Page 1

Page 2

Page 3

Contents

Safety Instructions

Before using the boiler

How to use

The structure and its description

Room Thermostat

Room Thermostat On/Off

Room Temp. Mode

Heating Water Temp. Mode

Timer Mode

Power Heating Mode

Outing Mode

Setting Hot Water Temp.

Hot Water Mode

Remote Operation by telephone

Safety device

Everyday checking

How to install

Converter-CV2

Multi Floor System

Room Thermostat Installation

How to replace the parts

Electric wiring diagram

How to locate troubles and solve

Error code

The Specification

4

5

7

10

11

12

13

14

15

16

16

17

18

19

21

22

25

28

30

32

33

34

35

36

37

Page 4

Safety Instructions

4

Safety-related messages and instructions have been provided in this manual

and on boiler to warn you and others of a potential injury hazard.

Read and follow all safety messages and instructions throughout this manual.

It is very important to understand these safety section for operating,

installing and servicing of boiler.

This is safety alert symbol. It is used to alert you to potential

personal injury hazards.

Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates an imminently hazardous situation which,

if not avoided, could result in severs injury or death.

DANGER

Indicates a potentially hazardous situation which,

if not avoided, could result severe injury or death.

WARNING

Indicates an imminently hazardous situation which,

if not avoided, could result in minor moderate injury.

CAUTION

Meaning of symbols

in the guide for use

Make ground

Dismantling

arbitrarily is forbidden

Use of fire

forbidden

Dangerous

electric current

Touching is

forbidden

Page 5

Before using the boiler

5

Checking points before starting up

It is essential to use only kerosen or light oil.

(Don’t use gasoline, alcohol)

It is better to use kerosene when the temperature

goes down below -5ఁ

In winter, don’t use the light-oil for summer.

Store in the Place where there is no eect

of oil, re, rain, and keep out of the sun.

Pay attention that water or dust may not

get in on time of feeding oil.

(Water or dust may cause the combustion

failure or shorten the boiler span.)

Wipe o the oil spilled.

Close the lid of the oil inlet without fail.

Feed oil after turning the power o and

locking the tank valve.

Check out if or not oil leaks in the

connecting part of the oil pipe.

Fuel

Page 6

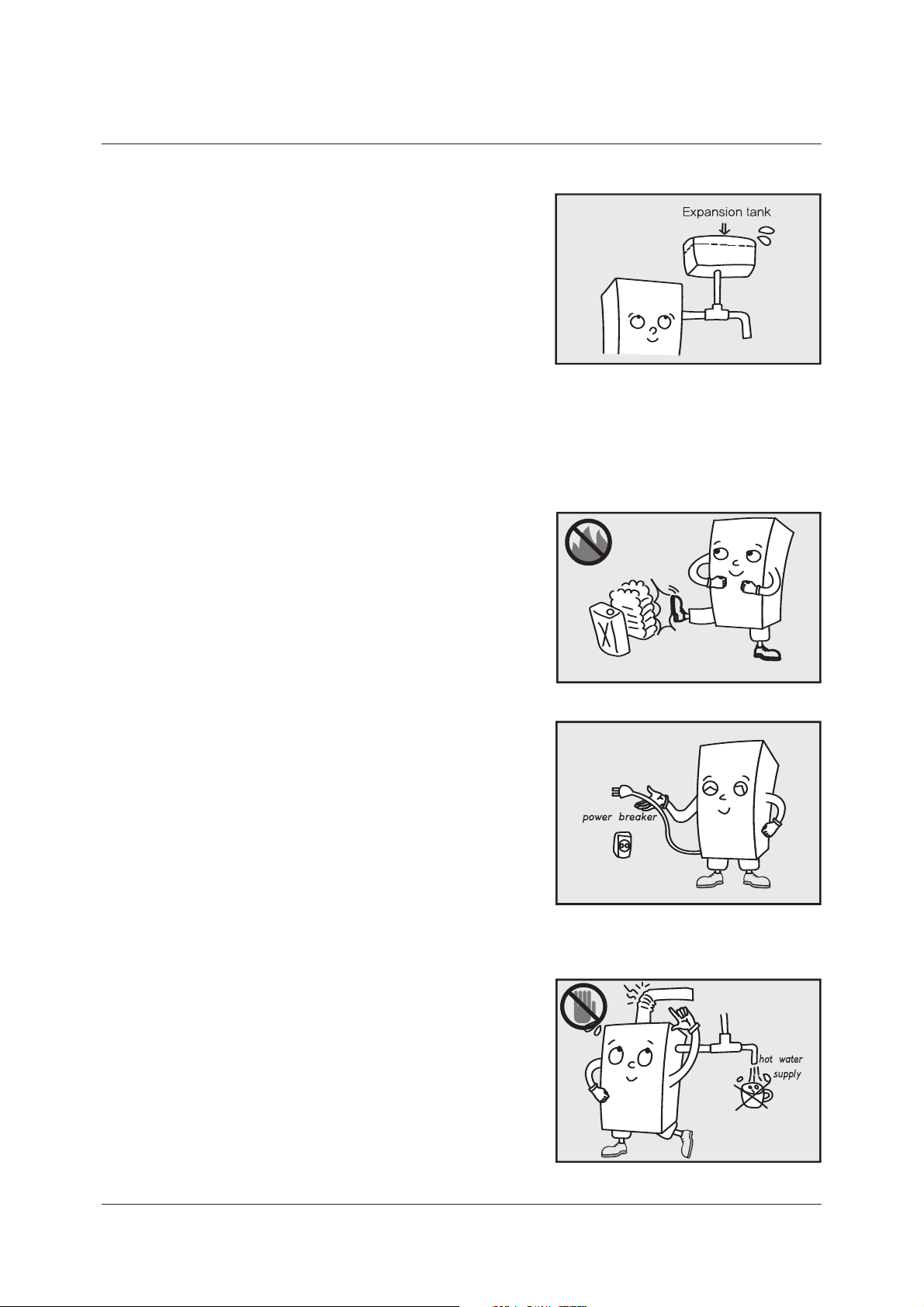

Check out that there is enough water in

the body of the boiler without failure.

Expansion tank type-Check out if there is

water in the Expansion tank, and in case

that there is no water, please ll water in

the body of the boiler.

Open Expansion Tank type-check out if

there is water in the expansion tank, and in

case that there is on water, press the power

button. Then, ‘Low Water Level’ lamp turns on

and water is supplied automatically.

