Series PM130

Powermeters

Installation

and Operation

Manual

BG0306 Rev. A1

Series PM130

Powermeters

Installation and

Operation Manual

i

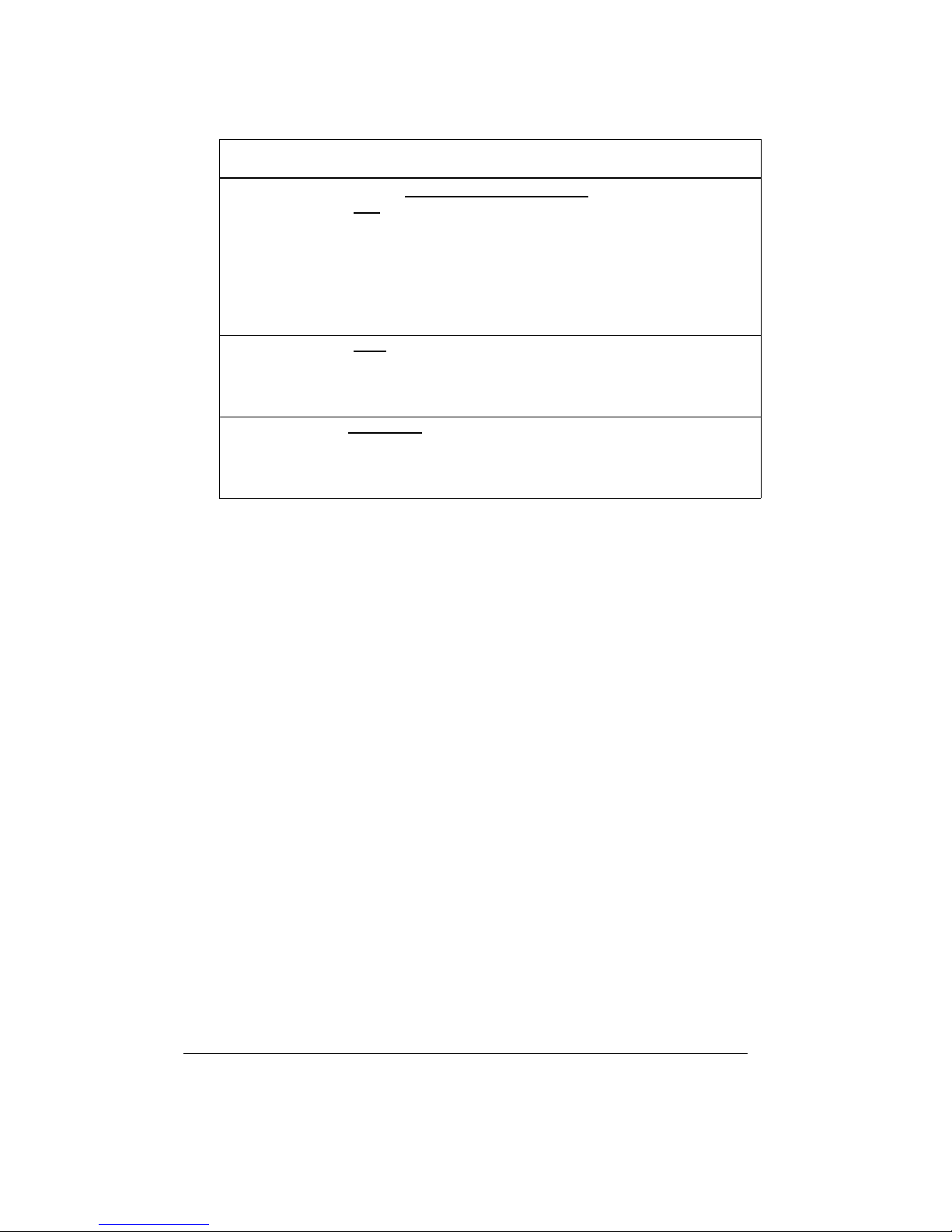

LIMITED WARRANTY

The manufacturer offers the customer an 24-month functional warranty on

the instrument for faulty workmanship or parts from date of dispatch from

the distributor. In all cases, this warranty is valid for 36 months from the

date of production. This warranty is on a return to factory basis.

