Page 1

SATURN

LOW SPEED AND DUAL SPEED

FLOOR MACHINE

OWNER’S/OPERATOR’S MANUAL

17LS3-SS, 17LS3-BK

20LS3-SS, 20LS3-BK

20DS3-SS

17LS4-Bk, 20LS4-BK

WWW.EDIC-USA.COM

Page 2

UNPACKING YOUR NEW SATURN:

When your package is delivered, check each of the 3

cartons carefully for signs of rough handling. If the

SATURN is damaged, notify the carrier immediately

and request an inspection. Be sure to keep the cartons,

packing inserts, packing lists and carrier’s receipt until

the inspector has veried your claim.

EDIC’s liability ceases when the carrier picks up the

shipment. However, our customer service sta will be

happy to furnish any information needed in connection

with the claim and will attempt to expedite a resolution.

PLEASE READ BEFORE

OPERATING YOUR NEW SATURN:

Read the manual carefully and completely before attempting to operate the unit. is manual has important

information for the use and safe operation of the machine. Keep this manual handy at all times.

is equipment has been engineered and manufactured

to provide excellent performance and service. To ensure

that your equipment will continue to perform as intended:

• Maintain and inspect equipment regularly

• Use only original EDIC parts when servicing.

• Operate equipment with care.

If additional information is needed, please contact EDIC

at: 800-338-3342 or email info@edic-usa.com

All information and specications printed in the manual

are current at the time of printing; however, because of

EDIC’s policy of continual product improvement, we

reserve the right to make changes at any time without

notice.

FAILURE TO COMPLY WITH THE FOL-

LOWING WARNINGS AND INSTRUC-

TIONS WILL VOID THE WARRANTY.

WARNING!

• Do not operate the machine unless trained and authorized.

• Do not leave the machine unattended when plugged

in. Unplug from the outlet when not in use, before

servicing, and when changing the brushes or pads.

• Use indoors only.

• Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

• Do not bypass or defeat the safety “lock-out lever.”

• e machine was designed for use as per instructions and recommendations written in this manual.

Any deviation from its proper use or purpose and

the consequential damage that may occur is the sole

responsibility of the end user.

• Do not use with damaged cord or plug. If the machine is not working as it should, or it has been

dropped, damaged, le outdoors or dropped into

water, take it to an authorized service center.

• Do not pull or carry by cord, use cord as handle,

close a door on the cord or pull cord around sharp

edges or corners. Do not run machine over cord.

Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp

the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Make sure the machine is plugged into an electrical

outlet with the same voltage and frequency rating

as shown on the nameplate of the machine. Do not

attempt to plug a 115- volt machine into a 230- volt

outlet.

• Do not immerse or use this machine in standing

water. Such use can cause electric shock.

• Keep the electrical supply cord from contacting the

rotating brush or drive block.

• Do not expose machine to freezing temperatures.

• To avoid electric shock, do not expose the unit to

rain. Store indoors only.

• Connect to a properly grounded outlet only. See

“Grounding Instructions.”

• Turn o all controls before unplugging.

• When using an extension cord, use a 3 conductorgrounding cord, 12 gauge wire or heavier. Do not use

more than 25’ of extension cord.

• Do not put any object into openings.

• Do not use with any opening blocked. Keep free of

dust, lint, hair and anything that may reduce air ow.

• Do not operate machine in ammable or explosive

areas.

• All servicing of EDIC equipment should be per-

2

Page 3

formed by an EDIC authorized service center.

• Keep hair, loose clothing, ngers and all parts of

body away from openings and moving parts.

• Use extra care when cleaning near stairs.

• When servicing machine, use manufacturer’s supplied or approved replacement parts.

• Do not wrap the cord too tightly when storing.

• Work only in well lit areas.

• is equipment is heavy. Use proper liing techniques when liing heavy equipment.