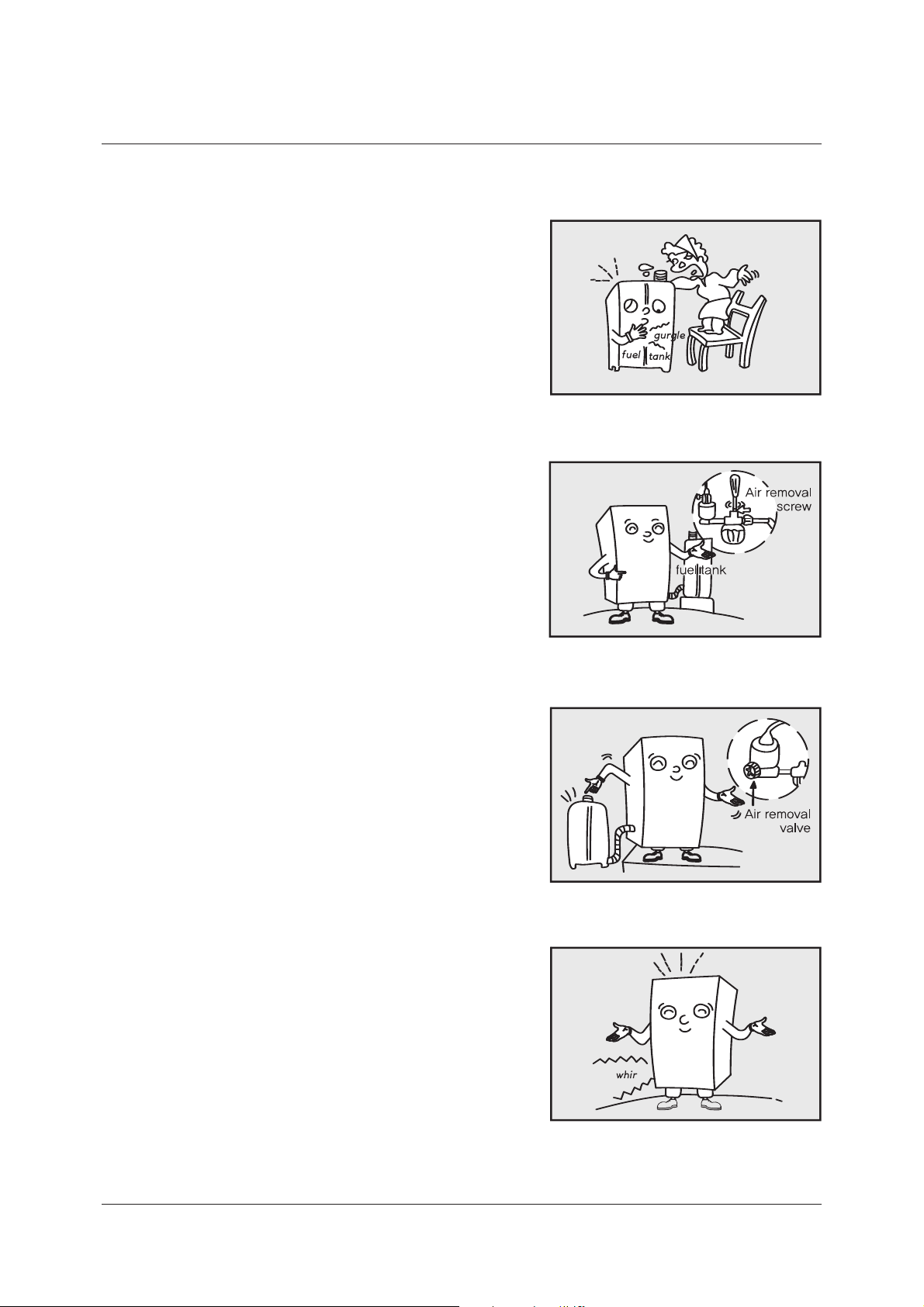

Notes when using

Put the surroundings of the boiler in order

and don’t put the ammables near the boiler.

Check out whether the ignition and

the combustion is normal.(Checking through

the ame inspection window.)

When the boiler is going to be not in use for

a long time, cut o the power.(Don’t pull out

the power cord when there is a danger of freezing.)

If you pull out the power plug on time of

thunder and lightening, you can prevent the

damage on the boiler by the falling of the

thunderbolts.

Be careful not to get burned due to the

high temperature of the exhaust/inhale pipe

(exhaust pipe).

In case of emergency such as you may feel

the abnormality of the boiler, cut o the

power.

Don’t use the hot water for food.

6

Page 7

How to use

How to exhaust

Be careful that the oil tank may not run out

of oil completely.

In that case, even though oil is supplied,

air may get in. As a result, ignition failure or

operation failure may occurs.

Untighten the screw for exhaust in the oil

lter by a screwdriver, the air goes out.

When oil ows out, please tighten it.

(This is possible only in case that the oil

tank is above the oil lter.)

If the oil tank is below the oil lter or the air

ows out enough like the above, lock the

screw for exhaust and remove the air with

the exhaust valve.

In such case, open the exhaust valve turn

the power on to operate the boiler.

After about 6-7 Seconds, the electronic

pump exhaust the air o with noise,

and “CHECK” lamp on, the boiler stops.

7

Page 8

Preparation and checking before starting to operate

Now press the power button on the panel

repeatedly, and the oil ows out.

Lock the valve and press the power button

again, and the boiler gets ignited.

In case that after removing air completely,

the igni-tion has failed repeatedly about

three times, contact the sales agency or the

commercial agency.

