satoh s-650g Instruction Book

SATOH TRACTOR

S•&SOG

with

4-cylinder

INSTRUCTION BOOK

PB

Gasoline Engine

SATOH AGRICULTURAL MACHINE MFG.

KINSAN BLDG.

NO.

5,

4-CHOME NIHONBASHI-MUROMACHI

TOKYO JAPAN

PUBLICATION No.

CO.,

LTD.

-018

INTRODUCTION

Equipped with a high-powered· four-cylinder gasoline engine, SATOH

S-650G

incorporated SATOH's latest technological innovation as well

years

outstanding

recognized through

Every piece

materials

combines SATOH's highest standards

therefore,

However,

a must. For this reason,

periodical service,

in this manual.

however,

requested

skilled level of techniques. Once

the

qualified mechanic.

Prior

"Periodical Service"

this manual

For

SERIAL and ENGINE NUMBER of

tractor

ot

technical informations described

to

further questions, apply

does

an

extensive range

research

and

both

to

in

to

the

and

performance

of

by

longer service life and versatility are secured.

work

order

have a

use

on

hand

experience

many

severest tests.

the

tractor

the

world's

out

these potentialities,

but

These

of

not

also he

instructions can

to

get easier and quicker operations, an

fu

II

knowledge of

this new tractor, be sure

in

this manual. It

so

that

in

and

high efficiency have been already

S-650G

most

only

must

strictly follow

the

he

can look

to

your

of

farming jobs. Because it

manufacturing farm tractors, its

is

made

of

the

advanced machine tools.

of

design

the

must

operator

in

nearest SATOH dealer, giving

your

operator's

he

perform daily

be

followed even

the

service procedures

this manual,

to

is

desired

into

it whenever necessary.

tractor.

selected quality

and

the

instructions given

is

fully

acquainted

he

read

"Operation"

that

an

as

It

workmanship,

cooperation

check

by

a novice,

operator

and

will become a

operator

many

also

and

with

and

keeps

the

is

is

is

a

CONTENTS

Precautions with a New

50-hours Service . . . . . . . . . . . . .

External View

SECTION

1.

Starting

Controls . . . . . . . . . . . 6

1. Oil Pressure Warning Lamp 6

2.

Battery

3.

Water

4. Lighting Switch

5.

Tractor

6.

Throttle

7. Clutch 8

8. Brake 8

9. 6-speed Transmission Gear 9

10.

·seat

11. Differential Lock

12. P.T.O. Operation

13. Tread Adjustments 12

14. Ballast Weights

15. Tire Pressure

16. Installing the

17. Hydraulic System . . . . . 15

17-1. Features . . . . . . . . .

17·2. Mechanism and Operation

18. Draw-bar

and

OPERATION

and

Stopping

Charge Warning Lamp 6

Temperature

Meter 7

Lever 8

. . . . . . 10

Tractor

Nomenclature

the

Engine 5

Warning Lamp 7

and

Flood

3-point

............

Linkage

. . . . . .

of

each Part

light

of

Hydraulic System . 16

· · · · · · · · ·

Page

1

1

2

7

10

11

14

14

14

15

18

SECTION 2. REGULAR MAINTENANCE

1. Service

1-1. Daily Inspection.

1-2. A Service

1-3. B Service

1-4. C Service

1-5. D Service

1-6. E Service

2.

Recommended Lubricants

3.

Greasing Diagram

......

.

19

20

20

24

25

25

25

26

27

SECTION 3. SERVICE

1.

Caution Under Cold Climate

2. Carburetor and Fuel Pump

3. Governor . . .

4. Valve Clearance

5. Engine 0 il

6. Cooling System

7.

Tightening Cylinder Head Bolts

8.

Air

Cleaner

9. Battery

10.

Alternator

11. Starting

.......

Motor

12. Fan and Governor Belts

13. Fuse

14. Brake

15.

16. Center

17. Electrical Wiring Chart

Clutch

.....

Adjustment

Adjustment

Beam

INFORMATION

.

.....

and

.

. . .

Front

.

Hub.

28

29

29

29

30

30

30

31

31

31

32

32

33

33

34

34

35

SECTION 4. SPECIFICATION AND

Engine

Cooling System . .

Fuel Equipment

lubrication

Electrical System

Engine Performance Curves .

