Saturn NHC 25B/30B/41B, NHC 25E/30E/41E, NHC 25H/30H/41H, NHC 25EH/30EH/41EH Instruction Manual

Installation, Maintenance and User Guide

Instruction Manual

Instruction Manual

Read the instructions fully before installing or using the appliance.

INSTALLER, this manual is to be axed adjacent to the boiler.

CONSUMER, retain this manual for future reference purposes.

Constant development eorts may result in minor deviations in

illustrations, functional steps and technical data without prior notice.

Pictures and drawings in the instructions can be dierent from the

appliance. All product images are provided by the manufacturer and are

for reference purposes only.

NHC 25B/30B/41B (Boiler House w/ Combi Option)

NHC 25E/30E/41E (External w/ Combi Option)

NHC 25H/30H/41H (Boiler House w/ Heat Only)

NHC 25EH/30EH/41EH (External w/ Heat Only)

Contents

Homeowner

4

5

6

7

8

9

10

11

12

13

14

18

20

22

23

24

26

30

31

36

37

42

43

44

45

Safety instructions

Product Fiche

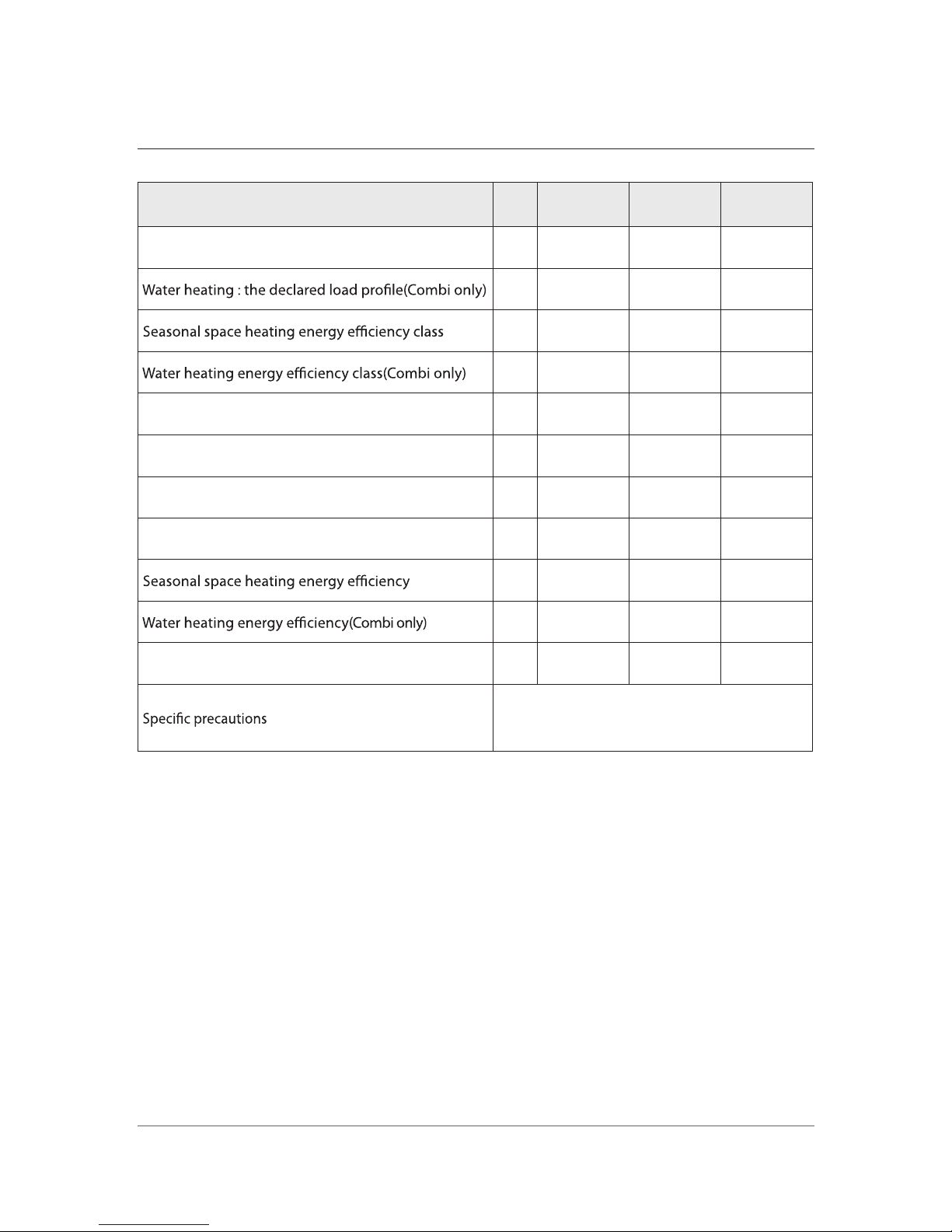

Operation & Display Panel (OBC100)

Room Thermostat (LCR-2WE) - Combi Only

Vacation/Standby Mode - Combi only

Heating Mode - Combi only

Hot water Mode - Combi only

Fault Codes

Installer

Design Standards

Safety

Flue Regulations

Before Using The Boiler

How To Use

Safety Devices

Everyday Checks

Servicing The Boiler

Plumbing Schematic

Commissioning The Boiler

Component Overview

Electric Wiring Diagram

Wiring - Installation Variations

OTC Mode

Troubleshooting

Fault Codes

Product Information

Spare Parts

Specifications

Warranty

46

49

50

4

Safety Instructions

Safety-related messages and instructions have been provided in this manual

and on the boiler to warn you and others of a potential injury hazard. Read

and follow all safety messages and instructions throughout this manual.

It is very important to understand this safety section for operating,

installing and servicing of the boiler.

In addition to this, under the Consumer Protection Act 1987 and Section

6 of the Health & Safety Act 1974, we are required to provide

information on substances hazardous to health.

The small quantities of adhesives and sealants used in the product are

cured. They present no known hazards when used in the manner for

which they are intended.

This is a safety ale

rt symbol. It is used to alert you to potential

personal injury hazards.

Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates an imminently hazardous situation which

if not avoided, could result in severe injury or death.

Indicates a potentially hazardous situation which,

if not avoided, could result in severe injury or death.

Indicates an imminently hazardous situation which,

if not avoided, could result in minor moderate injury.

Earth

Use of fire

forbidden

Dangerous

electric current

Product Fiche

5

KD Navien Unit NHC 25B NHC 30B NHC 41B

Space heating : temperature application Medium Medium Medium

XL XL XXL

A A A

B B B

Rated heat output kW 24.0 27.9 36.8

Space heating : annual energy consumption kWh 76 89 116

Water heating : annual electricity consumption(Combi only) kWh 94 93 105

Water heating : annual fuel consumption(Combi only) GJ 22 23 30

% 91 90 91

% 64 62 67

Sound power level dB 68 66 69

Read the user's information and installation

manual before the application is assembled,

installed or maintained.

LCD indicate the temp of heating water,

the value of K-Factor, and occurrence of

trouble displayed the failure code.

* See page 11 for Error Code Table

LC

R-2WE Programmer- Combi only

The LCR-2WE remote control panel will

activate by pushing the power on/off button.

6

Operation and display panel (OBC100)

