*

{-^

SATOH

TRACTOR

f

L

s-65()G

REnAIR

MANML

SATOH AGRICUTTURAL

MACHINE

7

Publication

No.

03

MFG.

CO*LTD,

CO}ITENTS

ENGiINE

SYSTEM

...-....."""""""""'t"r"""""""""""'t"""".."""

A

CLUTCH

SYSTEM

//../..I{.|EE..L,

r

.

..'

r, r r, .

. r.,

/'..r(.hEE..k

rr...rrrrrrr..r.r..rt!r.

B

STEERI

ilG

LI

I{KAGE

SYSTEII

TRANsMlssl0il sysTE

|l

.#6rn.

A.....

KEo.*

fr.i.r{s..........

ll

BRAKE

SYSTEM...r..r.......r.........r...........................r..................rrr.

E

ELECTRI0AL

SYSTEM

r

e.

r

.,frn6.

DRAFT

CoNTRoL.....,...........................r................................r.......

H

p0UuER

ASSISTED

STEERIJ{G......................................................

I

I

Tt

SATOH

TruTOR

ENGINE

SYSTEM

.

PUBLICATI0il

JIo.03-A

MoDEL

s.65()(G

REPAIR

MANUAL

I

i

t

I

(i

{-

I

CONTENTS

THE ENGINE

.

GENERAL

1.

Cylinder

Head

2. Cylinder

Block

3.

Pistons and

Crankshaft

4.

Valve

Mechanism

5.

lntake

and

Exhaust

Mechanism

6. Governor

7.

Cooling

System

8. Lubricating

Mechanism

9.

Elestrical

SYstem

ETUGINE

Disassembling

Order

1-1

.

Removing

the

Engine

.

.

1-2.

Disasembling

the

Engine

Checking

Maintenance

and Limit

of

Adiustment

2-1

.

Cylinder

Head .

.

2-2.

Piston

and Cylinder

Block

2-3. Connecting

Rod

24.

Crankslraft

and

Main

Bearing

Metal

2-5.

Camshaft

.

.

2-6.

Timing

Chain Sprocket

and

Chain

Adiuster

AssemblingOrder ..

..

3-1

. Assembling

the

Engine

3-2.

Mounting

the

Engine

Spgcifications

.. ..........

LUBRICATIOT{SYSTEM

....

1.

Lubrication System

-

General

2. Disassembling

the

Oil

Pump

.

.

.

.

2-1

.

Removing

the

Oil

Pump

2-2.

Disasembling the

Oil

Pump

3. Checking,

Maintenance

and Limit

of Adiustment

3-1

. Checking

and

Adjusting

the

Oil

Pump

3-2. Oil

Filter

Replacement

3-3.

Checking

and

Adjusting the Oil

Pump

Driven Gear

Shaft

34.

Adjusting

the

End

Play

of

Oil

Pump

Driven Gear Shaft

4

tT'I?"ruili,ff':

:

:

1.

2.

3.

4.

3

3

3

7

15

15

18

21

23

25

26

27

27

38

38

39

39

40

40

40

40

40

41

41

42

42

42

42

5, Specif

ications

51.

Oil

Pump

Specifications

5-2.

Oil

F

ilter Specif

ications

SYSTEM

....

Cooling

System

-

General

- .

Disasembling

Order

.

.

2-1

.

Removing the

Water

PumP

2-2.

Disassembling

the

Water

PumP

Checking

Maintenance

?nd

Limit of

Adiustment

31 .

lnspection of

Water

PumP

.

.

3l2. Checking

the

Thermostat

AssemblingtheWaterPumP

....

..

Mounting

thg

Water

Pump .

. .

. . . .

. .

.

lrstalling

the

Thermostat

. . . . . . .

. .

.

Specifications

..

..

7-1

.

WaterPump

r.

.

. . .

. . . .

. . .

.

7-2.

ThgrmosEt..

,o....o.

.42

.42

.42

.43

j

COOLING

1.

2.

3.

*4.

5.

6.

7.

FUEL

SYSTEM

Fuel

System

-

.Generct

AirCleaner o o

. .

.

2-1

.

Rennving

the

Air

Cleaner

Element

2-2. Checking

the

Air

Cleaner

. . . .

2-3.

Air

Cleaner Specifications

.

.

Fugl

Pump...,.....

31

"

Removing

the

Fuel

Pump

. .

3-2. Disasembling

the

Fuel Pump

.

.

3-3. Checking the

Fuel

Pump

34.

Assembling

the

Fuel

Pump

.

.

35.

lnsUlling

the

Fuel

Pump

36.

Fuel

Pump

Specifications

.

. .

.

4.

Fugl Filtgr

. . .

. . . ...

. , . . .

.

5. Carburetor

..

..

51

.

C"onstruction

.

.

5-2.

Disassembling the

Carburetor

$3.

Checking,

Maintenance

and

Limit of

5.4.

Assembling

the

Carburetor

.

.

t5.

MountingtheCarburetor

.... .

$6. Specif

ications

.

.

1.

2.

43

43

43

43

4

M

4

4

45

45

45

45

45

47

47

47

47

47

47

47

47

48

48

48

49

49

49

50

50

50

54

55

55

55

I_

gOiustment

6. Governor

6-1.

Governor System

-

General

6-2.

Governor

-

Operation

and

Construction

6-3.

Purpose

of Governor

Adjustments

&4.

Maintenance

6-5.

lnterlock

Adjustment between

C;rburetor

Spark

Plug

.55

55

.56

.58

.58

.58

.59

59

59

59

59

59

59

60

61

61

61

6l

63

.63

.63

.63

.63

.63

.63

.63

.63

.64

.il

.64

.u

.64

.u

.64

.65

.65

.65

.65

.65

and

Governor

IGTTIITION

SYSTEM

1.

Spark

Plug

1

-1

.

lnspection and

Adjustment

of

1-2.

Spark

Plug

Specifiiitions

Distributor

2-1 .

Removing

the

Distributor

2-2. Disasembling the

Distributor

2-3.

Checking,

Maintenanc€ and

Limit

of

Adjustment

24. Asembling

the

Distributor

2-5.

Mounting

the

Distributor

2-6.

lgnition Timing

lnspection and

Adiustment

2-7 . Distributor

Specifications

TOURBLESHOOTI]UG

1.

The Ergine

Lacks

Power .

.

1

-1

.

Fuel

C.omprssion

is

lnsuff

icient

1-2. lgnition

Timing

is

lncorrect

1-3. Fuel

Lsrel

is

Low

14.

Carburetor

Dravw

lnsufficient

Amount

of

Air

1-5. Engine

Overheats

.

.

.

.

2.

Fuel

Canzumption

is

Excessive

2-1 .

Engine

Oil

Leaks

2-2.

Oil

Comes

Up

into the

Combustion

Chamber

2-3. Oil

Comes

Down

from

Valve

System

Engine is

Hard

to Surt

3-1.

Engine

has

Starting

Difficulty

:

.

3-2.

lgnition System

is Defective

3-3.

Engine

34. Carburetor

Engine

is

Noisy

4-1

.

Piston

+2. Crankshaft

+3.

ConnectingRod

.... ....

U.

tMiscellaneous

3.

4.

I

l

6.

5.

F

iring

lrregularities

S1.

lgnition

System

*2.

Air-fuel Mixture

$3.

Valves

.

.

u. cylinderHead

.. ....

lncorrest

ldle

Speed

Adiustment

.

.

Gl .