Capacities

Dimensions

Performance

Power

Clutch

Brakes

P.T.O.

Tread

3·point

Wheel Equipment

Travel

.....

System

lift

Adjustment

linkage

Speeds

.

DATA

36

36

36

36

36

37

38

38

38

38

38

39

39

39

39

39

40

PRECAUTIONS

All

component including

factory assembly. It

special care. For

heavy

duty

heavy toad,

WITH A NEW

is

the

work.

If

the

gear should be one stage lower than requested.

50-HOURS SERVICE

TRACTOR

the

engine

is

advisable

first

25-

circumstances require

subject

that

a new tractor should be used with

50

hours, it should

to

rigorous checks during

not

tractor

be operated for

to

operate with

the

After first 50-hours

serviced.

(

1)

Replace

(2)

Replace

(3) Retighten the cylinder head bolts and adjust

(4)

Retighten all bolts, nuts and screws.

(5)

Check and adjust

(6)

Check

This 50-hours Service must be performed

essential

the

the

the

in

order to keep the tractor always

of

operation, the following points should be

engine oil and

the

oil filter.

transmission oil.

the

fan and governor belts.

wheels for tire pressure and tire condition.

without

in

the

the

valve clearance.

fail because it

top

condition.

is

__..,

page

1

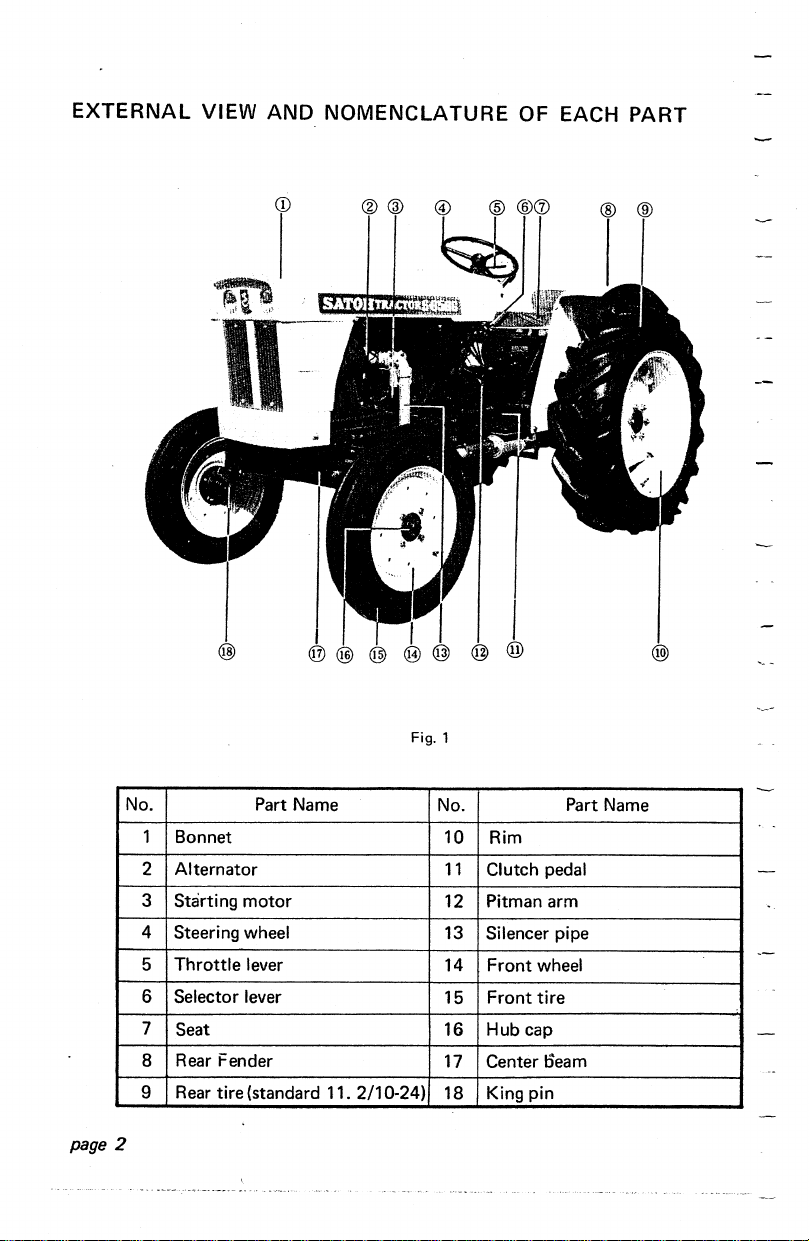

EXTERNAL

VIEW AND

NOMENCLATURE

OF EACH PART

No. Part Name

1 Bonnet

2 Alternator

3 Starting

4 Steering wheel

Throttle

5

6 Selector lever

7

Seat

8

Rear

9

Rear

page

2

Fig. 1

motor

lever

Fender

tire (standard 11. 2/1 0-24)

No.

10 Rim

11

Clutch pedal

12 Pitman arm

13 Silencer pipe

14

Front

15

Front

Hub cap

16

17

Center oeam

18 King pin

Part

wheel

tire

Name

@-----------------1)

No.

19 Louver

20 Filler

21

Air

Control lever

22

23

Flood light 28

Part Name No.

cap

cleaner

Fig. 2

24

Instrument panel

Step

25

Fuel cap

26

Steering lever

27

Head

Part Name

lamp

page 3

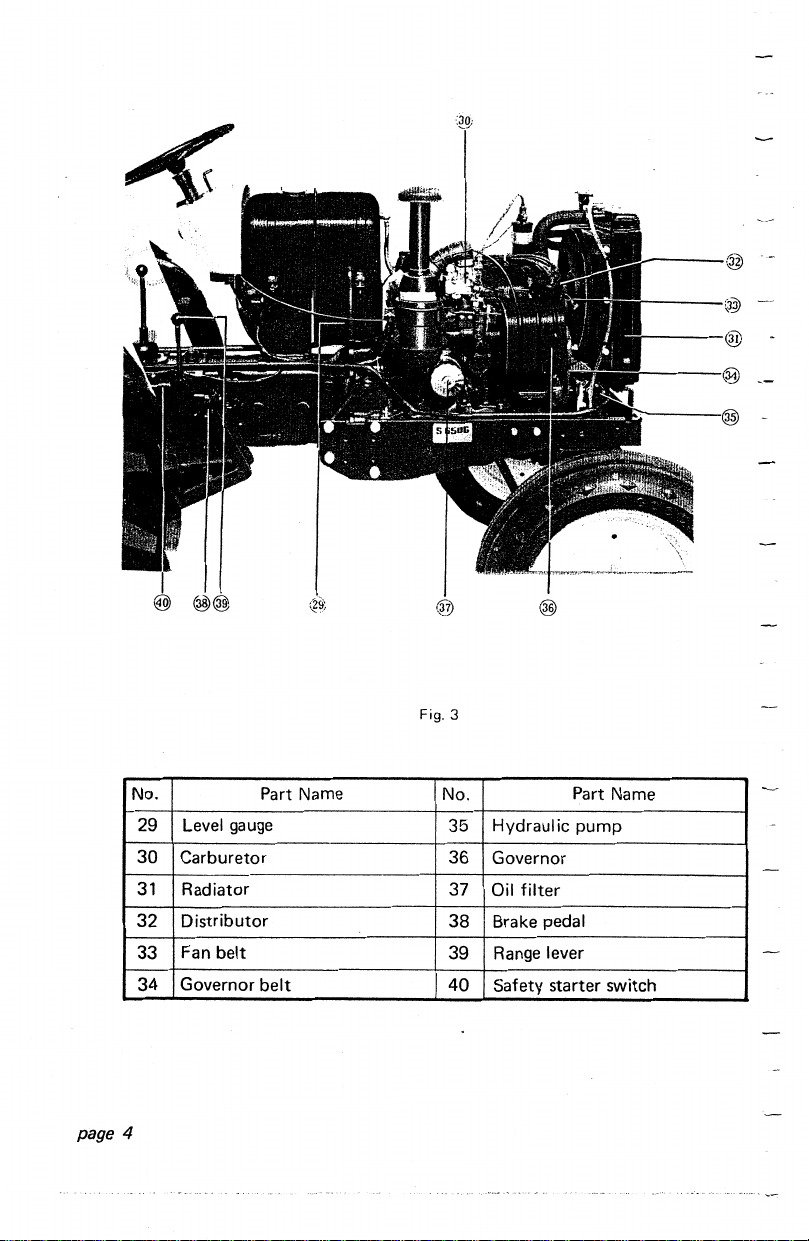

Fig. 3

No. Part Name No. Part Name

Level gauge

page

29

30

31

32

33

34

4

Carburetor

Radiator

Distributor

Fan

belt

Governor

belt

Hydraulic

35

36

Governor

37

Oil filter

38 Brake pedal

Range lever

39

40

Safety

pump

starter

switch

SECTION

1.