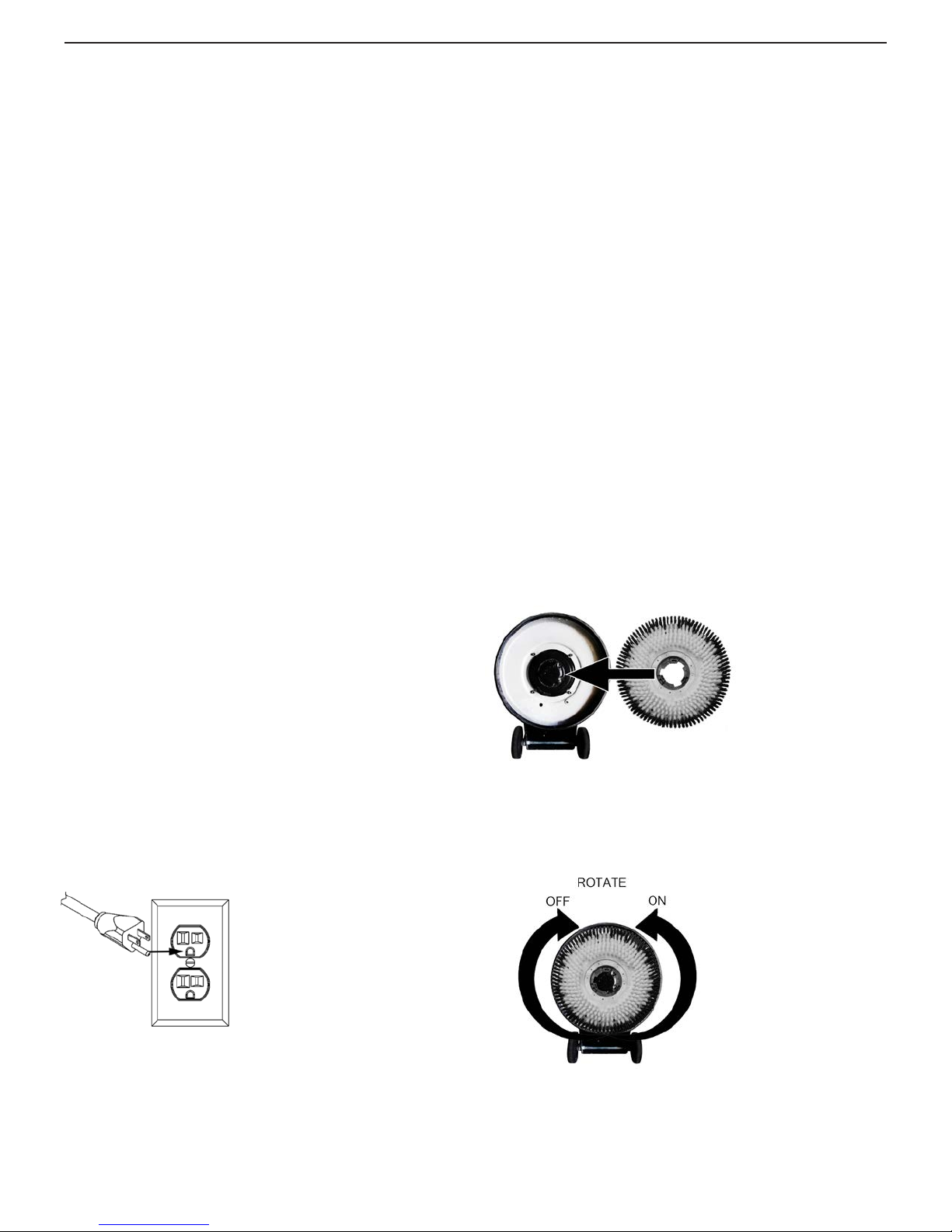

GROUNDING INSTRUCTIONS:

is piece of equipment must be grounded. Should an

electrical malfunction occur, grounding provides a path

of least resistance for electrical current- reducing the risk

of electric shock. is piece of equipment is furnished

with a cord that has a grounding conductor and grounding plug. e grounded plug must only be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING:

Connecting the equipment to an improperly grounded

outlet can result in an increased risk of electric shock. A

qualified electrician should be consulted if you are unsure that the outlet is properly grounded. Do not modify

the plug provided with the equipment. If it will not fit

the outlet, have a proper outlet installed by a qualified

electrician.

Servicing:

In the event that your SATURN requires service, please

contact EDIC at:

800-338-3342

or email info@edic-usa.com

Do not attempt repairs yourself. EDIC will assist you in

locating an indepedent service contractor.

PREPARING THE MACHINE FOR

OPERATION

Your oor machine will operate in a wide variety of hard

oors and carpet cleaning applications. Consult with

your local dealer or EDIC Customer Service to select the

correct accessories for the job you are going to perform.