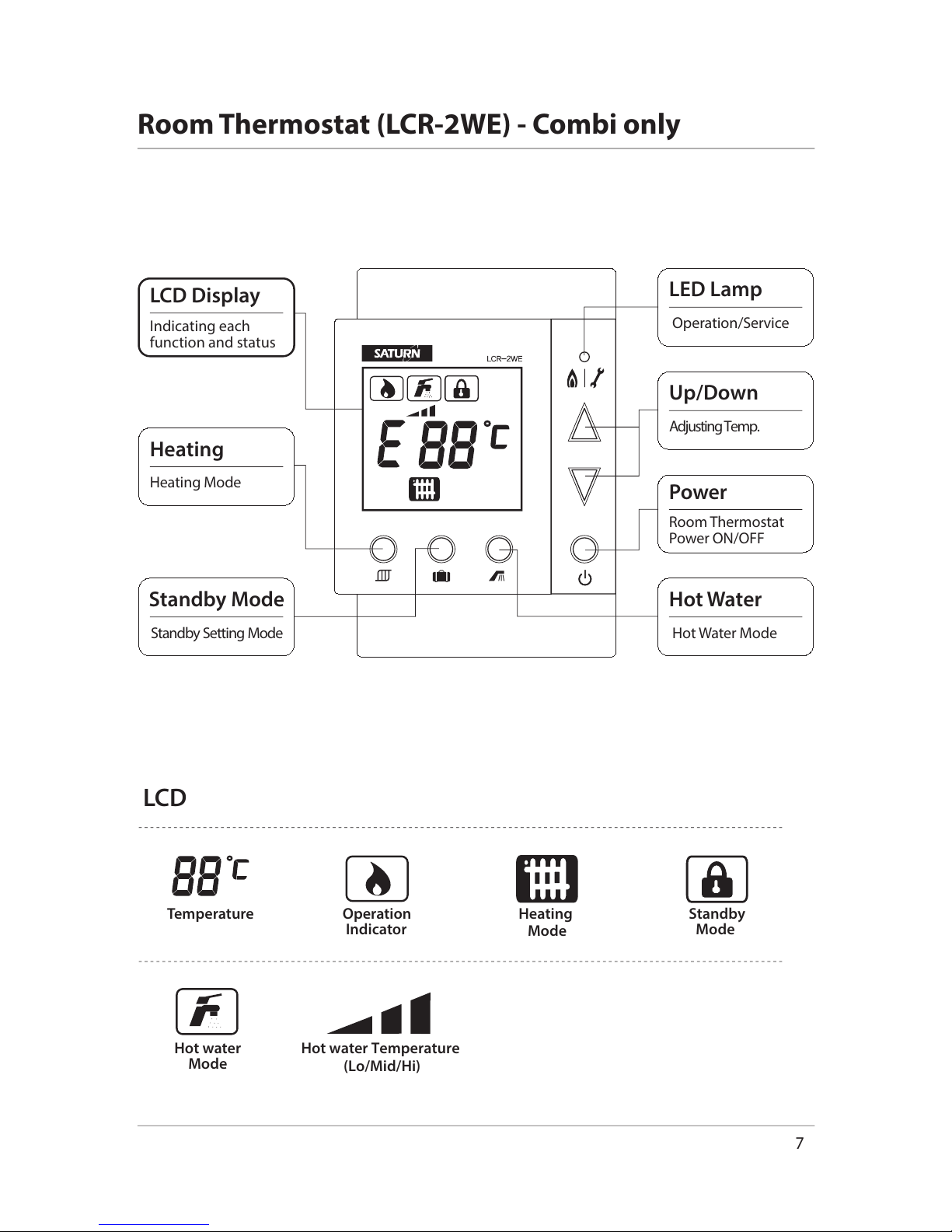

7

Hot water Temperature

(Lo/Mid/Hi)

Standby

Mode

Heating

Mode

Hot water

Mode

Temperature Operation

Indicator

Indicating each

function and status

LCD Display

Room Thermostat

Power ON/OFF

Power

Heating Mode

Heating

Adjusting Temp.

Up/Down

Standby SettingMode

Standby Mode

Hot Water Mode

Hot Water

Operation/Service

LED Lamp

Room Thermostat (LCR-2WE) - Combi only

LCD

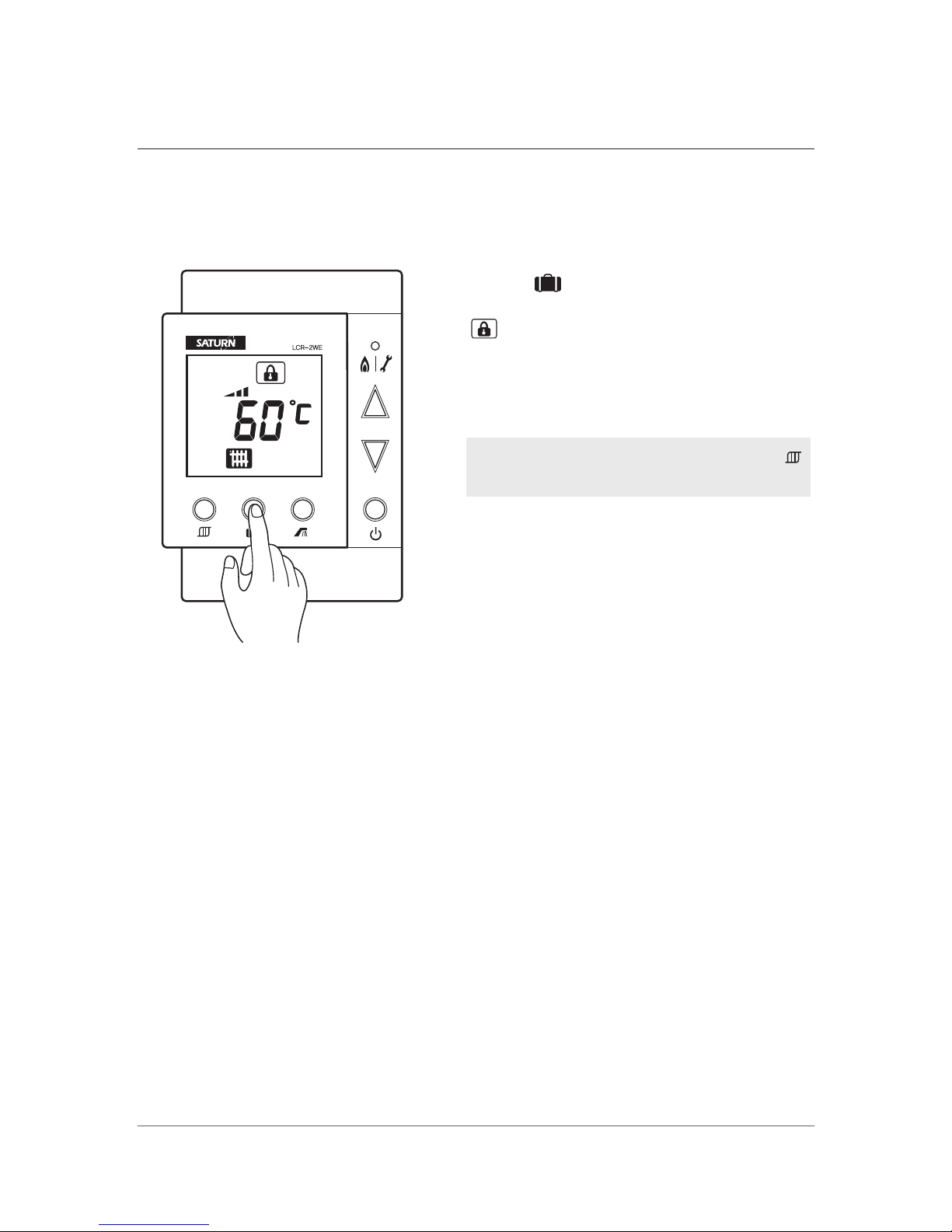

If you are not at home, you can set the Standby Mode to save heating

energy by pressing.

To cancel vacation/standby mode press the

button to return to the heating mode.

will be displayed and Standby Mode

will be set.

Press button.

