Any

Prior

improper

to

the

handling

operation

Manual carefully and have a

In

particu lar,

the

strictly followed.

{;{

When

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

{;{

running

bra

ke

pedals

Make

sure

shaft.

Always

jackets,

danger

When

leaving

pull

out

Never

make a sharp

When

descending a slope

the

brake.

Never

operate

When

making a sharp

Never

operate

clutch,

Be

careful

Do

not

implement.

When

towing,

When

refuelling,

not

catch

Use a

safe

the

fuel

Never

touch

had

sufficient

Always

Never

operate

can

collect.

Do

not

proper

When

mounting

given

in

the

are

that a guard

wear

relatively

shirts

sleeves

of

catching

the

the

starter

the

the

brake,

throttle

particularly

carry

set

fire.

fuel

container.

cap

securely.

engine

time

keep

positive

the

allow

children

instructions.

"Safety

tractor

interlocked

them

tractor,

key.

turn

differential

tractor

any

the

be

to

tractor

an

Precautions"

of

of

instructions

at

so

is

in

place

tight

and

or

other

in

moving

be

sure

at

high

in

reverse,

turn,

comfirm

on a slope

lever

and

when

running

persons

hitch

point

sure

to

stop

Fill

parts

after

cool.

battery

post

engine

to

operate

implement

the

tractor

the

tractor,

thorough

given

high

speed

that

they

when

belted

loose

parts,

to

stop

speed.

be

lock

when

that

that

steering

on a slippery

on

the

below

the

engine.

the

tank

operating

covered

in a

closed

the

on

the

in

theimplement

could lead

understanding

in

or

on

wi

II

not

operating

clothing

clothing

engine

the

sure

not

running

the

differential

seems

wheel

tractor,

the

center

Also

outdoors

the

with

building

tractor,

tractor,

be sure

"Safety

roads,

be

operated

the

when

should

or

implement.

engine,

to

abruptly

on a public

to

be

abruptly

road.

nor

line

take

and

tractor

rubber

where

nor

be

sure

Operation

to

an ,accident.

to

read this

Precautions"

make

belt

pulley

operating

not

be

apply

lock

dangerous.

on a slope

on

the

of

the

special

wipe

up

or

the

engine

boot

on

carbon

adults

to

follow

Manual.

Instruction

of

the

description.

sure

the

right

independently.

or

P.T.O.

the

tractor.

worn

because

the

parking

operate

the

road.

is

disengaged.

Do

not

as it

is

linkage

drawbars

rear

axle.

care

so

that

spilled

fuel.

until

the

end

of

monoxide

to

operate

the

instructions

must

and

driven

Loose

of

brake

clutch

operate

dangerous.

fuel

Replace

parts

have

the

cable.

fumes

it

without

be

left

the

and

or

the

and

will

With 2-cylinder KE-130 -

138

Diesel Engine.

6-3 3-CHOME,

KANDA,

TOKYO,

KAJI-CHO,

JAPAN

PUBLICATION

CHIYODA-KU,

No. S-630US-5

-

Equipped with a 2-cylinder, 25

S-6300

with big capacity, high quality performance and outstanding durability

providing increased economy.

Making

SATOH engineers, the S-630 and

their components which consist

The careful assembling work coupled with quite severe performance

strict quality control makes assurance

for

tractors are, respectively, 2-wheel and 4-wheel drive

the

best use

the

S-630 and S-6300.

of

long experiences and the latest technology

HP

diesel engine,

S-6300

of

unsurpassed and precision machined parts.

are built sturdy and rugged

of

high quality and

the

SATOH S-630 and

type

farm tractors

top

performance

test

of

in

the

all

and

This instruction manual contains information on

of

and maintenance

prehensive and essential, and

utilizing your tractor.

How well your SATOH

depends greatly upon

requested

the operation and maintenance services will properly be carried

to keep the

Should any information

dealer or distributor stating

tractor

We

that

tractor

concerned.

are sure you will be happy with SATOH tractor.

your SATOH

tractor

the

this manual be read carefully and kept ready for use so

in

top

mechanical condition at

as

tractor.

is

designed

continues

manner

to

your

the

machine and engine serial numbers

The information contained

to

in

which

tractor

be required, consult

the

operation, lubrication

assist you,

to

give

it

is

if

unexperienced,

satisfactory performance

operated. It is, therefore,

all

times.

out

your

is

com-

that

in

order

SATOH

of

the

in

Tractor Serial No.

Engine Serial No.

Safety Points

Introduction

Treatment

50-Hour Service

External View and Nomenclature

Starting and Stopping

Instruments and

Clutch. , . ,

Brake

Parking Brake

12-Speed Transmission

Differential Lock, ,

Power Take-Off

4-wheel Drive Shift Lever

Seat

Tread Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ballast Weight

Tire Pressure

3-Point Linkage

of a New

Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping.

Tractor Meter

Oil

Battery Charge Warning

Water Temperature

Light Switch

Safety Starter Switch

Glow Plug

Glow Signal Lamp

Speed Control Lever

Foot

Engaging the Differential Lock

Releasing the Differential Lock

........

Front

2-Wheel Drive

4-Wheel Drive

Rear Wheel.

Rear Wheel Installation

in

Pressure Warning Lamp

Th

rattle,

..

..

, , , ,

Wheel

......................................

Tractor

.................................

Cold Weather

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls.

..................

...................................

....................................

, . , ,

, . , , . ,

... , ..

.... , ..

.. , .. , ..

....

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

'

.................................

...................................

..................................

..................................

...................................

.....................................

....................................

.............

of

Each

the

Engine. . . . . . . . . . . . . . . . . . . . . .

.........................

. . . . . . . . . . . . . . . . . . . . . . . . . .

...................

Lamp.

Meter.

.............................

...............................

....................

..

, , . ,

.... , ...

, . ,

......

, ,

..

.....

.............................

............................

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

.... , ..

, . , , ,

,

....

, , ,

..

, . , , . ,

, ,

.. , ....

, , . " ,

.. , .. , ... , ....

..

, ,

...

..

, ,

, . . . . . . . . . . .

Part.

. . . . . . . . . . . .

,

..............

, , . , , , ,

... , .....

, , ,

... , ......

.... , ..

, , . , , ,

.. , ...........

, . ,

.... , ..

... , ...

, . . . . . . . .

.... , ....

, , , , . , , .

, . , , , , , . 14

'.

. . .

, . , ,

, . , . , , 15

..

" 2

..

..

..

" 7

..

..

..

, 8

..

..

..

, , . 13

, , . , 14

..

,

...

'"

2

3

6

6

8

8

8

9

9

9

10

10

11

11

12

12

'12

15

16

17

18

18

18

19

20

20

21

22

23

...

Hydraulic System

Control

Drawbar

Service Schedule

Daily Inspection

A-Service (Every 50 hours

B-Service (Every 100 hours

C-Service (Every 300 hou

D-Service (Every 600 hours

Maintenance Interval Chart

Recommended Lubricants

Greasing Diagram

.........................................

Position Control

Flow Control &

External Hydraulic Service

Single

Action

Double

........................................

Service Schedule Chart

50 Hours Service

50 Hours Service

..................................

................................

Lift

..................................

Action

.................................

...................................

...................................

for

for a Tractor

..................................

Lock

.........................

.........................

............................

of

operation)

a New

Tractor

of

operation)

rs

of

operation).

of

operation).

............................

and

Fuel

...................

...................

That

is

...................

......................

Not

New

...........

..................

..................

23

23

23

24

25

25

26

26

27

28

28

29

29

29

30

31

31

32

33

34

Precautions

Antifreeze

Fuel System

Fuel Filter

Fuel Pump

Fuel Pipe

Engine Oil Replacement

Injection Nozzle Inspection

CYlinder

Valve Clearance

Timing

Cooling System

Air

Cleaner

Engine Oil Filter Replacement

Fuel

Transmission

Rear

Washing Hydraulic Oil

to

Be

Taken in Cold Weather

....................................

Air

Bleeding

Air

Air

Air

Bleeding

Head

Bolt

Adjustment

Adjustment

....................................

.........

Filter

Element Replacement.

Case

Axle Housing Oil Replacement

.............................

Bleeding

Bleeding

............................

..............................

............................

Tightening

Procedure

,

........................

Oil Replacement

Filter

...................

...........................

...........................

..........................

.......

..........................

...........................

'

....................

.......................

.......................

......................

......................

'

.....

35

35

36

36

37

37

37

38

39

39

40

40

41

41

42

42

44

44

Replacement

Replacement

Replacement

Replacement

Clutch Pedal Adjustment

Free Play Adjustment

Brake Pedal Adjustment

Free Play Adjustment

Throttle Lever Adjustment

Foot Throttle Adjustment

Fan Belt Tension Adjustment

Differential Lock Pedal Adjustment

Hydraulic Control Adjustment

Flow Control Lever Adjustment.

Hydraulic Pump Relief Valve

Hydraulic Cylinder Relief Valve Adjustment

External Hydraulic Service

Front Axle Center

Battery

AC

Generator

Starter Motor

Regulator

Glow Plug

Box

Fuse

Safety Starter Switch Adjustment

Circuit Diagram

of

4-Wheel Drive Front Axle Oil.

of

Front Axle Diff. Case

of

Front Kingpin Gear Case

of

Kingpin Gear Case Grease

.............................