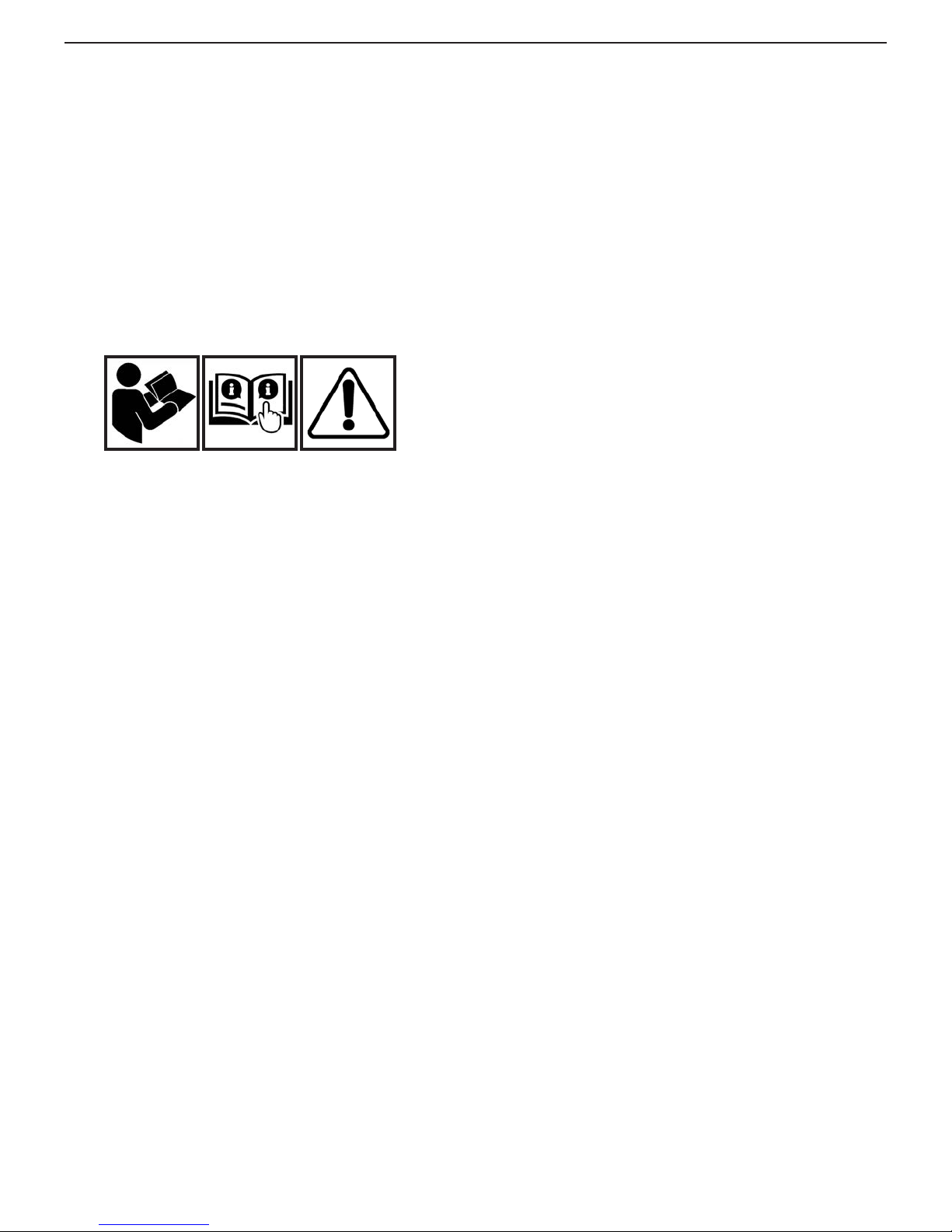

BRUSH, PAD DRIVER

INSTALLATION

Lock the handle in the upright position and tip the machine back so it rests on the handle and wheels. Fit the

three slots of the clutch plate in the back of the brush

or pad driver over the three lugs of the drive plate (Fig.

1). Push it rmly into position and turn it counterclockwise until it locks in place (Fig. 2).

is appliance is designed for use on a 120-volt circuit.

e grounding plug provided looks like the plug illustrated in Figure 1. Replace the plug if the grounding pin

is damaged or broken.

Figure 1

e Green (or Green/Yellow) wire in the cord is the

grounding wire. When replacing a plug, this wire must

be attached to the grounding pin only.

DO NOT use extension cords.

Fig. 1

Fig. 2

3

Page 4

TO REMOVE PAD DRIVER:

Tip the machine back so it rests on the

handle and wheels. Turn the brush or pad driver

clockwise until it disengages and lis o. Do not store

the machine with the brush or pad drivers installed.

PAD INSTALLATION

TO INSTALL PAD: Tilt the machine back on wheels

until machine is resting on handle. Center the pad on the

pad holder and press the pad onto the pad holder.

TO REMOVE PAD: Simply remove the pad from the

pad holder by pulling it away from the pad holder with

steady force.

MACHINE OPERATION

1. Install the pad driver and pad, brush or attachment.

2. Plug in machine.

3. Lower the handle to the desired operating position.

4. Place both hands on the handle grips with your ngers around the ON/OFF lever which extends from

one side to the other underneath the handle grips.

5. e safety LOCK-OUT lever is located underneath

the right side handle grip and ON/OFF lever. To

unlock the LOCK-OUT lever, use your right hand

forenger to press the lever down toward the back of

the switch box

6. While pressing the LOCK-OUT lever, pull the ON/

OFF lever on either side of the handle to start the

machine.

7. e LOCK-OUT lever will automatically lock when

you release the ON/OFF lever preventing the machine from being turned on until it is unlocked

again.

ning. Always wait until motor has stopped completely

before changing speeds.

Storage:

Wipe with a clean damp cloth aer every use.

Store in a clean dry place.

CORD STORAGE:

• Unplug the cord- Clean and inspect for damage.

• Wrap the cord around the le side handle grip.

• Do not wrap too tightly.

TO MANEUVER YOUR FLOOR MACHINE

1. Raise the handle slightly and the machine will go to

the right. e higher you raise it, the faster it will go.

2. Lower the handle and the machine will go le. e

more you lower it, the faster it will go.

3. Practice on a smooth surface to gain experience in

operating the unit before moving on to other surfaces.