8

Vacation/Standby Mode - Combi only

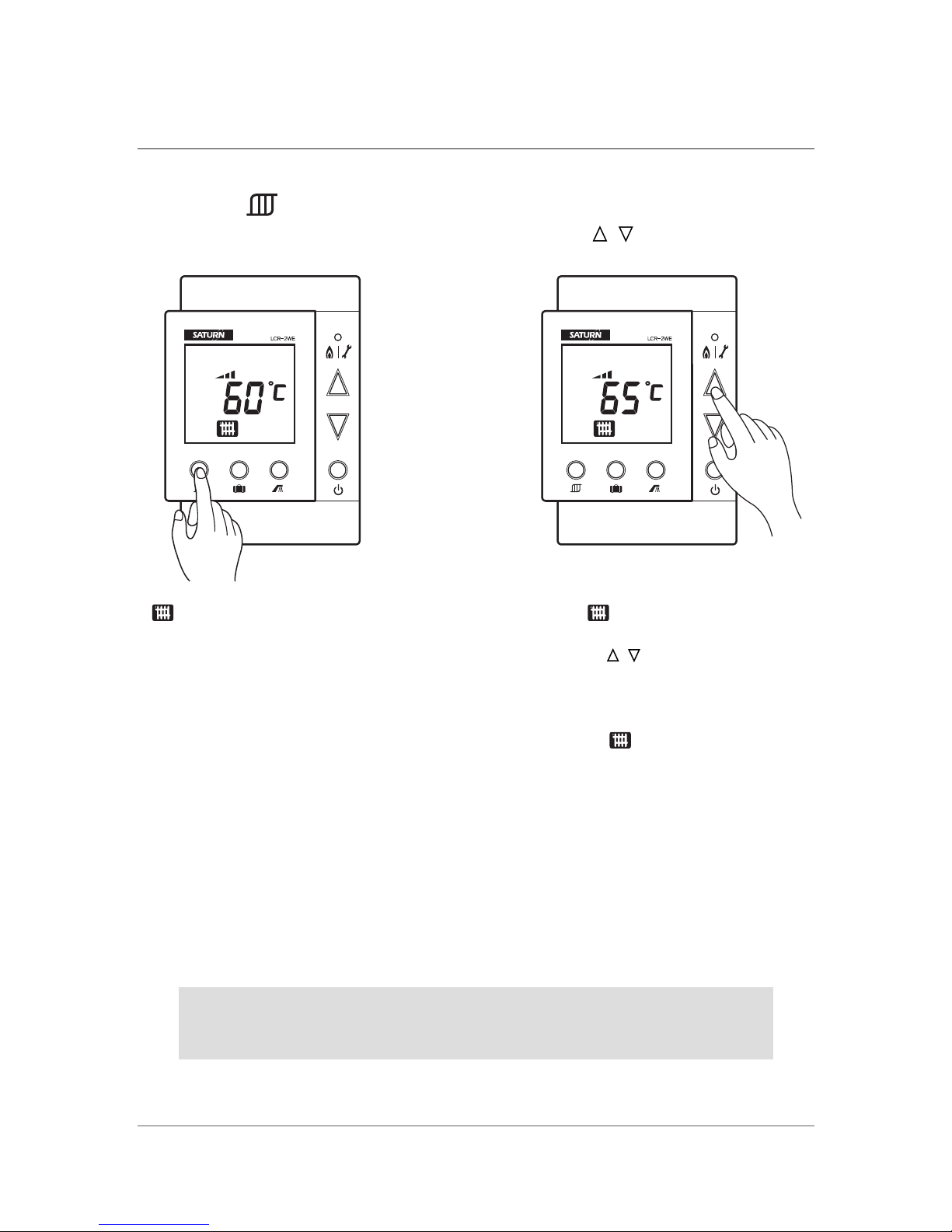

blinks when selecting

Boiler Temp. Mode

when blinks, set the desired

boiler temp. between 40~80˚C by

adjusting / button, after a while,

it is automatically saved. Boiler

temp. can be set by 1˚C. After the

required temperature has been

selected, is on and current

boiler water temp. is displayed.

Set the heating temp.

with / button.

Press the button.

The LCR-2WE room thermostat is designed to control a heating system

according to time and temperature, in connection with a valve controller

(red colored cable).

9

Heating mode - Combi only

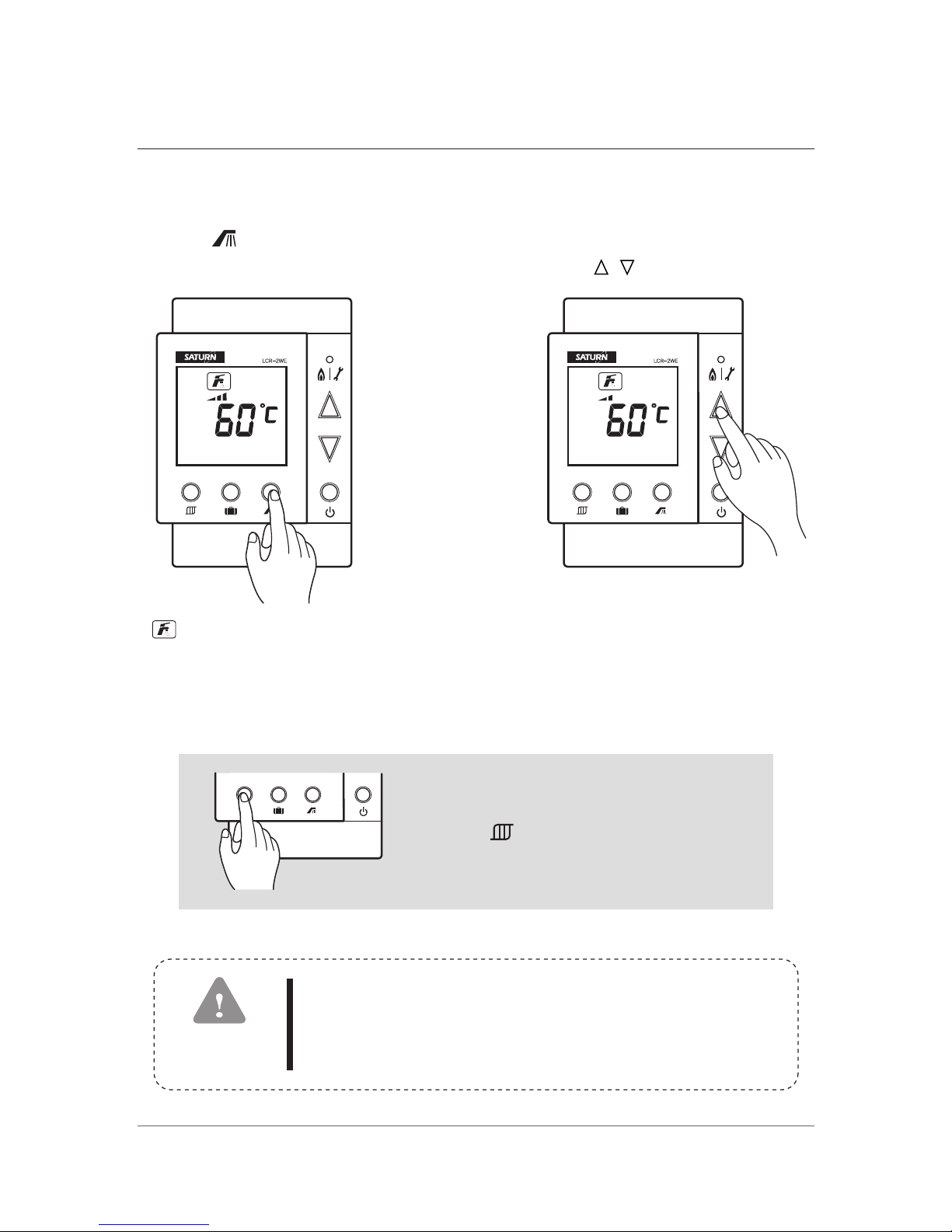

will be displayed and

Hot Water Mode will be set.

Adjusting hot water temp. by

3step; Low load, Medium load,

High load capacity of

combustion.

Set the heating temp.

with / button.

Use this function only when hot water is needed.

1. Please be careful that infants and young children do not use

hot water without a guardian present.

2. While others are using hot water, do not change the hot

water temp. setting for safety.

CAUTION

Press button.

You can determine whether the changeover

from DHW mode to Heating mode by

pushing “ " button.

1

0

Hot Water Mode - Combi only

Fault at the boiler

Fault codes take priority over all other display functions in the event of a system

fault occurring and the LCD shows one of the following numeric error codes.

If multiple faults occur, the corresponding fault codes are displayed alternately

for about two seconds each.

To reset the boiler switch the power button on -> off -> on.

If problem persists, contact your local installer.

02

03

04

05

06

12

16

Low water level

Temp. sensor wire

disconnected

Short circuit of

Temp. sensor

High limit thermostat

Error Code

Cause

Fault at the room controller

51

52

Electrical backup system

failure

Functional button

defective

Error Code

Cause

Electrical backup

The LCR-2WE retains the setting

parameters when the power

or shut down by power outages

and back to the preset operation.

11

Fault Codes

12

Design Standards

EMC Directive (Electromagnetic compatibility) 89/336/EC

Standards:

EN 61000-6-1: Electromagnetic Compatibility Generic Standard –

Immunity for residential, commercial and light industrial environments.

(Feb 2001)

EN 61000-6-3: Electromagnetic Compatibility Generic Standard – Emission

standard for residential, commercial and light industrial environments.

(Feb 2001)

LV Directive (Low voltage) 73/23/EEC

Standard:

EN 60335-1: Household and similar electrical appliances - Safety (May

2001)

Boiler Efficiency Directive 92/42/EEC

Standard:

BSEN 304: Oil boilers with forced draft burners.

Fuel Spillage

1. Switch off all electrical and other ignition sources.

2. Remove all contaminated clothing to safeguard against fire risk and skin

damage. Wash affected skin thoroughly with soap and water and remove

clothing to a safe well ventilated area and allow to air before cleaning.

3. Contain and smother the spill using sand or other suitable oil absorbent

media or non-combustible material.

4. Do not allow fuel to escape into drains or water courses. If this happens,

contact the relevant authorities in your area. (Ireland only). Contact the

Environment Agency on 0800 807060 (UK Only)

5. Consult local authority about disposal of contaminated soil, see

http://www.housing.gov.ie/local-government/administration/localauthorities/local-authorities

INSTALLER SECTION

13

Safety

Safe use of kerosene.

These fuels give off a flammable vapour when heated moderately. Vapour ignites

easily, burns intensely and may cause explosion. The vapour can follow along at

ground level for considerable distances from open containers and spillages

collecting as an explosive mixture in drains, cellars, etc.

Fuel

s remove natural oils and fats from the skin and this may cause irritation and

cracking of skin. Barrier cream containing lanolin is highly recommended together

with good personal hygiene and where necessary appropriate personal protection

equipment. (P.P.E.) Gas oil may also cause irreversible damage to health on

prolonged or repeated skin contact.

Alwa

ys store fuels in a properly constructed and labelled tank. Always handle fuel in

open air or well ventilated space away from sources of ignition and refrain from

smoking.