OPERATION

STARTING

Before starting

water, transmission

daily check specified

(

1)

The engine

not run excepting when

Accordingly, when starting the engine, place range lever

"NEUTRAL".

2)

Set

(

the

warning lamp, battery charge warning lamp, and water temperature

warning lamp. Turn the starter switch

engine will start

your hand from

AND

STOPPING THE

the

engine, be sure to check

oil

in

is

provided with a safety switch, so

starter switch

to

the

and hydraulic

1-1

of

SECTION

the

range lever

to

"0

N", and confirm

run. After

starter switch.

the

ENGINE

the

oil

for quantity,

2-

is

engine has been started, keep off

engine oil, cooling

in

that

in

"NEUTRAL"_

to

the starter will

the

"START",

addition

oil

pressure

then,

the

in

the

-

(3)

Avoid turning

more.

U"nder

(4)

(5)

the cold climate, disengage

the

pedal, then, fully pull

the

stop

throttle

the

with

started, release

while observing

run smoothly, keep

To

running) position, and

After stopping, be sure

Fig. 4

the

starting motor for 15 consecutive seconds or

the

clutch by fully depressing

out

lever in

the

clutch pedal and slowly push in the choke lever

the

engine condi.tion. When

the

engine,

turn

set

to

the choke button.

the

idle running speed.· After

engine under idle running for warming-up.

the throttle lever

the

starter switch

remove the main switch key.

the

engine started

to

the

to

"OFF".

Start

the

engine

the

engine

to

"SLOW" (idle

page 5

CONTROLS

In

engine, it will

Control System

through 12.

1.

OIL

When

turned on. Always

whether

started,

operation,

is

faulty.

pressure switch condition.

case

the

starter switch turns off under

be

caused

to

have a trouble of "DIESELING".