Carburgtor

. . .

.

. . . .

G2.

AirEnteringFuel

Line

....

....

6-3.Va1vgs...........o....

il.

Cylindgr

Head . .

.

. . . .

.

. . .

.

Engine

Runs

not

Smoothly

(when

acceleratedl

.

. . .

7-1

. Carburgtor

. o

. . . . . . . . . . . . . . . .

7-2.

lgnitionSystgm

..

......

...

7

3" Ergine, . .

. . . . .

. . . . . .

.

.

.

. .

. . .

.

.

.

.

65

65

65

65

66

66

66

66

66

66

66

66

66

66

7.

THE

ENGINE

-

GENERAL

TllE

ENGINE-GENERAL

This

PB

engine is a

high

performance,

water-cooled,

4-cylinder,

in-line

gasoline

engine,

employing

the overhead

valve

and

high

cam

shaft system.

The

cylinder

bore

and the

piston

stroke

measure

2'6772

in'

(68

mm) and

2'6772

in'

(68

mm)'

respectively. ln

this sense, the

cylinder

is

o{ a

square type,

having a total

displacement

of

60.2 cu.

in'

(987

cc)

and a

compr.ession

ratio

of

8.6 to l.

The maximum output

is

25

PS

at

2,800

r.p.m. and

the

maximum torque

46'9

lt-lbl2,2$O

r.p.m.

(6.5

kg-m/2,2OO r.p.m.). The description

of

the

engine is as

follows:

t

1.

Cylinder

Head

Being

made

of

a

light

alloy, the

cylinder

head

is light

in

weight,

provid

ing excellent

rad iation

eff

iciency.

The

domeshaped combustion

chamber

is shrinkage-

fitted

with

ductile cast iron

valve seats.

The

intake

and the

exhaust

valves

are

arranged

opposite

to

each

other the

cylinder head;

that

is,

the

cros-flow

design

is

employed

for

better combustion

eff

iciency.

2. Cylinder

Block

The

cylinder

block

is

precisioncast

from a

light

alloy

meEl

by

means

of

pressure

die

casting.

To

support

the

crankshaft,

f

ive

bearings

of

the deep

skirt

type

are

employed.

The

cylinder

liners

are

made

of

special

cast iron

and

replaceable.

They

are directly

cooled

by

water

and sealed

with

two

"4"

rings.

3.

Pistons

and

Crankshaft

The

pistons

are

of a

conical ellipse type

manufacturd

by

LO-EX.

The

crankslraft

is made

of

ductile

cast

iron

supsior in

durability

and wear-resistance,

and

supported

by

five main

bearings.

The

main

bearings

are

made

of an aluminum alloyed

with

tin,

which

is

also excellent in

durability

and

wear-resistance.

4.

UalYe

Meclnnism

The

high

cam

shaft design

is employed,

along

with

five

special

iron

bearings,

for increased rigidity.

This

permits

high

speed

relolutions.

The

cam

shaft

is

driven

by a

Renold-made

chain,

wtrose tension

is

adjustable

by

means

of

the

chain.

adjuster

and

vibration

dampr. To

reduce the

cfrain

noise, the

contacting

surfaces of

the

chain

is

finished with

heat-proof

and

wear-proof

rubber.

5.

lntake

and

Exhaust

Mechanism

The

exhaust

manifold

is made

of cast

iron,

and

the

intake

manifold

made of

a

light

alloy

metal.

Both

manifolds ?re

of

independent

branch

Wpe.

The hot

spot

is heated

by

warmed

"cooling

water".

ln

the

intake system,

a Stronberg

type

carburetor,

having a

downdraft

double-venturi

is used.

6.

GoYernor

The

Governor

is

of

f

ly weight

type

and controlled

by

means of

all

speed

governor

system.

-1

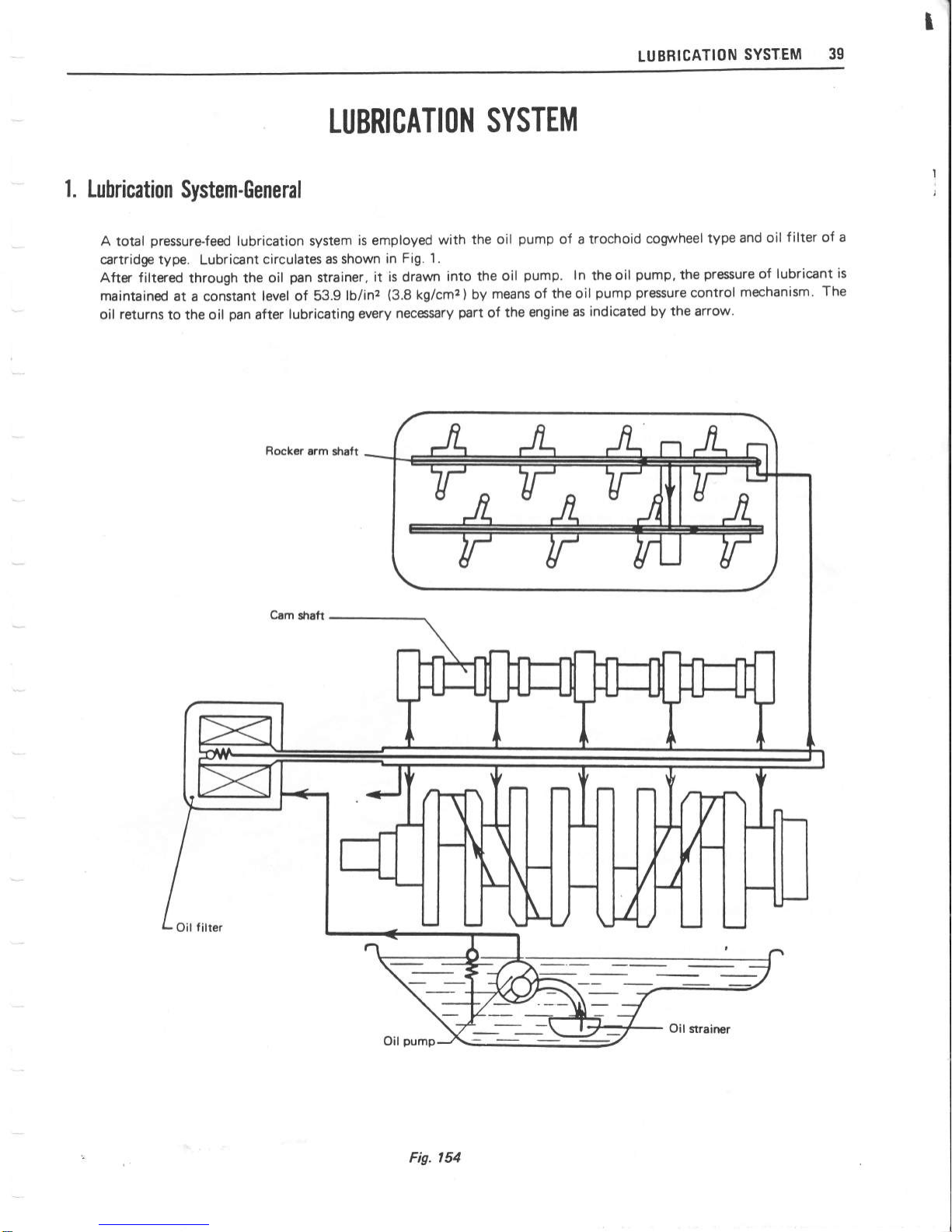

8.