Alwa

ys drain fuel using a proper fuel retriever, funnel or mechanical siphon. Never

apply heat to a fuel tank, container or pipework. Never siphon fuel through tube by

mouth. If accidentally swallowed contact doctor immediately and do NOT induce

vomiting. Avoid inhaling fuel vapour as this can cause light headedness and

seriously impair judgement.

First Aid

If fuel is accidently swallowed:

Seek medical attention immediately and DO NOT induce vomiting.

If fuel is splashed into your eyes:

Wash out with running water for at least ten minutes and seek medical attention as

soon as possible.

14

Flues Regulations

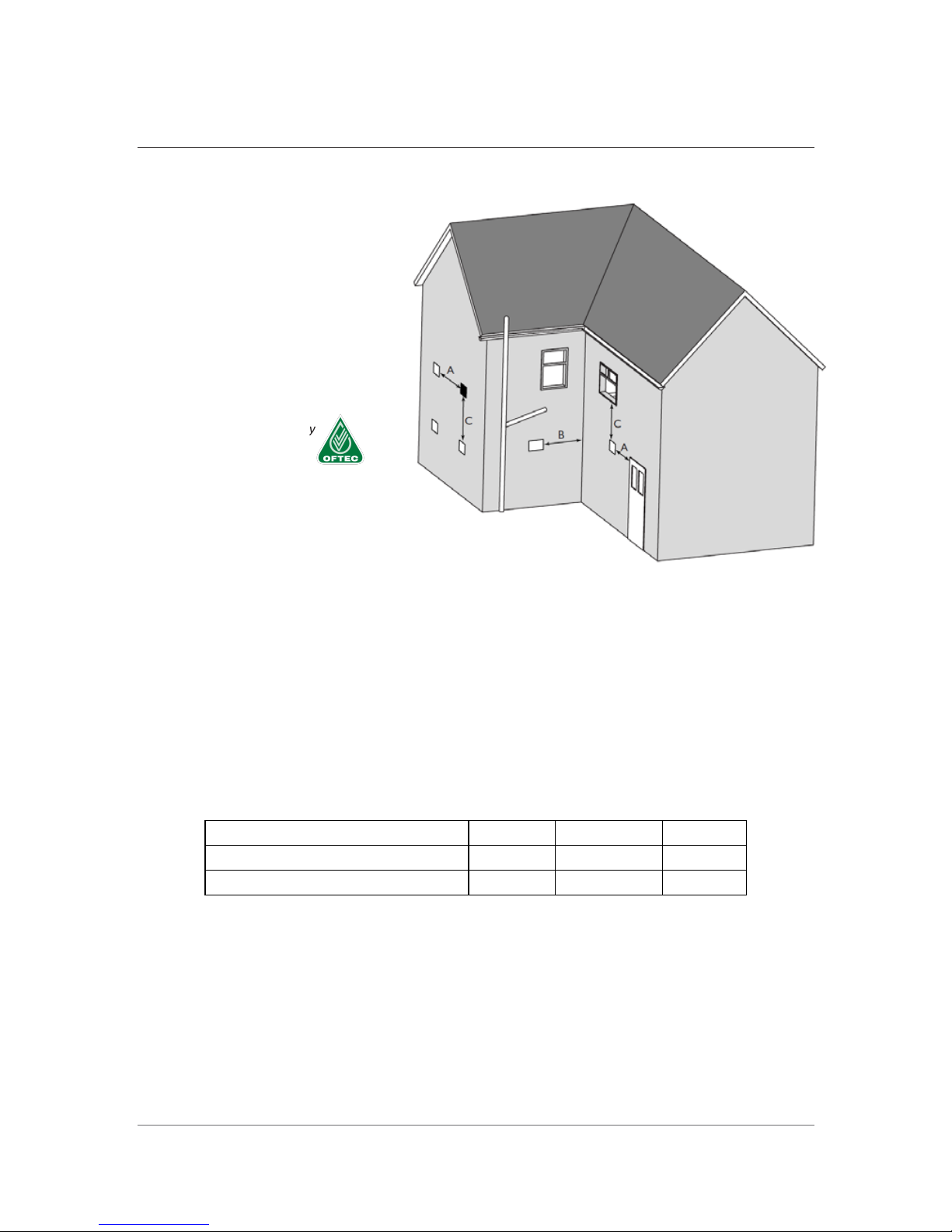

Balanced Flue Siting

Note:

1. Terminal should be positioned to avoid combustion products entering the building

or accum

ulating in stagnant pockets around buildings.

2. The terminal must be protected by a guard if it is less than 2 metres above ground

level or in a position where any person has access.

3. A heat protection shield should be fitted if the terminal is less than 850mm from a

plastic or painted gutter or less than 450mm from painted eaves.

Saturn Heating recommends as per OFTEC recommendations that the flue should

be a minimum distance of 1 metre from openings so that it does not cause a

nuisance and permits the dispersal of combustion products.

Building Regulations

A B C

Northern Ireland 600 600 600

Republic of Ireland 600 600 600

Where the terminal is within 1 metre of any plastic material, such material should be

protected from the effects of combustion products of fuel. There are additional general

requirements in most regulations and standards that the flue must be positioned so that it

does not cause a nuisance and permits the dispersal of combustion products.

Note:

The Building Regulations clearances shown above are the minimum allowed.

Contact Saturn Heating Technical Department for futher advice in this regard.

ALWAYS CHECK FOR ANY BUILDING REGULATIONS AMENDMENTS WHICH

MAY HAVE BEEN ISSUED AFTER THE PUBLICATION OF THIS MANUAL

a) Horizontal from opening,

airbrick, opening window

etc.

b) From an internal or external

corner.

c) Below an opening, airbrick,

opening window etc.

Information supplied by

Book Four, 2010.

Please see note at foot of page.

15

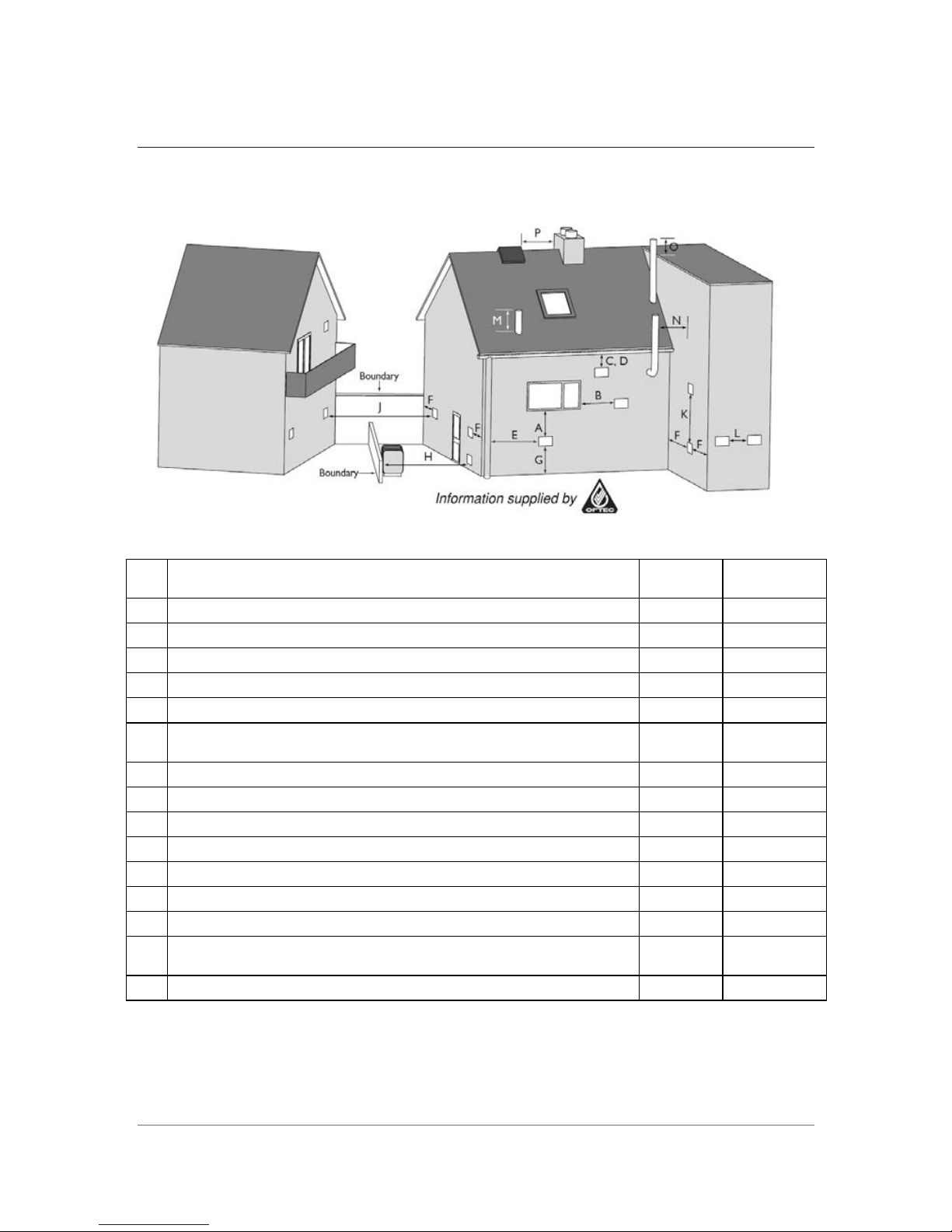

Flues Regulations

Clearances advised by the British Standards, provided by OFTEC, for open flues, low level

balanced flues and balanced flues fitted to oil fired boilers.

