KDB-GOM

Series

- 1 -

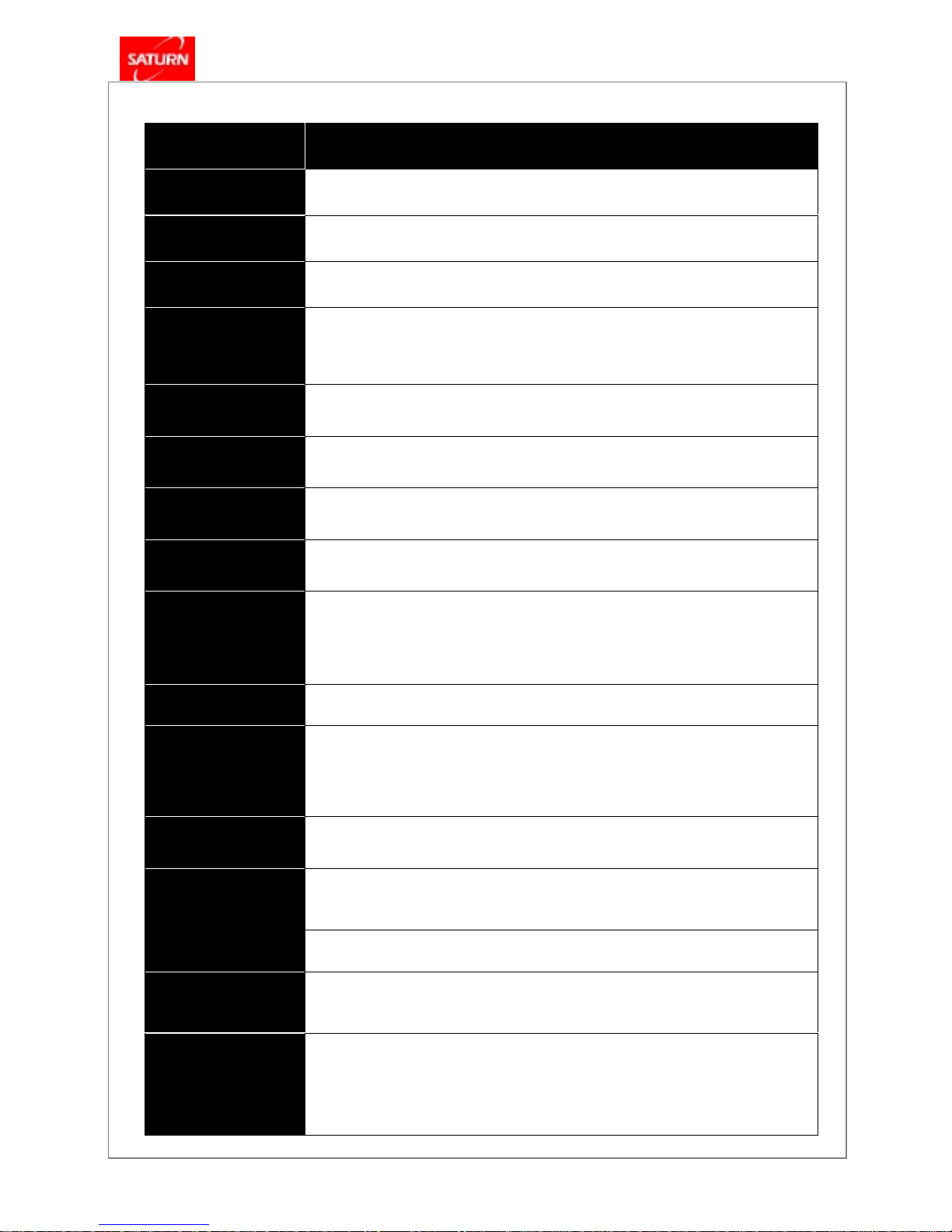

1. Specifications of the KDB-GOM series

1.1 Kyungdong Boiler Product Features and Functions

1.2 Specifications

2. Operating Types/Constructions/Schematic Diagram

2.1 Operating Types

2.2 Constructions of the Boiler

2.3 Schematic Diagram of Operating

3. Equipment Protection and Personal Safety

4. Specifications and Functions of the Major Components

4.1 Main Heat Exchanger

4.2 Fan Assembly

4.3 Circulation Pump

4.4 Modulating Gas Control Valve

4.5 3-Way Valve

4.6 Expansion Tank

4.7 Air Pressure Switch

4.8 Hot Water Flow Sensor

4.9 High Limit Sensor(Bimetal Type)

4.10 High Limit Fuse(Fuse Type)

4.11 Heating Temperature Sensor

4.12 Ignition Transformer

4.13 Power Transformer

4.14 Domestic Hot Water Heat Exchanger

4.15 Burner Assembly

4.16 Nozzle Holder Assembly

4.17 Wiring Diagram

4.18 Main Controller

I.

Technical Information

KDB-GOM

Series

- 2 -

THE KDB -GOM

THE KDB -GOMTHE KDB -GOM

THE KDB -GOM

KYUNGDONG BOILER’S VARIABLE-CAPACITY-MULTI-PURPOSE

82%+ HYDRONIC HEATING SYSTEM

How does it work?

The KDB-GOM provides 2 different heating functions that operate independently from the same boiler. One mode

provides space heating water to heat the home. The other mode provides a continuous circuit of hot water for domestic

use eg, bath, laundry, etc. Both circuits are separate and operate at different temperature ranges.

The space-heating water is controlled by the FR-5 thermostat. A special thermostat has been provided that enables the

user to either set the room temperature required of set the heating water temperature. In some cases this thermostat may

not be suitable for multi-system applications. (The installing contractor will make this determination and install suitable

alternative controls.

The domestic hot-water is controlled by the user. Because the KDB-GOM is a multi-purpose design, it can provide hot

water on demand, there is no storage tank to hold hot water, when there is no use for it. The KDB-GOM will only produce

hot water when you use it : instantaneous. The modulating gas burner allows water to heat up as evenly as it is being

used. The KDB-GOM will continue to heat the water until the source or sources are shut off. This on-demand-use also

helps to prevent water being held in the boiler for long periods of time.

IMPORTANT:

A thermostatic mixing valve should be installed on the domestic water supply pipe to control the supply water

temperature and prevent any possibility of scalding.

Domestic hot water priority

The GOM prioritizes bath water over space-heating water and will immediately stop producing space-heating water the

moment a hot water valve is opened anywhere in the home. Once the valve has been turned off, the boiler will return to

the home-heating function again.

The seal-combustion process

The KDB-GOM is designed with a special sealed-combustion venting process. Both sides of the combustion process

(inlet oxygen and outlet carbon monoxide) are isolated from each other and are totally sealed-off from the air supply within

the home. This reduces drafts, caused by infiltration, by as much as 82% making the KDB-GOM one of the safest, most

comfortable and clean-burning boilers in the world.

1. Specifications of the KDB-GOM series

1. 1 KyungDong GOM Product Features and Functions

A. Continuous Hot Water

Its On Demand! KyungDong Boiler makes running-out-of-hot-water obsolete.

B. Everything Built-in

Installs in half the time. We tried to think of all the parts and accessories you’ll need (plus a few you might have

forgotten) and built them into this multi-purpose hydronic heating system. You’ll spend less time driving to all the supply

houses.

KDB-GOM

Series

- 3 -

C. Baked-in Beauty

The high quality porcelain finish is bake on and keeps the exterior looking new and lustrous for years to come.

D. System Timer

Save energy during times the home is unoccupied. Just set and activate the timer and leave. The unit turns off for

pre-programmed intervals until you return.

E. Room Thermostat FR-5

Convenient and accurate, large digital display is easier to read, easier to use. Our new room thermostat gives the

consumer digital control over several heating function.

F. Performance Indicator

With the use of the FR-5 electronic room thermostat, the (LED) will conveniently display the current operating

condition of the unit such as temperature of heating water, room temperature, normal operation, etc.

G. Continuous-Discharge Ignition(C.D.I.)

Direct ignition design requires no wasteful pilot burner and offers fuel savings.

H. Combustion Safety Protection

If the unit fails to ignite after the “ON” switch is pressed, or if the flame is extinguished due to a gas shortage, the

flame sensor will shut down the unit.

I. Always Balanced Operation

Despite fluctuating wind conditions, changes in atmospheric pressure and other external disturbances, the

variable-speed combustion blower provides steady performance.

J. Exhaust Safety Protection

While operating, the exhaust-discharge fan is continuously monitored. The units will be immediately stopped to

prevent fumes from entering the home if the wind gusts become excessive or if the flue exhaust has been clogged.

K. Smart Re-Start

Should the unit’s flame fail due to strong winds or temporary low gas pressure, the unit will automatically restart. In

cold weather climates, manual resets could cause freeze damage.

L. Safety Protection during Power Outages

When the power fails, the gas is automatically shut down and the units are stopped.

M. Automatic Fill & Refill

If for any reason the water level in the system drops to an unsafe level, makeup water will automatically fill to the

appropriate levels.

N. Automatic Air Bleed

Each unit has 2 built-in air bleed devices. One is manual and used for quick fill and venting convenience; the other

is air-activated and operates and automatically.

O. Removal of Impurities

Each unit come equipped with a built-in, clearable, heavy duty, particulate water filter for trapping impurities and

preventing the clogging of pipes. This is a maintenance item.

P. Air-Ratio Controller

Air ratio is monitored, adjusted and controlled prior to and during each operating cycle and will automatically adjust

the combustion rate. The air-ratio controller guarding against unsafe operating conditions also senses excessive

gusts of wind filling the flue system.

Q. Proportional Temperature Control

This control is designed to continually analyze water flow and usage while maintaining the outgoing water at a

constant, even temperature.

KDB-GOM

Series

- 4 -

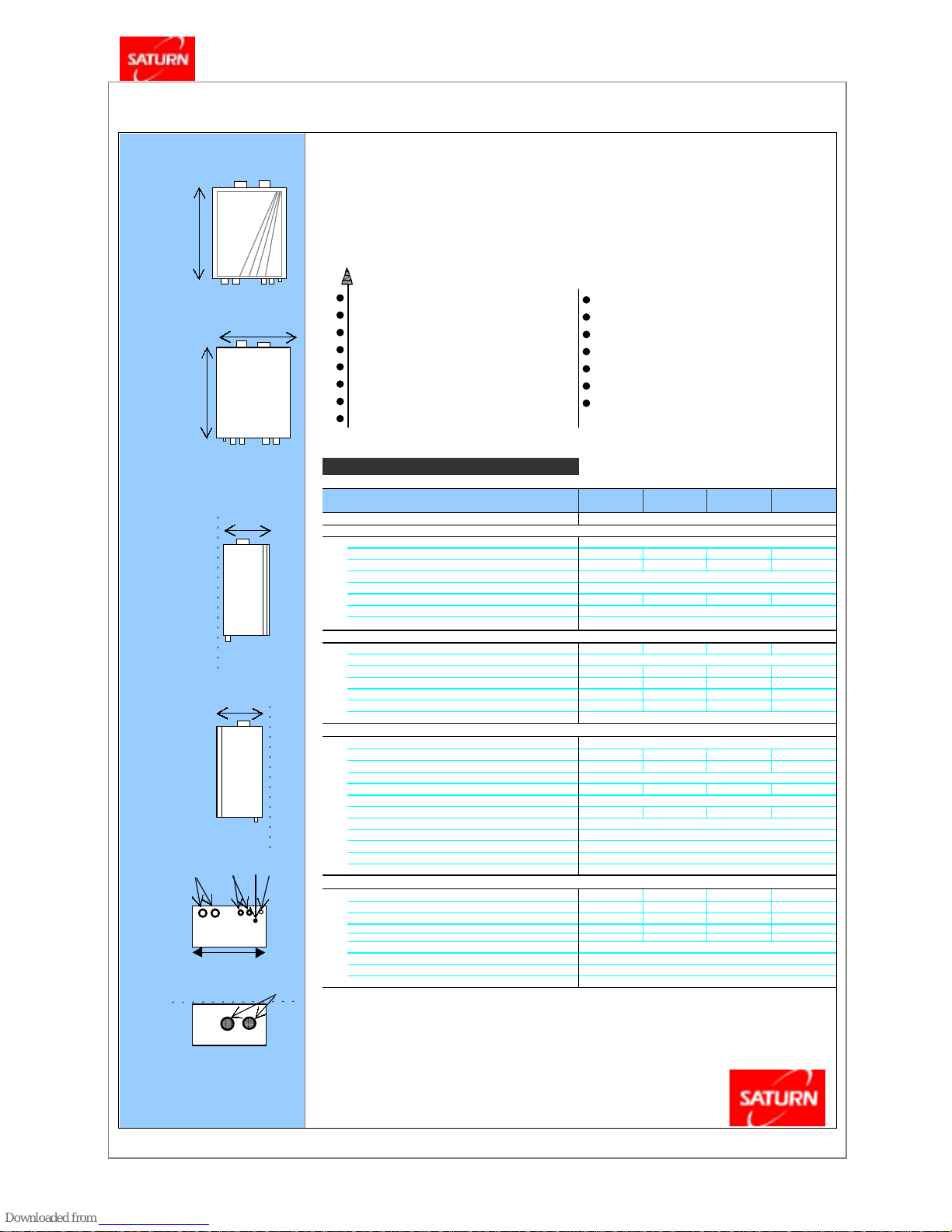

1.2 Specifications

GAS WALL-MOUNT

FRONT

View

A

Full, Dual Function Heating Design.

Natural and Propane Gas M odels.

B

Pow er-Vent, 2-Pipe C ombustion Process.

Modulating Gas for Precis ion Tem peratures.

REA R

Built-in Circulation Pump Assembly .

View

Built-in Ex pans ion Tank. Quiet, Vibration-Free Operation.

A

Built-in Freez e Protection.

Digitally Controlled, Full-Logic T hermostat.

C

Funct ion

SIDE Vi

ew

CENTR AL HEATING WATER

(LEFT

)

Const ructi on of Heat Exchanger

Heat Output (kcal/hr)

6,400

~ 16,

000

8,000

~ 20,

000

10,000

~ 25,

000

12,000

~ 30,

000

Max.Effici ency (%) 82 82 83 84

(wall)

Temperature Setting Range (℃)

Maxim um Working Pressur e (kgf/cm2)

Pre- Charged Ex pansion Tank (l iter ) 6.5 6.5 8.5 8.5

Circulation Pump

Freeze Protection Device

DOMESTIC HOT WATER

Heat Output (kcal/hr)

6,400

~ 16,

000

8,000

~ 20,

000

10,000

~ 25,

000

12,000

~ 30,

000

Max.Temperature Setting (℃)

Conti nuous DHW product ion

△T = 25 ℃

(liter )

10.7 13.3 16.7 20.0

Conti nuous DHW product ion △T = 33 ℃ (liter )

8 10.0 12.5 15.0

Conti nuous DHW product ion △T = 40 ℃ (liter )

6.7 8.3 10.4 12.5

C

Conti nuous DHW product ion △T = 50 ℃ (liter )

5.3 6.7 8.3 10.0

SIDE Vi

ew

Maxim um Working Pressur e (kgf/cm2)

(RIGHT)

OTHER DATA

Gas Type

Gas Consumption - LP (kg/hr)

1.58

1.98 2.48 2.97

(wall ) Gas Consumption (natural gas) (kcal/hr ) 19,000 23,700 29,700 35,600

Gas Inlet Supply Pressur e (natural: kPa) ( min - max)

Manifold Pressure (kPa) 0.16 ~ 0.92 0.16 ~ 0.96 0.25 ~ 0.94 0.14 ~ 0.96

Usage ( Heating & H ot Water )

Water Storage Capacity (liter) 0.7 0.7 0.8 0.8

Power (volts/cycle)

Power Consumption (watts)

Ignition

NOx Emi ssions

(Ref:0%, O2 in flue gas natural gas, ppm)

E F G D

Temp. of Exhaust Gas (℃)

WEIGHT AN D DIMENSIONS

Net Weight (l bs) 31 31 39 39

BOTTOM

A Physi cal Dimensions: Hei ght (mm) 630.0 630.0 685.0 685.0

View

B Wi dth (mm) 485 485 525 525

C Depth (mm) 235 235 250 250

D C onnection: Gas Inlet 15A, 1/2" 15A, 1/2" 20A, 3/4" 20A, 3/4"

E C onnection: Heating Water Supply/Return

B

F C onnection: Domestic H ot Water Supply/Return

(front) G C onnection: Primary Power (AC220V-50Hz)

H F lue Diameter (Intake / Exhaust) (mm)

TOP

H

Specif ication s s ubject to c hange with out prior not if ication

View ( wall )

- 2865 PELLISSIER PLACE - W HITTIER, CA 90601 - (562) 463-0880

15A, 1/2"

15A, 1/2"

70 / 75

28 (l ess than)

150 (l ess than)

20A, 3/4"

Dual

AC 220V- 50Hz

120 ~ 160

ELECT RONIC

80

17.5

Liquefied Petroleum ( L.P.) or Natural Gas

0.98 ~ 2.45

40 ~ 80

3

Self Pr imi ng

Ther mis tor

MODEL NUMBER

Combo Boiler

Stainl ess Steel / Copper

161 GOM 201 GOM 251 GOM 301 GOM

w ith 1-Year on Parts.

KYUNGDONG BOILER SPECIFICATIONS

C on trols Bo th Water F unction s Separ ately .

On-Demand Hot Water Delivery.

Com pact, Space-sav ing Design.

Limited Warranty on Heat Exc hanger

---- KEY FEATURES

Prov ides Hi-Temp Water for Heating the Home.

Pr ov ide s Hot Wate r fo r B athing & Wa s hing.