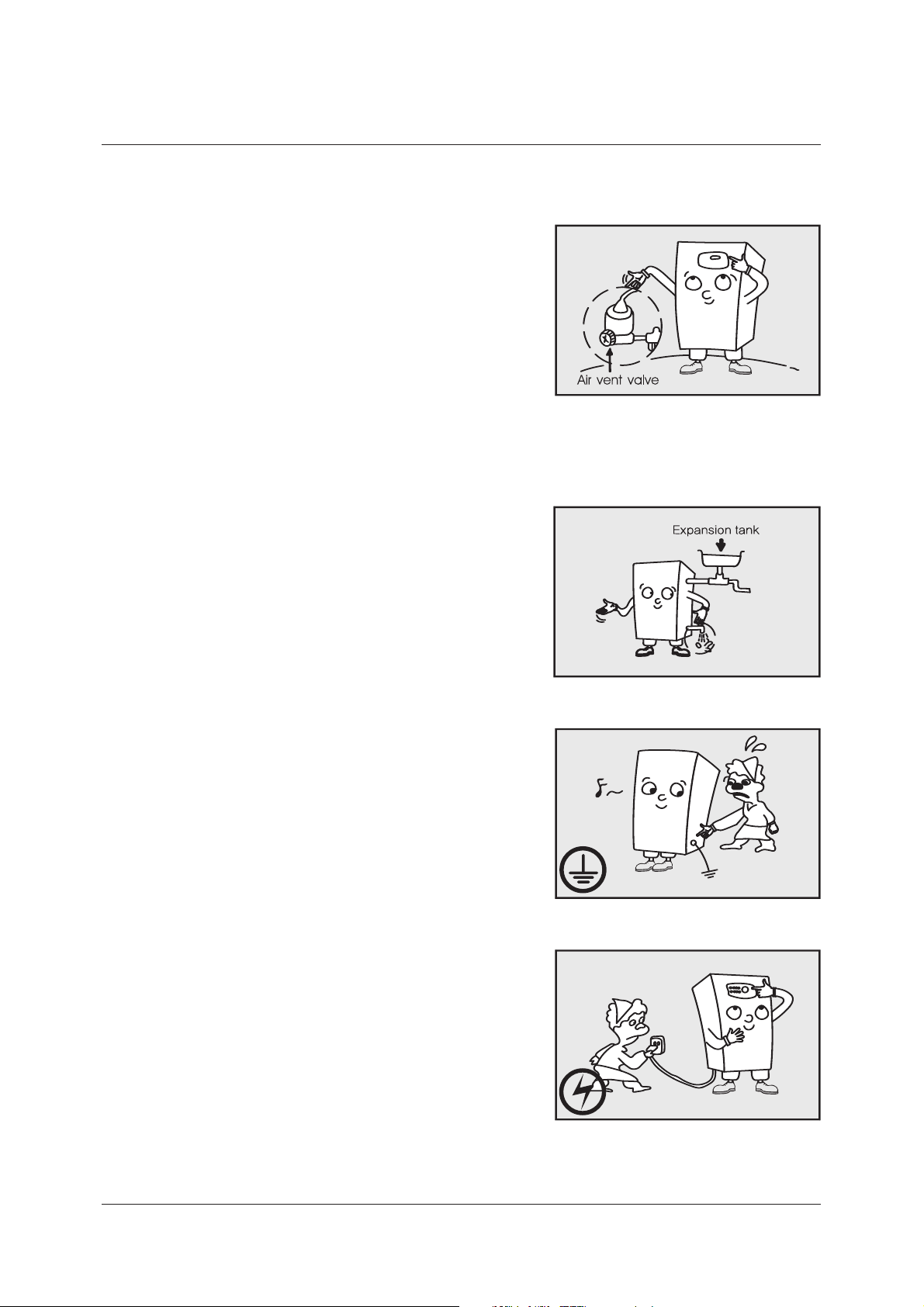

Open the drain valve, and check out whether

there is water in.

Check out whether the pipes is lled with water.

Check out that the boiler is grounded to

earth. (Don’t ground to the gas pipe or

a lightening conductor)

Plug the power plug in the outlet.

(Checking if the outlet power is 220V)

Press the power button, and check out if

“RUN” lamp turns on a little later.

8

Page 9

How to use

Open the window door of the Operation and

Display Panel and set the thermostat to the

position you like.

Pressing the power button starts fan motor

And the boiler gets started, turning the

“COMBUSTION” lamp on.

If ignition fails and the operation stops.

“check” lamp turns on, In this case, press the

power button on the panel.

In case that the ignition fails with pressing

the power button four or ve times, contact

the sales agency or the commercial agency.

9

Page 10

Heating temp.

LED indicate the temp.

of heating water, and

occurrence of trouble

displayed the failure code.

02. LOW WATER LEVEL

03. MISFIRE

04. PSEUDO-FLAME

05. TEMP. SENSOR FAILURE

12. MISFIRE IN COMBUSTION

16. BIMETAL OVERHEAT

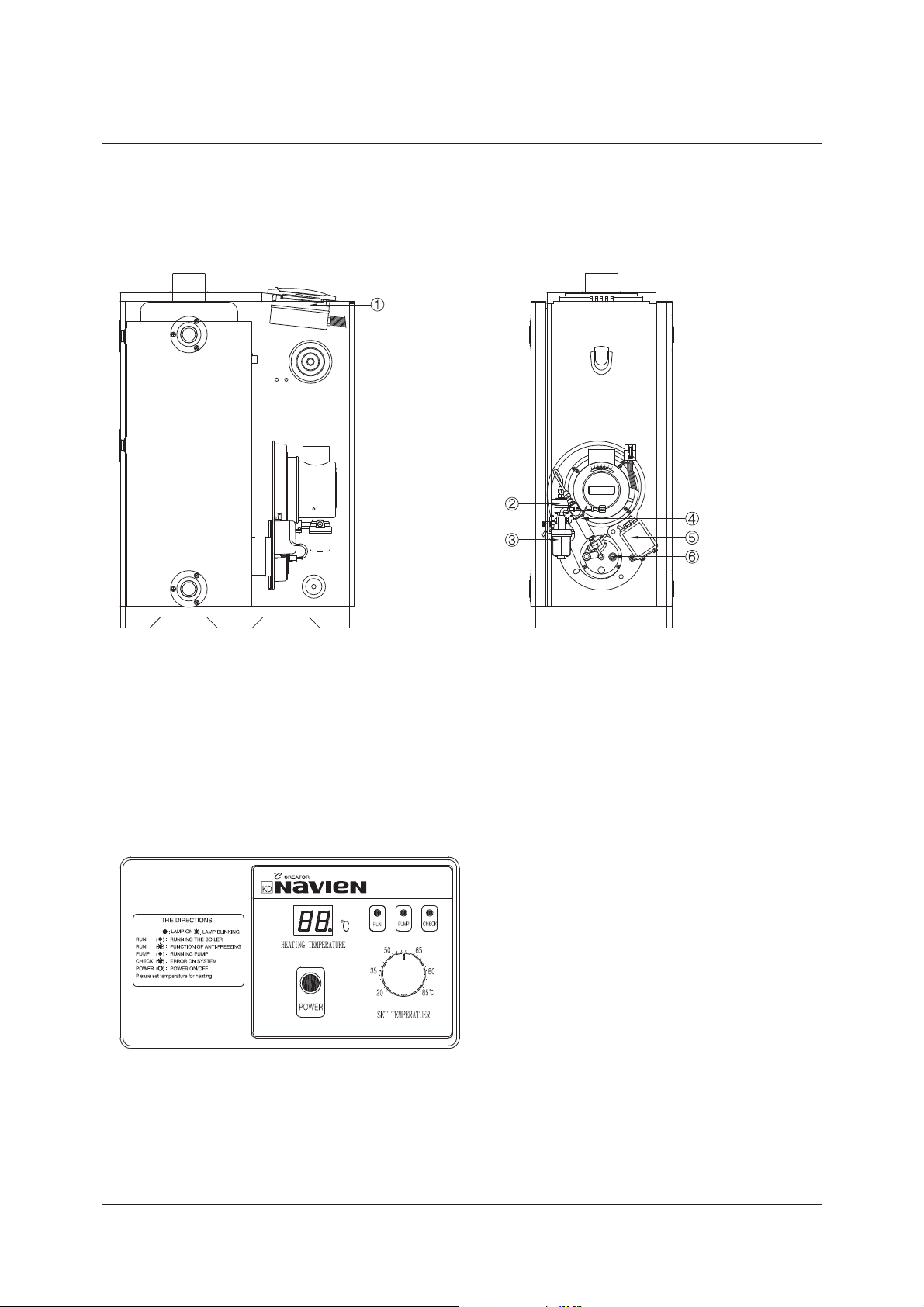

The Structure of the boiler

(Model No : LST-17,21,24,30,41K / LFA-17,21,24,30,41K)

Operation and display panel (KDC-106M)

CONTROLLER

ELECTRONIC PUMP

OIL FILTER

PRE-HEATER

I.G TRANS

FLAME DETECTOR

(C.D.S)

