the message

height should not be lower than 40, or the printing message will be

missing. Decrease the value of “Change SPEC” to further lower down

the message height.

(4) The “Frequency Multiple” in <Encoder Setup> should be 1 to the

greatest extend, or there will be a error in Length counter.

(5) After changing parameters, press on Shift + F1 to quick save.

4-16

Installation

Set up the Printer

Final Installation Topics

Tools and Supplies

Needed

Your S420 printer is now ready for its final installation set-up.

The final set up includes:

tools and supplies needed

calibrating the ink flow time and set it

loading with the ink and make-up

adjusting ink stream and breakoff

The following are essential for proper printer set-up:

SATURN ink

SATURN make-up fluid

Wash Pan (Service Tray)

Printhead Holder & Thumb Screw

Magnifier Glass

Flush the system and

Load the Ink

Selection of hand tools

CAUTION: Instructions for flushing the system with make-up

fluid and loading it with ink, as well as the following calibration

procedure, are found in Chapter 6, Maintenance.

WARNING: Make certain to ground the service tray to the printer,

and install the printhead into the service tray. Failure to properly

ground the service tray and printhead when using flammable ink

may cause fire due to static discharge.

WARNING: Ensure that the work area is well-ventilated.

WARNING: The printer must be flushed with make-up fluid

before ink is loaded into the system for the first time. The system

must also be flushed with make-up when it is brought back

on-line from storage.

Follow the System Flush procedure (Chapter 6, Maintenance) to

calibrate flow time and load the system with ink.

Be sure to include these steps:

1. Prepare the printer

2. Flow time calibration

3. Load the ink

4. Load the make-up fluid

5. Print head temperature calibration and setup

6. Ink stream calibration

7. Ink stream breakoff adjustment

4-17

INK JET PRINTER OPERATION

5

Ink Jet Printer Operation

In this chapter you will find how to operate the printer to meet

production demand.

Turn to page 5-2 for a chapter-level Table of Contents.