KDB - 161 / 201 / 251 / 301 GOM

Residential Gas Hydronic Heating System

GAS FIRED, WALL-MOUNT ED, MULT I-PURPOSE, HYDRONIC HEATING SYS T EMS

MODEL RAN GE : 16, 000 ~ 30,000 kcal/hr

KDB-GOM

Series

- 5 -

2. Operating Types/Constructions/Schematic Diagram

2.1 Operating Types

Item Specification

Installation

Wall Mount Type

Flue Type

Both Use FF and FE

Usage

Both Use Heating and Domestic Water (Single Pipe, 2 Waterways)

Water Supply for

Heating

Maintain normally at a constant water pressure by pressure reducing valve

(Auto / Manual)

Control Method

Proportional Control Method by MICOM

Heat Exchanger Type

Single Dry Type (131/161/201GOM) and Single Wet Type (251/301/351GOM)

Combustion Method

Air Intake Method by Semi-Bunsen Burner

Gas Flow Control

Current Proportional Control Method by Thermistor

Heat Exchange

Method of Hot Water

y Heat Exchange Method : Indirect Heat Exchange by Secondary Heat Exchanger

y Heat Exchange Type : Plate Formed Brazing Heat Exchange

y Heat Exchange Circuit : Parallel Circuit

Ignition Method

Continuous Discharge, Direct Ignition Method

Heating

/

Domestic Water

Changeover

Heating Priority, Changeover to Domestic Water Circuit by 3-way Valve

Domestic Water Signal

Detect Flow by Flow Switch

y Motor : Condenser Type

y Casing : Engineering Plastic

Circulator Pump

y Impeller and Shaft Coupled : Magnetic Type

Expansion Tank

y Type : Expansion Tank

y Volume:6.5Liter(161/201GOM), 8.5Liter(251/301GOM)

Pressure Reducing /

Flow Limiting Control

and Water Hammering

Prevention

Control Pressure Reduction/Flow Limit and Prevent Water Hammering

by Diaphragm

KDB-GOM

Series

- 6 -

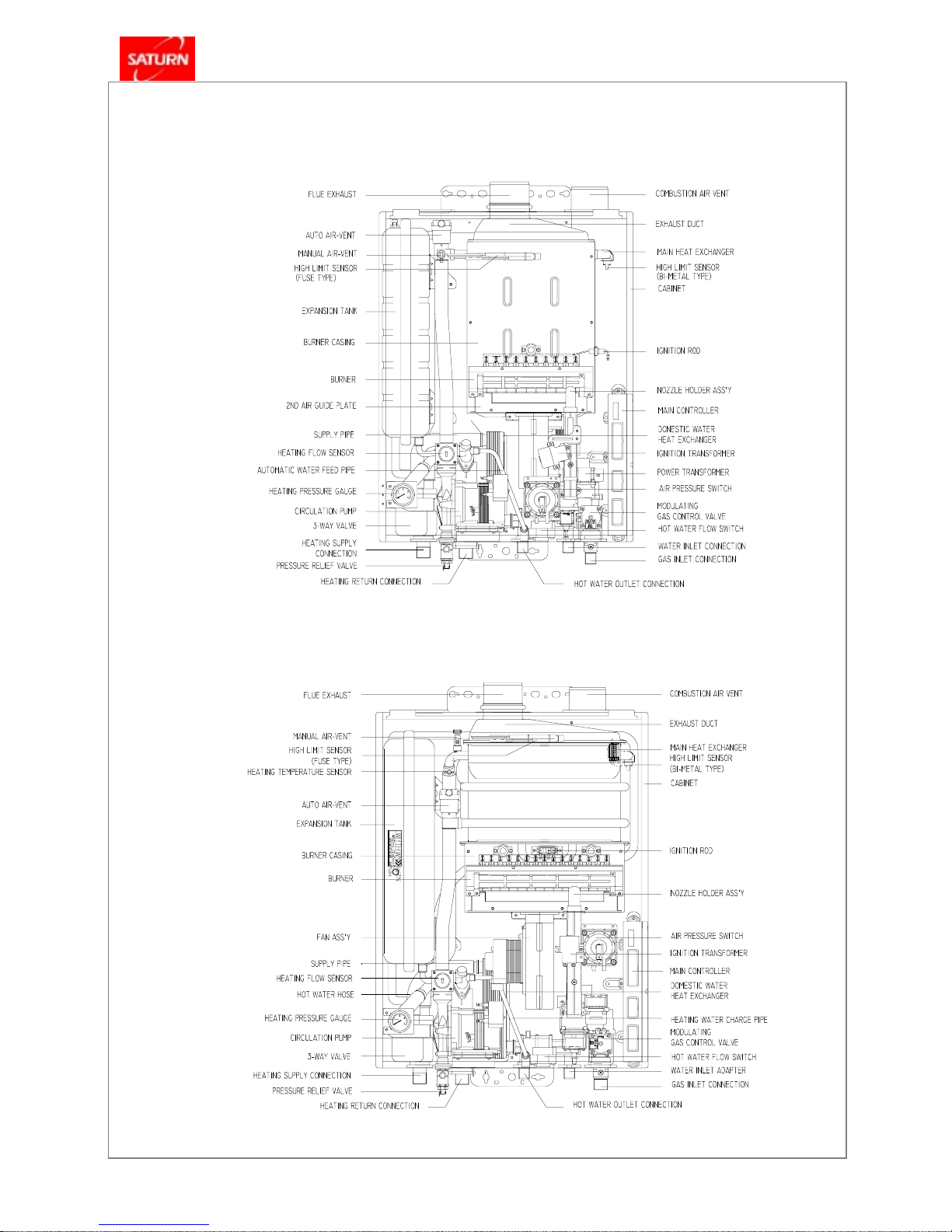

2.2 Constructions of the Boiler

■

Model : KDB

Model : KDB Model : KDB

Model : KDB – 251 / 301 GO M

251 / 301 G OM 251 / 301 G OM

251 / 301 G OM

■

Model : KDB – 161 / 201GOM

KDB-GOM

Series

- 7 -

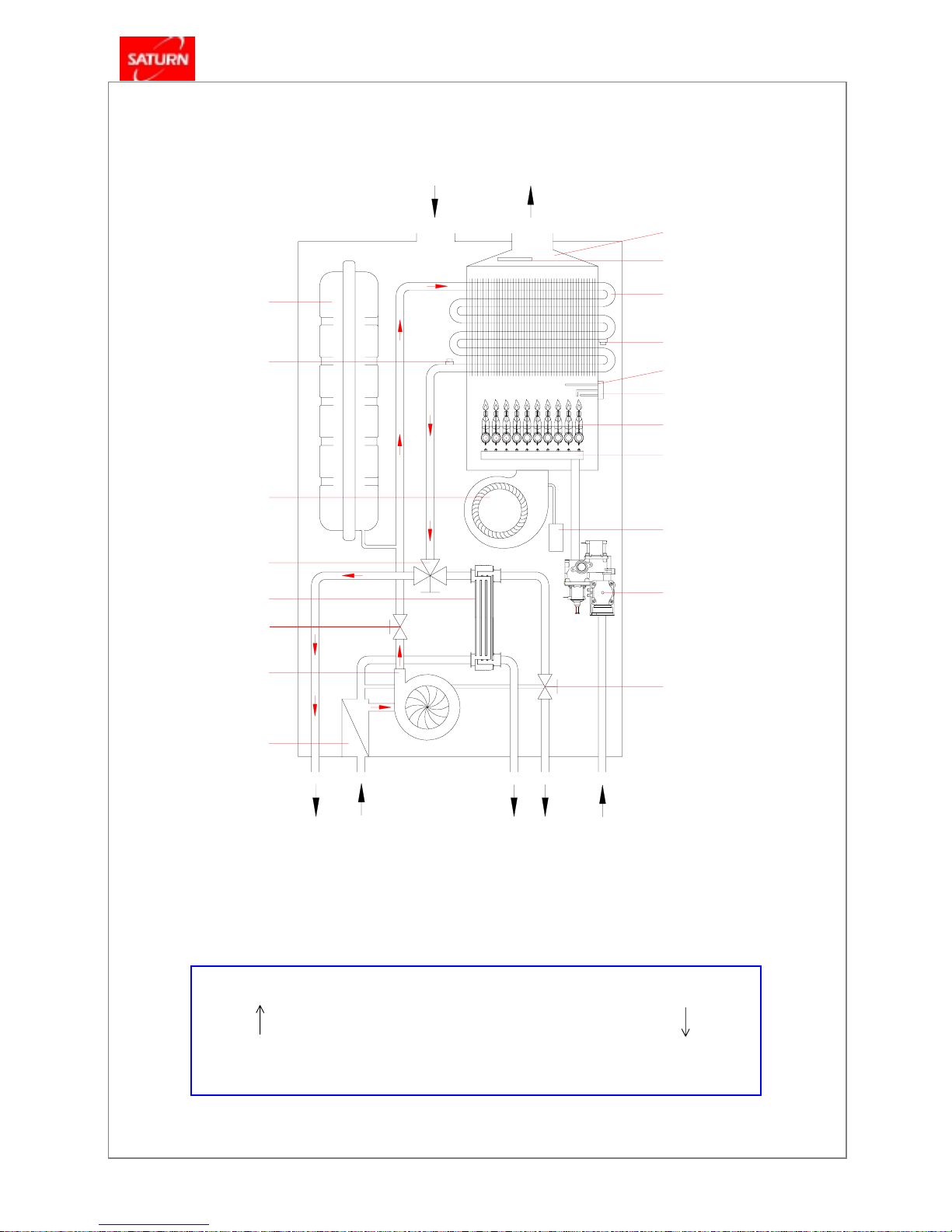

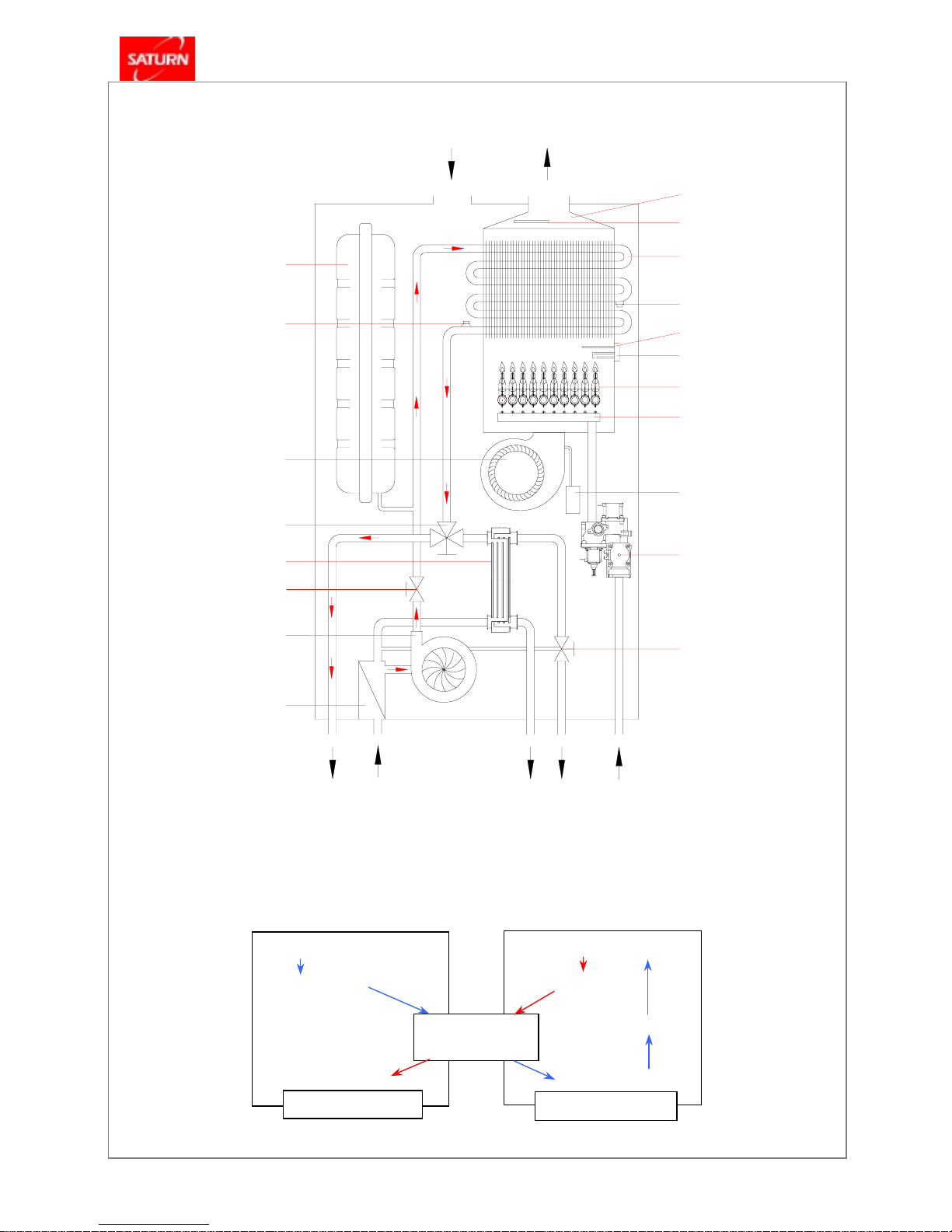

2.3 Schematic Diagram of Operating

2.3.1 Schematic Diagram at the Heating Water Supply

High Limit Fuse

Fan Assembly

Heating Temperature

Sensor

Hot Water Flow Switch

Modulating

Gas Control Valve

Expansion Tank

Air Pressure Switch

Nozzle Holder Assembly

Burner Assembly

Flame Detector

Electrode

High Limit Sensor

②

Main Heat Exchanger

Exhaust Duct

③

3-Way Valve

Gas Inlet

Domestic Water Outlet

Tap Water Inlet

⑥

Heating Return

④

Heating Supply

⑦

Heating Strainer

①

Circulator Pump

Flue Exhaust

Heating Flow Sensor

Combustion Air Inlet

Domestic Water

Heat Exchanger

①

Circulator Pump → ② Main Heat Exchanger → ③ 3-Way Valve → ④ Heating Supply

⑦

Heating Strainer → ⑥ Heating Return → ⑤ Room Heating(Heating Coil, Radiator)

KDB-GOM

Series

- 8 -

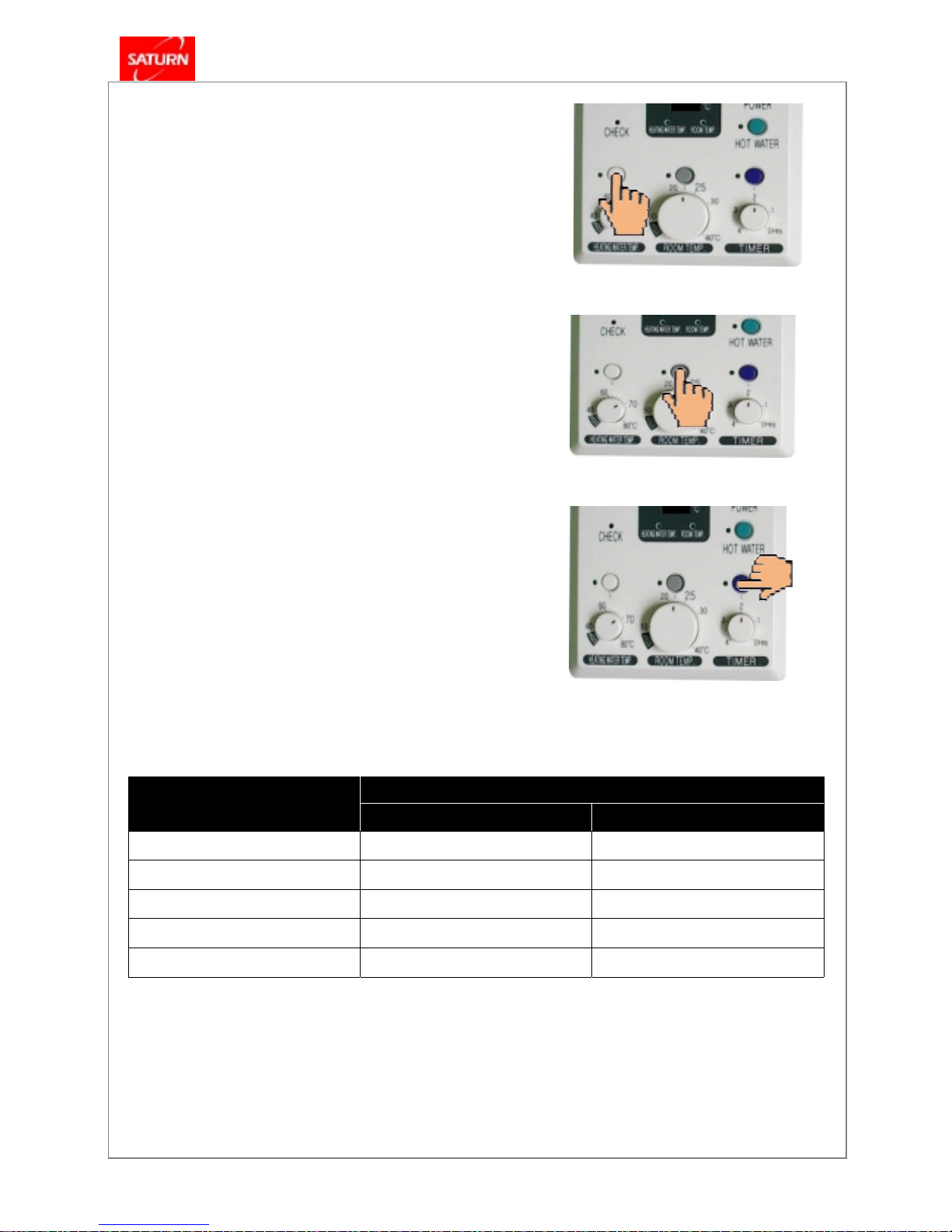

2.3.2 Controls of the Heating Temperature

2.3.2.1 When the heating water temperature is selected

- Setting Temperature: 40 ~ 80

℃

- To stop the run, turns the “HEATING WATER

TEMP.” dial to “OFF” position.

2.3.2.2 When the heating is controlled by the room

temperature

- Setting Temperature: 10 ~ 40

℃

- To stop the run, turns the “ROOM TEMP.” dial to

“OFF” position.

2.3.2.3 When the heating with the repetition time

(TIMER)

- The timer sets the stop time between 0 to 4-hours.

- Press the “TIMER” button, the boiler runs for 20minutes and stops for the time set by the timer.

- The temperature of the heating water is

automatically set at 80 ℃ and the temperature

indicator displays the room temperature.

※

If the range of control has been exceeded due to the change in the set temperature or to abrupt change in

flow, the set temperature will be reached through the proportional control with the delay of 30±3 seconds.

If 83 ℃ is exceeded, the delay of 30±3 seconds will not be performed.

Control Range

Setting Temperature,

“T” set

ON OFF

Over 78

℃

63±2.0

℃

83±2.0

℃

70 ~ 77

℃

“T” set – (14±2.0)

℃

“T” set – (6±2.0)

℃

60 ~ 69

℃

“T” set – (12±2.0)

℃

“T” set – (6±2.0)

℃

50 ~ 59

℃

“T” set – (10±2.0)

℃

“T” set – (5±2.0)

℃

Below 49

℃

“T” set – (10±2.0)

℃

“T” set – (5±2.0)

℃

KDB-GOM

Series

- 9 -

2.3.3 Schematic Diagram at the Domestic Water Supply

Fan Assembly

Heating Temperature

Sensor

②

Hot Water Flow Switch

Modulating

Gas Control Valve

ⓐ

Expansion Tank

Air Pressure Switch

Nozzle Holder Assembly

Burner Assembly

Flame Detector

Electrode

High Limit Sensor

ⓒ

Main Heat Exchanger

High Limit Fuse

Exhaust Duct

ⓓ

3-Way Valve

Gas Inlet

Domestic Water Outlet

Tap Water Inlet

Heating Return

Heating Supply

Heating Strainer

ⓑ

Circulator Pump

Flue Exhaust

Heating Flow Sensor

Combustion Air Inlet

③

Domestic Water

Heat Exchanger

③

Domestic Water

Heat Exchanger

Domestic Water Line

Heating Water Line

ⓒ

Main Heat Exchanger

④

Domestic

Water Outlet

②

Hot Water

Flow Switch

①

Tap Water Inlet

ⓓ

3-Way Valve

ⓑ

Circulator Pump

ⓐ

Expansion Tank

KDB-GOM

Series

- 10 -

2.3.4 Controls of the Domestic Water Temperature

2.3.4.1 Possible use of hot water in heating/not-at-home mode and hot water exclusive mode, according to the

flow volume detection of the hot water sensor.