.............................

..............................

.............................

............................

.............................

..........................

..........................

........................

.........................

Pin

and

Front

Hub

.........................................

.....................................

.....................................

........................................

.......................................

........................................

........................

....................................

......................

...............

Oil

...............

Oil

.............

...............

.....................

..............

.....................

45

45

45

45

46

46

47

47

48

49

50

50

51

51

52

52

52

53

53

54

55

55

56

56

56

57

..........................................

Engine

Cool ing System

Fuel Equipment

Lubrication System

Air Cleaner

Governor

Electrical System

Engine Performance Curves

Glow Plug

Dimentions of Standard Type

Clutch

..........................................

Transmission

Power Take Off

....................................

...................................

.................................

.......................................

........................................

...................................

............................

........................................

.....................................

....................................

..........................

58

58

58

58

58

59

59

59

60

60

60

60

60

Brakes

..........................................

Steering

Tread Adjustment

Hydraulic Power Lift

3-Point Linkage

Wheel Equipment

Travel Speed

Capacities (Approximate initial fill)

.........................................

..................................

................................

....................................

..................................

......................................

......................

61

61

61

61

61

61

62

62

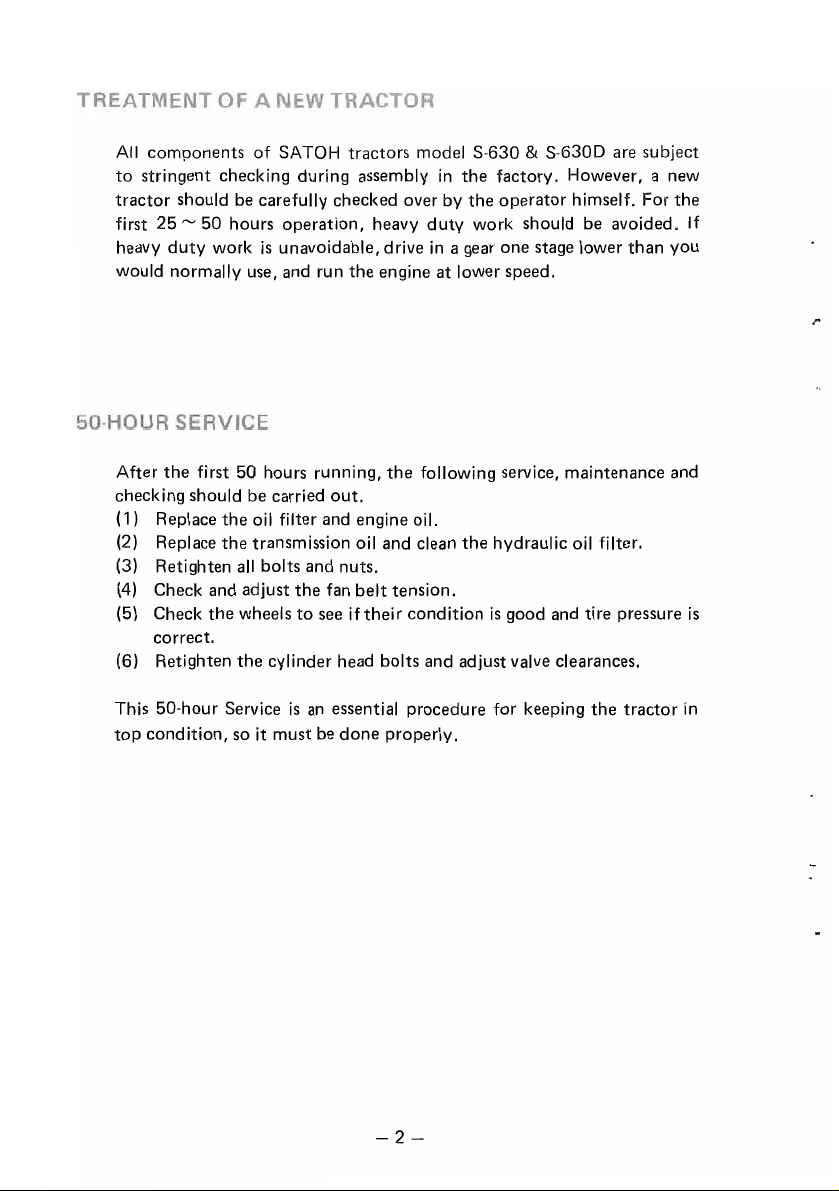

All

components of SATOH tractors model S-630 &

to

stringent checking during assembly

tractor

first

heavy

would normally use, and run the engine at lower speed.

should be carefully checked over by

25'"

50

hours operation, heavy

duty

work

is

unavoidable, drive

in

the

factory. However, a new

the

operator himself. For

duty

work should be avoided.

in

a gear one stage lower than you

S-6300

are subject

the

If

After the first 50 hours running,

checking should be carried

(1) Replace the oil filter and engine oil.

(2)

Replace the transmission oil and clean

all

(3) Retighten

(4)

Check and adjust

(5) Check

correct.

(6) Retighten

This 50-hour Service

top

condition, so it must be

bolts and nuts.

the

fan belt tension.

the

wheels

to

see if

the

cylinder head bolts and adjust valve clearances.

is

an

the

following service, maintenance and

out.

their

condition

essential procedure for keeping

done

properly.

the

hydraulic oil filter.

is

good and tire pressure

the

tractor

is

in

-2-

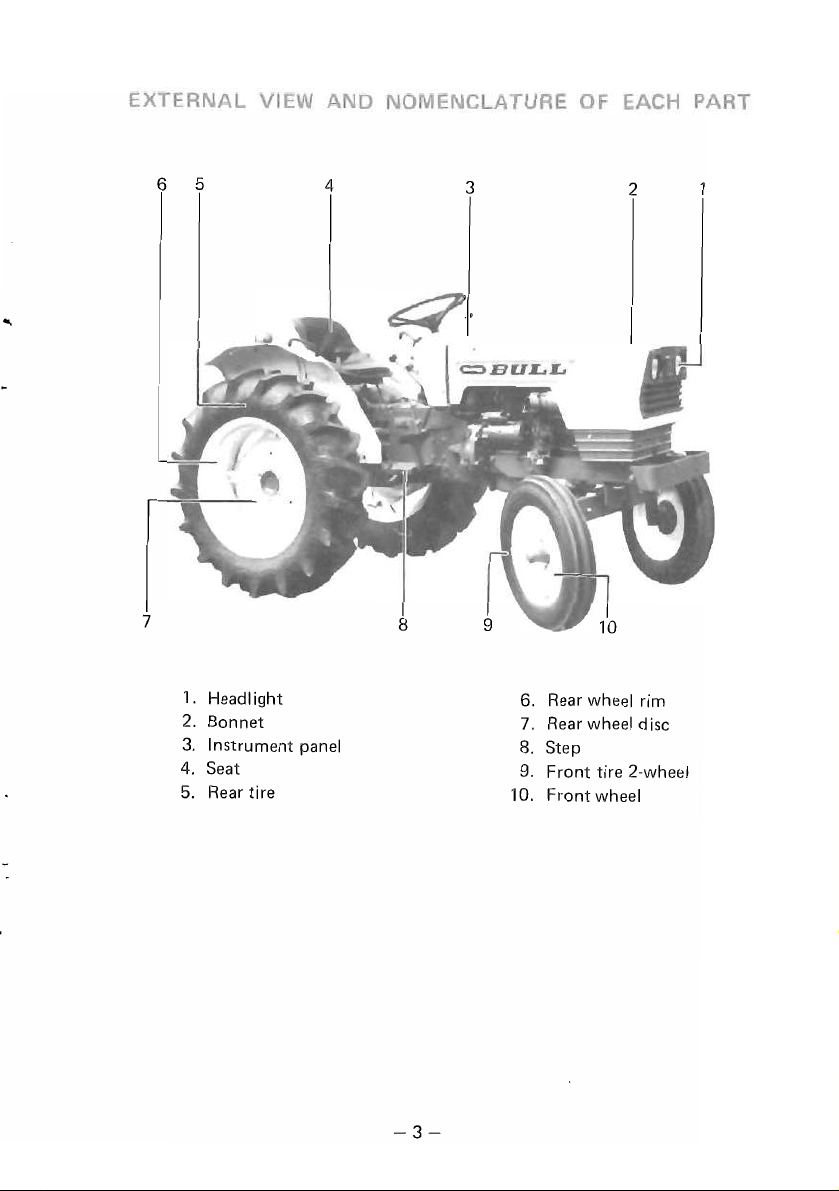

6 5

4

3

2

1.

Headlight 6.

Bonnet 7.

2.

3. Instrument panel

4. Seat

5. Rear tire

-3-

Rear wheel rim

Rear wheel disc

Step

8.

9. Front tire 2-wheel

Front wheel

10.

