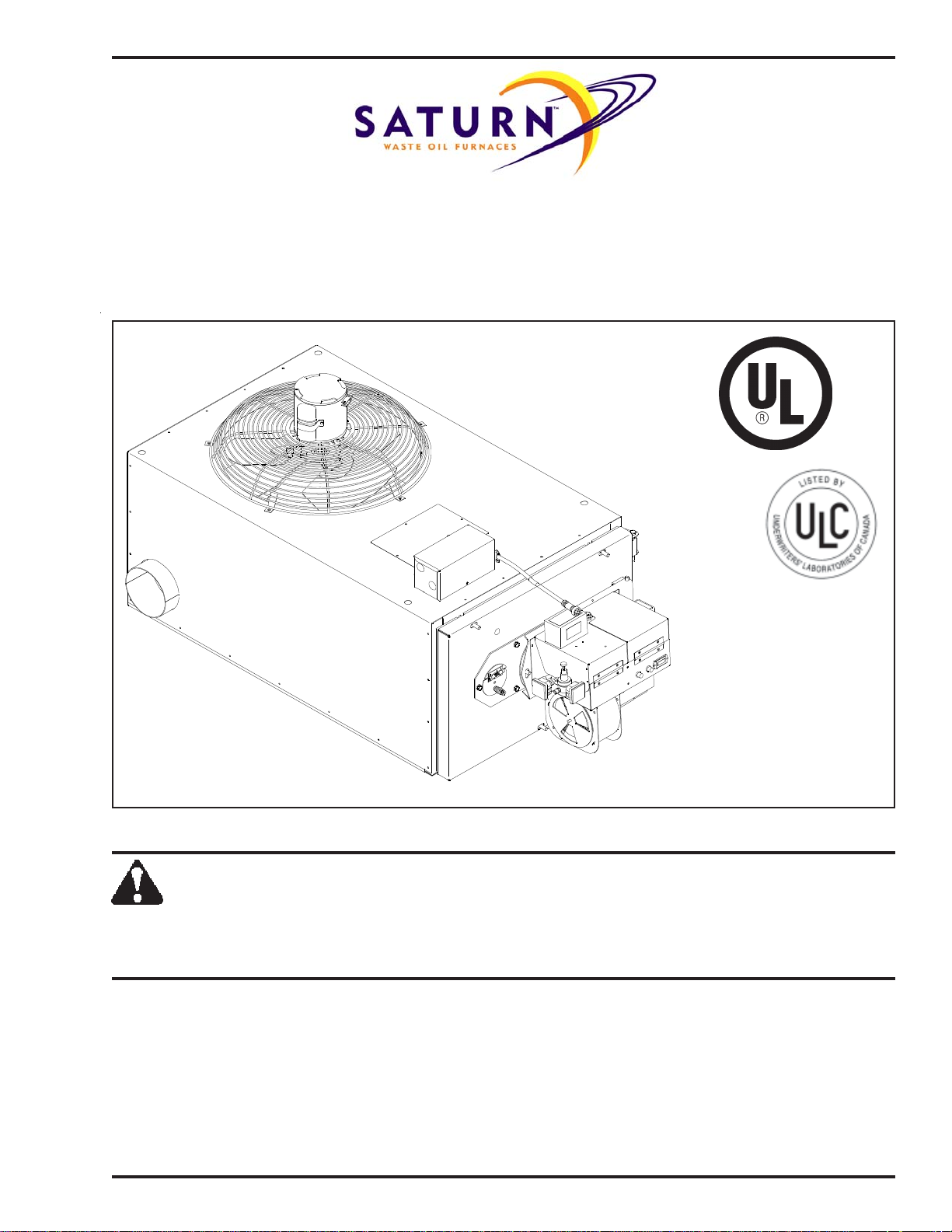

OPERATOR'S MANUAL

FURNACE MODELS: SATURN™ 140 and SATURN™ 230

MULTI-OIL FURNACES

with SATURN™ 125 BURNER

U.L. Listed Used Oil

Burning Appliance

#MH15393 (N)

U.L.-C Listed

#CMP217

PUBLICATION DATE: 6/13/11, Rev. 3 CLEAN BURN PART # 43224

WARNING: DO NOT assemble, install, operate, or maintain this equipment without first

reading and understanding the information provided in this manual. Installation and

service must be accomplished by qualified personnel. Failure to follow all safety precautions

and procedures as stated in this manual may result in property damage, serious personal injury

or death.

IMPORTANT FOR U.S. INSTALLATIONS: All installations must be made in accordance with state and local codes

which may differ from the information provided in this manual. Save these instructions for reference.

IMPORTANT FOR CANADIAN INSTALLATIONS: These instructions have been reviewed and accepted by

Underwriters' Laboratories of Canada as being appropriate for the installation of the ULC labelled products

identified herein. The use of these instructions for the installation of products NOT bearing the ULC label and

NOT identified herein may result in an unacceptable or hazardous installation.

IMPORTANT FOR CANADIAN INSTALLATIONS: The installation of this equipment is to be accomplished by

qualified personnel and in accordance with the regulation of authorities having jurisdiction and CSA Standard B 139,

Installation Code for Oil Burning Equipment.

WARRANTY INFORMATION

Clean Burn, LLC., MANUFACTURER, hereby warrants that MANUFACTURER's SaturnTM 140 and SaturnTM 230 furnace

models shall be free from defect in material and workmanship under normal use according to the provisions and limitations

herein set forth. MANUFACTURER warrants the heat exchanger/combustion chamber for three (3) years from the date of

purchase by the purchaser and pro rata thereafter according to the following schedule: (a) If the defect occurs during the

fourth year, customer pays 70% of parts, replacement or repair. (b) If the defect occurs during the fifth year, customer pays

80% of parts, replacement or repair. (c) If the defect occurs during the sixth year, customer pays 90% of parts, replacement or

repair. MANUFACTURER warrants all other Clean Burn components for a period of one (1) year from the date of purchase by

the purchaser.

LIMITATIONS:

The obligation of MANUFACTURER for breach of warranty shall be limited to products manufactured by MANUFACTURER (1) that are

installed, operated and maintained according to MANUFACTURER's instructions furnished and/or available to the purchaser upon

request; (2) that are installed according to all other applicable Federal, State and local codes or regulations; and (3) that the purchaser

substantiates were defective in material and workmanship notwithstanding that they were properly installed and correctly maintained as set

forth above and were not abused or misused.

The obligation of MANUFACTURER shall be limited to replacing or repairing the defective product, at the option of the

MANUFACTURER. MANUFACTURER shall not be responsible for any labor or costs of removal or reinstallation of its products and

shall not be liable for transportation costs to and from its plant in Lancaster, Pennsylvania.

Use of parts for modification or repair of the product or any component part thereof not authorized or manufactured by

MANUFACTURER specifically for such product shall void this warranty.

This warranty shall not apply to any damage to or defect in any of MANUFACTURER's products that is directly or indirectly caused by (1)

force majeure, Act of God or other accident not related to an inherent product defect; or (2) abuse, misuse or neglect of such product,

including any damage caused by improper assembly, installation, adjustment, service, maintenance or faulty instruction of the purchaser.

Other than as expressly set forth hereinabove, MANUFACTURER makes no other warranty, express or implied, with respect to any of

MANUFACTURER's products, including but not limited to any warranty of merchantability or fitness for a particular purpose.

And in no event shall MANUFACTURER be responsible for any incidental or consequential damages of any nature suffered by purchaser

or any other person or entity caused in whole or in part by any defect in any of MANUFACTURER's products. Any person or entity to

whom this warranty extends and who claims breach of warranty against MANUFACTURER must bring suit thereon within one year from

the date of occurrence of such breach of warranty or be forever barred from any and all legal or other remedies for such breach of warranty.

MANUFACTURER is not responsible for and hereby disclaims any undertaking, representation or warranty made by any dealer, distributor or other person that is inconsistent with or in any way more expansive than the provisions of this limited warranty.

This warranty grants specific legal rights and shall be read in conformity with applicable state law. In some jurisdictions, the applicable

law mandates warranty provisions that provide greater legal rights than those provided for herein. In such case, this limited warranty shall

be read to include such mandated provisions; and any provision herein that is prohibited or unenforceable in any such jurisdiction shall, as

to such jurisdiction, be ineffective to the extent of such prohibition or unenforceability without invalidating the remaining provisions and

without affecting the validity or enforceability of such provision in any other jurisdiction(s).

TRADEMARKS

The Clean Burn logo and Saturn logo are trademarks of Clean Burn, LLC. All other brand or product names mentioned are the

registered trademarks or trademarks of their respective owners.

COPYRIGHT

Copyright © 2011 Clean Burn, Inc. All rights reserved. No part of this publication may be reproduced, or distributed without

the prior written permission of Clean Burn, LLC. 4109 Capital Circle Dr, Janesville, WI 53546. Subject to change without notice.

TABLE OF CONTENTS

SECTION 1: INTRODUCTION.................................................................................... 1-1

Guide to this Manual........................................................................................................1-1

For Your Safety... ............................................................................................................. 1-2

Guidelines for Furnace Usage ...................................................................................1-4

Guidelines for Used Oil Tanks..................................................................................1-5

Safety Labels ............................................................................................................. 1-6

SECTION 2: UNPACKING ......................................................................................... 2-1

Removing the Shipping Crate..............................................................................................2-1

Unpacking and Inspecting All Components .........................................................................2-1

Furnace Component List .............................................................................................2-1

Warranty Registration.........................................................................................................2-2

SECTION 3: FURNACE ASSEMBLY......................................................................... 3-1

Understanding Assembly ................................................................................................. 3-1

Required Tools and Materials ......................................................................................3-1

Overview of Furnace Assembly ..........................................................................................3-2

Installing the Observation Port ............................................................................................3-3

Installing the Air Outlet Louvers ..........................................................................................3-3

Installing the Combustion Sleeve .........................................................................................3-5

Installing the Burner ............................................................................................................3-6

Checking the Burner Nozzle and Electrodes .................................................................3-6

Mounting the Burner on the Hinge Bracket ...................................................................3-7

Installing the Connector Block, Oil Line Tubing, and Air Line Tubing ...................................3-8

Installing the Connector Block on the Furnace Door .....................................................3-8

Installing the Oil Line Tubing ........................................................................................3-8

Installing the Air Line Tubing ........................................................................................3-9

Locking the Burner into Firing Position .........................................................................3-9

SECTION 4: FURNACE INSTALLATION .................................................................. 4-1

Understanding Installation ...................................................................................................4-1

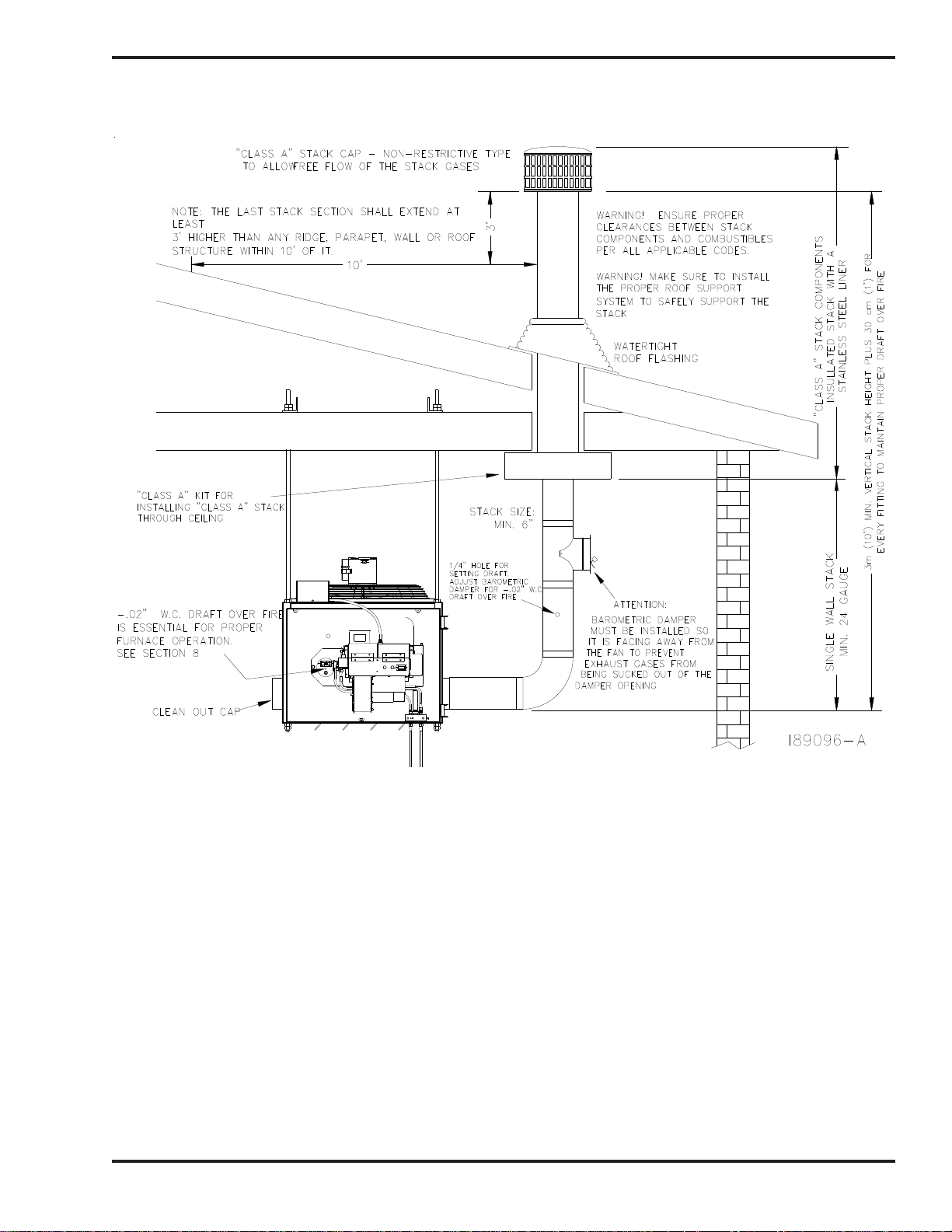

Typical Installation Illustration ......................................................................................4-2

Selecting a Location ...........................................................................................................4-3

Guidelines for Selecting a Location...............................................................................4-3

Clearances for Installation ............................................................................................4-3

Mounting the Furnace.........................................................................................................4-4

Ceiling Mounting .........................................................................................................4-4

Raised Platform Mounting............................................................................................4-5

Floor Mounting ...........................................................................................................4-5

Oil Tank Installation Specifications......................................................................................4-7

Installing the Tank Vent and Emergency Vent ...............................................................4-8

Installing the Metering Pump ...............................................................................................4-9

Preparing for Installation ..............................................................................................4-9

Standard Mounting: Vertical Positioning ......................................................................4-9

Alternate Mounting: Horizontal Positioning ................................................................4-11

TABLE OF CONTENTS

SECTION 4: FURNACE INSTALLATION (continued)

Wiring the Furnace and Pump...........................................................................................4-12

Wiring to the Furnace ................................................................................................4-12

Wiring to the Metering Pump .....................................................................................4-12

Installing the Suction Oil Line Components........................................................................4-13

Installing the Pressure Relief Oil Line Back to the Tank .....................................................4-16

Installing the Pressure Oil Line Components ......................................................................4-17

Installing the Compressed Air Line....................................................................................4-17

Installing the Stack ...........................................................................................................4-18

Installing the Interior Stack.........................................................................................4-21

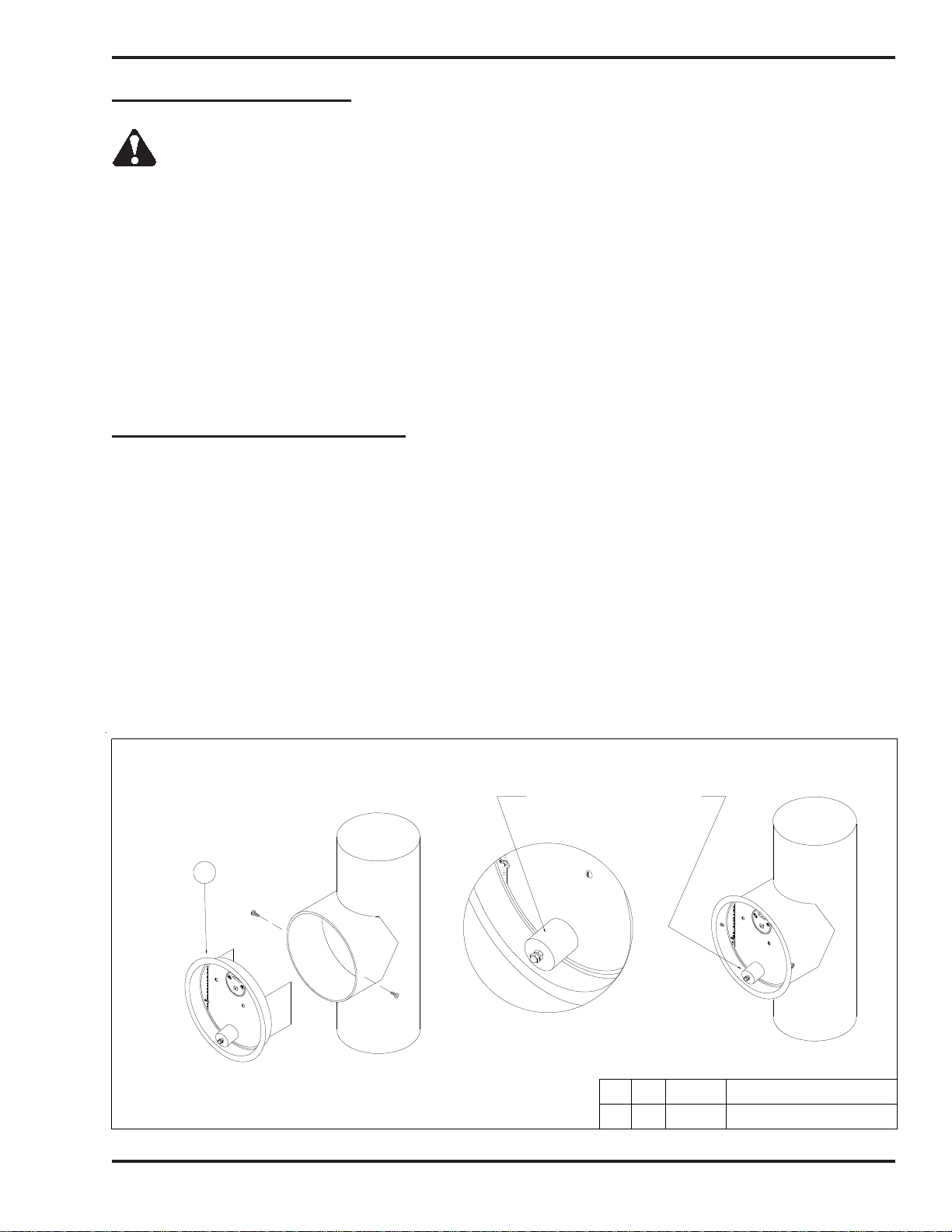

Installing the Barometric Damper ...............................................................................4-21

Installing the Stack Safety Switch For Canadian Installations.......................................4-22