The structure and its description

10

Page 11

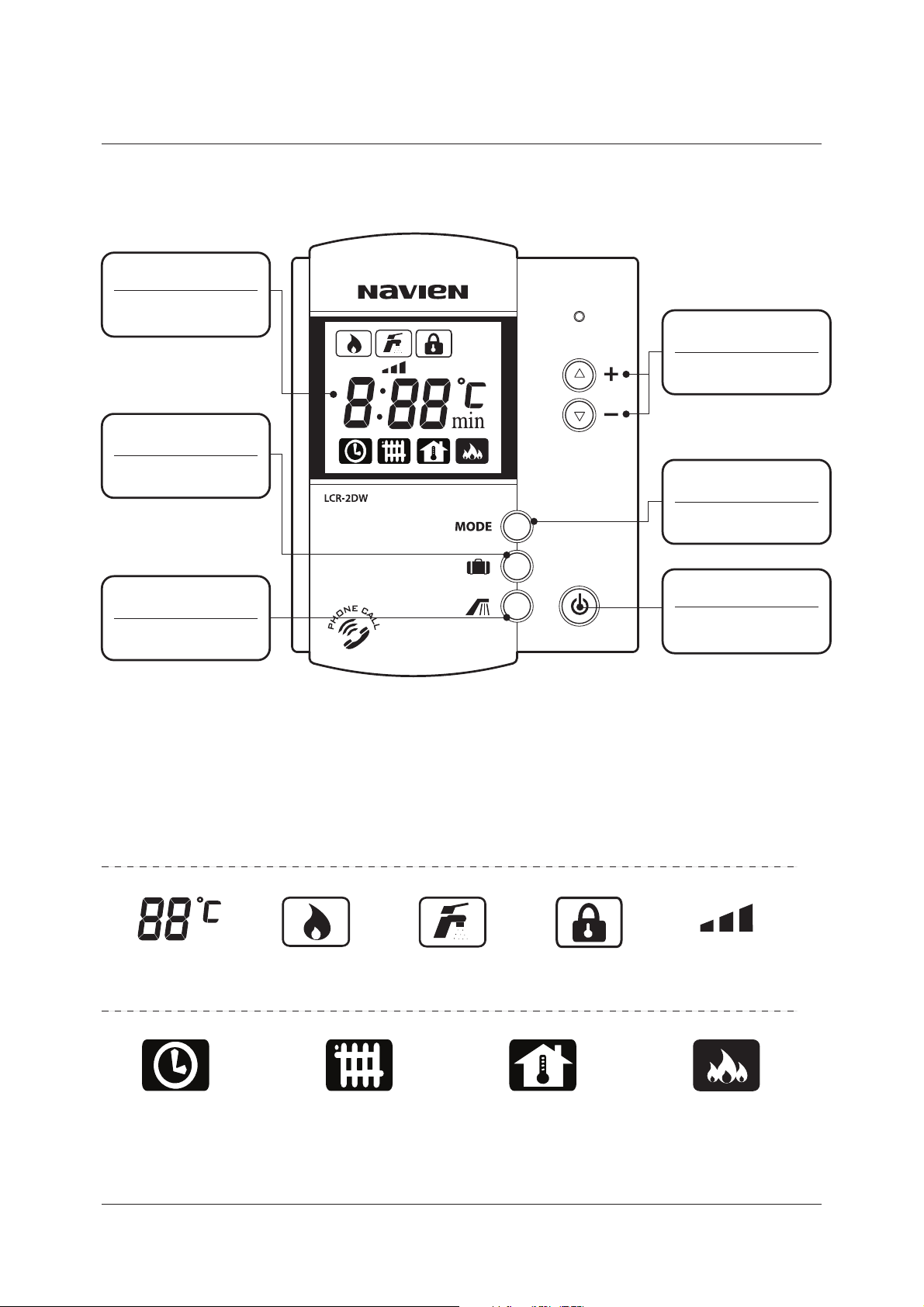

LCD

Indicating each

function and status

LCD Display

Room Thermostat

Power ON/OFF

Power

Outing Setting Mode

Outing Mode

Temp. & Timer Mode

UP/DOWN

Select Mode

MODE

Hot Water Mode

Hot Water

Room Thermostat (LCR-2DW)

11

Temperature

Timer

Heating

Operation

Indicator

Heating

Water Temp.

Hot water

Mode

Outing

Mode

Room Temp Power Heating

Hot Water

Temp. (3 Step)

Page 12

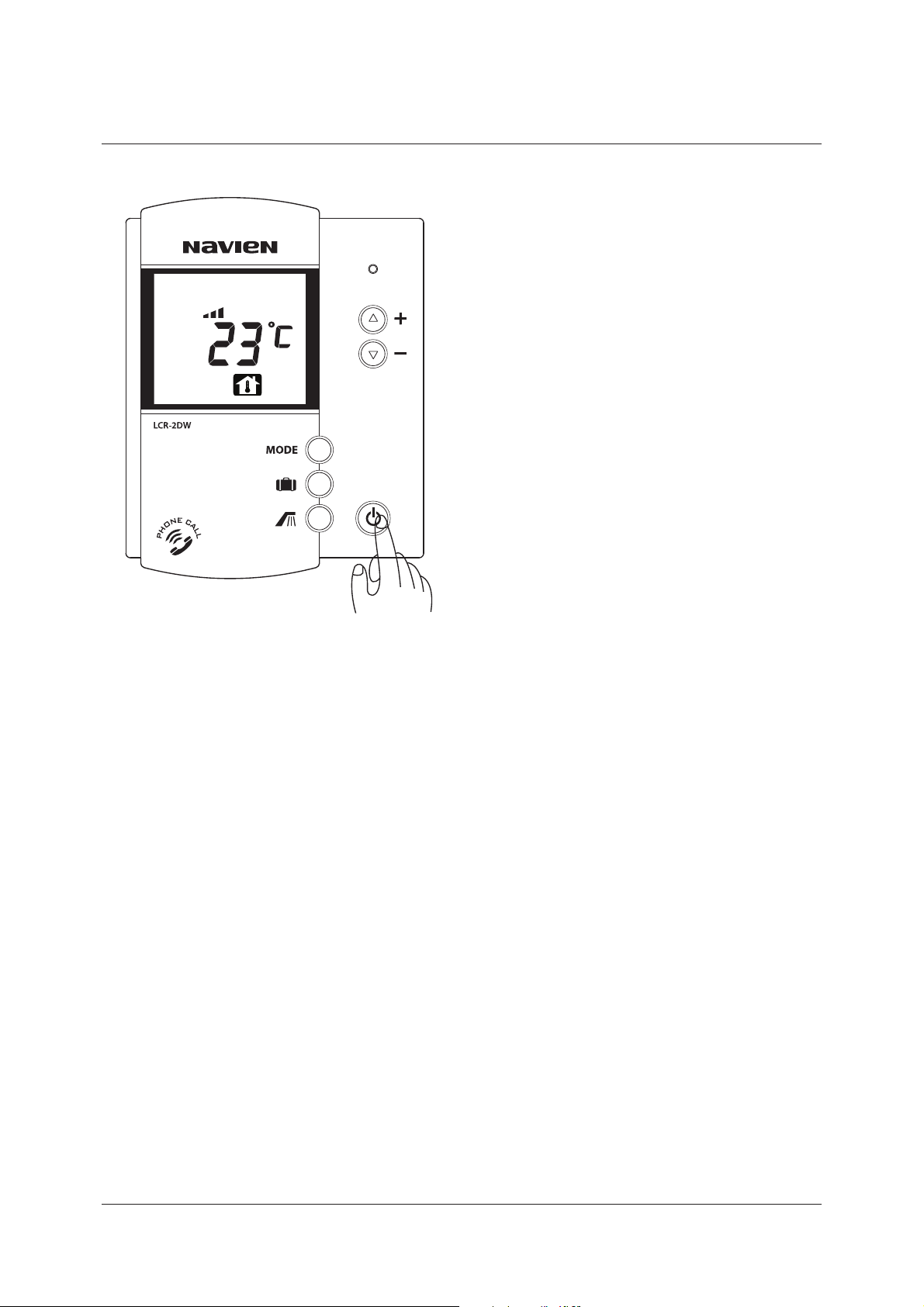

Room Thermostat On/Off

Press the power button.