DUAL SPEED FUNCTION FOR 17DS3-BK &

20DS3-BK:

Use the black switch located directly behind the motor

to switch between low speed (180RPM) and high speed

(320RPM). Do not change speeds while machine is run-

4

Page 5

NOTES

5

Page 6

LOW SPEED

WIRING

AC MOTOR

B

W

G

B

W

G

SWITCH

B

W

G

HANDLE MOTOR

6

Page 7

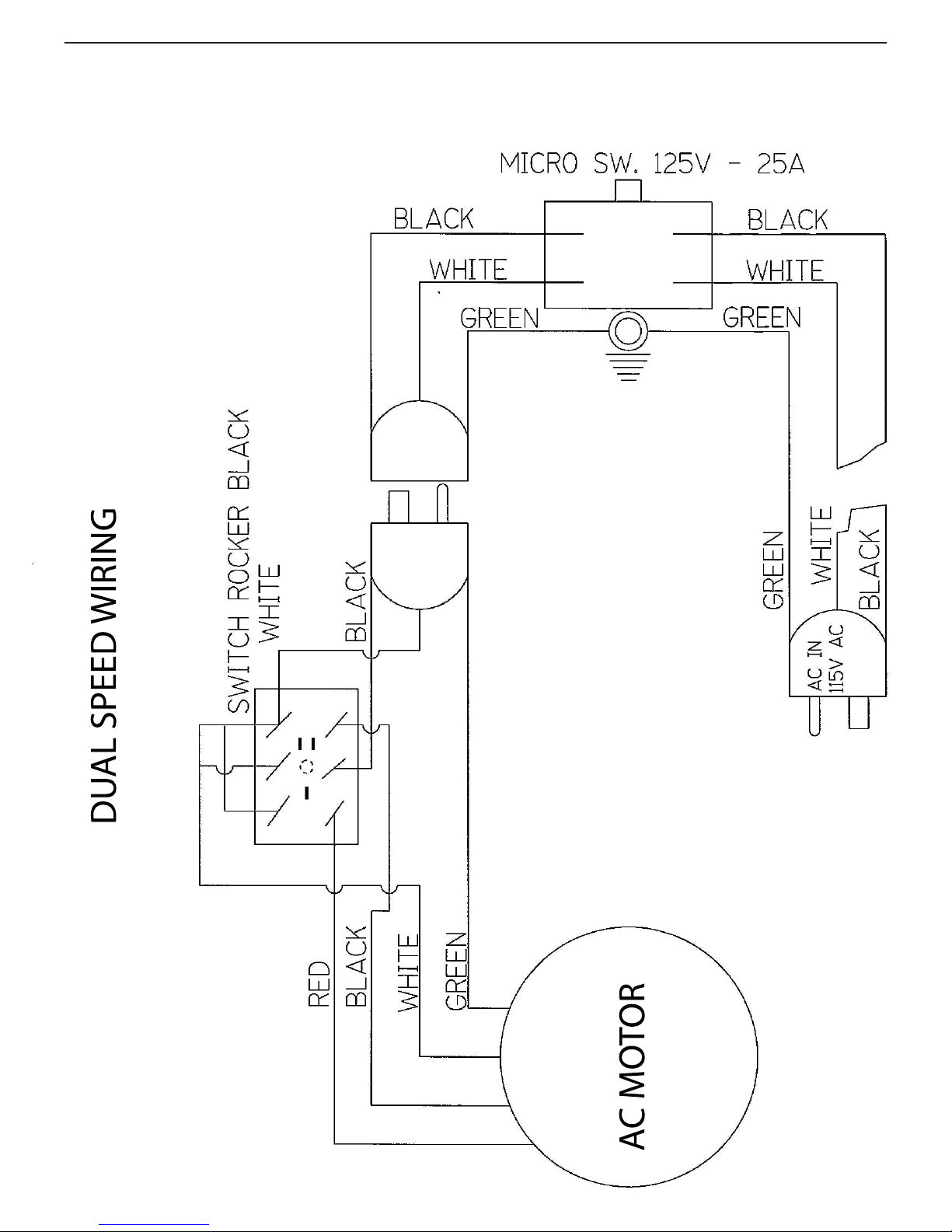

DUAL SPEED WIRING

AC MOTOR

7

Page 8

1 43 5 6 7

ITEM

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 0.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