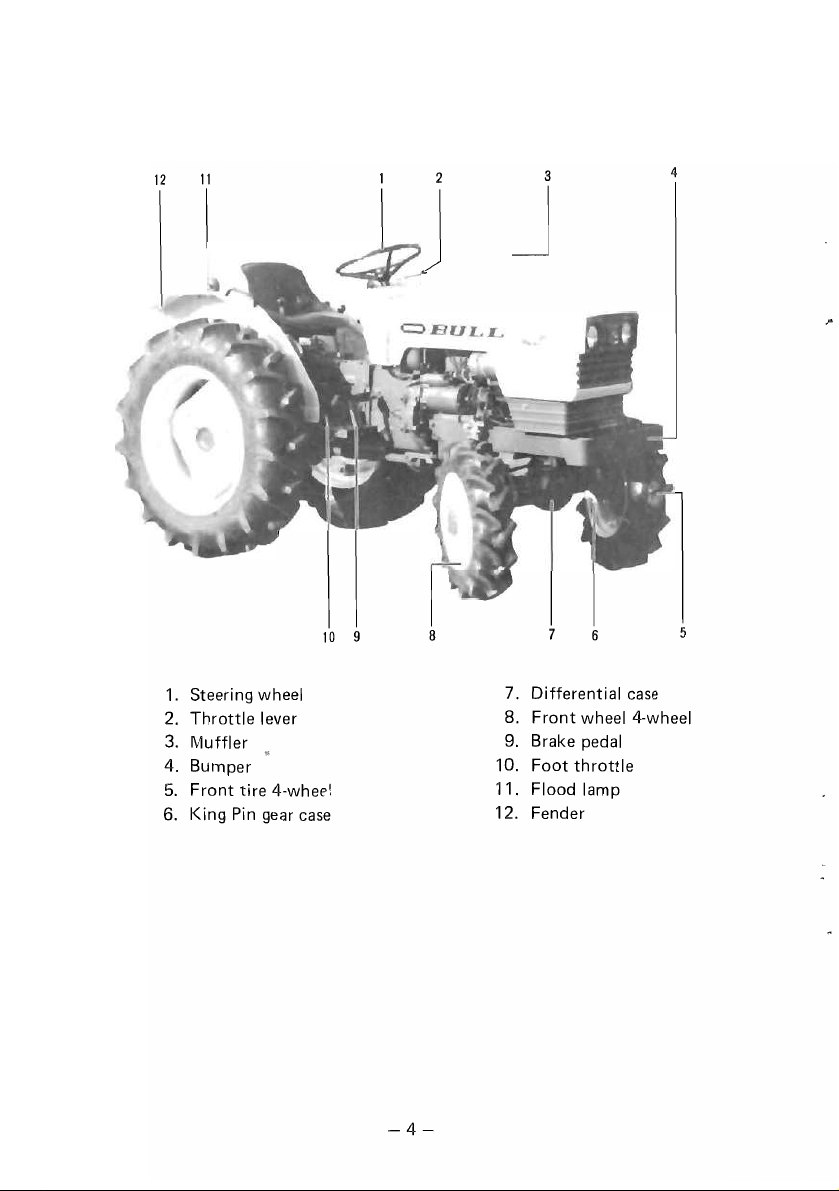

12

11

3

J

4

1.

Steering wheel

Throttle lever

2.

3. Muffler

Bumper

4.

Front tire 4-whee!

5.

King

Pin

6.

gear case

10

9

8 6

7.

Differential case

8.

Front wheel 4-wheel

9. Brake pedal

10.

Foot

throttle

11.

Flood lamp

12.

Fender

5

-4-

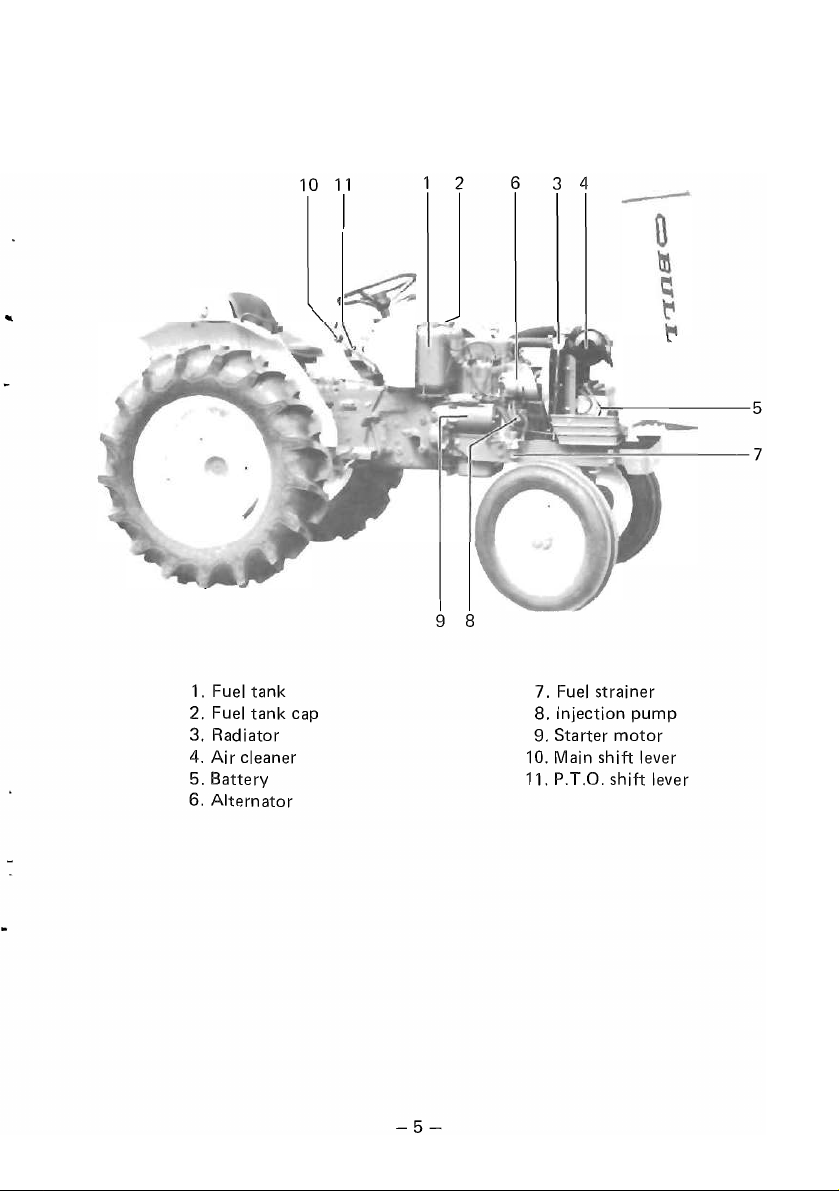

10

11

2

3 4

6

------5

-'------7

9 8

1. Fuel tank 7. Fuel strainer

2. Fuel tank cap 8. Injection pump

3. Radiator

4. Air cleaner 10. Main shift lever

5. Battery

6. Alternator

9. Starter

11. P.T.O. shift lever

motor

-5-

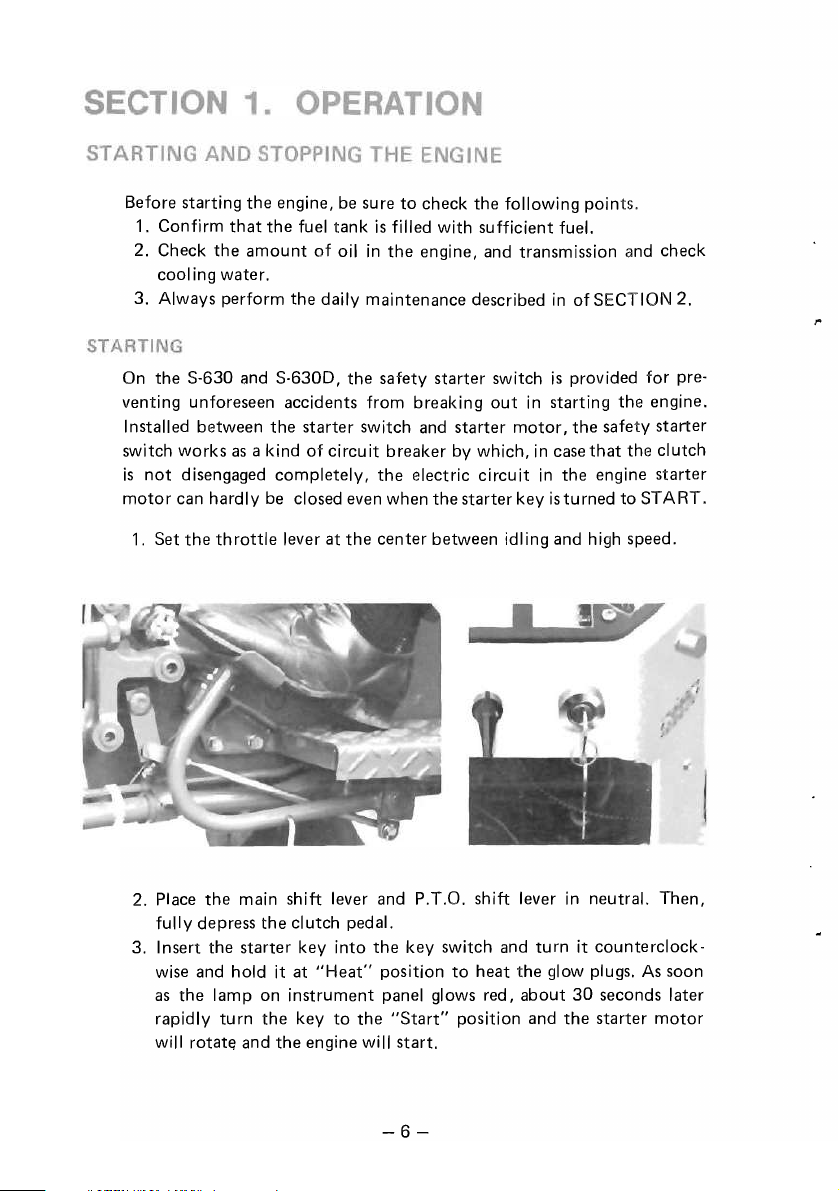

Before starting the engine, be sure

1.