of

the engine and tractor are as shown

PRESSURE WARNING LAMP

the

starter switch

the

engine

the

lamp

the

engine oil may be insufficient or

Stop

the

is

set

to

the

lamp should be watched, because it indicates

is

properly lubricated. Normally, after

is

turned

off. If the. lamp keeps

operation, and check

"ON",

the

high speed running

the

oil pressure warning lamp

to

light

the

oil pressure switch

quantity

of

the

oil and

in

the

on

Figs. 7

of

the

is

--

engine ·

during

·-

the

oil

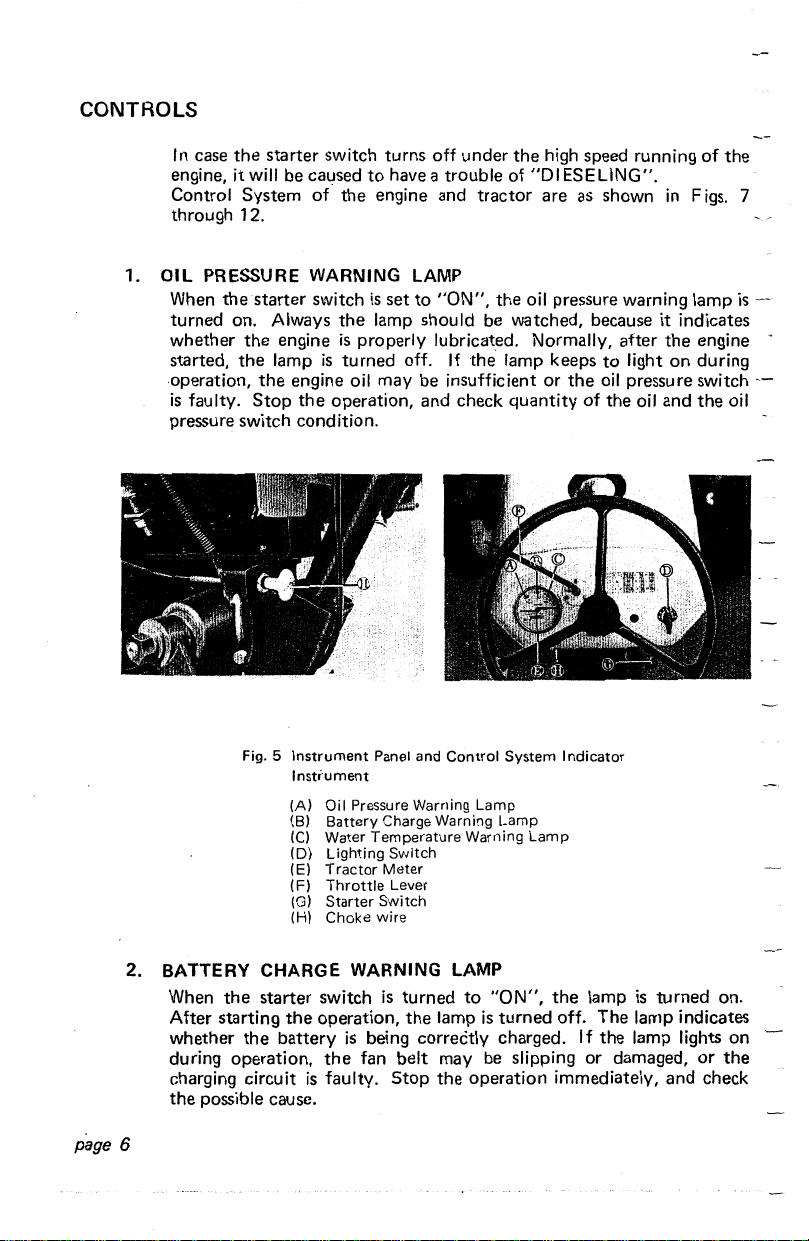

Fig. 5

Instrument

Instrument

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

Panel and

Oil

Pressure Warning

Battery

Charge Warning

Water

Temperature

Lighting

Tractor

Meter

Throttle

Starter

Switch

Choke

wire

2. BATTERY CHARGE WARNING LAMP

When

the

page

After starting

whether

during operation,

charging circuit

the

possible cause.

6

starter

the

switch

the

operation,

battery

the

is

faulty.

is

is

being correctly charged. If the lamp lights on

fan belt may be slipping or damaged, or the

Control

System

Indicator

Lamp

Lamp

Switch

Lever

turned

the

Stop

Warning

to

lamp

the operation immediately, and check

"ON",

is

turned

Lamp

the

lamp

is

off. The lamp indicates

turned on.

3. WATER TEMPERATURE WARNING LAMP

Dust accumulations will adversely affect the radiation efficiency of

radiator. If

(100°C)

on. Immediately

radiator for dust and water. If necessary, clean

water.