Minimum distances to terminals in millimetres as measured from top of the chimney or

the rim of a low level discharge opening.

Aplliance Burner Type

Pressure

Jet

Vapourising

A

Directly below an opening, air brick, opening window etc

600

Not allowed

B

Horizontally to an opening, air brick, opening window etc

600

Not allowed

C

Below a gutter, eaves or balcony without protection

75

Not allowed

D

Below a gutter or a balcony without protection

600

Not allowed

E

From vertical sanitary pipework

300

Not allowed

F

From an internal or external corner or surface or boundary

alongside the terminal

300

Not allowed

G

Above ground or balcony level

300

Not allowed

H

From a surface or boundary facing the terminal

600

Not allowed

J

From a terminal facing a terminal

1200

Not allowed

K

Vertically from a terminal on the same wall

1500

Not allowed

L

Horizontally from a terminal on the same wall

750

Not allowed

M

Above the highest point of an intersection with the roof

600

1000

N

From a vertical structure on the side of the terminal

750

2300

O

Above a vertical structure less than 750mm from the side of the

terminal

600

1000

P

Directly below an opening, air brick, opening window etc.

1500

Not allowed

Notes:

- Terminals should be positioned so as to avoid products of combustion accumulating in

stagnant pockets around the building or entering into buildings.

- Appliances burning Class D oil have additional restrictions (See OFTEC Book 4 2010)

- Vertical structure in N, O and P include tank or lift rooms, parapets, dormers etc.

16

Flues Regulations

- Terminating positions A to L are only permitted for appliances that have been approved

for low level flue discharge when tested to OFS A100 or A101

- Terminating positions must be at least 1.8 metres distant from an oil storage tank unless

a wall with at least 30 mins fire resistance and extending 300mm higher and wider than the

tank is provided between the tank and the terminating position.

- Where a flue is terminated less than 600mm away from a projecti

on above it and the

projection consists of plastic or has a combustible or painted surface, then a heat shield of

at least 750mm wide should be fitted to protect these surfaces.

- For terminals used with vapourising burners, a horizontal distance of at least 2300mm is

required between the terminal and the roof line.

- If the lowest part of the terminal is less than 2 metres above the ground, balcony, flat

roof or other place to which any person has access, the terminal must be protected by a

guard.

- Notwithstanding the dimensions given in the drawing and table, a terminal should not be

sited closer than 300mm to combustible material.

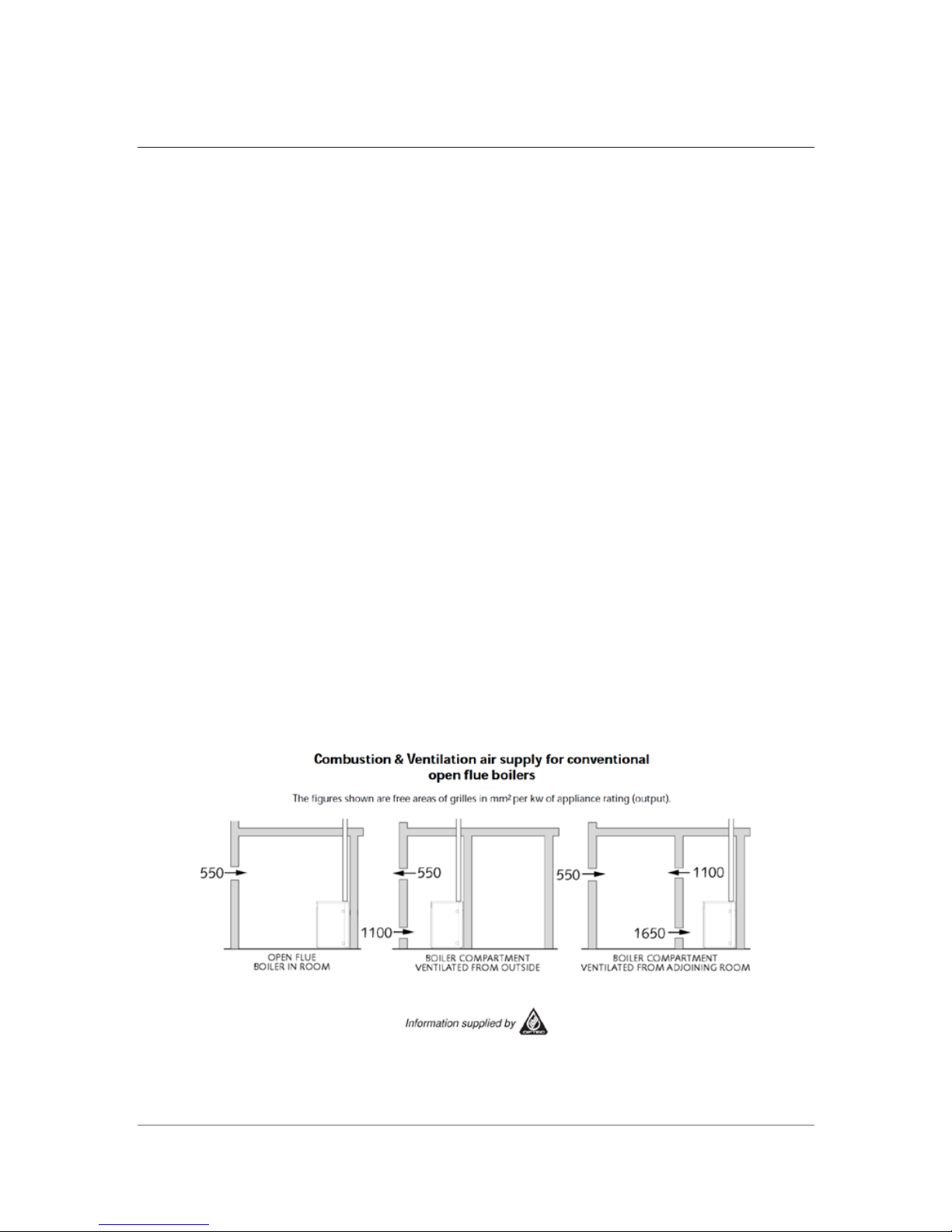

Ventilation & Combustion Air

Conventional Flue Boilers

An adequate supply of combustion and ventilation air is essential for efficient and safe

boiler operation and the openings for this should be positioned to cause least possible

draught, with no possibility of being accidentally blocked. Please note, the British Standard

Code of Practice for Oil Firing BS5410:Part 1, requires a permanent air inlet opening of

550mm

² per kW (above 5kW) of boiler rated output. (Note: 1kW = 3412 Btu/h).

Also when the boiler is installed in a compartment or confined space, ventilation openings are

required to ventilate and to avoid overheating in the boiler area.

FULL TEXT of both BS 5410 Part 1: 1997 and appropriate Building Regulations for each country

should be obtained and fully applied.

17

Flues Regulations

N.B. Please Carefully Note:

In OFTEC Book Four, 2010 page 33, 6.6.5 states that for the Republic of Ireland, “It is

not permitted to install open flue appliances in domestic garages, therefore only room

sealed balance flue appliances should be installed in a garage location”

Definitions:

Combustion Air:

Air required directly by boiler oil burner for combustion process.

Ventilation Air:

Air required in the room for ventilation, cooling, etc. and to promote a

healthy living environment.

Check all pipe connections thoroughly for

leaks before start-up.

Before using the boiler

18

Fuel

It is essential to use only

kerosene or light oil.

It is better to use kerosene when the temperature

can drop below -5 ˚C.

Choose a fuel storage location in accordance with

local regulations (See page 14 - Flue Regulations).

Take care to avoid the ingress of water and/or dirt

during re-lling as this can lead to f lame failure or

aect the lifespan of the boiler.

Ensure that the power is turned o and

the oil tank is isolated before relling.

A fuel filter with a filter rating of 70microns or

better must be fitted to the fuel supply, to the

appliance.

Pre-Start Checks

and that the low water level alarm is not activated.

suitable measurement equipment to ensure

correct combustion is taking place.

Do not plug out the power supply as this will

de-activate the frost protection.