Lubricating

Mechanism

Total

pressure

lubrication is carried

out by

a

trochoid

gpar

oil

-pump,

which is

driven

by

the

cam shaft drive

gear.

A

cartridge

type oil

f ilter

is

employed.

9.

Electrical

System

Electrical

component

is

of

12-volt

capacity.

The

alternator

is

l

Samp.

capacity, and the starter of

1.O-kW.

As

the

battery,

the

N40L

Wpe

is used,

and

the distributor

is

provided

with

a

vacuum

and

centrif

ugal

type

automatical

advancer.

7. Cooling

System

Cooling

system

is

the type

of

forcedcirculation,

and

the

pressure

in the

radiator

is 9.954 lbs/sq.

in.

by

which

the

high

efficiency

of

heat

radiation is secur-

ed.

Their

qystem

is

incorporated

with

the

Wax

type

thermostat

and

the

water

pump

is

of the

centrifugal

type.

The miterial

of

cooling

fan

is the synthetic

resin,

consisting

of

4

wings,

ENGINE

ENGINE

1.

Disassembling

0rder

Note:

Notes

on

Engine Dirssembly

Both

engine and

transmission

are very

heavy

in weight. ln

addition,

they

must

be

kept in

a

horizontal

position

while

being disassembled,

and therefore,

engine

disassembly operations

should

be

performed

on solid

f loors.

To keep

the

tractor in a

horizontal

position,

place

a

wooden wedge between the

front extension and

the

axle beam.

Be sure

that

necessary wrenche, such as

a special

tool

(No.

N033S

SOCKET

WRENCH SET), special

tool

(No.

BT-100 DOUBLE

OFFSET

BOX

WRENCH SET),

and

(No.

BT-9 OPEN-END

WRENCH

SET),

and other

special tools

including a

chain

block are all available on

hand.

Put

a rnark

on

each engine

component

part

such as a

piston.

piston

ring,

valve, valrre spring,

metal,

tappet,

push

rod. etc. in order of the

cylinders,

so that

you

will not

corifuse

dbout

parts.

Take

special

care not

to datnage

the

removed

parts,

and

put

them

in order.

l-1

.

Remoying

the Engine

1.

Bemove

the negative

(-)

corde

from

the

battery.

2.

Remove

the

wires from

the alternator

(A)

,

starting

motor

(B)

and

hed

light

(cl.

c

o

o

o

o

b

\

Fig. I

Remove

the

bonnet.

Disconnect

the

wires

from

the oil

pressure

switch

(A)

and

the

water heat

gauge

(B)

.

Fig.

2

5.

Removing

the

radiator

Throughly

drain

off the cooling water from

the

radiator

and

cylinder

block. Loose

the water hose

clip

(A)

and

pull

out

the

water

hose from

the

radiator.

Remove

the

radiator

mounting

bolts

(B)

,

(C),

and

fitting

nut for

radiator

support

(D),

and

remove

the

radiator.

3.

4.

Fig.

3

ENGINE

6.

Removing

the

tractor

meter

cable,

throttle

wire

and

choke

wire

Remove

the

governor

cover

{A),

and

disconnect

the

tractor meter

cable

(B)

,

throttle

wire

(C)

and

choke

wire

(D)

.

Remove

the

governor

cover.

*l

Fig.

4

7 .

Removing

the

fuel

pipe

Remove

the

fuel

pipe

(Al

.

To

prevent

entering

the

fuel

tank, cover

it

with

a

cloth

"

Fig.

6

9.

Figr'

7 end

I

10.

Removing

the hydraulic

oil

pipe

a.

Remove

the

hydraulic

oil

pipe

clamp

(A).

Removing

the

silencer

pipe

Remove

the

nut

(A)

mountlng

both

exhaust

manifold

and silencer

pipe,

and

remove

the

silenc-

er

mounting nut

(B).

Then

remove

the

silencer

pipe.

dust

from

clean

dry

Fis.

5

8.

Removing

the

drag

link

Pu

ll

out

the split

p

in

from

the

ball

socket

connecting

the

Pitman

arm

and

drag

link,

and

remove

the slotted

nut

(A).

Remove

the

ball

socket

by

using

the

special

tool

(No.

TRH-12

TIE

ROD

END

REMOVEBI

Fig. 9

EN GINE

Fig.

l0

c.

Remove

the banjo bolt

(Cl"

Fig.

I I

d. Loosen

the strainer

body

(D),

and

take it

out.

Fig.

t 2

e.

b.

Remove

the magnet

plug

(B),

and

drain

off the

hydraulic

oil case.

When reusing

the oil,

put

it

in a

clean

container

while

taking

care

not

to

allow dust

to

enter

the

oil.

Remove

the

pump

flange

mounting

bolt

(E)

from

both

inlet

and outlet

sides. Cover the

ends

of the

pipe

so that

no

dust

will enter

the

pipe.

Removing

the

hydraulic

pump

and

pump

bracket.

Remove

the

four

bolts setting

the

pump

joint

(A),

and

remove

the

pump

joint.

Remove

the

four nuts

(B)

from

the

pump

(C).

Remove

the

two

screw

(M8

x

25l,

and

three bolts

(MB

x 45)

from

the

pump

bracket,

and

remove

the bracket

(D).

Note:

As alignment

of

the center

line

betureen

crankshaft

and the

hydraulic

oil

pump

had

been

correctly

fixed

at

0.001

181

in.

(0.03

mm)

during

factory

assembly, do

not

attempt

to

remove

the

pump

unless otherwise

it is definitely

necsary

to

work

out

its

remowt.

Removing

the

flange

coupling

and

CG-type

rubber

coupling

Remove

the

three

bolts

which

fasten

the

CG-type

rubber

coupling

to

the

crak

pulley,

and

remove

the

flange

coupling

and

CG-type rubber

coupling.

Fig.

l3

11.

Fig.

14

12.

EN

G INE

13.

Remove

the

engine

mounting

rubber

mounting

nut

(A)

on

both

right

and

left sides,

and

remove the

engine support

mounting bolt

(B).

Fig. 15

14.

Removing the

alternator

and

V-belt

a.

Remove

the

bolt

as shown

in

Fig.

16,

and

remo\€

the alternator

strap

tB)

from

the

alternator

(A)-

b.

Remove

the

alternator

mounting

nut and bolt,

and

remove

the

alternator

and

V-belt

(C)

from

the

alternator

bracket.

i,,'

{e

Fig.

16

15.

lnstall the chain

block

on

the engine

hanger

(A)

on

the

manifold on

both exhaust

and

inuke

sides.

Do

not

hoist

the

engine, but

pull

the

wire so that

it

becomes

slightly tight.

Place

a

garage

jack

under

the clutch

housing.

Do

not

iack

up the tractor,

Just

raise

the

jack

so

that

it is

just

tightly

locked under

the

tractor.

Remove

the'bolts

(A)

,

four

each on both

right

and

left sides,

and

the

four

bolts

(B)

,

also

four

each

on

both sides,

which

mounting

the

chasisand

clutch

housing.

Remove

the three

screws

(C)

from

the

re*,r

plate,

and

pull

the

re:,r

plate

downuard.

Pull

out

the

clrasis

and

front

axle

toward the

front.

Removing

the

engine mounting

and

alternator

bracket

Remove

the

mounting

nut,

and

remove

the

engine

mounting

(A)

from

the

alternator

bracket.

l

Fig. l7

16"

17.

Fig. t

8

18.