2.3.4.2 Indirect control of the hot water temperature based on the heating water temperature.

2.3.4.3 Control at 80℃ when using hot water during heating.

2.3.4.4 Control at 70℃ when not-at-home or hot water exclusive mode

2.3.4.5 Stand by after hot water use

y when stopped after hot water use, the fan does not perform post purge and maintain the ON status for 90

seconds.

y the pump stops after the post purge (60 seconds)

y when using hot water again and after the hot water sensor detects the flow volume

pre-ignition Æ fuel supply Æ flame detection Æ post-ignition

y return to the before-hot-water-use status 90 seconds after the use of hot water.

2.3.4.6 Combustion in progress while in stand-by for hot water (90 seconds) or after 12 seconds of the post purge

time ( while in heating mode after the hot water sensor if “OFF”). Hot water stand-by time in progress separately.

3. Equipment Protection and Personal Safety

A. Ignition Failure

If the ignition fails, the gas supply is automatically cut off. An error code will appear as a flashing 2-digit code on the room

thermostat(models FR-5 only). The error codes are discussed in the troubleshooting section of the installation manual.

B. Flame Detection

If the fails and/or the re-ignition attempt fails, the gas supply is automatically cut off. An error code will appear on the room

thermostat(models FR-5 only).

C. Power Interruption

When the power is restored after a power failure, the boiler will automatically start and return to normal

operation(Manual reset is not required).

D. Excessive Air Pressure

Occasionally an excessive gust of wind from outside may be forced into the flue pipe. The air-ratio control module

will detect these strong back-drafts. To prevent any products of combustion from re-entering the building through the

open flue, the gas supply will be automatically cut off. An error code will appear on the room thermostat(models FR5 only).

E. Explosive Re-ignition Protection

Abrupt, noisy startups and backfires are prevented by means of soft ignition, a trademark of our air-ratio control

module.

F. Overheat Protection

Any overheating of the burners or heat exchanger will automatically shut down the supply of gas to the burners.

An error code will appear on the room thermostat(models FR-5 only).

G. Low Water-Level Safety

Water levels in the heating pipes are continuously monitored to prevent the boiler from operating if there is no

water or a restricted flow through the piping. The boiler will automatically shut down and an error code will appear

on the room thermostat(models FR-5 only).

KDB-GOM

Series

- 11 -

H. Automatic Water Fill

Should the water level in the system drop too low, a sensor will automatically activate the re-fill circuit.

I. Freeze Protection

During the heating season, a sensor inside the boiler will automatically detect and initiate safe heating cycles to prevent internal

equipment damage from occurring should freezing temperatures surround the boiler.

Note !

- When there is no gas supply

available, the circulating pump will automatically start up to guard the pipes from freezing (available only in boilers equipped with a

circulation pump).

J. Gas Pressure Control

To prevent internal damage from rupture, each boiler is protected from occasional surges in gas pressure by a regulating governor

device located in the gas valve.

K. Short-Circuit Protection

Any short-circuits occurring inside the boiler’s electrical circuit will immediately ‘blow’ the internal glass fuse(s)

and automatically cut off the gas supply.

L. Lightening Protection

Each boiler is specially grounded inside and out to protect against lightening strikes.

M. Combustion air flow control

When the combustion airflow is disrupted due to a defective, obstructed or an abnormal back-pressure of the

flue, the combustion is shut off safely.

N. Thermostat Control Failure

Should the thermostat fail to function properly, as a safeguard, the boiler’s gas supply will be automatically shut

down.

KDB-GOM

Series

- 12 -

4. Specifications and Functions of the Major Components

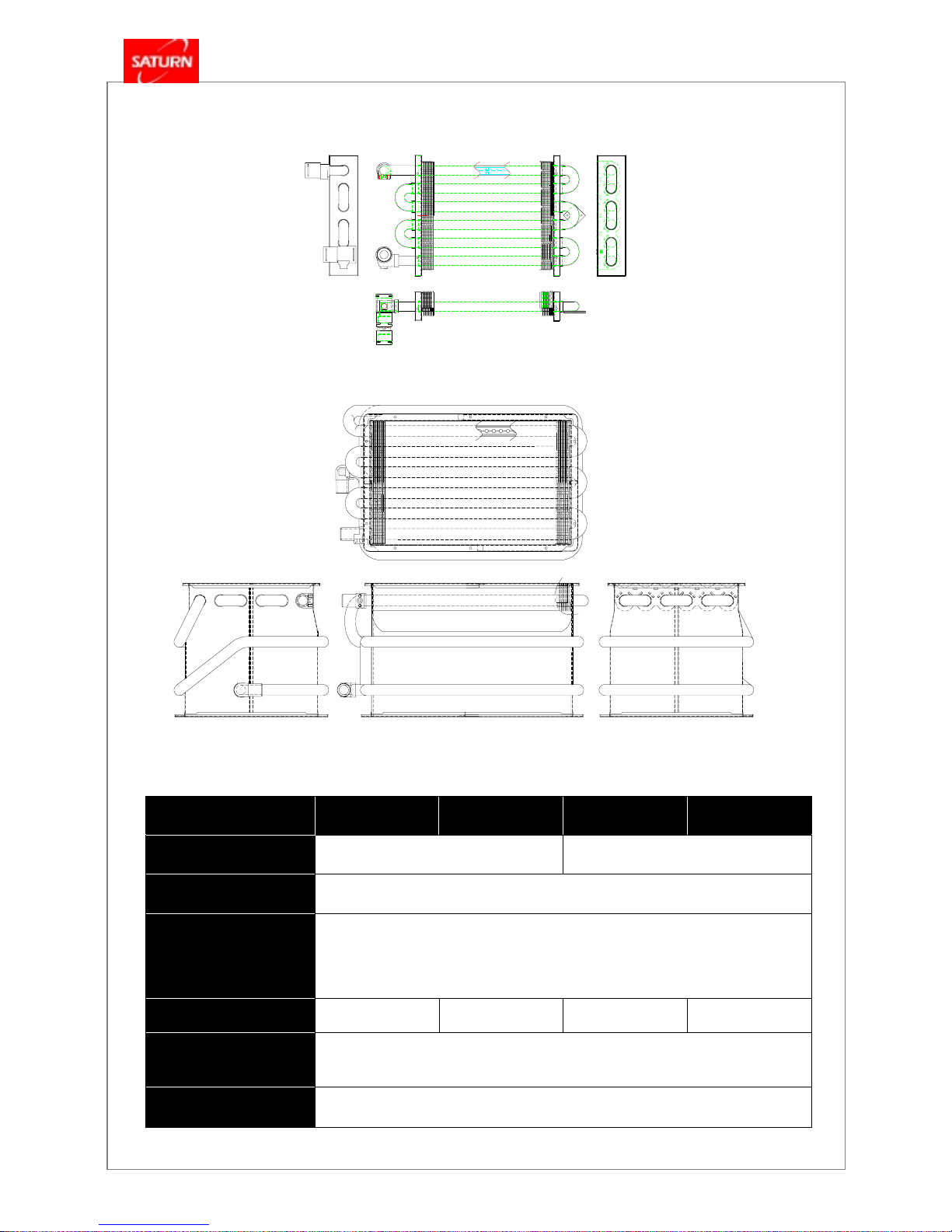

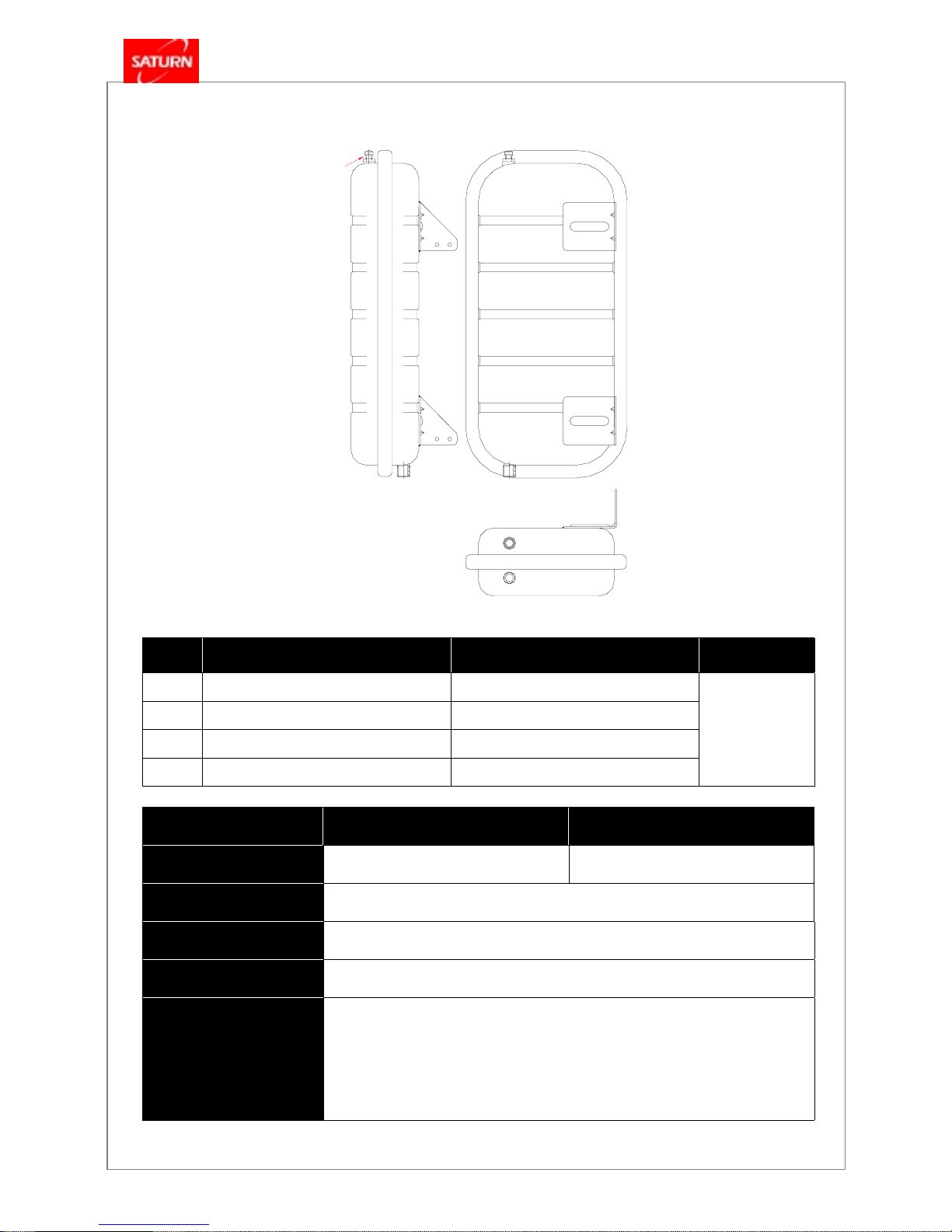

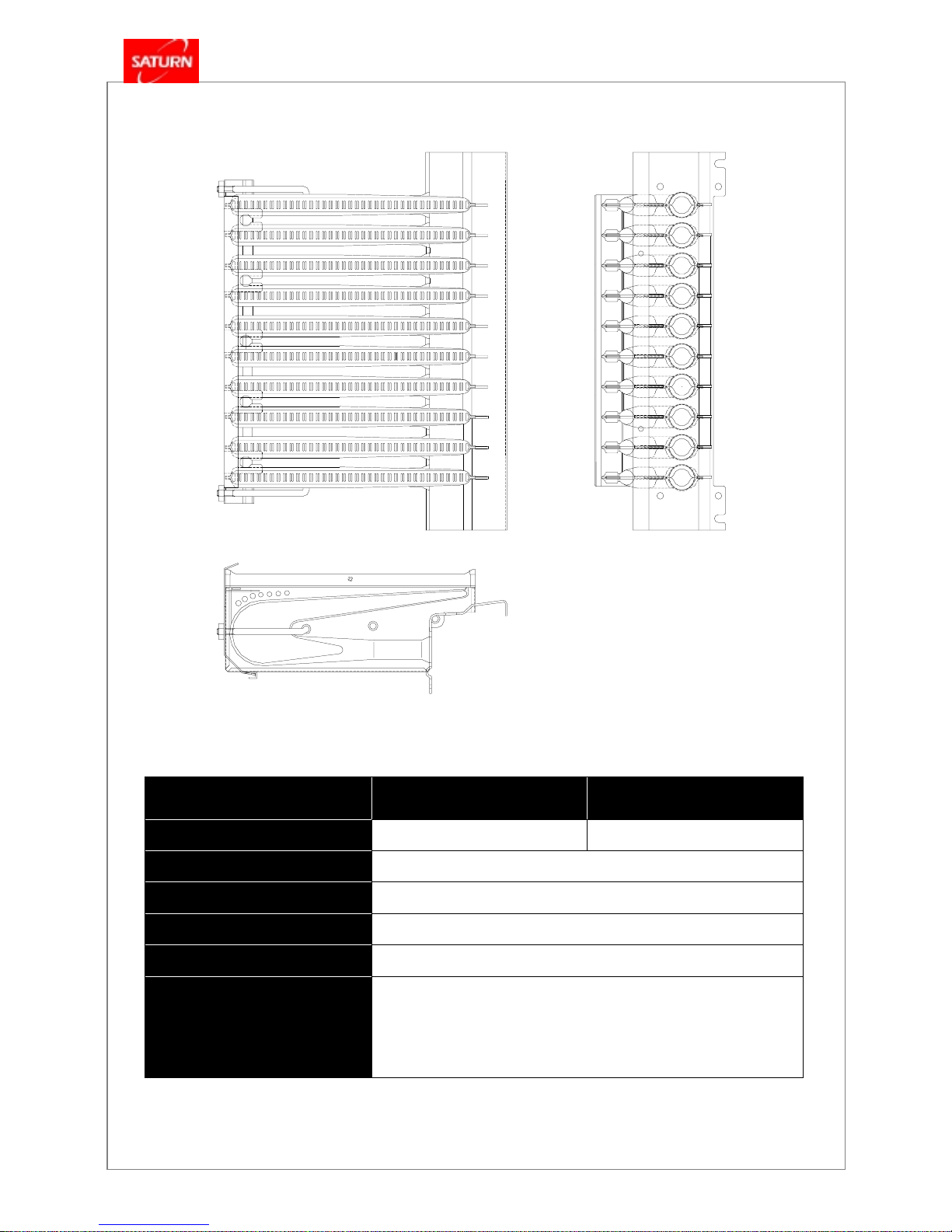

4.1 Main Heat Exchanger

Item

161GOM 201GOM 251GOM 301GOM

Typ e

Single Dry Type Single Wet Type

Structure

Copper Fin+Copper pipe Brazing

Function

- For use of heating and hot water, absorb generated heat from main burner and

then transmit it to heating pipe and hot water heat exchanger.

Number of Heat Fin

72 Fin 80 Fin 106 Fin 112 Fin

Material & Dimension

- Copper Pipe:C1220T-H(φ15.88).

- Heat Fin:C1220P-1/4H(t=0.4)