The manufacturer does not accept liability for any damage caused by

instrument malfunction. The manufacturer accepts no responsibility for

the suitability of the instrument to the application for which it was

purchased.

Failure to install, set up or operate the instrument according to the

instructions herein will void the warranty.

Your instrument may be opened only by a duly authorized representative

of the manufacturer. The unit should only be opened in a fully anti-static

environment. Failure to do so may damage the electronic components

and will void the warranty.

NOTE

The greatest care has been taken to manufacture and calibrate your

instrument. However, these instructions do not cover all possible

contingencies that may arise during installation, operation or

maintenance, and all details and variations of this equipment are not

covered by these instructions.

For additional information regarding installation, operation or maintenance

of this instrument, contact the manufacturer or your local representative or

distributor.

IMPORTANT

Please read the instructions this manual before performing

installation, and take note of the following precautions:

Ensure that all incoming AC power and other power sources are

turned OFF before performing any work on the instrument. Failure

to do so may result in serious or even fatal injury

and/or equipment

damage.

Before connecting the instrument to the power source, check the

labels on the side of the instrument to ensure that your instrument is

equipped with the appropriate power supply voltage, input voltages,

currents and communication protocol for your application.

Under no circumstances should the instrument be connected

to a power source if it is damaged.

ii

To prevent potential fire or shock hazard, do not expose the

instrument to rain or moisture.

The secondary of an external current transformer must never be

allowed to be open circuit when the primary is energized. An open

circuit can cause high voltages, possibly resulting in equipment

damage, fire and even serious or fatal injury

. Ensure that the current

transformer wiring is made through shorting switches and is secured

using an external strain relief to reduce mechanical strain on the

screw terminals, if necessary.

Setup procedures must be performed only by qualified personnel

familiar with the instrument and its associated electrical equipment.

DO NOT open the instrument under any circumstances.

Modbus is a trademark of Modicon, Inc.

Read this manual thoroughly before connecting the meter to the

current carrying circuits. During operation of the meter,

hazardous voltages are present on input terminals. Failure to

observe precautions can result in serious or even fatal injury or

damage to equipment.

BG0306 Rev. A1

ii

i

Table of Contents

Quick Start......................................................................... iv

Chapter 1 Introduction ....................................................1

1.1 About This Manual ..............................................................1

1.2 About The PM130 ................................................................1

Chapter 2 Installation ...................................................... 6

2.1 Mechanical Installation .......................................................6

2.2 Electrical Installation...........................................................8

Chapter 3 Using The Menus ...........................................17

Chapter 4 Setup Menus................................................... 19

4.1 Basic Setup Menu ...............................................................19

4.2 Communications Port Setup Menu....................................21

4.3 Pulsing Output Setup Menu (PM130E) .............................. 22

4.4 Alarm/Event Setpoints Setup Menu...................................23

4.5 Relay Operation Control Menu...........................................27

4.6 Display Setup Menu ............................................................28

4.7 User Selectable Options Menu...........................................29

4.8 Access Control Menu.......................................................... 30

4.9 Reset/Synchronization Menu .............................................31

Chapter 5 Data Display.................................................... 32

5.1 Navigating in the Display Mode .........................................32

5.2 Data Display Formats.......................................................... 34

5.3 Self-Test Diagnostics Display ............................................39

Chapter 6 Viewing Status Information........................... 41

6.1 The Status Information Menu ............................................. 41

6.2 Status Display Formats.......................................................42

Appendix: Technical Specifications ...............................43

iv

Quick Start

TYPICAL INSTALLATION

(see Section 2.2.4 for full instructions)

Wiring Mode: 4LL3

v

SETUP (see Chapter 4 for full instructions)

All setups can be performed directly on the front panel or via

communications using PComTest communication software, except for

Communications and Display setups which must be performed directly on

the instrument panel.