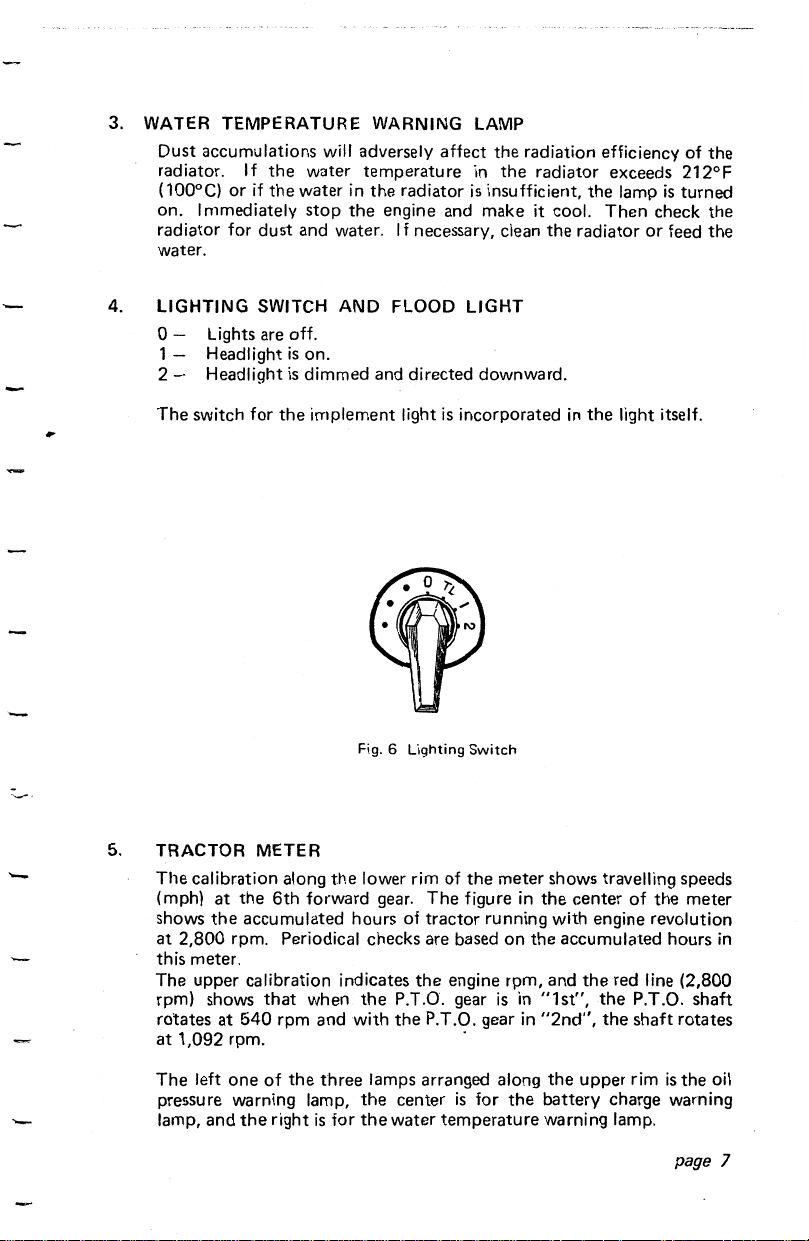

4.

LIGHTING

0 - Lights are off.

1 - Headlight

2-

Headlight

The

switch for

or

if

SWITCH

the

water

the

water in

is

on.

is

dimmed and directed downward.

the

temperature

the

stop

AND

implement light

radiator

the

engine and make it cool.

FLOOD

in

is

insufficient,

LIGHT

is

incorporated

the

radiator exceeds 212°F

the

radiator

in

the

lamp

Then

the

light itself.

is

check

or

feed

the

turned

the

the

-

Fig. 6

5.