LCD is on when pressing the power button.

Hot water and heating operation stops

and LCD is turned o when pressing

the power button again.

12

Page 13

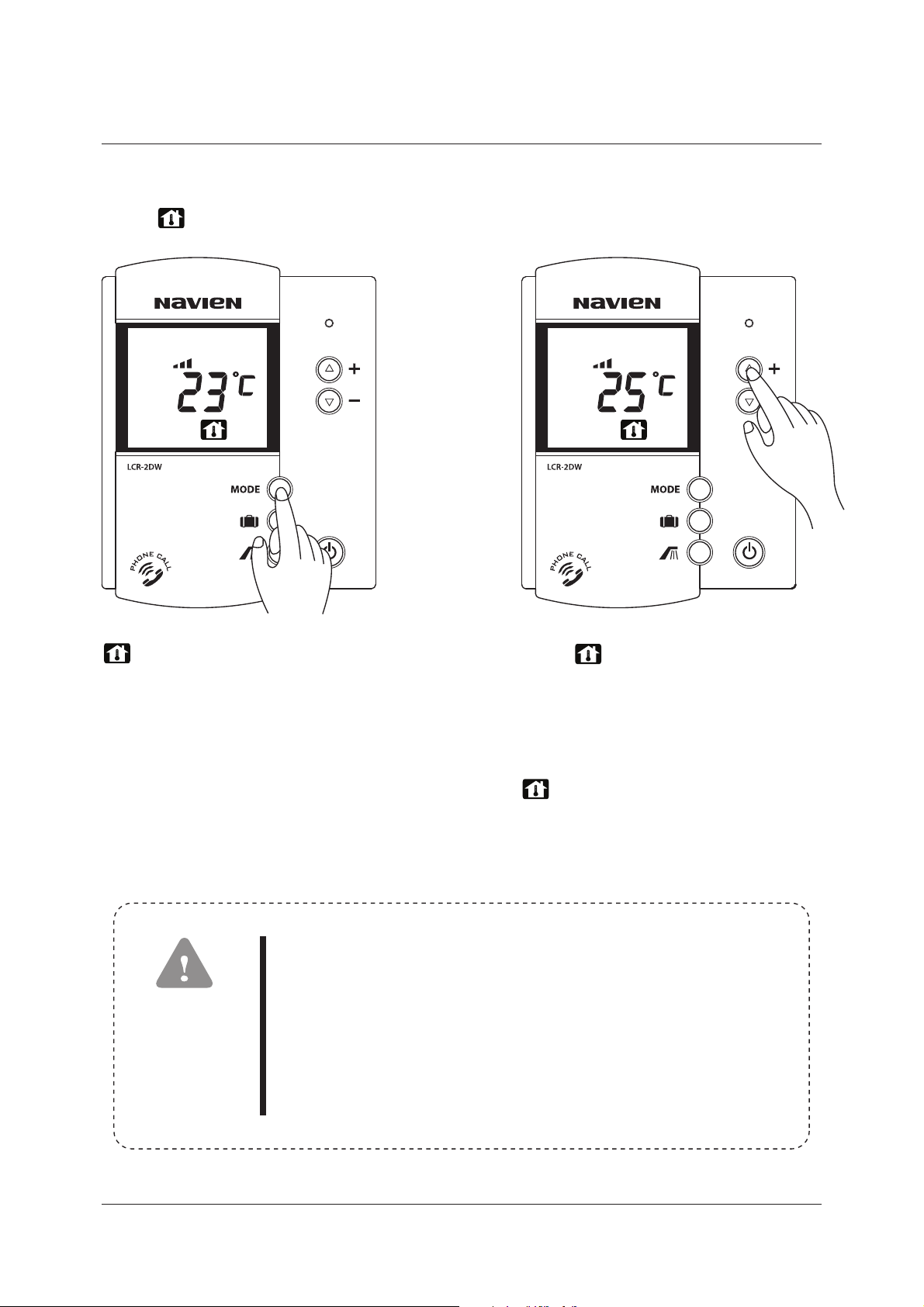

Room Temp. Mode

Press the Mode button repeatedly,

until is displayed.

Set the heating temp.

with +/- button.

blinks when selecting

Room Temp. Mode

If a room thermostat is programmed with Room Temp. Mode

and it is placed in the following places when using Room Temp.

mode, it may cause some errors to recognize temperature.

CAUTION

1. Frequently opened and closed door and drafty place.

2. A place where direct sunlight is eected and high humidity.

3. A place under direct inuence from heat, such as radiator.

When blinks, set the desired

heating temp. between 10~40丯 by

adjusting +/- button, after a while,

it is automatically saved.

Heating temp. can be set by 1丯.

After the setting is done,

is on and current room temp.

is displayed.

In that case, Heating Water Temp. is recommended.