Confirm

2. Check

that

the

the

amount

fuel tank

of

oil

to

check the following points.

is

filled with sufficient fuel.

in

the

engine, and transmission and check

cooling water.

in

3. Always perform the daily maintenance described

On

the S-630 and S-6300, the safety starter switch

venting unforeseen accidents from breaking

out

of SECTION 2.

is

provided for pre-

in

starting the engine.

Installed between the starter switch and starter motor, the safety starter

switch works

is

not

motor

1.

Set

as

a kind of circuit breaker by which,

disengaged completely,

the

electric circuit

can hardly be closed even when the starter key

the

throttle

lever at

the

center between idling and high speed.

in

case

that

the clutch

in

the engine starter

is

turned to START.

2. Place the main shift lever and P.T.G. shift lever

fully depress

3. Insert the starter key into

wise and hold it at

as

the lamp on instrument panel glows red, about

rapidly turn

will

rotat~

and

the

the

the

clutch pedal.

the

"Heat"

key

to

position

the

"Start"

engine will start.

key switch and turn it counterclock-

to

heat the glow plugs.

position and

-6-

in

neutral. Then,

30

seconds later

the

starter

As

soon

motor

4. When

5. After starting the engine, make sure the battery charge warning lamp

6.

7.

1.

2. To start

3. When starting

the

engine has started, take your hand off the key and

to

the

"ON"

then automatically returns

in

the

"ON"

position while the engine

Never rotate the engine at high revolutions. Run the engine at

approximately 1

rises, shift

and engine oil pressure warning lamp are

ture meter functions properly.

meter reads abnormal temperature, stop

isolate

the

If

the

engine does

starter

Warm

Shift

and then the injection pump smoke set starts operating and fuel

injection

to

clutch pedal fully.

plug

When

raise

motor

well

up

the

is

the

the

the

and restart

the

throttle

,300'"

the

throttle

cause and then take necessary countermeasures.

continuously more than 1 0 sec. Then, heat the glow

engine especially

increased.

engine starts the smoke set

engine

temperature sufficiently

the

1 ,500 rpm and if the engine temperature

lever

to

SLOW

If

either or both lamps are on or the

not

start on the first attempt,

the

engine.

in

cold weather, before working.

lever

to

the

position of the maximum revolution,

in

cold weather, heat

engine, disengage the clutch by depressing the

position. The key must be

is

running.

(800 rpm).

off

and the water tempera-

the

engine immediately,

do

is

automatically released.

the

glow plug long enough

in

the combustion chamber.

the

not rotate

key

the

-7-

NOTES:----------------------------------------

1)

After

the

engine has started, comfirm

that

the

engine

smoothly listening carefully to ascertain if nothing abnormal

sounds, and inspect for oil and water leakage.

2)

In

case fuel runs

filling

the

even stopped soon

fuel

out,

tank;

be sure

otherwise

after

to

bleed

the

fuel system after

the

engine may

not

be started (or

started). (See SECTION 3. BLEEDING

THE FUEL SYSTEM)

is

running

re-

Never use

After idling

ether

to

the

engine for a while by setting

propriate position, bring

is

then

cut

rn

the

off and

starter

leaves

and fuel

Be

sure

When

to

the

tu

operator

start

the

the

the

engine of model S-630 & S-630D tractors.

the

the

key

tractor,

throttle

engine

"0

F F" when

lever fully

wi

II

stop.

the

take

out

throttle

to

engine has been

the

key.

the

lever at

"STOP"

the

ap-

position,

stopped.

,"

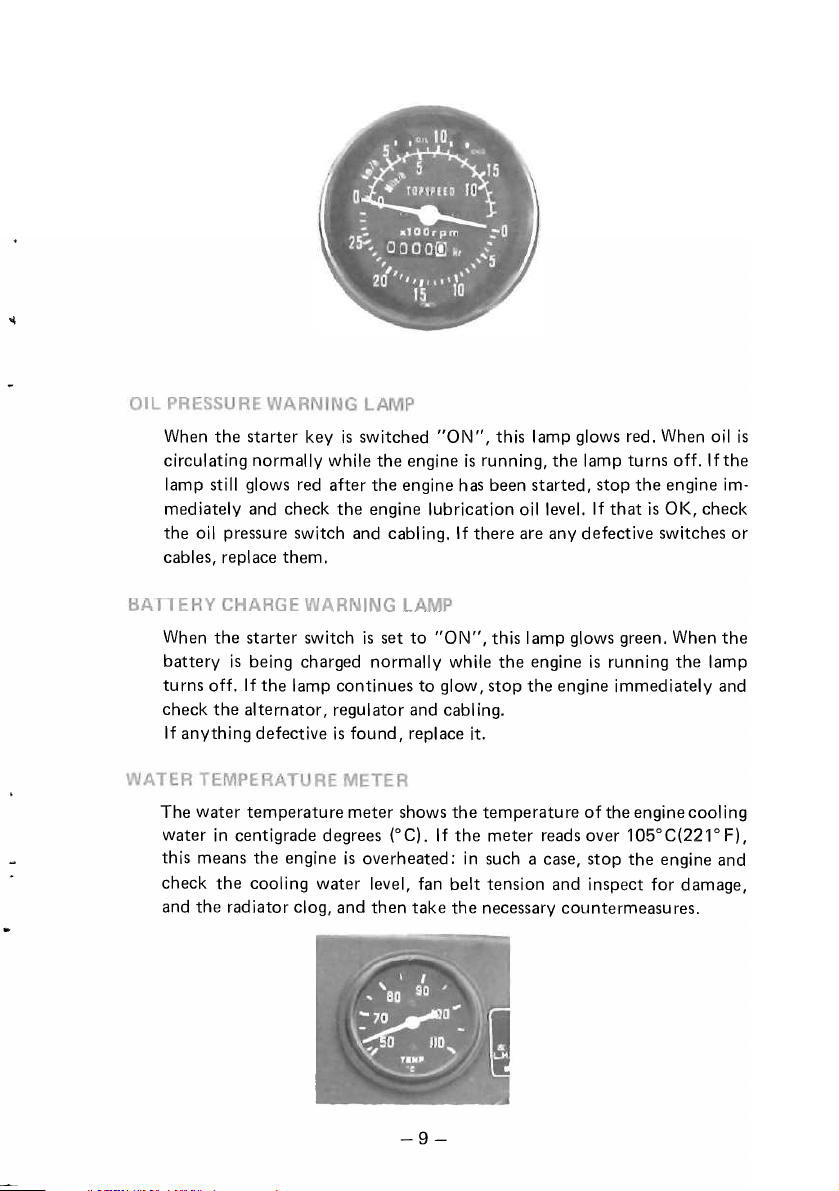

The

tractor

meter shows

the

engine speed,

tractor

travelling speed

(km/h

and mil/h) and running hours (accumulated hours). The engine speed

the

reads on

lower side

the upper side of the same. The

and mil/h

shows

In

addition the

battery

at

the

the

accumulated running hours

charge warning lamp.

of

the

meter and

tractor

9th

speed. The hours meter read on

tractor

meter includes oil pressure warning lamp and

the

travelling speed

at

the

tractor

travelling speed

is

shown

the

lower

rated engine speed.

in

km/h

center

on

-8-

When

the

starter key

is

switched

"ON",

circulating normally while the engine

lamp still glows red after

mediately and check

oil

the

pressure switch and cabling.

the

engine has been started, stop

the

engine lubrication oil level.

cables, replace them.

the

When

battery

turns off.

check

If

anything defective

starter switch

is

being charged normally while the engine

If

the lamp continues to glow, stop the engine immediately and

the

alternator, regulator and cabl

is

set

to

"ON",

is

found, replace it.

this lamp glows red. When

is

running,

If

there are any defective switches

the

lamp turns off.