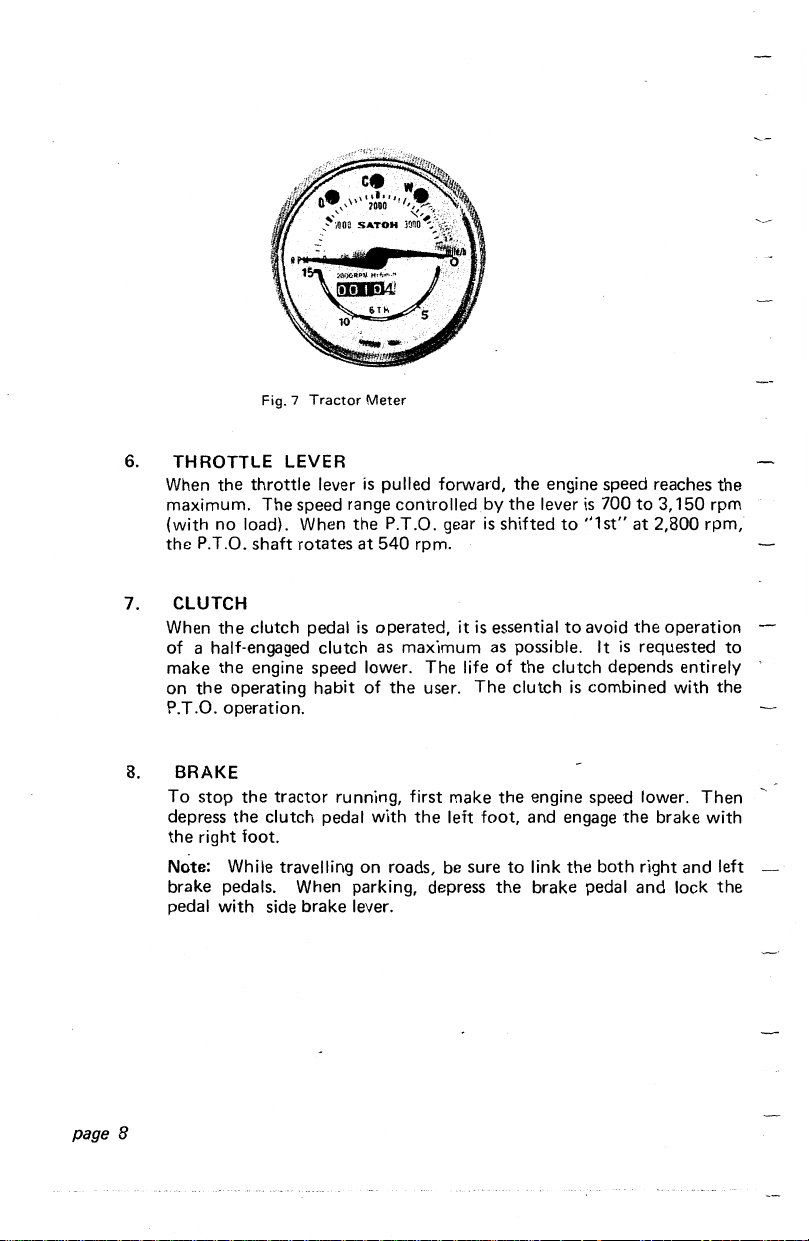

TRACTOR METER

The

calibration along

(mph)

at

the

the

shows

at 2,800 rpm. Periodical checks are based

this meter.

The upper calibration indicates

rpm) shows

rotates

at 1 ,092

The

pressure warning lamp,

lamp, and

accumulated hours of

that

at

540

rpm. ·

left

one

of

the

6th

forward gear.

when.

rpm

and

the

three

right

is

the

lower rim of

the

with

lamps arranged along

the

for

the

Lighting

the

The

figure in

tractor

the

engine rpm, and

P.T.O. gear

the

P.T.O. gear

center

is

water

temperature

Switch

meter shows travelling speeds

the

center of

running with engine revolution

on

the

accumulated hours

the

"1st",

"2nd",

the

upper

battery charge warning

warning lamp.

for

is

in

in

the

the

meter

red line (2,800

the

P.T.O. shaft

the

shaft rotates

rim

is

the oil

page

in

7

Fig. 7

Tractor

Meter

6.

THROTTLE LEVER

When

the

maximum.

throttle

(with no load). When

the

P.T.O.

shaft

lever

is

The

speed range controlled

rotates

pulled forward,

the

P.T.O. gear

at

540

rpm.

by

is

shifted

the

7. CLUTCH

When

the

clutch pedal

of a half-engaged clutch as maximum as possible. It

make

the

engine speed lower.

the

on

operating habit

P.T.O. operation.

8. BRAKE

To

stop

the

tractor

depress

the

Note: While travelling

the

clutch pedal with

right foot.

brake pedals. When parking, depress

pedal with side brake lever.

is

operated, it

of

the

The

user.

is

life

The

running, first make

the

left foot, and engage

on

roads, be sure

essential

of

the

to

the

the

engine speed reaches

lever

is

700

to

to

the

clutch depends entirely

clutch

is

to

"1st"

at

avoid

the

is

requested to

combined with

engine speed lower.