13

Page 14

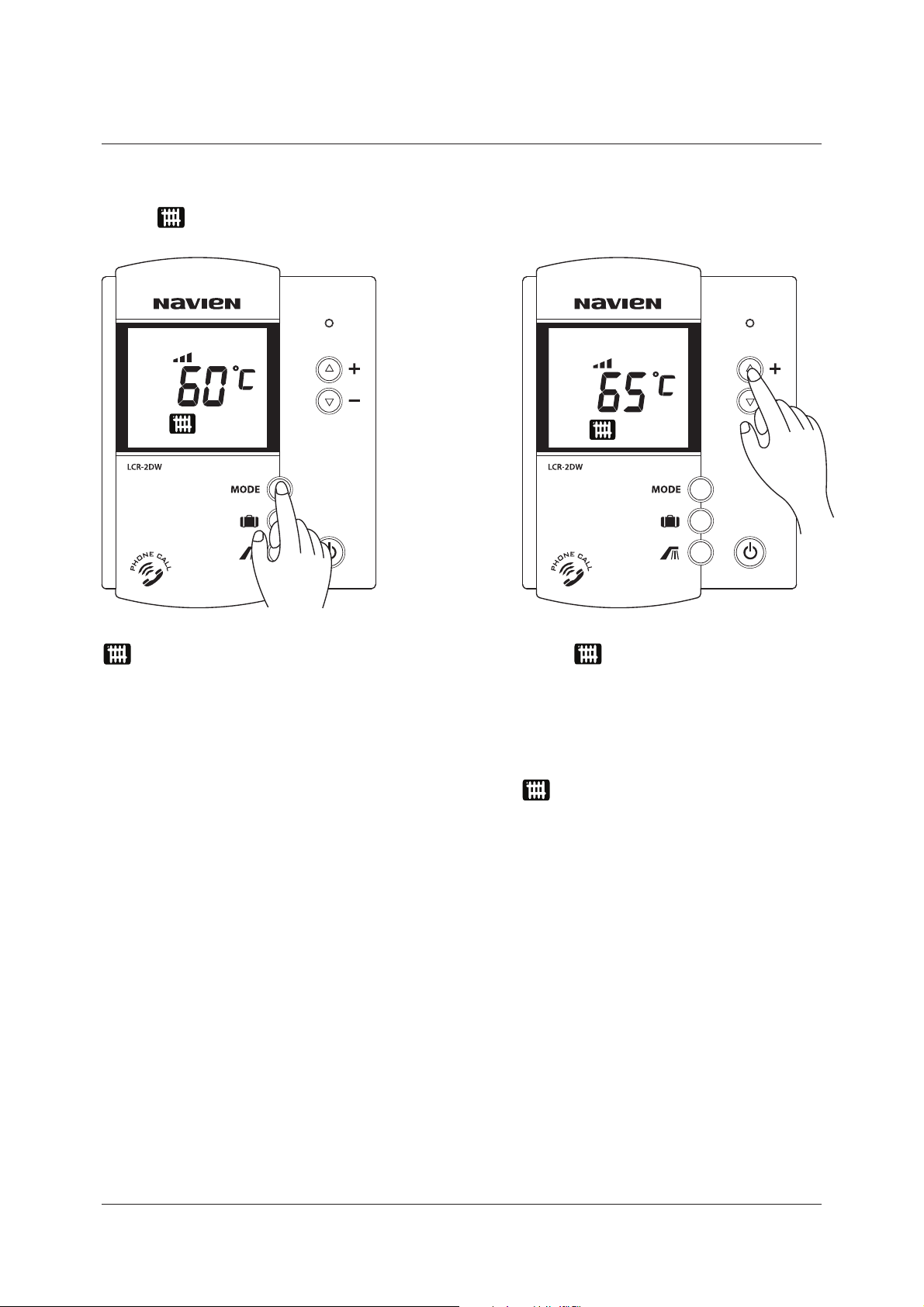

blinks when selecting

Heating Water Temp. Mode

When blinks, set the desired

heating temp. between 40~80丯 by

adjusting +/- button, after a while,

it is automatically saved.

Heating temp. can be set by 1丯

After the setting is done,

is on and current heating water

temp. is displayed.

Press the Mode button repeatedly,

until is displayed.

Set the heating temp.

with +/- button.

Heating Water Temp. Mode

14

Page 15

Timer Mode

Timer Mode is a function that boiler repeatedly operates 20- minute stop and

again that can be set in the range of hour 0~9, 50 minutes.

Press the Mode button repeatedly,

until is displayed.

Set the heating stop time

with +/- button

blinks when selecting Timer Mode. When blinks, set the desired

heating stop time.

It can be set by 10 min., up to 50min

in the range of hour 0~9 by adjusting

+/- button, after a while, it is

automatically saved.

After the setting is done, is on

and current room temp. is displayed.

Heating stop time ‘0’ means boiler is continuously operates.

In this case, heating temperature keeps increasing.

CAUTION

so, please be careful.

15

Page 16

Press the MODE button and select the

desired heating to cancel the Outing Mode.

When selecting Power Heating, is displayed

and it is combustioning for 30 minutes continuously.

After 30 minutes, it returns to previous

heating mode.

Press the Mode button repeatedly,

until is displayed.

Power Heating Mode

Outing Mode

will be displayed and Outing Mode

will be set.

Press button

Use this function when operating the boiler with minimum capacity without

heating and there is no one at home.

16

Page 17

Setting Hot Water Temp.

Press button. Set the hot water temp.

with +/- button.

is displayed when pressing

the Hot Water button.

Please make sure the hot water temp. is not too hot or too

cold before taking a shower or bath.

CAUTION

When blinks, set the desired

hot water level among low, mid, and

high by adjusting +/- button,

after a while, it is automatically saved.

low mid high

17

Page 18

Press the MODE button and select

the desired heating to cancel the

Hot Water Mode.

will be displayed and Hot Water

Mode will be set.

Press button.

Hot Water Mode

Use this function only when hot water is needed.

1. Please be careful that infants and young children do not use

hot water without a guardian for safety.

2. When others use hot water, do not change the hot water temp.

setting for safety.

CAUTION

18

Page 19

When using outside telephone, call the phone, after the call is connected to

the boiler after ringing the preset number of times, you will hear a 'beep' sound.

Then, manipulate the buttons as described above.

TIP

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

With phone network, heating function of room thermostat can be set.

Activating the boiler

1. Press "#" button 3 times. 2. Hang up the phone, when hearing

'beep-beep' sound.

The boiler is operated with ‘Power Heating Mode‘ for 30 minutes and returns to

the previous mode (If the room thermostat is o, return to Outing Mode.)

Remote Operation By Telephone

*

*

*

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

*

CM

AM

1 2 3

4 5 6

7 8 9

*

0 #

#

#

#

#

Suspending the boiler

1. Press "#" button 3 times. 2. Hang up the phone, when hearing ‘

'beep-beep-beep' sound.

Then, it changed to Outing Mode

19

Page 20

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

0

0

0

0

CM

AM

1 2 3

4 5 6

7 8 9

*

0

#

When altering the number of ringing

1. Press"0" button 3 times. 2. 'beep-beep-beep-beep'

sound will be ringing 4 times.

3. Press a button you select out of

5,6,7,8,9, or 0 three times.

4. After 'beep-beep-beep-beep-beep'

sound, hang up the phone.

1. If you don't press any buttons for 10 seconds or longe after

pressing '#' or '*' button, the telephone will automatically

hang up.

2. Make sure to hang up the phone after hearing activation

or suspension signal.

3. If you don't hear the 'beep' sound while using it, manipulate

it again slowly.

CAUTION

20

Page 21

When it doesn’t light even with the power

button “ON” or it gets extinguished due to

running out of oil, the FLAME Detector(Cds)

gets to work and stops the operation

Combustion safety device

If water is insucient in the boiler, it

interrupts the operation of the boiler with

the power cut o.

When water rells, the boiler starts again

automatically.

Low water level blocking device

If the temperature of the boiler rises up too

high, it is dangerous. So, in such case, this

device cuts o the power automatically.

When the overheating preventer gets to

operated the combustion stops and “CHECK”

lamp turn on.

If the overhead temperature is fall “CHECK”

lamp turn o and “RUN” lamp turning on

automatically.

If the operation stop is repeated again, contact

the sales agency or the commercial agency.

Overheating preventer

During the hard winter, the circulation pump

or the burner operates automatically to

prevent the heating circuit from freezing.

In winter, keep on plugging in the power

cord and turning the power button “ON”.

(the insulation state of the pipes must be

normal)

Freezing preventer

If the power gets o, oil gets blocked

automatically and the combustion stops.

Safety device on power-failure

Safety device

21

Page 22

Check out whether the combustibles is near.

Keep cleaning all the time and don’t let the

dust accumulated.

Check out whether oil leaks from, is stacked

on, or soaks into the oil tank, oil pipes, the

body of the boiler, etc.

Check out whether there is any water leakage

from the body of the boiler and the pipes.

Open the drain plug of the oil tank regulaly

and remove water.

Points to be checked once or more a year

Everyday Checking

22

Page 23

Cleaning of boiler

Much soot accumulated inside the boiler

will reduce the life and eciency.

At least once a year, clean the boiler inside.

Cleaning the oil filter

In case that the oil lter gets dirty, stop

operating, lock the oil valve, and remove

dust or rust accumulated below the oil cup.

Detach the oil cup by rotating right and left.

Pull down the lter.

Wash the lter and the inside of the oil cup

with clean kerosene and light oil.