If

that

the

engine

is

OK, check

this lamp glows green. When

is

running the lamp

ing.

oil

If

is

the

im-

or

the

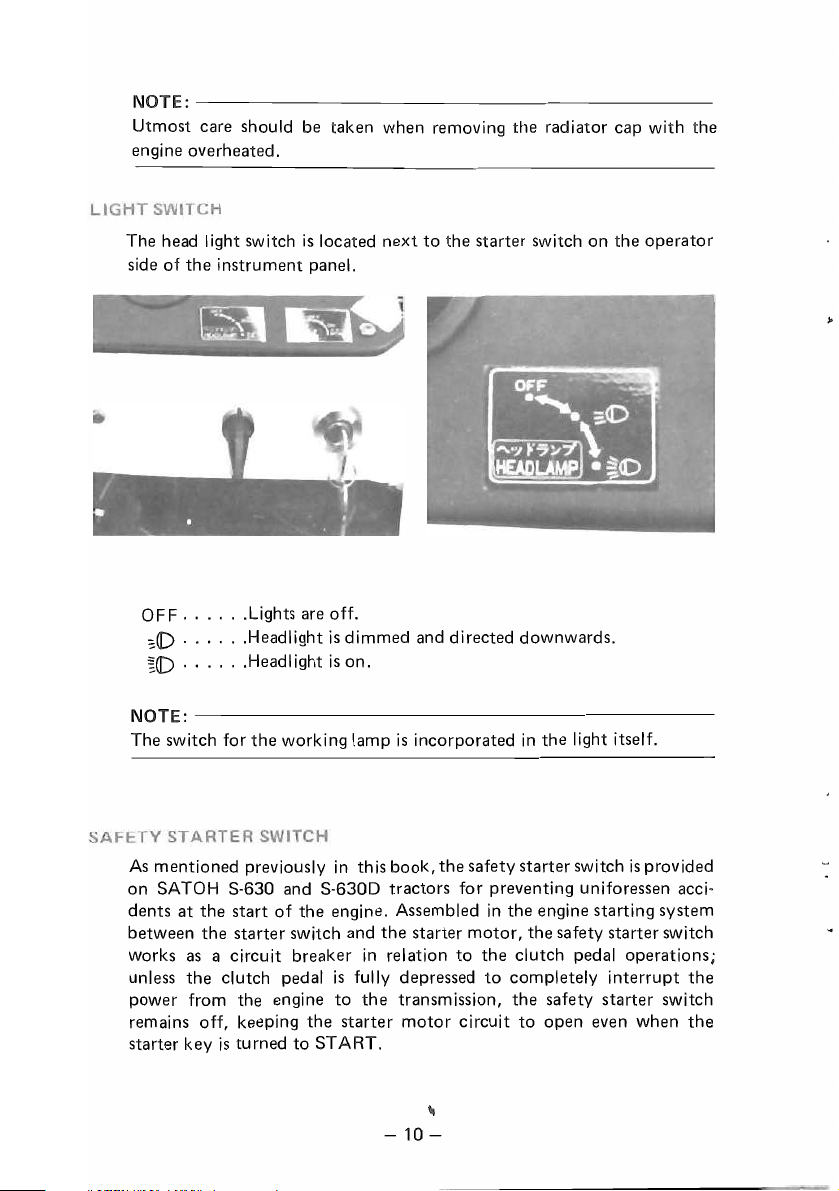

The water temperature meter shows the temperature

water

in

centigrade degrees

this means the engine

(OC).

is

overheated;

If

the

meter reads over 105°C(221° F),

in

such a case, stop

ofthe

engine cooling

the

engine and

check the cooling water level, fan belt tension and inspect for damage,

and the radiator clog, and then take the necessary countermeasures.

-9-

NOTE:--------------------------------------------

Utmost care should be taken when removing the radiator cap with

engine overheated.

is

The head I ight switch

side of the instrument panel.

OF F

......

~(J)

......

~(J)

......

Lights are off.

Headlight

Headlight

located next

is

is

dimmed and directed downwards.

on.

to

the starter switch on the

operator

the

NOTE:---------------------------------------------

The switch for

As

mentioned previously

on SATOH S-630 and S-630D tractors for preventing uniforessen acci-

dents

at

between the starter switch and

as

works

unless the clutch pedal

power from the engine to

remains off, keeping the starter

starter key

the

working lamp

the start

a circuit breaker

of

the engine. Assembled

is

turned to START.

is

incorporated

in

this book, the safety starter switch

the

starter motor, the safety starter switch

in

relation

is

fully depressed

the

to

transmission, the safety starter switch

motor

circuit to open even when

in

the

in

the engine starting system

the clutch pedal operations;

to

completely interrupt

light itself.

is

provided

the

the

."

-

10-

The

engine

sheathed

the

engine

The

glow signal

in

the

combustion

seen

from

of

type

may

the

heating

the

SATOH

glow plugs

be

started

lamp

which

chamber

condition

tractors

which

easily even in

indicates

is

model

preheat

installed

of

the

S-630 & S-6300

the

combustion

cold

weather.

the

heating

on

the

instrument

glow

singallamp

state

is

fitted

chamber

of

the

glow

panel.

It

resistance

so

is

easily

wire.

with

that

plug

-

11

-

When the speed control lever

engine speed reaches the maximum of 2,750 rpm.

of

The rated speed

engine speed

life from

therefore, to run the engine

your

the Engine Model KE-130-138

is

not only the most appropriate one to get the longest service

tractor

but

is

pulled fully toward the operator, the

also the most economical one. It

at

the rate

of

2,500 rpm.

is

2,500 rpm. This

is

the best

The foot

hand

to be at any speed within

throttle

throttle

lever

pedal

is

is

installed on the right side

in

the

idling position,

the

range by depressing the pedal.

of

the

engine can be controlled

NOTE:---------------------------------------------

When

the

hand

throttle

also moves into

lutions cannot be controlled by means

below

the

the

revs. set by hand lever.

lever

is

in

a high rev. position,

position for those revs. When this

of

the

foot

pedal within

the step. When

the

foot

throttle

is

done the revo-

the

the

range

to

Depress the clutch pedal fully

the

gear

halt when shifting

propelling speed. For shifting

Lowering

clutch or changing gear at high speed will damage

the

speed, when

in

the

the

bring the machine

the

transmission for changing the machine

P.T.O. gears, follow

tractor

is

overloaded, by half engaging

-

12-

the

the

clutch lining.

to

a complete

similar manner.

the

De-clutching must be performed completely

ment with

the

engine revs. lowered

as

much

in

one clean quick move-

as

possible.

The brake on SATOH tractors model S-630

type

and

is

expansion

There are

two

dirt and water proof.

pedals provided on

the

right side

which are interlocked by a locking plate. The brake

the

sing these pedals. To stop

tractor,

depress the clutch pedal and then the brake pedal. To shorten

ing

distance, lower the engine revolutions quickly, depress

pedal and then

For turning

independently by removing

the

clutch pedal just before

in

a confined space the right and left axles can be braked

the

locking plate interlocking the right and

& S-630D

lower

the

engine stops.

is

of internal

of

the transmission case

is

applied by depres-

the

engine revolutions,

the

the

brak-

brake

left brake pedals. When travelling at high speed or on roads make sure

that

the right and left brake pedals are interlocked by means

ing

plate.

When starting

ated more often than the

brakes beforehand. It

If

you

brake pedals, there

fail

to

travel on roads after one

other,

is

also necessary to check brake balance once a week.

to

check

the

brake balance or

is

the most likelihood

of

the

check the bal ance of the right and left

to

interlock the right and left

that

an accident will occur.

brakes has been oper-

of

the

lock-

-13-

When parking, apply

in

the

following manner:

I nterlock

the

the

right and left brake pedals by

pedals depressed, lock

For releasing lock

further stronger, and push

the

parking brake by locking

the

pedals by the park

of

the

parking brake, depress the brake pedal

the

parking lever forwards.

the

main brake pedals

the

locking plate. Keeping

ing

brake lever.

The transmission on

gear

type,

providing a total

the

combination

located on

of

the

operator's seat respectively.

of

the

upper right

the

S-630 and

of

12 speeds - 9-forwars and 3-reverse - by

the

main shift lever and

of

the

-

14-

S-6300

is

of

selective sliding mesh

the

sub shift lever, which are

transmission case and on the left side

NOTE:---------------------------------------------

When you change

clutch pedal

tractor,

shift

to

the

the

gear shift, lower the engine speed and depress

disengage

gears.

the

transmission clutch. After stopping

the

the

This device links

them at the same speed

increase traction force.

the

Before

your

right foot and engage

does not engage at

If

it still does

the

running clutch, repeat

tractor

not

the

right and left wheels

slips and

the

engage, lower the engine speed and after disengaging

in

the

transmission and rotates

to

prevent either wheel from slipping and

the

speed

is

lowered, depress

the

differential lock.

first

attempt,

the

whole operation described above.

repeat

If

the

the

operation more forcibly.

-15-

to

the

pedal with

differential lock

The differential lock

when you

put

conditions, there may be occasions when the lock does

When this occurs, depress

quickly until the lock

is

automatically released by the force

your right

is

foot

off

the pedal. However, under particular

not

release.

the

right and left brake pedals alternately and

released.

If

this happens during plowing, depress

of

the

spring

the pedal on the unplowed side and the lock will be released .

.