C00306 Roll Pin, .125 X 1.75

16

D11523 Spring, Trigger

17

D11479 Handle, Chrome, Floormachine

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

D11497 Handle, Locking Clamp

22

C11538 Cap Nut, .31 in, Push-On

23

C00259 Washer, Slotted, Zinc

24

C11536 Spade Bolt, .375-16 X 4 in

25

D11507 Cord Hook Clamp

26

D11507-2 Cord Hook Body

27

C11558 Locknut, .375-16, Nylon

28

C11502 Socket Cap Screw, .375-16 X 2.5 in

29

C11537 Dowel Pin, .31 X 1.5 in

30

C13101 Screw, Hex Cap, M14-2.0

31

B10719 Power Cord, 25', 16-3

32

B11518 Switch Insulation

33

B11751 Switch, Rocker, DPDT, Black

34

C00293 #8 X .5in Pan, Black SMS, Phillips

35

D11582 Bracket, Switch Mount

36

C00297 Screw,#8 X .25 in, Pan Head

37

D11646 Switch Bracket Cover

38

B00177-1 Terminal Lug, Female, QD, .25 X .032

39

B00177 Terminal Lug, Female, QD, .25 X .032

40

K00674 Bushing, .50 in, Nylon

41

D11510 Axle, Floor Machine

42

D11482 Handle Brace, Right, Black

43

C00240 Washer, Shoulder, Nylon

44

C11559 Washer, .515 X .875 X .032

45

G11943 Wheel, 5 in Saturn

46

C02305 Cap Nut, .5in Push-on

47

B00185-30 Wire, 14 Ga X 2 ft, White, UL195

48

B00185-40 Wire, 14 Ga X 2 ft, Black, UL1015

49

B00185-86 Wire, 14 Ga X 2 ft, Red, UL1015

50

B00228-2 1 Foot Shrinktube, .375 in, Poly

51

C11619 Allen Wrench, .31 in

52

C11501 Socket Cap Screw, .31 - 18

53

C00251 Lockwasher, .31, Split

54

E11478 Bumper, 20 in Floor Machine

55

D11486-SS Brush Cover, 20 in, Stainless

56

K11521 Spacer, Base, Floor Machine

57

D11483 Frame, Motor, Black

58

D11545 Motor Screen

59

G11573 Motor

60

B00181 Butt Connector, Blue, 1 Wire

61

B00179-1 Closed End Cntr, 16-3

62

D11481 Handle Brace, Left, Black

63

K11517 Spacer, .19 ID X .375 High X .50 OD, Nylon

64

B11199 Strain Relief, Pigtail w-Locknut

65

H10976-1 Label, UL STD 561-507

66

H00565-5 Label, Serial #, Standard

67

H03545 Cover, Serial #, Label

68

H11490C-H Drip Cover w - Light, Chrome

69

H11830 Label, Saturn, Drip Cover

70

B02196-1 Light, Motor Carbon Brush Wear

71

C13100 Nut, M14-2.0 Nylon Insert

72

B10734 Strain Relief, Handle

73

B11513 Cord, Handle, 14-3 SJTW

74

B11762 Terminal Lug, Nylon, Female

75

B11465 Switch, DPST, Pushbutton

76

C00252 Washer, .375 in, Flat

77

C11541 Washer, .375 in, Star

78

C00284 Screw, 10-32 X .375 Ground

79

B00187 Cable Clamp, Nylon, .43 in.