Performing Basic and Communications Setup

Press .

Press to activate middle window.

Press ▲▼ to scroll to desired option.

Press to activate lower window.

Press ▲▼ to scroll to desired value.

Press to save selected value.

Basic and Communications Setup Options (∗ default setting)

Code Parameter Options Description

ConF

Wiring mode 3OP2 3-wire open delta using 2 CTs

4Ln3∗

4-wire Wye using 3 PTs

3dir2 3-wire direct connection using 2 CTs

4LL3 4-wire Wye using 3 PTs

3OP3 3-wire open delta using 3 CTs

3Ln3 4-wire Wye using 2 PTs

3LL3 4-wire Wye using 2 PTs

Pt

PT ratio

1.0∗ - 6,500.0

The potential transformer ratio

Ct

CT primary current 1-50,000A

(5*)

The primary rating of the current

transformer

d.P

Power demand

period

1, 2, 5, 10,

15*, 20, 30,

60, E

The length of the period for power

demand calculations, in minutes.

E = external synchronization

n.dp

Number of power

demand periods

1-15

(1*)

The number of demand periods to be

averaged for sliding window demands

1 = block interval demand calculation

A.dP

Ampere/Volt

demand period

0-1800

(900*)

The length of the period for

volt/ampere demand calculations, in

seconds 0 = measuring peak current

buF

Averaging buffer

size

8∗,16,32

The number of cycles for RMS sliding

averaging

rSt

Reset

enable/disable

diS∗, En

Protects all reset functions, both via

the front panel or communications

Freq

Nominal frequency 50, 60 Hz The nominal power utility frequency

Prot

Communications

protocol

ASCII∗, rtu,

dnP3

ASCII, Modbus RTU or DNP3.0

protocol

rS

Interface standard 485 RS-485 interface (not changeable)

Addr

Address

ASCII: 0∗-99, Modbus: 1∗-247, DNP3.0: 0∗-255

bAud

Baud rate 110, 300, 600, 1200, 2400, 4800, 9600*, 19200 bps

dAtA

Data format 7E , 8E (7/8 bits, even parity), 8n* (8 bits, no parity)

E

E

SELECT

CH

G

ENTER

SELECT

SELECT

ENTER

bASc

4L-n

ConF

Port

ASCII

Prot

men

u

option

value

men

u

option

value

Chapter 1 Introduction 1

Chapter 1 Introduction

1.

1.1 About This Manual

This manual is intended for the user of the PM130 Powermeter.

The PM130 is a microprocessor-based instrument used for measurement, monitoring, and management of electrical parameters.

This chapter gives an overview of this manual and an introduction

to the PM130.

Chapter 2, Installation, provides instructions for mechanical and

electrical installation.

Chapter 3, Using the Menus, presents the structure of menus for

setup and status viewing.

Chapter 4, Setup Menus, provides instructions for performing

parameter setup via the front panel.

Chapter 5, Data Display, guides you through the display pages.

Chapter 6, Viewing Status Information, tells you how to access

additional status information on the instrument. This information

may be useful during installation.

Technical Specifications for the PM130 are found in the Appendix.

1.2 About The PM130

The PM130 is a compact panel mounted 3-phase AC Powermeter,

specially designed to meet the requirements of users ranging from

electrical panel builders to substation operators. The PM130 is

available in three models: the PM130 for basic voltage, current

and frequency measurements; the PM130P which adds power and

power factor measurements; and the PM130E which adds power

demands and energy measurements. All models are suitable for

mounting on both 4-inch round and 92x92mm square cut-outs.

Features

Display: The front panel features bright LED displays (three

windows, up to 38 pages) with adjustable display update time, and

a LED bar graph showing percentage load with respect to userdefinable nominal (100%) load current. In the common

measurements group (see Chapter 5), Display Auto Scroll is

available with a programmable scroll interval of 2 to 15 seconds.

Chapter 1 Introduction

2

Automatic return to the main screen is available after 30 seconds

of uninterrupted use.

Setup is menu driven, with optional password protection.