5-1

INK JET PRINTER OPERATION

Chapter 5 Contents

Introduction - - - - - - - - - - - - - - - - - - - - 5-4

Menu Organization - - - - - - - - - - - - - - - - - - - - - - 5-4

Keyboard Description - - - - - - - - - - - - - - - - - - - - - - 5-5

Ink Jet Printer Operation - - - -- - - - - - - - - - - - - 5-9

Printer Startup Sequence - - - - - - - - - - - - - - - - - - 5-9

Printer Shutdown Sequence - - - - - - - - - - - - - - - 5-9

Message Edit - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

Clear Message - - - - - - - - - - - - - - - - - - - 5-10

Print Message - - - - - - - - - - - - - - - - - - - - - - - - 5-10

Select Font - - - - - - - - - - - - - - - - - - - - - - - - 5-10

Insert Clock - - - - - - - - - - - - - - - - - - - - - 5-11

Insert Serial Number - - - - - - - - - - - - - - - - - - - - - - 5-12

Reset Serial Number- - - - - - - - - - - - - - - - - - - 5-13

Shift Code - - - - - - - - - - - - - - - - - - - - - - - - 5-14

Insert Message - - - - - - - - - - - - - - - - - - - - - 5-15

Insert 2D Code- - - - - - - - - - - - - - - - - - - - - 5-16

Insert Serials Radom Number- - - - - - - - - - - - - - 5-17

Message Store - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

Select Message - - - - - - - - - - - - - - - - - - - 5-20

Save Message - - - - - - - - - - - - - - - - - - - - - 5-21

Save As - - - - - - - - - - - - - - - - - - - - - - - 5-21

Delete Message - - - - - - - - - - - - - - - - - - - 5-22

Download Message - - - - - - - - - - - - - - - - - - - 5-23

Upload Message - - - - - - - - - - - - - - - - - - - 5-24

Memory Format - - - - - - - - - - - - - - - - - - - - 5-25

Program Update - - - - - - - - - - - - - - - - - - 5-25

Execute Orders from U-disc - - - - - - - - - - - - - -5-26

Fonts Operation - - - - - - - - - - - - - - - - - - 5-26

Print Setup - - - - - - - - - - - - - - - - - - - - - - - - 5-29

Print Delay - - - - - - - - - - - - - - - - - - - - - 5-29

Message Width - - - - - - - - - - - - - - - - - - - 5-30

Message Height - - - - - - - - - - - - - - - - - - 5-30

Print Repeat - - - - - - - - - - - - - - - - - - - - - - 5-31

Bold Message - - - - - - - - - - - - - - - - - - - 5-31

Message INV/REV - - - - - - - - - - - - - - - - - - - - 5-32

Encoder Setup - - - - - - - - - - - - - - - - - - - - - 5-32

Product Counter - - - - - - - - - - - - - - - - - - - 5-33

Length Counter - - - - - - - - - - - - - - - - - - - - 5-34

System Setup - - - - - - - - - - - - - - - - - - - - - - - - 5-35

System Clock - - - - - - - - - - - - - - - - - - - - - 5-35

User Password - - - - - - - - - - - - - - - - - - - - 5-36

System Status - - - - - - - - - - - - - - - - - - - - 5-36

5-2

INK JET PRINTER OPERATION

Software Version - - - - - - - - - - - - - - - - - - - - 5-36

Machine ID - - - - - - - - - - - - - - - - - - - - 5-36

System Maintenance - - - - - - - - - - - - - - - - - - - - - 5-37

Ink(On/Off) - - - - - - - - - - - - - - - - - - - - - 5-37

H.V.(On/Off) - - - - - - - - - - - - - - - - - - - - - 5-37

Print Test - - - - - - - - - - - - - - - - - - - - - 5-37

Nozzle Drive - - - - - - - - - - - - - - - - - - - - - 5-38

Phase Select - - - - - - - - - - - - - - - - - - - 5-39

Ink Flow Time - - - - - - - - - - - - - - - - - - - - - 5-40

Hydraulic System Maintenance - - - - - - - - - - - - - - 5-40

Auto Flush - - - - - - - - - - - - - - - - - - - - - 5-40

Drain Fluid - - - - - - - - - - - - - - - - - - - - - 5-40

Auto Flush - - - - - - - - - - - - - - - - - - - - - 5-40

Flow Time Calibrate - - - - - - - - - - - - - - - - - - - - - 5-41

Printhead Temperature setup - - - - - - - - - - - - - - - - 5-41

Manual Control - - - - - - - - - - - - - - - - - - - - - 5-42

Charge SPEC. - - - - - - - - - - - - - - - - - - - - - - - - 5-43

Lock Keyboard - - - - - - - - - - - - - - - - - - - - - - - - - 5-43

Logo & Font Editing Instruction - - - - - - - - - - - - - - - - - - 5-44

5-3

INK JET PRINTER OPERATION

Menu Organization

5-4

INK JET PRINTER OPERATION

r

Keyboard Description

Ink Jet

Key

Print

Key

Display Screen

Display organization as following:

System St atus

Zone

Message

Edit Zone

Parameter

Setup Zone

Fault Report

System Status:

Printer is off

Inkjet Printer.

2007 / 12/ 13

Message

Edit (F1)

Display Screen

Right Adjust

Keys

Function

Select Key

Menu Name

Main Menu -1

2007 / 12 / 13 10:26

Message

Store (F2)

Current Flow Time: 4200

Print

Setup (F3)

Function

Select Ba

5-5

INK JET PRINTER OPERATION

System Status Zone

Displays the current status of the machine like “Printer is off”,

“Printer is starting up”, “Printer is shutting down”, “Printer is ready”,

“Printer is ready to print” etc.

Menu Name

Displays the menu name or function name in the current menu, such

as “Main Menu – 1” or “Insert Clock”.

Message Edit Zone

Message Edit Zone is used to edit message you want under the

“Message Edit Menu”, or check the current printing message in other

menus.

On the lower right-hand corner of Message Edit Zone, it displays

“FONT: 0507 INS CAP X: 0000 Y: 0000”, which matches to

corresponding the current edit status, “5X7 font, insert, capital, X and

Y axis of cursor.”

Caution: It could not display Message Edit Zone in some certain

menus.

Message Bar

When the length of the message is beyond the screen, it shows the

approximate position of the cursor.

Parameter Setup Zone

Displays parameter under the certain function.

Function Select Bar

Displays 3 menus or functions at most, and displays the three

functions as 3 function key label on the screen. The <Adjust keys> on

the both sides of <Function Select key> can roll all the optional

functions as 3 functions per group (if the number of the functions

over 3). After every rolling, the function key label will be changed. The

function of the key will be changed correspondingly to match the

label.

Fault Report Zone

Displays fault or warning messages if the printer has a fault or

warning.

It will display the faults or warnings repeatly if there are several faults

or warnings.

The warning message will be disappear until the warning status is

clear and the fault message will be displayed constantly until the fault

status has been clear in order to remind the users that the fault

occurred on the printer which need to be repaired in time. If you want

to clear the fault message, please just press <SHIFT>+ <F2>.

Caution: On the right side of “Fault Report”, it will display the ink flow

time all the time.