When

the right and left brakes are interlocked,

turning the steering wheel sharply

differential lock

is

not released by any

to

the left and

of

these means, reverse

the

lock

the

right. When

is

released by

the

tractor

a short distance.

NOTE:--------------------------------------------

Refrain from using

a road.

By

operating

mission case, the four P.T.O. speeds - 555 rpm, 774 rpm, 1 rpm,

1,320 rpm - can be selected.

When shifting the P.T.O. shift lever, depress the clutch pedal fully

to interrupt the power from the engine and make sure

brought

to

a complete halt.

the

differential lock when running at high speed or on

the

P.

T.O. shift lever located on

the

upper left

of

the

the trans-

machine

the

is

-16-

First

.. , ...

Second

Third,

Fourth

Standard

.....

....

....

p.T.a,

540

1,000

555

rpm/2,500

774

rpm/2,500

1,025

rpm/2,500

1,320

rpm/2,500

speed:

rpm/2,432

rpm/2,439

engine rpm

engine rpm

engine rpm

engine rpm

engine

rpm

engine rpm

(first)

(third)

NOTES:-------------------------------------------

1) When

2) When

3)

4)

5) Avoid using a

6)

any

so

that

the

the

the

slide

loaded.

To

reduce

possible, it

any

load.

Lubricate

Special

shaft

is

care

well

implement

universal

tractor

clutch

on

the

thrust

is

advisable

the

P.T.D.

square-shaped

should

balanced.

is

joint

is

working

the

driven

be

towed

by

does

not

with

implement

load

to

to

test

operation

shaft

drive

given

to

the

weJI.

shaft

the

the

tractor,

form

an

impact

side so

P.T.D.

as

yoke

an angle

load,

that

the

driven

with

an

much

position

care

as

should

more

than

correctly

P.T.D.

is

shaft

as

implement

possible.

so

that

be

15°.

not

much

without

the

driven

taken

adjust

over-

as

The

4-wheel

case

and

machine

it

and

Correct

drive

should

P.T.D.

shift

be

speed

lever

is

operated

shift

located

in

levers.

the

on

the

similar

Incorrect

left

of

manner

the

transmission

1O

that

for

the

-

17-

A

deluxe

S-630D

it

to

. It

the

operator's

foam

is

2-WHEEL DRIVE

Front

tread

57.9

In.

(1,470m/m)

Make

adjustment

1.

Apply

jack

2.

Loosen

the

rubber

adjustable

stature.

is

adjustable

as

under

tie-rod

operator's

in 3

to

follows

the

center

clamp

stages

in

five

meet

according

bolt

seat

at

stages

the

requirement

beam

and

is

intervals

between

to

the

and

jack

take

out

provided

of

42.1

of

type

of

up

the

the

on

1.10"

in.

each

works

front.

pin.

the

S-630

(28mm)

(1

,070m/m)

usage

to

be

and

to

suit

and

purpose.

required.

1.

Clamp

2. Snap

3.

Front

4.

Center

bolt

pin

axle

beam

tightening

5.

Axle

Tie

Tie

outer

rod

rod

inner

6.

7.

-

18-

.'

3. Loosen

perly

Tightening

After

4.

and then

Clamp

the

front

for

its

usage

torque:

obtaining

tighten

Toe-in

bolt

tightening

t-E-----57.9

axle setting

purpose.

72.2 - 86.7

the required tread make proper

the

cl

amp

0.16

- 1.31

torque:

50.0

~---53.9

bolt,

adjust

ft-Ib

(10 -

bolt.

(4 -8m/m)

12.3 - 14.4

in.

(1,270

mm)

in.

(1,370

mm)--~

in.

(1,470mm)---~

the

axle

outer

12

kg-m)

adjustment

ft-Ib

(1.7 - 2.0 kg-m)

tread

of

pro-

toe-in

The tread

Front

Front

Axle

of

the 4-wheel drive

tread:

35.8

in.

(910mm)

wheel

tightening

center-and-kingpin

tractor

torque:

case

tightening

-

19-

is

35.8 in.

86.8 -97.6

torque:

(910mm).

ft-Ib

(12.0 - 13.5 kg-m)

28.9 - 36.2

(4 - 5 kg-m)

ft-Ib

1.

Avoid widening

switching the right and left

troubles on

2.

Check at

frequent

tightened securely

and kingpin case are secured each

2-wheel and 4-wheel

Rear wheel tread

and

50.4

in. (1,280 m/m) by combination shown below.

Jack up

with reference

Tightening

the

torque:

rear

to

of

the

front

the

steering linkage.

is

adjustable

the

tractor

following figu

Hub

Rim

tread of

intervals

to

specified torque and

in

six stages between 38.0 in. (965

front

to

make sure

other

the

4-wheel drive

tires

as

that

to

this may cause serious

specified torque.

and make adjustment

reo

bolt

72.2 - 86.7 ft-Ib (10 -

& Disc 112 - 126 ft-Ib (15.5 -

the

that

of

front

the

tread

12

tractor

by

wheel

axle center

m/m)

as

required

kg-m)

17

kg-m)

is

2

38

in.

(965

NOTE:

1.

Tighten each

torque

mm)

bolt

with special

39.5

in.

(1,005

secu rely accord

attention

to

tightening rims and wheel disc.

mm)

ing

to

the

specified tighten

2. Tread adjustment requires enough space and careful job.

-20

-

44.1

3

in.

(1,120mm)

ing

Make sure

form

the

that

the

staggered V's

rear tires are mounted

in

series

as

viewed from the front

so

Front

that

the

lugs on

of

the

the

tractor.

tire

The slipping not only damages

•

ficiency and greater fuel consumption. Slipping, therefore, must be

minimized

available

as

much

as

possible. For

as

optional equipment. It

provided with ballast weights when working

likely

to

occur. The ballast weights can be attached on front and rear

wheel discs and the front

putting water into

the

tires instead

operation, pay particular attention

In

cold weather where the temperature drops below 32° F(O°C), use water

with antifreeze and never

4

the

tire

but

also results

that

purpose, ballast weights are

is

recommended

in

the

of

the

chassis. Ballast can also be applied by

of

using

the

ballast weights. For this

to

the

temperature and air pressure.

fill

the tire with only

in

that

place where slipping

water.

5

working inef-

the

tracror

It

'is

of

course

6

be

is

45.3

in.

(1,150

mm)

45.8

in.

-21-

(1,165

mm)

50.4

in.

(1,280

mm)

possible for you to employ a combination

of

water

in

the tires and

ballast weights. Consult your dealer concerning the water injector and

method

of

injection.

Front wheel weight:

Inside

Rear wheel weight:

Chassis weight:

27.5 Ib(12.5

55 Ib(25

44

Ib(20

kg)

kg)

kg)

x 4 = 110 Ib(50

x 4 =

220

Ib(100

x 4 = 176.2 Ib(80

kg)

kg)

kg)

Tire pressure should be checked frequently. Either

pressure results

tires, make sure

Front

AG

Rear

Front

ES

Rear

Front

WTT

Rear

2WD

4WD

2WD

4WD

2WD

4WD

deterioration

that

the

Tire

size Ply

500-15

6-14

11.2-24

5.90-15

6-14

11.2/10-24

20><800-10

6-14

13.6-16

tire pressure

4

4

4

4

4

4

4

4

4

of

the

tire. To properly maintain the

is

checked at least once a week.

Pressure

36.93

psi

(2.6

kg/cm

28.44

psi

(2.0

kg/cm

16.00

psi

(1.13kg/cm

28.44

psi

(2.0

kg/cm

28.44

psi

kg/cm

(2.0

17.0

psi

(1.2

kg/cm

12.0

psi

(0.84kg/cm

28.44

psi

(2.0

kg/cm

22.0

psi

(1.55kg/cm

in

NOTE:----

Air pressure

the

on

of

the tires must be changed according

tires. For more details, please call and talk with your local Satoh

Dealer.

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

Valve

type

TR-15

TR-13

TR-218A

TR-15

TR-13

TR-15

TR-413

TR-13

TR-218A

to

too

high or

Remarks

Inflation

shown

Inflation

shown

the

loading weight

too

pressure

is

the

pressure

is

the

low

ma><.

ma><.

-22

-

The 3-point I inkage

is

designed for a wide range

of

of

TP

the

the

of

in

the

engine.

is

implement.

1/4

the system.

Employed

makes the hydraul

running,

case

The oil used

system, and

Control levers located on

control, position control, flow control (lowering speed control) and lift

lock

The

services

of

S-630 and

S-630 and

hydraulic

is

SAE

filtered through a 100-mesh oil filter.

tap

hole

S-6300

ic

energy available whenever needed while

pump

#80

is

furnished, ensuring easy external maintenance

S-6300

of

implements.

being directly mounted on

gear oil,

the

right

belongs

is

SATOH 'live' hydraulic system

the

same

as

of

the

operator's seat are for lift

to

the Category

that

for

the

the

timing gear

the

transmission

1,

which

that

engine

is

To control

control lever.

in

the

the

some

Moving

spool valve

flows into

If,

the

implement

control lever more

in

the

control valve, through which

cyl inder, causing

duty

operations, the implement

in

lifting and lowering, operate

-23

or

less along

the

implement

-

the

quadrant

the

oil from

to

be

lifted or lowered.

is

required

the

hydraulic

actuates

the

to

limit its lift

the

pump

to

be

below

desired

to

To

control

right

To

reduce

further.

