System 295

Powermeter &

Harmonic Analyzer

Installation and

Operation Manual

BG0130 Rev. A2

SYSTEM 295 POWERMETER

& HARMONIC ANALYZER

Installation & Operation Manual

LIMITED WARRANTY

The manufacturer offers the customer an 24-month functional warranty on the instrument

for faulty workmanship or parts from date of dispatch from the distributor. In all cases,

this warranty is valid for 36 months from the date of production. This warranty is on a

return to factory basis.

The manufacturer does not accept liability for any damage caused by instrument

malfunction. The manufacturer accepts no responsibility for the suitability of the

instrument to the application for which it was purchased.

Failure to install, setup or operate the instrument according to the instructions herein will

void the warranty.

Your instrument may be opened only by a duly authorized representative of the

manufacturer. The unit should only be opened in a fully anti-static environment. Failure to

do so may damage the electronic components and will void the warranty.

NOTE

The greatest care has been taken to manufacture and calibrate your instrument. However,

these instructions do not cover all possible contingencies that may arise during

installation, operation or maintenance, and all details and variations of this equipment are

not covered by these instructions.

For additional information regarding installation, operation or maintenance of this

instrument, contact the manufacturer or your local representative or distributor.

IMPORTANT

Please read instructions contained in this manual before performing

installation, and take note of the following precautions:

1. Ensure that all incoming AC power and other power sources are turned OFF

before performing any work on the instrument. Failure to do so may result in serious

or even fatal injury and/or equipment damage.

2. Before connecting the instrument to the power source, check the labels on the

side of the instrument to ensure that your instrument is equipped with the appropriate

power supply voltage, input voltages, currents, analog output and communication

protocol for your application.

3. Under no circumstances should the instrument be connected to a power

source if it is damaged.

4. To prevent potential fire or shock hazard, do not expose the instrument to

rain or moisture.

Introduction 3

5. The secondary of an external current transformer must never be allowed to be

open circuit when the primary is energized. An open circuit can cause high voltages,

possibly resulting in equipment damage, fire and even serious or fatal injury. Ensure

that the current transformer wiring is made through shorting switches and is secured

using an external strain relief to reduce mechanical strain on the screw terminals, if

necessary.

6. Setup procedures must be performed only by qualified personnel familiar

with the instrument and its associated electrical equipment.

7. DO NOT attempt to open the instrument under any circumstances.

Modbus is a trademark of Modicon, Inc.

F Read through this manual thoroughly before connecting the meter to

the current carrying circuits. During operation of the meter, hazardous

voltages are present on input terminals. Failure to observe

precautions can result in serious or even fatal injury or damage to

equipment.

BG0130 Rev. A2

About This Manual

Chapter 1, Introduction, includes a description of the PM295 basic features.

Chapter 2, Installation, provides instructions for mounting, installing and

interfacing the PM295.

Chapter 3, Operating the PM295, contains an overview of the PM295 measurement

and operation techniques.

Chapter 4, Operation Techniques, provides instructions on the manual operation of

the PM295.

Chapter 5 describes Communications Operation.

Chapter 6 provides Technical Specifications of the PM295.

Appendices

Appendix A specifies all of the display formats available for operational mode and

shows the corresponding front panel displays.

Appendix B lists the instrument programmable parameters that can be accessed

either through the front panel or communications.

Appendix C provides a sample of setpoint programming form.

Appendices D, E and F contain cable drawings for computer, printer and modem

communications connections.

Related Manuals

This operating manual contains information required for installation and operation

of the PM295. Information concerning the serial communications protocols is found

in the documents: "System 295 Powermeter and Harmonic Analyzer - ASCII

Communications Protocol - User's Guide" and "System 295 Powermeter and

Harmonic Analyzer - Modbus Communications Protocol - User's Guide" shipped

with your PM295 on diskette in Microsoft Word document format.

Introduction 1

Table of Contents

1. Introduction...............................................................................................1

1.1 About The PM295..................................................................................1

1.2 Instrument Features Summary...............................................................1

1.3 Measurement Capabilities......................................................................5

2. Installation...............................................................................................11

2.1 Initial Inspection................................................................................... 11

2.2 Mechanical Installation......................................................................... 11

2.3 Input/Output Terminals.........................................................................14

2.4 Power Source Connection....................................................................15

2.5 Voltage Input Connections ...................................................................15

2.5.1 660V Input..............................................................................................15

2.5.2 120V Input..............................................................................................16