the

link

the

brake pedal

both right and left

and

the

3,150

rpm

2,800 rpm,

operation

the

Then

brake with

lock

the

page 8

Fig. 8 Brake Pedal

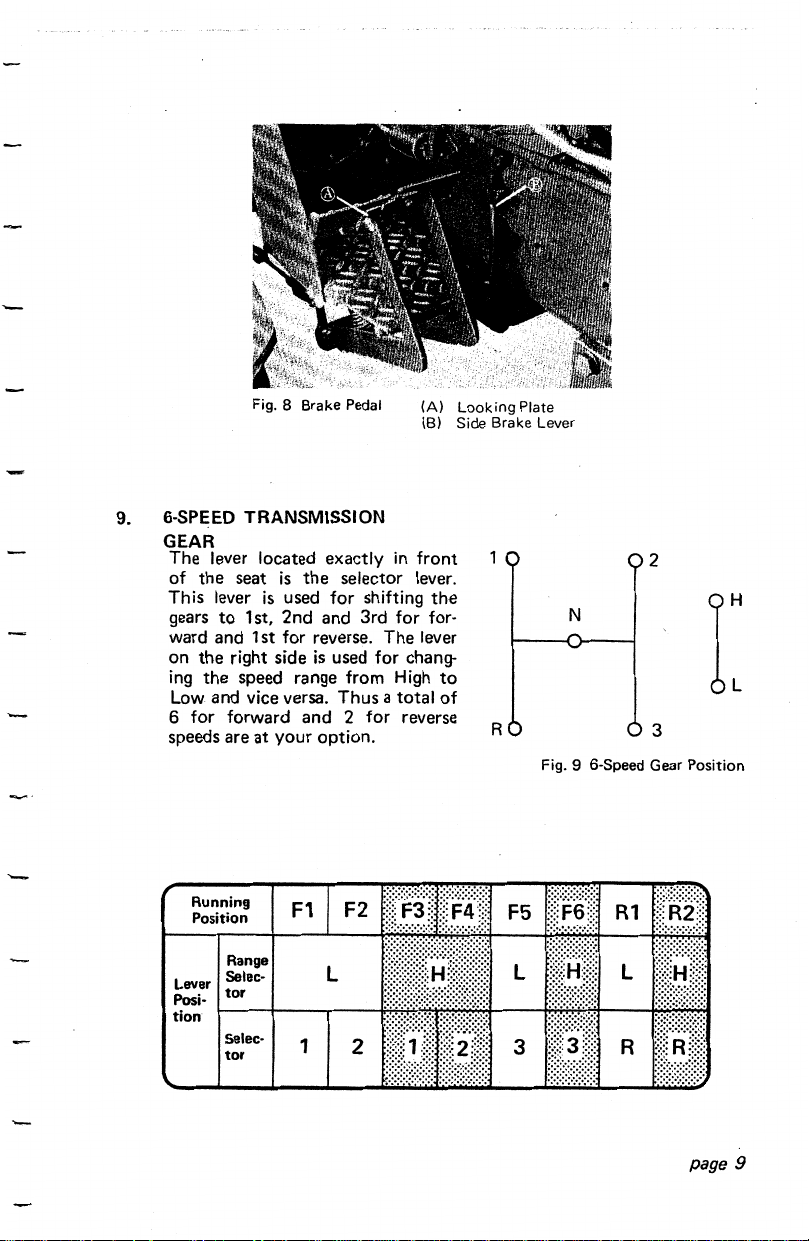

9. 6·SPEED TRANSMISSION

GEAR

The lever located exactly

the

seat

is

the

of

This lever

gears

ward and 1st for reverse. The lever

on

the

ing

Low and vice versa. Thus a total

6 for forward and 2 for reverse

speeds are at your option.

is

to

1st, 2nd and 3rd for for-

right side

the

speed range from High

selector lever.

used for shifting

is

used for chang-

in

(A)

Looking

Side Brake Lever

(8)

front

the

to

of

Plate

N

R

Fig. 9 6-Speed Gear Position

2

[

3

Running

Position

Lever

Posi-

tion

Range

Selec-

tor

Selec-

tor

F1

1

page

9

10.

SEAT

The

operator's

both

for

most suitable posture.

11.

DIFFERENTIAL

The

differential lock

.speed so

front

Fig.

that

seat

can be adjusted

and

rear directions so

10

Seat

LOCK

is

either

of

in

a device for making

the

left or right wheel will

the

range of 1.77 in.

that

the

operator

the

rear wheels

not

slip.

(45

can have

at

the

mm)

the

same

page

Fig.

11

Differential

How

to

engage

the

differential lock:

To

engage

the

slip

or

slow

differential lock,

down

the

heel. Faulty engagement

Lock

stop

tractor

speed, then, depress

at

one

time

the

tractor

depressing

operation repeatedly with harder depressing. If either

right wheel has already begun slipping;

running or disengage

pedal. Make sure

is

depressed,

10

the

that

lock

the

the

is

in effect.

clutch, then, depress

pedal

turn

is

fully depressed. As far

running before

the

is

the

throttle

the

pedal by

requested

of

lever

the

to

the

the

the

differential lock

as

the

start

to

right

same

left or

idle

pedal

Loading...

Loading...