Heat Exchange Method

Instantaneous Method

KDB – 251 / 301 GOM

KDB – 161/201GOM

KDB-GOM

Series

- 13 -

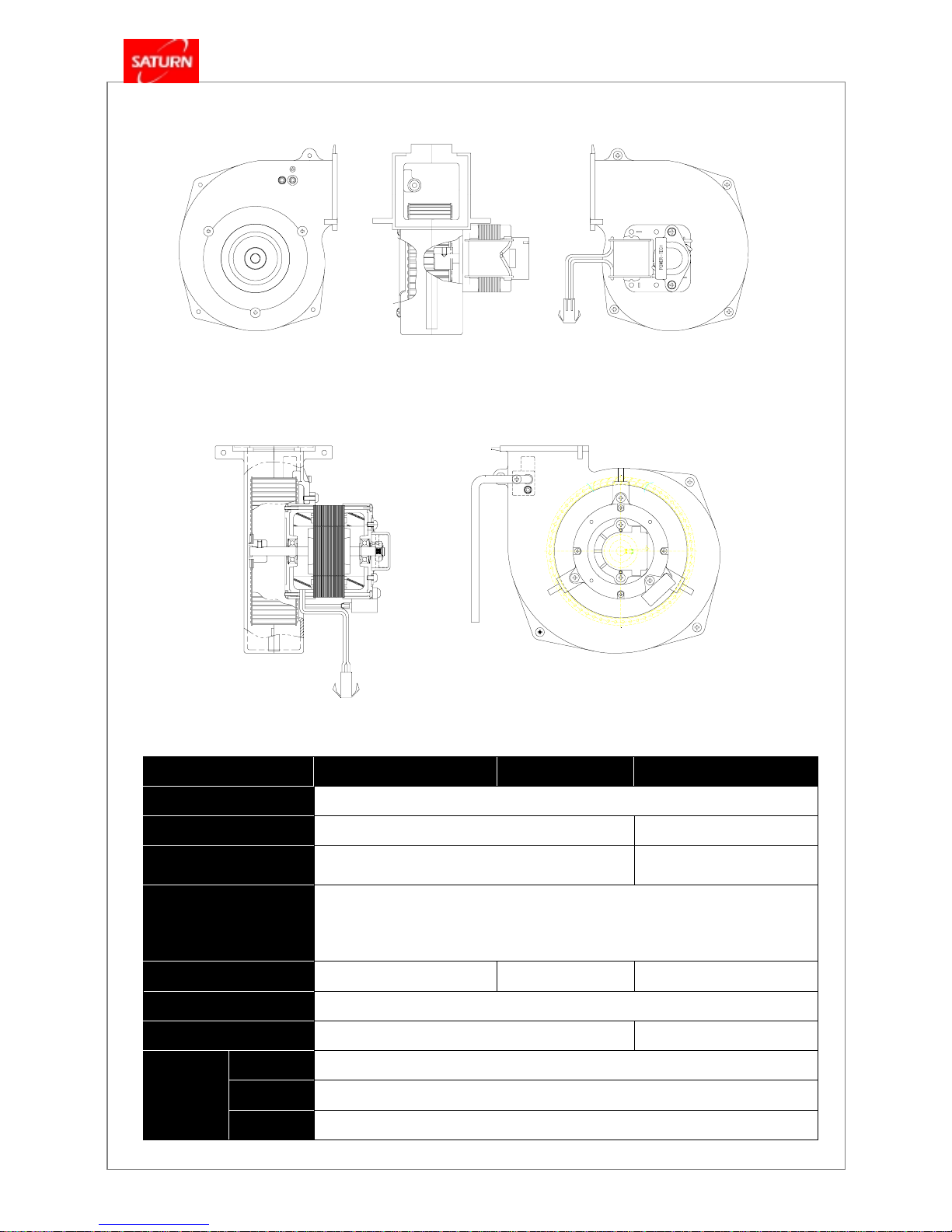

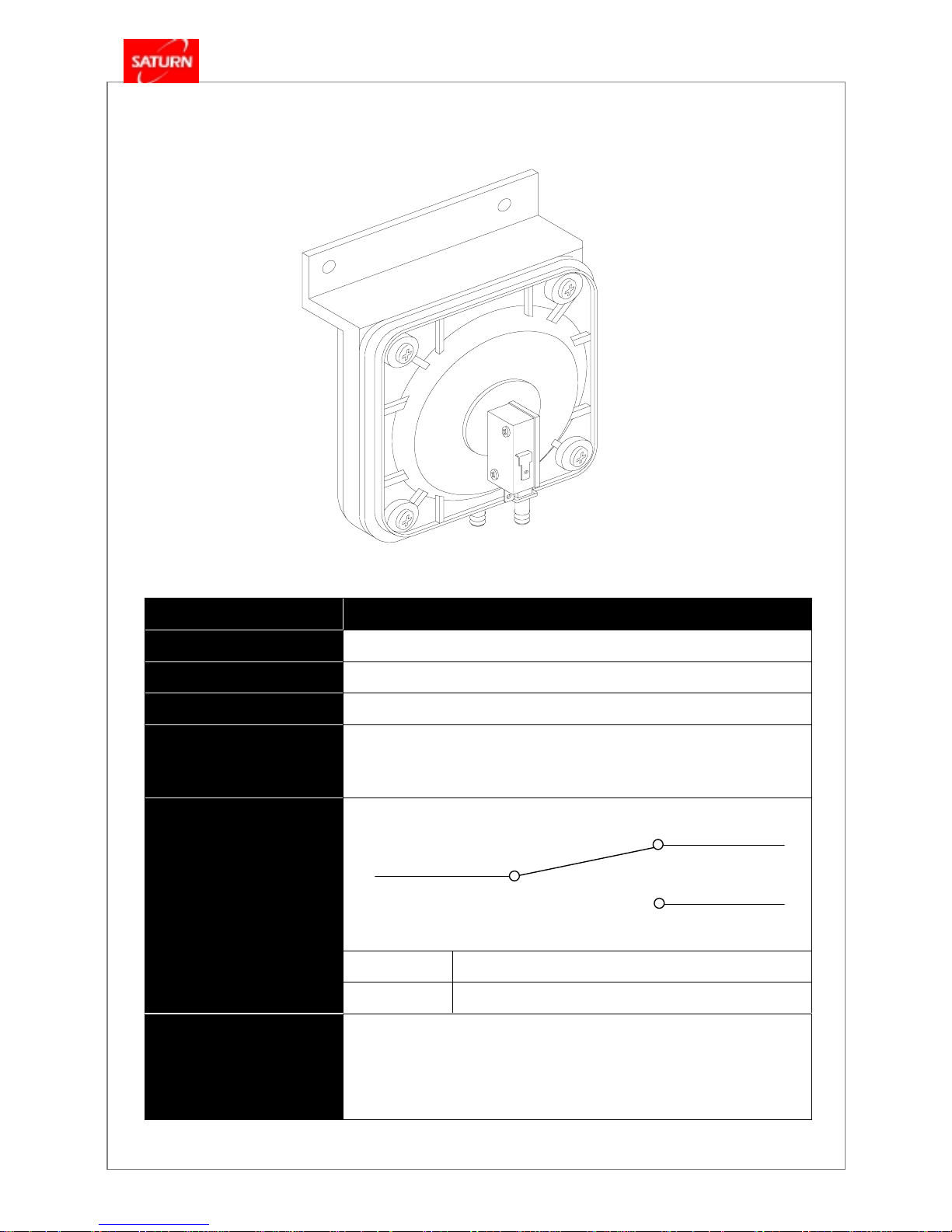

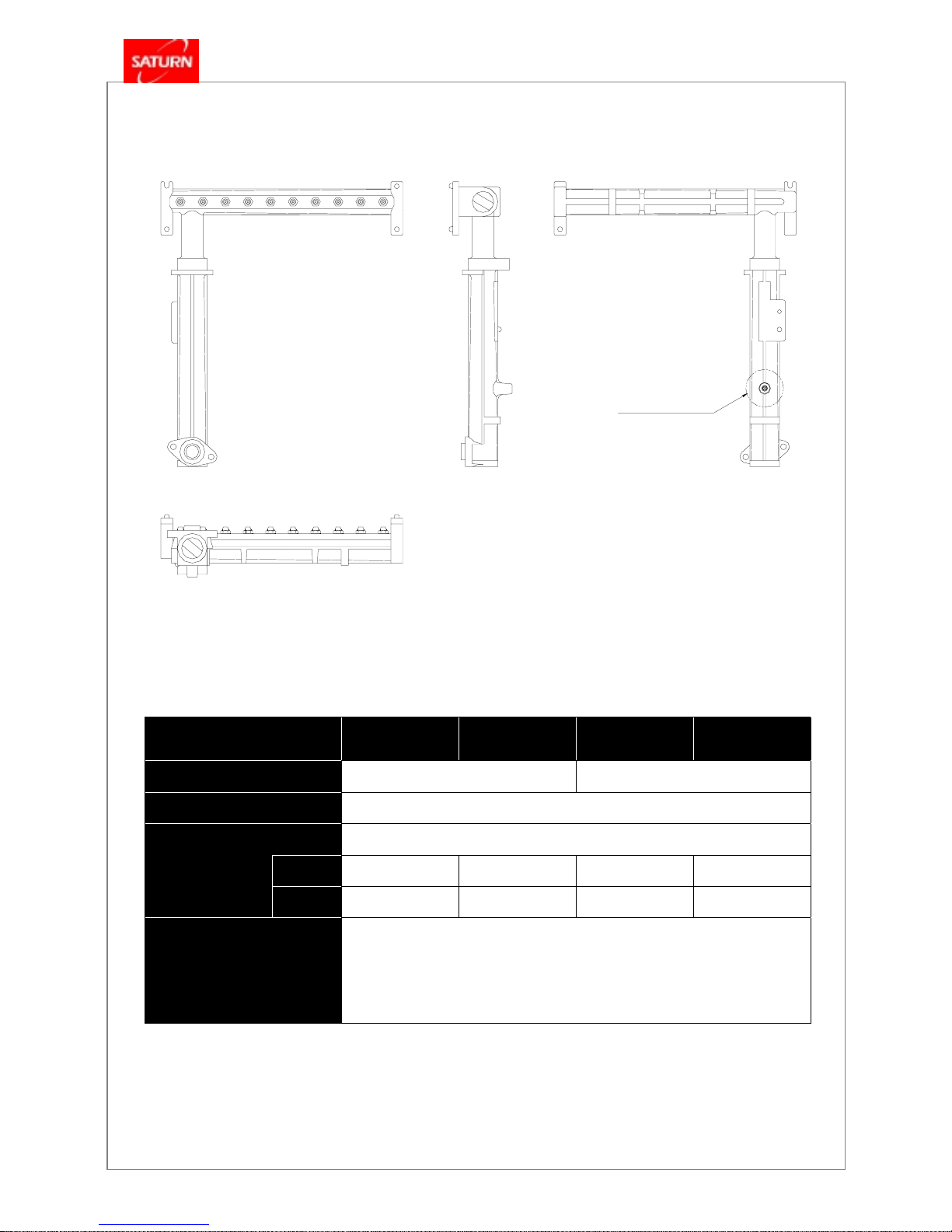

4.2 Fan Assembly

Item

161GOM 201GOM 251/301GOM

Fan Type

Phase Controlled Air Intake Fan

Motor Type

Shading Coil Induction Motor Condenser Induction Motor

Blower Dimension

(mm)

φ

100 X 40L X 45 Fin

φ

134 X 40L X 60 Fin

Function

- Supply air needed for combustion and exhaust the remained gas before and after

combustion in order to prevent explosion in advance.

Bell Mouth(mm)

φ

60

φ

70 -

Rated Voltage

AC 220V, 50Hz

Power Consumption

Max.: 36.4 W, Min.: 14.0 W Max.: 75 W, Min.: 30 W

Casing

ALDC12

Blower

AL 5052

Material

Venture

ALDC12

KDB – 161 / 201GOM

KDB – 251 / 301GOM

KDB-GOM

Series

- 14 -

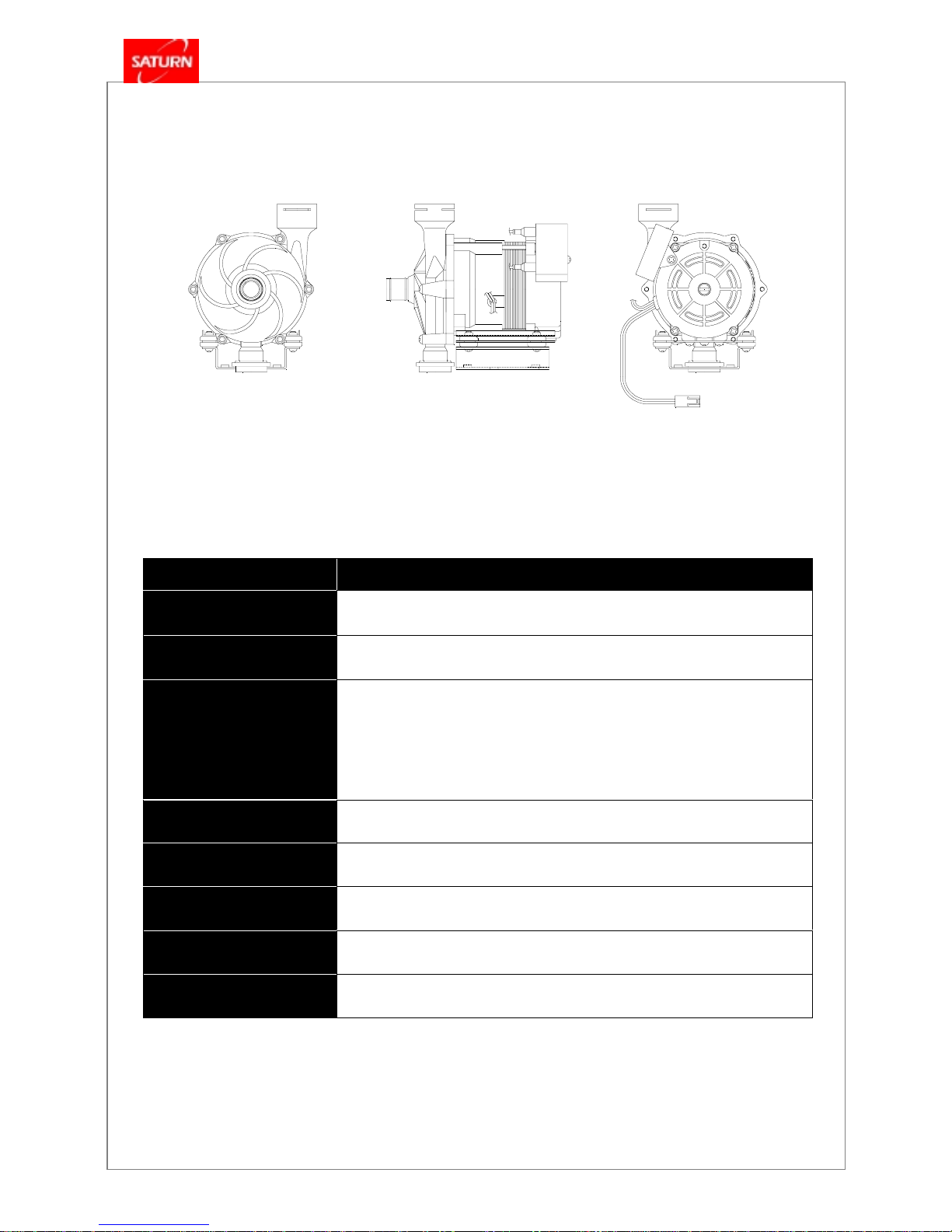

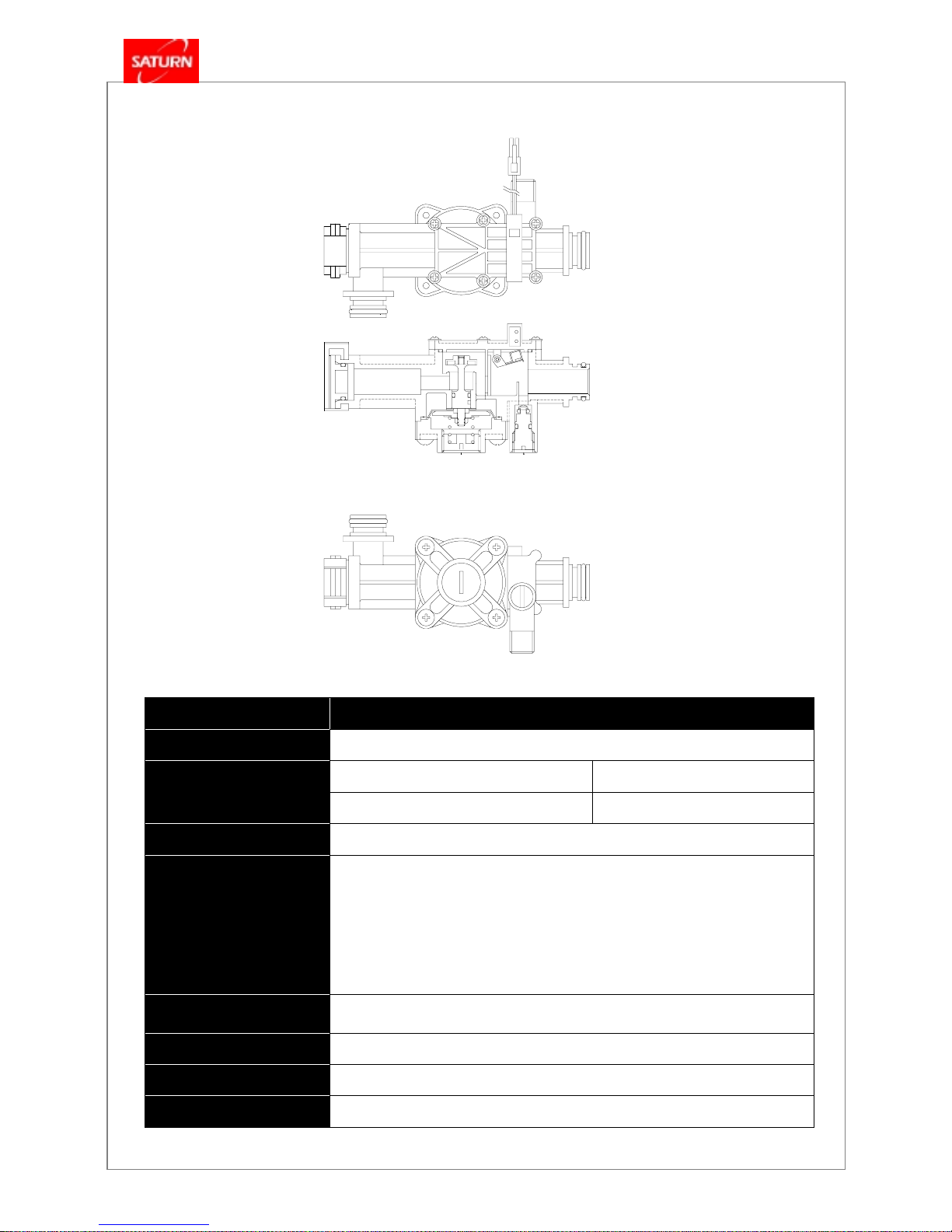

4.3 Circulation Pump

Item

All GOM models

Pump Type

Magnet Type

Motor Type

Single Phase, 2 Pole Induction Motor

Function

- Transmit the absorbed heat from main heat exchanger to heating pipe by

circulating heating water when use heating.

- Transmit the absorbed heat from main heat exchanger to hot water heat

exchanger by circulating heating water inside of boiler when use hot water.

Maximum Pump Head

10M(at 0 gal/ min )

Rated Voltage

AC 220V, 50Hz

Power Consumption

90 W

Condenser Capacity

2.5

㎌

Weight

2.45 kg

KDB-GOM

Series

- 15 -

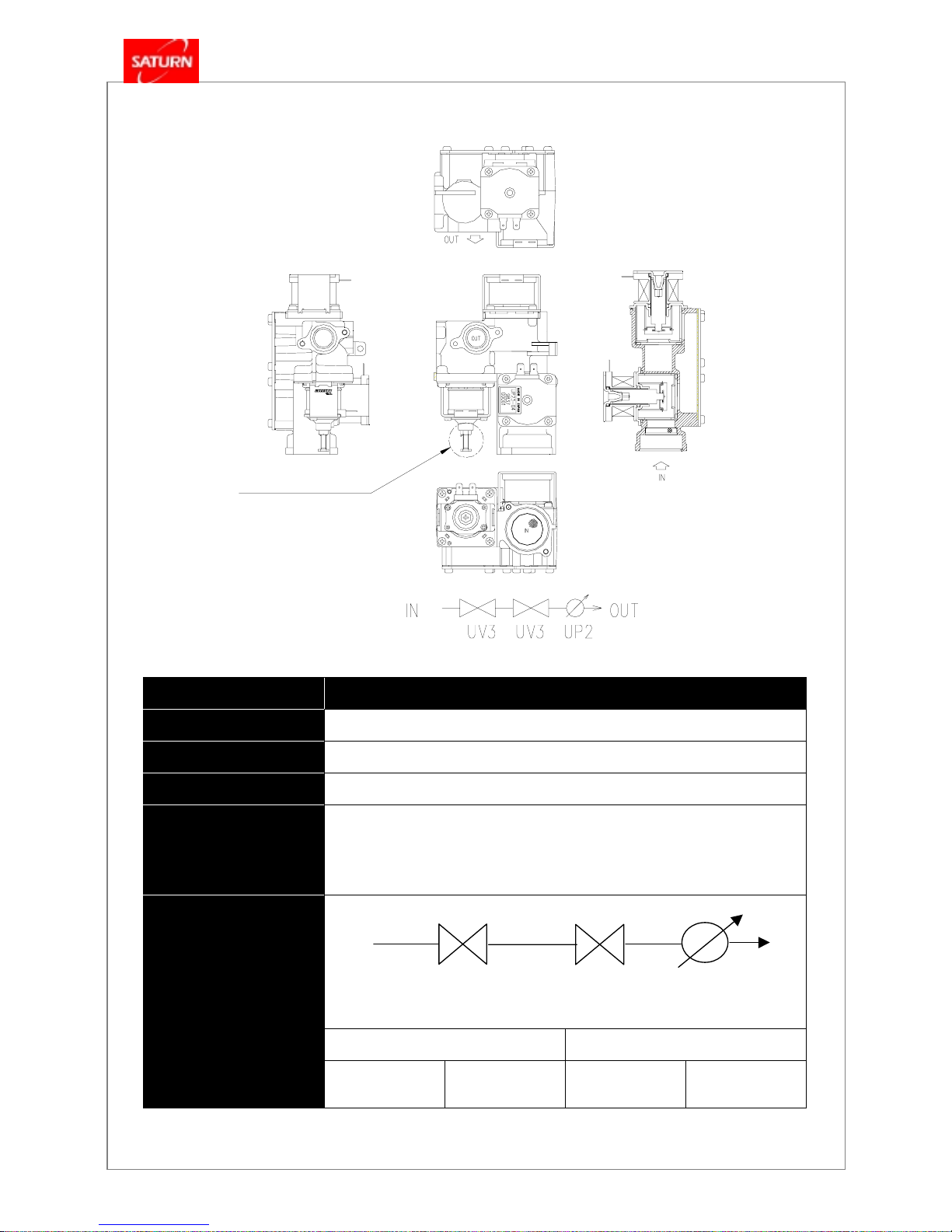

4.4 Modulating Gas Control Valve

Item

All GOM models

Model No.