2.6 Current Input Connections....................................................................16

2.7 Harmonic Measurement Connections...................................................17

2.8 Wiring Configurations...........................................................................18

2.9 Auxiliary Current Input Connections.....................................................25

2.10 Analog Output Connections.................................................................. 26

2.11 Relay Output Connections....................................................................27

2.12 Discrete Input Connections...................................................................28

2.13 Communications.................................................................................. 28

3. Operating The PM295.............................................................................30

3.1 Instrument Turn On..............................................................................30

3.2 Operational Mode.................................................................................30

3.2.1 Front Panel Operation.............................................................................30

3.2.2 Selecting a Display Page.........................................................................31

3.2.3 Display Formats......................................................................................31

3.3 Programming Mode..............................................................................32

3.3.1 Front Panel Operation.............................................................................32

3.3.2 General Operations.................................................................................34

3.3.3 Menu Map..............................................................................................35

3.3.4 Entering/Quitting Programming Mode......................................................35

3.3.5 Entering the Password............................................................................37

3.3.6 Selecting the Setup Group......................................................................37

3.3.7 Basic Setup ............................................................................................38

3.3.8 Serial Port Setup.....................................................................................39

3.3.9 Discrete Input Setup ...............................................................................39

3.3.10 Counter Setup ........................................................................................41

3.3.11 Analog Output Setup...............................................................................41

3.3.12 Analog Expander Setup ..........................................................................43

3.3.13 Pulsing Relay Setup................................................................................44

3.3.14 Event/Alarm Setpoints.............................................................................45

3.3.15 Timer Setup............................................................................................51

3.3.16 Real Time Clock Setup............................................................................51

3.3.17 Date Format Setup .................................................................................53

3.3.18 Reset Functions......................................................................................53

3.3.19 Password Protection Control...................................................................54

3.4 Self-Test Diagnostics...........................................................................55

4. Operation Techniques............................................................................ 56

4.1 Sampling Technique............................................................................ 56

4.2 Measurement Modes............................................................................56

4.2.1 Real-time RMS Measurements................................................................56

4.2.2 Averaging...............................................................................................57

4.2.3 Minimum/Maximum Logging....................................................................57

4.3 Demand Measurements.......................................................................58

4.3.1 Demand Readings ..................................................................................58

4.3.2 Block Interval Demand............................................................................58

4.3.3 Sliding Window Demand..........................................................................59

4.3.4 Thermal Demand....................................................................................59

4.3.5 Accumulated and Predicted Demands.....................................................60

4.3.6 Demand Interval Measurement ...............................................................61

4.3.7 Resetting the Demands...........................................................................62

4.3.8 Demand Interval Pulse............................................................................63

4.4 Energy Measurements......................................................................... 63

4.4.1 Measurement Modes..............................................................................63

4.4.2 Resetting the Energies............................................................................64

4.4.3 Energy Pulsing........................................................................................64

4.5 Harmonic Measurements..................................................................... 64

4.5.1 Measurement Technique.........................................................................64

4.5.2 Harmonic Parameters.............................................................................65

4.5.3 Real-time Waveform Capture..................................................................66

4.6 Auxiliary Measurements.......................................................................66

4.6.1 Voltage and Current Unbalance...............................................................66

4.6.2 Calculated Neutral Current......................................................................67

4.6.3 Auxiliary Current Input Operation.............................................................67

4.6.4 Frequency Measurements.......................................................................67

4.6.5 Phase Rotation.......................................................................................68

4.6.6 Phase Angles..........................................................................................68

4.7 Time-Of-Use System ...........................................................................68

4.7.1 TOU System Operation...........................................................................68

4.7.2 TOU System Registers ...........................................................................69

4.7.3 TOU Calendars.......................................................................................70

4.7.4 Daily Profiles...........................................................................................70

4.7.5 Connecting with Energy-counting Meters.................................................70

4.7.6 Tariff Interval Pulse.................................................................................70

4.8 Discrete Input Operation ......................................................................70

4.9 Relay Output Operation........................................................................71

4.10 Analog Output Operation......................................................................72

4.11 Analog Expander Operation................................................................. 74

4.12 Counter Operation................................................................................75

4.13 Timer Operation...................................................................................75

Introduction 3

4.14 User Programmable Events .................................................................76

4.15 On-Board Data Recording....................................................................77

4.15.1 Event Logging.........................................................................................79

4.15.2 Data Logging..........................................................................................80

4.15.3 High-speed Waveform Logging...............................................................81

4.15.4 High-resolution Waveform Logging..........................................................82

4.16 Monitoring And Recording Disturbances...............................................82

4.16.1 Disturbance Analysis...............................................................................82

4.16.2 Monitoring Disturbances..........................................................................83

4.16.3 Recording Disturbances..........................................................................83

4.17 Setpoint Operation...............................................................................84

4.17.1 General ..................................................................................................84

4.17.2 Setpoint Programming.............................................................................84

4.17.3 Triggering Conditions ..............................................................................85

4.17.4 Delaying Setpoint Operations..................................................................88

4.17.5 Setpoint Actions......................................................................................88

4.17.6 Special Considerations............................................................................90

4.17.7 Setpoint Programming Techniques..........................................................91

4.18 Update Rates And Response Time.......................................................99

5. Communications Operation................................................................. 101

5.1 General.............................................................................................. 101

5.2 Eia Interface Standards...................................................................... 101

5.2.1 EIA RS-232 Standard............................................................................101

5.2.2 EIA RS-422 and EIA RS-485 Standards................................................102

5.3 Configuring The Communications Port............................................... 102

5.3.1 Communications Mode..........................................................................102

5.3.2 Interface...............................................................................................103

5.3.3 Communication Address .......................................................................103

5.3.4 Baud Rate ............................................................................................103

5.3.5 Data Format .........................................................................................104

5.3.6 Handshaking.........................................................................................104

5.3.7 DTR/RTS Control Line ..........................................................................105

5.3.8 Configuring the Printer Parameters........................................................105

5.4 Response Time..................................................................................106

5.5 Print Mode......................................................................................... 106

6. Technical Specifications...................................................................... 108

Appendix A Display Formats....................................................................... 113

Appendix B Programmable Parameters...................................................... 124

Appendix C Setpoint Programming Form...................................................... 152

Appendix D Cable Drawings - Computer Connection...................................153

Appendix E Cable Drawings - Serial Printer Connection.............................. 159

Appendix F Cable Drawings - Modem Connection.......................................163

INDEX..........................................................................................................164

Introduction 1

1. Introduction

1.1 About The PM295

The PM295 is an advanced microprocessor-based digital instrument that

incorporates the capabilities of the network analyzer, data recorder and

programmable controller allowing for user network monitoring, analysis and control.

The instrument provides three-phase measurements of electrical quantities in power

distribution systems, monitoring external events, operating external equipment via

relay contacts, fast and long-term on-board recording of measured quantities and

events, harmonic network analysis and disturbance recording.

The PM295 can communicate with PLCs and PC based workstations via serial

communications and directly by transducing analog and discrete signals, serving as

excellent partner in power network management. All measurement functions of the

PM295 are remotely programmable via the communications port.

The accompanying PAS295 software package provides easy remote programming

for the instrument, data acquisition, analysis and on-screen presentation.

1.2 Instrument Features Summary

Processing Block

• CPU - microcontroller 80C196KC20 with a 20 MHz oscillator

• Extended nonvolatile RAM with battery backup for data recording - 512K byte

module

• On-board real-time clock

• A I0-bit A/D converter

• Power supervisory circuit

• External watch-dog

Analog Inputs

• 3 isolated voltage inputs - 660 VAC/120 VAC options

• 3 isolated current inputs - 1A or 5A secondary options

• 1 isolated auxiliary current input for ground leakage/neutral current

measurements - 5 mA/1A/5A secondary options (upon order)

Discrete Inputs

• 8 programmable optically isolated digital inputs free programmable for sensing

external contacts’ status and pulses.

Applications:

- monitoring external dry contacts

- sensing an external synchronization pulse for demand interval

measurements

- counting external pulses

- connecting with external energy-counting meters

- triggering setpoints from external alarm/event sources

- selecting output values for internal multiplexed analog output

Analog Outputs

• one internal multiplexed scalable free-programmable optically isolated current

output - 0-20/4-20 mA (upon order). Provides time-sharing output for up to 16

analog parameters that can be controlled externally by a combination of binary

signals on the instrument's discrete inputs (from 1 to 4 inputs can be operated)

• extension for up to 14 analog outputs is available using external analog

expanders (up to 2 units per instrument)

Discrete Outputs

• 4 digital free-programmable relay outputs (dry contact)

Applications:

- alarm activations

- load control

- energy pulsing

- time reference pulses for synchronization demand and tariff calculations

Timers

• 4 programmable a 1 sec resolution timers for repeated setpoint operations and

data recording

Counters

• 8 programmable large-scale counters with scalable input for counting input

pulses and various internal events

User Programmable Events

• 8 programmable flags for asserting user-definable events, allowing manual

control and expansion of setpoint operations

Introduction 3

Setpoints

• 16 programmable setpoints for monitoring various events:

- up to 4 triggering conditions for each setpoint combined by OR/AND

logical operations

- up to 4 actions for each setpoint on setpoint operation

- programmable hysteresis (dead-band) for analog triggers

- programmable delay for setpoint operation/release

• each setpoint can be combined with other setpoints if extended number of

conditions or actions needed

• any measured or sensed quantity/status/pulse/event can be used as a trigger

condition for setpoint operation

• voltage disturbance and phase rotation monitoring are available for triggering

setpoint operations

• setpoint actions available:

- operating relay output

- increment/decrement/clear counter

- assert/clear user programmable event

- reset total accumulating energy registers

- reset extreme demand registers

- reset TOU system accumulating energy registers

- reset TOU system demand registers

- clear all counters

- clear Min/Max log registers

- event logging on setpoint operation

- data logging in selected data log partition

- high-speed waveform logging for disturbance analysis

- high-resolution waveform logging for harmonic analysis

• each setpoint can be programmed to be operated manually via

communications by overriding present conditions or by gating setpoint

operations in addition to other setpoint conditions (for example when

event/data recording is needed for a user-defined time interval)

• each setpoint can be programmed to allow the setpoint operations to be

recorded in the event log on any setpoint transition - operate, release or either

transition

On-board Data Recording

• 19 free-programmable extended memory partitions for recording events,

measured data, and captured waveforms:

- one event logging partition for recording various events and setpoint

operations, providing storage for up to 36864 events with a 512K

memory module (assuming the entire memory allocated for the

partition)

- 16 programmable data logging partitions, each for recording from 1 to

16 user programmable parameters per record, providing total storage

for up to 114,688 parameters with a 512K memory module (assuming

the entire memory allocated for data logging)

- one partition for high-speed waveform recording (32 samples x 16

cycles x 6 inputs per record) for disturbance analysis, and one partition

for high-resolution waveform recording (128 samples x 4 cycles x 6

inputs per record) for harmonic analysis, each providing storage for up

to 19, 40, or 82 records with a 512K memory module (assuming the

entire memory allocated for the partition)