Resetting the Stack Safety Switch ........................................................................4-23

Understanding the Function of the Stack Safety Switch .........................................4-23

Installing the Stack Penetration...................................................................................4-24

Installing the Exterior Stack........................................................................................4-24

Installing the Stack Cap .............................................................................................4-24

Installing the Optional Draft Inducer ...........................................................................4-24

Installing the Wall Thermostat ...........................................................................................4-26

Replacing the Wall Thermostat Batteries ....................................................................4-26

Inspecting the Furnace Installation.....................................................................................4-26

SECTION 5: METERING PUMP PRIMING ................................................................5-1

Understanding Metering Pump Priming .......................................................................... 5-1

Required Tools and Materials ................................................................................... 5-1

Priming the Metering Pump.................................................................................................5-2

Vacuum Testing the Oil Pump.............................................................................................5-4

SECTION 6: STARTING AND ADJUSTING THE BURNER ......................................6-1

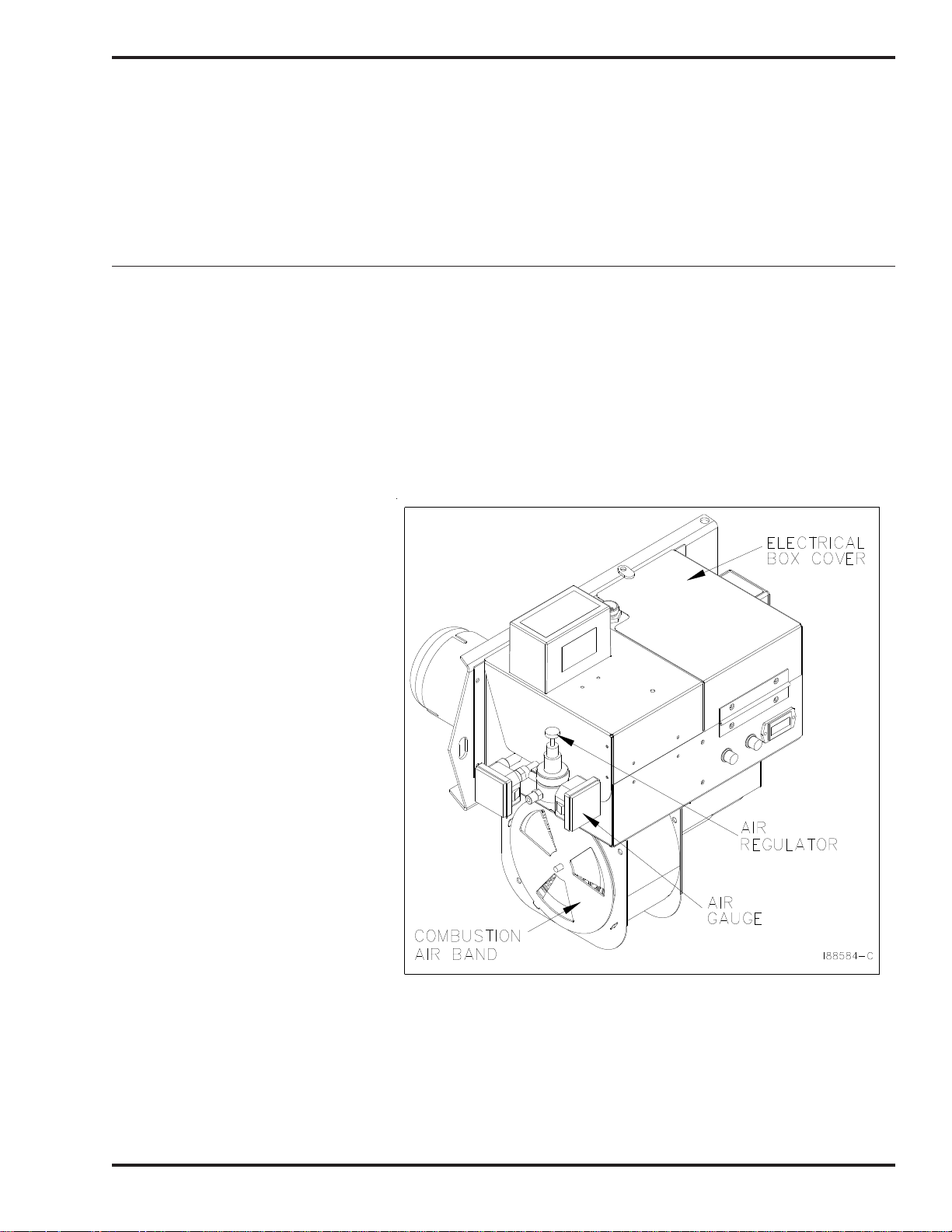

Understanding Burner Startup and Adjustment ...............................................................6-1

Preparing the Burner for Startup ......................................................................................6-1

Starting the Burner .............................................................................................................6-2

Checking the Operation of the Fan/Blower Motor...............................................................6-4

SECTION 7: RESETTING THE OIL PRIMARY CONTROL .......................................7-1

Understanding the Oil Primary Control ...........................................................................7-1

Using the Reset Button .......................................................................................................7-1

The Blower/Fan Switch ......................................................................................................7-2

The High Temp Limit Switches ...........................................................................................7-2

Understanding the L-200 High Temp Limit Switches ....................................................7-2

Understanding the L-290 Auxiliary Auto Reset High Temp Limit Switch .......................7-2

TABLE OF CONTENTS

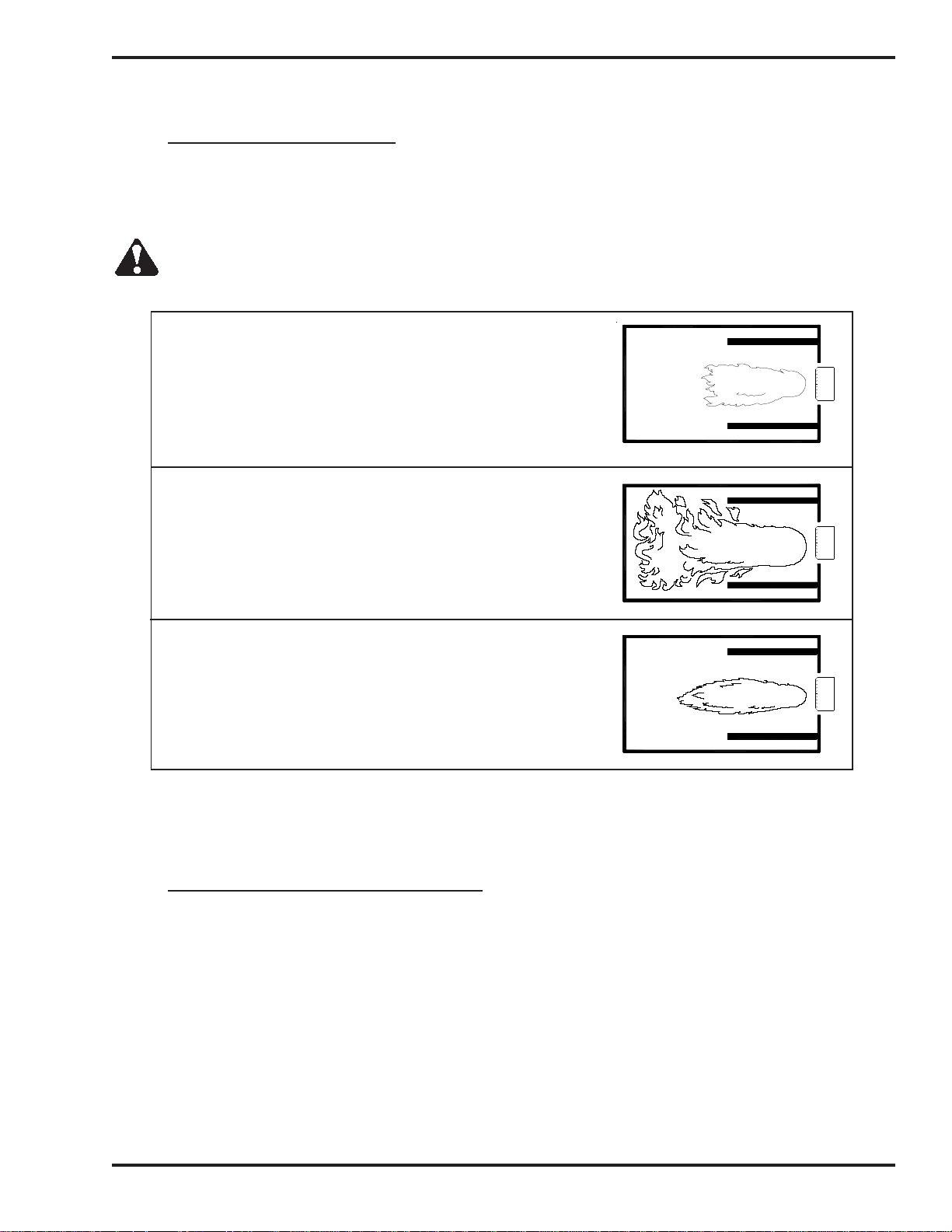

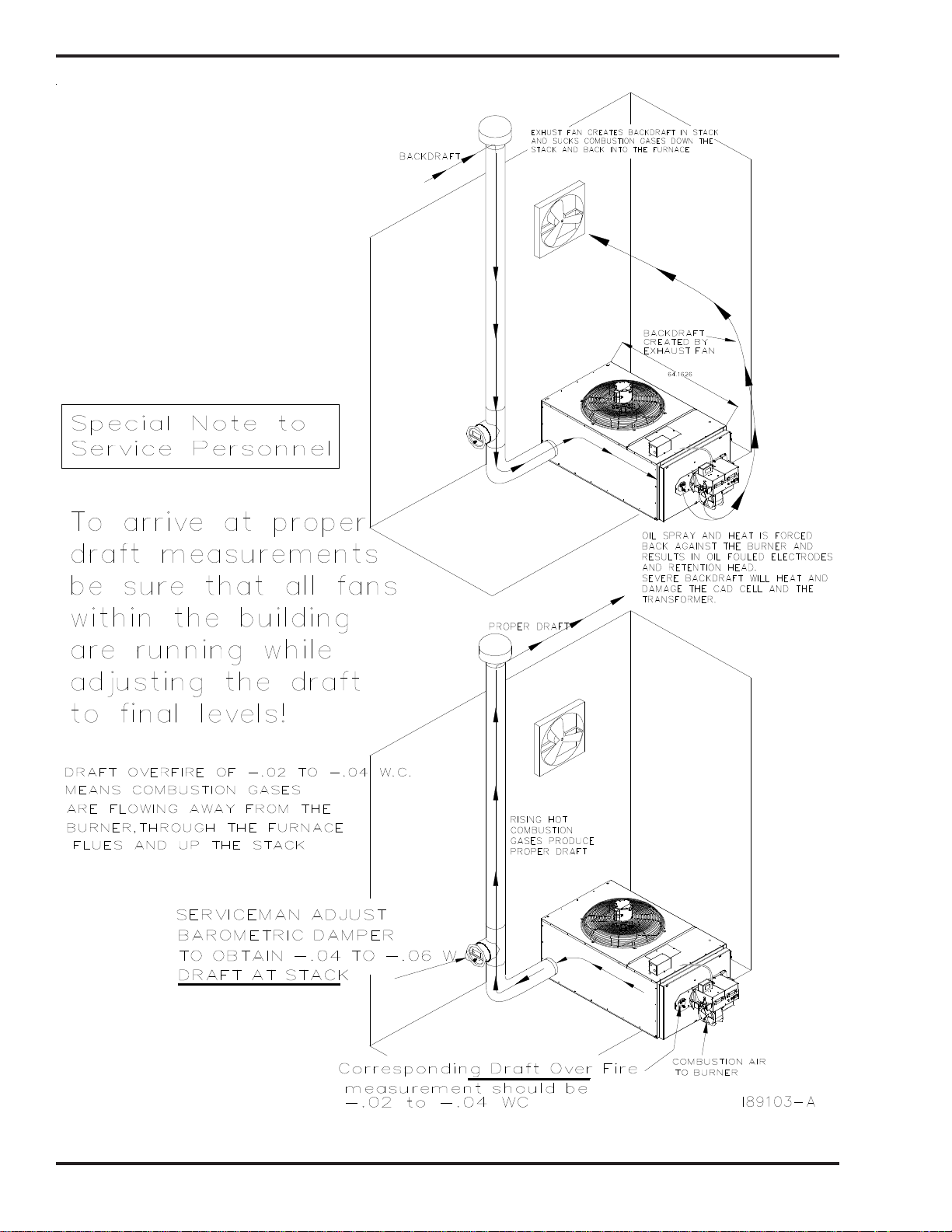

SECTION 8: ADJUSTING THE DRAFT OVER FIRE ................................................8-1

Understanding the Importance of Draft ...............................................................................8-1

Checking for Correct Draft Over Fire .................................................................................8-1

Adjusting the Barometric Damper .......................................................................................8-2

Solving Draft Over Fire Problems .......................................................................................8-2

Understanding the Effect of Exhaust Fans on Draft .......................................................8-3

Checking Draft Over Fire to Determine Severity of Backdraft ......................................8-3

Installing a Make-up Air Louver ..................................................................................8-5

SECTION 9: MAINTENANCE ....................................................................................9-1

Understanding Maintenance................................................................................................9-1

Periodic Burner Inspection .................................................................................................9-1

Cleaning the Canister Filter .................................................................................................9-2

Servicing the Metering Pump ..............................................................................................9-3

Cleaning the Check Valve / Screen .....................................................................................9-3

Cleaning the Tank ..............................................................................................................9-4

Cleaning Ash from the Furnace ...........................................................................................9-5

Annual Burner Tune-Up .....................................................................................................9-7

End of Season Maintenance ...............................................................................................9-7

Cleaning and Maintaining the Optional Draft Inducer ...........................................................9-7

SECTION 10: TROUBLESHOOTING ......................................................................10-1

Flow Chart ......................................................................................................................10-2

Troubleshooting Tables ....................................................................................................10-3

APPENDIX A

Detailed Furnace Specifications ......................................................................................... A-1

Burner Technical Specifications ......................................................................................... A-2

Furnace Dimensions .......................................................................................................... A-3

Burner Components .......................................................................................................... A-4

Removing the Nozzle for Cleaning.............................................................................A-11

Saturn™ 140 Cabinet Components ................................................................................. A-12

Saturn™ 230 Cabinet Components ................................................................................. A-14

Metering Pump Components ........................................................................................... A-16

APPENDIX B

Wiring Diagrams ............................................................................................................... B-1

Furnace Wiring Diagram ............................................................................................. B-1

Saturn™ 125 Burner Wiring Diagram ......................................................................... B-2

Ladder Schematic ...................................................................................................... B-3

Metering Pump Wiring Schematic ............................................................................... B-4

APPENDIX C

Furnace Service Record .................................................................................................... C-1

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

SECTION 1: INTRODUCTION

Guide to this Manual

This manual contains all the information necessary to safely install and operate the Clean Burn furnace models

Saturn™ 140 and Saturn™ 230 . Consult the Table of Contents for a detailed list of topics covered. You'll

find this manual's step-by-step procedures easy to follow and understand. Should questions arise, please

contact your Clean Burn dealer before starting any of the procedures in this manual.

As you follow the directions in this manual, you'll discover that assembling and operating your new

furnace involves five basic activities as outlined here:

• UNPACKING.................................................................................................... (Section 2)

• ASSEMBLY ...................................................................................................... (Section 3)

• INSTALLATION ............................................................................................. (Section 4)

• OPERATION

• Metering Pump Priming ...................................................................... (Section 5)

• Starting and Adjusting the Burner ..................................................... (Section 6)

• Resetting the Oil Primary Control...................................................... (Section 7)

• Adjusting the Draft............................................................................... (Section 8)

• MAINTENANCE ............................................................................................. (Section 9)

The manual also contains important and detailed

technical reference materials which are located at the

back of the manual in the Appendixes.

Please read all sections carefully--including the

important safety information found in this section-before beginning any installation/operation

procedures; doing so ensures your safety and the

optimal performance of your Clean Burn furnace.

WARNING!

STOP

YOUR SAFETY IS AT STAKE!

DO NOT INSTALL, OPERATE OR

MAINTAIN THIS EQUIPMENT

WITHOUT FIRST READING

AND UNDERSTANDING THE

OPERATOR'S MANUAL!

1-1

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety...

For your safety, Clean Burn documentation contains the following types of safety statements (listed here

in order of increasing intensity). Note the safety key words printed in bold for each:

• NOTE: A clarification of previous information or additional pertinent information.

• ATTENTION: A safety statement indicating that potential equipment damage may occur if

instructions are not followed.

CAUTION: A safety statement that reminds of safety practices or directs attention to unsafe

practices which could result in personal injury if proper precautions are not taken.

WARNING: A strong safety statement indicating that a hazard exists which can result in

injury or death if proper precautions are not taken.

DANGER! The utmost levels of safety must be observed; an extreme hazard exists which

would result in high probability of death or irreparable serious personal injury if proper

precautions are not taken.

In addition to observing the specific precautions listed throughout the manual, the following general

precautions apply and must be heeded to ensure proper, safe furnace operation.

DANGER! DO NOT create a fire or explosion hazard by storing or using gasoline or other

flammable or explosive liquids or vapors near your furnace.

DANGER! DO NOT operate your furnace if excess oil, oil vapor or fumes have

accumulated in or near your furnace. As with any oil burning furnace, improper installation,

operation or maintenance may result in a fire or explosion hazard.

WARNING: DO NOT add inappropriate or hazardous materials to your used oil, such as:

• Anti-freeze

• Carburetor cleaner

• Paint thinner

• Parts washer solvents

• Gasoline

• Oil additives

• Any other inappropriate/hazardous

material

WARNING: Burning chlorinated materials (chlorinated solvents and oils) is illegal, will

severely damage your heat exchanger, immediately void your warranty, and adversely affect

the proper, safe operation of your furnace. Instruct your personnel to never add hazardous

materials to your used oil.

1-2

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

WARNING: Never alter or modify your furnace without prior written consent of

Clean Burn, LLC. Unauthorized modifications or alteration can adversely affect the proper,

safe operation of your furnace.

WARNING: The burner which is shipped with your Clean Burn furnace is to be used only

with your furnace according to the instructions provided in this manual. DO NOT use the

burner for any other purpose!

WARNING: The Best Operator is a Careful Operator! By using common sense,

observing general safety rules, and adhering to the precautions specific to the equipment, you,

the operator, can promote safe equipment operation. Failure to use common sense, observe

general safety rules, and adhere to the precautions specific to the equipment may result in

equipment damage, fire, explosion, personal injury and/or death.

WARNING: The installation, operation, and maintenance of this equipment in the U.S.

must be accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and with all national, state, and local codes or authorities

having jurisdiction over environmental control, building inspection and fuel, fire and

electrical safety and the following standards:

NFPA 30 Flammable and Combustible Liquids Code

NFPA 30A Automotive and Marine Service Station Code

NFPA 31 Standard for the Installation of Oil Burning Equipment

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

NFPA 88A Parking Structures

NFPA 88B Repair Garages

NFPA 70 National Electrical Code

The International Mechanical Code

The International Building Code

The International Fire Code

The International Fuel Gas Code

Likewise, the installation, operation, and maintenance of this equipment in Canada is to be

accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and in accordance with the regulation of authorities having

jurisdiction and the following CSA Standards:

B139 Installation Code for Oil Burning Equipment

B140.0 General Requirements for Oil Burning Equipment

C22.1 Canadian Electrical Code, Part 1.