Communications are available using an RS-485 standard, with

ASCII/Modbus or ASCII/DNP3.0 protocols. 120 user assignable

registers are available. Transmitter and receiver status are

displayed on the status information page (see Chapter 6).

One multi-purpose relay (optional) is provided for energy pulsing

(KYZ) or alarm and remote control. Up to 16 setpoints can be

assigned to the relay.

Four time operation counters are provided which are operated

and released by user-defined triggers. These are for counting total

generator time or transformer or power line time overload.

External synchronization of the power demand interval is

provided through communications in the PM130E.

Three user-selectable options are provided:

Power calculation mode (P.cAL):

Mode 1: Reactive power calculation (rEAc)

Active power P and reactive power Q are measured

directly and apparent power S = √ P

2

+ Q2

Mode 2: Non-active power calculation (nAct)

Active power is measured directly, and apparent

power S = V × I (V, I - rms voltage and currents)

and non-active power N = √ S

2 - P2

Mode 1 is recommended for electrical networks with low

harmonic distortion (voltage THD < 5%, current THD < 10%);

Mode 2 is recommended for all other cases. (

The PM130 does

not measure harmonics; contact your distributor for information on

instruments that provide harmonic measurement).

Energy rollover value (roll – PM130E only)

This option specifies the point at which the energy value rolls

over to zero. For example, if the roll value is 10.E4, then the

energy counter has 4 digits, i.e., energy is displayed up to 9999

kWh (kvarh, kVAh) with resolution 1 kW-hour.

Roll value Maximum Energy Resolution

10.E4 9999 kWh (kvarh, kVAh) 1 kWh (kvarh, kVAh)

10.E5 99999 kWh (kvarh, kVAh) 1 kWh (kvarh, kVAh)

10.E6 999.99 MWh (kvarh, kVAh) 10 kWh (kvarh, kVAh)

10.E7 9999.9 MWh (kvarh, kVAh) 100 kWh (kvarh, kVAh)

10.E8 99999. MWh (Mvarh, MVAh) 1 MWh (Mvarh, MVAh)

Chapter 1 Introduction 3

The roll value may be changed in accordance with the average

load of the power line. For example, if average power equals 400

kW and the counter must reset every 3 months (2160 hours),

then energy during this period equals 864000 (6 digits) and the

roll = 10.E6.

Phase energy calculations mode (Ph.En)

This option is used to enable or disable phase energy calculations.

Measured Parameters

Note: Real-time values are measured over 1 cycle of fundamental frequency;