• each memory partition can be sized to store desired number of records, from

1 record and up to the entire memory size, using an arbitrary combination of

partitions

• each memory partition can be programmed to store the oldest records without

overwriting previously recorded data when a partition is filled up, or to wrap

around by writing new records over the oldest records so that stored records

will always contain the most recent data

Time-of-Use System

• 8 programmable accumulating energy registers for 16 tariffs, each

configurable for counting kWh/kvarh/kVAh or pulses from up to 8 external

energy-counting meters

• 3 programmable demand registers for 16 tariffs, configurable for recording

extreme (minimum and maximum) demands using varying calculation

techniques: block interval/sliding window/thermal demand

• 16 daily profiles (types of days) with up to 8 tariff changes per day

• 2-year calendar

Communications

• one programmable optically isolated serial port - RS-232/RS-422/RS-485

embedded options with a user-selectable baud rate of 110 to 38400 BPS

Display

• multi-page display composed of 11 windows with high-brightness seven-

segment digital LEDs. A total of 55 display pages are available

Keypad

• four membrane long-life push-buttons for page scrolling and programming

Power Supply

• 90-264 V AC, 10-290 V DC options

Introduction 5

1.3 Measurement Capabilities

Table 1-1 lists quantities and signals measured, calculated and sensed by the PM295. Measurement readings can be

accessed via the front panel and communications. These readings can also be transferred through internal analog and

relay outputs, and used as triggers for alarm/event setpoint operations. Ranges and full scale values for measurement

parameters are summarized in technical specifications (see Chapter 6). Chapter 3 describes measurement functions and

modes of measuring input values.

Table 1-1 Measured Quantities and Sensed Signals

Measurement Mode Usage/output

Parameter Real-

time

Sliding

average

Demand Min/

Max

Display Commu-

nications

Analog

output

Pulse Data

logging

Trigger

setpoint

Per phase Measurements

Voltage (L-N/L-L) À

• • • • • • • • •

Current

• • • • • • • • •

kW Á

• • • • • • • •

kvar Á

• • • • • • • •

kVA Á

• • • • • • • •

Power factor (signed) Á

• • • • • • • •

Voltage THD Â

• • • • • • • •

Current THD

• • • • • • • •

K-Factor

• • • • • • • •

Three-phase total measurements

Total kW

• • • • • • • • •

Total kvar

• • • • • • • • •

Total kVA

• • • • • • • • •

Total power factor signed

• • • • • • • •

Total power factor lag

• • • • • • •

Table 1-1 Measured Quantities and Sensed Signals

Measurement Mode Usage/output

Parameter Real-

time

Sliding

average

Demand Min/

Max

Display Commu-

nications

Analog

output

Pulse Data

logging

Trigger

setpoint

Total power factor lead

• • • • • • •

Auxiliary measurements

Auxiliary current (ground

leakage/neutral current)

• • • • • • • •

Neutral current (calculated)

• • • • • • • •

Frequency

• • • • • • • •

Voltage unbalance

• • • • • • • •

Current unbalance

• • • • • • • •

Low values on any phase

Low voltage (L-N/L-L) À

• • • • •

Low current

• • • • •

Low kW Á

• • • • •

Low kvar Á

• • • • •

Low kVA Á

• • • • •

Low power factor lag Á

• • • • •

Low power factor lead Á

• • • • •

Low voltage THD Â

• • • • •

Low current THD

• • • • •

Low K-Factor

• • • • •

High values on any phase

High voltage (L-N/L-L) À

• • • • •

High current

• • • • •

High kW Á

• • • • •

High kvar Á

• • • • •

Introduction 7

Table 1-1 Measured Quantities and Sensed Signals

Measurement Mode Usage/output

Parameter Real-

time

Sliding

average

Demand Min/

Max

Display Commu-

nications

Analog

output

Pulse Data

logging

Trigger

setpoint

High kVA Á

• • • • •

High power factor lag Á

• • • • •

High power factor lead Á

• • • • •

High voltage THD Â

• • • • •

High current THD

• • • • •

High K-Factor

• • • • •

Demands

Volt demand per phase À

• • • Ã • • • •

Ampere demand per phase

• • • Ã • • • •

Total kW demand (block interval,

sliding window, thermal)

• • • Ã • • • •

Total kvar demand (block interval,

sliding window, thermal)

• • • Ã • • • •

Total kVA demand (block interval,

sliding window, thermal)

• • • Ã • • • •

Predicted demands

Total kW demand (accumulated,

sliding window)

• • • • • •

Total kvar demand (accumulated,

sliding window)

• • • • • •

Total kVA demand (accumulated,

sliding window)

• • • • • •

Total energies

kWh (import, export, net, total)

• • • • •

Table 1-1 Measured Quantities and Sensed Signals

Measurement Mode Usage/output

Parameter Real-

time

Sliding

average

Demand Min/

Max

Display Commu-

nications

Analog

output

Pulse Data

logging

Trigger

setpoint

kvarh (import, export, net, total)

• • • • •

kVAh (total)

• • • • •

Per phase harmonic measurements

Voltage harmonics (1-40), % Â

• • Ä • • • •

Current harmonics (1-40), %

• • Ä • • • •

Harmonic voltages (for odd

harmonics 1-39) Â

• • Ä • • • • •

Harmonic currents (for odd

harmonics 1-39)

• • Ä • • • • •

Three-phase total harmonic measurements

Harmonic total kW (for odd

harmonics 1-39)

• • Ä • • • • •

Harmonic total kvar (for odd

harmonics 1-39)

• • Ä • • • • •

Harmonic total power factors (for odd

harmonics 1-39)

• • Ä • • • • •

TOU energy registers

8 registers for 16 tariffs, free

programmable for counting

kWh/kvarh/kVAh or pulses from

external energy-counting meters

• •

TOU demand registers

3 registers ( kW/kvar/kVA demands)

for 16 tariffs, free

• • • •

programmable for registration

block interval/sliding window/

thermal Min/Max demands

• • •

v

Introduction 9

Table 1-1 Measured Quantities and Sensed Signals

Measurement Mode Usage/output

Parameter Real-

time

Sliding

average

Demand Min/

Max

Display Commu-

nications

Analog

output

Pulse Data

logging

Trigger

setpoint

TOU system parameters

Active tariff

• • •

Active profile

• • •

Pulse counters

8 large scale counters for counting

external pulses or internal events

• • • •

Discrete inputs

8 discrete inputs, free configurable for

sensing external contacts or pulses

• • • •

Timers

4 timers with 1 sec resolution

•

Internal events

kWh pulse (import/export/total)

• •

kvarh pulse (import/export/total)

• •

kVAh pulse

• •

Start demand interval

• •

Start tariff interval

• •

Time/date parameters

Year, month, day of month, day of

week, hour, minute, second

•

Special measurements

Voltage disturbance

•

Phase rotation

• •

Phase angles per phase

•

NOTES

¬ For all applications/outputs, the voltage parameters can represent line-to-neutral or line-to-line voltages depending on the

wiring configuration selected in the Powermeter. (4Ln3/3Ln3 = line-to-neutral voltages; all other configurations = line-to-line

voltages).

- In 3-wire connection schemes, the individual phase values for power factor, active power, apparent power and reactive power

will be zero, because they have no meaning. Only total three-phase power values can be used.

® In all grounded connections using either 4Ln3 or 4LL3 wiring configurations, harmonic voltages will represent line-to-neutral

voltages. In a 3-wire direct connection, harmonic voltages will represent line-to-neutral voltages that arise on the Powermeter's

input transformers. In a 3-wire open delta connection, harmonic voltages will comprise L12 and L23 line-to-line voltages.

¯ Display readings are the maximum demands over entire time of survey.

° Measurements can be made via 16 programmable Min/Max registers.