19.

a.

EN

GI

NE

Fis.

l9

b.

Remove

the

three

mounting

nuts, and

remove

the

alternator

bracket

(B)

from

the

cylinder

block-

Fis. fr

20.

Remove

the

starter

starter.

mounting

nut,

and

remove

the

Remove

the

four

nuts

(A)

and

nuts

(B)

(one

each

on both

right

and

left

sides)

,

which

mounting

the

engine

and

clutch

housing.

Next,

adjust

the

chain

block

suspending

the

engine

so that

the

stud bolt

will not be

under

excessive

load.

Then

pull

the

engine toward

the

front.

Fig.

22

1-2.

Dlsasembling

the

Engine

1. lnstall

the

engine on

the

special

tool

(No.

@90010

ENGINE

STAND)

by

mears of

one

bolt

and

three

nuts then

renpving

the

clutch

unit.

Fig.

23

21

.

Fis.

2l

_l

EN

GIN

E

2.

Draining

the

engine lubricants

Remove

the drain

plug

and

drain

off the engine

lubricants.

Fig.

24

3-

Remove

the

clutch, flywheel

and

crank

pulley

a.

As

shown

in

Fig.

25,

remove

6

pcs.

of scrarus

and

remove

the

clutch"

Make

sure

that

the

removal

order

for

screws

should

be diagonally

done.

Fig.

25

b. As

shown

in

Fig.

26, raise

up

the

lock

washer

of

its

bent

portion.

c.

As

shown

in

Fig.

26, install

the

special

tool

(No.

0490100

RtNG

GEAR

BRAKE)

so

that

the crank-

shaft

and

f lywheel

cannot

be

rotated.

d. Remove

6

pcs.

of the

rock

bolts

and

remove

the

flywheel

(A)

from

the

crankshaft.

Fig.

fi

e. Rernove

lock

bolt from

the

crank

pulley

(A)

at

the

front

of the

engine.

Fig"

27

f

.

Remove

the

special

tool

(No.

0490100

R

tNG

GEAR

BRAKE).

4. Removing

the

air

cleaner

a.

Loosen

two hose

bands,

and

remove

the hot

air

hose

(A)

from

the

air

cleaner

and

the

carburetor.

Fig.

28

b,

Loosen

two wing

nuts,

and

raise

the

clamp

(B).

Remove

the air

cleaner

bands

(c)

and

remove

the

air cleaner"

'*t

J

EN G INE

R

emoving

the

d

istributor

Pull

the

high

tension

wire

out of

each

spark

plug,

Pull

out

the vacuum

advance

hose

(A)

connected

to

the

distributor,

as

shown in

Fig.

30.

Unscraru

the nuts

(B),

and

pull

upward

the

distributor,

as

shown in Fig.

31.

Fig.

3l

Removing

the

V-belt

and

idler

assembly

Screw

in

the

adjusting

bolt

(A)

to make

the

V-belt

tight,

and

loosen

the

governor

pulley

lock

nub,

as

shown

in

Fig.

32.

Loosen

the adlusting

bolt

and

move

the

idler

pulley

(B

)

in the

direction

of

the

arrow

shown

in

F

is

33.

Then

pull

down the

governor

operating

lever

(C)

to the carburetor

side, and

remove

the

V-belt

(D)

from

each

pulley.

Unscrew

two

nuts

and

bolts, and

remove

the

idler

assembly

(E)

from

the

governor

bracket

and

the

timing

chain

cover.

Fb.

33

7.

Removing

the

governor

and

governor

bracket

a.

Remove

the

lock nut which

has

been already

loosened

according

to 6-a

above,

and

slip

the

governor pulley

(A)

off

the

governor

shaft. Then

remove

the

key

(B)

on

the

governor

shaft.

b

c.

Fig.

29

Fig.

fi

6.

a.

5.

ct.

b.

c.

';.

Fis.

32

Fig.

34

I

10

EN

GINE

b.

Remove

the

governor

operating

lever

and

remove

the

rod

assembly.

c.

Remove

the

nuts

and

bolts shornrn

in

Fig.

35.

d. Unscrew

three

nuts

shown in

Fig.

36,

and

remove

the

governor.

Remove

the

governor

bracket

and

remove

the engine

bracket

from

the cylinder

block.

Fig.35

e.

Unscrew

three

bolts and nuts

(

D), then,

the

gpvernor

(A),

the

go\emor

bnacket

(B)

and

the

engine

bracket ,(C)

which

have

already

.bem

removed

aaording

to 74

above, can

be separated.

Fig. 37

8.

Removing

the

cooling fan and

cooling

fan

oom-

plete

a. Unscrew

four

bolts, and

remove

the cboting

fan

(A)

,

fan

spacer,

pump

pulley

(B)

from

the

cooling

fan

complete.

b.

Unscrew

three

nuts,

and

remove

the cooling

fan

complete

(C)

and

alternator

strap from

the

rylin-

der

head.

c.

Take

out the thermosEt

from

the thermostat

casing.

'Removing

the

water

pump

Pull

the

inake rnanifold

water

hose

(A)

out

of

the

water

pump

by loosening

the clip.

Unscrew

four nuts,

and

remove

the alternator stay

(C)

and

water

pump

(B)

from

the cylinder head.

Fig.

fi

Fig.

39

:Fig.

s6

b.

Fig.

4l

EN

GIN

E

11

R

emoving

the

oil

f

ilter

Pull

out

the oil

level

gauge.

Remove

the oil

f

ilter

from the

cylinder

block

by

using an

special

tool

(No.

0490130 OIL

FILTER

WRENCH}

(A).

Fig.

42

I 1. Removing

the

fuel

filter

a. Unscrew the carburetor

connecting bolt,

remove

the

f

uel

hose

(Al

connected

to

carbu

retor.

b. Unscrew

two

nuts,

and

remove

the

fuel

pump

from

the cylinder block.

Then remove

the

and

the

(B)

in-

su

lator.

c.

Remove

the

oil

pressure

switeh

(C)

and

the

breather

pipe

(D).

Fis.

43

12.

R

emoving

the

carburetor

Unscrew

two

nuts, and

remove

the carburetor

(A).

Remove

the

insulator

(B)

from

the

intake

manif

old.

Fig.

44

13.

Removing

the

intake

manifold

Unscrew

eight

nuts

and

remove the

engine

hanger

(A).

Then

remove

the

intake

manifold

(B)

from

the

cyl

inder

head,

together

with the

governor

cover

stay

and the

a

ir cleaner

stay

mounted

thereon.

Fig. 45

14"

Rernoving

the exhaust manifold

Unscrew

eight nuts, remove

the

engine

hanger

(A)

,

and

then

remove

the

exhaust

manifold

(B)

from

the

cylinder

head.

10.

a.

b.

Fig.

46

-l

12

EN

GI

NE

-trlE

Fig.47

15.

Removing

the

rocker

arm cover

Unscrew

two

bolts

and

remove

the

rocker

arm

cover

from

the

cYlinder

head-

16.

Removing the

cylinder

hed

assembly

a. Unscrew ten

cylinder

head

nuts.

b.

Pull

upward

rocker

arm

asembly

(A).

c.

Pull

upward

eight

push

rods

(B).

d.

Remove

the

cylinder

head

assembly

(C)

from the

cylinder block.

e.

Remove the

cylinder

had

gasket.

Fis.

48

17.

Pull

eight

tappet

followers

from

the

cylinder

head

by using

a

proper

tool

such as

a magnet.