Cleaning the oil tank

Water may get mired in during feeding oil or

get accumulated naturally during the long

period in the oil tank. In this case, drain water

o through the drain plug in the oil tank,

and when oil starts to get out, lock it.

23

Page 24

Cleaning the flame detector

If the light-receiving surface(sensing surface)

gets darkened with soot, the bad sensitivity

cause the wrong automatic operation.

You can pull out the ame detector(black)

which is attached in the lower part of the

burner.

Wipe the glassy surface of the ame

detector with a scrap and x it in its position.

Checking the exhaust pipe

At least once a year,check for any loose

joints in the discharge(piping and ue),

clogging in ue, corrosion or leak. If any

abnormality is found, contact out sales

agency for checking up.(blocking pipes or

holes, and so on)

24

Page 25

For the place to install the boiler, choose the place possible to do the accompanying

works, such as water supply works or electric works.

For the place to install, choose the place conformed to the installation standards

of the boiler and the construction act of the code of each city or municipality

Install the boiler in the place as wide as possible for the maintenance and the re

prevention.

Install the boiler in the place convenient for controlling and manipulation of the

temperature.

If there is no electric outlet in the proper position, do wiring by requesting to a

company designated by the electric power company.

Around the installation place, there must be no place which stores and treats the

combustibles and the inammables.

There should be equipped drainage in the in stalling spot.

How to install

Choosing of the installation place

Open cistern tank

The diagram of the standard piping : Cistern tank install type

Never install any valve between

the boiler and cistern tank.

Supply Water

Pipe

Minimum 1.5m

Circulation Pump

Distributor

Distributor

Condensate

Outlet

Drain Drain

F.L

Install the condensate outlet hose for condensing model as above

Expansion Tank

Supply Water Pipe

Roop water

tank

Water

Water

Expansion tank

Circulation Pump

Bypass Pipe

Install the pipe as above when circulation pump

install heating water inlet

In casa of water inlet through

roof water tank

Expansion Tank

Water

Hot Water Inlet

Hot Water Outlet

Hot Water Outlet

Heating Water

Inlet

Cold Water

Hot Water

Heating Coil

Fan Coil

Radiator

Boiler Back

25

Page 26

1.

2.

3.

4.

5.

6.

7.

8.

The distributor on the return water distributor side should be placed lower than

the heating inlet.

Connection should be made by installing a safety valve with 3.5kgf/偌 or lower

opening the discharge piping to the cistern tank.

The maximum operation pressure is 3.5kgf/偌. Do not supply water at a higher

pressure or directly connect the water pipe having the pressure higher than.

Overow of water during the heating to the cistern tank means short tank

capacity. Exchange it with a larger one.

Backow of water during the running or stopping of the circulation pump to the

cistern tank is caused by too much air in the pipe. Remove air by opening valves

on the distributor one at a time, while running the circulation pump.

Evaporation at the cistern tank means failure in the system. Contact your

representative to receive the check.

Never install any valve between the boiler and the cistern tank.

We will not be liable for any defect or breakdown caused by the failure to

comply with the above precautions.

Sealed cistern tank

Precautions

Safety Valve

Air exhaust Valve

Filter

Reducing Valve

Check Valve

Circulation Pump

Distributor

Condensate

Outlet

Drain Drain

F.L

Sealed Expansion Tank

Install the condensate outlet hose for condensing model as above

Install the pipe as above when circulation pump

install heating water inlet

Bypass pipe

Circulation Pump

Filter

Reducing Valve

Check Valve

Water

Hot Water Inlet

Hot Water Outlet

Heating Water Outlet

Cold Water

Hot Water

Heating Coil

Fan Coil

Radiator

Boiler Back

26

Page 27

It is recommend that the length of ue shall be less than 3 miters and the exuosity

shall be less than 2 point.(Except for the exuosity at the end of the ue)

It is recommend that use the ue tting in the connection caliber.

Be careful not to narrow down the ue. And please, maximize the radius of exuosity

when to work.

It is recommend that keeping the ue warm by using the noninammable insulation.

Oil boiler model : LST-17, 21, 24, 30, 41K / LFA-17, 21, 24, 30, 41K

It is imperative that there are no windows

around the end of the ue within 600mm.

IF the waste gas should come into the

room, you will suer from the waste gas

poisoning.

Flue Work of Forced Exhaust(FE)

The example of a standard installation

CAUTION

hG

GG

G]WWGv}ly

]WWGv}ly ]WWGv}ly

]WWGv}ly

O|u{aP

27

Page 28

CONVERTER-CV2

28

1. Check the electric voltage before you operate the boiler.

2. Tele-room controller can be adapted to voltage DC 24-31V form the main controller

of boiler.

3. Make sure to connect the electric port properly. One is far room controller , the other is

for telephone.

Check point for safety

1. Fix the room controller on the wall of room or living room. The height is about 1.5m.

2. Fix on the properly spot to sense the room temperature.

3. Avoid to x near the heater or under the sun light, this can cause the torsion of the

case and do a harm to the electric parts inside the case.

4. Avoid to x in the place there is dirty, humid, this can do harm to the electric parts

inside the case.

Check point for fixing

1. You had better take care to prevent the metallic parts (Needle, Coin)

or in ammables (Paper, Match stick) form entering into the air vent hole of the case.

This can make a short-circuit or re.

2. Do not open the case, and treat your self.

3. Be careful the power line not to exposed in the room.

4. Keep out form the volatiles (Thinner, Benzene, Solvent…)

5. Before you polish the room controller , plug the power cord out and use a smooth cloth.

Check point for usage

Description & Function

£Run (Normal operating)

¤Hot w+ater supply

¥Heating mode

¦Boiler stop

§Check (Operating error)

¨Power on/o

Signal lamp

©7HPSHUDWXUH(UURUGLVSOD\

ª%RLOHUZDWHUWHPS

FRQWURONQRE

«3RZHU5HVHWVZLWFK

Operation & Sensor

Page 29

Telephone line

Power (Ac 220V)

Hot Water

Flow Sensor

29

1. Connect rmly the room controller wire(2 Line) form the boiler , to the room controller

port in the back of the room controller.

2. Connect rmly the KD-SP wire to the telephone port in back side of the converter-CV2

3. Fix the room controller rmly on the wall, using the converter-CV2 bracket.

4. Wiring

Fixing & Wiring

Telephone

Main

Controller

Boiler

Adaptor

L1

L2

Page 30

Multi Floor System

30

CONVERTER-CV2

Cold Water

M.F.S Converter

(KDC-5P)

DR-5P

TMR-5P

M.F.S Converter

(KDC-5P)

Fan

Valve

Radiator

Fan

Valve

Radiator

Fan

Valve

Radiator

VALVE Actuator : Erie VT2325G13A01A

AC24V 2WAY WATT6.5

DR-5P

TMR-5P

M.F.S Converter

(KDC-5P)

DR-5P

TMR-5P

3rd Fl.

2nd Fl.

1st Fl.

Power(AC220V)

Pump

KDC-104P

KDC-106M

Main Controller

water flow

detector sensor

Boiler

Roomcon Terminal No.