Set

operations.

lift

not

control

of

the

increase

the

the

position,

lever

lever

the

more

than

the

furnished

operator's

the

speed,

to

maximum

at

which

the

limited

lowering

to

seat.

lowering

turn

the

the

desired

stroke,

the

control

speed

the

speed,

lever

speed

set

the

lever

position

of

the

hydraulic

turn

clockwise;

position

stopper

stops,

at

all

implement,

lift case

the

lever

to

according

on

the

quadrant

causing

times.

counterclockwise.

lock

the

operate

located

the

to

implement

the

on

the

lever,

the

to

lower

turn

type

the

flow

To

it

of

-

24-

The SATOH S-630 and

S-6300

take off tap for transmitting

If

the implement

control valve provided on

the

When

implement

of

single action cylinder

the

of

action control valve which

Start

the

engine and lift

the

valve clockwise until

Fit

the

control lever

set

the

stopper right behind the control lever. Moving

forward over

the

implement

to

the

stopper allows

lowering.

are equipped with

the

power from the tractor

tractor.

double action

is

available

the

cut

as

an

implement.

is

locked.

on

the

upper portion

the

implement

the

type

is

type

is

used, install a

optional part.

Then,

turn

to

lift; pull backward for

hydraulic power

to

the implement.

mounted,

the

flow control

of

the

quadrant

the

control lever

use

the

double

and

Adjust

screw

,J

Guide

Hydraulic

-25

control

-

lever

NOTE:--------------------------------------------

When

the

implement

return the control lever

in

no-load condition.

Push the control lever forward over the

by

the

stopper provided

into the double action control valve optionally installed.

The oil hose should also be installed beforehand, through which

from

the

double action system returns

is

firmly lifted up

to

the

cut

in

front

of

Adjust

screw

to

the desired position, be sure

(neutral position)

cut

in

the

the

lever so

to

the transmission case oil inlet.

so

that

quadrant. Set

that

the oil keeps flowing

the

pump

the

the

to

is

lever

oil

Hydraulic

control

lever

NOTE:

In

the case

mission before starting works with

enough supply oil up

The required transmission oil for supplying

The SATOH S-630 and

of

hydraulic external take

to

the

specified level.

S-6300

off

an

implement mounted and

are equipped with a rigid

26-

-

check

the

is

1.057 gal.(4

oil

level

Q).

of

the trans-

type

if

not

drawbar.

To

keep

your

tractor

proper

inspection

the

reduced.

entail

maintenance.

Maintenance

items,

greasing and

given in

servicing

50-hour

The

performance

is

indispensable. If

result

will

Also a

much

more

and servicing

however,

periodic

this

manual.

must

be

service

A-service .......... Service every

B-service .......... Service every

C-service .......... Sercice every

D-service .......... Service every

NOTE:--------------------------------------------

tractor

oil pan plug and filler·

tools

unit,

dust

resulting

replacement.

room

should

for

repairing inside

clean

the

or

water

in

loss

The

and it

is

as

and reliability

be

such

major

expence

the

procedure

carried

to

be

carried

always

tools

before

gets in

of

tractor

clean

operating

your

that

its

breakdown

than

of

SATOH S-630 &

service

In

addition

out.

out

50

100

300

600

be

kept

cap,

be

sure

the

engine,

use.

the

fuel, engine

power

as

and

should

possible.

in

the

for

tractor

performance

is

more

that

which

is

very simple.

by

carefully

to

on a new

hours

hours

hours

hours

clean.

to

wipe

transmission,

Be

careful especially

the

be

serviced

top

condition

a long

period

is

not

and

likely

you

S-630D

Carry

following

tractor

Before greasing

the

surface clean. When using

trouble

unexpected

indoors

and

of

periodically

operating

to

occur,

would

are very

out

the

or

fuel

tank

when

will be

necessity

where

to

assure its

tim~,

periodic

serviced,

life will

which

pay

for

important

daily

checking,

instructions

the

following

removing

or

hydraulic

refueling. If

experienced,

of

is

plenty

be

will

regular

the

parts

of

•

Observe

tractors

is

frequently

more

frequently

clean

the

must

be

the

following service

which

are

operated

operated

and

air filter

carried

element

out

in

muddy

when

the

or

according

schedule.

under

normal

tractor

fuel filter

to

the

-27

-

This service

conditions.

places, greasing

is

often

operated

more

frequently.

situation.

schedule

When

must

be

in

Extra

is

applied

your

carried

dusty

to

tractor

out

places,

servicing

Hours of operation

50

100

150

200

250

300

350

400

450

500

550

600

A

B C

0

service service service service

0 0

0 0

0

0 0

0

0 0

0

0 0

0

0 0

0

0 0 0 0

0

* After completing the first 600 hours operation, repeat

cording

* Usually

however, B service should be carried

1.

to

the service schedule given

'B

service

Check for leakage

is

carried

of

out

oil, water

in

the above chart.

every 100 hours. For a new

out

at

the 50 hours service.

or

fuel and if any repair the part.

the

2. Check the engine oil, transmission oil and cooling water.

is

not

quantity

3. After finishing work, replenish fuel within 1 inch

fuel

tank

4. After working

after working

proper, remedy the shortage.

filler cap.

in

a dusty place, clean

in

a place with

dry

th~

grass, clean

(25 mm) below the

air cleaner element and

the

radiator screen.

5. Tightening nuts and bolts

Make further tightening of

wheel, rim and wheel disc and

6.

After working

in

a muddy place, grease the king pins, front hubs,

then

front axle center pin and brake shaft via

setting bolts

of

other

the

of

front wheel, rear

bolts and nuts.

grease nipples provided.

the

7. Check the tire pressure and adjust if necessary.

-28

-

items

tractor,

If

ac-

the

8.

Check

the

brake

and

clutch

pedals

for

If it

is

not

as

specified,

9.

All

moving

so

that

extremely

in

such a place.

10.

Check

level add distilled

11. Check

12. Check

gear case

NOTES:-------------------------------------------

1)

A new

carefully

2)

Some

special care

service.

they

dry

the

electrolyte

the

fan

the

of

tractor

to

items

portions

work

or

belt

oil level

the

4-wheel drive

needs

understand

described

should

make

must

smoothly.

dusty

place.

level

water.

tension

in

the

careful

all

here are

be

given

necessary

be

cleaned and

Lubrication

Therefore

in

the

and

if it

front

axle

tractor.

attention.

the

things

the

to

them

battery,

is

same

free play.

adjustments.

lubricated

has

the

avoid

if it

slack

adjust

differential

The following

to

be

done.

as

for

when

carrying

with

reverse

lubrication

is

below

the

it.

case

and

should

daily

inspection

out

engine

effect

if

specified

the

the

oil

in an

working

front

be read

but

50

hours

1.

Replace

2. Replace

3.

Clean

4.

Clean

5.

Replace

6. Check

7. Clean

8.

Tighten

9.

Check

the

the

the

the

the

the

the

the

the

10. Replace oil

of

the

4-wheel drive

11.

Check and replace

1. Cleaning

Thoroughly

the

dust

the

pan

engine oil.

engine oil filter.

engine fuel filter.

air

cleaner

transmission

oil

hydraul

engine

front

in

air

clean

and

element.

oil.

of

rear axle housing case.

ic

oil filter.

cylinder

hub

for

end-play.

the

front

axle

tractor.

the

battery

cleaner

the

body.

element

element

(See SECTION

-29

head

bolts

differential

electrolyte.

using

-

and

adjust

case and

compressed

3.

SERVICE

the

valve clearances.

the

front

gear case

air. Wipe

INFORMATION)

dust

off

2. Brake adjustment

that

the

Adjust the brakes so

brakes evenly. Adjust

play. (See SECTION 3. SERVICE INFORMATION)

3. Clutch adjustment

Adjust the clutch pedal so

(See SECTION 3. SERVICE INFORMATION.)

4. Cooling water replenishment

Check

that

the specified

is

not,

fill

with water up

The maximum

eration. When cooling water has been completely drained,

new water, then run

fill

then

the

Check

NOTE:

In

mixture.

------------------------------------------

cold weather, check

level

to

the

specified level again.

water hose for damage and inspect joint sections for leaks.

the

of

the

right and left brake pedals

pedals so

as

to

quantity

to

1 inch (25.4 mm) below the filler cap.

cooling water

engine at low rev. for a short period and

the

specific gravity

that

they have

obtain proper free play.

of

cool

ing

water

cannot

be filled up

of

the

operate

the

proper free

is

put

antifreeze water

in

in

and

one

fill

the

if

op-

with

it

5. Tightening nuts and

all

Tighten

always noticed when

check

6. Greasing

See page 35, "Greasing diagram".

7. Checking

8.

Washing the fuel filter

9. Checking and replacing

nuts and bolts

the

ballast weight bolts for tightness.

the

bolts

as

much

the

tractor

front hub for end-play.

the

battery

as

possible because vibration

is

operated. At

electrolyte.