The domestic hot water supply is not

recommended for potable use.(Combi only)

19

Notes when using

Take care when positioning

the boiler.

Do not locate in the immediate

vicinity of flammable materials.

Avo o e e oe

Avoid complete emptying of the oil tank.

This can lead to air being introduced to

the fuel system and may result in ignition failure.

the fuel supply line to vent. When oil starts to

In negative head oil supply applications the

fuel supply line must be purged using the

screw must be in the tightened position.

oil pump vent screw. For this the oil lter

Open the oil pump vent screw and switch

on the power to the boiler. After 6-7 seconds

the pump has purged the air and the

“CHECK”light will show on the control panel.

The boiler will stop.

Loosen the screw in the oil lter. This will allow

ow re-tighten the screw (this is only possible

in positive head oil supply applications).

How to use

20

Purging the oil supply

Ensure the system is full and at suitable

operation pressures. Fill and thoroughly

purge all connected pipework.

21

Reset the boiler by turning the power off and on.

Close the oil pump vent, press the power button

again and the boiler will ignite. If the boiler fails to

fire after 3 successive attempts contact the Saturn

technical helpline on 1890 929 112.

Preparation and checking before start-up

The boiler must always be correctly

grounded according to relevant local regulations.

Connect the boiler to the main 220v supply

and press the power button. The “RUN”

light should show after a short period.

Volt free boiler call (Orange cable)

Warning: Connecting power to this cable will

damage the boiler control panel.

Full wiring instructions on pages 36-41

When the boiler does not ignite, or if the flame

falls the flame detector (photocell) will

deactivate

the boiler.

Ignition safety device

Low water level safety device

2

2

Safety devices

If the water level is insufficient in the boiler

the low water level sensor will deactivate

the boiler. Once the system is adequately

refilled this will automatically reset.

Overheat prevention

If the temperature of the boiler rises to

dangerously high levels the overheat

sensor will deactivate the boiler.

In this instance the “CHECK” light will show. To

reset press the “RESET” button on the overheat

preventer.

Frost freezing prevention

At a boiler temperature of 9°C the circulating

pump will be activated. At a boiler temperature

of 2°C the burner will ignite. For this reason,

power must be maintained to the boiler, even if

the system is not in use.

Power-failure protection

In the event of power failure the oil supply will

automatically be isolated from the combustion

chamber.

Ensure that combustible materials are

not stored near the boiler.

Check for fuel leaks within the fuel

storage/supply system and check for

water leaks within and around the boiler.

Inspect the inside of the oil tank

for water or debris.

Keep

the area around the boiler clean and free

from obstruction to allow for free air flow.

2

3

Everyday checks

Points to be checked once or more a year

Soot build-up within the boiler will reduce its

The boiler should be serviced annually

by an approved service engineer.

Cleaning of the boiler

Wash the filter and the inside of the coil

cup using clean kerosene.

The oil tank should be checked during the

annual service and cleaned of all water

and debris as required.

Cleaning the oil filter

Cleaning the oil tank

24

To clean the oil filter, first isolate the oil supply.

Remove the oil cup

by unscrewing and pulling

the cup downwards.

Servicing The Boiler

If the flame detector (photocell) becomes sooty

or dirty the reduced sensitivity will cause erratic

and

incorrect boiler operation.

Cleaning the flame detector

Remove the flame detector (photocell) which

is located at the

top of the burner.

Wipe the glass surface

of the flame detector

(photocell) using a clean rag and replace.

During the annual service the flue system should

be checked for correct

installation, blockages,

corrosion or leakage. Any abnormalities found

should be rectified immediately.

Checking the flue pipe

25

Open cistern tank

Never install any valve between

boiler and cistern tank

Supply Water

Pipe

Minimum 1.5m

Circulating Pump

Distributor

Distributor

Condensate

Outlet

Drain Drain

F.L

Expansion Tank

Combi only

Water

Cold Water Inlet

Heating Flow

Heating Return

Cold Water

Hot Water

Boiler Back

2

6

Plumbing Schematic

Choosing of the installation place

Choose an installation site that allows easy access for installation, maintenance and operation.

When choosing an installation site, take care to conform to all local regulations and standards.

Allow as much free space around the boiler as possible for maintenance and reduced fire

hazard. Ensure that the boiler is accessible in order to allow for easy adjustment of the boiler

temperature.

The boiler should not be sited close to storage areas of combustible materials.

Consider condensate and boiler drainage requirements when choosing the boiler location.

Installation diagram : Cistern tank install type

Heating Coil

Fan Coil

Radiator

1. The system should be installed with a pressure safety valve rated to 3.5 Bar or less.

2. The maximum operating pressure is 3.5 Bar. Neither the boiler nor any connected pipe

work should be exposed to pressures in excess of this.

3. Always install the boiler and the connected system according to local regulations.

Sealed System

Precautions

Safety Valve

Air Exhaust Valve

Filter

Reducing Valve

Check Valve

Circulation Pump

Distributor

Condensate

Outlet

Drain Drain

F.L

Sealed Expansion Tank

Install the condensate outlet hose as above

Water

Cold Water Inlet

Hot Water Outlet

Heating Water Outlet

Cold Water

Hot Water

Heating Coil

Fan Coil

Radiator

Boiler Back

Combi only

27

It is recommended that the ue system not exceed 7 metres in length and that no

more than 2 bends be used. Subtract one metre for every 90° bend and 500ml for

every 45° bend.

Condensing boiler model : NHC25B/30B/41B

Flue Installation

Allowing combustion gas to re-enter the

boiler room can result in a build up of

carbon monoxide, which could result in

poisoning. Saturn recommends the

installation of a suitable carbon monoxide

detector on all installations.

CAUTION

VENTILATING OPENING

10˚ OVER

300mm OVER

AIR INLET

FIREPROOF INSULATION

MATERIAL

150mm OVER

FIREPROOFINSULATION

MATERIAL

FIREWALL, SEMIFIRE WALL

The flue should be installed at an angle of no more than 10°. The flue should be

made

from heat-resistant non-corrosive material.

28

Example of a standard installation

1. Condensate is produced when the condensing boiler is running and should be

piped to the drainage system.

2. Link the drain hose with the outlet of the neutralization system which is located at

the bottom of boiler and then connect the end of the hose to a soak pit.

3. Please make sure that the neutralizer in the boiler is filled with water.

4. The condensate drain system should be installed to minimise the risk of freezing.

Ensure the condensate is sent

to a suitable waste outlet in

accordance with regulations.

29

Commissioning The Boiler

30

1. Prime the boiler with kerosene and press the power button on, ensuring there

is a heat request from your time clock. The boiler then takes 3 attempts to go

into ignition phase.

2. The fan will start up and purge the air through the heat exchanger

- Troubleshooting if sequence missed:

• No heat request, or incorrect wiring, please refer to "Wiring The Boiler"

3. The transformer will begin to generate a spark at the electrodes

- Troubleshooting if sequence missed:

• Photocell disconnected/dirty: reconnect/clean

4. The oil pump will engage to pump oil to the burner

- Troubleshooting if sequence missed:

• Not fully primed with oil bowl filled and oil line clear of air

• This will be apparent by the pump making a loud noise

5. Successful ignition can be seen through the sight glass

All boilers come pretested from the factory, so minimal adjustments are

needed on commissioning. Using a flue gas analyser, you are looking for the

following read outs:

- 11.5% Co2

- 50-60 PPM

Simply adjust the damper opening on the burner to achieve these numbers

Component Overview

31

The structure of the boiler

ModelNo: NHC 25B/30B/41B

Neutralizer assembly

Burner Assembly

Return water pipe for space

heating

Electronic pump &

Oil filter

Overheat preventer

Low water level sensor

Temperature sensor

Controller

Heat Exchanger

FE flue, Φ75

Component Overview

32

The structure of burner

ModelNo: NHC 25B/30B/41B

Damper

Fan 3

Fan 2

Fan 1

Fan Causing

Fan Motor

Ignition Electrode

Blow tube & ame holder

Air holder

Nozzle

Inner tube

Flame detector

Component Overview

33

The principle of the burner

ModelNo: NHC 25B/30B/41B

Construction of Burner

Air Flow

Oil Fluid

Air Flow

Oil inlet

1) Fan (motor) working

2) Ignition transformer is working

3) Electronic pump is working ; oil

pressure increase

4) Sensing combustion and

flame

5) Continuous combustion

Burner Running Mechanism

Flame holder : Oil & air mixing zone

Air holder : assist the ignition

Component Overview

34

The structure of the heat exchanger

ModelNo: NHC 25B/30B/41B

Bae plates

H.E. for DHW

Combustion chamber

Straight pipes

ýNHC-25H/30H/41H doesnot come with an in-built DHW heat exchanger.

ý

NHC-25EH/30EH/41EH doesnot come with an in-built DHW heat exchanger.