Failure to comply with these standards and requirements may result in equipment

damage, fire, explosion, personal injury and/or death.

1-3

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

Guidelines for Furnace Usage

This furnace is listed for commercial and/or industrial use only; it is not listed for

residential use.

This furnace is listed with Underwriters Laboratory and Underwriters' Laboratories

of Canada to burn the following fuels:

• #2 fuel oil

• Used crankcase oil up to 50 SAE

• Used hydraulic oil

• Used transmission fluid (U.S.)

• #4 and #5 fuel oil (U.S.)

Make sure you comply with all EPA regulations concerning the use of your furnace.

EPA regulations require that:

• Your used oil is generated on-site. You may also accept used oil from

"do-it-yourself" oil changers.

• Hazardous wastes, such as chlorinated solvents, are NOT to be mixed

with your used oil.

• The flue gases are vented to the outdoors with an appropriate stack.

• Your used oil is recycled as fuel for "heat recovery". DO NOT operate

your furnace in warm weather just to burn oil.

Contact your Clean Burn dealer for current EPA regulations.

If your furnace ever requires service, call your Clean Burn dealer. DO NOT allow

untrained, unauthorized personnel to service your furnace. Make sure that your

furnace receives annual preventative maintenance to ensure optimal performance.

1-4

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

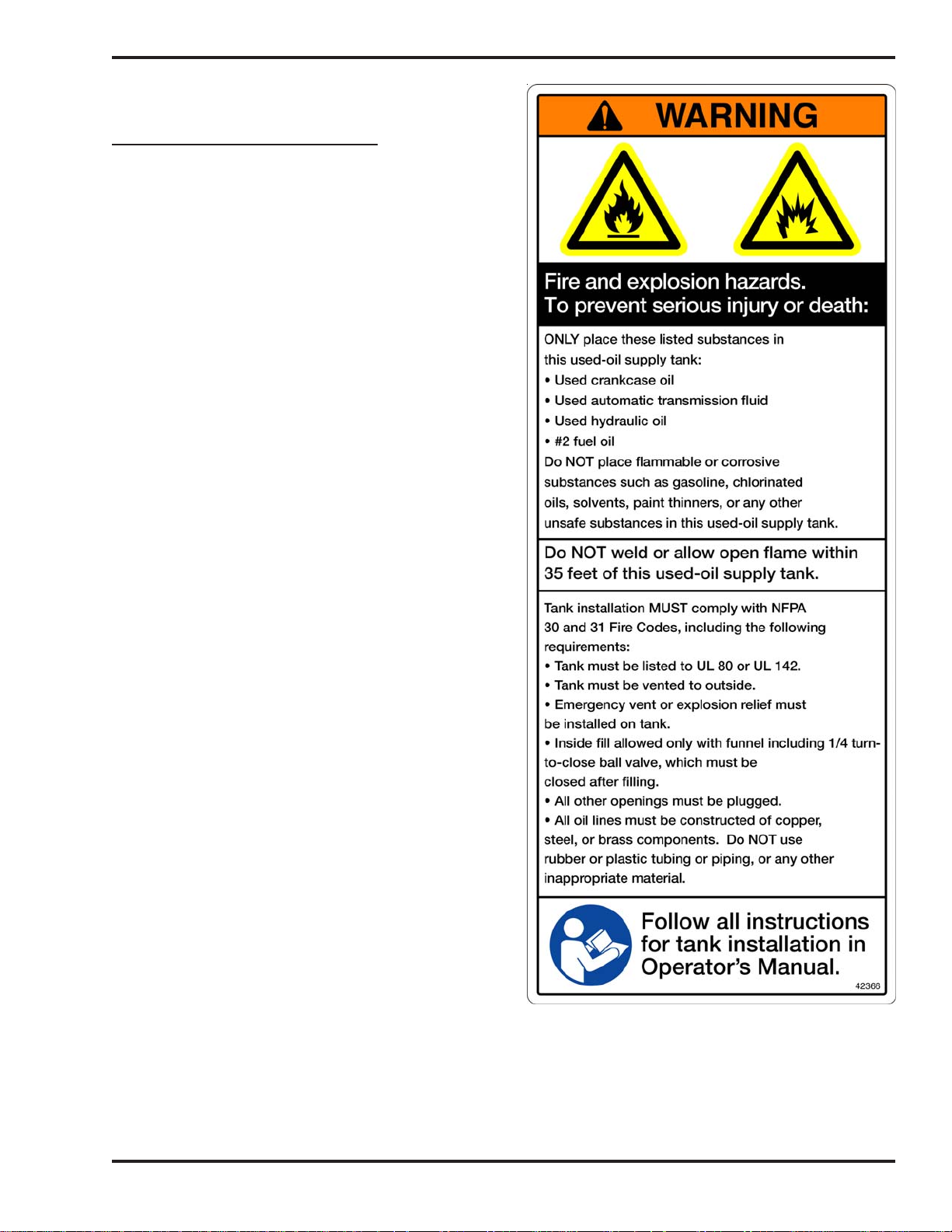

Guidelines for Used Oil Tanks

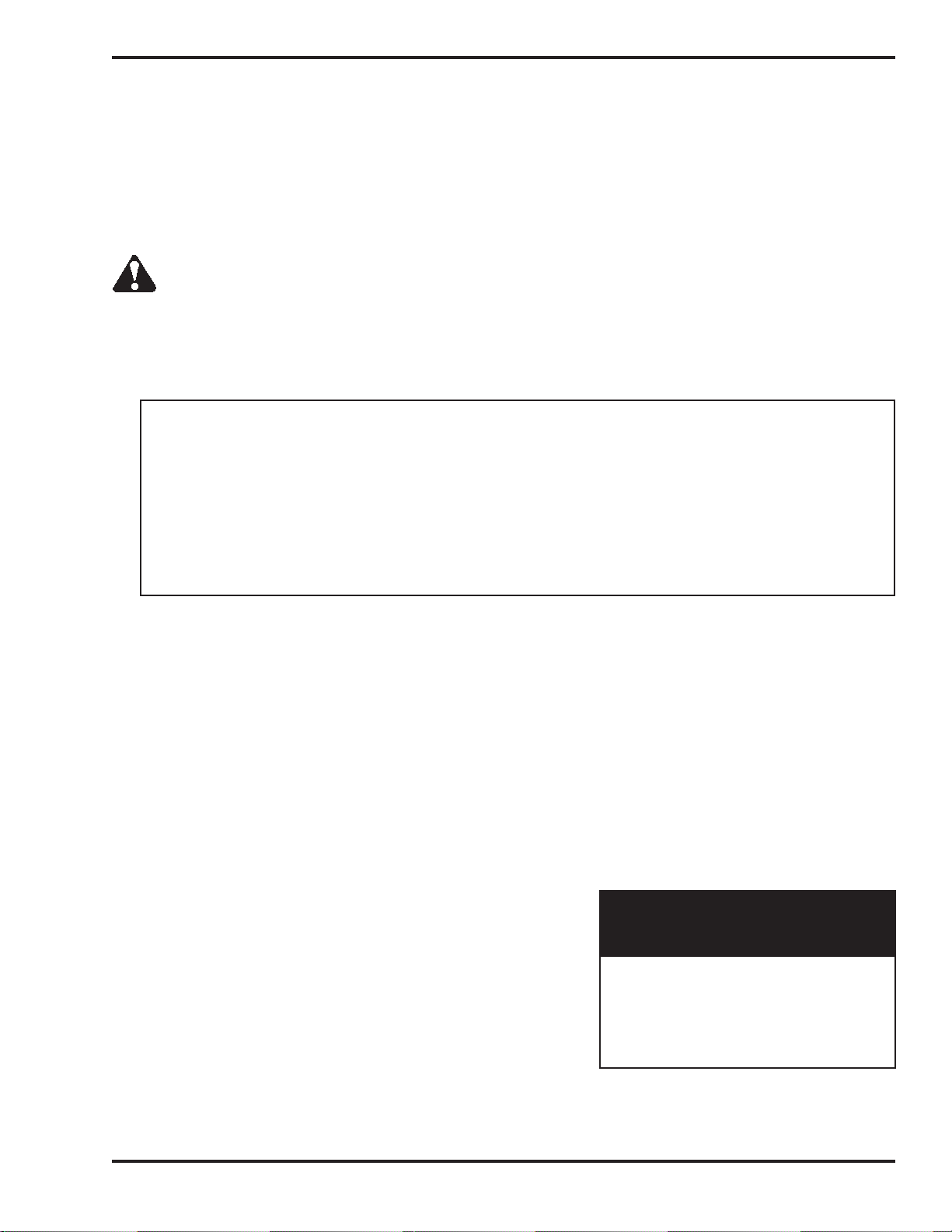

For the safe storage of used oil and the safety of

persons in the vicinity of the used oil supply tank,

ensure that your tank installation adheres to the

following safety guidelines:

• The tank installation must meet all

national and local codes. Consult your

local municipal authorities for more

information as necessary.

• Review and adhere to the safety

guidelines for used oil supply tanks

as stated in the WARNING shown.

• Ensure that the tank for your furnace

installation complies with all code and

safety requirements as stated here. If the

tank does not comply, DO NOT use it.

• If you do not have a copy of the tank

safety label pictured at right, please

contact your Clean Burn dealer for the

label, which is to be affixed directly on

your used oil supply tank.

1-5

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

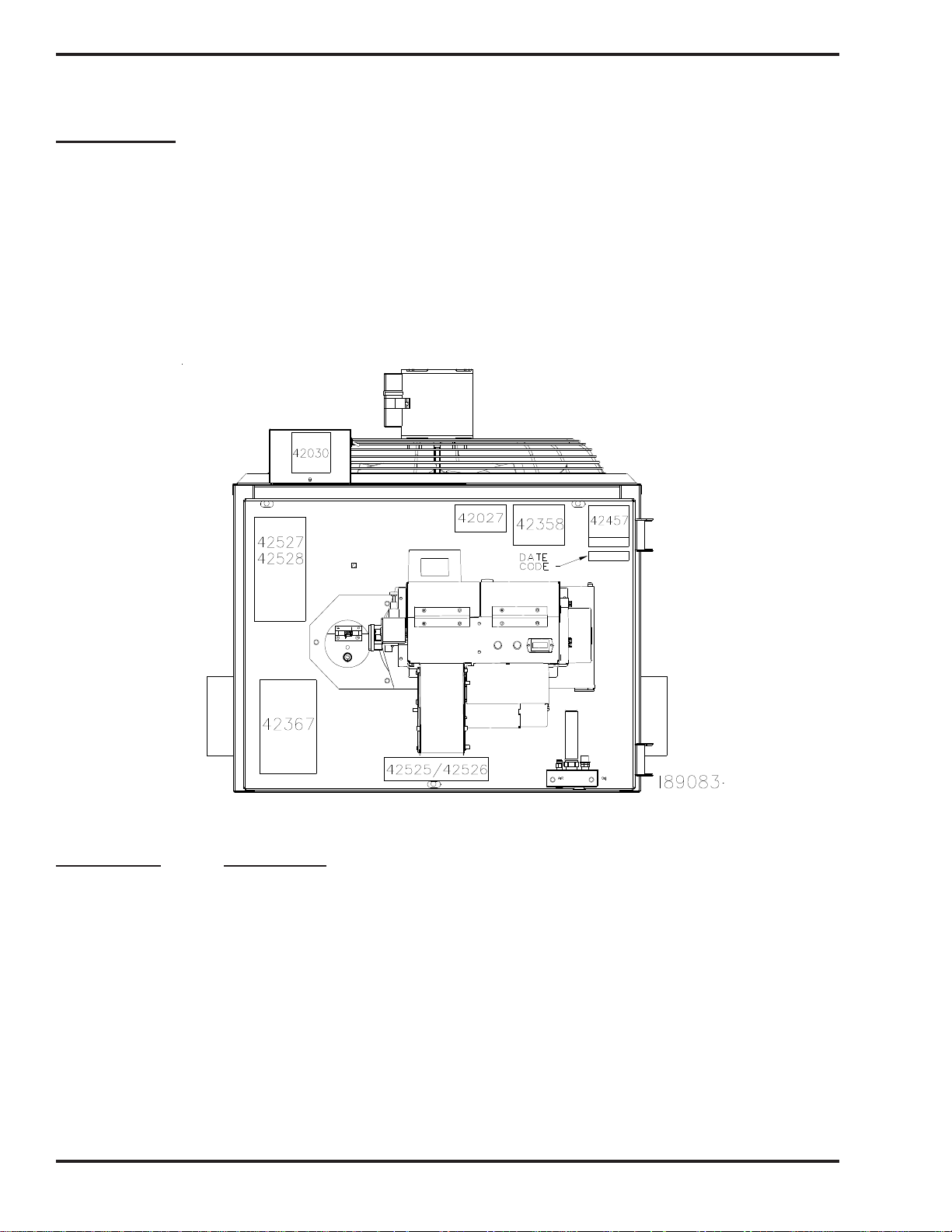

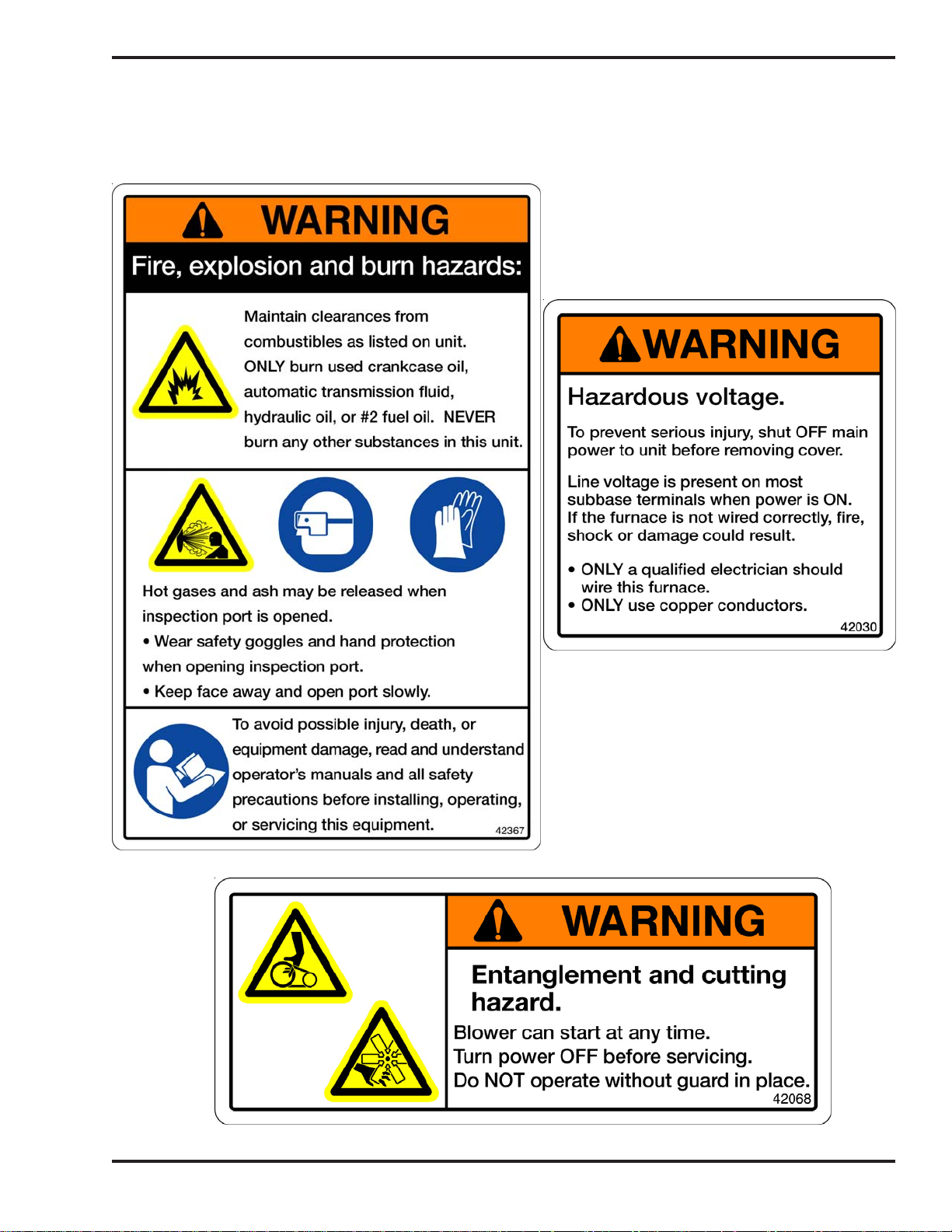

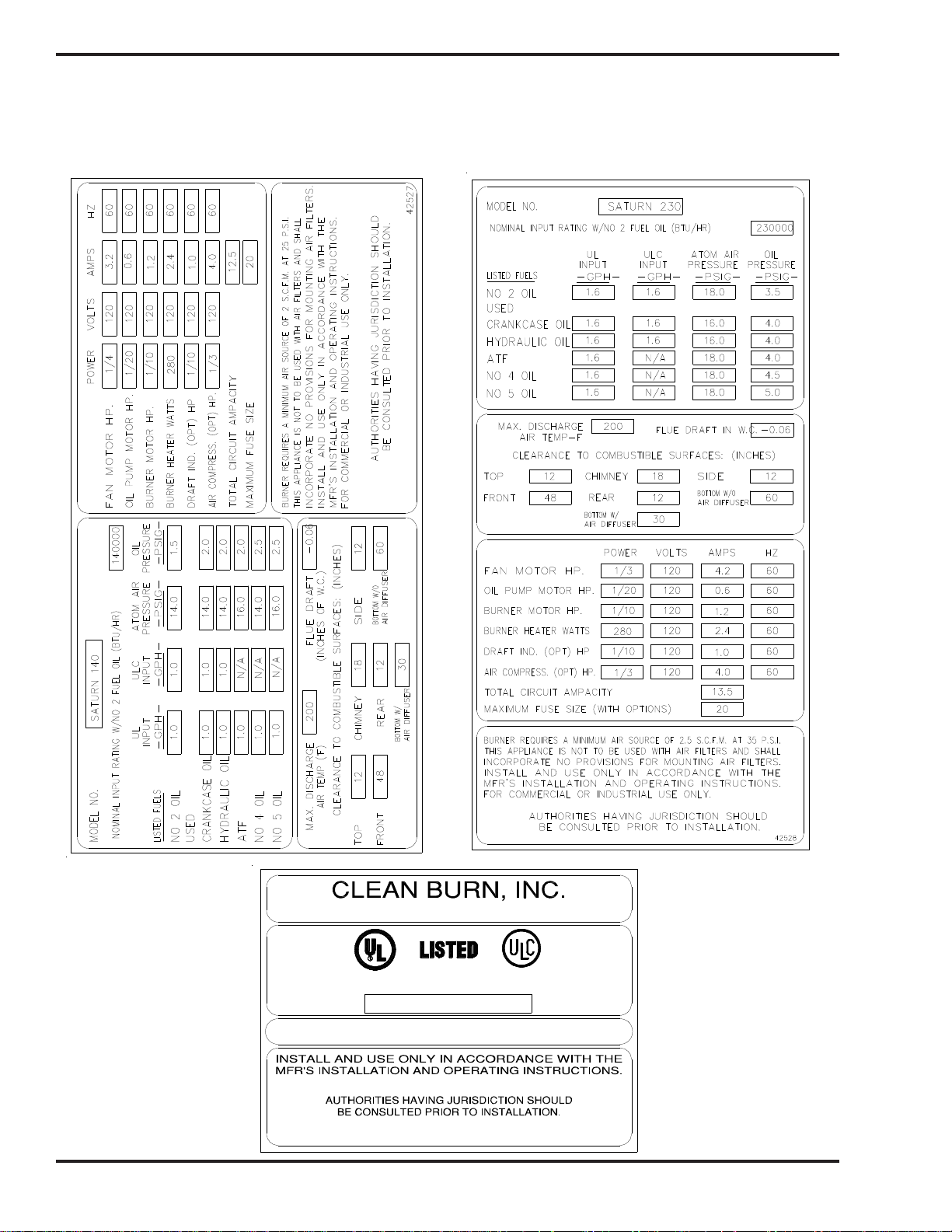

Safety Labels

Following are the locations and descriptions of all labels on your Clean Burn Saturn™ furnace. The following

illustrations show the location of labels on your furnace. Please note that some labels denote model number,

model description, etc. while others contain important safety messages.