Average values are of 8, 16 or 32 real-time values

available in the PM130P/PM130E

Output

Parameter Display Comm. Pulse Alarm

Average Values: Amps, Volts,

Frequency

$ = setup via PC

# = setup via panel

Average RMS Voltage per phase

#$

Average RMS Current per phase

#$

Average Frequency

#$

Average Neutral Current

#$

Voltage & Current unbalance

Amps & Volt Demand Parameters

Ampere Demand per phase

#$

Volt Demand per phase

#$

Ampere Maximum Demand per phase

Voltage Max. Demand per phase

Average Power values

Average Active Power per phase

Average Reactive Power per phase

Average Apparent Power per phase

Average Total Active Power

#$

Average Total Reactive Power

#$

Average Total Apparent Power

#$

Average Power Factor per phase

Average Total Power Factor

#$

Power Demand Parameters

Active Power Accumulated Demand

#$

Apparent Power Accumulated Demand

#$

Active Power Demand

#$

Active Power Sliding Demand

#$

Apparent Power Demand

#$

Apparent Power Sliding Demand

#$

Active Power Predicted Demand

#$

Apparent Power Predicted Demand

#$

P

P E

P E

E

P E

P E

Chapter 1 Introduction

4

available in the PM130P/PM130E

Output

Parameter Display Comm. Pulse Alarm

Active Power Maximum Demand

Apparent Power Maximum Demand

Energy Per Phase

Active Energy Import per phase

Reactive Energy Import per phase

Apparent Energy per phase

Total Energy

Total Active Energy Import

#$

Total Active Energy Export

#$

Total Reactive Energy Import

#$

Total Reactive Energy Export

#$

Total Reactive Energy net

Total Reactive Energy Absolute

#$

Total Apparent Energy

#$

Min/Max Log

Min/Max Volts

Min/Max A, Neutral current

Min/Max frequency

Min/Max kW, kvar, kVA, PF

Real-time Amps, Volts, Frequency

RT RMS Voltage per phase

#$

RT RMS Current per phase

#$

RT Frequency

#$

RT Neutral Current

RT Voltage & Current unbalance

#$

Real-time Power Values

RT Active Power per phase

RT Reactive Power per phase

RT Apparent Power per phase

RT Total Active Power

RT Total Reactive Power

RT Total Apparent Power

RT Power Factor per phase

RT Total Power Factor

Phase Rotation

#$

Counters

Remote Relay Control

Alarm Trigger Status

Self-Diagnostic Tests

E

E

P E

P E

P E

P

E

P

E

P E

Chapter 1 Introduction 5

Instrument Dimensions

Figure 1-1 PM130 Dimensions

Chapter 2 Installation

6

Chapter 2 Installation

2.

2.1 Mechanical Installation

1- Position Powermeter in cut-out

2- Affix the Powermeter using washers and nuts

Figure

2-1 Mounting the PM130 (Square or Round Cut-out)

Chapter 2 Installation 7

Figure 2-2 The PM130 Terminations

Chapter 2 Installation

8

2.2 Electrical Installation

) Before installation ensure that all incoming power

sources are shut OFF. Failure to observe this practice can

result in serious or even fatal injury and damage to

equipment.

Connections to the PM130 are made via terminals (voltage input,

power supply, communication and optional relay output) and CT

cores located on the rear of the instrument as shown in Figure 2-3.

Note: If your PM130 was not ordered with the optional relay, it will

not have the relay connector.

Figure 2-3 PM130 Connections - Rear View

2.2.1 Power Supply Connection

The power supply can be dedicated-fused, or from a monitored

voltage if it is within the instrument’s power supply range.

Connection to the AC power supply is: Line to terminal L; Neutral

to terminal N.

Chapter 2 Installation 9

2.2.2 Current Inputs

To ensure accurate readings, the input current should not exceed

1.5A RMS for the 1A CT secondary, or 7.5A RMS for the 5A CT

secondary.

The PM130 does not have current terminals. To connect to the

external CT, you must pass the external CT wire through the

instrument CT core (see Figure 2-4).

In the case of a retrofit where each external CT ends with two

wires, pass one wire through the core and connect it to one of the

instrument termination screws; connect the second wire from the

termination screw to the external CT to close the loop. One wire

must pass through the core; observe the arrow which indicates

the current direction (see Figure 2-4).

2.2.3 Ground

Connect the ground PM130 terminals of the power supply and

communication connectors to the switchgear earth ground using

1.5 mm

2

/14 AWG dedicated wire.

Chapter 2 Installation

10

Figure 2-4 Current Input Connection

Chapter 2 Installation 11

2.2.4 Voltage Inputs

690V Inputs (Standard):

690V inputs are usually used with direct connection. Use any of the

seven wiring configurations shown in Figures 2-5 through 2-11.

120V Inputs (Option U):

120V inputs usually implies use of a potential transformer (PT).

The PT requires use of any of the four wiring configurations shown

in Figures 2-7 through 2-10.