>'*.g-

ap

18. Removing

the

oil

pump

drive

gear

shaft.

a. Unscrew

two

nutS

and

remove the

oil

pump

drive

gear

cover

(A).

b.

Unscrew

three

nuts and

remove the

blind

cover

(B).

c.

Lift

off

the oil

pump

drive

gear

shaft

(D)

together

with the

shim

(E)

and

the

thrust

washer

(C)"

Fig.

fi

19. Turn

the

engine upside

down and

noW

the

oil

pan

is

upward.

20.

Removing

the oil

pan.

Undo twenty-two

nuts securing

the oil

pan

(B)

and

lift off the oil

pan

from

the

rylinder

block.

21

.

Unfasten

the

lock

bolts

and

remove the crank*raft

Pullqr

(A)

from

the crankshaft.

Fig.

5l

?E

,#€

Fi,.

49

EN

GI

]'IE

13

22.

Removing

the

timing

chain

cover

Undo

nine

nuts

and

remove the

timing chain

cover

(A)

Fig.

52

23.

Removing

the

chain

adjuster

assembly.

a. Undo

two nuts and

remove

the

chain

adjuster

assembly

(A).

b.

Remove

the oil baffle

plate

(B)

from

the

crank-

shaft.

c.

Remove

the

key

(C)

from

the

crankshaft.

d. Undo two nuts

and

remove

the

vibration damper

assembly

(D),

Fis.

53

24.

Removing the timing chain.

a"

Undo two

nuts securing the camshaft

(A)

b.

Remove

the

camshaft

& camsprocket

wheel

and

the timing

sprocket

wheel

together

with

the

timing

chain

(B)

from

the crankshaft

and

the

rylinder

block as

shown

in

Fig.

54.

{-t

Fig. 54

25.

Removing the

front

Plate.

Undo

two

nuts and

r'emove

the

front

plate

from

the

cylinder

block.

Fig.

55

n.

Removing

the oil

pump.

a. Loosen the

conn€tion nuts

and detach the oil

pipe

(A)

from

the

cylinder

block.

b.

Unscrew two

nuts

and

remove

the oil

strainer

(B)

from

the

oil

pump

(C).

c.

Unscrew

four

nuts

and lift up the oil

pump.

)

>-,

'\\

4,

{rir*

\

*

''

rl-.

l>*

Il

1r Il

ll

t

f=1

Di'r-

Fig.

56

>\-{

14

EN

GI

NE

27.

Removing

the

connecting

rod

cap

Loosen

eight

connecting

rod

lock

bolts

and

re-

move four

connecting

rod

caps

(A)

together

with

the

connecting

rod

bearing

metal

and

the

lock

bolts.

Note:

The

connecting rod

caps are marked

with

rylinder

numbers

(1,2,3

and 4),

respectively.

Fig.

57

28.

Removing

the

main

bearing

cap

a.

Straighten

the

bent

edges

of the lock washer

and

ten

nuts

securing

the

main

bearing

caps.

Fis.

58

b.

Remove

five

main

bering caps

together

with

the

main

bearing

metal.

n.

Removing

the

carnkshaft

Fig'

6o

a.

Remove

the

crankshaft from

the

cylinder

block

32.

Fig.

59

b.

Remove

five main

bearing

metals

from

the

cylin-

der block.

30"

Lift

up

four

piston

&

connecting

rod

assemblies

from

the

rylinder

block.

31.

Disassembling

the

piston

&

connecting

rod

as-

sembly.

Remove

three

pbton

rings

and

the

expander.

Remove

the

clips

at both ends of the

piston

pin.

Heat

the

piston

with

the

piston

heater

250

^'r'

300"F

1120

^,

150oC) and

pull

out

the

piston

pin

(

by

means

of

the special

tool

(No.

e190070

PISTON

PIN

INSTLLER)

(A)

and

detach

the

piston

from

the connsting

rod.

Disassembling

the

cylinder

head

asembly.

Disasemble

each

valve mechanism

in

the

following

procedure.

Press

the

valve

by

means

of the

special

tool

(No.

0490030

VALVE

SPR

ING

Ll

FTER

)

(A)

and

remove the

taper

sleeves

(B).

a.

b.

c.

ct.

ENGINE

15

Fig.

6l

b.

Remove the

valve

spring

lifter

and

dismantle

the

valve

springs,the

spring

Seat

upper

and

lower,

and

va I

ves.

Cylinder

Head

Bend

Limit

Grinding

Limit

0.006 in.

(0.15

mm)

0.008

in.

(0.20

mm)

Fig. 63

3.

Valve

seat

Check

the

valve

seat

for

wear

and

damage,

and if it

is

defective,

correct it

with

a special

tool

(No.

0490140 VALVE

SEAT

currERl

{A}

.

Besides,

if

the sinking

of

the

valve

sear is more

than 0.0s9

in.

(1.5

mm) replace

the cylinder head

with

a new

one.

2.

Checking

Maintenance

and

Limit

0f

Adiustment

2-1

.

Gylinder

Head

Wash

the cylinder

head

if

there

is

much

fur in

the

v\nter

passage

of the cylinder

head.

check

the oil

apertures

for

blockage.

:

Bend

of the

cylinder

head

bottom

To

check

the

cylinder

head

bottom

for

bend,

measure

the

points

(1)

'\'

(6)

of

the cylinder

head

bottom

shown

in

Fig.

63

using a

thicknes

gauge

and a

surface

gauge.

lf

the measured wlue

is

beyond the

limit, correct

it with

a

surface

grinder.

o

o

o

Notes:

Before

inspecting

the engine.

Clear each

component

of

dust, carbon,

fur, etc.

and

wash it in solvent.

Check

the

cylinder hed and

cylinder

block

for

leakages

and damage.

Blow dust and

so on off

the oil aperture

of

each component

by

means of an air

gun

to

ensure

that

there

is no

blockage.

Put

the

valves. bearing

metals.

bearing

caps,

etc.

to

be

joined

in

good

order and

see

that

they

do

not

get

mixed.

1.

2.

I

16

EN

GI NE

Fb.il

Fig.

65

4.

Valve

face

Check

the

valve

face

for wear

and

darnage,

and

if is

defective, correct it with a valve

face

grinder.

Besides,

if

the

valve

head is

less

than

0.039

in.

(1

mm) thick,

replace it with

a

n€nru

one as

shown

Fig.

66.

Note:

After

grinding

the

valve

sheet

and

rralve

face, insen

and

adjust the

valve

spring sheet lower

into

the spring

bottom

to

obtain the

standard

measurement

(A)

1.596

in.

{40.5

mm},

The

valve

spring

seat lower is

0.020

in.

(0.5

mm)

thick

as shown

Fig.

67.

Fig.

ffi

Fig.

67

5.

Valve

stem

diameter

Check the

diameter

of

the

ralve

stem

with

a

micrometer.

lf the valve stem

is

worn

more

than

the

limit

compared

with

the standard

diameter,

replrce

the

valve with

a

new

one.

Standard

Valve

Stem Diameter

Wear

Limit

lN

valve

0.27s6-l

3:33??

'n

(7.0ri3:31!'*r

0.O02 in.

(0.O5

mm)

EX valve

0.27b6

l3:333!

i"

(7.ooi3:3f!n.'"r

0.O02 in.