Each Safety Label contains an important safety message starting with a key word as discussed earlier in

this section (e.g. ATTENTION, CAUTION, WARNING, DANGER). For your safety and the safe

operation of your furnace, review all labels and heed all safety messages as printed on the labels.

If any labels on your Clean Burn furnace ever become worn, lost or painted over, please call your Clean

Burn dealer for free replacements.

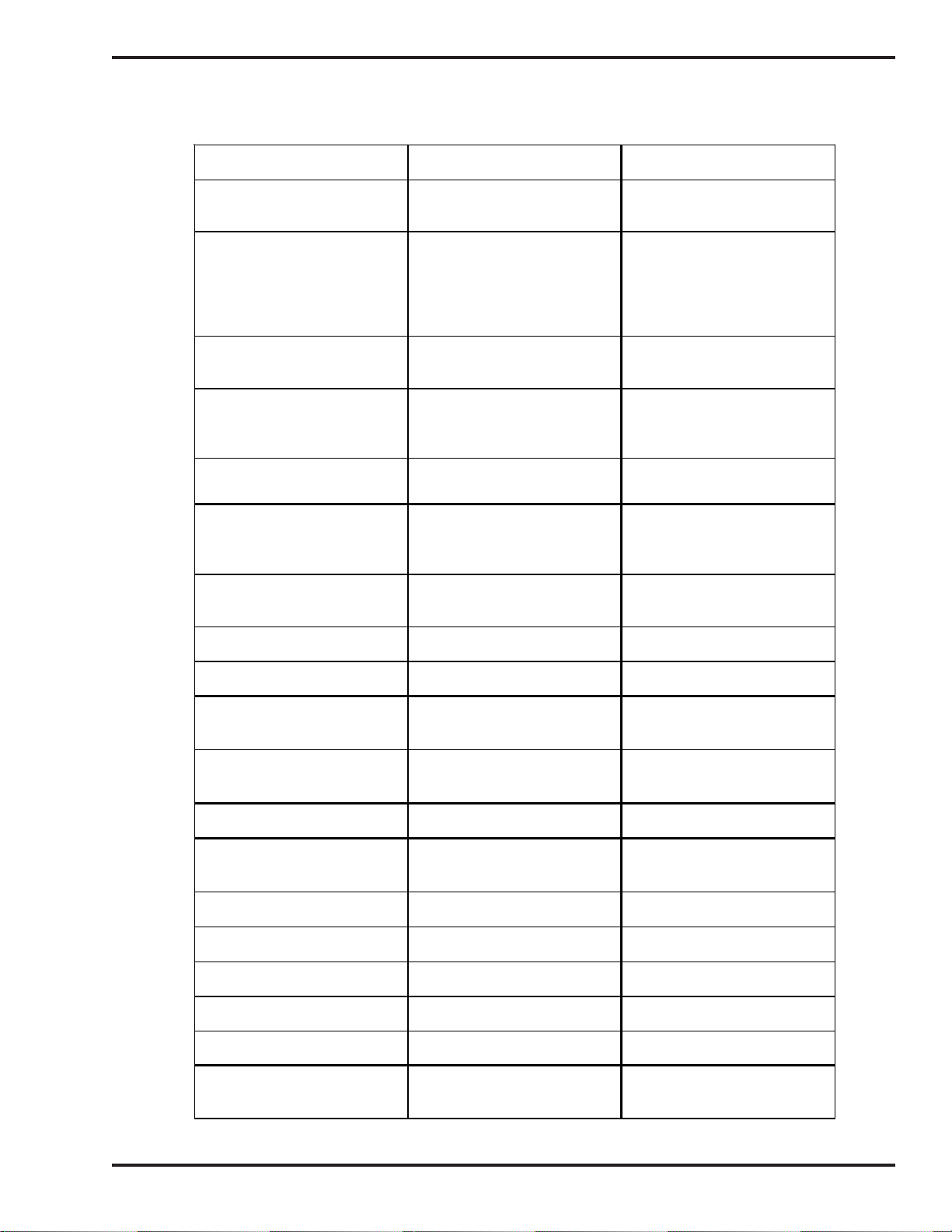

Saturn™ Furnace Cabinet Labels

Label Part # Description

42525 Saturn™ 140 Name Label

42526 Saturn™ 230 Name Label

42367 Furnace Safety Warning Label (Multiple Messages - Fire/Shock/Burn Hazards)

42527 Saturn™ 140 UL Data Label

42528 Saturn™ 230 UL Data Label

42358 UL Header Label

42457 Made in USA / Patent Pending Combination Label

42030 Furnace Electrical Shock Hazard Warning Label

42068 Fan Entanglement Hazard Warning Label (on top near fan)

1-6

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

Saturn™ Furnace Cabinet Safety Labels

1-7

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

Saturn™ Furnace Cabinet Safety Labels

LANCASTER, PENNSYLVANIA (USA)

MH15393

USED−OIL BURNING APPLIANCE

NO.

USED OIL−FIRED FURNACE

USED OIL−FIRED BOILER

For use with Integral Primary Safety Control

MULTI−OIL HEATING SYSTEM

FOR COMMERCIAL OR INDUSTRIAL USE ONLY.

CERTIFIED TO ELECTRICAL AND FUEL BURNING REQUIREMENTS ONLY.

1-8

13084

42358

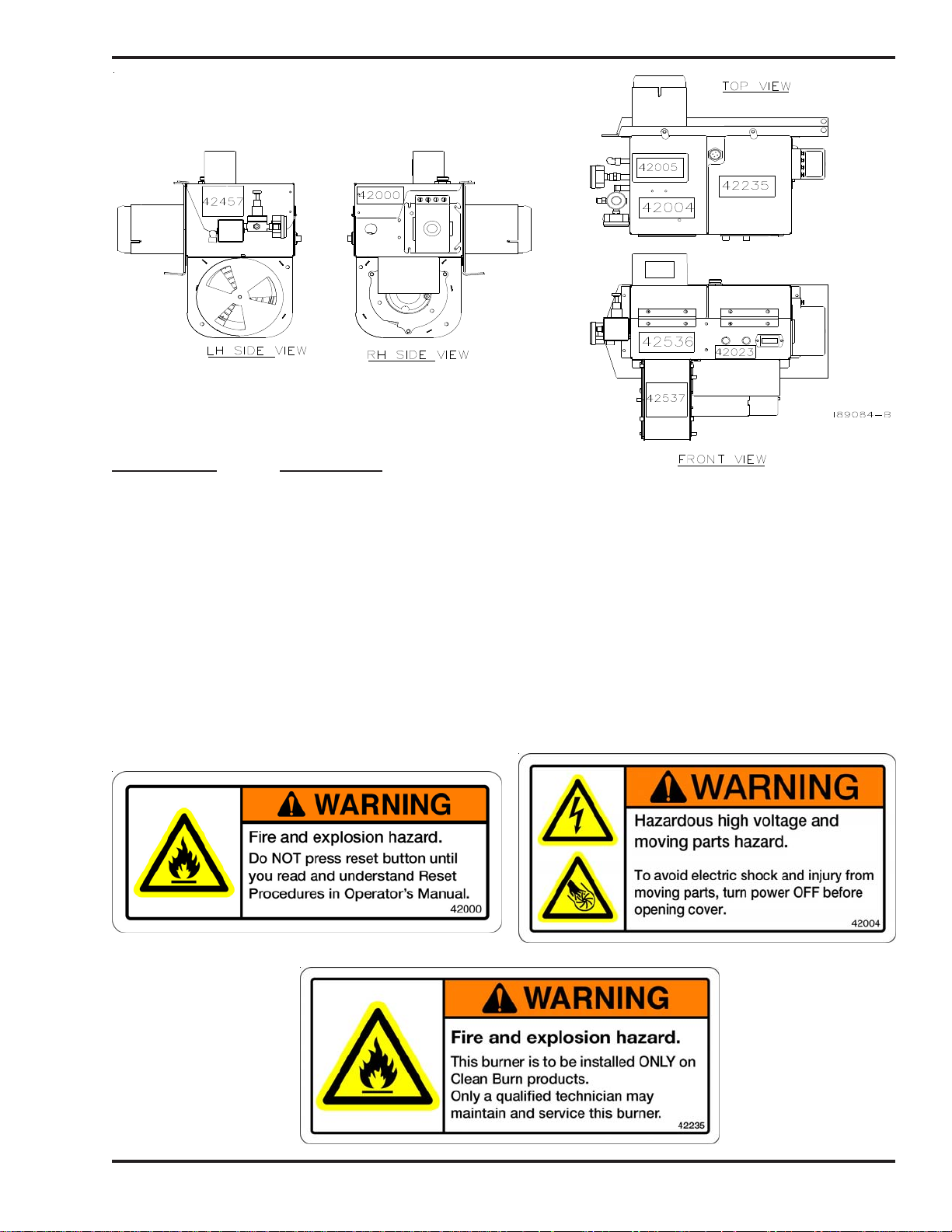

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

For Your Safety... (continued)

Saturn™ 125 Burner Labels

Label Part # Description

42000 Reset Warning Label

42004 Voltage / Moving Parts Warning Label

42005 Serviced-By Label

42023 Power / Pump Label

42235 Burner Warning Label

42457 Made In USA Label

42536 Saturn™ Series Logo Label

42537 Saturn™ Series Serial Number Plate

Saturn™ 125 Burner Safety Labels

1-9

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

1-10

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

SECTION 2: UNPACKING

Before assembling your furnace, you must accomplish the following activities described in this section:

• Removing the Shipping Crate

• Unpacking and Inspecting All Components

• Warranty Registration

Removing the Shipping Crate

NOTE: Remove the shipping crate prior to assembly and installation of the furnace. DO NOT use the

crate as a platform for furnace installation!

1. Carefully remove the top boards of the shipping crate. Then remove the front, back, and side

panels of the shipping crate.

2. Carefully lift the furnace off the shipping pallet with a fork lift.

ATTENTION: DO NOT attempt to slide the furnace cabinet out of the shipping crate--you may

damage the furnace cabinet.

Unpacking and Inspecting All Components

Following is an itemized list of all components you should have received in your Clean Burn furnace

shipment. Open all shipping containers and inspect all components according to the list. Immediately

notify the freight company and your Clean Burn dealer in case of shipping damage or shortage(s). Keep

all components together so you will have them as needed for furnace assembly and installation.

Furnace Component List

ONE SKID containing:

• Furnace cabinet

• Items packed inside furnace cabinet (combustion chamber):

NOTE: Please refer to the procedure on the following page to remove these items.

• Louvers

• Furnace Accessories (items below in one box):

• Canister Filter

• Vacuum Gauge

• Check Valve and Check Valve Screen

• Wall Thermostat

• Barometric Damper

• Connector Block

• Burner Oil Line and Air Line Components

• Assorted bolts/fittings for assembly/installation of furnace components

• Operator's Manual Literature Packet (includes Tank Safety Label)

ITEMS PACKED IN INDIVIDUAL BOXES:

• Burner

• Combustion Sleeve

• Metering Pump (includes Suction Oil Line Fittings Package)

NOTE: You may have received additional boxes or skids if you ordered optional accessories.

2-1

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

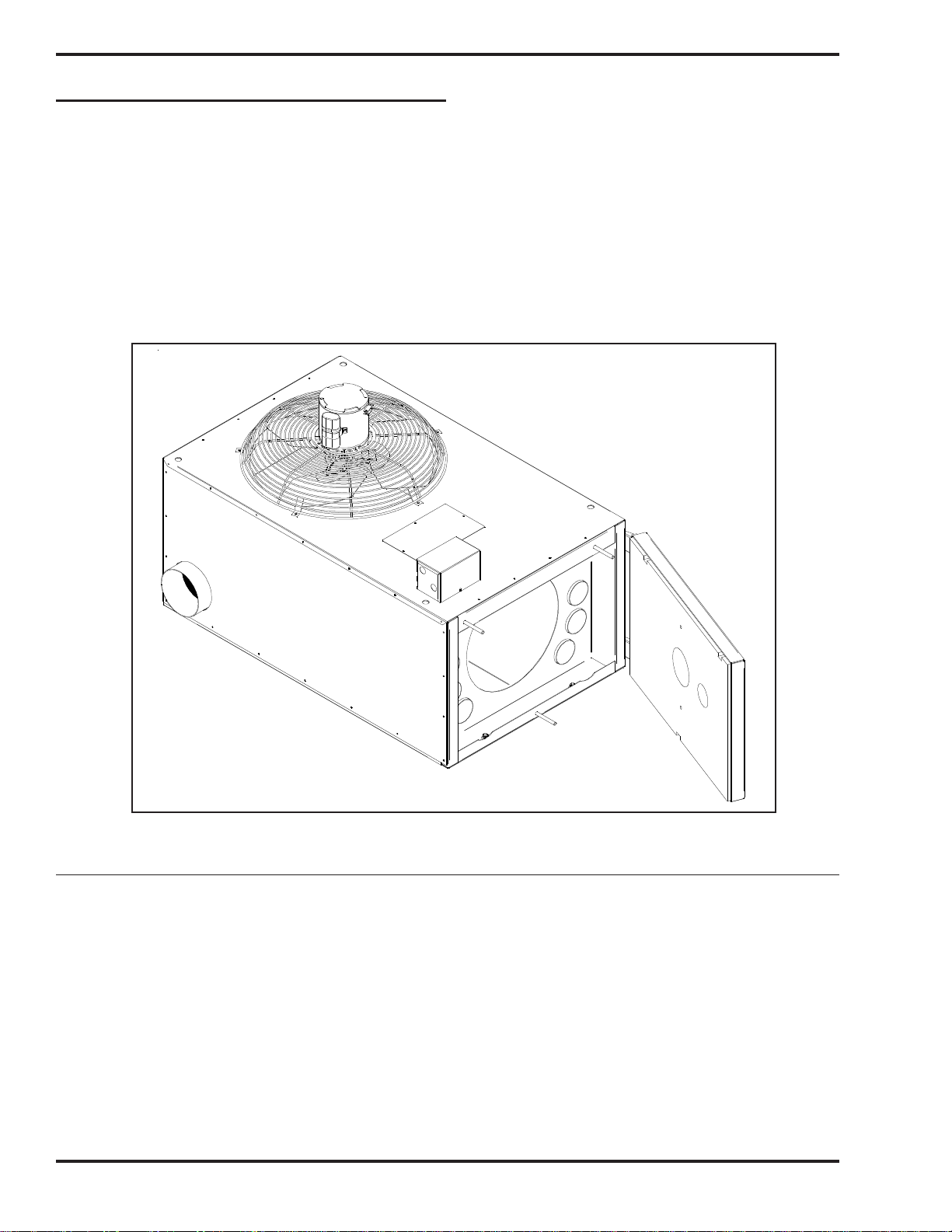

Unpacking Items Packed Inside the Furnace

To unpack the items packed inside the furnace cabinet (in the combustion chamber), you will need to

open the combustion chamber door.

1. Remove the three nuts which hold the combustion chamber door closed. Set the nuts aside in a safe

place for later re-installation after the combustion sleeve has been installed (Section 3).

2. Carefully swing the combustion chamber door open. Remove and inspect the components packed

inside.

3. Leave the door unfastened (open) for assembly/installation procedures to be accomplished in the

next section.

I89085

Figure 2A - Accessing the Combustion Chamber

Warranty Registration

For proper warranty registration, Clean Burn requires that you fill out the provided warranty registration

card and return it within 30 days to:

CLEAN BURN WARRANTY REGISTRATION

Clean Burn, LLC.

4109 Capital Circle Drive

Janesville, WI 53546

2-2

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

SECTION 3: FURNACE ASSEMBLY

Understanding Assembly

Assembling your Clean Burn Furnace includes the following steps:

(1) Installing the Observation Port

(2) Installing the Louvers

(3) Installing the Combustion Sleeve

(4) Installing the Burner

(5) Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

Clean Burn recommends that you review all assembly procedures before proceeding, paying careful

attention to safety information statements.