Wiring Configurations 'Wiring Mode' Definition

(See parameter setup instructions in Section 4.1)

3-wire direct connection using 2

CTs (2-element)

3dir2 (Figure 2-5)

4-wire WYE direct connection

using 3 CTs (3-element)

4Ln3 or 4LL3 (Figure 2-6)

4-wire WYE connection using 3

PTs, 3 CTs (3-element)

4Ln3 or 4LL3 (Figure 2-7)

3-wire open delta connection

using 2 PTs, 2 CTs (2-element)

3OP2 (Figure 2-8)

3-wire open delta connection

using 2 PTs, 3 CTs

(2½ -element)

3OP3 (Figure 2-9)

4-wire WYE connection using 2

PTs, 3 CTs (2½-element)

3Ln3 or 3LL3 (Figure 2-10)

4-wire delta direct connection

using 3 CTs (3-element)

4Ln3 or 4LL3 (Figure 2-11)

Chapter 2 Installation

12

Figure 2-6

Four Wire WYE Direct

Connection Using 3

CTs (3-element)

Wiring Mode = 4LL3

or 4Ln3

Figure 2-5

Three Wire Direct

Connection Using 2 CTs

(2-element)

Wiring Mode = 3dir2

Chapter 2 Installation 13

Figure 2-7

Four Wire WYE

Connection Using 3

PTs, 3 CTs (3element)

Wiring Mode = 4LL3

or 4Ln3

Figure 2-8

Three Wire Open

Delta Connection

Using 2 PTs, 2 CTs

(2-element)

Wiring Mode = 3OP2

Chapter 2 Installation

14

Figure 2-10

Four Wire Wye

Connection Using 2

PTs, 3 CTs

(2½-element)

Wiring Mode = 3LL3

or 3Ln3

Note

This configuration

will provide accurate

power measurements

only if the voltages

are balanced.

Figure 2-9

Three Wire Open

Delta Connection

Using 2 PTs, 3 CTs

(2½-element)

Wiring Mode = 3OP3

Chapter 2 Installation 15

Figure 2-11 Four Wire Delta Direct Connection Using 3 CTs (3 element)

Wiring Mode = 4LL3 or 4Ln3

2.2.5 Relay

One relay (optional) is provided for energy pulsing, alarms or

remote control.

Figure 2-12 Relay Connection

c99-07014

RELAY

N

120V AC

LOAD

10A FUSE

Chapter 2 Installation

16

2.2.6 Communications

A connection to the RS-485 communication port can be made from

a distance of up to1200 meters, with up to 32 instruments on one

multi-drop line.

Figure 2-13 RS-485 Multidrop Computer Connection

NOTE: Where an RS-232/RS-485 converter is used on a computer

connection, R1 is not applicable since it is built in to the converter.

Activity on the communications port lines is indicated via the

Status Information menu (see Chapter 6).

A full description of the communication protocols may be found in

the PM130 ASCII, Modbus or DNP3.0 Communications Manuals

provided with your instrument.

Chapter 3 Using the Menus 17

Chapter 3 Using The Menus

3.

Press to enter the setup mode. The primary menus will

appear:

Press again to activate the window of the desired primary

menu. Press

.

Select CHG to initialize or modify the instrument setup, or to clear

the accumulated values stored in the instrument. Entry to this

menu can be protected by a password.

Select StA to view extended status information which may be

useful during installation and in certain applications.

Select OPS for viewing (not editing) the instrument setup options.

After selecting either OPS or CHG, the list of setup menus is

displayed in the upper window. Figure 3-1 presents a complete

menu list. Depending on the model of your instrument, some

menus may not appear.

Password

The Setup Change Menu can be secured by a user-defined

password comprised of 4 digits. The instrument is shipped with

password protection disabled. To enable password protection, go

to the Access Control Menu (see Section 4.13).

The Password Menu appears if password protection is enabled.

To enter a password:

Set the first digit using the up and down arrow keys.

Press to advance to the next digit. As you

advance, the previous digit will become invisible.

Set the other password digits in the same manner.

Press to continue setup. If your password is incorrect,

you will return to the Primary Selection Menu.

SELECT

SELECT

ENTER

SELECT

StA

ENTER

SELECT

CH

G

ENTER

SELECT

OP

S

ENTER

StA

CHG

OPS

- Status Information Menu (see Chapter 6)

- Setup Options Menu

- Setup Change Menu (see Chapter 4)

PASS

0000

SELECT

ENTER

Chapter 3 Using the Menus

18

Figure 3-1

Menu Structure

SELECT

StA

OP

S

CH

G

PAS

S

bAS

c

Port

Pul

S

SetP

Status Information

Setup Options

Setup Change

Password

Basic Set

up

diSP

rSt

AccS

Port Set

up

Pulsing Setpoints

Alarm/Event Setpoints

Display Setup

Reset Functions

Selectable Options

ENTER

ENTER

PHA

S

rEL

Cnt.1

Cnt.