Installation 11

2. Installation

2.1 Initial Inspection

Upon receipt, the instrument should be free of damage and in perfect order. To

confirm this, first inspect the instrument for physical damage incurred in transit. If

the instrument is damaged, inform your local distributor immediately. Only after you

have determined that the instrument is damage-free, test the electrical performance.

2.2 Mechanical Installation

Location

The instrument should be mounted away from heat sources in a dirt-free

environment. The instrument should not be operated in direct sunlight nor should it

come into contact with oil or moisture.

Although designed to operate in an electrically noisy environment, the instrument

should not be placed near very high electric fields. It must be placed at least one-half

meter (1.64 feet) from current lines carrying up to 600 amperes. For currents greater

than 600A and up to 2,000A, this distance must be at least 1 meter (3.28 feet).

In the event that the instrument is mounted in a harsh, noisy environment with high

potential for electromagnetic impulses from heavy switch gears, motors or lightning,

it is recommended to install appropriate protective devices such as lightening and

over-voltage arresters to all incoming voltage inputs.

Mounting

The PM295 is designed to be panel mounted. The dimensions of the cutout

necessary both for front (standard) and rear panel mounting are shown in Figures 2-

1 and 2-2.

For either front or rear mounting, the instrument is positioned through the cutout,

and the bracket(s) are then screwed to the back of the instrument as shown in the

figures. For front mounting, the four thrust screws are tightened against the panel to

affix the instrument in place.

Figure 2-1 Front Mounting (standard)

Installation 13

Figure 2-2 Rear Mounting

Step 1

Connect the

bracket to the

instrument

Step 2

Mount the O-ring

on the instrument

Step 3

2.3 Input/Output Terminals

Connections to the PM295 are made via terminals located on the back of the

instrument as shown in Figure 2-3 and detailed in Figure 2-4.

Figure 2-3 Location of Terminal Strips and Communications Connector

Figure 2-4 Connection Terminal #1

Installation 15

2.4 Power Source Connection

The instrument can be operated from any single phase AC power source supplying

90-264 VAC 50/60 Hz, or from DC power supply 10-290 VDC. Power supply

options are available upon order.

For the power source wiring, see Figure 2-4. If an AC power supply is used, the live

line of the control power should be connected to terminal 1 and the neutral to

terminal 3. If a DC power supply is used, the positive supply wire should be

connected to terminal 1 and the negative wire to terminal 3.

F The ground lug must be connected to the ground.

2.5 Voltage Input Connections

2.5.1 660V Input

Direct Connection

For some power systems, the 660V input option allows the user to use direct

connection without applying potential transformers (PT). This will depend on the

power system configuration and on the system voltage level. In the case of systems

with line-to-line voltage up to 660V, direct connection may be used for 4-wire and

3-wire systems. Wiring diagrams for these are provided in Figures 2.5, 2.8, and 2.9.

F To ensure accurate readings, the measured voltage between terminals

2-11, 5-11 and 8-11 should not exceed RMS value 550 VAC and

amplitude value 900V.

NOTE

When direct connection without potential transformers is used, set the PT RATIO in the

instrument to 1.

Using Potential Transformers

For high voltage applications (above 660V line-to-line voltage) potential

transformers (PT) must be used to scale down the input voltage to rated input scale

of the instrument. The instrument is intended to be wired via potential transformers

with secondary line-to-line voltage up to 120V +20%. The instrument supports 3-

wire open delta systems and 4-wire Wye systems. Wiring diagrams for these are

provided in Figures 2-6, 2-7, 2-10 and 2-11.

NOTE

When using potential transformers, the input voltage scale is defined in the instrument by

the PT RATIO parameter, which is the relation of the PT primary rated voltage to the

secondary rated voltage. For example, using a PT with the ratings of 165 kV : 110 V, the

PT RATIO would be 165,000/110 = 1500. The PT RATIO must be specified correctly for

the instrument to provide accurate voltage readings.

2.5.2 120V Input

The instrument with the 120V input option is intended to be wired via potential

transformers with secondary line-to-line voltage up to 120V +20%.

F To ensure accurate readings, the measured voltage between terminals

2-11, 5-11 and 8-11 should not exceed RMS value 144 VAC and

amplitude value 226V.

2.6 Current Input Connections

The PM295 is designed to measure phase currents via external current transformers

(CTs) with either 1 A or 5 A secondaries. The current input ratings are factory

installed. All current inputs are galvanically isolated using internal current

transformers.

Using 3-wire connections, only two current transformers are required. It is also

possible to use three current transformers (see Figure 2-7). If necessary, the return

side of the current transformers (terminals 3, 6 and 9) may be grounded.

F To ensure accurate readings, the input current should not exceed: for

the 1A secondaries - RMS value 1.2A and amplitude value 1.76A, and

for the 5A secondaries - RMS value 6A and amplitude value 8.8A. At

least one of the L1 or L3 phase voltages must be connected to provide

correct measurements of the current.

F The CTs must be connected in the correct order and with the correct

polarity as shown in the wiring diagrams for the instrument to operate

properly. If the instrument displays a power factor of zero or close to

it, or if power readings show unreasonable values, the polarity of the

CT connections might be reversed.

For the line current inputs overload, see technical specifications in Chapter 6.

NOTE

The phase current input scale is defined in the instrument by the CT PRIMARY CURRENT

parameter. It is equal to the primary rating of the current transformer.

Installation 17

2.7 Harmonic Measurement Connections

Harmonic measurements can be made only on signals that are present on the

instrument inputs. In some of the 3-wire configurations, there may be one of inputs

missing, so the user might not get the appropriate readings.

4-wire Configurations

In 4-wire configurations, no special considerations are necessary. All harmonic

quantities will be measured correctly. In the '4Ln3', '4LL3', '3Ln3' or '3LL3' wiring

modes, harmonic voltages will represent line-to-neutral voltages. In '3Ln3' or '3LL3'

wiring modes, harmonic voltage will be measured only for two phases and the total

power harmonics will be calculated inaccurately.

3-wire Direct Connection

In a 3-wire Direct Connection, harmonic voltages will represent the three phase lineto-neutral voltages that appear on the instrument input transformers. If the system

load is not symmetrical, the voltage readings will have no meaning. In the case of the

symmetrical load, harmonic voltages will not reflect all the multiples of order 3

harmonic.

Using 2 CTs, harmonic currents will be measured only for two phases and the total

power harmonics will be calculated inaccurately.

3-wire Open Delta Connection

Readings for harmonic voltages will represent two line-to-line voltages L12 and

L23. Current harmonics will be taken using 2 or 3 CTs, according to the wiring

configuration.

Total harmonic powers will be measured properly using two input line-to-line

voltages and two currents.

2.8 Wiring Configurations

The WIRING MODE must be set in the instrument in accordance with the wiring

configuration. The wrong wiring mode may result in incorrect readings.

There are seven possible wiring configurations:

No. Wiring Configuration Wiring Mode

1 3-wire direct connection using 2 CTs (2-element)

3DIR

2 3-wire open delta connection using 2 PTs, 2 CTs (2-element)

3OP2

3 3-wire open delta connection using 2 PTs, 3 CTs (2½-

element)

3OP3

4 4-wire WYE direct connection using 3 CTs (3-element)

4Ln3 or 4LL3

5 4-wire delta direct connection using 3 CTs (3-element)

4Ln3 or 4LL3

6 4-wire WYE connection using 3 PTs, 3 CTs (3 element)

4Ln3 or 4LL3

7 4-wire WYE connection using 2 PTs, 3 CTs (2½-element)

3Ln3 or 3LL3

In 4-wire configurations, '4Ln3' or '3Ln3' wiring modes represent line-to-neutral

voltage readings; '4LL3' or '3LL3' wiring modes represent line-to-line voltages.

For 3-wire configurations, voltage readings will always represent line-to-line

voltages. These do not affect readings for harmonic voltages (see Section 2.7).