{0.05

mm}

Seat

Cutter

Pilot

43

cutter

(for

lN

side sheet)

45"

cutter

(for

EX

side

sheet)

15o

cutter

(for

lN

side

port)

15"

cutter

(for

EX

side

port)

TS

cutter'(for

lN

side

face)

TS

cutter

(for

EX

side

face)

Valve

-

S€t

1.74

{0.O684

in)

1.4

(0.0551

in)

'

3?4

(1.2599

inl

24

(0.9449

inl

24.W

(0.9649

in)

26.W

(1,O433

inl

'

35o

(1.378O

in)

2W

(1.1023

inl

28.W

(1.1220

inl

310

11.2212

inl

Valve Head

Standard

Thickness

lN

side

0.059

in.

(1.5

mm)

EX

side

O.G59

in"

(1.5

mm)

ENGINE

17

Fig. 68

Fig.

Z0

6.

Clearance

between

the

valve stem

and

valve

guide

check

the

clearance

between

the

valve

stem

(A)

and

valve

guide

(B).

lf

the clearance

exceds

the

limit,

replace

the

valve

and

valve

guide.

Standard

Stem

and

Guide

Clearance

Limit

lN

side

0.001

-

0.003

in.

{0.020

-

O.O3b

mm}

O.O08

in.

lO.2

mml

EX

side

0.002

-

0.003

in.

(0.040

-

0.085

mm)

0.0O8 in.

lO.2

mm)

The valve

guide

at

lN

side is

different

from

that

as

EX

side

as

shown in

Fig.

71 .

EX side

lN

side

ln

case

the valve

seal

fitted

to

the

lN

and

EX

valve

guides

is

defective,

replace

it

with

a

new

one

using

a

special

tool

(No.

0490000

VALVE

SEAL

PUSHER).

Valve

spring

check

check

the

valve

spring

for

free

length,

spring

pressure,

and

squareness

in

the

procedure

outlined

below,

and

if

it

is

defective,

replace

it

with

a new

one.

Measure

sguareness

of

the

valve

spring

with

a level

block

and

a square.

Replace

the

spring

if

out

of

squareness

is

0.118

in.

(3

mm)

per

3,g37

in.

(100

mm).

Fig.

7l

b.

8.

a.

Valve

Guide

F.,,

Fig. 69

7. Valve

guide

replacement

a.

Remove

the

valve

guide

from

the

rylinder

head

and n€i\ru

one with

a

special

tool

(No.

0490050

VALVE

GUIDE INSTALLER)

(A)

as

shown

in

F

is.

70.

18

ENGINE

Valve

Spring

SPecif

ications

rree

rensth

l;3?3r'*,,.,.,r

set

length

1 .378

in.

(35.00

mm)

spnng

pressure

46,3

tb

(21.ookg)

Fig.

72

b. Measure

the

free

lengrth

of the

valve

spring.

Replace

the spring

if it decreases

more

than

3o/o

ol

the standard d

i

mension.

Fis.

73

c.

Measure

the spring

tester.

Replace

the

under set condition

sundard

dimension.

pressure

with

a

valve spring

spring

if

the spring

pressure

reduces more

than

15o/o of

the

Fig.

74

Note:

Before

measuring

the

free

length

and

pres-

sure

of

the

valve

spring,

press

the

valve

Spring

several

times

to

be

fitted.

9.

Rocker

arm

shaft

checking

a.

Measure the

clearance

between

the

rocker

arm

shaft and

rocker

arm,

and

if the

measured

value

exceeds

the

limit,

replace the

rocker

arm

or

rocker

arm shaft.

Standard

Limit

Clearance

between

the straft and

arm

0.001

-

O.0O3

in.

(0.032

-

0.068

mml

O.OO4

in.

{0.1

mm}

Fig.

75

b.

lf there

is

a

rernarkable

bend

in

the

rocker

arm

shaft, corect

it

to

less than

0.0004 in.

(0.001

mm)

by

means

of

.a press.

2-2.

Plston

and Gylinder

Block

1.

Piston

checking

a.

Check

the

piston

for

crank and

damage.

lf

it is

defective,

replace

it.

b.

Measure

the

(A)

thrust diameter

just

below the sil

ring

and

(B)

thrust skirt diameter.

Standard

diarneters of

(A)

and

(B)

are as

follows:

(A)

2.6756

t

0.0004

in.

(67.96

t

0.01

mm)

(B)

2.6779

t

0.0004

in.

(68.02

t

0.01

mm)

EN

GINE

19

Fig.76

2.

F

itting

the

piston

and

piston

pin

Measure the allowance

between

the

piston

pin.

lf the

rneazured

value

is

replace

the

piston

and

Piston

Pin-

Standard

allowance betrrueen

I

0.0002

-

0.OO09

in.

the

piston

and

piston pin

I

{0.004

-

0.023 mm}

Fig.

77

Note: When

fitting and removing

the

piston

ard

piston pin,

heat

the

piston

to

250

-

300"F

(12A

-

150"C).

3.

Clearance

between

the

piston

ring

and ring

groove

Measure

the clearance

between the

piston

ring and

ring

groove

with

a special tool

(No.

N026

STAN-

DARD

FEELER

GAUGE).

lf

the

measured

wlue

exceeds

the

clearance

limit,

replace

the

piston

ring.

Parts

Standard

clearance

Clearance

limit

Top

R

ing

0.001

-

0.003 in.

(0.035

-

0.070 mm)

0.006 in.

(0.15

mm)

Second

B

ing

0.001

-

0.003 in.

(0.030

-

0.064

mm)

0.0O6 in.

(0.15

mm)

Oil

R

ing

0.001

-

0.002 in.

{0.030

-

0.062 mm)

0.0O6 in.

(0.15

mm)

Fig.

78

4.

Piston

ring

end

gap

Meazure

the

piston

ring end

gap

with a special

tool

(No.

N026 STANDARD

FEELER GAUGE)

(A)

thickness

gauge.

lf

the

measured

value exceeds

the

standard

end

gap

remarkably,

replace

the

piston

ring.

Parts Standard

end

gap

Top

Fl

ing

Second

R

ing

Oil

R

ing

0.008

-

0.016

in.

(0.20

-

0.40

mm)

Fig.

79

5.

Cylinder

block

a.

check

each

water

passage

and

oil

apefture

of

the

cylinder

block,

and

if

much

fur

is

found,

wash

it

altay

in

solvent.

b. The

cylinder

is

a

wet

type.

check

the inside

of

the

cylinder

for

scratching,

and

if

it

is

defective,

reprace

the

cylinder

liner.

c.

Check

the inside

of the

cylinder

liner

for

wear

at

six

points

shown

in

Fig.

81 .

piston

and

too

small,

I

2A

ENGINE

6. Cylinder

liner

replacing

When

removing

and

fitting the

cylinder

liner

from

and

to the

cylinder

block, use

a special

tool

(No.

O49OO9O

CYLINDER

LINER

PULLER)

(A)

.

Fig.

82

shows

pulling

the

cylinder

liner out

from

the

cylinder block.

J

t

t:

t

t'.

Fig.

80

lf

the

measured

value

is

0.006

in.

(0.15

mml

more

than the standard

value

below,

replace

the

cylinder

liner.

Cylinder

mark

Standard

value

Wear limit

A

2.6z72oi

3:3ffi3

,n.

{68

613.3;;

mm}

0.0O6 in.

(O.15

mml

No

Mark

z.6ztzr

l3:3ffi!

'".

(68

613.313

mml O.OO6 in.

c

2.67720

I3:3ffi

,',.

(68

613:ffi3

mml

0.006

in.