2

Cnt.3

Cnt.4

Port

Ph

ase Rotatio

n

Relay Status

Counter #

1

Counter #

2

Counter #3

Counter #

4

Port status

E

available in the PM130E

E

SELECT Selects an active window

Enters menu/sub-menu

Quits menu/sub-menu

Scrolls options forward

Scrolls options backward

ENTER

ESC

E P

available in the PM130P

P

EP

rELo

Relay Operation

OPt

S

A

LAr

Alarm status

Chapter 4 Setup Menus 19

Chapter 4 Setup Menus

4. CHAPTER 3 SETUP MENUS

NOTE: Instrument setup can be performed directly on the front

panel using the setup menus or via communications using

PComTest communication software. PComTest is supplied with your

instrument and provides full setup capabilities for your instrument.

For information on using PComTest, refer to the user documentation

supplied with your instrument.

4.1 Basic Setup Menu

This menu contains the basic configuration options which define

the general operating characteristics of your instrument, such as

wiring mode, input scales, the size of the RMS averaging buffer,

etc. Table 4-1 lists the basic setup options, their code names and

applicable ranges.

Activate the middle window to scroll through the list of available

options, and then activate the lower window to set the option

value.

To select and view a setup option:

Press to activate the middle window

Use the up/down arrow keys to scroll to the desired option.

The current value for this option appears in the lower

window.

To change the value of the selected option:

Press to make the lower window active.

Press the up/down arrow keys to scroll to the desired

value.

Press to store the selected value, or press

to quit the setup menu.

Table 4-1 Basic Setup Options (∗ default setting)

Code Parameter Options Description

ConF

Wiring mode 3OP2 3-wire open delta using 2 CTs

(2 element)

4Ln3∗

4-wire Wye using 3 PTs (3 element),

line to neutral voltage readings

3dir2 3-wire direct connection using 2 CTs

(2 element)

4LL3 4-wire Wye using 3 PTs (3 element),

line to line voltage readings

SELECT

SELECT

bASc

4L-n

ConF

ENTER

ESC

SELECT

CH

G

ENTER

bAS

c

ENTER

Chapter 4 Setup Menus

20

Code Parameter Options Description

ConF

Wiring mode 3OP3 3-wire open delta using 3 CTs

(2½ element)

3Ln3 4-wire Wye using 2 PTs (2½

element), line to neutral voltage

readings

3LL3

4-wire Wye using 2 PTs (2½

element), line to line voltage

readings

Pt

PT ratio

1.0∗ -

6,500.0

The potential transformer ratio

Ct

CT primary

current

1-50,000

(5*)

The primary rating of the current

transformer, in A

d.P

Power demand

period

(PM130E)

1, 2, 5,

10, 15*,

20, 30,

60, E

The length of the period for power

demand calculations, in minutes.

E = external synchronization

n.dp

Number of

power demand

periods

1-15

(1*)

The number of demand periods to

be averaged for sliding window

demands

(PM130E)

1 = block interval demand calculation

A.dP

Ampere/Volt

demand period

0-1800

(900*)

The length of the period for

volt/ampere demand calculations, in

seconds

0 = measuring peak current

buF

Averaging

buffer size

8∗,16,32

The number of measurements for

RMS sliding averaging

rSt

Reset

enable/disable

diS∗, En

Protects all reset functions, both via

the front panel or communications.

Freq

Nominal

frequency

50, 60 Hz

The nominal power utility frequency

Synchronization of the power demand interval can be made through

communications (see the PM130 Communications Reference Guides) or via

the front panel (see Section 4.9). If the power demand period is set to E, an

external synchronization pulse denoting the start of the next demand interval

can be simulated by using the synchronization command sent via

communications.