Installation 19

1) Three Wire Direct Connection Using 2 CTs (2-element)

This connection can be applied to systems with line-to-line voltage up to 660V. The

three line voltages are taken at terminals 2, 5 and 8 as shown in Figure 2-5.

Figure 2-5 3-wire Direct Connection Using 2 CTs (2-element) WIRING MODE 3DIR

Readings represent line-to-line voltages. The two line currents are monitored via

two CTs. The third current is calculated based on the two measured currents.

2) Three Wire Open Delta Connection Using 2 PTs, 2 CTs (2-element)

This configuration, shown in Figure 2-6, can be used with either 660V or 120V

input. Readings represent line-to-line voltages. The two line currents are measured

via 2 CTs; the third current [LINE 2(B)] is calculated based on the two measured

currents. The common taps of the PT secondaries are connected to terminal 11.

Note the connection between terminals 5 and 11.

Figure 2-6 3-Wire Open Delta Connection Using 2 PTs, 2 CTs (2-element)

WIRING MODE 3OP2

Installation 21

3) Three Wire Open Delta Connection Using 2 PTs, 3 CTs (2½element)

This configuration, shown in Figure 2-7, can be used with either 660V or 120V

input. Readings represent line-to-line voltages. All three line currents are measured.

The common taps of the PT secondaries are connected to terminal 11.

Note the connection between terminals 5 and 11.

Figure 2-7 3-Wire Open Delta Connection Using 2 PTs, 3 CTs (2½-element)

WIRING MODE 3OP3

4) Four Wire Wye Direct Connection Using 3 CTs (3-element)

The instrument takes the three line-to-neutral voltages and three line currents as

shown in Figure 2-8. The system neutral is connected to terminal 11.

Figure 2-8 4-Wire Wye Direct Connection Using 3 CTs (3-element) WIRING MODE 4Ln3/4LL3

Installation 23

5) Four Wire Delta Direct Connection Using 3 CTs (3-element)

The instrument senses the three line-to-neutral voltages and three line currents as

shown in Figure 2-9. The system neutral is connected to terminal 11.

Figure 2-9 4-wire Delta Direct Connection Using 3 CTs (3-element)

WIRING MODE 4Ln3/4LL3

6) Four Wire Wye Connection Using 3 PTs, 3 CTs (3-element)

This configuration can be used with either 660V or 120V input. The instrument

senses the three line-to-neutral voltages and three line currents as shown in Figure 2-

10. The common taps of the PT secondaries are connected to terminal 11.

Figure 2-10 4-wire Wye Connection Using 3 PTs, 3 CTs (3-element) WIRING MODE 4Ln3/4LL3

Installation 25

7) Four Wire Wye Connection Using 2 PTs, 3 CTs (2½-element)

This configuration can be used with either 660V or 120V input. The instrument

senses the 2 line-to-neutral voltages and 3 line currents as shown in Figure 2-11. The

common taps of the PT secondaries are connected to terminal 11. This configuration

will provide accurate power measurements only if the voltages are balanced.

Figure 2-11 4-wire Wye Connection Using 2 PTs, 3 CTs (2½-element) WIRING MODE 3Ln3/3LL3

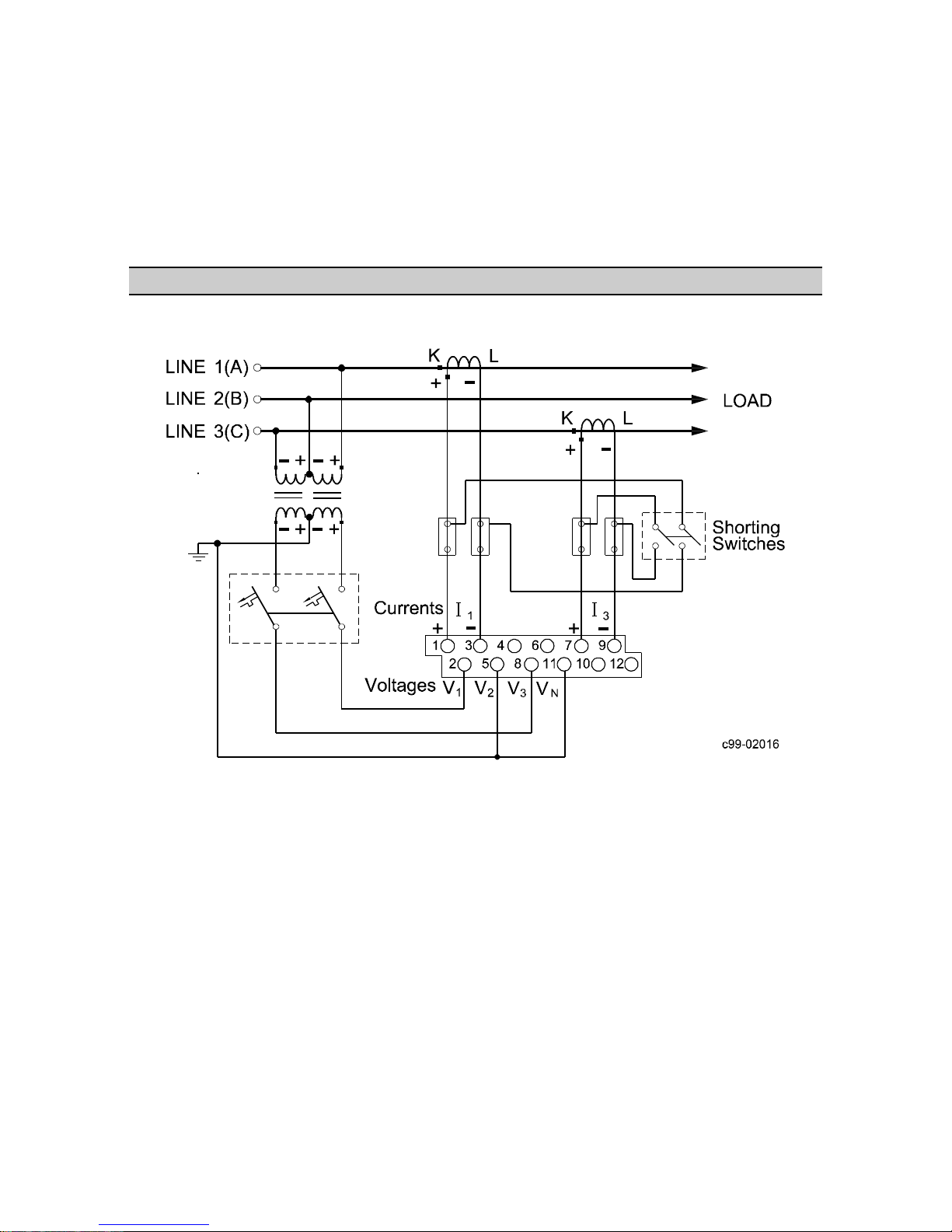

2.9 Auxiliary Current Input Connections

The PM295 can be equipped with an auxiliary current input (optional). Figure 2-12

shows examples of the auxiliary current input connections. This input can be used

for direct measurement of either ground leakage or the neutral current.

The secondary rating of the CT connected to the auxiliary current input is either 1

A, 5 A, or 5 mA, as per your order. The CT PRIMARY CURRENT parameter for

the auxiliary current input is set in the instrument independently of the phase current

inputs.

97-04023

31

2 5 8

4

1011

6 7129

+ -

L

N

+

K

LOAD

-

L3 (C)

L2 (B)

L1 (A)

11

123

5 8

4 6

N

L1 (A)

L2 (B)

L3 (C)

10

7 9

+12-

+ -

LOAD

a) Neutral current b) Ground leakage current

Figure 2-12 Auxiliary Current Input Connections

2.10 Analog Output Connections

Figure 2-13 shows wiring for an analog output. The analog output is optically

isolated and has an internal source +24 VDC to power the current loop. Analog

output range is 0-20 or 4-20 mA, as per your order.