5-6

INK JET PRINTER OPERATION

Keyboard

INK JET KEY

System St atus

PRINT KEY

(Green LED)

Warning Status

(Yello w LED)

Fault Status

(Red LED)

Press INK JET KEY for 2 seconds to start or turn off the printer. Do not switch off the

printer by using the main power switch or unplugging the power supply until the

printer displays "printer off"

Besides the <INK JET KEY>, there are 4 LEDs to show the status of the printer:

Power Supply

System St atus

Warning Status

Fault Status

Print Status

(Green LED)

Power Supply

INK JET KEY

Shows that printer is power on.

System status LED flashed when the printer is starting up or

shutting down. It stays on when the printer is ready to print.

Shows warning status, and the printer needs to be maintained.

However, it doesn’t influence printing. After all the warnings are

cleared, the LED will be off.

Shows faults status, and the printer needs to be repaired.

Moreover, the printer can not print. After the faults are all cleared,

the light will be off.

After the printer is ready, then press <Print KEY> to enter

the printing status, the print status LED will on,

meanwhile, “Printer is ready to print” will be displayed on

the “System Status Zone” at LCD screen.

Press <Print KEY> again to exit the printing status, and

the print status LED will be off, meanwhile, “Printer is

ready” will be displayed on the “System Status Zone” of

the screen.

(Green LED)

5-7

INK JET PRINTER OPERATION

General Key

Directions Key

Used to move the cursor in the LCD screen.

Adjust Key

Used to move the function options left or right if the

number of the options is over three.

In certain function options, which is used to adjust

the parameter setup or change the setup

value( increasing or decreasing);

Press <Adjust Key> and <SHIFT> together to adjust

the screen contrast.

Function Select Key

The three function keys (F1, F2 and F3) are used to

select the upper corresponding function options.

Some shortcuts are realized by pressing shift and the

function key together:

SHIFT+F1: To quickly save the current message and

parameters;

SHIFT+F2: To clear the fault report when fault occurs;

Caps lock key

Push it to change the letter to lower case, then the light is off;

Shift key

Push it again to return capital letters; Default status is capital

letter.

Use with other keys simultaneously.

Exit key

Return to last menu or quit from current function.

Delete key

Delete useless character.

Confirm key

Confirm to make it effective after operation.

SHIFT+F3: Turn on or off the keypad tones.

5-8

INK JET PRINTER OPERATION

Ink Jet Printer Operation

Printer Startup Procedure

Press the “Power Supply Switch” at the right side of cabinet. About 2 seconds later

“Printer is off” will be displayed on the “System Status Zone” at LCD screen.

Printer is ready to startup. Following is 2 methods to start up the printer:

1. Normal startup: press (ink jet key) for 2 seconds. "Printer is starting up",

“Printer is ink on”, “Printer is ready” will be displayed on the status zone of

the screen successively. Printer will be ready to print two minutes later. The

printer has now completed the normal start up sequence. Press Print, the LED

on the key will be light up. The status zone of the screen will display “Printer is

ready to print”. Then the printer can print message.

2. Quick startup:

Enter “Service Menu-1”, select “Ink On/Off”, and “Printer is Ink on” will

be displayed on the “System Status Zone” of the screen. Now the printer

has been jet the ink.

Then select <HV On/Off>, “Printer is ready” will be displayed on the

“System Status Zone” of the screen. Till now the printer finishes the

quick start up sequence.

Press <Print Key> to enter printing status and “Printer is ready to print”

will be displayed on the “System Status Zone” of the screen. Then the

printer is ready to print messages on objects.

Caution:

to perform normal shut down procedure in order to recover the ink remains at ink

system.

If not start up printer at short period after maintenance, it is better

Printer Shutdown Procedure

There are two methods to shutdown the printer:

1. Normal shutdown: Press <INK JET KEY> for above 2 seconds. The printer will

execute normal shutdown procedure, this procedure cost about 4 minutes.

“Printer is shutting down”, “Printer is off” will be displayed successively on

the “System Status Zone” of the screen. Switch off the printer after ‘printer is

off’.

Caution:

on the screen. Otherwise it is possible to lead to some problems when the

printer starts next time. Follow the way of normal shutdown is suggested.

2. Quick shutdown: If the printer required shutdown less than 5 minutes, you can

shutdown the printer in quick shutdown procedure in order to avoid autoflush

procedure in the normal shutdown sequence. Follo wing steps are procedure of

“Quick Shutdown Sequence”:

DO NOT switch off printer before “Printer is off” displayed

Press <Print Key> to go to the status of “Printer is ready”.