Component Overview

35

The principle of the heat exchanger

ModelNo: NHC 25B/30B/41B

Construction of Condensing Boiler

Heat Fluid

Heat transfer Fluid

Figure of Heat transfer method

Parallel Flow Counter Flow

Counter Flow

Condensate outlet

Chamber Temp. about 800 C

Fluid Flow

200 C under

75 C under

Counter Flow : 2 times

Parallel Flow : 1 time

ýNHC-25H/30H/41H doesnot come with an in-built DHW heat exchanger.

ýNHC-25EH/30EH/41EH doesnot

c

ome with an in-built DHW heat exchanger.

3

6

Color : White

1

A

B

6

4

C

531

642

BLACK TUBE

Orange

Blue

A

B

C

A

B

C

Blue

D

5

3

01

11

02

12

03

13

04

14

05

15

16

17

06

18

07

19

08

20

09

10

21

White

Red

Red

Black

Skyblue

Brown

Yellow

Green + Yellow

EARTH

LOW WATER SENSOR

HIGH LIMIT STAT

Black

Black

Skyblue

Brown

Brown

Black

Blue

Brown

OIL PREHEATER CABLE

CIRCULATION PUMP

Blue

Brown

HEATING WATER TEMP. SENSOR

VOLT-FREE HEAT REQUEST

D

D

C

C

OIL PUMP

Blue

Brown

Power cord

Green + Yellow

Blue

Yellow

[BOILER]

[BURNER]

Brown

OUTDOOR TEMP. SENSOR

AUXILIARY SENSOR

Black

BOOSTER PUMP

1

4

6

4

6

5

3

1

5

3

Electric wiring diagram

Blue

Brown

Green + Yellow

(White)

WEATHER

COMP MODE

WEATHER

COMP MODE

(White)

ModelNo: NHC 25B/30B/41B

37

Electric Wiring – Installation Variations

Note:

Boiler temperature display will only be shown when there is a heat request

through the switch live as permanent supply has not been provided.

3 Core Wiring Diagram

(Warning, without permanent supply, the frost stat is disabled)

38

Electric Wiring – Installation Variations

Note:

Due to the above setup using a 230v switch live, for a heat request from the

boiler, an NO stepdown relay or a motorised valve is needed to connect into

the low voltage heat request orange cables.

4 Core Wiring Diagram

39

Electric Wiring – Installation Variations

Note:

Simply

join single auxiliaries from multiple MV’s and bring to the boiler in 2

core fashion. If any MV opens, the volt free auxiliary will call for a heat

request.

5 Core Wiring Diagram

40

Electric Wiring – Installation Variations

Note:

Simply connect the volt free orange heat call to the back of the combi

controller, and now the red cables coming from the controller, by

extension, become your low voltage heat call.

5 Core Wiring Diagram - Combi Only

41

All wiring must be in accordance with its instructions for connections with the valve

controller properly and unused wire should be insulated and short-circuited.

1. Connect the cables of room thermostat properly to the terminal of valve contoller

in accordance with following each colored cable;

- Red : Heating

- Blue : Fault signal

(NA)

- Yellow : Combus

tion signal (NA)

Unused wire should be insulated and short-circuited.

2. The pin rail on the back of the thermostat must connect to 2 orange cables from the boiler.

3. Fix the wall socket with the screws provided.

Boiler

AC 220V

Main Controller

Valve Controller

Red wires

Auxillary wires

L

N

MV

Room thermostat

Input/output

terminal

Room thermostat (LCR-2WE) - Combi only

4. Carefully push and t the thermostat on to the wall socket until it clicks in position.

42

OTC Mode

If a

n outdoor temperature probe is connected, the weather compensation

function can be used in conjunction with the weather comp' relay available at

your local Saturn stockist .

1) With this function, the target primary temperature is automatically

set according to the outdoor temperature (K-Factor).

2) When the outdoor temperature sensor is connected, OTC lamp is turned on.

3) The outdoor temperature sensor should be placed in an area to avoid

temperature fluctuations caused from direct sunlight. Preferable the sensor

should be located in a north facing location.

K-Factor

43

1. Check that the Outdoor Temp

sensor has been connected properly.

2. Check the OTC mode is working by

returning to Central Heating mode

(Press the Mode button repeatedly,

until or is displayed.)

※ Please contact Saturn Technical department for any unclear matters.

1. On pressing the

power button, the

motor doesn’t work

2. The motor rotates,

but the boiler doesn’t

ignite

3. The boiler ignites, but

immediately stops

4. The electronic pump

makes noise

2.

Check and clean electrode.

Check nozzle and change if

necessary.

6. Smoke and soot

build up

1.

2.

The oil is bad or has impure

materials.

The

air for combustion is

short.

1.

2.

Replace the oil.

Check external filter bowl.

1. The oil valve is locked.

2. There is no oil in the tank.

3. There is air in pipes.

4.

1.

2.

3.

4.

1.

2.3.There is air in the oil line.

The oil tank is empty.

1.

Open the valve.

2. Supply oil.

3.

4. Clean the boiler.

1.

2.

3.

1.

2.

1.

2.

3. No heat request.

1.

2.

This is not a problem.

When the temperature of the

boiler goes down, it will restart.

Check 5 AMP fuse spur/power.

3. Check time clock and stats for

heat request.

Happening Cause Solution methods

8. The appliance does not

go into OTC mode

1.2.The Outdoor Temperature

sensor is not connected

correctly.

Hot Water activation

Troubleshooting

The temperature in the

boiler is abov

e the set

temperature.

No power.

The oil in the oil tank is

insucient.

The ame detector

cannot sense.

The oil lter is blocked.

Impurities in the oil.

Supply more oil.

Clean the ame detector.

Clean the oil lter.

Replace the oil with good oil.

4.

The oil lter is blocked. Clean the oil lter.

Vent the oil line.

3. Ref i ll the oil tank.

5. On igniting, it backres

1.

Electrode fault.

OTC Mode turns o during

Dirty nozzle.

2.

1.

44

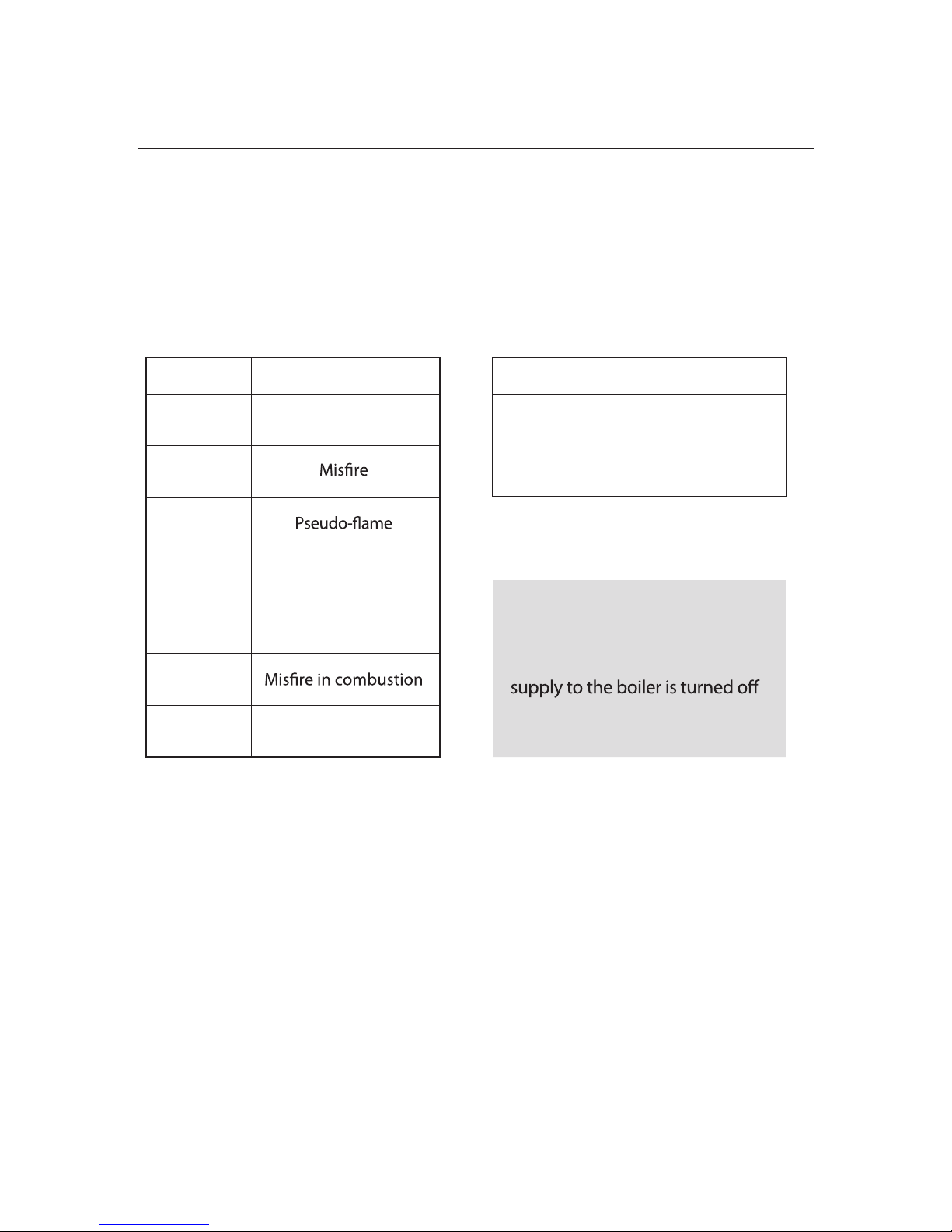

Fault Codes

When an error occurs, the LCD shows one of the following numeric error codes

with letter ’E’.