R

L

max 510 Ohm

15

13

+

-

Figure 2-13 Analog Output Connections

The permitted range for the current loop resistance is 0 to 510 Ω.

In many industrial applications, it may be necessary to protect the output from

accidental shorts to AC line voltages, in addition to high common-mode voltages.

The circuit shown in Figure 2-14 can be used for this purpose.

R

C1

L

VR1 = 25 VRMS

VR1

13

15

C1 = 0.1 mF/50V

+

-

Figure 2-14 Protective Circuit For Analog Output

Installation 27

2.11 Relay Output Connections

The PM295 is equipped with four electromechanical relays. Relays #1, #2, and #4

are two-contact Form A (SPST) relays, and relay #3 is a three-contact Form C

(SPDT) relay. Relay #1 is a reed relay that is intended for a small load, for example,

to output pulses. For the relay ratings, see technical specifications in Chapter 6.

Figure 2-15 illustrates wiring connections for the relays.

All relays are normally de-energized.

19

23

K321K1

K2

22

24

26

28

K4

25

27

Figure 2-15 Relay Output Connections

Relay Contact Protection

When using relay outputs for switching lamp, capacitive or inductive circuits, some

form of transient suppression may be necessary to keep the relay contacts within the

voltage or current ratings. The following diagrams recommend some variants of

protective circuits for relay outputs.

LOADVs

Figure 2-16 Inductive load - Zener Diode

Protection

LOADsV

Figure 2-17 Inductive load - Diode Protection

LOADsV

+

-

Figure 2-18 Inductive Load - Diode/resistor Protection

2.12 Discrete Input Connections

The PM295 provides eight optically isolated dry-contact sensing (voltage-free)

discrete inputs. Figure 2-19 shows wiring for discrete inputs.

K1 K2 K3 K4 K5 K6 K7 K8 COM

6 8 1210 14 16 18 20 11

+5 V

0 V

1 kOhm

PM295

Figure 2-19 Discrete Input Connections

The dry contacts connected to discrete inputs must be floating relative to the ground

with a minimum rating of 5 VDC, 5 mA. It is also recommended to perform

connections using a shielded, twisted pair cable that is isolated from noise sources.

2.13 Communications

Connector Pinout

The communications port is optically isolated and supports both EIA RS-232 and

RS-422/485 standard interfaces (user-selectable). The serial interface connector is

standard D-type 9 pin female plug-in, located at the top center of the back of the

instrument. Tables 2-1 and 2-2 list the pinout of the connector.

NOTE

The functions of pins 4 and 5 can be programmed via keypad upon the needs of the user.

Refer to Section 5.3 on how to select the appropriate pin function.

Table 2-1 RS-232 pinout

Pin Name Function

1 0V Common

2 TXD Transmit Data

3 RXD Receive Data

4 DTR/RTS Data Terminal Ready/Request to Send

5 DSR/CTS Data Set Ready/Clear to Send

Installation 29

Table 2-2 RS-422/RS-485 pinout

Pin Name Function

1 0V Common

6 TXD+ + Transmit Data

7 RXD+ + Receive Data

8 TXD - - Transmit Data

9 RXD - - Receive Data

For RS-485 communications, connect together pins 6-7 (TXD+ and RXD+), and pins 8-9

(TXD- and RXD-).

Receive/Transmit Indicators

The PM295 has two LED indicators, showing activity on the serial port lines. They

are located to the left of the communications connector. The left LED is connected

to the receive line and flashes when the instrument is receiving data, and the right

LED is connected to the transmit line and flashes when the instrument is

transmitting data.

Cable Connections

For the cable drawings, refer to Appendices D, E and F.

For RS-422/RS-485 balanced data transmission, a shielded, twisted pair cable

should be used for each communication link. To minimize reflections and reduce

cross talk, it is recommended to terminate the ends of lines with the termination

resistor of 200-500 Ω.

For RS-232 connections, a flat cable can be used.

The conductor size of the 2 wires shall be 24 AWG or larger with wire resistance

not exceeding 30 Ω per 1000 feet per conductor.

When lines are routed through an electrically noisy environment, input protection

against switching or lightening induced surge voltages may be required in addition to

line termination.

3. Operating The PM295

3.1 Instrument Turn On

Connect the PM295 to a suitable power source. When power is applied, the PM295

initiates a series of self tests. Upon completion of self tests, all the front panel LEDs

light up for one second and indicate a one-digit diagnostic code. An ‘8’ represents

normal power up. If a different diagnostic code continually appears when you apply

power to the instrument, contact your local distributor. For error codes, refer to

Section 3.4.

Upon power up, the PM295 assumes the operational mode.

3.2 Operational Mode

3.2.1 Front Panel Operation

Operational mode is the default mode of the instrument, in which measurement

readings appear in the 11 windows on the front panel display. Various display

formats can be selected using the front panel keypad. Figure 3-1 shows the front

view of the instrument.

Figure 3-1 PM295 Front View

Operating The PM295 31

The instrument keypad consists of four membrane long-life push-buttons allowing

the user to perform all of the front panel functions. The following descriptions detail

the keys and their functions in operational mode.

UP ARROW t Scrolls display pages forward

DOWN ARROW u Scrolls display pages backward

SELECT Enters programming mode

ENTER Toggles the display between main and subpage level

When a key is pressed, it is entered into a key register, which may be polled through

communications.

3.2.2 Selecting a Display Page

The instrument provides a total of 55 display pages, which can be accessed on the

two display levels: six pages on the main level, and the remaining pages - on the

sub-page level. The active page number is indicated on the display. It illuminates

continuously when you are on the main level, and flashes when you enter the subpage level. At power up, the instrument always returns to the page that was last

displayed.

To scroll through pages on either level:

Ä Press the up arrow key to scroll forward.

Ä Press the down arrow key to scroll backward.

To enter the subpage level:

Ä Press ENTER.

To return to the main level:

Ä Press ENTER once more.

3.2.3 Display Formats

Appendix A specifies all of the pages available for operational mode. Each page is

listed with a corresponding front panel display.

The display illustrations indicate the measurement data that can be viewed on a

corresponding display page, and the abbreviated window labels and page numbers

that appear on display exactly as indicated in illustrations. The measurement data is

indicated using a plain style, and the window labels and page numbers are accented

by a boldface. Sub-pages are referred to by the corresponding page number followed

by the sub-page number.

Table A-1 in Appendix A contains a cross reference to display pages and lists all

parameters that can be accessed via the front panel display with their respective

location and available resolution.

3.3 Programming Mode

3.3.1 Front Panel Operation

Programming mode allows the user to configure the instrument for a particular

application, and to perform protected management functions such as the resetting of

the data keeping registers and the setting of RTC.

Password Protection

Programming mode has various levels of authorization to provide safeguards

against unauthorized changes in the instrument setup configuration:

• view level non-protected level: can view all setups and list configuration

parameters. No changes allowed. No password needed.

• protected level can view/modify setups and perform management functions

(reset, RTC update)

• superuser level- privileged level: all functions allowed at the protected level

plus user protection override. This level is intended for

service procedures, and is not normally accessed by the user.

It is protected by the factory set superuser password.

Entering the protected level is protected by the user password. The user can set

password, and disable or enable password control. With password control disabled,

the user enters the protected level without password checking.

NOTE

The instrument is shipped with password protection disabled. To restore password

protection, the user should explicitly enable password control from the

PASSWORD PROTECTION CONTROL menu (see below).

F When password protection is enabled, the instrument automatically

prompts for the password when you attempt to access the protected

level. Store your password in a safe place. If you do not provide the

correct password, you will need to contact your local distributor for

the superuser password to override password protection.

Operating The PM295 33

Menus

Manual operation of the instrument in programming mode is performed through

menus.