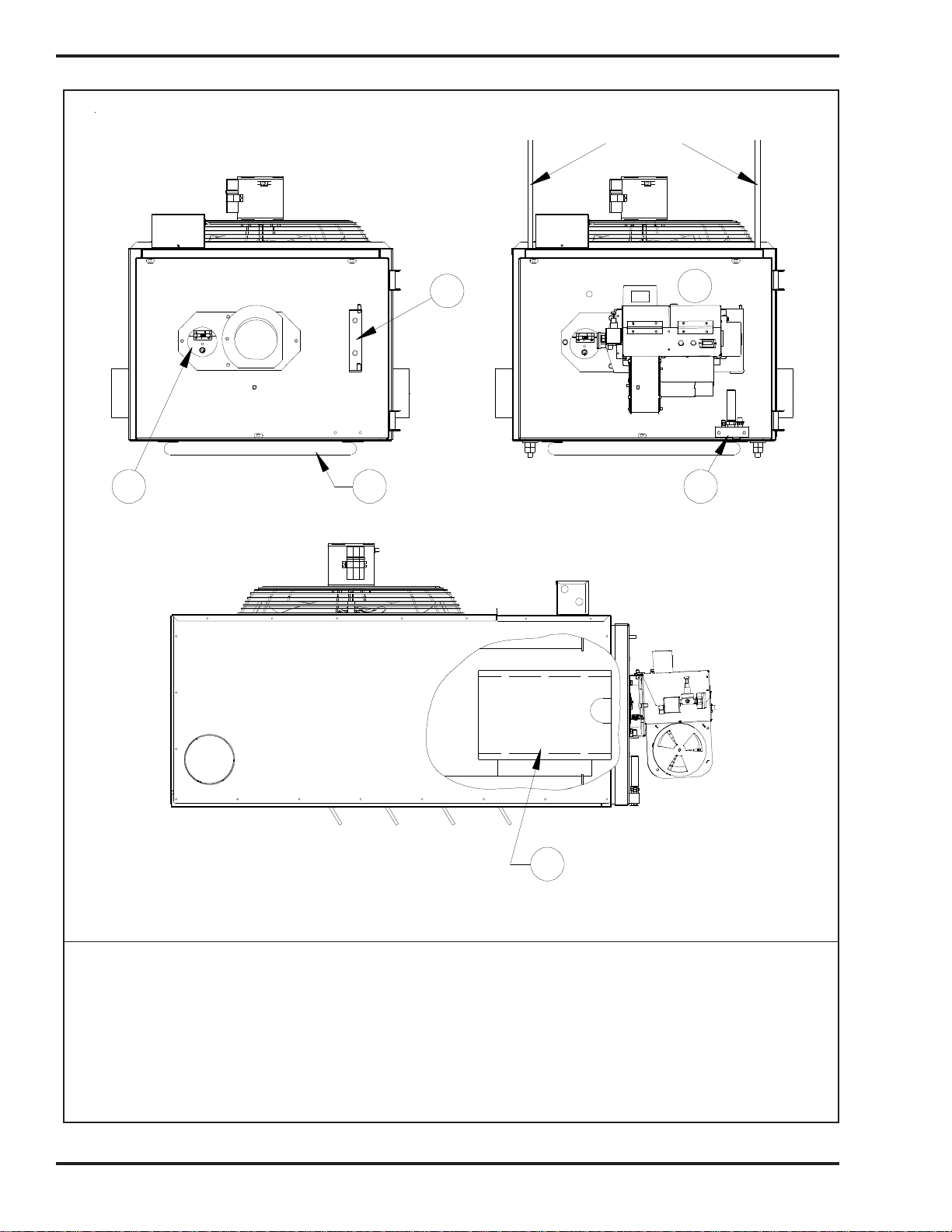

Figure 3A on the following page provides a general overview of the furnace components and their

proper assembly.

Required Tools and Materials

The following tools are required for furnace assembly and should be gathered before starting any procedures:

• 9/16" open-end wrench

• Medium flat-blade screwdriver

• Medium adjustable wrench

• 1/4" nut driver attachment for drill

• 5/16" nut driver attachment for drill

• Variable speed drill

3-1

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

"ALL THREAD" RODS

BURNER

MOUNTING

BRACKET

4

4

1

OBSERVATION

PORT

I89086-A

2

LOUVERS

CONNECTOR

BLOCK

COMBUSTION SLEEVE

3

INSTALL E D IN CHA MBER

ON 2" X 2" BLOCKS

5

Complete assembly of the furnace according to the following list of activities as illustrated above:

(1) Installing the Observation Port

(2) Installing the Louvers

(3) Installing the Combustion Sleeve

(4) Installing the Burner

(5) Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

NOTE: Corresponding procedures provided in order in this section.

Figure 3A - Overview of Furnace Assembly

3-2

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Observation Port

CAUTION: To prevent serious personal injury, the observation port must be correctly installed

according to the following procedure. A properly installed observation port permits safe observation of

the flame during furnace operation. Be sure to follow all safety procedures as outlined in this manual when

observing the flame through the port.

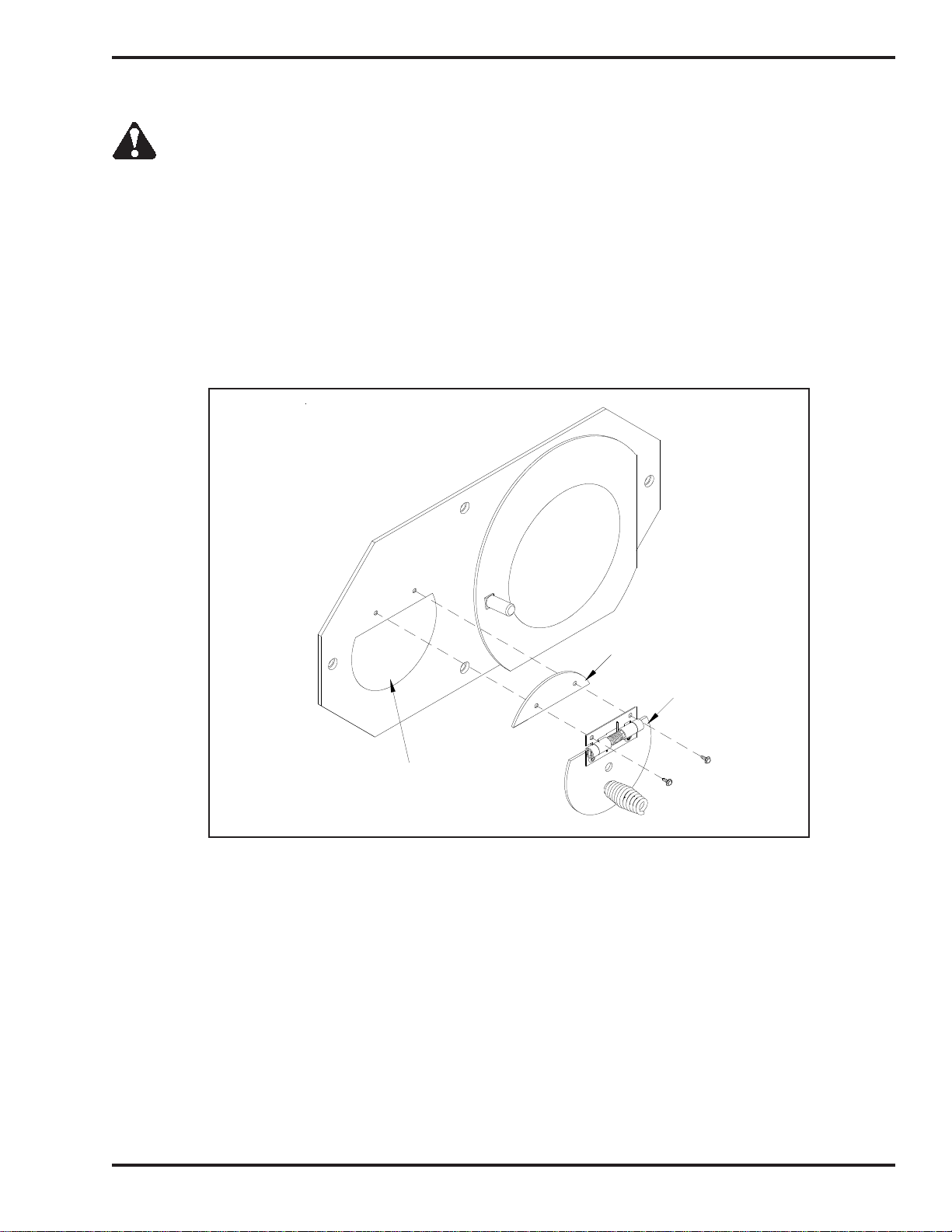

1. Refer to Figure 3B.

2. Use a 1/4" nut driver to remove the two (2) self-tapping screws from the half-moon piece.

3. Position the half-moon piece and the faceplate on the observation port, and install the two

self-tapping screws.

4. Open the port and make sure the faceplate moves and closes freely. If the faceplate hangs up,

loosen the hex-head screws slightly until the faceplate closes correctly.

HALF−MOON

PIECE

FACE

PLATE

OBSERVATION

PORT

I89087

Figure 3B - Assembly of Observation Port

Installing the Air Outlet Louvers

Air Flow Discharge Installation Guidelines:

• It is very important to properly install the louvers to direct the flow of hot air away from the furnace. The

air flow may be directed front, back, or to either side depending on how the louvers are installed.

• Note that each furnace is supplied with four (4) louvers which may be installed all in the same direction

OR the louvers may be split for partial air discharge out either side or front to back.

• When determining the placement of the air discharge louvers, you also need to consider the required

clearances from combustibles as stated in Section 4 of this manual.

• DO NOT restrict the flow of the hot air from the furnace by keeping the louvers completely closed, or the

furnace may not operate properly.

3-3

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Air Outlet Louvers (continued)

ATTENTION: If the bottom clearance is less than 60 inches use a hot air diffuser as described under Floor

Mounting in Section 4.

1. Refer to Figures 3C. Determine the desired air flow discharge direction. Note that each furnace is

supplied with four (4) louvers.

2. Hold each louver against the base with the bend pointing down. Install the louvers in the desired

direction(s) with the self-tapping screws provided. Holes are pre-drilled in the furnace base to

accommodate installation of the louvers.

3. Rotate the louvers to help direct the hot air away from the furnace.

Figure 3C - Installing the Hot Air Discharge Louvers

CAUTION: The Saturn™ 140 and Saturn™ 230 are Unit Heater furnaces ONLY. DO NOT install

ductwork on these furnaces.

3-4

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Combustion Sleeve

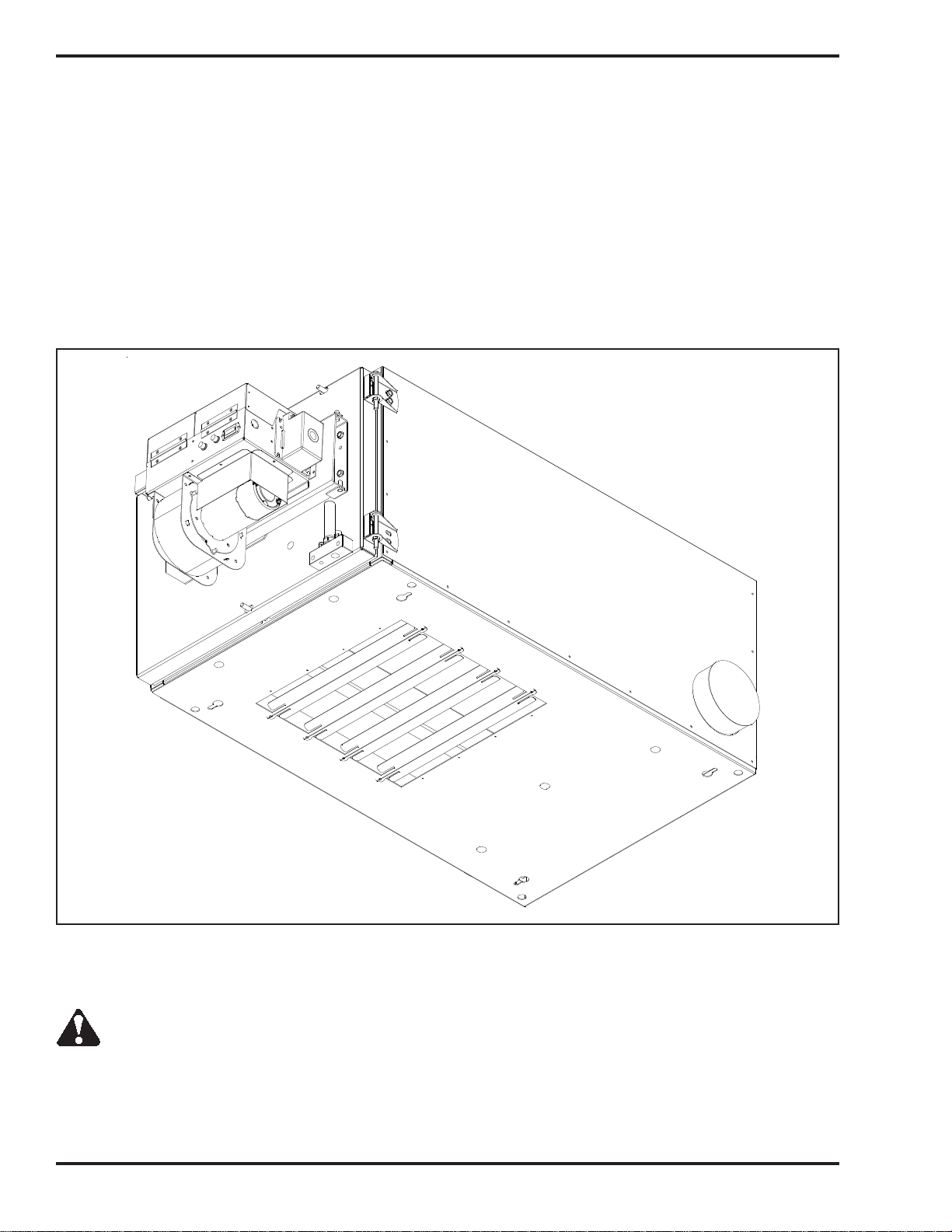

Installing the Combustion Sleeve Inside the Combustion Chamber

ATTENTION: DO NOT fire your furnace without the Combustion Sleeve in place, or poor flame retention

will occur. Handle the Combustion Sleeve carefully to avoid damage.

1. Refer to Figure 3A and 3D to review the proper position of the Combustion Sleeve and 2" x 2"

mounting Blocks.

2. Swing open the clean-out door on the front of the furnace to gain access to the combustion chamber.

3. Refer to Figure 3D. Place the two (2) soft fiber board blocks (2" x 2" x 8") on the bottom of the

combustion chamber against the indicator tabs. The notch in the support blocks should fit over the front

flue plate.

4. Gently set the Combustion Sleeve on top of the two Blocks. The combustion sleeve needs to seat

firmly against the door insulation for proper combustion. Carefully position the Combustion Sleeve on

the blocks so that it extends out slightly beyond the door opening. The door will push the Combustion

Sleeve in place as it is closed.

COMBUSTION S LEEVE

SUPPORT BLOCK

LOCA TION INDICATOR TAB

I89090

NOTCH IN SUPPO RT BLOCK

OVER FRONT FLUE PLATE

TIGHT AGAINS T FRONT

DOOR INSULATION

Figure 3D - Installing the Combustion Sleeve

Closing the Furnace Door

1. After the Combustion Sleeve has been installed, close the furnace clean-out door.

2. If necessary, loosen the door hinges to allow the door to seal tight.

2. Tighten the three (3) lock-down nuts until all are snug.

3-5

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Burner

Checking the Burner Nozzle and Electrodes

NOTE: The burner nozzle is factory installed. Both furnace models use a Delavan 9-5 nozzle. The nozzle

size is indicated on the nozzle as shown in Figure 3E. Refer also to Appendix A at the back of the manual for

additional specifications/instructions on the burner nozzle.

ATTENTION: Check the electrode settings as specified in Figure 3E. The electrode settings must be correct

for your burner to operate properly.

BURNER NOZZLE

NOZZLE IS STAMPED EITHER 9−5

OR −5 ON FLAT OF NOZZLE HEAD

SIDE VIEW − AA

3/16" GAP BETWEEN

ELECTRODES & NOZZLE

3X

CRITICAL DIMENSION:

NOZZLE MUST BE 1/8"

AHEAD OF THE DISK.

NOZZLE MUST NOT BE

BEHIND THE DISK.

A

A

−

V

I

E

W

−

B

B

W

E

I

V

1/8"

SPARK

GAP

SIDE VIEW − BB

I88340

Figure 3E - Burner Nozzle and Electrode Specifications

3-6

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Burner (continued)

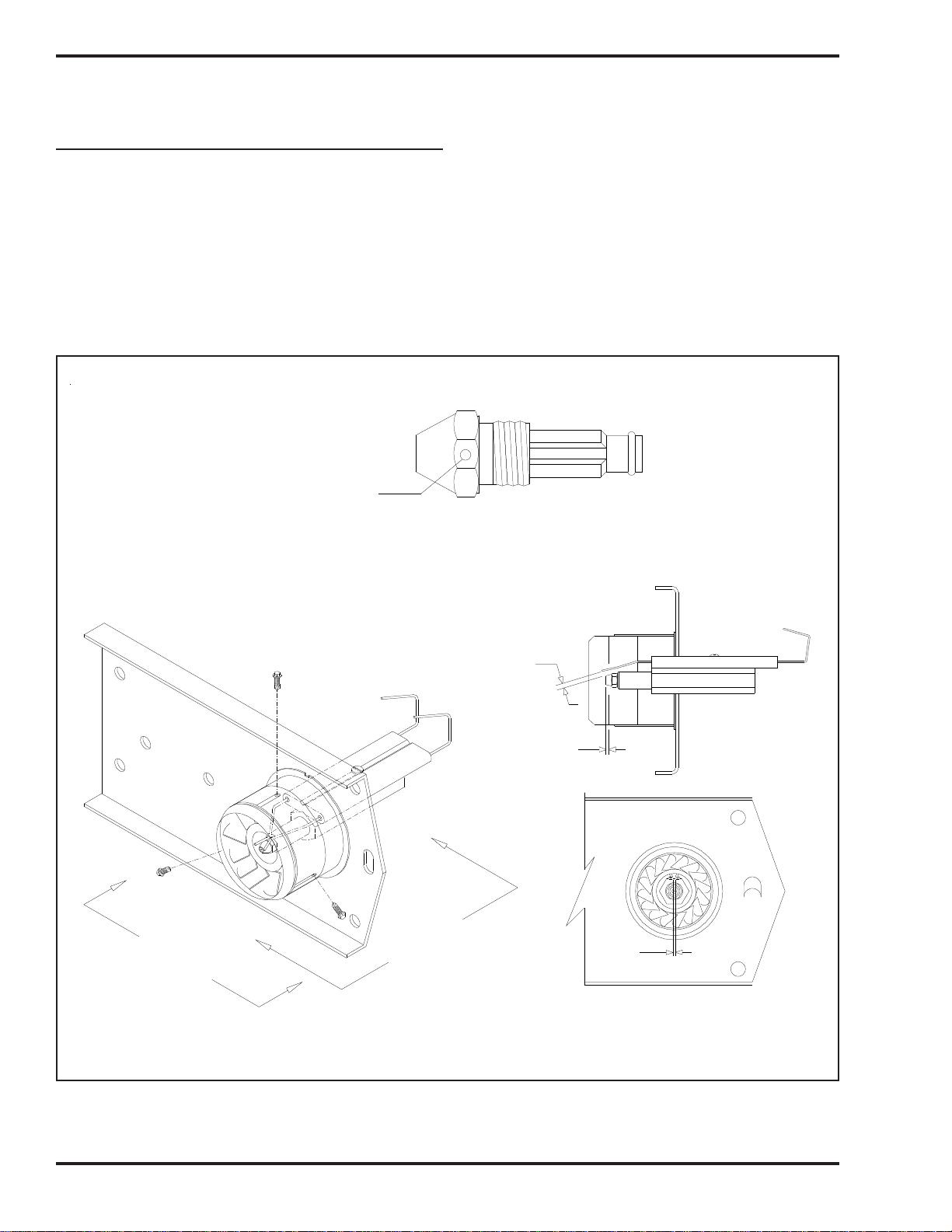

Mounting the Burner on the Hinge Bracket

ATTENTION: Burner tube components (e.g. electrodes and retention head) are factory set. Handle the

burner with extreme care so that burner components are not damaged.

1. Remove the nut from the mounting flange of the furnace cabinet, and set it aside for later use.

2. Lift the burner into position so that it is mounted on the hinge bracket on the furnace cabinet.

3. Carefully swing the burner so the retention head enters the throat of the furnace.

4. Check the clearance between the retention head and the furnace throat. There must be at least

1/8" clearance, so the retention head is not "bumped" as you swing the burner into firing

position.