80

B00180-10-3 Ring Terminal, #10 Center

81

B11505 Strain Relief Nut, Metal

82

C11560 Washer, .93 ID X 1.5 OD

83

B11504 Strain Relief, Metal

84

H02548-2 Label, Important, Cord

84

79

70

78

77

69

68

13

67

62

61

60

59

58

57

56

55

54

66

36

2

76

63

65

64

75

39

74

73

72

71

32

8

80818283

39

33

39

32

34

8

9

10

11

12

13

14

15

16

17

18

19

20 21

22

23

24

25

29

26

28

30

31

27

35

36

37

38

39

4241 43 4544 46

40

47

48

49

20DS3-SS

10-9-07

50515253

Page 9

20DS3-SS 10-9-07

ITEM

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

C11528 Screw, 10-32 X .25 in

3

4

H12066 Label, 0.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

K11519 Lever Grip, Lockout, Black

9

10

C00278 Locknut, 10-32, Nylon, SS

D11494 Lockout Bracket

11

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

C00306 Roll Pin, .125 X 1.75

D11523 Spring, Trigger

16

17

D11479 Handle, Chrome, Floormachine

D11495 Trigger, Zinc Plated

18

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

D11497 Handle, Locking Clamp

22

C11538 Cap Nut, .31 in, Push-On

23

C00259 Washer, Slotted, Zinc

C11536 Spade Bolt, .375-16 X 4 in

24

25

D11507 Cord Hook Clamp

26

D11507-2 Cord Hook Body

C11558 Locknut, .375-16, Nylon

27

28

C11502 Socket Cap Screw, .375-16 X 2.5 in

29

C11537 Dowel Pin, .31 X 1.5 in

C13101 Screw, Hex Cap, M14-2.0

30

31

B10719 Power Cord, 25', 16-3

B11518 Switch Insulation

32

33

B11751 Switch, Rocker, DPDT, Black

C00293 #8 X .5in Pan, Black SMS, Phillips

34

35

D11582 Bracket, Switch Mount

36

C00297 Screw,#8 X .25 in, Pan Head

D11646 Switch Bracket Cover

37

38

B00177-1 Terminal Lug, Female, QD, .25 X .032

B00177 Terminal Lug, Female, QD, .25 X .032

39

40

K00674 Bushing, .50 in, Nylon

41

D11510 Axle, Floor Machine

D11482 Handle Brace, Right, Black

42

43

C00240 Washer, Shoulder, Nylon

C11559 Washer, .515 X .875 X .032

44

45

G11943 Wheel, 5 in Saturn

46

C02305 Cap Nut, .5in Push-on

B00185-30 Wire, 14 Ga X 2 ft, White, UL195

47

48

B00185-40 Wire, 14 Ga X 2 ft, Black, UL1015

B00185-86 Wire, 14 Ga X 2 ft, Red, UL1015

49

50

B00228-2 1 Foot Shrinktube, .375 in, Poly

51

C11619 Allen Wrench, .31 in

C11501 Socket Cap Screw, .31 - 18

52

53

C00251 Lockwasher, .31, Split

E11478 Bumper, 20 in Floor Machine

54

55

D11486-SS Brush Cover, 20 in, Stainless

56

K11521 Spacer, Base, Floor Machine

D11483 Frame, Motor, Black

57

58

D11545 Motor Screen

59

G11573 Motor

B00181 Butt Connector, Blue, 1 Wire

60

61

B00179-1 Closed End Cntr, 16-3

D11481 Handle Brace, Left, Black

62

63

K11517 Spacer, .19 ID X .375 High X .50 OD, Nylon

64

B11199 Strain Relief, Pigtail w-Locknut

65

H10976-1 Label, UL STD 561-507

H00565-5 Label, Serial #, Standard

66

67

H03545 Cover, Serial #, Label

H11490C-H Drip Cover w - Light, Chrome

68

69

H11830 Label, Saturn, Drip Cover

70

B02196-1 Light, Motor Carbon Brush Wear

C13100 Nut, M14-2.0 Nylon Insert

71

72

B10734 Strain Relief, Handle

73

B11513 Cord, Handle, 14-3 SJTW

B11762 Terminal Lug, Nylon, Female

74

75

B11465 Switch, DPST, Pushbutton

76

C00252 Washer, .375 in, Flat

C11541 Washer, .375 in, Star

77

78

C00284 Screw, 10-32 X .375 Ground

79

B00187 Cable Clamp, Nylon, .43 in.

B00180-10-3 Ring Terminal, #10 Center

80

81

B11505 Strain Relief Nut, Metal

82

C11560 Washer, .93 ID X 1.5 OD

B11504 Strain Relief, Metal

83

84

H02548-2 Label, Important, Cord

PART NUMBER

DESCRIPTION

9

QTY.

1

2

1

1

1

1

1

2

1

1

1

1

4

1

2

2

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

3

1

2

1

4

2

1

11

2

1

1

6

6

2

2

1

1

1

1

1

4

4

1

1

4

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

Page 10

68

ITEM

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

16

C00306 Roll Pin, .125 X 1.75

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

29

C11502 Socket Cap Screw, .375-16 X 2.5 in

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11477 Bumper, 17 in Floor Machine

42

D11485B Brush Cover, 17 in, Black

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490B Drip Cover, Black

51

H12913 Label, Drip Cover, White

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

52

51

50

46

45

44

43

42

41

40

39

1

2

3

4

5 6

7

8

9

67

62

61

60

59

49

48

47

66

58

65

10

64

63

555657

54

53

10

12 13 14 15

11

16

17

18 19

29

30

31

32

33

34

17LS3-BK

10-19-07

35

36

20

21

22

23

24

25

26

27

28

37

38

Page 11

17LS3-BK 10-19-07

ITEM

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

D11496B Switch Box Cover, Black

6

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

13

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

16

C00306 Roll Pin, .125 X 1.75

D11523 Spring, Trigger

17

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

C11502 Socket Cap Screw, .375-16 X 2.5 in

29

30

C11537 Dowel Pin, .31 X 1.5 in

C13101 Screw, Hex Cap, M14-2.0

31

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11477 Bumper, 17 in Floor Machine

42

D11485B Brush Cover, 17 in, Black

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490B Drip Cover, Black

51

H12913 Label, Drip Cover, White

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

PART NUMBER

DESCRIPTION

QTY.

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

6

6

2

2

4

4

1

1

4

1

1

1

1

1

1

1

1

3

1

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

11

Page 12

1

ITEM

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

16

C00306 Roll Pin, .125 X 1.75

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

29

C11502 Socket Cap Screw, .375-16 X 2.5 in

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11477 Bumper, 17 in Floor Machine

42

D11485-SS Brush Cover, 17 in, Stainless

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490C Drip Cover, Chrome

51

H11830 Label, Saturn, Drip Cover

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

2 3 4 5 6 7

8

68

67

52

51

50

46

45

44

43

42

41

40

39

66

61

60

59

49

48

47

65

64

63

565758

62

55

54

53

10

10

9

11 12

17LS3-SS

10-30-07

13 14 1615

32

33

29

30

31

34

17 18

35

36

?