The following sections in this chapter specify all of the menus available for the

instrument programming via the front panel. Each PM295 menu is listed with a

corresponding front panel display. Menus that require values to be input show the

applicable range limits. A map illustrating the instrument menus is provided in

Section 3.3.3.

Display in Programming Mode

Menus normally appear in windows 4 through 6, where menu items are indicated.

Each window can represent one of three types of display controls:

• static window - a labeled window identifying the displayed menu. Static

window may not be accessed with the front panel keys.

• button-window - a labeled window allowing the user to perform an action, to

enter or quit a menu. Button-window acts as labeled button

and displays an abbreviated character label of the action or

menu entry.

• edit-window - a window used in defining a parameter requiring a numeric or

character input. Edit-window allows the user to select a

predefined value from an associated list or enter a number for

a numeric parameter.

All of the key operations relate to the currently active window, which is accented by

flashing.

Keys in Programming Mode

The following details the keys and their functions in programming mode:

UP ARROW t Scrolls values forward in the active window

DOWN ARROW u Scrolls values backward in the active window

SELECT Scrolls through menu windows

ENTER Accepts a value entered in the active window, or runs action

indicated in the active window

3.3.2 General Operations

Selecting a Window

An active window is selected by scrolling through menu windows until the target

window flashes. Pressing SELECT advances you to the next window.

To select a desired window:

Ä Press SELECT until the window you want to activate flashes.

Selecting and Entering Values

The value in the active window is selected with the up/down arrow keys. When the

window represents a list of menu entries or a list of parameters, the up/down arrow

keys provide scrolling through a list of applicable options. When a window

represents a numeric value, the up/down arrow keys provide adjustment of the

number to the desired value.

To scroll through a list of parameters or to adjust a number:

Ä Press the up arrow key to scroll values in the window forward.

Ä Press the down arrow key to scroll values in the window backward.

To enter the selected value:

Ä When desired item or value appears in the window, press ENTER.

If the value in the currently active window is selected correctly, after pressing ENTER, you

will exit the window. If the window is still flashing, then the value is entered incorrectly or

incompatible with other setup parameters. Check the value for applicable range and for

compatibility with previously specified parameters.

To leave the value in the window unchanged:

Ä Press SELECT to move to another window.

Accelerating the Display Updates

When you press and release the up or down arrow key, the numeric value currently

displayed in the active window changes by incrementing or decrementing the right

most digit.

When you press and hold the key, the value changes at accelerated rate that will

depend on the time while you hold the key pressed. For the first 5 seconds, the value

is updated twice per second, and then the updating rate is accelerated up to eight

times per second. Later on, every 5 seconds, the window position being updated is

moved one digit left.

Operating The PM295 35

3.3.3 Menu Map

Figure 3-2 shows a map illustrating the PM295 menus. Setup groups are accessed

via 13 primary menus that are selected by main menu entries. For setup groups, a

map shows the abbreviated labels of menu entries accented with boldface. Primary

menus can have enclosed secondary menus and sub-menus. Menu dependent

information is provided in this manual for each setup group individually.

To enter the main menu, you should select an access mode that specifies an

authorization level for setup operation. Entering the view level allows you to inspect

all setups, but does not permit changes in setup configuration. To change setup

parameters, you should enter the main menu at the protected level. If password

protection is enabled, you will be prompted to enter a password.

3.3.4 Entering/Quitting Programming Mode

To enter programming mode from operational mode:

Ä Press SELECT.

The first menu you enter from operational mode provides a selection of the

ACCESS LEVEL for setup operation. The menu has three entries indicated by

labeled button-windows, as shown in the following illustration. The SEE entry lets

you pass into the view level, allowing to inspect the present setup configuration. The

CHG entry lets you pass into the protected level allowing the changing of

programmable setups and the performing of management procedures.

SEE

CHG

ESC

To enter the view level:

Ä Press SELECT to choose the SEE window.

Ä Press ENTER.

To enter the protected level:

Ä Press SELECT to choose the CHG window.

Ä Press ENTER.

To quit programming mode and return to operational mode:

Ä Press SELECT to choose the ESC window.

Ä Press ENTER.

PASSWORD

MAIN

MENU

BASIC SETUP

SERIAL PORT

SETUP

Port

bASc

dinP

DISCRETE

INPUT SETUP

Cnt

COUNTER

SETUP

Aout

AEPn

ANALOG OUTPUT

SETUP

PulS

SEtP

ALARM/EVENT

SETPOINTS

t-r

TIMER SETUP

rtc

RTC SETUP

diSP

rSt

RESET/CLEAR

AccS

PROTECTION

CONTROL

SELECT

PASSSEE

CHG

ESC

OOOO

bASc

ESC

DATE FORMAT

PULSING RELAY

SETUP

ANALOG EXP.

SETUP

ACCESS

LEVEL

Figure 3-2 Menu Map

Operating The PM295 37

3.3.5 Entering the Password

The PASSWORD menu appears when you enter the programming mode at the

protected level while password protection enabled. If you enter an incorrect

password, you will return to the previous menu.

The upper menu window is a static menu label. A password is entered into the

second edit-window. A password is four digits long. Each digit in the password

window can be selected individually. When you enter the PASSWORD menu, the

first password digit is currently accessible.

PASS

0000

To enter a password:

Ä Set the first digit with the up/down arrow keys.

Ä Press SELECT to advance to the next digit.

Ä Set the second digit with the up/down arrow keys.

Ä In the same manner, set the other password digits.

Ä Press ENTER.

3.3.6 Selecting the Setup Group

The setup parameters are organized into 13 groups accessed via primary menus. The

user enters a setup primary menu from the MAIN menu shown below.

The MAIN menu consists of two button-windows. The upper window displays a list

of the primary menu entries. For the entire list of the setup menus and menu labels,

refer to a map shown in Figure 3.2. The lower labeled button-window allows the

user to return to the previous menu.

ESC

bASc

To select a setup group:

Ä Ensure that the upper window is currently active (it must

flash). If it is not, press SELECT.

Ä Scroll through menu entries with the up/down arrow keys

until the label of the desired setup group appears.

Ä Press ENTER.

To quit the main menu:

Ä Press SELECT to choose the ESC window.

Ä Press ENTER.

3.3.7 Basic Setup

Select the bASc entry from the MAIN menu and press ENTER.

Basic setup specifies the general operating characteristics of the instrument, such as

wiring mode, input scales, the size of the RMS averaging buffer, etc. The BASIC

SETUP menu uses three windows: the upper window is a menu label, the second

window displays a list of the setup parameters, and the lower window is the editwindow allowing the user to view and change the indicated parameter. Table B-2 in

Appendix B lists all basic parameters with the corresponding labels and applicable

ranges.

bASc

ConF

4L-L

To select and view a setup parameter:

Ä Ensure that the central window is currently active (it must

flash). If it’s not, press SELECT.

Ä Scroll through parameters with the up/down arrow keys

until the label of the desired parameter appears. The

parameter value will be indicated in the lower window.

When the parameter value exceeds the number of places in the window, the high order

digits are expanded to the left window providing a resolution up to 7 digits.

To change the setup parameter:

Ä Press SELECT to choose the lower window.

Ä Scroll through applicable values with the up/down arrow keys, until the desired

value appears.

Ä Press ENTER to return to the central window.

To leave the setup parameter unchanged:

Ä Press SELECT to return to the central window.

To quit the menu:

Ä Ensure that the central window is currently active. If it is not, press SELECT.

Ä Press ENTER to return to the MAIN menu.

NOTE

The actual changes in the basic setup configuration will be made after you exit the

protected level. The basic setup parameters are used as a reference for other

setups. Therefore, exit the programming mode after changes are made to the

basic setup configuration, before performing other setups.

Operating The PM295 39

3.3.8 Serial Port Setup

Select the Port entry from the MAIN menu and press ENTER.