NOTE: If the retention head "bumps" the furnace throat, adjust the hinge bracket bolts

as follows:

• While supporting the burner, slightly loosen the two (2) hinge bracket bolts.

• Carefully re-position the burner so it swings freely into its firing position.

• With the burner in its firing position, re-tighten the hinge bracket bolts.

3-7

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

ATTENTION: DO NOT use teflon tape on any fittings. Teflon tape residues will plug vital burner

components and void your warranty.

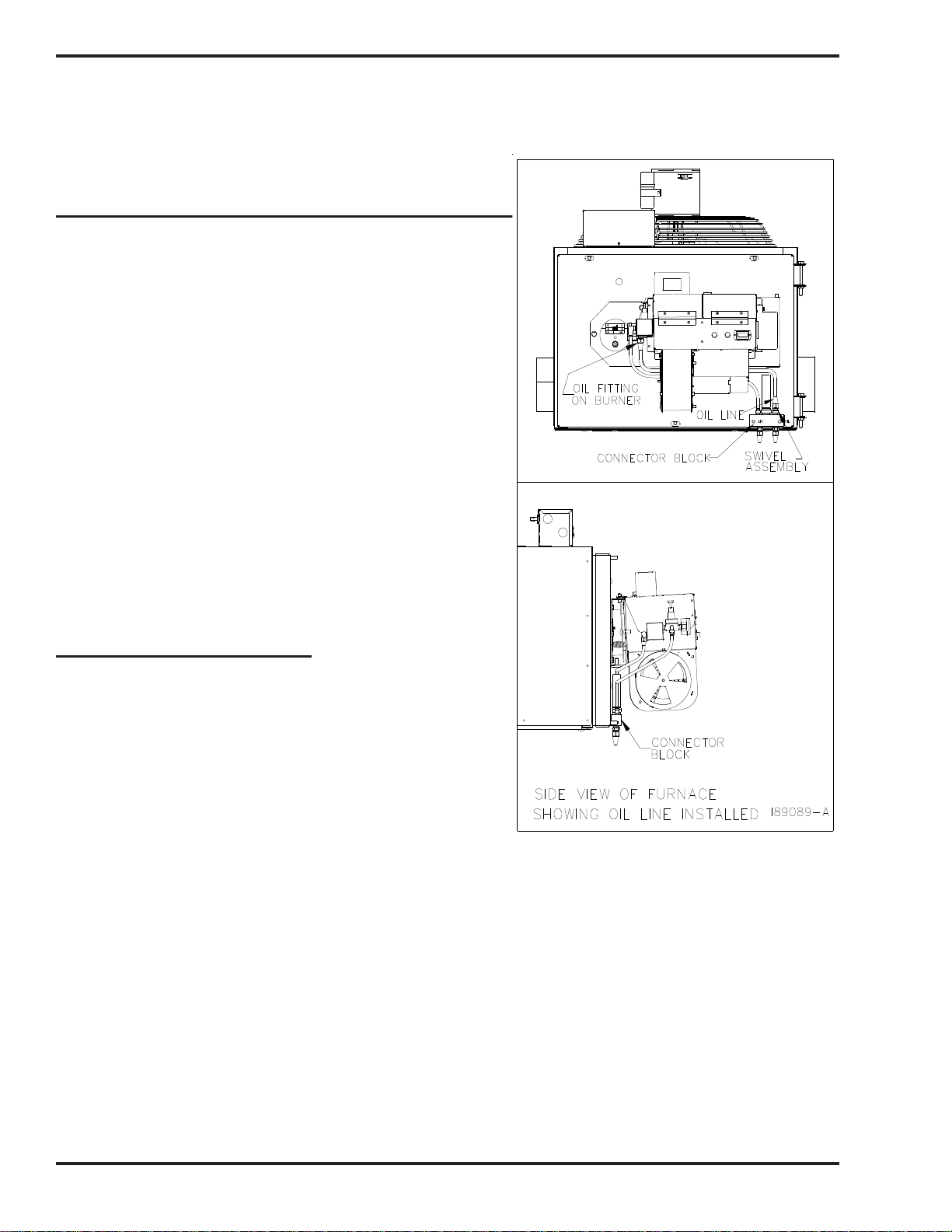

Installing the Connector Block on the Furnace Door

1. Refer to Figure 3F.

2. Use the two (2) bolts to install the aluminum

connector block onto the furnace door.

3. Remove and discard the red caps and plugs from the

fittings and ports on the connector block. DO NOT

allow any dirt/debris to enter these components

during furnace assembly.

ATTENTION: The connector block includes an

accumulator. The accumulator functions like a shock

absorber on the oil line to prevent pressure buildup and

protect vital burner components. It is important that the

connector block is installed as shown so that the accumulator

is in a vertical position to prevent sediment from settling in

the accumulator. Never operate your furnace without the

connector block and accumulator properly installed on the

furnace, or damage may occur to vital burner components.

Installing the Oil Line Tubing

ATTENTION: DO NOT disassemble the compression

fitting from the swivel fitting. To prevent leaks, the NPT

threads of the compression fitting have been sealed with

hydraulic sealant during assembly of the fittings at the

factory.

1. Remove and discard the red caps from the oil line

tubing.

2. Install the oil line tubing into the swival fitting on the

connector block.

3. Slightly bend the tubing as shown in Figure 3F, if required, to "line up" the oil line with the oil line fitting

on the burner. If necessary use a wrench to rotate the oil line fitting on the burner to line up the tubing.

4. If necessary, use a tubing cutter to cut the tubing to the proper length.

5. Make sure that the curl in the oil line is positioned so that the burner is able to swing open.

6. Install the oil line tubing and tighten the nuts on the compression fittings. DO NOT overtighten

these fittings to avoid damaging the ferrules.

Figure 3F - Installation of Connector

Block and Oil Line

3-8

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

(continued)

Installing the Air Line Tubing

1. Remove and discard the red caps from the air line tubing.

2. Push the air line tubing into the push fitting on the connector block until the tubing bottoms out in the

fitting.

3. Repeat this procedure to connect the air line tubing to the air line fitting on the the burner.

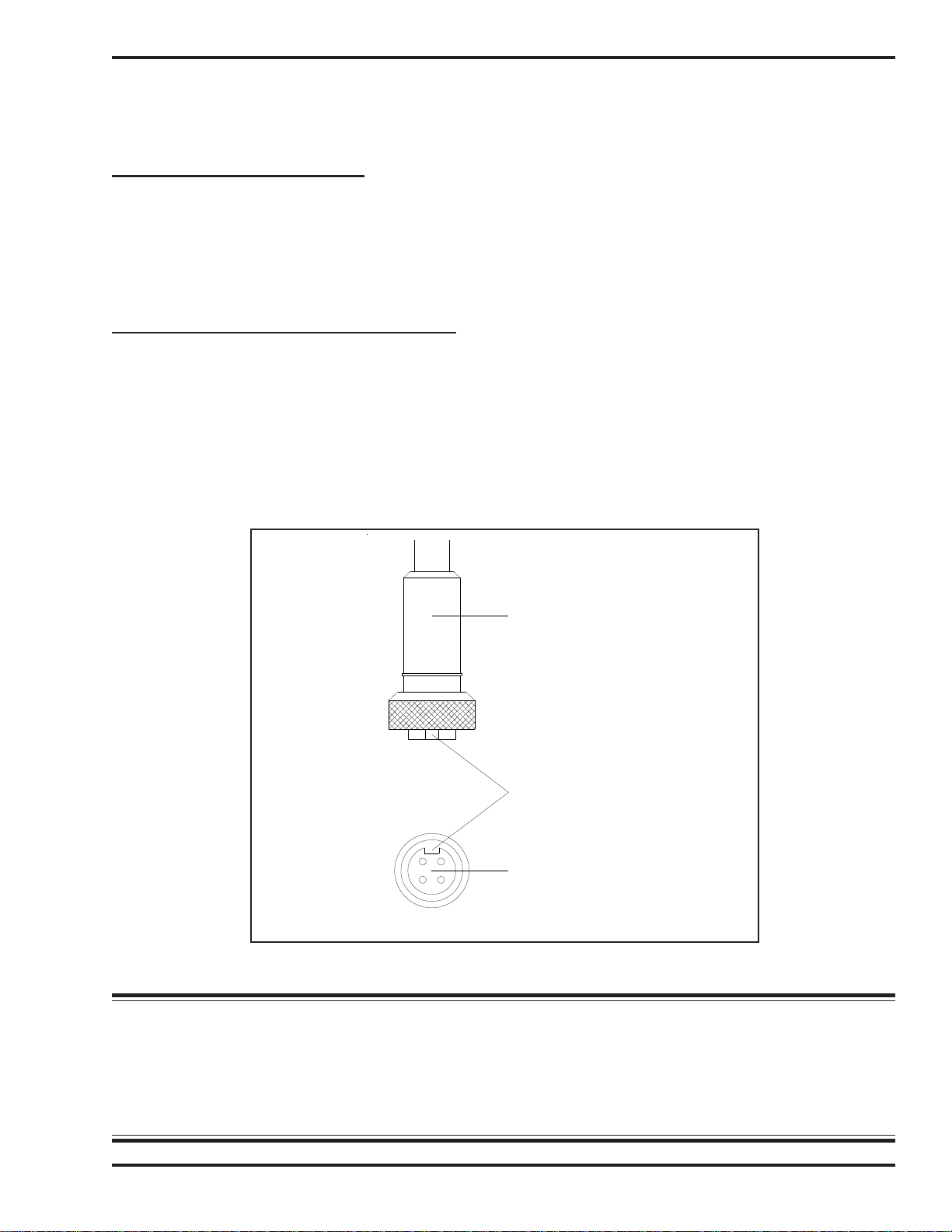

Locking the Burner into Firing Position

1. Swing the burner into firing position.

2. Install and tighten the lock-down nut on the mounting plate bolt to secure the burner in its firing position.

3. Plug the burner electrical cable into the receptacle on the top of the burner housing.

4. Tighten the locking ring to secure the electrical cable.

NOTE: Be sure to properly align the plug when plugging it into the receptacle. See Fig 3G.

CONNECTOR PLUG

KEY IN PLUG

MUST ALIGN

WITH SLOT IN

RECEPTACLE

RECEPTACLE ON

TOP OF BURNER

I88641−B

Figure 3G - Detail of Burner Electric Receptacle

NOTE: Your furnace is now assembled and ready for installation. Install the furnace as

soon as possible so the burner and/or fan are not "bumped" or damaged. If you must

store the furnace for a period of time before installation, make sure it is located in a safe,

secure area.

3-9

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

3-10

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

SECTION 4: FURNACE INSTALLA TION

Understanding Installation

Installing your Clean Burn furnace is a multi-step process which includes:

(1) Selecting a Location (6) Installing the Oil Lines

(2) Mounting the Furnace (7) Installing the Compressed Air Line

(3) Oil Tank Specifications (review) (8) Installing the Stack

(4) Installing the Metering Pump (9) Installing the Wall Thermostat

(5) Wiring the Furnace and Pump (10) Inspecting the Installation

Clean Burn recommends that you review all procedures before beginning installation, paying careful attention to

safety information statements. Figure 4A and 4B provide a general overview of a typical furnace installation and

should be reviewed closely before proceeding.

WARNING: The installation, operation, and maintenance of this equipment in the U.S.

must be accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and with all national, state, and local codes or authorities having

jurisdiction over environmental control, building inspection and fuel, fire and electrical safety and the following

standards of the National Fire Protection Association.

NFPA 30 Flammable and Combustible Liquids Code

NFPA 30A Automotive and Marine Service Station Code

NFPA 31 Standard for the Installation of Oil Burning Equipment

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

NFPA88A Parking Structures

NFPA 88B Repair Garages

NFPA 70 National Electrical Code

Likewise, the installation, operation, and maintenance of this equipment in Canada is to be accomplished by

qualified personnel and in compliance with the specifications in the Clean Burn Operator's Manual and in

accordance with the regulation of authorities having jurisdiction and the following CSA Standards:

B139 Installation Code for Oil Burning Equipment

B140.0 General Requirements for Oil Burning Equipment

C22.1 Canadian Electrical Code, Part 1

Failure to comply with these standards and requirements may result in equipment damage, fire,

explosion, personal injury and/or death.

WARNING: Improper installation can adversely affect the proper, safe operation of your

furnace. It is critical that your furnace installer reads and follows the instructions provided in

this manual.

4-1

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

W ARNIN G: When in s talling y our fu r n a c e ,

adhere to the minimum clearance s from

combustible surfaces as stated in Section 4.

These clearance s also provide adequate

sp a c e fo r s e r v ic in g . F ailur e to mainta in

proper clearances may result in fire,

explosion, personal injury, or death.

Figure 4A - Typical Saturn™ 140 / 230 Furnace Installation

4-2

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Selecting a Location

Guidelines for Selecting a Location

The location you select for your furnace must allow the following:

• Unobstructed, even heat distribution.

• Safe, easy access for servicing.

• Unobstructed passage for shop vehicles and equipment.

• Proper clearances from combustibles. Verify according to your local safety codes.

• Adequate combustion air per local codes.

• Proper stack installation.

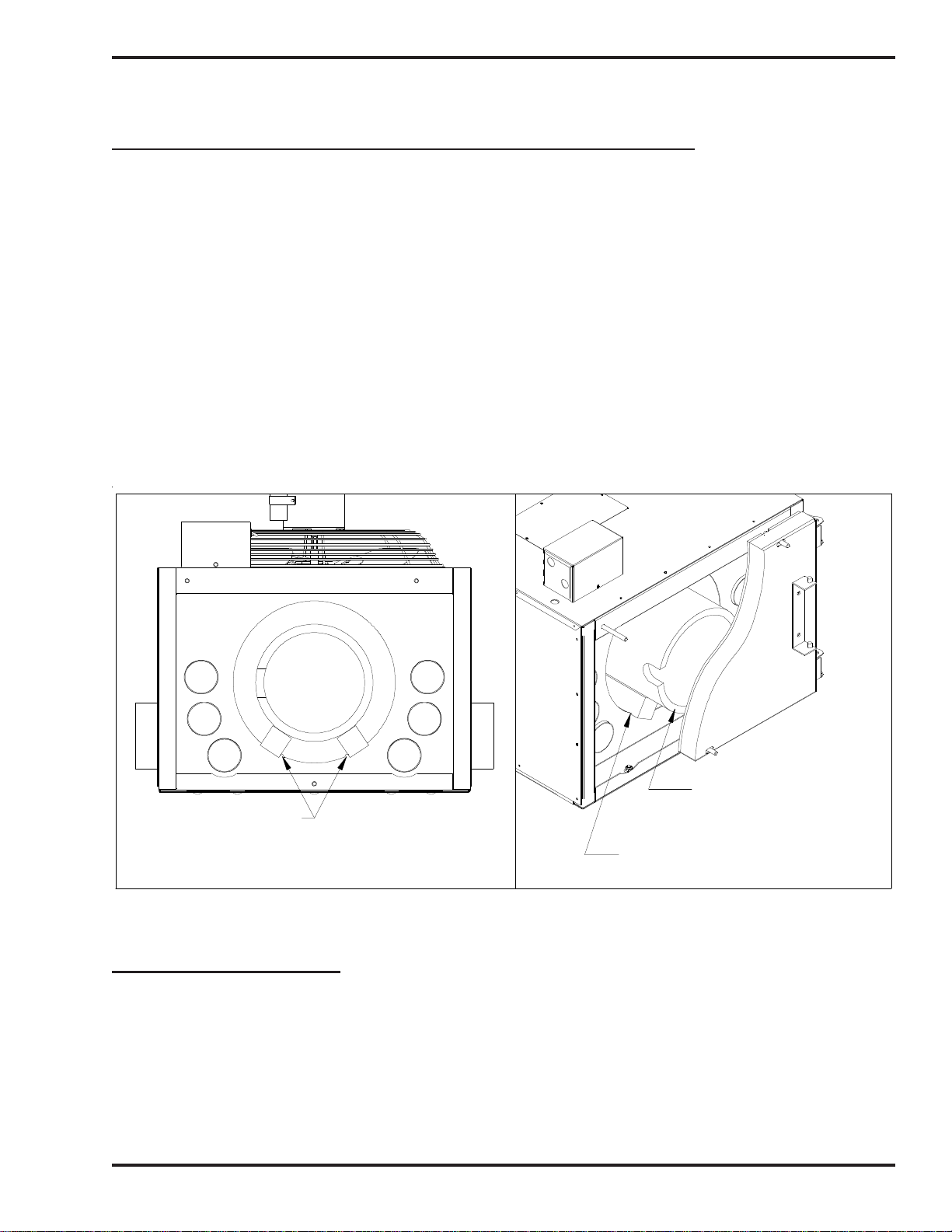

WARNING: Adhere to the following minimum clearances from combustible surfaces and

to provide adequate clearance for servicing (also refer to Figure 4B for visual reference); failure to

maintain proper clearances may result in fire, explosion, personal injury or death.

Figure 4B - Clearances from Combustibles

CLEARANCES FOR INSTALLATION

• TOP (of furnace)............................... 12"

• FRONT (burner) ............................... 48"

• SIDE (with or without stack)............. 12"

• CHIMNEY CONNECTOR ................. 18"

• REAR ................................... .... 12"

• BOTTOM (with air diffuser) ............... 30"

• BOTTOM (without air diffuser) .......... 60"

NOTE: See Appendix A for furnace cabinet dimensions.

4-3

WARNING: Codes may require

that your furnace is mounted a

minimum of eight (8) feet off the ground when

installing the furnace in a repair facility. Refer to

NFPA-88B, Standard for Repair Garages,

Chapter 3, Hazards, Sec. 3-2.3.1.

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Mounting the Furnace

After selecting a safe and appropriate location for your furnace, construct the mounting system as required by

the location and the following specifications.

Ceiling Mounting

WARNING: To prevent serious personal injury, ensure that your furnace mounting system can

safely bear the suspended weight of the furnace and allow safe servicing of furnace components. Use

adequately sized square tubing or angle iron bridged across sufficient structural members to safely support the

furnace.

1. Refer to Figure 4C.

2. Follow the instructions as provided in the diagram.

3. Use a spirit level to make sure the cabinet is level side to side and front to back.

Figure 4C - Ceiling Mounting Installation Overview

4-4

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Mounting the Furnace (continued)

Raised Platform Mounting

WARNING: To prevent serious personal

injury, make sure the platform is designed to

safely bear the weight of the furnace and allow safe

servicing of furnace components. The platform must be

constructed of non-combustible materials (e.g. steel)

and must be securely anchored to an adjacent wall.

1. Refer to Figure 4D.

2. Follow the instructions as provided in the

diagram.

3. Use a spirit level to make sure the cabinet is

level side to side and front to back.

Figure 4D - Furnace Installed on

Raised Platform

Floor Mounting

WARNING: To prevent serious personal injury, make sure the floor can safely bear the weight of the

furnace.

CAUTION: The minimum distance allowed from the floor to the base of the unit is 60 inches. If the

clearance is less than 60 inches to the base of the unit a hot air diffuser, or hood, must be used to direct

the hot air away from the furnace.