UP 33 –06 (TIME CO.)

Rated Voltage

AC 220V, 50 / 60Hz

Power Consumption

8 W

Function

y Controls the flow of gas supply by the current value received from main

controller.

y Cut off the gas to prevent danger by the signal of sensor when happen troubles

caused by improper combustion.

Magnet Valve Proportional Valve

Schematic Diagram

SV1

(UV3)

SV2

(UV3)

PV

(UP2)

(SV1)

(SV2)

(PV)

Secondary pressure

Adjust Screw

Gas flow diagram

KDB-GOM

Series

- 16 -

4.5 3-Way Valve

Item

All GOM models

Rated Voltage

AC 220V, 50 / 60Hz

Power Consumption

3 W

Body Material

NYLON 66

Function

- Block the passage of heating water by the flow detection in flow switch and flow

heating water into the hot water heat exchanger when use hot water, and lead to

exchanging the heat of hot water with heating water in the hot water heat

exchanger. (When stop using hot water, the water passage is changed over to

the way of heating pipe automatically.)

Heating → Hot Water 10 ± 2 sec

Operating Time

Hot Water → Heating 10 ± 2 sec

Wire Identification

y RED : Heating, y BLUE : Hot Water y BLACK : Common

Model

Motor Speed

2.5 ~ 3 RPM

Direction of Motor

Rotation

CCW

KDB-GOM

Series

- 17 -

4.6 Expansion Tank

NO. Part Name Material Remarks

1 Body SBHG1 , 2.0t

2 Bracket SBHG1 , 2.0t

3 Diaphragm BUTYL , 2.0t

4 Nipple S10C , PF3/8”

Item KDB – 161 / 201GOM KDB – 251 / 301GOM

Vol um e

6.5 Liter 8.5 Liter

Body Material

SBHG 1

Charging Gas

Nitrogen

Charging Pressure

1.0 kg/cm2 (14.2 psig)

Function

y Vent the generated air in the heating pipe.

y Absorbs pressure generated in the pipe by the expansion of heating water due to

increasing temperature of heating water.

y Maintain the water volume in the boiler at a constant by low water level sensor.

Nitrogen gas

Charging point

KDB-GOM

Series

- 18 -

4.7 Air Pressure Switch

Item All GOM Model

Electric Rating

0.1A –125V AC, 0.1A –30V DC (Micro Switch)

Typ e

Differential Pressure Type (Vertical Type), Normal Close Type

Body Material

Nylon 66 (GF 30%)

Function

- Stop the combustion safely and automatically by monitoring the high pressure

or the adverse wind in the flue.

Contact Arrangement

ON more than 2.0 mmH2O

ON / OFF Operating

Pressure

OFF 7.0 ± 2 mmH

2

O

Reference

- Normal Close Type : The contact is always connected, and if the wind

pressure switch is operated by adverse pressure, this contact is opened and

stop the combustion in the boiler.

P3 (COM)

P1 (NC)

P2 (NO)

KDB-GOM

Series

- 19 -

4.8 Hot Water Flow Switch

Item All GOM models

Body Material

Nylon 66 (GF 30%)

ON 2.3 ± 0.3 liter / min

Operating Flow

OFF 1.5 ± 0.5 liter / min

Installation Type

Horizontal Installation

Function

- When use hot water, detect the flow of hot water and transmit the signal to

controller, and operate 3-way valve to usable hot water.

- Reduce the pressure of discharging hot water in case of high water pressure

area (water supply pressure : more than 1.5 kgf/㎠) and maintain the optimum

condition of hot water use through flow limited by reduced pressure.

Reducing Pressure

Capability

P1 : 0.3 ~ 10 kgf/

㎠

→ P2 : 0.3

~

3.0 kgf/

㎠

Contact Rating

10 VA (W)

Maximum Contact Current

AC, DC 0.5A

Contact Resistance

less than 300 m

Ω

수동물보충

KDB-GOM

Series

- 20 -

4.9 High Limit Sensor (Bimetal Type)

Function

- When the bimetal plate in the high limit sensor detects the increase in the

heating water temperature or in causing surface temperature, it is

transformed to move the shaft and to let the contact “OFF”

- The “OFF” signal from the high limit sensor is sent to the controllers so that

the check lamp on the room thermostat comes “ON” and the failure code

NO. 16 is displayed on the temperature indication. When the running is

resumed, only the check lamp is kept “ON”.

- In case of reduced discharge of combustion exhaust or overheat of heat

exchangers, the high limit sensor automatically cut off the gas control valve to

close it when the send the sensed the temperature of the heat exchanger

reaches 95 ℃ or higher. The check lamp on the room thermostat is lit and

failure code NO. 1 is indicated on the indication panel.

Model MS-1, Manual Reset

Type Bimetal Type

Operating Temp. 95

℃

Structure

Recovery Temp.

80

℃

Voltage Rating 125 ~ 250 V

Electric Rating

Current Rating 15 A

[Automatic, MS-1]

KDB-GOM

Series

- 21 -

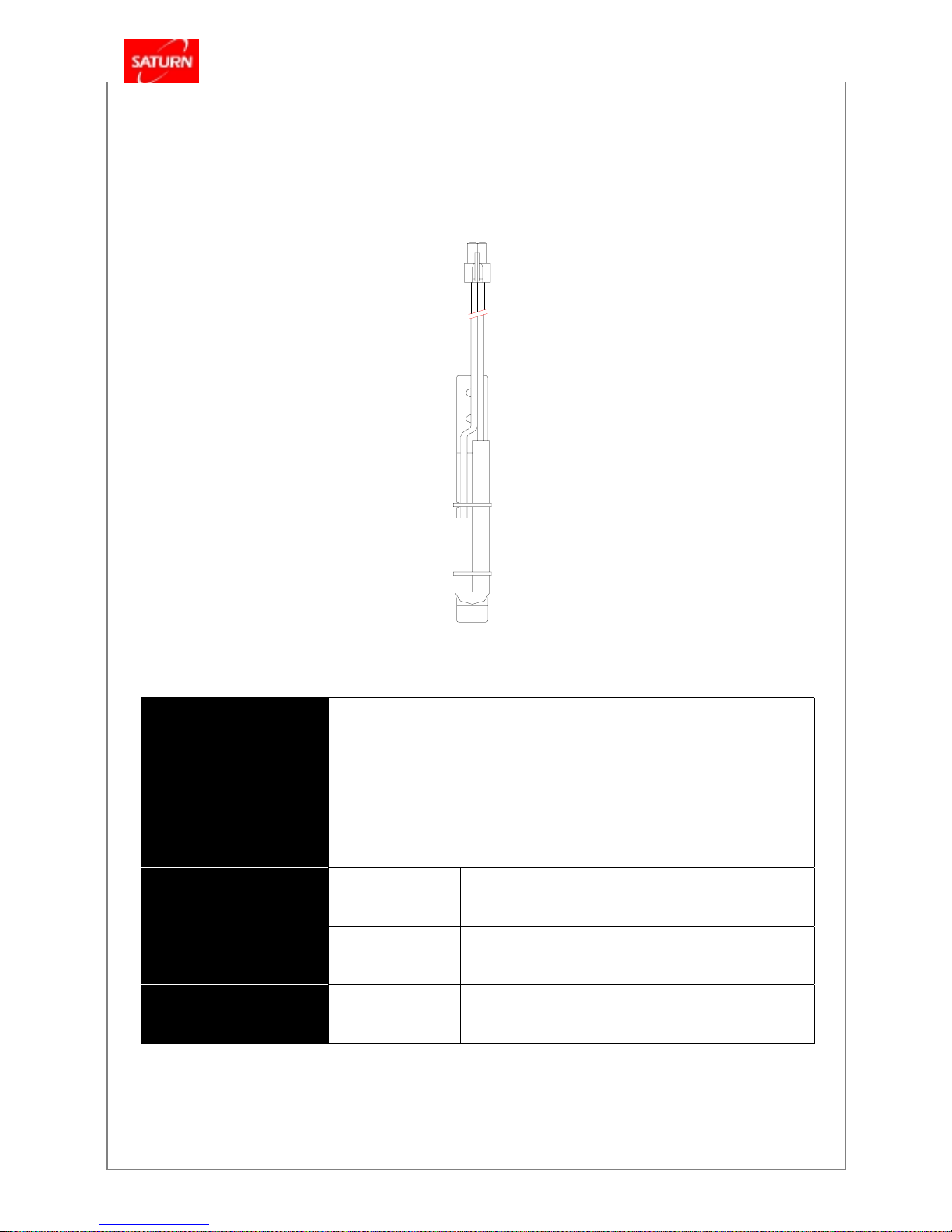

4.10 High Limit Fuse (Fuse Type)

Function

- In case of abnormal overheat of heat exchanger, the temperature of sensor

part will be more than 195 ℃, high limit fuse will cut off the power of

modulating gas control valve to close the modulating gas control valve and

secure the safety.

- Check lamp will on in the room thermostat and failure code # 03 will be

indicated.

Type Fuse Type

Structure

Operation Temp. OFF point: 195

℃

Electric Rating

Resistance

61.1 Ω at 20

℃

KDB-GOM

Series

- 22 -

4.11 Heating Temperature Sensor

Item All GOM models

Model No.

DKS - 902ET - 330C

Resistance

R50 = 3.485 ㏀ ± 3%

B Constant

R0 / R100 = 3449 K ± 1%

Thermal Radiation Constant

0.7

mW /

℃

Thermal Time Constant

Within 10 seconds

Function

- Detect the temperature of heating water and transmit the signal

to main controller. The main controller controls the flow of air /

gas needed for achieving and maintaining the setting

temperature.

KDB-GOM

Series

- 23 -

4.12 Ignition Transformer

Function

- Electric energy provides high voltage and current to the main burner for

ignition of gas.

Primary Rating AC 220 V , 50 / 60 Hz

Secondary Rating 19 kVo-p±2

Power Requirement

Secondary Current

7 mA±2

Casing Non-Combustible ABS

Structure

Cable Silicon

KDB-GOM

Series

- 24 -

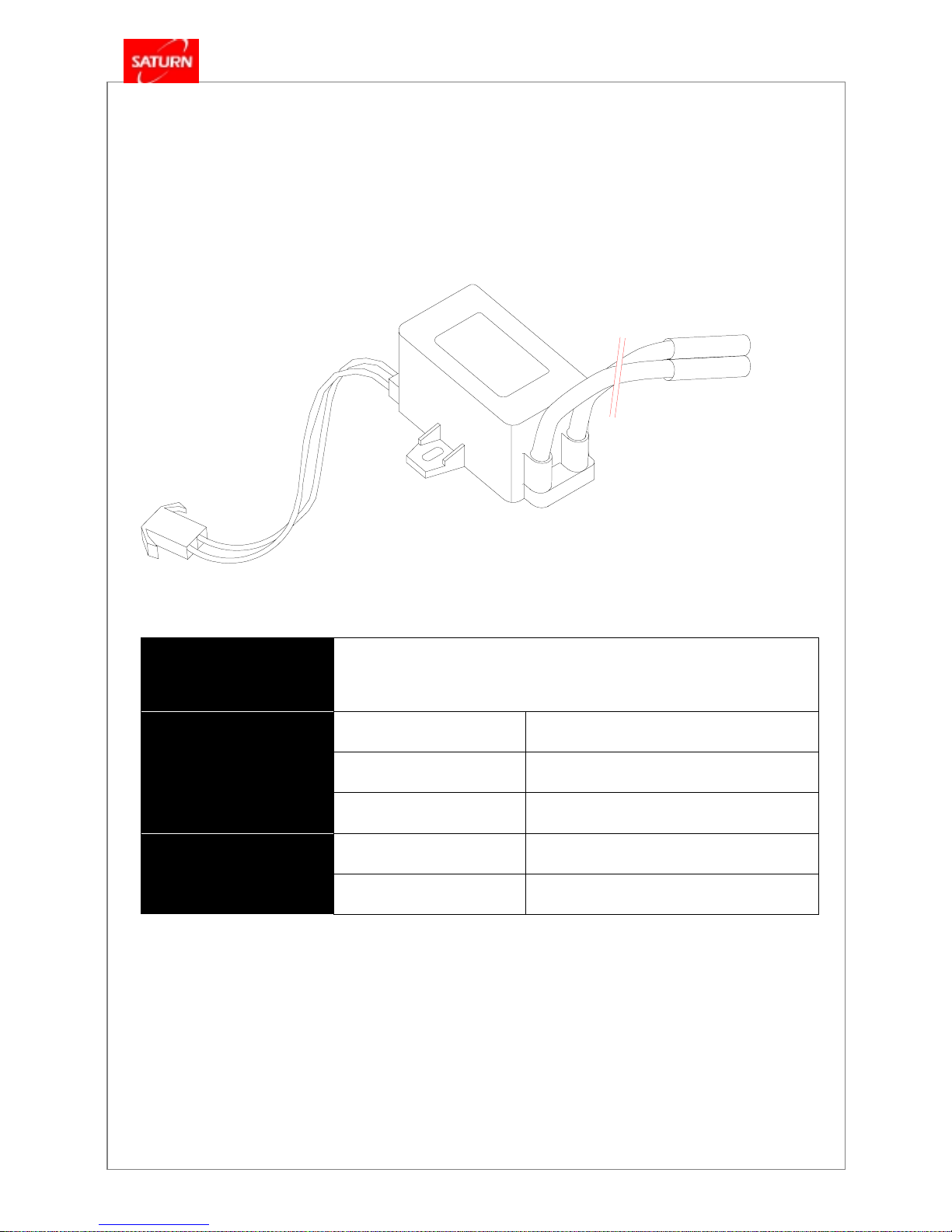

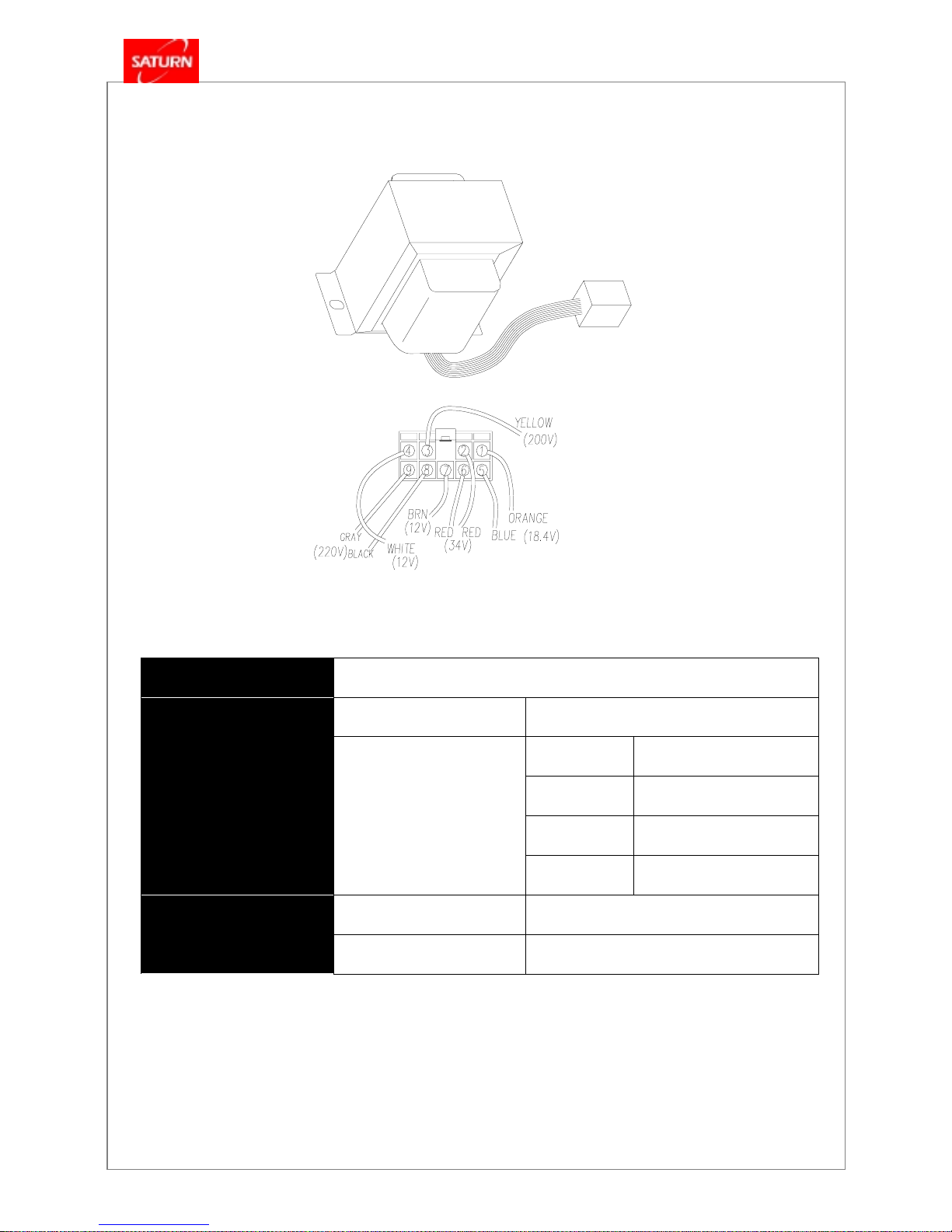

4.13 Power Transformer

Function

- Supply the power source to boiler.