Serial port setup specifies communications parameters that the PM295 needs to

communicate with a master computer or a printer. The SERIAL PORT SETUP

menu operates the same as the BASIC SETUP menu (see above). Table B-3 in

Appendix B lists all communications parameters with the corresponding labels and

applicable choices. For more information on communications operation, refer to

Chapter 5.

Port

Prot

ASCII

To select and view a setup parameter:

Ä From the central window, scroll through parameters with

the up/down arrow keys until the label of the desired

parameter appears. The parameter value will be indicated in

the lower window.

To change the setup parameter :

Ä Press SELECT to choose the lower window.

Ä Scroll through applicable values with the up/down arrow keys until the desired

value appears.

Ä Press ENTER to return to the central window.

To quit the menu:

Ä From the central window, press ENTER to return to the MAIN menu.

3.3.9 Discrete Input Setup

Select the dinP entry from the MAIN menu and press ENTER.

The DISCRETE INPUT SETUP menu consists of four sub-menus, as shown in the

following illustrations:

S.InP

1.1.1.1.

1.0.0.0.

Status

inputs

P.InP

0.0.0.0.

0.0.1.1.

Pulse

inputs

0.0.0.0.

0.0.0.1.

An.SL

Analog

output

selector

E.Snc

0.0.0.0.

0.0.0.1.

External

synchronization

pulse

input

Each sub-menu uses three windows: the upper window lists sub-menu entries, two

others indicate the allocation status of the eight discrete inputs for the selected input

group. Discrete inputs are numbered from the left to right: inputs #1 through #4 - in

the central window, and inputs #5 through #8 - in the lower window. The input state

of 0 indicates that the input is not allocated, and the state of 1 - that the input is

allocated to the group. Each discrete input can be allocated individually. For

information on discrete input operation, refer to Section 4.8.

To select and view an allocation group setup:

Ä From the upper window, scroll through sub-menus with the up/down arrow keys

until the label of the desired entry appears.

To change the discrete input allocation:

Ä Press SELECT to choose the desired discrete input.

Ä Set the input allocation status with the up/down arrow keys.

Ä Press ENTER to return to the upper window.

To quit the menu:

Ä From the upper window, press ENTER to return to the MAIN menu.

The illustrations above show an example of discrete inputs allocation. Here, inputs

1-5 are allocated as status inputs, and inputs 7-8 are allocated as pulse inputs.

Status inputs 1-2 are allocated to the 4-channel multiplexed analog output selector,

and pulse input 8 is allocated for sensing the external synchronization pulse to use

as a reference for demand interval measurements.

TROUBLESHOOTING

If your setting is not accepted by the instrument, one of the following might be the

cause:

• Make sure the status inputs and pulse inputs are not overlapping.

• If you are allocating inputs for the analog output selector, check whether they

were allocated as status inputs.

• If you are trying to allocate input for the external synchronization pulse, check

whether it was allocated as a pulse input.

NOTE

In the event that you re-allocate the discrete input allocated previously to the

analog output selector or external synchronization pulse, the prior allocation will be

automatically disabled.

Operating The PM295 41

3.3.10 Counter Setup

Select the Cnt entry from the MAIN menu and press ENTER.

The COUNTER SETUP menu consists of eight sub-menus, each meant for one of

eight counters. The upper window lists sub-menu entries, the central window lists

pulse inputs that can be connected to the counter, and the lower window displays

scale factor for the selected counter. For information on counter operation, see

Section 4.12.

Cnt1

InP1

1

To select and view a counter setup:

Ä From the upper window, select the desired counter with

the up/down arrow keys.

To connect a pulse input to the counter:

Ä Press SELECT to choose the central window.

Ä Select the input for the selected counter with the up/down

arrow keys. The nonE entry disables external input

To change the scale factor for the counter:

Ä Press SELECT to choose the lower window.

Ä Adjust the scale factor for the counter with the up/down arrow keys. The

applicable range is 1 to 9999. You can set the scale factor for the counter

regardless of the counter input to provide counting of internal events.

To enter the changed parameter(s):

Ä Press ENTER to return to the upper window.

To quit the menu:

Ä From the upper window, press ENTER to return to the MAIN menu.

NOTE

The external input connected to the counter should be allocated as a pulse input.

3.3.11 Analog Output Setup

Select the Aout entry from the MAIN menu and press ENTER.

The ANALOG OUTPUT SETUP menu consists of 16 sub-menus, each meant for

one of 16 multiplexed analog channels. The upper window lists sub-menu entries,

the central window lists setup parameters for the selected analog channel, and the

lower window displays the value for the selected parameter. See Section 4.10 for

information on analog output operation.

An 1

GrP

nonE

To select an analog channel setup:

Ä From the upper window, select the desired channel with the

up/down arrow keys.

To view the analog channel parameters:

Ä Press SELECT to choose the central window.

Ä Scroll through the list of parameters with the up/down

arrow keys.

The following illustrations show what the parameter windows look like:

An 1

GrP

rt.Ph

Output

parameter

group

An 1

Out

U 1

Output

parameter name

An 1

Lo

0

Zero

(low)

scale

An 1

Hi

660

Full

(high)

scale

All measured parameters that can be assigned to the analog output channel are

organized in groups listed in Table B-4a (see Appendix B) with the corresponding

group label. The analog output parameter is defined by both the parameter group

and parameter name within the group. All applicable parameters are listed in Table

B-4b with their default zero and full scales.

NOTE

When the analog scale value exceeds the number of places in the window, the

high order digits are expanded to the left window giving a resolution up to 7 digits.

If the value still exceeds the maximum available resolution, it is converted to

higher units (for instance, kW to MW) and a decimal point is placed in the window

to indicate the new measurement range.

To assign the parameter to the analog output channel:

Ä In the central window, select the GrP entry with the up/down arrow keys.

Ä Press SELECT to move to the lower window.

Ä Scroll through the group labels with the up/down arrow keys until the desirable

entry appears.

Ä Press ENTER to return to the central window.

Operating The PM295 43

Ä In the same way, select the Out entry and choose the output parameter. After the

new group has been selected, a list of output parameters starts from the first

parameter in the group.

To adjust the scales for the analog output channel:

Ä In the central window, select the Lo entry with the up/down arrow keys.

Ä Press SELECT to choose the lower window.

Ä Adjust the output zero scale with the up/down arrow keys.

Ä Press ENTER to return to the central window.

Ä In the same way, select the Hi entry and adjust the output full scale.

To quit the current channel setup:

Ä From the central window, press ENTER to return to the upper window.

To quit the menu:

Ä From the upper window, press ENTER to return to the MAIN menu.

TROUBLESHOOTING

1. If your setup for either scale isn’t accepted by the instrument, check whether

the low scale value does not exceed the parameter full scale.

2. The output scales for the signed power factor are set permanently in the

instrument and may not be changed via the front panel.

NOTE

Each time you change the output parameter for the analog channel, its zero and

full scales are set by default to the lower and upper parameter limits, respectively.

If you want to restore the scales for any output to their default values, just change

and restore the output parameter.

3.3.12 Analog Expander Setup

Select the AEPn entry from the MAIN menu and press ENTER.

The ANALOG EXPANDER SETUP menu has 14 sub-menus for 14 extended analog

channels. The menu operates in the same way as the ANALOG OUTPUT SETUP

menu operates (see Section 3.3.11 above). Refer to Section 4.11 for information on

analog expander operation.

3.3.13 Pulsing Relay Setup

Select the PulS entry from the MAIN menu and press ENTER.

The PULSING RELAY SETUP menu consists of 4 sub-menus, each meant for one

of 4 relay outputs. The upper window lists sub-menus for relay outputs, the central

window lists available outputs for the selected relay, and the lower window displays

the pulsing value in units per hour for the energy pulsing parameter. Available

outputs for pulse relay are listed in Table B-5 (see Appendix B) with the