19

37

20

21

22

23

24

25

26

27

28

38

Page 13

17LS3-SS

10-30-07

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

PART NUMBER

B11487 Power Cord, 14-3, 50 FT, SJTW

K11498 Grip

C11528 Screw, 10-32 X .25 in

H12066 Label, 1.5 HP, Saturn

H11831 Label, EDIC, Black-Silver

D11496B Switch Box Cover, Black

H11493 Label, Safety, Floor Machine

C11529 Screw, 10-32 X .375 in

K11519 Lever Grip, Lockout, Black

C00278 Locknut, 10-32, Nylon, SS

D11494 Lockout Bracket

D11524 Spring, Lockout

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

C11491 Screw, 10-32 X 1 in, SS

D11479 Handle, Chrome, Floormachine

C00306 Roll Pin, .125 X 1.75

D11523 Spring, Trigger

D11495 Trigger, Zinc Plated

K11520 Lever Grip, Trigger, Black

11507A Assembled Locking Handle, Cord Hook

C11619 Allen Wrench, .31 in

D11497 Handle, Locking Clamp

C11538 Cap Nut, .31 in, Push-On

C00259 Washer, Slotted, Zinc

C11536 Spade Bolt, .375-16 X 4 in

D11507 Cord Hook Clamp

D11507-2 Cord Hook Body

C11558 Locknut, Black Oxide, Thin

C11502 Socket Cap Screw, .375-16 X 2.5 in

C11537 Dowel Pin, .31 X 1.5 in

C13101 Screw, Hex Cap, M14-2.0

K00674 Bushing, .50 in, Nylon

D11510 Axle, Floor Machine

D11482 Handle Brace, Right, Black

C00240 Washer, Shoulder, Nylon

C11559 Washer, .515 X .875 X .032

G11943 Wheel, 5 in Saturn

C02305 Cap Nut, .5in Push-on

C11501 Socket Cap Screw, .31 - 18

C00251 Lockwasher, .31, Split

E11477 Bumper, 17 in Floor Machine

D11485-SS Brush Cover, 17 in, Stainless

K11521 Spacer, Base, Floor Machine

D11483 Frame, Motor, Black

G11468 Motor W-Gearbox, 1.5 HP

D11481 Handle Brace, Left, Black

H10976-1 Label, UL STD 561-507

H00565-5 Label, Serial #, Standard

H03545 Cover, Serial #, Label

D11490C Drip Cover, Chrome

H11830 Label, Saturn, Drip Cover

C11916 Screw, 10-32 X .375 Phillips

C13100 Nut, M14-2.0 Nylon Insert

B10734 Strain Relief, Handle

B11513 Cord, Handle, 14-3 SJTW

B11762 Terminal Lug, Nylon, Female

B11465 Switch, DPST, Pushbutton

B00177 Terminal Lug, Female, QD, .25 X .032

C00252 Washer, .375 in, Flat

C11541 Washer, .375 in, Star

B11518 Switch Insulation

C00284 Screw, 10-32 X .375 Ground

B00187 Cable Clamp, Nylon, .43 in.

B00180-10-3 Ring Terminal, #10 Center

B11505 Strain Relief Nut, Metal

C11560 Washer, .93 ID X 1.5 OD

B11504 Strain Relief, Metal

H02548-2 Label, Important, Cord

DESCRIPTION

QTY.

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

6

6

2

2

4

4

1

1

4

1

1

1

1

1

1

1

1

3

1

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

11

Page 14

1

ITEM

NO.

PART NUMBER

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

16

C00306 Roll Pin, .125 X 1.75

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

29

C11502 Socket Cap Screw, .375-16 X 2.5 in

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11478 Bumper, 20 in Floor Machine

42

D11486B Brush Cover, 20 in, Black

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490B Drip Cover, Black

51

H12913 Label, Drip Cover, White

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

68

67

52

51

50

46

45

44

43

42

41

40

39

2

66

62

61

60

59

58 57 56

49

48

47

3 5 6 7 8

4

10 11 12 13 14

9

65

64

63

55

54

53

10

15

16

17

18 19

20

21

2930 28

20LS3-BK

10-20-07

22

23

24

25

26

27

31

32

33

34

35

36

37

38

Page 15

ITEM

PART NUMBER

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

D11496B Switch Box Cover, Black

6

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

C00278 Locknut, 10-32, Nylon, SS

10

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

C00306 Roll Pin, .125 X 1.75

16

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

C11619 Allen Wrench, .31 in

21

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

C00259 Washer, Slotted, Zinc

24

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

C11502 Socket Cap Screw, .375-16 X 2.5 in

29

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

C00251 Lockwasher, .31, Split

40

41

E11478 Bumper, 20 in Floor Machine

D11486B Brush Cover, 20 in, Black

42

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490B Drip Cover, Black

51

H12913 Label, Drip Cover, White

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

20LS3-BK

10-20-07

DESCRIPTION

QTY.

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

6

6

2

2

4

4

1

1

4

1

1

1

1

1

1

1

1

3

1

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

11

Page 16

1

ITEM

NO.