Page 31

Multi Floor System Room Converter

Converter –CV2

31

<KDC-5P>

VALVE

(AC24V 6VA)≥

VALVE or FAN

(ACPOWER VOLT 100VA)

AC POWER INPUT

KDC-104P, 207TP

WIRE DRAW

M.F.S ROO M CONVERTER

ROOMCON

-6P,7P

Red

6 5 4 3 2 1

11 10 78912

13

Blue

Green

White

Orange

KDC-5P (AC220V)

(10, 21)

Brown

AC250V 5A

KyungDong

161

4-Φ4.5 HOLE

149

139

46

68

45

87

50

53

Page 32

Room Thermostat Installation

1.

Fix the bracket by using bolts.

2.

Connect rmly the two wires from the boiler to the screws on the back side

of the room thermostat.

Connect rmly the two wires from the telephone code to the screws on the

3.

back side of the room thermostat.

Fix the room thermostat on the bracket.

4.

32

Bolier

Main

Controller

R/C

T P

Telephone Connections

Page 33

How to replace the parts

There are no parts which gets wear in a short period,

but when the replacement of the parts is needed,

consult to out sales agency or commercial agency.

For the repair of the boiler, request to our sales

agency or commercial agency, or to the A/S center.

Repairing the boiler by a man without qualication

cause another trouble, so never do that

33

Page 34

Electric wiring diagram

MODEL NO : LST-17, 21, 24, 30, 41K / LFA-17, 21, 24, 30, 41K

<#0*-&3>

34

Page 35

1. Even with pressing the

power button, the

motor doesn’t work

2. The motor rotates,

but the boiler doesn’t

ignite.

3. The boiler ignites, but

immediately stops.

4. The electronic pump

makes big noise

5. On igniting, it backres. 1.

2.

3.

The wind ow back in the

exhaust pipe.

The ignition device is bad.

Others.

Contact the sales agency or

commercial agency.

6. The abnormal noise of

the combustion

happens.

1.

2.

3.

The air for combustion is

excessive.

The amount of oil feed is

excessive.

Others.

Contact the sales agency or

commercial agency.

7. Smoke and soot occurs. 1.

2.

3.

The oil is bad or has impure

materials.

The air for combustion is

short.

Others.

1.2.The fuel pipes leaks.

The water pipes leaks.

1.2.Replace the oil.

Contact the sales agency or

commercial agency.

8. Others.

1.

2.

3.

4.

5.

The oil valve is locked.

There is no oil in the tank.

There is air in pipes.

The oil lter is locked.

Others.

1.

2.

3.

4.

5.

The oil in the oil tank is

insucient.

The ame detector(CdS),

cannot sense.

The oil lter is locked.

There is mixed impure

materials in the oil.

Others.

1.

2.

3.

The oil lter is locked.

There is air in pipes.

Others.

1.

2.

3.

4.

5.

Open the valve.

Supply oil.

Drain o air.

Clean the boiler.

Contact the sales agenct or

commercial agency,

1.

2.

3.

4.

Supply oil more.

Clean the ame detector.

Clean the oil lter.

Replace the oil with good oil.

Contact the sales agency or

commercial agency.

1.

2.

3.

Clean the oil lter.

Drain o air.

Contact the sales agency or

commercial agency.

1.

2.

3.

he temperature in the

boiler is above the set

temperature.

The room controller is o.

Others.

1.

2.

3.

This is not a trouble.

When the temperature of the

boiler goes down, get restarted.

Set the room controller to the

operation condition.

Contact the sales agenct or

commercial agency.

※Please contact your local shop and distributor for other unclean matters.

Happening Cause Solution methods

How to locate troubles and solve

Contact the sales agency or

commercial agency.

35

Page 36

Error Code

When an error occurs, the LCD shows one of the following numeric error codes

with letter 'E'.

Error Code Error Code

01

02

03

04

05

06

09

10

Heating sensor wire

Cause Cause

Overheat

Low water level

Ignition failure or

overheated unit

Pseudo ame

disconnected

Short circuit of

heating sensor

Fan RPM failure

Air pressure failure

13

14

15

16

17

27

28

29

Heating water ow

S/W failure

Gas alarm (optional)

MICOM failure

Bimetal overheat

(Mechanical)

DIP S/W setting error

Air pressure sensor error

Pipe leaking

Thee-way valve error

11

12

Water level detection

failure

Flame failure during

combustion

51

52

Black out

compensation error

Operation button

error

36

Page 37

The specification

STANDARD OIL BOILER

ITEM

UNIT

HEAT OUTPUT

HOT WATER OUTPUT

FOR USE

FUEL

ROOM SIZE

MAXIMUM WORKING

PRESSURE

HEAT TRANSFERING SIZE

FUEL CONSUMPTION

TYPE OF AIR / EXHAUST GAS

HEATING EFFICIENCY

MODEL

G

˶I

FE(%)

FF(%)

LST - 17K

16 20 25 30 40

16 20 25 30 40

Less than 96 Less than 119 Less than 135 Less than 172 Less than 238

1.90 2.43 2.84

LST - 21K LST - 24K LST - 30K LST - 41K

HEATING AND HOT WATER

Heating Oil(Light Oil)

3.5

(343)

0.84

FE (FF)

90

90

0.92 1.08

3.47 4.60

HOT WATER EFFICIENCY

ELECTRICITY

CONSUMPTION

COMBUSTION

POWER

WATER STORAGE CAPACITY

EXTERNAL SIZE

WEIGHT

HEATING

CONNECTION

PIPING

HOT WATER

CONNECTION

DIAMETER OF FLUE

FE(%)

FF(%)

W

V, Hz

˶

WÝLÝH

mm

A

A

Φ

107 117

18

327×543×777

36.5

90

90

120

220V, 50Hz

25 32

15

EXHAUST : 75

131 177

20 25

370×543×

836

42.0 52.0

370×673×

858

The specication in this operating manual can be changed for improvement without prior notice.

※

37

Page 38

38

※

The specication in this operating manual can be changed for improvement without prior notice.

The specification

STANDARD OIL BOILER

MODEL

LFA - 17K

HEATING AND HOT WATER

Heating Oil(Light Oil)

Less than 96 Less than 119 Less than 135 Less than 172 Less than 238

1.0

(98)

0.84

21.5 2.42 2.72

FE (FF)

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

88

105 110

20.5

˶

18

327×543×777

52

25 32

15

EXHAUST : 75

90

401×673×858

40

126

220V, 50Hz

133 179

3.40 4.51

0.92 1.08

18.3 20.0 23.0 29.0 38.0

18.3 20.0 23.0 29.0 38.0

LFA - 21K LFA - 24K LFA - 30K LFA - 41K

UNIT

ITEM

HEAT OUTPUT

Φ

FE(%)

FF(%)

FE(%)

FF(%)

W

V, Hz

WÝLÝH

mm

A

A

˶I

G

HOT WATER OUTPUT

FOR USE

FUEL

ROOM SIZE

MAXIMUM WORKING

PRESSURE

HEAT TRANSFERING SIZE

FUEL CONSUMPTION

TYPE OF AIR / EXHAUST GAS

HEATING EFFICIENCY

HOT WATER EFFICIENCY

ELECTRICITY

CONSUMPTION

COMBUSTION

POWER

WATER STORAGE CAPACITY

EXTERNAL SIZE

WEIGHT

PIPING

HEATING

CONNECTION

HOT WATER

CONNECTION

DIAMETER OF FLUE

Page 39

memo

39

Page 40

40

memo

Page 41

memo

41

Page 42

42

memo

Page 43

Page 44

Loading...

Loading...