Input Rating AC 220 V , 50 / 60 Hz

AC 220 V # 8-BLACK, # 9-GRY

AC 34.0 V # 2-RED, # 6-RED

AC 18.4 V # 1-ORANGE, # 5-BLUE

Power Requirement

Output Rating

AC 12.0 V # 4-WHITE, # 7-BROWN

Casing Non-Combustible ABS

Structure

Cable Silicon

KDB-GOM

Series

- 25 -

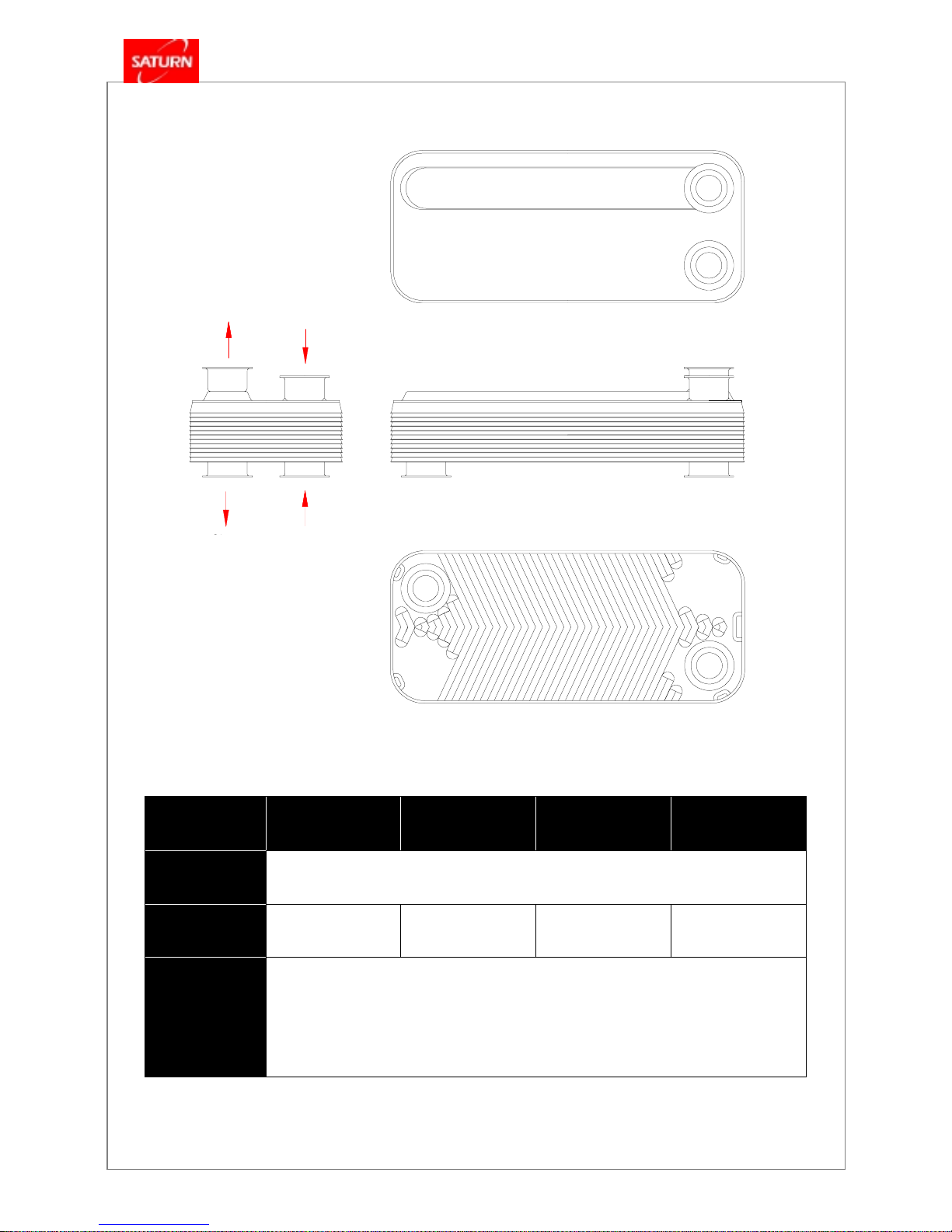

4.14 Domestic Hot Water Heat Exchanger

Item

161GOM 201GOM 251GOM 301GOM

Material

STS 304

Capacity

10 Pieces 12 Pieces 16 Pieces 18 Pieces

Function

- When use hot water, supply the heating water heated in main heat exchanger to hot water

heat exchanger and heat-exchange water (water supply) with heating water supplied in

hot water heat exchanger to be usable hot water.

Domestic Water

Outlet

Heating

Supply

Tap Water

Inlet

Heating

Return

KDB-GOM

Series

- 26 -

4.15 Burner Assembly

Item

161 / 201GOM 251 / 301GOM

Quantity of Secondary Nozzle

10 EA 15 EA

Material of Secondary Nozzle

ALSTAR

Slit (Flame Holder) Material

STS 430

Front Bracket

SBHG 1

Rear Bracket

STS 430

Function

- Supply heat sources by mixing and combusting the supplied gas and

air.

KDB-GOM

Series

- 27 -

4.16 Nozzle Holder Assembly

Item

161GOM 201GOM 251GOM 301GOM

Quantity of Primary Nozzle

10 EA 15 EA

Material of Primary Nozzle

C3602 BD

Material of Nozzle Holder

A6063S

LNG

φ

1.33

φ

1.46

φ

1.37

φ

1.50

Diameter of

Nozzle(mm)

LPG

φ

0.92

φ

1.06

φ

0.95

φ

1.06

Function

- Supply gas needed for combustion according to demands.

Secondary

gas pressure

measuring hole

KDB-GOM

Series

- 28 -

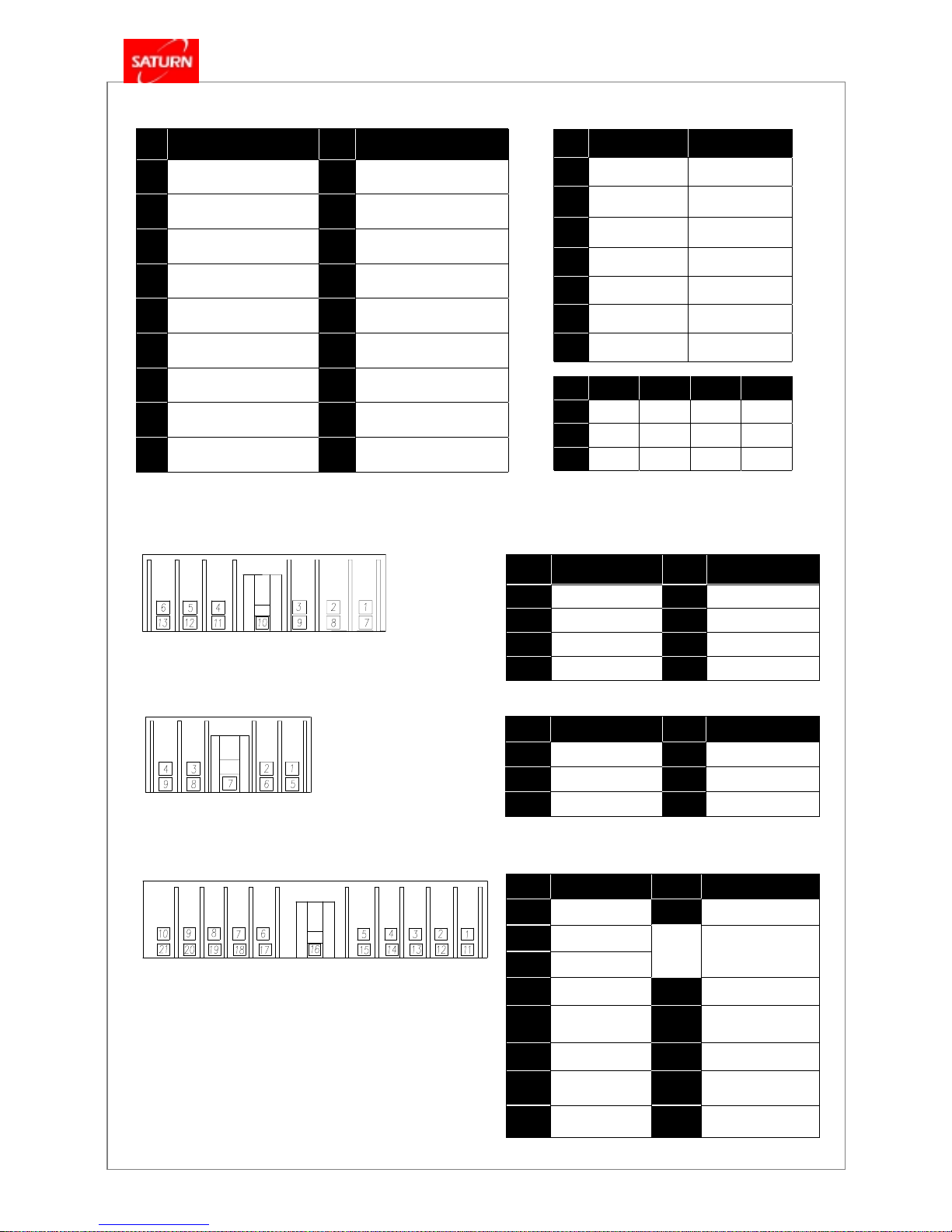

4

.17 Wiring Diagram

4

NO Function NO Function

1, 3

Gas Valve 1

7, 12

Ignition Transformer

2, 3

Gas Valve 2

8, 12

3-Way Hot Water

4, 11

AC 220V

9,13

3-Way Heating

5, 6

Circulation Pump

10

Ground

NO Function NO Function

1, 11

Water Filling

9, 20

Room Thermostat

2, 12

Fan

3, 13

Control Voltage

4

RPM Power Sourc e

14

RPM Input

5, 15

Heating Temp.

Sensor

15

RPM Ground

6 16

Flame Detector

7, 20

Air Pressure

Switch

17

Heating Flow Sensor

8, 20

Hot Water

Flow Switch

18, 19

Overheat

NO Function NO Function

1,5

AC 20V

4,7

AC 12V

2,6

AC 40V

8,9

AC 220V

3

AC 200V

4.17.3.3 21 Pin Wiring Connecting Diagram

4.17.3.2 9 Pin Wiring Connecting Diagram

4.17.3.1 13 Pin Wiring Connecting Diagram

4.17.3 Wiring Connecting Diagram

4.17.1 Fault repair codes (room thermostat, FR-5)

NO ON OFF

1

Trial Run Normal

2

Forced Max.

Combustion

Normal

3

Forced Min.

Combustion

Normal

4

FE FF

5

L.P. Gas Natural Gas

6

Close-Air Type Open Tank System

7

50 Hz 60 Hz

NO

161GOM 201GOM 251GOM 301GOM

8

OFF OFF ON OFF

9

ON ON OFF OFF

10

ON OFF ON ON

4.17.2 DIP S/W Setting on Main Controller

FND

No.

Problems FND

No.

Problems

01

Overheat

10

Air pressure failure

02

Low water level

11

Water level detection failure

03

Ignition failure

12

Flame failure in combustion

04

Flame sensor

(Lower gas pressure)

13

Heating water switch failure

05

Heating sensor wire

disconnected

14

Gas alarm(optional)

06

Short circuit of

heating sensor

15

MICOM failure

07

Hot water sensor wire

disconnected

16

Mechanical overheat

08

Short circuit of

hot water sensor

17

DIP switch setting error

09

Fan R.P.M. failure

18

KDB-GOM

Series

- 29 -

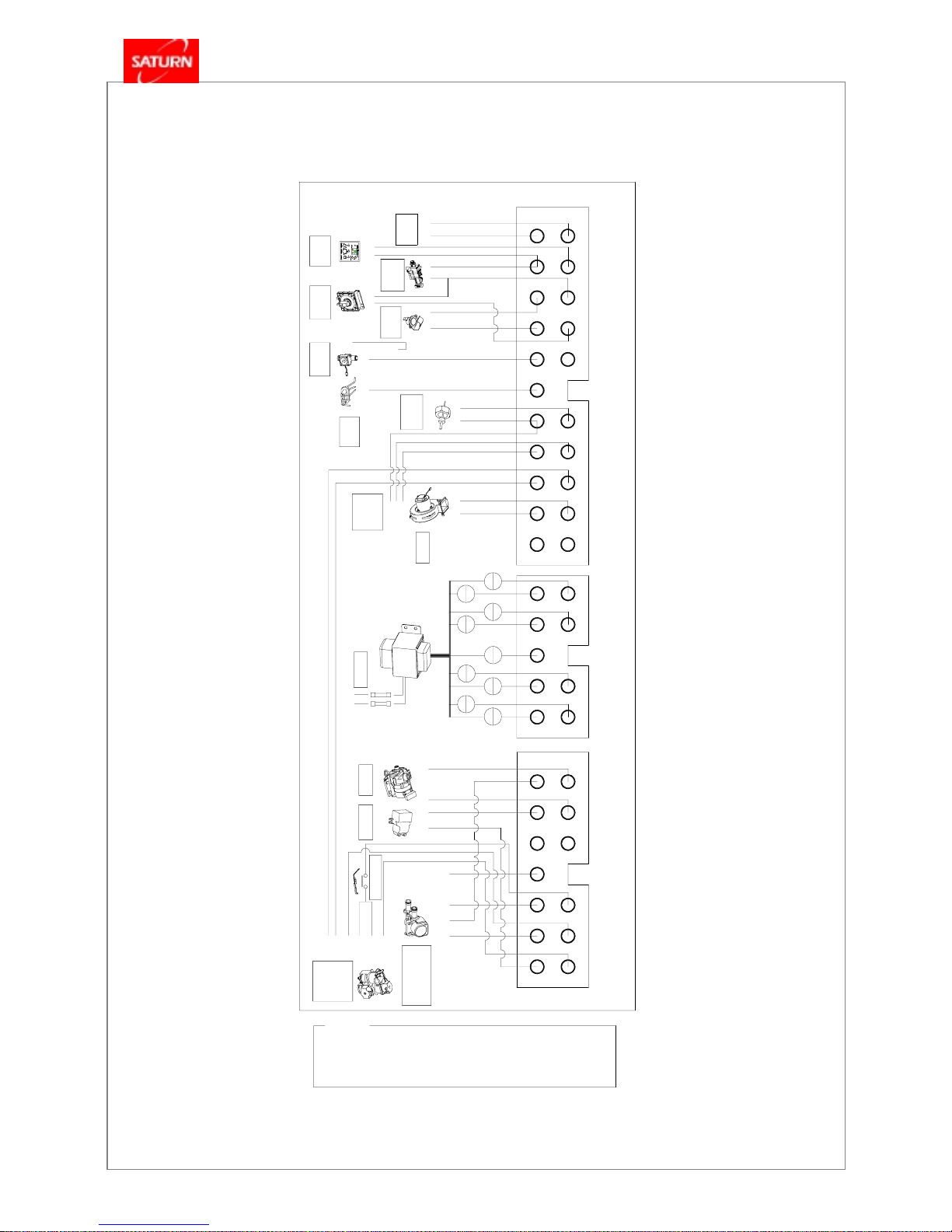

4.17.3 Wiring Diagram

WHT : WHITE

ORG : ORANGE

AC34V

AC220V

AC18.4V

IGNITION TRANS

LEGEND

GRY : GRAY

RED : RED

BLK : BLACK

BLK

2)BRN: Secondary valve

2)BLK: Currency

.

.

Modulation

YEL : YELLOW

BLU : BLUE

1)BLU : Primary valve

TIME UP 33-06

GAS VALVE

BLU

BLK

EV 1

BLU

BLU

RED

.

.

BRN

BRN

EV 2

HIGH LIMIT FUSE

2)BLK,BLU : HOT WATER

1)BLK,RED : HEATING WATER

THREE WAY VALVE

.

.

GRN

RED BLK

BLU

EARTH

AIR PRESSURE

: DC 5V : DC 5V

SWITCH

INPUT SIGNAL

HEATING FLOW

SWITCH

INPUT SIGNAL

: DC 20V

THERMOSTAT

INPUT SIGNAL

ROOM

: DC 5V

HOT WATER

FLOW SWITCH

INPUT SIGNAL

WHT

RED

SUPPLY POWER

BLK

WHT

FUSE , 3A - 2EA

PUMP

POWER TRANSFORMER

1)WHT : AC 5V

BLK

BLK

INPUT SIGNAL

: AC 200V

3)BLK : Ground

2)RED : DC 12V

FLAME

DETECTOR

EARTH

SUPERVISION

FAN ROTATION

BLK

RED

BLK

: DC 20V

YELYEL

GRN

PREVENTION

INPUT SIGNAL

OVERHEAT

SKYSKY

BLUBLU

ORG

BLK

RED

GRY

AC220V

: DC 5V

TEMPERATURE

HEATING WATER

INPUT SIGNAL

WHT

FAN

RED

RED

BLK

BLU

RED

RED

BLU

: DC 5 - 20V

68

F

50

176

3

86

99 4

F

2

Hrs

1

0

140

104

ORGORG

ALARM WIRE

INPUT SIGNAL

GAS LEAKAGE

BLK

BLK

RED

( - )

(+)

[13 PIN]

.

.

1

2

3

4

GRN : GREEN

BRN : BROWN

9

7

8

10

11

[9 PIN]

[21 PIN]