PART NUMBER

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

4

H12066 Label, 1.5 HP, Saturn

5

H11831 Label, EDIC, Black-Silver

6

D11496B Switch Box Cover, Black

7

H11493 Label, Safety, Floor Machine

8

C11529 Screw, 10-32 X .375 in

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

12

D11524 Spring, Lockout

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

14

C11491 Screw, 10-32 X 1 in, SS

15

D11479 Handle, Chrome, Floormachine

16

C00306 Roll Pin, .125 X 1.75

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

28

C11558 Locknut, Black Oxide, Thin

29

C11502 Socket Cap Screw, .375-16 X 2.5 in

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

35

C00240 Washer, Shoulder, Nylon

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11478 Bumper, 20 in Floor Machine

42

D11486-SS Brush Cover, 20 in, Stainless

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

46

D11481 Handle Brace, Left, Black

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

49

H03545 Cover, Serial #, Label

50

D11490C Drip Cover, Chrome

51

H11830 Label, Saturn, Drip Cover

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

56

B11762 Terminal Lug, Nylon, Female

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

61

B11518 Switch Insulation

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

65

B11505 Strain Relief Nut, Metal

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

68

H02548-2 Label, Important, Cord

68

67

52

51

50

46

45

44

43

42

41

40

39

2

66

62

61

60

59

58 57 56

49

48

47

3 5 6 7 8

4

10 11 12 13 14

9

65

64

63

55

54

53

10

15

16

17

18 19

20

21

2930 28

20LS3-SS

10-20-07

22

23

24

25

26

27

31

32

33

34

35

36

37

38

Page 17

ITEM

PART NUMBER

NO.

1

B11487 Power Cord, 14-3, 50 FT, SJTW

2

K11498 Grip

3

C11528 Screw, 10-32 X .25 in

H12066 Label, 1.5 HP, Saturn

4

5

H11831 Label, EDIC, Black-Silver

D11496B Switch Box Cover, Black

6

7

H11493 Label, Safety, Floor Machine

C11529 Screw, 10-32 X .375 in

8

9

K11519 Lever Grip, Lockout, Black

10

C00278 Locknut, 10-32, Nylon, SS

11

D11494 Lockout Bracket

D11524 Spring, Lockout

12

13

C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS

C11491 Screw, 10-32 X 1 in, SS

14

15

D11479 Handle, Chrome, Floormachine

C00306 Roll Pin, .125 X 1.75

16

17

D11523 Spring, Trigger

18

D11495 Trigger, Zinc Plated

19

K11520 Lever Grip, Trigger, Black

20

11507A Assembled Locking Handle, Cord Hook

21

C11619 Allen Wrench, .31 in

22

D11497 Handle, Locking Clamp

23

C11538 Cap Nut, .31 in, Push-On

24

C00259 Washer, Slotted, Zinc

25

C11536 Spade Bolt, .375-16 X 4 in

26

D11507 Cord Hook Clamp

27

D11507-2 Cord Hook Body

C11558 Locknut, Black Oxide, Thin

28

29

C11502 Socket Cap Screw, .375-16 X 2.5 in

30

C11537 Dowel Pin, .31 X 1.5 in

31

C13101 Screw, Hex Cap, M14-2.0

32

K00674 Bushing, .50 in, Nylon

33

D11510 Axle, Floor Machine

34

D11482 Handle Brace, Right, Black

C00240 Washer, Shoulder, Nylon

35

36

C11559 Washer, .515 X .875 X .032

37

G11943 Wheel, 5 in Saturn

38

C02305 Cap Nut, .5in Push-on

39

C11501 Socket Cap Screw, .31 - 18

40

C00251 Lockwasher, .31, Split

41

E11478 Bumper, 20 in Floor Machine

D11486-SS Brush Cover, 20 in, Stainless

42

43

K11521 Spacer, Base, Floor Machine

44

D11483 Frame, Motor, Black

45

G11468 Motor W-Gearbox, 1.5 HP

D11481 Handle Brace, Left, Black

46

47

H10976-1 Label, UL STD 561-507

48

H00565-5 Label, Serial #, Standard

H03545 Cover, Serial #, Label

49

50

D11490C Drip Cover, Chrome

51

H11830 Label, Saturn, Drip Cover

52

C11916 Screw, 10-32 X .375 Phillips

53

C13100 Nut, M14-2.0 Nylon Insert

54

B10734 Strain Relief, Handle

55

B11513 Cord, Handle, 14-3 SJTW

B11762 Terminal Lug, Nylon, Female

56

57

B11465 Switch, DPST, Pushbutton

58

B00177 Terminal Lug, Female, QD, .25 X .032

59

C00252 Washer, .375 in, Flat

60

C11541 Washer, .375 in, Star

B11518 Switch Insulation

61

62

C00284 Screw, 10-32 X .375 Ground

63

B00187 Cable Clamp, Nylon, .43 in.

64

B00180-10-3 Ring Terminal, #10 Center

B11505 Strain Relief Nut, Metal

65

66

C11560 Washer, .93 ID X 1.5 OD

67

B11504 Strain Relief, Metal

H02548-2 Label, Important, Cord

68

20LS3-SS

10-20-07

11

DESCRIPTION

QTY.

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

6

6

2

2

4

4

1

1

4

1

1

1

1

1

1

1

1

3

1

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

Page 18

17LS4-BK

10

Page 19

17LS4-BK

11

Page 20

20

17LS4-BK

10

Page 21

20

20

17LS4-BK

11

Loading...

Loading...