Saturn™ 140 hot air diffuser Clean Burn part #90244

Saturn™ 230 hot air diffuser Clean Burn part #90245

1. Refer to Figure 4E.

2. Use a spirit level to make sure the cabinet is level side to side and front to back.

WARNING: The support stand must be constructed of non-combustible materials (e.g. steel) and

must be securely anchored to the floor.

4-5

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Mounting the Furnace (continued)

Floor Mounting (Continued)

Figure 4E - Furnace Installed on a Mezanine With a Hot Air Outlet Diffuser

4-6

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Oil Tank Installation Specifications

Ensure that your tank installation adheres to the following

safety guidelines as stated here and in

Section 1 of this manual.

The tank safety label (shown at right) also

summarizes these important specifications for tank

installation and usage. If you do not have a copy of this

label, please contact your Clean Burn dealer for

a copy, which is to be affixed directly to your used

oil supply tank.

• The tank installation must meet all

national and local codes. Consult your

local authorities for more information as

necessary.

• The tank must be listed to UL 80, UL 142,

or equivalent standard.

• Use a minimum 250-gallon tank.

DO NOT use a 55-gallon drum as a

substitute for an appropriate tank. The

tank must be large enough to allow water,

sludge, etc. to settle out of the used oil.

• Single wall tanks should have a manual shut-

off type valve on the side of the tank to

allow the water, sludge, etc. to be drained

from the bottom of the tank.

• All unused openings in the tank must be

plugged or capped off.

• For optimal system functioning, Clean Burn

Recommends inside tank installations as

shown in Figures 4A, 4F, and 4J.

• Some codes require the tank to be vented to

the outside of the building using iron or steel

pipe and fittings with an approved vent cap.

• Carefully review the oil tank and pump

installation details as shown in Figures 4A,

4F, and 4J. Pertinent information also

supplied with the metering pump and oil line

installation procedures (following in Sec. 4).

• Ensure that the oil supply tank is properly

maintained; refer to Section 9 in this manual

for related procedures.

ATTENTION: For outside tank installations and/or tanks larger than 500 gallons, contact your local

Clean Burn Distributor for installation recommendations and specifications.

4-7

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

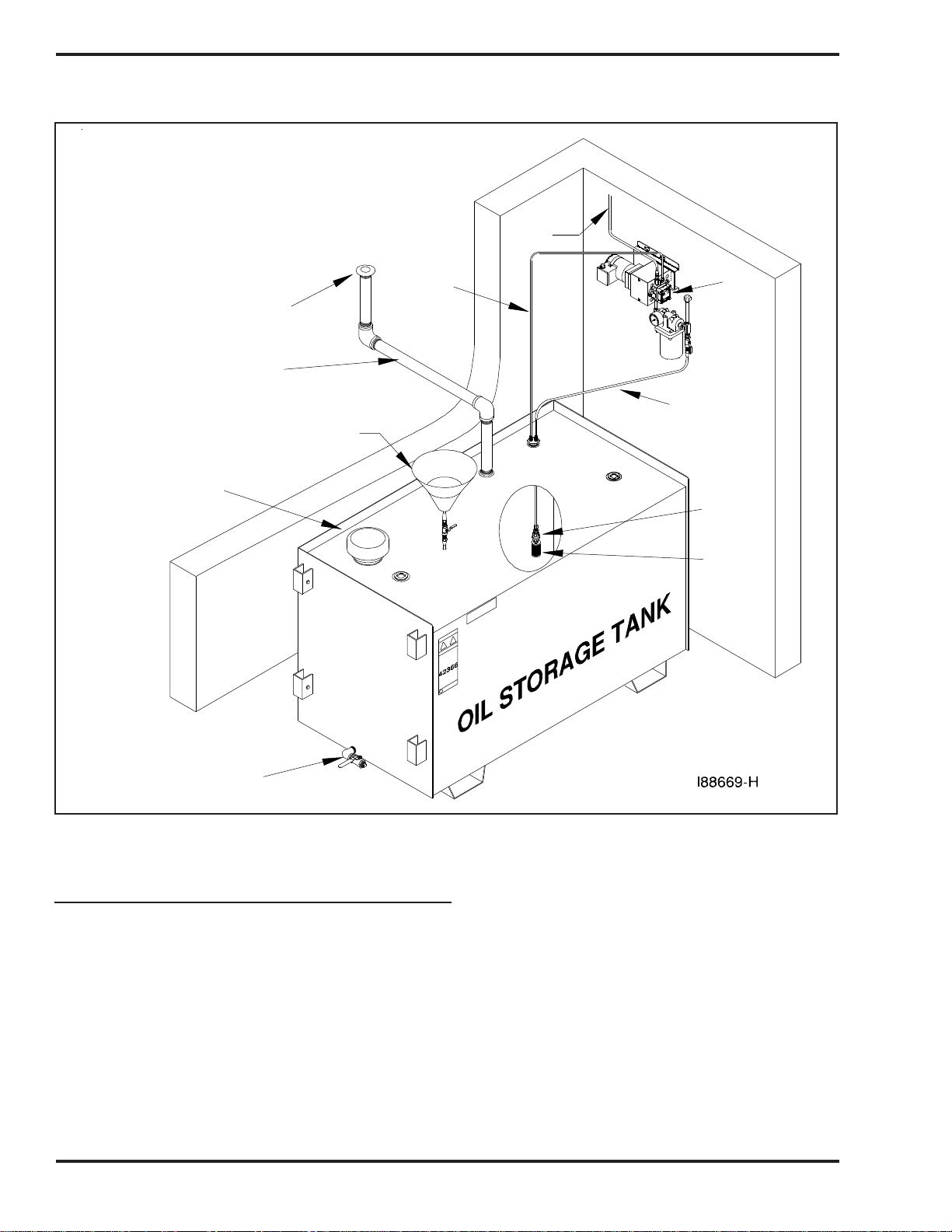

Oil Tank Installation Specifications (continued)

TANK VENT KITS AVAILABLE FROM CLEAN BURN:

CB Part # 70380 − 4" Tank Vent Kit

(2) elbows

(2) 6" nipples

(1) mushroom cap vent

(1) emergency vent

MUSHROOM

CAP VENT

STEEL PIPE

(USER SUPPLIED)

FUNNEL WITH

BALL VALVE

EMERGENCY

VENT

PRESSURE

RELIEF OIL

LINE BACK TO

THE TANK

PRESSURE

LINE

PUMP

SUCTION LINE

ASSEMBLY

CHECK

VALVE

FILTER

SCREEN

CLEAN−OUT

(TANK DRAIN)

Figure 4F - Typical Metering Pump Installation with Inside Tank

Installing the Tank Vent and Emergency Vent

Some codes require that you install a tank vent (to the outside) and an emergency vent for your tank as shown

in Figure 4F. Tank Vent Kits are available from Clean Burn; contact your local Clean Burn dealer to order.

Be sure to check your local codes for any additional tank installation requirements, and adhere to the following

installation guidelines:

• Install a length of minimum 2" steel pipe (user-supplied) terminating outside with a proper

vent cap as shown in Figure 4F. Consult local codes for information and requirements

concerning the proper venting of oil storage tanks.

• Install an emergency vent as shown in Figure 4F. Contact your tank manufacturer for

information concerning the proper emergency vent for your tank.

4-8

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

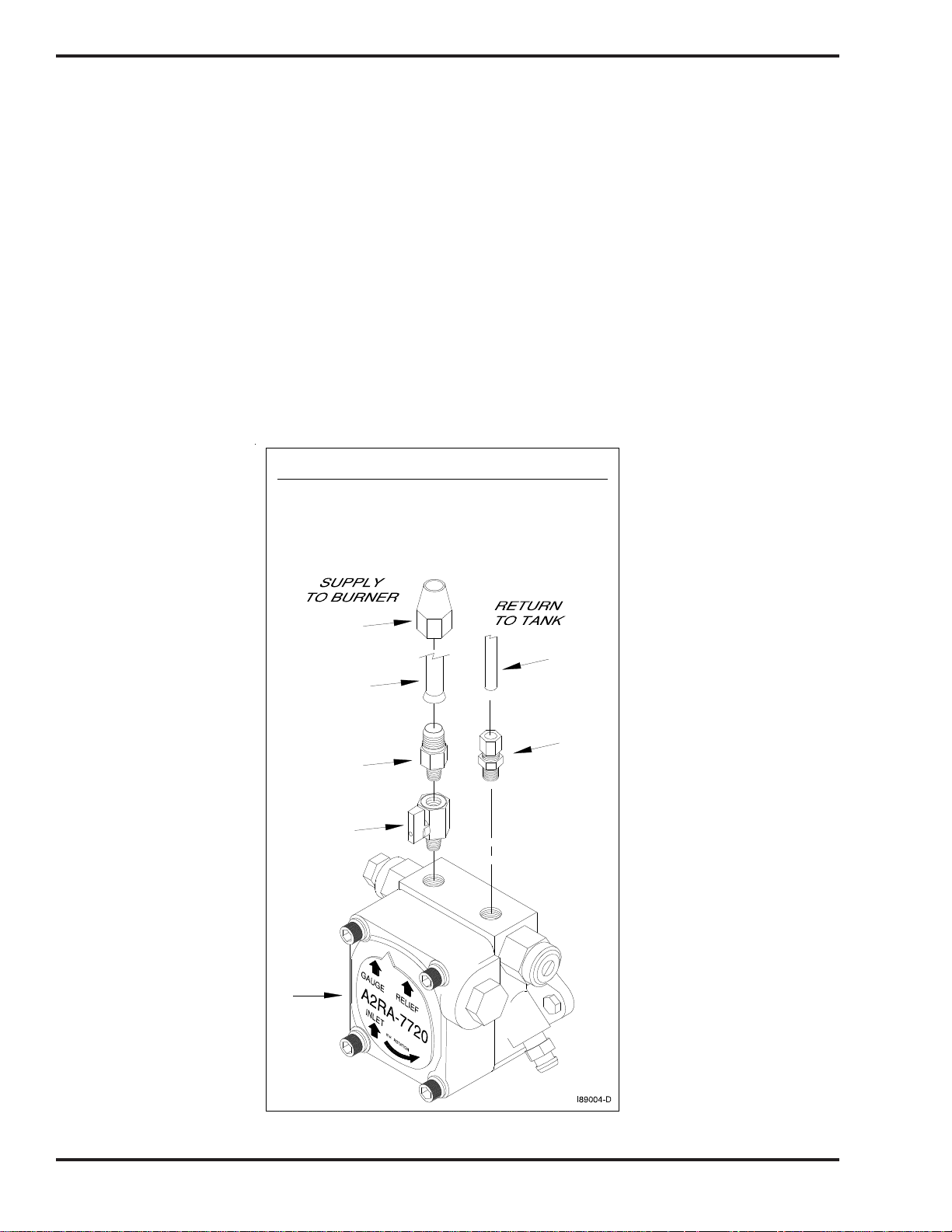

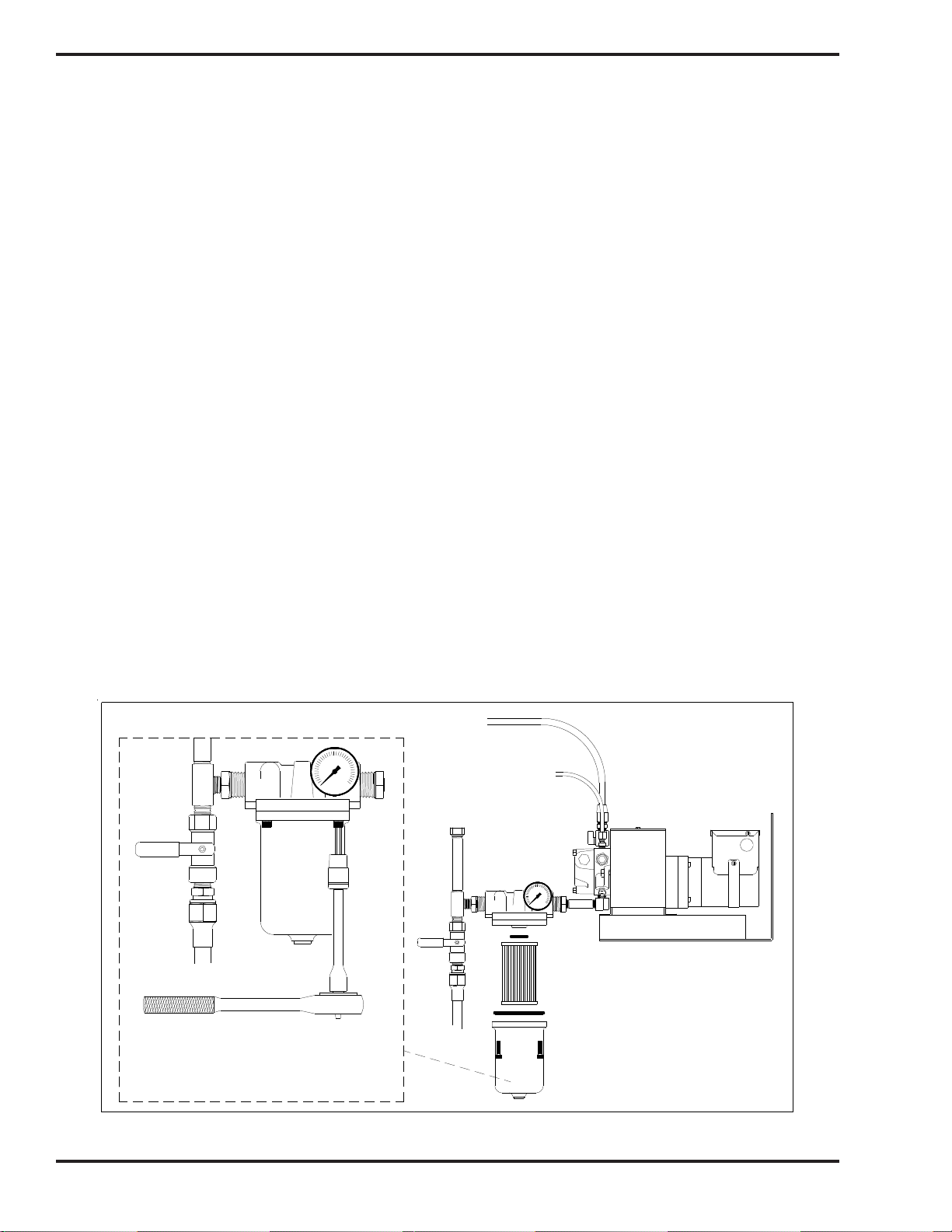

Installing the Metering Pump

Preparing for Installation

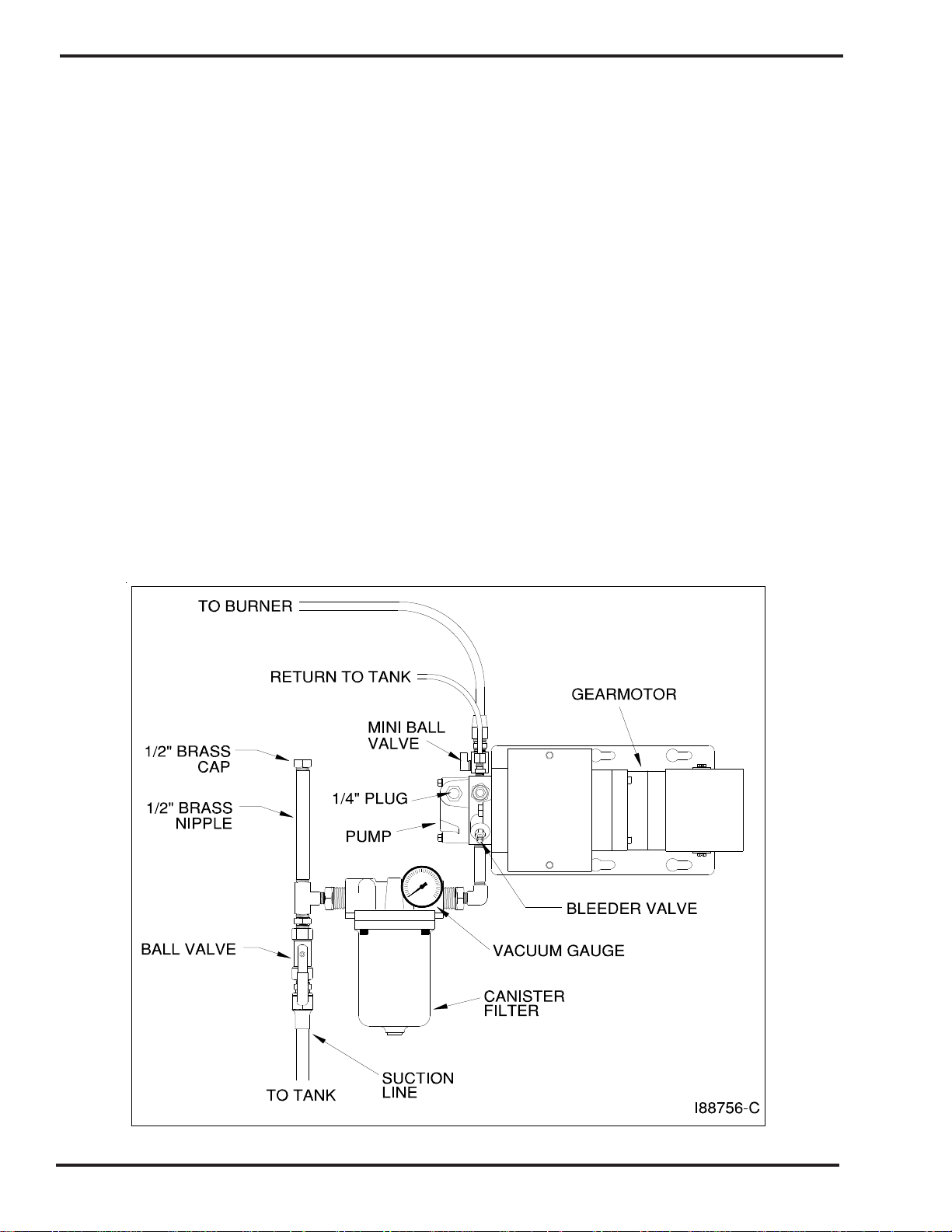

Before starting installation of the metering pump, review Figures 4G, 4H, and 4I to become familiar with the

metering pump components. You will also need to accomplish the following activities:

• Verify that you have the proper metering pump for your furnace (note the specific gear motor

part numbers shown in Figure 4H).

• Gather all required tools and materials as needed for installation; as indicated in the

following procedures, some materials (e.g. fittings, tubing) are to be user-supplied.

• Standard mounting is vertical mounting on a wall; this pump installation is recommended.

Alternate mounting is horizontal mounting on a bracket. Be sure to carefully follow the

appropriate procedures/diagrams for pump mounting.

• For optimal metering pump functioning, mount the pump at a distance from the oil tank that will

comply with the following requirements:

The suction oil line may NOT exceed 6 feet TOTAL vertical lift AND 4 feet TOTAL

horizontal lift.

Standard Mounting: Vertical Positioning

1. Refer to Figures 4G, 4H, and 4I. Note that the metering pump is shipped with the pump head

already positioned for vertical wall mounting.