20

BLU

AC18.4V

RED

BRN

YEL

WHT

AC34V

AC12V

AC200V

AC12V

5

6

1

2

3

4

12

13

5

8

6

7

9

1

2

3

4

6

7

8

5

13

11

12

14

15

17

16

18

19

9

10

21

KDB-GOM SERIES WIRING DIAGRAM

AC220V, 50/60Hz

220VAC 50Hz

AC220V, 50Hz

AC220V, 50Hz

AC 220V, 50/60Hz

AC 220V, 50/60Hz

Operating Temp. : 156

°

C

KDB-GOM

Series

- 30 -

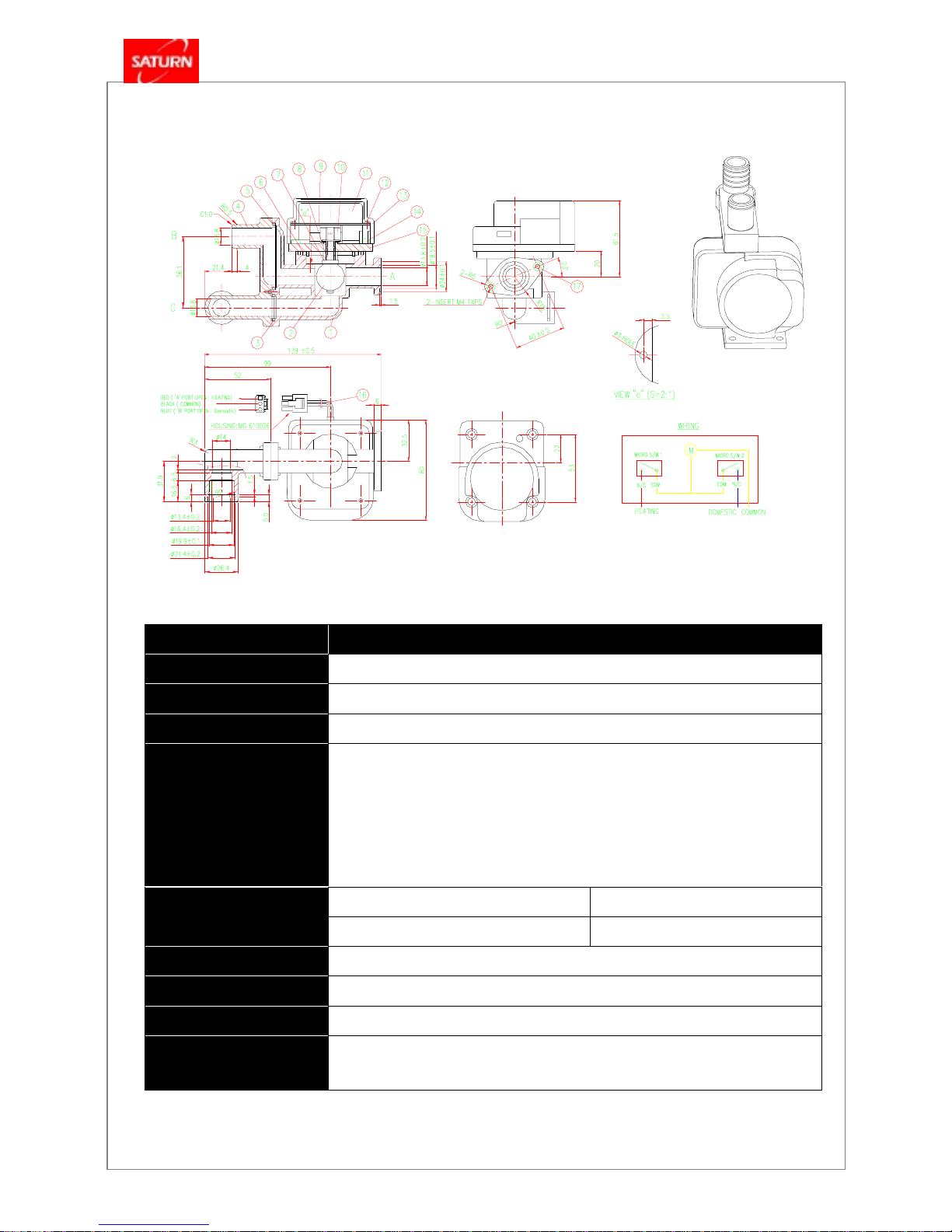

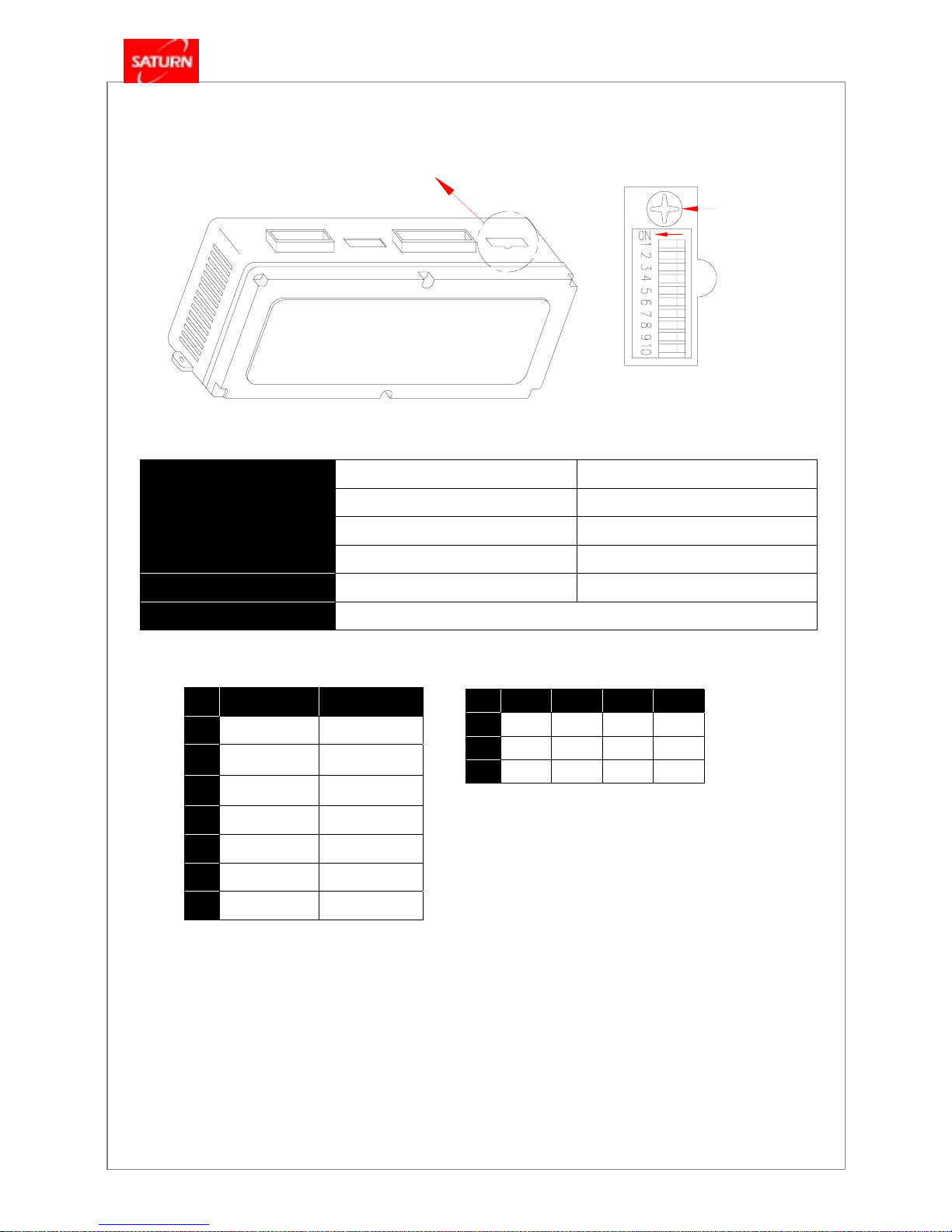

4.18 Main Controller

Voltage , Frequency AC 220V , 50 / 60 Hz

Voltage Range +10% to –15%

Ambient Temp. -15℃ to 70

℃

Electric Spec.

Ambient Humidity 45 – 90 %

Structure

Casing ABS

Model

KDC – 208-1M

4.18.1 DIP switch setting on main controller

4.18.2 Functions of Main Controllers

4.18.2.1 Pre-Purge

When the boiler operates, the function is to operate blower (fan) first and exhaust the remained air in the combustion

chamber before combustion starts, in order to prevent from immoderate ignition. Pre-Purge time is by achieving the fan’s

light-up RPM ± 200 rpm with more time than 4 ± 1 seconds.

4.18.2.2 Pre-Ignition

After Pre-Purge, the function is to operate ignition transformer previously in order to light up easily before supplying the

fuel (gas) for combustion. Pre-Ignition time is from ON time of ignition transformer till ON time of fuel supply device (gas

valve 2).

DIP Switch adjust part

Max. adjust screw

for secondary gas

pressure

NO ON OFF

1

Trial Run Normal

2

Forced Max.

Combustion

Normal

3

Forced Min.

Combustion

Normal

4

FE FF

5

L.P. Gas Natural Gas

6

Close-Air Type Open Tank System

7

50 Hz 60 Hz

NO

161GOM 201GOM 251GOM 301GOM

8

OFF OFF ON OFF

9

ON ON OFF OFF

10

ON OFF ON ON

KDB-GOM

Series

- 31 -

1 ± 1 second

4.18.2.3 Post- Ignition

The function is to keeps operation of ignition transformer until flame detector monitors and combustion flame is stable

after fuel supplied and ignited. Post-Ignition time is from the time of fuel supply till OFF time of ignition transformer.

4 ± 2 seconds

4.18.2.4 Post-Purge

The function is to exhaust the remained gas of combustion after flame extinguished when boiler stops. Post-Purge time is

from OFF time of fuel supply device till OFF time of fan.

Blower : 20 ± 2 seconds / Pump : 60 ± 6 seconds

4.18.2.5 Safety Shut-Off (No Light-Up)

The function is to stops fuel supply for safety when the flame signal isn’t detected even though boiler’s blower is operated,

and Pre-Purge, Pre-Ignition done and fuel supplied. Safety shut-off time is from ON time of fuel supply device till OFF time

of fuel supply. At that time, ignition transformer is also OFF.

3 ± 1 seconds

4.18.2.6 Boiler Stopping by Safety Shut-Off

If fuel supply and ignition transformer is OFF by the function of safety shut-off, the restarting operation

repeats (operation of Pre-Purge, Pre-Ignition, Fuel supply, Flame detection, etc by a series of control sequence) and

counts their cycle. If the number of safety shut-off is 3 times in series, transmits ignition trouble signal to the temperature

controller and fan is OFF after Post–Purge done. (Only if water temperature in the pipe is more than 80 ± 2.0

℃

, fan and

pump operate.)

4.18.2.7 Misfire (Flame Extinction or No Flame Detection) During Combustion

When misfire is monitored during combustion, stops fuel supply and performs the ignition operation by re-starting function

(Pre-Purge, Pre-Ignition, Fuel supply, Flame detection, etc by a series of control sequence) and counts their cycle. If the

number of fire loss is 10 times, fuel supply device is OFF and transmits the misfire signal to temperature controller, and

then fan is OFF after Post-Purge done. (Only if water temperature in the pipe is more than 80 ± 2.0

℃

, fan and pump

operate.)

4.18.2.8 Flame Detection during Pre-Purge (The Early Pseudo Flame)

When monitored flame signal during Pre-Purge time, stops to be progress even though Pre-Purge done, and transmits

the pseudo flame signal to temperature controller after checking continuously for 3 ± 1 seconds. Post-Purge performs in

series, and release automatically when pseudo flame is disappeared and then is returned the function as before. (Only if

circulation pump operate continuously until release the pseudo flame.)

4.18.2.9 Combustion Stop / Flame Detection during Standby (The Last Pseudo Flame)

When extinguishes by stopping fuel supply and performs Post-Purge, transmits the pseudo flame signal to the

temperature controller if flame isn’t extinguish actually or the flame signal is monitored during waiting combustion and isn’t

disappear within 3 ± 1 seconds. Post-Purge performs in series, and release automatically when pseudo flame is

disappeared and then is returned the function as before. (Only if circulation pump operate continuously until release the

pseudo flame.)

4.18.2.10 Low Water Level, Normal Water Level

When the power of boiler is ON, monitors always water level from low water level and normal water level sensor. If

monitors low water level that water is not enough in the boiler, the boiler stops running. Auto water filling valve is ON and

filling a boiler with water after pump is OFF, and transmits low water level signal to the temperature controller. (If the boiler

is filled with water by normal water level, the signal is released automatically and returned the status as before.) Closed air

type boiler doesn’t use normal level sensor and the heating water flow switch is attached on the low water level sensor. If

pump operates and heating water flow switch is ON within 6 ± 1 seconds, consider normal water level, and if heating

water flow switch is not ON, transmit abnormal status signal to temperature controller and pump is OFF and then

maintain this condition until restarting. (Only if water temperature in the pipe is more than 80 ± 2.0

℃

, fan operate.)

KDB-GOM

Series

- 32 -

4.18.2.11 Water Level Sensor Trouble (Opened Air Type)

If monitors water level that there are water at the normal water level sensor and no water at the low water level sensor,

consider the trouble of normal water level sensor or low water level sensor, and operates immediately a serial of operation

as same condition of low water level. (Only if water temperature in the pipe is more than 80 ± 2.0

℃

, fan operate.)

4.18.2.12 Heating Temperature Sensor Trouble

If finds the trouble of disconnection / short-circuit by checking heating temperature sensor as long as the power of boiler

is ON, the boiler is stopped (The burner stops and the pump / blower operate continuously, and stop the pump / blower

after temperature sensor is returned to normal and check water temperature to be less than 80 ± 2.0

℃

in the pipe.) and

the failure status of sensor is indicated in temperature controller.

4.18.2.13 Combustion Indication

Combustion indication in the temperature controller displays by the presence of flame signal. (Not by the presence of

fuel supply)

4.18.2.14 Air Pressure Switch

Air pressure switch is always ON regardless of blower. When air pressure is excessive, aind pressure switch is OFF

and the boiler is stopped and the abnormal status of air pressure is transmitted to the temperature controller. Blower

operates continuously and release automatically when return to normal state. (Only if water temperature in the pipe is

more than 80 ± 2.0

℃

, pump operates. The abnormality of RPM isn’t monitored in the abnormal status of wind pressure.)

4.18.2.15 Gas Leakage Alarm

When the gas leakage signal is input from outside, the boiler is stopped and blower operates to ventilate air. When the

gas leakage signal is released, the abnormal status is disappeared automatically and then returns to the status as before.

(Only if water temperature in the pipe is more than 80 ± 2.0

℃

, pump / blower operate.)

4.18.2.16 Pump Trouble

Water level control method of the closed air type boiler is decided by the input presence of flow switch within 6 ± 1

seconds after pump is ON. When there is no signal of flow switch within 3 ± 1 seconds, delay Pre-Purge by 6 ± 1

seconds. When the signal is, operate normally. If flow switch is ON continuously more than 15 ± 3 seconds before pump

operates, consider the trouble of pump or flow switch and transmit abnormal status to the temperature controller. Pump is

OFF and maintains this status until re-operate the temperature controller. (Only if water temperature in the pipe is more

than 80 ± 2.0

℃

, fan operate.)

4.18.2.17 Time Multiple Function When Control Heating

When heating combustion operates continuously at a steady heating value by heating command of the temperature

controller, calculate average heating value and is converted into running time / stop time according to heating value. And

then maintain the stopping state (same as outdoor state) for regular time after running combustion for regular time. If

changed heating command or setting temperature in the temperature controller or operated hot water combustion, etc

except heating function within heating running time or forced stop time, the time should be always initialized. (Only in hot

water combustion, it doesn’t stop function.)

4.18.2.18 MICOM Trouble

As the part of deciding trouble inside of the controller, considers that there is trouble of MICOM when external AC

power of 50/60Hz isn’t monitored, stops all output and transmits trouble status to the temperature controller and then

maintains the current state until re-operate the temperature controller. (If water temperature in the pipe is more than 80 ±

2.0℃, pump operate.)

4.18.2.19 Heating Control when Hot Water Use

Proportional control uses the indirect control method of hot water temperature by heating water temperature and hot

water temperature is as follows.

In case of FR-5 use, water temperature in the pipe is 80℃ when choose heating, and is set 70℃ when choose

outgoing and hot water .

4.18.2.20 Heating Temperature Control

The temperature of heating water at the discharge may be set in the range of 30~80±4.0℃ at the room thermostat. If

the temperature of the heating water is lower than 83℃, the ratio control(PID) will be performed in accordance with the

specified procedures.

If the range of control has been exceeded due to the change in the set temperature or to abrupt change in flow, the set

temperature will be reached through the proportional control with the delay of 300±15 seconds.(If 83±4.0℃ is exceeded,

the delay of 30±3 seconds will not be performed.)

KDB-GOM

Series

- 33 -

ON/OFF Control Range

Set Temperatures (“T” set)

ON OFF

80

℃

“T” set - (18±2)

℃

“T” set - (5±2)

℃

70 ~ 77

℃

“T” set - (14±2)

℃

“T” set - (7±2)

℃

60 ~ 69

℃

“T” set - (12±2)

℃

“T” set - (6±2)

℃

50 ~ 59

℃

“T” set - (10±2)

℃

“T” set - (5±2)

℃

40 ~ 49

℃

“T” set - (8±2)

℃

“T” set - (4±2)

℃

30 ~ 39

℃

“T” set - (6±2)

℃

“T” set - (3±2)

℃

If the combustion is delayed due to the temperature increase as above, the pump will be continuously run and the

resumption of combustion will be delayed for 300±30 seconds. (If the combustion stops at 85℃, the forced delay of 300

seconds will not be executed.)

If other functions than the heating, such as a different function or change in the set temperature, is performed during the

heating time or forced stop time, the time should be changed to the initial value.(In the case of heating domestic hot water

supply, the boiler will not be stopped.)

4.18.2.21 Re-Use Standby after Use Domestic Hot Water

When hot water flow switch is OFF by stopping use of hot water, fuel supply stop. Fan doesn’t perform Post-Purge

caused by stopping fuel supply and maintains ON status for 90 ± 9 seconds. If hot water flow switch is ON within this time,

performs pre-Ignition, fuel supply, flame detection, and Post-Ignition. And return the status as before when expires 90 ± 9

seconds after using hot water.

Only if the heating signal is input in the temperature controller during hot water standby (90 ± 9 seconds) or after hot

flow switch is OFF, turn immediately to heating. At this time, combustion should start always from the beginning after

combustion is OFF, and Post-Purge time is 15 ± 3 seconds and hot water standby time progress separately.

4.18.2.22 Freezing Prevention

When heating water temperature is lowered less than 10 ± 2.0℃, circulation pump operates for 30 ± 2 seconds by the

interval of one hour. If circulated water temperature is lowered less than 6 ± 2.0

℃

, operates circulation pump and starts

combustion for freezing prevention after output of freezing running in temperature controller. When the heating water

temperature is more than 21 ± 2.0

℃

, the circulation pump and combustion stop.

4.18.2.23 The Number of Fan Rotation Trouble

The RPM signal monitors after running fan and the related status is indicated in the temperature controller as follows.

- After reaching within ignition rpm ± 200rpm during ignition, ignition is started by controlling gas valve. If it doesn’t reach

within 13 ± 2 seconds, consider as one time failure of ignition. When re-ignition is performed and it doesn’t reach for 3

times in series within 13 ± 2 seconds, stop the ignition. After perform purge for 15 ± 2 seconds, start re-ignition again.

(Only if repeats for 10 times of the above operation and doesn’t ignite, consider as the number of rotation trouble.)

- If ignite normally and progress the combustion, initialize the count of above operation.

- If the number of rotation maintains less than 400 ± 200rpm or more than 3200 ± 200rpm for 12 ± 1 seconds during

normal combustion, consider as the RPM trouble.

- When the RPM trouble is happens by the above mention, re-check trouble of blower for 30 ± 3 seconds after indicating

first the trouble status in the temperature controller. If decide as normal status (1000 ± 200rpm), release it automatically

and return to normal status.

4.18.2.24 Bimetal (Mechanical Type) Overheat Control

When overheat signal is monitored continuously for 1 ± 1 second from mechanical overheat sensor during combustion

and stopping, transmits bimetal overheat status to the temperature controller and safety shut-off performs. Fan and

circulation pump operate continuously and stop when heating water temperature is less than 80 ± 2.0

℃

.

4.18.2.25 DIP Switch Setting Trouble

The voltage of wind pressure switch is always monitored during combustion and stopping of the boiler, and it is

compared with current setting of DIP switch. When finds trouble, indicates trouble status in the temperature controller and

stops combustion. (Only if set normal status, release automatically.)

KDB-GOM

Series

- 34 -

4.18.2.26 Test Operation Function

- It is priority of the set function of DIP switch.

- Pump operates for 2 hours. In case of open type, operate continuously after auto water filling when low water level is

happens.

- If releases test operation by manipulating DIP switch in standby status after performing test operation and sets again,

initializes test operation function and starts test operation.

- When low water level (pseudo flame) happens in case of closed air type, releasing automatically by the interval of one

minute and progresses continuously.

- When flow switch is ON in case of closed air type, stops pump and checks trouble.

- When DIP switch sets test operation, the power lamp flickers by repetition of ON for 1 second and OFF for 1 second.

4.18.2.27 Forced Maximum / Minimum Combustion Function

- When change-over switch sets to forced Max or forced Min, combusts by the set Max or Min according to the capacity

of the boiler after normal ignition. (PID control doesn’t.)

- When DIP switch sets for both forced Max and Min at the same time, combusts by forced Min.

- During combustion of forced Max / Min, operation of stopping time isn’t performed.

- If the test operation is ON in status of forced Max/Min operation, the function of forced Max / Min operation isn’t work.

4.18.2.28 Fault repair codes(room thermostat, FR-5)

FND No. Problems FND No. Problems

01

Overheat

10

Air pressure failure

02

Low water level

11

Water level detection failure

03

Ignition failure

12

Flame failure in combustion

04

Flame sensor

(Lower gas pressure)

13

Heating water switch failure

05

Heating sensor wire disconnected

14

Gas alarm(optional)

06

Short circuit of heating sensor

15

MICOM failure

07

Hot water sensor wire disconnected

16

Mechanical overheat

08

Short circuit of hot water sensor

17

DIP switch setting error

09

Fan R.P.M. failure

18

4.18.2.29 Current Proportional Range Compensation

- Maximum current change by adjusting variable resistor for maximum current compensation.

- Current compensation range can be variable more than ± 20mA of maximum current.

4.18.4.30 The Others

- Heating flow switch is used to monitor water level of closure type (closed air type).