Enter “System Maintenance”, select the function of “Ink On/Off”, about 5

seconds later the printer will be shutdown quickly and “Printer is off”

will be displayed on the “System St atus Zone” of the screen.

Caution:

to perform normal shut down procedure in order to recover the ink remains at ink

system.

If not start up printer at short period after maintenance, it is better

5-9

INK JET PRINTER OPERATION

Message Edit

Clear Message

Print Message

Select Font

If there is a message on the “Message Edit Zone”, you can select this

function to clear the old message in order to edit a new one.

When you have finished editing message, select “Print Message” to

confirm the content of printing.

The normal fonts for ink jet printer as following: 5X5, 5X7, 7X9, 10X16,

12X16, 16X24 etc.

The default font is 5x7, if you want to select another font, please

follow these procedures before editing messages:

1. Enter<Message Edit-1>, select <Select Font> function, it displays

current font and character sample in the “Parameter Setup Zone”,

the example as below:

2007 / 12 / 213 12:01

2. Use up or down <Direction Key> to change the font, and the

character sample changes after that, find the font needed.

3. Select <Ok> and the cursor changes along with the font size in

the “Message Edit Zone”.

Caution:

some kinds of fonts could not be selected. And it displays warning

“No enough space available, can’t select this font”.

Caution:

font, you may insert the first one or several letter of the name directly

to choose and use <Direction Key> to find the font you want.

If the cursor coordinate on Y axis is not “0000”,

If you know the name of the font when you select

Caution:

Caution:

“Message Edit Zone” when editing messages.

1. Directly press <Direction Key>, and the cursor will move by the

size of current font.

2. Press <SHIFT>+<Direction Key> at the same time, and the cursor

will move by a dot.

the size of the font shows the actual pixel.

There are two ways to move the cursor in the

5-10

INK JET PRINTER OPERATION

Y

/

/

Insert Clock

The printer can print real time, including year, month, date, hour,

minute, second. And the time can be offset by days or hours when

you want to print the expiry time.

The procedure of “Insert Clock” as following:

1. Enter <Message Edit-2>, select <Insert Clock> function, displays

as below:

Status:

Printer is ready.

2007 / 12/ 26

12 : 24 : 36

Format

YYY

HH : MM

Offset

0 0 Hours

OK (F1)

MM

Days

Insert Clock

2007 / 12 / 26 12:00

DD

SS

:

Exit (F3)

Current Flow Time: 4200

2. Using <Direction Key> to move the select box to the position

needed.

3. Use Right or Left <Adjust Key> to change format. Julian date

function is available at the first select box, press left <Adjust

Key> to call Julian date.

4. Using <Direction Key> to move the select box to the offset days

or hours, enter the number of days or hours you want to offset if

you want to offset the time by days or hours.

5. Select <Ok> to finish inserting clock. And the clock information

you select will be displayed in the “Message Edit Zone”.

Caution

:

In the first line, the formats of the clock are as below:

YYYY-- Year, 4 digits, like “2010”; YY-- Year, 2 digits, like “10”;

MMM-- Month, 3 digits, like “JAN”; MM-- Month, 2 digits, like “01”;

DD-- Date, 2 digits, like ‘12’;

st

In 1

line, the three list forward slash can be selected as below:

“/”, “\” SPACE or no slash;

nd

line, the formats of the clock are as belo w:

In 2

HH(Hour)、MIN(Minute)、SS(Second);

In 2nd line, the three list forward slash can be selected as below:

“:”, “/”, “\” SPACE or no forward slash;

Caution

: If you want to change the format or offset time of the

clock inserted, move the cursor to the “clock” block, and this block is

reverse video in the “Message Edit Zone” of the screen, then select

5-11

INK JET PRINTER OPERATION

Insert Serial Number

<Insert Clock>, set up the formats or the offset time of the clock again

and the changed clock information you setup will be displayed in the

“Message Edit Zone”.

Caution

: Two serial numbers can be inserted at most.

The procedures of “Insert Serial Number” as below:

1. Enter<Edit Message-2>, select <Insert Serial Number>, menu

displays as below:

Status:

Printer is ready

2007 / 12/ 13

12 : 24 : 36

0013

Name

End Value

Current Valu e

OK (F1)

1

0 Start Value

9999

13

Cancel (F2)

Insert Serial Number

2007 / 12 / 13 12:00

Leading Zeros

Step Size

Repeat Count

Exit (F3)

Current Flow Time: 4200

Yes

1

1

2. Using <Direction Key> to move the select box to the position

needed.

3. Select <OK> to finish setup, the serial number will be displayed