Error Code

Cause

02

03

04

05

06

12

16

Low water level

Temp. sensor wire

disconnected

Short circuit of

Temp. sensor

High limit thermostat

Flame failure

Misre in combustion

Misre

45

Product Information

KD Navien

symbol Unit NHC 25B NHC 30B NHC 41B

Condensing boiler

YES YES YES

Low-temperature(**) boiler

NO NO NO

B1 boiler

NO NO NO

Combination heater

YES YES YES

Rated heat output

Prated kW 24.0 27.9 36.8

ηs % 91 90 91

Useful heat output

"At rated heat output

and high-temperature regime(*)"

P4 kW 24.0 27.9 36.8

"At 30% of rated heat output

and low-temperature regime(**)"

P1 kW 7.7 9.3 11.9

"At rated heat output

and high-temperature regime(*)"

η4 % 92.1 91.3 91.7

"At 30% of rated heat output

and low-temperature regime(**)"

η1 % 97.4 96.0 96.6

Auxiliary electricity consumption

At full load

elmax kW 0.136 0.145 0.163

At part load

elmin kW 0.057 0.060 0.066

In standby mode

Psb kW 0.013 0.014 0.012

Other items

Standby heat loss

Pstby kW 0.111 0.111 0.140

Ignition burner power consumption

Pign kW 0 0 0

Annual energy consumption

QHE kWh 76 89 116

Sound power level, indoors

LWA dB 68 66 69

For combination heaters

XL XL XXL

Daily electricity consumption

Qelec kWh 0.443 0.440 0.468

Annual electricity consumption

AEC kWh 94 93 105

ηwh % 64 62 67

Daily fuel consumption

Qfuel kWh 28.617 29.532 35.339

Annual fuel consumption

AFC GJ 22 23 30

Contact details

Saturn Heating Ltd, Shercock Road, Carrickmacross

Co. Monaghan, Ireland

(*) High-temperature regime means 60˚C return temperature at heater inlet and 80˚C feed temperature at heater outlet.

(**) Low-temperature means for condensing boilers 30

˚C

, for low-temperature boilers 37˚C and for other heaters 50˚C return

temperature (at heater inlet).

Seasonal space heating energy eciency

Declared load prole

Water heating energy eciency

46

Spare Parts List (Burner)

No. Part No. Part Name NOTE

1 30007780D Harness ALL MODEL

20014282A Upper Plate NHC-25B

20005292A Upper Plate NHC-30,41B

20014294A Fixing plate NHC-25B

20005531A Fixing plate NHC-30,41B

4 30007195A Window Ass'y ALL MODEL

20014284A Side Cover(left) NHC-25B

20012251A Side Cover(left) NHC-30B

20012483A Side Cover(left) NHC-41B

20014286A Side Cover(right) NHC-25B

20012274A Side Cover(right) NHC-30B

20012494A Side Cover(right) NHC-41B

20014288A Rear Cover NHC-25B

20012298A Rear Cover NHC-30B

20005373A Rear Cover NHC-41B

20017026A Front Cover NHC-25B

20017126A Front Cover NHC-30B

20017127A Front Cover NHC-41B

9 30012754A PCB Ass'y ALL MODEL

10 30002845A Preheater Assembly ALL MODEL

11 30003527B Internal Flue ALL MODEL

30010383B Electric Pump Assembly NHC-25B

30010388B Electric Pump Assembly NHC-30B

30010389B Electric Pump Assembly NHC-41B

13 30004241A booster pump ALL MODEL

14 30004377D Oil Filter Ass'y ALL MODEL

15 20010104D Flexible Hose ALL MODEL

16 30003745A

Condensate Neutralizing Equipment

ALL MODEL

30003760B Condensate Hose NHC-25B

20016346B Condensate Hose NHC-30,41B

18 30002556A High Limit Switch ALL MODEL

19 30002661A Low Water Level Sensor ALL MODEL

30003457A Silence Adaptor NHC-25B

30003491A Silence Adaptor NHC-30,41B

30005321A Oil Burner Assembly NHC-25B

30005328A Oil Burner Assembly NHC-30B

30005336A Oil Burner Assembly NHC-41B

12

2

3

5

6

7

8

17

20

21

47

Spare Parts List (Burner)

NO. PART CODE DESCRIPTION MODEL

20010476A OIL Nozzle NHC-25B

20010484A OIL Nozzle NHC-30B

20010506A OIL Nozzle NHC-41B

2 30004397A

Photocell (flame detector)

ALL MODEL

30005541A Motor NHC-25,30B

30005542A Motor NHC-41B

30004721C Flame Holder NHC-25B

30004727C Flame Holder NHC-30B

30004728C Flame Holder NHC-41B

5 30004361D Ignition Transformer ALL MODEL

6 20010578A Ignitor ALL MODEL

NO. PART CODE DESCRIPTION MODEL

1 30000670A Outdoor Sensor ALL MODEL

3

1

4

48

Spare Parts List (Burner)

49

SATURN CONDENSING OIL BOILER

ITEM UNIT NHC 25B NHC 30B NHC 41B

HEAT OUTPUT HEATING kW 24.0 27.9 36.8

FOR USE(Combi only) Heating

FUEL Light Oil

BUILDING SIZE

㎡

Less than 132 Less than 165 Less than 232

MAXIMUM WORKING PRESSURE

Bar 3.5

(kPa) 343

HEAT TRANSFERING SIZE

㎡

1.60 2.08 2.40

FUEL CONSUMPTION kg/h 2.07 2.43 3.19

TYPE OF AIR / EXHAUST GAS FE

HEATING EFFICIENCY % 97.6 96.8 97.2

ELECTRICITY CONSUMPTION COMBUSTION W 136 145 163

POWER V, Hz 220V, 50Hz

WATER STORAGE CAPACITY ℓ 34.0 41.0 48.0

BOILER HOUSE DIMENSIONS

W×L×H

410×665×1,031 444×706×1,051 444×706×1,186

mm

WEIGHT kg 59 64 72

PIPING

HEATING

A 1"

HOT WATER

A 1/2"

DIAMETER FLUE Φmm EXHAUST : 75

Oil Nozzle Type 0.60 / 60˚EH 0.75 / 60˚ES 1.00 / 80˚ES

kg/h

10 10 10

0-1 0-1 0-1

Fuel Flow Rate 2.07 2.43 3.19

%

11.5

11.5 11.5

EXTERNAL CABIN PACK DIMENSIONS

W×L×H

600×725×1,090 635×780×1,110 635×780×1,180

mm

Oil Pressure

Smoke Number

Bar

CO2

°C 60-65 65-70 70-75 Flue Gas Temperature

50

CE marking

In accordance with the following European Standard

EN 267, EN 304, EN 15034, EN 55014-2, EN 61000-3-2, EN 61000-3-3,

EN 60335-1, EN 60335-2-102

In accordance with the following Directives

Directive 92/42/EEC

ErP Ecodesign : Directive 2009/125/EC 813/2013

ErP Labelling : Directive 2010/30/EU 811/2013

Low voltage : Directive 2006/95/EC

Electoro-magnetic Compatibility : Directive 2004/108/EC

Navien, manufactures its product using a Quality Assurance system in compliance

with Standard EN-ISO 9001:2000.

1506

Warranty period begins from first day of operational use of boiler.

The warranty of the application is conditional upon correct installation, completion of the

passport document and returning the commissioning certificate to the appliance manufacturer if you don't do this the warranty could be invalid.

Boiler passport must be returned within 28 days of installation to validate warranty.

20016914E

BO-E-M-10-3

Saturn Heating

Distributed exclusively by:

Saturn Heating Ltd

Shercock rd.

Carrickmacross

Co. Monaghan

A81 HK09

Ireland

Technical Helpline: (IRE) 1890 929 112

Sales: (IRE) +353 (0)42 9692032

E-mail : info@saturnheating.net

www.saturnheating.net

Loading...

Loading...