- Power lamp is always lit in the condition of power ON and flickers by the repetition of ON for 0.5 second and OFF for 0.5

second in the abnormal condition.

4.18.2.31 Secondary Gas Pressure according to Capacity of Boiler (mmAq)

Model High Load Low Load

NG 104 20

KDB – 161 GOM

LP 170 20

NG 104 20

KDB – 201 GOM

LP 150 30

NG 104 20

KDB – 251 GOM

LP 165 38

NG 106 20

KDB – 301 GOM

LP 156 30

KDB-GOM

Series

- 35 -

1. Precautions before installation

1.1 Shipping from factory

1.2 Choosing the best location

1.3 Methods of installation

1.4 Check the kind of gas

1.5 Precautions for installation

2. Identifying the components of the boiler

3. Installation of water piping

4. Installation of the flue

4.1 PVC Venting Method

4.2

Flue pipes used for Standard Flue Kit models

5. Gas piping connections

6. Installation of the room thermostat

6.1 Choosing the Best Location

6.2 Installation

II.

Installation of Boiler & Accessory

KDB-GOM

Series

- 36 -

■

WARRANTY WILL BE CONSIDERED VOID IF THIS EQUIPMENT IS INSTALLED BY ANYONE OTHER THAN A

QUALIFI ED, TRAINE D AND L ICEN SED ( WHERE APPLICABL E ) HE ATING TECHNICIAN.

■

KYUNGDONG BOILER CORPORATION IS NOT RESPONSIBLE FOR PROBLEMS OR DAMAGE CAUSED BY IMPROPER

INSTALLATION IN CONSISTENT WITH THIS M ANUAL.

■

THE IN STALLING CO NTRACTOR M UST I NSTRUCT THE OWNE R ON THE FU LL OPERATION OF THIS PRODUCT.

■

THE INSTAL LI NG CON TRACTO R M UST GI VE THE OWNE R THE APPO RPR IATE WARRANTY CERTIFICATE AFTER

THE IN STAL LATIO N H AS BEE N CO MP LETE D.

1. Precautions before installation

1.1 Shipping from factory

The units are released from our facility specially packaged to prevent handling damage and contamination in transit.

Dropping or throwing the boilers or moving them while outside of their shipping container may cause damage or

internal contamination by any moisture remaining after testing. Do not stand the boilers up by resting on the

connections piping.

1.2 Choosing the best location

■

Never locate the unit outdoors,

Such as an open porch or patio or exposed to the wind, rain snow and cold temperature.

Special consideration must be given to where the venting will terminate outdoors.

■

Do not locate the unit in an equipment room that has an exhaust fan.

■

Install the unit securely on any non-combustible wall that is capable of supporting the 40 kg weight of this

equipment.

■

Maintain an 150mm clearance to the left and right of unit including 150mm clearance in front of the unit for safety

inspections and future access.

■

Do not install unit in an underground or semi-underground location unless using the model FF or designated

concentric flue kit for KDB-GOM models.

■

When installing the unit, consideration must be given to the proper location. The location selected should be as

close to the vent pipe termination outside the building, and as centralized with the water piping system as

possible.

■

A minimum clearance of 100mm must be allowed for access to replaceable parts such as the thermostats, drain

valve and relief valve.

■

As the gas boiler is to be installed indoors, they shall not be installed outdoors, such as in the porch.

■

Do not install boiler on combustible wall in a high humidity location.

There is a risk in using fuel burning appliances in rooms or areas where gasoline, other flammable liquids or engine

driven equipment or vehicles are stored, operate or repaired. Flammable vapors are heavy and travel along the floor

and may be ignited by the igniter or main burner flames causing fire or explosion. Some local codes permit operation of

gas appliances if installed 18-inches or more above the floor. This may reduce the risk if location in such an area cannot

be avoided.

Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or

adjacent to the boiler.

Open containers of flammable material should not be stored or used in the same room with the boiler.

1.3 Methods of installation

■

The units must be firmly secured on the wall, which can sufficiently hold the unit weight.

■

Exhaust vent pipe has a maximum length of 5.0M with up to 3-90° elbow. Vent pipe must be angle 2-3° toward

the boiler to return condensate.

■

The units should be grounded to prevent electric shock.

1.4 Check the kind of gas

■

Check if the gas indicated on the rating plate is being used. If not, change the nozzle

by consulting the service center or dealers.

KDB-GOM

Series

- 37 -

CONVERSION OF THIS APPLIANCE FROM NATURAL GAS TO PROPANE OR PROPANE TO NATURAL GAS

CAN ONLY BE PERFORMED by a QUALIFIED TECHNICIAN.

1.5 Precautions for installation

■

Piping for heating and hot water should be cleaned before connecting to the unit.

Lime scale accumulation can reduce the life of the equipment, reduce efficiency and waste fuel. Boiler failure due to

lime or scale buildup voids the warranty.

Check the metal tag on the relief valve and compare it to the heater’s rating plate. The pressure rating of the relief valve

must not exceed the working pressure shown on the rating plate of the heater. In addition, the hourly heat capacity

rated temperature discharge capacity of the relief valve shall not be less than the input rating of the heater. NO VALVE

IS TO BE PLACED BETWEEN THE RELIEF VALVE AND TANK. DO NOT PLUG THE RELIEF VALVE.

The drain line connected to this valve must not contain a reducing coupling or other restriction and must terminate

near a suitable drain to prevent water damage during valve operation. The drain line shall be installed in a manner to

allow complete drainage of both the valve and line. DO NOT THREAD, PLUG OR CAP THE END OF THE DRAIN

LINE.

■

The boiler needs a large quantity of air for combustion, the specified vent must be

installed. Incomplete combustion will occur and prevent normal operation of the boiler.

For safe operation, an ample supply of air must be provided for proper combustion and ventilation in accordance with the national fuel

gas code or applicable provisions of the local building codes (latest editions). An insufficient supply of air may result in a yellow, luminous

burner flame, carboning or sooting of the finned heat exchanger, or create a risk of asphyxiation. Do not obstruct the flow of combustion

and ventilation air.

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO THE OUTDOORS AND HAS ADEQUATE AIR

SUPPLY TO AVOID RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR ASPHYXIATION.

■

The boiler should be at least 600mm away from electric appliances.

The boiler is set up for AC 220V, 50/60Hz.

The flow of combustion air to the boiler must not be obstructed.

The boiler area must be kept clear and free from combustible materials, gasoline and other flammable vapors and

liquids.

■

Flue made of stainless steel.

■

To facilitate the discharge of exhaust gas, the flue

should be installed with fewest possible bents and

curves. The flue should have a diameter larger than

that of the flue of the boiler.

■

Do not place flammable item near the boiler.

Never place combustibles such as vinyl bags,

match, thinner, etc on boiler.

Read first before connection to power supply

Low Voltage

(Thermostat Wire)

Orange

Orange

Blk

Red

Black

White

Green

Low Voltage

(for optional gas alarm)

Gray Wire

(to live voltage)

More than 600mm

Only for AC220V, 50Hz

KDB-GOM

Series

- 38 -

2. Identifying the components of the boiler

■

Model : KDB – 251 / 301GOM

■

Model : KDB – 161 / 201GOM

KDB-GOM

Series

- 39 -

3. Installation of water piping

■

The piping materials used should meet local codes and industry standards.

■

Piping must be cleaned and flushed-out before installation.

■

Do not apply torch heat within 300mm of the bottom connections of the unit.

■

Perform all solder connections at a safe distance from the (brass) male

connectors below the unit. Allow fittings to cool, before attaching to unit. Use only approved coupling unions with

O-rings to attach field piping to unit.

■

The ‘heating’ pipe should be 3/4" and of type-L copper. Never use aluminum, plastic, or galvanized steel piping.

■

The pipe size used for supply heating water should be the same size used for the return heating water.

■

Use only copper piping with lead-free solder for the domestic water side.

■

Since the expansion tank has already been installed in the unit, no separate tank is required.

■

The size of the domestic hot water pipe should be 1/2" diameter.

■

The length of piping should be as short as possible and the piping should have minimal number of bends and

connections.

■

Use only ball type isolating valves. Do not use gate valves.

■

Never leave the heating pipes disconnected while operating the unit as a boiler. This will cause damage to the

heat exchanger and void the manufacturers warranty.

■

All piping should be insulated.

■

After making the piping connections, check for gas or water leaks.

■

If the water supply pressure is 10 kgf/cm² or higher, install the reduction valve on the water supply piping.

■

If the water supply pressure is 0.3 kgf/cm² or lower, install a pressurizing pump.

KDB-GOM

Series

- 40 -

A THERMOSTATIC MIXING VALVE MUST BE ADDED TO THIS SYSTEM TO PREVENT SCALDING. IF YOU

CANNOT FIND A MIXING VALVE LOCALLY, PLEASE CONTACT YOUR QUIETSIDE DEALER OR LOCAL

SPECIALITY PLUMBING SUPPLIER.

Mixing type valve:

- Controls the desired hot water temperature and ensures constant hot water temperature in the faucets

- Ensures safety through the built-in anti-burn/scald safeguard. Limits the deposits and accumulation of scale.

- Includes built-in wire mesh filters and check valves for long and trouble-free operation.

Fig. Schematic of piping installation

There is a risk in using fuel burning appliances in rooms or areas where gasoline, other flammable liquids or engine

driven equipment or vehicles are stored, operated or repaired. Flammable vapors are heavy and travel along the floor

and may be ignited by the igniter or main burner flames causing fire or explosion. Some local codes permit operation of

gas appliances if installed 5.0M or more above the floor. This may reduce the risk if location in such an area cannot be

avoided.

Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or

adjacent to the boiler.

Open containers of flammable material should not be stored or used in the same room with the boiler.

DO NOT INSTALL THIS BOILER DIRECTLY ON A CARPETED FLOOR. A FIRE HAZARD MAY RESULT. INSTEAD

THE BOILER MUST BE PLACED ON A METAL OR WOOD PANEL EXTENDING BEYOND THE FULL WIDTH AND

DEPTH BY AT LEAST 75mm IN ANY DIRECTION. IF THE HEATER IS INSTALLED IN A CARPETED ALCOVE OR

CLOSET, THE ENTIRE FLOOR SHOULD BE COVERED BY THE PANEL.

99 F

50

113

104

ROOM TEMP.

140 F

OFF

MAX

122

68

131 86

77

KDB-GOM

Series

- 41 -

4. Installation of the flue

4.1 PVC Venting Method

■

The KDB-GOM Series boiler may be vented using 75mm schedule-40 venting materials.

■

Cut all lengths of pipe cleanly maintaining a 90-degree square edge. Use long radius elbows whenever possible.

■

Use only the type of adhesive recommended by the stainless pipe manufacturer.

■

Keep an uphill slant from boiler to the outside to ensure that all condensed water inside the pipe will return back to

the boiler.

■

Do not place the outdoor termination kit in an area where discharge gasses will be directed towards evergreen

shrubbery.

■

Assemble the flue using the following illustration as a guide. Your installation may vary slightly from the illustration

shown below.

Use the optional Vent Termination Kit for venting the KDB-GOM boiler to outside area.

Use the optional Vent Termination Kit for venting the KDB-GOM boiler to outside area.Use the optional Vent Termination Kit for venting the KDB-GOM boiler to outside area.

Use the optional Vent Termination Kit for venting the KDB-GOM boiler to outside area.

- Standard : The Stainless Steel Concentric Flue Kit for KDB-GOM models.

“A” : 75

㎜×

㎜×㎜×

㎜×

1.0m LENGTH STAINLESS FLUE PIPE

“B” : 75

㎜×

㎜×㎜×

㎜×

0.5m LENGTH STAINLESS FLUE PIPE

“C” : 75

㎜×

㎜×㎜×

㎜×

90-DEG. STAINLESS ELBOW

Shown : 75

㎜㎜㎜㎜

(3

″″″″

) Stainless Venting.

“C”

“A” or “B”

(Maximum Allowable

Flue Length = 5 m)

Min. 250㎜ (10″)

Vent Termination Kit

Exhaust

Intake Air

Min. 600㎜ (2 ft) from ground

(Note! - Install the vent termination kit in an

area away from plants,

people and

animals)

φ75㎜

(3

″″″″

)

Type 304

stainless steel

only

NOTE

ⅰ) Intake Air : φ75㎜ (3

″″″″

) stainless steel.

ⅱ) Exhaust : φ75㎜ (3

″″″″

) Stainless steel.

ⅲ) Maximum three 90° elbows.

ⅳ) Slant flue pipe 2-3° away from boiler to outside,

to drain condensate.

Ground

KDB-GOM

BOILER

“C”

To Dr a i n

Install Horizontal Drip

Te e

If Required

KDB-GOM

Series

- 42 -

4.2 Flue pipes used for STS exhaust flue kit

■

When the flue duct (including extension) passes through a combustible wall or ceiling with combustible materials,

it should be insulated with 25mm or thicker insulation and then set apart from the wall or materials by 50mm or

more. When it passes through the ceiling, include an opening for inspection of the flue.

■

If the air supply duct is separated from the flue duct, the total length of the flue duct should be 3.0 M or less and

with 2 or less elbows.

■

The connection of the air supply hose must be sealed by the wire clamp to prevent any air loss. In the connection

of the flue duct and the flue elbow, In O-ring must be inserted to prevent leakage.

■

Do not use any aluminum duct as an extension. Use extension duct sets or elbows available through your

kyungdong distributor.

■

The flue duct which carries combustion waste gas should be firmly secured by the clamp so that it will not loosen

due to vibration. The parts where the band clamp is not used should be sealed with aluminum tape.

In the event the exhaust pipe passes through a combustible wall or an combustible ceiling, insulate it with

nonflammable materials of 25mm thick or more and locate 50mm or more away from any combustible materials.

In addition, install a check port if flue passes through the ceiling.

Tie up a joint of the air intake hose with the wire clamp so as not produce a loss of an intake air, insert an O-ring in a

joint of the exhaust pipe and exhaust elbow so that the exhaust gas won’t leak.

Fix the exhaust pipe with the band clamp and screws so as not to pull due to shock. Make sure to wrap any pipe joint

not using a band clamp with aluminum tape.

Fig. Schematic of Standard Flue kit Installation

Ceiling

Seal opening to ensure that burne

d

waste gas does not enter the room.

In the event the intake hose is to

o

long, cut the shortest length as

possible and connect it.

Nonflammabl e

wall

150 or more

250or

more

500 or

more

Install the horizont al part of flue downwards(120mm)

so that the condense d water from the flue or rain doesn’t enter

into the boiler.

Install the flue in a place where there are no any obstacle

s

within 1.5M away from the flue.

Install the flue ensu ring no that it cannot be blocked by sno

w

falling from the roof eaves.

Install the flue in a place in a location opening exist within 500 m

m

from the flue so that exhaust gas can’t re circul ator in to the building.

Install the flue at least 600mm above the ground.

Unit : mm

KDB-GOM

Series

- 43 -

5. Gas piping connections

■

The heating water supply piping should be 3/4". An isolation (ball-type) valve should be installed before the piping is

connected to the units.

■

Black iron piping or 3/4" flexible connector (approved by the local authorities for gas) should be used for gas piping.

■

Do not use Teflon tape for gas pipe connections.

■

Install a gas drip leg at the unit.

■

Gas piping should be kept at the required distance away from any electric lines and the main service panel(check

with local authorities).

Items Distance (mm)

1. Distance from electric lines 150

2. Distance from electric heaters and electric panels 600

3. Distance from flue pipes and outlets 300

■

Install the ball valve(cut-off valve) before connecting the gas piping to the unit (Allow space for the lever’s full

movement, install valve as close to the units as possible).

■

After the gas pipe has been completed, all connections must be checked with soapy water.

Note!

- Do not test for

gas leaks by pumping air-pressure into the line without first disconnecting the gas line to the unit. Pressuring the

unit will void the manufacturers warranty. Releasing this pressure into the unit will cause immediate and severe

damage to the gas valve and its internal pressure regulating device and could result in property damage and/or

personal injury.

6. Installation of the room thermostat

6.1 Choosing the Best Location

■

Never locate the thermostat near or above a heat producing source(lamp, TV, fireplace, radiator, direct sunlight,

etc.).

■

Never locate in areas with drafts(stairwells, vestibules, foyers, against an outside/exterior wall, etc.).

■

Never locate in a room, which will be shut-off from the other living areas of the home.

■

On multi-story homes, locate thermostat on the ground floor.

■

Install at a height of about 1.2M to 1.5M above the floor.

■

Keep out of reach from children.

6.2 Installation

1. Remove the back plate from the FR-5 thermostat by grasping the faceplate with one hand and sliding the back plate

downward with the other hand.

2. Pull the thermostat wire through the back plate.

3. Connect 2(orange colored/stranded) wires from unit to the 2 screws located on the FR-5 thermostat.

Consult with your gas provider to determine the proper diameter of gas pipe. This will vary due to

input capacity, the number of elbows and length of pipe.

[On Hollow Plaster or Drywall]

[On Recessed Outlet]

KDB-GOM

Series

- 44 -

4. Mount the back plate to the wall using either of the above techniques(depending on the construction of the wall).

Recheck all connections both inside the unit and at the thermostat. Be careful not to pinch the control wires. Pinched

or shorted wires will prevent the system from operating. Do not over tighten wire nut connecting wires together.

5. Use countersunk type screws.

CAREFULLY TIGHTEN THE 2 SCREWS WHEN CONNECTING THE WIRES. DO NOT APPLY EXCESSIVE

FORCE.

IF THE INSULATION OF THE WIRES IS DAMAGED OR IF THE TERMINALS ARE ON POOR CONTACT, THE

ROOM THERMOSTAT WILL NOT WORK PROPERLY. BE CAREFUL TO PROTECT THE INSULATION OF THE

WIRES.

[Wiring FR-5 Thermostat]

DC 20V

FR-5 Thermostat

2 Orange Wires

Main

Controller

AC 220V, 50/60Hz

Grounded Power Supply

to Boiler

Boiler

KDB-GOM

Series

- 45 -

1. Checkup after installation

2. Checking for gas and water leaks

3. Checks before trial operation

4. Trial operation

4.1 Trial operation quick-fill

4.2 Procedure of trial operation

5. Routine maintenance

6. Troubleshooting

6.1 Troubleshooting - Error Codes

6.2 Troubleshooting - Occurs

III.

Trial operation & Checkup

KDB-GOM

Series

- 46 -

1. Checkup after installation

1) Check the flammability and rigidity of floor & wall materials. Ensure that all-minimum clearances to walls, ceilings,

overhangs, etc. have been met.

2) Freeze Prevention Device

The units must be wired-in to AC 220 volt electrical circuit once they have been connected to water piping and the

circuit has been filled with water. If the freeze prevention circuit starts due to a low-water condition, the pump will

begin running on “air” and cause premature failure and will void the warranty on the pump.

Check to see if the unit is properly connected and the piping is insulated properly.

If the insulation has worn off or is not fitted, the risk of freezing of piping and severe damage to the unit is

considerable. Thoroughly check the piping insulation and replace where necessary.

■

Measures to prevent fire must be taken and check that flue ducts are installed in compliance with the instructions?

2. Checking for gas and water leaks

■

Are there any water leaks in the heating and domestic hot water piping?

■

Are there any gas leaks in the gas piping?

3. Checks before trial operation

■