NOTE:-----------------------------------------------

Carry it

2. Replace

3. Check

out

at the same time

1.

Replacing the engine

The engine

again replaced after 50 hours running.

Thereafter,

oil

should be replaced at

replace

the

engine oil filter with a new one.

the

specific gravity

as

DAILY INSPECTION AND A-SERVICE

oil

the

oil every 100 hours

of

the

-30

battery

-

the

first 50 hours service and

of

operation.

electrolyte.

the

same

is

time,

•

Carry

out

as

follows along with DAILY INSPECTION, A-SERVICE and

B-SERVICE.

1. Checking injection nozzle

Checking

2. Replacing

3. Washing the hydraulic oil filter

4. Replacing

case

5. Check

Carry

A-SERVICE, B-SERVICE and C-SERVICE.

1. Replace

2. Repl ace

The element

operating conditions, judge the timing

ing

3. Replace

4. Clean

the

the

the

of

the 4-wheel drive

the

rear axle housing case oil.

out

as

follows at

the

rear axle housing case oil.

the

ai

the

element.

the

cool

the

outside

nozzle condition and injection pressure.

transmission case oil

oil

in

the

front axle differential case and

tractor

the

same time

r cleaner element.

is

usually replaced every

ing

water.

of

the

rad iator.

the

front gear

as

DAI

L Y INSPECTION,

600

hours,

but,

for different

of

the repl acement by inspect-

-31-

No.

Engine

oil

1.

Engine

2.

Engine

3.

repl

4.

Air

W

N

I

Il)jection

5.

T ransm ission 0 il repl

6.

Hydraulic

7.

Rear axle

8.

4-wheel

9.

oil

Specific

10.

•.....

O ..... Clean

E1l

•••••

replacement

oil

filter

fuel

filter

acement

cleaner

element

nozzle

oil

filter

housing

front

check

and

gravity

Replacement

up

Check

Items

50

100 150

• •

element

axle

replacement

of

replacement

element

cleaning-up

cleaning-up

pressure

check

acement

element

cleaning-up

case

oil

check & replacement.

diff.

case

and

battery

electrolyte

NOTE:----~----------------------------------------------------

It

is

advised

checking

requirement

and

and

replacement

front

gear

check

the

are

for

depending

intervals

the

• •

0 0

0 0

0

0 0

•

0 0 0

EB

case

EB

EB EB EB

EB

mentioned

standard

upon

cases and

the

usage

Maintenance

200 250

•

•

0 0

•

0 0

in

the

above list regarding replacing, cleaning-up and

then

desired

condition

of

Interval

400

300

350

450

500

550

• • •

• • • •

•

0

0 0

0 0

0

0 0 0

EB

•

EB

•

to

the

EB

make

tractors.

each

EB

work

so

as

600

•

•

EB

•

•

•

EB

to

meet

Thereafter

every

100

100

0

50

200

•

0

50

600

•

300

300

300

EB

300

600

•

300

100

the

I

I

I

I

I

'-

~

•

~

..i

•

4-

w

w

I

Application

Engine

Transmission

Hydraulic

system and

Steering

box

gear

Rear axle

housing

4-wheel

diff.

case.

Front

king

pin

case

Antifreeze

Air

Temperature

Below

20°F

(-7°C)

20°F

to

(-7°C

Above

(32°C)

Below

20°F

(-7°C)

20°F

to

(-7°C

Above

(32°C)

90°F

to

32°C)

90°F

90°F

to

90°F

32°C)

A.P.I.

cI

ass

fication

CC

CO

CC

CO

CC

CD

SAE

i-

Multigrade

SAE10W

Multigrade

SAE

SAE

SAE

SAE40

SAE

SAE

#80

Grade

20W

20

30

Multigrade

#80

#250

or

#90

Mobil

Mobil

Oelvac

Mobil

Oelvac

Mobil

Oelvac

Mobil

Oelvac

Mebilfluid423

or

Mobil

Mobilube

Mobilube

Parmagone

C80

GX

1210

1220

1230

1230

A.T.F

.-220

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Esso

LUBE

Essolub

or

Essolub

Esso

Gear

GP80

Esso

GP80

Esso

Antifreeze

Esso

0-3

HOX

HO

0-330

HOX

HD

0-340

HOX

HD

HOX

Oil

gear Oil

or

90

lOW

10W

lOW

30

30

40

40

10W

X03-10W

Shell

Shell

myrina

Shell

Rimula

Shell

Rotell a TX

Shell

Rotella

Shell

myrina

Shell

Rimul a CT

Shell

Rotella

Shell

Rotella

Shell

Multigrade

20W40

Shell

myrina

Shell

Rimul

Shell Roten a

Shell

Rotell

Oentax

80

Oentax

90

Shell Super

Shell

Antifreeze

oil

CT

SX

30

TX

SX

oil

aCT

TX

a SX

deluxe

lOW

lOW

10W-30

lOW

30

30

30

I

40

40

40

40

EP

Drag

link

Brake shaft

Front

axle center

2-wheel

4-wheel

4-wheel

Front

axle

Tie Rod

King

King

pin

Pin

case

Pin

NOTE:

____________________________________________

the

Two grease nipples are fixed on

counter

shaft

of four-wheel drive.

grease enough into

the

rear grease nipple (Mid. PTO case side).

-34

-

support

for

front

_

drive

This section describes service information required for regular mainte-

to

carry

out

nance and adjustment and also the ways

these jobs.

NOTE:

When carrying

tractor on

plugs, and covers, wipe clean the surrounding surfaces

dust

--------------------------------------------

out

the

maintenance services or adjustments, place the

as

or

open and

dirt

to

enter the inside of the engine and the tractor.

level

ground

as

possible. Before removing caps,

so

as

not

to

allow

Frozen cooling water may damage the cylinder block. To avoid such a

trouble, mix antifreeze into cooling water, or thoroughly drain cooling

water from the cylinder block

in

a long time

cold weather.

in

case the tractor

is

stored or

not

used for

When adding antifreeze solution, the following rules should be observed,

the

otherwise,

1.

This tractor's engine

of

cylinder block will rust.

is

cast iron. Therefore,

of

a diesel

su

type

and its cylinder block

itable antifreeze solution for such a cast

is

made

engine block must be used.

2. Before adding mixture of antifreeze and water, completely drain

cooling water and clean the radiator with detergent.

-35

-

3. Water

4. When antifreeze

5. Treat antifreeze carefully so

6.Any

7. Confirm

8. Antifreeze with proper density

9. When antifreeze

If

fuel

cleaned, air

must be bled after refilling

engine

to

be added

using detergent and

freeze drained from

cylinder block.

antifreeze solution (antifreeze and water), even

antifreeze, should

that

gasket.

be used.

specific gravity frequently.

NOTE:

Consult your dealer concerning detergent and antifreeze.

------------------------------------------

is

exhausted

is

induced into

cannot

be started.

to

antifreeze should be clean and soft water.

is

no longer used, drain and wash the cooling system

fill

it again with clean water.

the

engine.

that

it may not remove paint from

not

be used for more than 2 years.

there are no leak from

is

used over a long period

the

engine stops

the

fuel line.

the

fuel

the

hose joints

to

suit

the

climate

or

when the fuel filter element

In

such a case,

tank.

If

air

is

Do

not re-use anti-

if

it

is

or

cyl inder head

in

your

in

winter, measure

the

left

in

the

fuel line,

the

permanent

area should

the

fuel system

the

..

is

Fill

the

fuel tank up

fuel 'filter case. When

the

tighten

screw.

to

the proper level. Loosen

the

fuel starts overflowing from

-

36-

the

air vent screw

the

screw hole,

of

the

Loosen

When

no

the

more

air

vent

air

screw

bubbles

of

in

the

the

fuel

fuel,

pump

tighten

to

the

let

the

screw.

fuel

to

overflow.

Loosen

position.

properly

ified

Start

the

Then,

at

torque.

the

engine

nut

the

of

the

nozzle

start

loosened

according

the

and

engine

nozzle

to

the

shift

the

and

make

connection.

steps

covered

th

rottle

sure

Tighten

lever

the

by

"Starting

the

NOTE:----------------------------------------------

Unless air

case,

the

perform

system

is

completely

air

.

bleeding

bled,

again

the

engine

to

let

remaining

can

not

be

air

to

the

high

fuel

is

discharged

nut

to

the

started;

completely

speed

the

spec-

Engine".

in

such

out

a

of

.,

.

Remove

Supply

dirty

oil

Replacing

izontally.

the

the

is

plug

specified

more

engine

of

easily

oil

the

engine

oil

up

discharged

should

to

be

-37

oil

pan

the

specified

when

carried

-

and

it

out

is

while

completely

level. It

warm.

the

should

tractor

drain

the

be

is

used

noted

placed

oil.

that

hor-

When

the

injection pressure

deteriorates,

loss

of

the

engine power and

always maintain

of

the

exhaust

the

gas

becomes extremely black resulting

the

engine will also make more noise.

correct injection pressure

nozzle

is