{0,15

mm}

Fig.

8l

Fitting

tre

cylinder

liner

and top

deck

When fitting

the cylinder

llner

and top deck,

fit

them

togefier

bearing same

marks in

order to

keep

fre amount

of

protrusion

uniform

(marks

are

classified

into

t\ o,

A

and

no mark,

?s

shown

in

Table 1). Marks

are on the

rylinder

liner

f

ront

and

rear

and

on the

top

of the

top

deck.

Fig.

83

shovra

mea$tring

the cylinder

liner

protru-

sion.

Fig.

82

7.

Fig.

&l

Mark

Top Deck

Cylinder Liner

Protrusion

A

o.34on':3'*t2

in.

(B.sf

3'os

mm)

034ili3:ffi?3'n

(B.s

l3:313

mm)

0.OOO4

-0.0024

in.

(0.01Q

a'

0.060

mm)

No Mark

0.34fr

I3"00.,

zin.

{8.5

I3.0,

mm}

0.346s

l3:ffi13,n.

(B.s

l3:ffi3

mm)

0.0006

-0.O028

in"

(0.O1$

a,

O.O7O

mml

Cylinder

Liner

Protrusion

EN

GINE

21

Mark

Cylinder

Liner

Standard

Value

Piston

Standard

Value

Clearance

A

A A'qA

+

0.0008

.

z'ot tt

+

o.o0o5

In'

(68613:31!mm)

2

67s6

1

3.3331

,"

(67.e6ri3:33!mm)

03017

n

0.0022

in.

(A.O42

-0.056

mm)

No

Mark

z.677zi

3:ffi31

,n.

(68

e

l3:3J3

mm)

2.67561

3.*01

in.

(67.e6

o]

3.00,

mm)

0.0017

-

0.0O22

in.

(0.046

-0.055

mm)

c

z.aTzzl

3'o*2

in.

(68

01

3'o*

mml

2.67s6:3.3331

'n.

(o7.e6

r:

3:3ff;

*'r

0.0017

-

0.0022

in.

(0.043

-0.056

mm)

8.

Standard

clearance

between

the

cylinder

and

piston

The

standard clearance

between

the cylinder

and

piston

is

0.001

^.,

0.007

in.

(0.030

-

0.069

mm).

Clearance

between

the

tappet

and

guide

Check the clearance

between

the

tappet

and

guide,

and if

the

clearance

exceeds

the

limit,

replace

the

tappet.

Push

rod

Measure

the

push

rod

bend

with

a special tool

(No.

N026 STANDARD

FEELER

GAUGE) and

if

the

measured

value

exceeds the

accuracy

remarkably,

correct

or

replace

it

as

shown

in

Fig.

85.

less than

0.004

in.

Push

Rod

Bend

Accuracy

I it.*'i'nrn

0.1

mm)

Fig.

85

2-3.

Connecting

Rod

1.

Connecting

rod

and

piston

pin

check

the

clearance

between

the

connecting

rod

small

end

bush

and

piston

pin.

lf

the

clearance

exceeds

the limit,

replace

the

piston

pin

and

small

end

buslr.

The

cylinders and

pistons

(A,

no

mark,

and

C)

and

are

f

itted

together.

are

classified

into

three

those

with

same

marks

o

r/r

Fig.

84

10.

Tappet

and Guide

Standard clearance

Clearance

limit

0.0008

-

0.O029 in.

(0.020

-

O.O74

mm)

0.0O4 in.

(0.10

mm)

Fig.

86

_l

22 EN

GINE

Small

end bush

and

piston ptn

Standard

clearance

Clearance

limit

0.0004

-

0.O012

in,

{0.010

-

0.030

mm)

0.006 in.

(0.15

mm)

Connecting

rod small end

bush

replacing

When

pulling

and

press-fitting

the

samll

end

bush,

use a

bushing

tool

and

a

Press.

4" Connecting

rod deflection

Check

the

connecting

rod deflection

with

a

con-

rod

a ligner,

and

if the

measLl

red

value

is not

satisfactory

,

correct

the

con

necting

rod

with a

press

or

replace

it.

Connecting

rod

def lection

less

than

0.002

in.

per

3.94

in.

(less

than

0.04

mm

per

1OO

mm)

Distance

between

the large

end

and

srnall

end

4.84

t

0.O02

in.

n23

t

O,O5

mm)

-I

2.

FA.

W

Fig.

87

Note:

When

press-fitting

tre

small end

bush

to

the

connecting

rod,

align

the

oil aperture of the

small

end

bush

with

that of the

connecting rod.

3.

Connecting

rod large end

play

Measure

the connecting

rod

large end

play

with

a

special

tool

(

No. N026

STANDARD

F

EE

LER

GAUGE),

and

it is

good

if the

measured value is

in

the

range

of

0.004

^,

0,008 in.

{0.1

10

-

A.214

mm).

Note: On

the

side of

the

connecting

rod

cap

it,

inscribed

one

of

the

weight

marks

(8,

C,

D,

E,

F,

G and

H).

5.

Connecting

rod

bearing

metal

Check the

connecting rod

bearing

metal

for

scrape

and darnage,

and

if it

is defective,

replace it.

Note:

Connecting rod

bearing metals

are available

in

three

kinds

of

the

undersize

metal,

0.01

in.,

0.02

in.

and

0.03 in.

(0.25

mm,

0.50

mm

and

0"75

.

mm).

I

Samll

end bush

lnternal diameter

(after

pressfitted)

External

diameter

a.7s74r

i

3:3ffi?

'n

t2o

ol

3:313

mm)

o.eoss

ol$:ffi#,".

e3

o:3:333

mm)

Fig.

88

EN

GINE

23

6.

oil

clearance

benrueen

the

connecting rod

bearing

metal

and

crank

pin

check

the

oil clearance

between

the

connecting

rod

bearing metal

and

crank

pin

with

a

prastigauge

in

the

following

procedure.

a.

Clear

the

bearing

rnetal

and

crank

pin

of dust,

oil,

etc.

b.

Place

the

plastigauge

on

the crank

pin.

c.

Fit

the bearing

cap

to

the

connecting

rod and

secure

it

to

the

crank

pin

with

cap

bolts at the

specified

torque

of 25.3

-

28.9

ft-lb

(3.5

-

4.A

m-kg)'

d.

Loosen

the

cap

bolts

and

remove

the connecting

rod

and

place

the

plastigauge

as shwon

in

Fig.

g1.

Standard

Oil

Clearance

0.001

-

0.003

in.

lA.A27

-

0.O73 mml

24.

Crankshaft

and Main

Bearing

Meul

1 . Check

the crankshaft

for

crack and

it

is

defective,

replace

it.

Check

trre crankshaft oil

passage

shown in

Fig.

92.

damage,

and

if

in

dotted

line

Fig.

92

2. Crankshaft r,\,iarp

To

check

\

fiarp,

mount

the crankshaft

on the

center holding

device

and

m€sure

the \n€rp

with

special

tool

(No.

107M

DIAL INDICATOR,

No.

YM-l

MAGNETIC

BASE

FOR

DIAL lN-

DICATOR).

lf

the measured

value

exceeds

the

limit,

correct

it

with

a

press.

Fig.

9l

when

the

clearance

is rather

excessive

compared

with.the

standard

oil

clearance,

grind

the crank

pin

to

an

u

ndersize

and

use

the

undersize

bearing

metal

to obtain

the standard

oil

clearanqe.