2. Use the appropriate type of bolts and washers (user-supplied) to securely mount the metering

pump to the appropriate wall in your building at a distance from the tank that complies with the

suction oil line requirements.

Figure 4G - Vertical Mounting of the Metering Pump

4-9

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Figure 4H - Metering Pump Component Detail

4-10

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

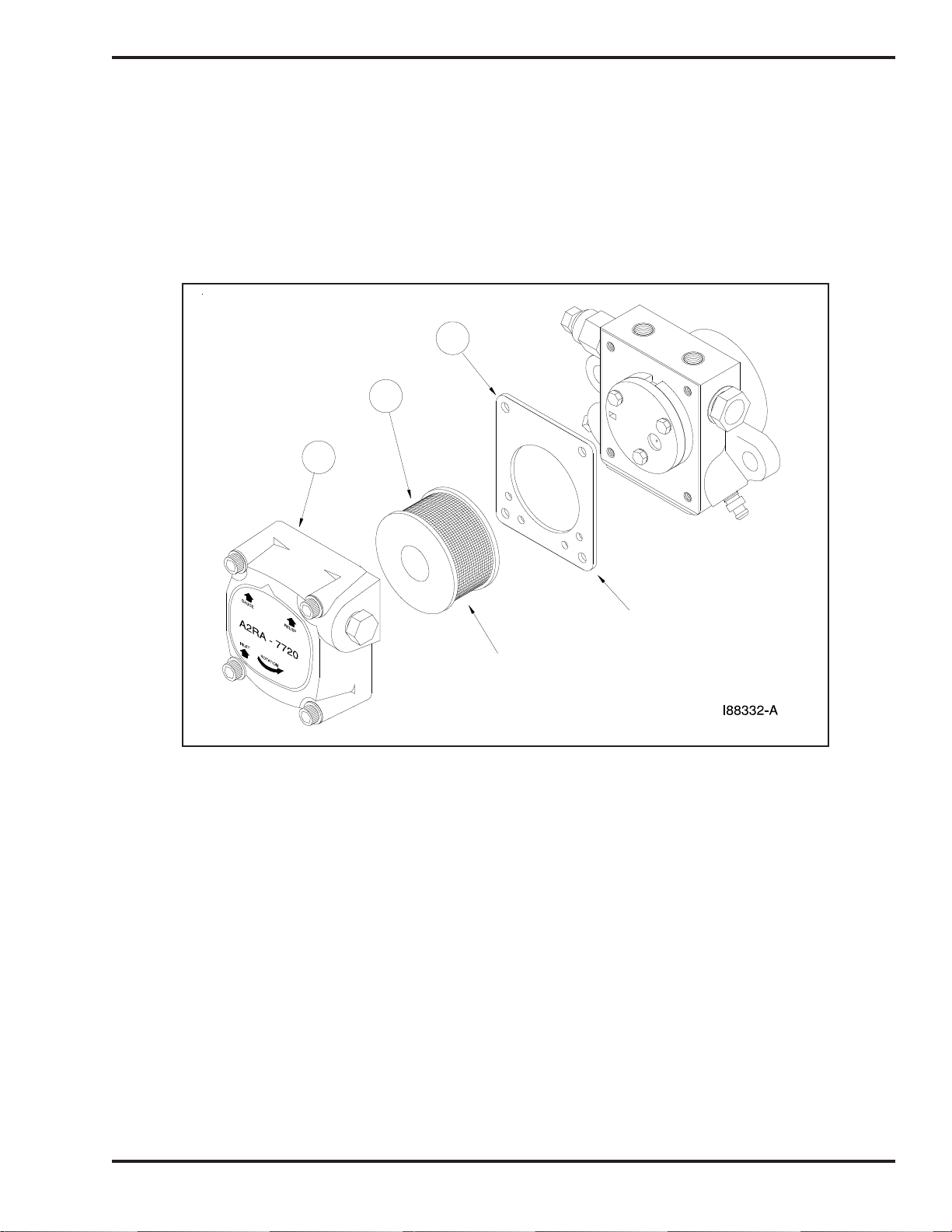

Installing the Metering Pump (continued)

Alternate Mounting: Horizontal Positioning

ATTENTION: If the metering pump is to be mounted horizontally or on a bracket as shown in

Figure 4I, the pump head must be rotated counterclockwise so that it is aligned in a horizontal position. The

gauge arrow on the pump head must point up, or the pump will not prime.

1. Refer to Figures 4H and 4I.

2. Remove the two pump mounting bolts. The coupling is keyed and does not have set screws.

3. Rotate the pump head 180 degrees to the horizontal position as shown in Figure 4I.

4. Reinstall and tighten the two pump mounting bolts.

5. Use the appropriate type of bolts and washers (user-supplied) to securely mount the metering

pump to the mounting bracket, which is to be installed on the appropriate wall in your building at a

distance from the tank that complies with the suction oil line requirements.

GAUGE

RELIEF

A2RA−7 720

INLET

ROTATION

RECOMMENDED SETUP

PUMP IS MOUNTED

LEFT ON WALL

I88708−B

GAUGE

RELIEF

A2RA−7720

INLET

ROTATION

INLETINLET

ALTERNATE MOUNTING

(NOT RECOMMENDED)

BLEED VALVE IS NOW CLOSE

TO THE WALL MAKING THE

BLEEDING DIFFICULT

A2RA−7720

INLET

ROTATION

GAUGE RELIEF

A2RA−7720

INLET

ROTATION

INLET

NON−STANDARD SETUP

PUMP HEAD HAS BEEN

ROTATED 90° CCW FOR

HORIZONTAL MOUNTING

(THE 1/4" STREET ELBOW AND

1/4" X 3" NIPPLE CHANGE PLACES

IN THE PLUMBING SEQUENCE)

RELIEFGAUGE

Figure 4I - Proper Positioning of Metering Pump Head

4-11

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Wiring the Furnace and Pump

WARNING: To avoid electrical shock, make sure that power to the furnace is turned OFF

before connecting any wires. A licensed electrician should install all wiring to your furnace. All wiring

must be in accordance with the National Uniform Electrical Code and local codes. Properly size all wires and

use electrical conduit for all electrical lines.

Wiring your furnace involves the installation of two lines:

(1) A dedicated electrical line to the furnace

(2) A pump electrical circuit from the furnace to the metering pump

Necessary wiring specifications are provided in this section and in the Wiring Schematics located in

Appendix B at the back of the manual.

Wiring to the Furnace

1. Install a dedicated electrical circuit to the electrical junction box on the furnace. Adhere to the

following specifications for wire type:

Model Wire Specification/Type

Model Saturn™ 140 12 gauge, 3-wire / copper wire ONLY

Model Saturn™ 230 12 gauge, 3-wire / copper wire ONLY

2. Wire the furnace according to the Wiring Schematic in Appendix B. Ensure that the ground wire is

attached to the GREEN ground screw in the furnace junction box.

3. Refer to the following chart and check for correct voltage at the furnace.

ATTENTION: Incorrect voltage will severely damage the fan motor/furnace components.

DO NOT operate your furnace on any non-specification power system.

Model Voltage Breaker Size Circuit Hertz

Saturn™ 140 110/120 20 amps* Dedicated 60

Saturn™ 230 110/120 20 amps* Dedicated 60

*NOTE: Breaker size with optional equipment is 20 amps. When installing any optional

equipment (e.g. air compressor or draft inducer), you do not need to "upgrade" the breaker size.

The breaker size listed above should be sufficient. Make sure a qualified electrician properly

sizes and installs this electrical circuit. 12-gauge copper wire is required for a 20 amp breaker.

Refer to NFPA-70 for wire size when the distance is over 100 feet.

4. DO NOT turn on main power until instructed to do so.

or electrical overload may occur.

WARNING: DO NOT

tie into an existing circuit,

Wiring to the Metering Pump

WARNING: DO NOT wire the pump directly into your building's electrical system. The pump

must be activated (receive power) from the burner via the pump electrical circuit. DO NOT wire the

pump directly to a wall outlet so that it runs continuously; this will seriously damage your metering pump and/or

furnace and may result in a fire or explosion hazard.

1. Install the pump electrical circuit from the furnace to the metering pump location.

2. Wire the pump circuit according to the Metering Pump Wiring Schematic in Appendix B at the

back of this manual.

4-12

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Suction Oil Line Components

ATTENTION: It is critical that you adhere to the following specifications for suction oil line

installation (oil line from the tank to the pump). If these specifications are not met, the metering pump will

not function correctly and the burner will shut down on reset. The majority of service problems with the

metering pump are caused by leaks at fittings in the suction oil line; these problems are eliminated by ensuring a

100% airtight suction oil line which slants up to the pump.

• All suction oil line components must be installed as shown in Figures 4H and 4J. Suction line size

is 1/2" diameter. Proper installation allows the suction oil line to be filled with used oil during initial

priming.

• The suction oil line may NOT exceed 6 feet TOTAL vertical lift and 4 feet total horizontal lift

(which equals 6.0” hg maximum operating vacuum). To determine if your suction oil line will meet

this specification for maximum operating vacuum, base the calculation for your installation on the

following equivalents:

(1) vertical foot = 0.75” hg (vacuum)

(4) horizontal feet = 0.75” hg (vacuum)

NOTE: ALSO ADD 0.75" hg to the final sum to account for every oil filter, shut-off valve, and

check valve on the suction side of the pump assembly.

Sample calculation: (6) vertical feet x 0.75" = 4.50" hg AND (4) horizontal feet = 0.75" hg

4.50" hg + 0.75" hg + 0.75" hg = 6.00 " hg vacuum

• The metering pump must be installed with a 3/4" check valve at the end of the suction oil line, or

the pump will not maintain its prime.

• Use Permatex #2 non-hardening gasket sealer on every threaded fitting. DO NOT use

teflon tape or teflon pipe dope compounds; the teflon can flake off and cause damage to the

pump head.

• The suction oil line must be 100% airtight for proper system functioning. Use only

high-quality flare fittings for the copper tubing. DO NOT use compression fittings.

DO NOT use any steel pipe unions. DO NOT use sweat copper pipe. These types of fittings

cause air leaks in the suction oil line and will require re-installation.

• The suction oil line must slant up to the pump; any high spots will trap air and will not

allow the pump to prime.

1. Assemble the suction oil line fittings (from the metering pump to the canister filter):

a. Refer to Figure 4H for a detailed look at the metering pump components and fittings.

b. Remove the plug from the 1/4" inlet port of the pump.

c. Install the 1/4" x 3" brass nipple into the 1/4" inlet port on the pump.

d. Install the 1/4" brass street elbow onto the 3" brass nipple; turn the fitting onto the nipple until it is

tight and faces away from the pump mounting plate.

e. Prepare the canister filter for installation:

• Install the 3/4" x 1/4" brass hex bushing into the outlet port of the canister filter.

Check the direction of the arrow for the proper flow.

• Install the 3/4" x 1/2" brass bushing into the inlet port of the canister filter.

4-13

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Suction Oil Line Components (continued)

(1.) (e.)Prepare the canister filter for installation (continued):

• Remove the plug from one of the 1/8" gauge ports in the canister filter and install the vacuum

gauge. Seal the threads of the gauge with Permatex #2 non-hardening gasket sealer.

• Install the 1/2" threaded pipe adapter into one side of the 1/2" ball valve.

• Install the 1/2" MPT x 1/2" flare adapter into the other side of the ball valve.

• Install this assembly into one side of the 1/2" brass tee.

• Install the assembled 1/2" tee into the 3/4" x 1/2" brass bushing, which is installed in

the inlet port of the canister filter. Make sure that the 1/2" flare adapter is pointing down.

• Install the canister filter assembly onto the 1/4" brass street elbow as shown in Figure 4H.

The canister filter must be installed with the arrow pointing towards the pump (direction of

oil flow).

• Install the 1/2" x 5" brass nipple into the top side of the 1/2" brass tee assembly.

• Loosely install the 1/2" brass cap onto this nipple. DO NOT tighten the cap at this

time.

Figure 4J - Oil Line Installation Overview

4-14

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

2. Install the suction oil line (from the the tank to the canister filter):

a. Refer to Figures 4H and 4J.

b. Prepare a piece of 1/2" O.D. copper tubing (user-supplied) which will function as the pick-up line

from the tank to the canister filter. This copper tubing must have the following specifications:

• The tube must be one continuous piece of 1/2" O.D. copper tubing with no kinks

or fittings.

• The tube is to slant up from the tank to the pump with no loops or high points to

trap air.

c. Locate the 2" MPT x 1/2" FPT x 1/2" FPT duplex, slip-thru hex bushing (which will eventually be

installed into one of the 2" openings on the tank). Note that the fitting is marked "S" for suction

and "R" for return.

d. Install the 1/2" MPT x 1/2" slip fitting into the "S" side of the 2" duplex slip-thru hex bushing.

e. Install the 1/4" MPT x 1/4" compression fitting into the 1/2" x 1/4" brass bushing.

f. Install the 1/2" x 1/4" brass bushing into the "R" side of the 2" duplex slip-thru hex bushing.

g. Measure the height of the oil tank (from the bottom of the tank, NOT the floor) to the 2"

opening that you are going to use for the supply oil line. Deduct 12" (305mm) from this

measurement and transfer this new measurement onto the 1/2" O.D. copper tubing.

h. Remove the locking nut and ferrel sleeve connector from the 1/2" slip fitting, and slide them

over the copper tubing.

i. Slide the 1/2" O.D. copper tubing through the 1/2" slip fitting, which is installed in the "S"

side of the 2" hex bushing.

j. Install the screen into one side of the 3/4" check valve (making sure the arrow is pointing

away from the screen assembly).

k. Install the 3/4" x 1/2" brass bushing into the 3/4" check valve.

l . Install the 1/2" MPT x 1/2" flare adapter into the 3/4" x 1/2" brass bushing.

m . Slide the 1/2" flare nut over the end of the 1/2" copper tubing, and flare the end of the tubing.

NOTE: Use a high-quality flaring tool (such as a Ridgid Flaring Tool) to ensure that all

flares are made properly (i.e. so they will be 100% airtight).

n. Install the flared oil line and nut onto the assembled check valve/screen and tighten.

o. Pick up the assembled oil line, and carefully guide the end of the tubing with the check valve through

the 2" tank opening.

p. Apply Permatex #2 non-hardening gasket sealer (or equivalent) to the threads of the 2" duplex

slip-thru tank bushing, and tighten this fitting into the tank.

q. Pull the 1/2" copper tubing back up through the slip fitting until you see the mark that you put on the

tubing earlier. Holding the tubing with one hand, push the ferrel sleeve connector and locking nut

down the tubing, then tighten onto the 1/2" slip fitting. The oil line is now installed in the correct

position off of the bottom of the tank.

r. Carefully bend the oil line up to the canister filter; use a spring bender over the oil line while bending

the tubing to prevent kinks in the oil line. Allowing for the flare nut, cut off the excess tubing.

s. Install the 1/2" flare nut onto the tubing, and flare the end of the tubing.

t. Install the end of the tubing with the flare nut onto the 1/2" flare adapter (on the ball valve assembly

at the canister filter).

u. Install a vent from the tank to the outside of the building according to code. The tank must be

properly vented to allow air to enter the tank as oil is pumped out and to safely vent fumes to the

outside. See Figure 4J.

v. Install plugs in all other tank openings as required by code.

w. Inspect the installation. For proper suction oil line operation, make sure all components are

installed and positioned as specified in this manual.

4-15

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Pressure Relief Oil Line Back to the Tank

ATTENTION: It is critical that you adhere to the following specifications for plumbing the pressure relief

back to the tank.

The metering pump requires the installation of a pressure relief oil line back to the tank that you are pulling oil

from as shown in Figures 4H, 4J, and 4K.

• The pressure relief will open and relieve pressure if there is a restriction in the pressure oil line,

clogged nozzle, etc.

Be sure to use Permatex #2 non-hardening gasket sealer to seal every threaded fitting. DO NOT use teflon

tape or teflon pipe dope compounds.

1. Refer to Figure 4K.

2. Remove the plug from the relief port on top of the metering pump head.

3. Install the 1/8 NPT x 1/4 tube compression fitting in the relief port on top of the metering pump head.

4. Install 1/4" O.D. copper tubing (user-supplied) from the pressure relief port back to the oil tank.

Refer to Figure 4J as needed.

# PART # DESCRIPTION

1 32475 METERING PUMP HEAD (7720)

2 32526 MINI BALL VALVE 1/8 MNPT X 1/8 FNPT

3 INSTALLER SUPPLIED 1/8 MNPT X 3/8 OR 1/2 FLARE

4 INSTALLER SUPPLIED 3/8 OR 1/2 COPPER OR ALUM. TUBING

5 INSTALLER SUPPLIED 3/8 OR 1/2 TUBE FLARE NUT

6 INSTALLER SUPPLIED 1/4 COPPER OR ALUM. TUBING

7 32037 1/8 MNPT X 1/4 TUBE COMP. FITTING

5

6

4

7

3

2

1

Figure 4K - Pressure Relief Oil Line Back to the Tank

4-16

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Pressure Oil Line Components

ATTENTION: It is critical that you adhere to the following specifications for pressure oil line installation (oil

line from the pump to the furnace); if these specifications are not met, the metering pump will not function

correctly and the burner will shut down on reset.

• The parameters for pressure oil line installation are:

Length of Pressure Line Line Size

Up to 100 feet 3/8" O.D. copper tubing

(Please note that some installations will allow for a greater pressure line length. Contact your

Authorized Clean Burn Distributor for more information.)

• The pressure oil line must slant up to the burner with no loops or high points to trap air.

• Local codes may require the installation of an in-line "Fire-O-Matic" safety valve.

Be sure to check all appropriate codes to ensure compliance.

1. Refer to Figures 4H, 4J, and 4K.

2. Make sure you have purchased all the necessary fittings to complete the installation correctly.

3. Install the fittings and components as shown in the related illustrations. Be sure to use Permatex #2

non-hardening gasket sealer to seal every threaded fitting. DO NOT use teflon tape or teflon pipe dope

compounds.

Installing the Compressed Air Line

NOTE: Your air compressor system must supply air pressure to the furnace with the following minimum

requirements: 50 psi and water trap or dryer. If you do not have shop air, an optional air compressor is

available. Contact your local Clean Burn dealer for more information.

1. Run a compressed air line from your shop air to the connector block on the furnace. Use

minimum 1/4" O.D. copper tubing or equivalent for the compressed air line.

2. Install an easily accessible shut-off valve in the air line so the burner can be serviced without

shutting off the shop air in your service area.

3. If necessary, install a pressure regulator (additional to the burner air regulator) in the air line, and

set it at 50 psi.

ATTENTION: DO NOT feed full shop air pressure to the burner or damage to burner

components may occur.

4. Install a water trap or extractor/dryer in the air line with an automatic drain so compressed air

(rather than water) is supplied to the burner.

ATTENTION: Water must not be fed to the burner, or the flame will be extinguished and the

burner will shut down. Be sure to drain water from your compressor tank on a regular basis to

keep water out of the air line.

4-17

Operator's Manual: Models Saturn™ 140 & Saturn™ 230

Installing the Stack

WARNING: Inappropriate stack materials or improper stack design/installation can adversely