Accuracy

Limit

Crankshaft

warp

less

than

0.OOO8

in.

(less

than

0.O2 mml

0.001

in.

(O.O3

mml

Fig.

93

24

EN

GINE

3.

Crank

pin

and main

journal

Measure

the diameter

of the

crank

pin

and

main

journal

with

a special tool

(No.

75MB OUTSIDE

MICROMETOR

CALIPER}.

ln

case

wear

is more

than

0.002

in.

(0.05

mm),

correct the

crankshaft

by

grinding

to the

undersize

of

0.01,

A.OZ

or

0.03 in.

(0.25,0.50

or

0.75

mm)

with

a

crankshaft

grinder.

4" Main

bearing metal

The main

bearing

metal

is

of

interchangeable

type,

and

fit

them together in

the

proedure

shown

in

Fis.

95.

Check

the

rnain

bering metal for

flaking

or any

damage,

and if it is

defective,

replace,it.

-5.

Oil clearance

betvveen

the

rnain

bearing

metal and

main

ioumal

Measure the

standard

oil

cleararrce

between

the

rnain

bearing

metal

and

main

journal

with

a

plastigauge.

The

measuring

and correcting

pr&

CedureS

are

aS

in

"Oil

Clerance

between

connect-

ing

rod

bearing

metal and

crank

pin".

Standard

oil

clearance

0.0007

-

O.O029

in.

(0.01$

a,0.073

mml

Main

bearing

cap torque

43

-47

ft-lb

(6.0

-

6.5

t-kgl

Undersize

metal

0.01

in.,0.02 in.,0.03

in.

(0.25

mm, O.5O

mm, 0.75

mm)

-I

Fig.94

Standard

diameter

Wear

limit

Grinding

limit

Crank

pin

1.7717

o:

3:331?

,n.

(4so-3:333mm)

0.O02

in.

(0.05

mml

0.O3 in.

(0.75

mml

Main

journal

z2crr.o:3:Sl?,^.

(s6o:

3:#3

mml

0.002 in"

10.05

mml

0.03

in.

(0.75

mm)

Fig.96

EN

GINE

25

6.

Crankshaft end

play

Measu

re

tha

cran

kshaf

t

end

play

with

a

special

tool

(No

N026 STANDARD

FEELER

GAUGE).

lf

the

measured value

exceeds

the

limit,

replace

th e th

rust washer inserted

into the

main

bearing

cap

rear with an oversize

washer

in

order

to

obtain

the standard

end

play.

Standard

value

Limit

Crankslraft

end

play

0.004-0.001

1in.

(0.1

1Q

'v

A.274

mm)

0.01

2

in.

t0.3

mm)

Oversize

I

O.Ot

in.,

0.02

in.,

0.03

in.,

thrust

washer

I

t0.25

mm,

0.50

mm

,4.7

5

rnm)

Camshaft

iournal

and

cam

height

Measure

the

diameter

of

the

camshaft

journal

with

a special

tool

(No.

75MB

OUTSIDE

MICRO-

METE R

CALIPER)

,

and

if the

measured

value

!s

more than

0.002 in.

(0.05

mm) smaller

than

the

standard diameter,

replace

the

journal.

2.

a.

b.

Measure

the

cam

height

with

replace

the

camshaft

if wear

is

(0.2

mm).

a

micrometer, and

more

than

0.008 in.

Fig.

97

2-5.

Camshaft

1

.

Check the

camshaft

pump

drive

gear

(A)

cam

and

journal

for

replace it.

distributor

drive

gear

and

oil

for

damagp and wear,

and the

damage. lf

one

is

defecti\re,

,-

,

,

t

I

I

i

t

a

,

v

Cam-

slraft

Journal

No.

Standard diameter

Wear

limit

1

1.88e8

:

3:33?l

'".

t4B:3:333

mm)

0.002

in.

(0.O5

mm)

2

1.8111-

3:3313'".

(46:

3:3??

mm)

3

1.7717:3:33i3'"

(45:

3:3??

mm)

4

1.7323:

3:3313

'n.

144_3:3??

mm)

5

1.6s2e

:

3:33??

,n

(43

:3:333

mm)

Cam height

(lN

and

EX)

Standard

height Wear

limit

1.4352

in.

(36.454

mm)

0.008 in.

(0.2

rnm)

Fig.

98

Fig.

99

26 EN G INE

3. Camshaft

warp

Measure the

camshaft

warp

with a

specia

I

tool

(No.

107M

DIAL

INDICATOR,

No-

YM-1

MAGNETIC BASE

FOR

DIAL

INDICATOR).

If

the measured

value

exbeeds

the

limit,

correct

it

with

a

press.

Accuracy

{standard

}

Limit

Camshaft

run-out

less

than 0.0OO4

in.

(less

than 0.01

mm)

0,001

in,

(0.03

mm)

5.

Camshaft

end

PlaY

Measure

the

camshaft

end

play

with

a

special

tool

(NO.

NO26

STANDARD

FEELER

GAUGE}.

RC-

place

the

thrust

plate

if

the

measured

value

exceeds

the

limit.

Camshaf

t

end

play

Standard

value

Limit

0.0008

-0.0071

in.

(0.02

a,,

Q.18

mm)

O.OOB

in.

(0.2

mm)

I

I

I

I

j

Fig.

100

4"

Fig.

,0,

Clearance

Measure the clearance

betnveen

the

camshaft

journal

and

rylinder

block

iournal

bearing.

Re

place

the

camshaft

and

cylinder block

if

the

measured value

is

0.006

in.

(0.1

5

mm)

more

than

the sta

ndard clearance.

2-6.

Timing

Ghain Sprocket

and Chain

Adiuster

Timing

chain

and

sprocket

wheel

Check

the

timing

chain

and

sprocket'wheel

for

wear and

damage,

and

if it

is

defective,

replace it.

Timing

chain

tension

To

check

the

timing

chain

tension,

remove the

timing

chain

cover,

and

it

is

good

if

(A)

dimension

of

the

chain

adjuster

is within

0.5

in.

(12

mm).

lf

it exceeds

0.5

in.

112

mm),

replace the

timing

chain

and

sprocket

wheel.

1.

2.

Journal

No.

Standard clearance

Clearance

limit

Camshaft

and

iournal

bearing

1,

5,

O.OOOB

-

0,0018

in.

(0.020

-

0.061

mm)

O.OO6 in.

(0.15

mm)

2,3,4,

0.001Q,v0.0027

in.

(0.025

-

O.O66

mm)

Fig.

102

I

ENGINE

27

J.

a.

Chain

adjuster

and

vibration

dar,tper

Check the

chain

adjuster

spring

(A)

for corrosion,

and the

sl ip

per

head

(

C)

f

or

wear.

I

f

one

is

defective,

replace

the assembly.

The vibration

damper

(B)

is

f

inished

with heat-

proof,

oil-proof

and

wear-proof

synthetic

rubber.

l

\

ffi.,

@nnecting

rod

as shown

in

Fig.

104.

Fit

a

clip

to

theclip

groove

at

the other

end

of the

piston

as shown

in

Fig.

104.

Fitting

the

pbton

ring

to the

piston

Fit

each

piston

ring

as

shown

in

Fig. 105 following

the

procedure

outlined

below:

Fit

the

expander

to

the

lornest

groove

on the

piston

and

next

the oil

ring

(A).

Fit

the second

ring

(B)

and

top

ring

(C).

Note:

Be

sure

to

fit

each