60 Hz default for North America; elsewhere, default is 50Hz.

NOTES

1) The maximum value for CT PRIMARY CURRENT × PT RATIO is

10,000,000. If this product is greater, power related values will be zeroed.

2) Always specify WIRING MODE, PT RATIO and CT PRIMARY

CURRENT prior to setting up alarm setpoints, otherwise the

alarm/event setpoints which use these parameters will automatically be

disabled.

Chapter 4 Setup Menus 21

4.2 Communications Port Setup Menu

This menu allows you to access the communications port options

that the PM130 uses to communicate with a master computer.

Table 4-2 lists the communications options, their code names and

applicable choices.

Activate the middle window to scroll through the list of available

options, and then activate the lower window to set the option

value.

To select and view a setup option:

Press to activate the middle window.

Use the up/down arrow keys to scroll to the desired option.

The option setting will appear in the lower window.

To change the selected option:

Press to activate the lower window.

Press the up/down arrow keys to scroll to the desired

value.

Press to store the selected value or press

to quit the setup menu.

Table 4-2 Communications Options (∗ default setting)

Code Parameter Options Description

Prot

Communications

protocol

ASCII∗

rtu

dnP3

ASCII protocol

Modbus RTU protocol

DNP3.0 protocol

rS

Interface standard

485

RS-485 (not changeable)

0∗-99 ASCII

Powermeter address

Addr

Address

1∗-247 Modbus

0∗-255 DNP3.0

bAud

Baud rate

110

110 baud

300

300 baud

600

600 baud

1200

1200 baud

2400

2400 baud

4800

4800 baud

9600∗

9600 baud

19.20

19,200 baud

dAtA

Data format

7E

7 bits, even parity

8n∗

8 bits, no parity

8E

8 bits, even parity

SELECT

Port

ASCII

Prot

SELECT

CH

G

ENTER

Port

ENTER

SELECT

ENTER

ESC

Chapter 4 Setup Menus

22

4.3 Pulsing Output Setup Menu (PM130E)

This menu allows you to program a relay (optional) provided by

your PM130E instrument to output energy pulses. Available

pulsing parameters are listed in Table 4-3.

To change the pulse relay setup:

Press to activate the middle window.

Use the up/down arrow keys to scroll to the desired

output parameter. Selecting nonE disables pulsing

through this relay.

Press to activate the lower window.

Use the up/down arrow keys to set the amount of

unit-hours per pulse. The available range is 1-9999.

Press to store the new setup, or press

to quit the setup without changes.

To quit the pulsing setup menu:

From the upper window, press or .

Table 4-3 Pulsing Output Parameters

Code Parameter Units

nonE Output disabled

Ac.Ei

Active energy import kWh import (positive)

Ac.EE

Active energy export kWh export (negative)

rE.Ei

Reactive energy import kvarh import (inductive)

rE.EE

Reactive energy export kvarh export (capacitive)

rE.Et

Reactive energy total kvarh total (absolute)

AP.Et

Apparent energy total kVAh total

NOTES

1. If your instrument is not equipped with the optional relay, then this

setup parameter will not appear on the display.

2. You will not be able to store your setup in the instrument if you

assigned a parameter to relay output with a zero number of unithours per pulse.

3. If a relay you allocated for pulsing has been manually operated or

released, it reverts automatically to normal operation.

4. If a relay you allocated for pulsing has been engaged by an

alarm/event setpoint, the setpoint is automatically disabled.

SELECT

SELECT

ENTER

ESC

ESC

ENTER

rEL

1

Ac.Ei

SELECT

CH

G

Pul

S

ENTER ENTER

Chapter 4 Setup Menus 23

4.4 Alarm/Event Setpoints Setup Menu

Your instrument provides 16 alarm/event setpoints that can

monitor a wide variety of events; in turn, these events can be

programmed to trigger specific actions. This menu is used to

specify the events to be monitored by the setpoints, and actions to

be triggered by those events.

To program a setpoint (all 16 can be assigned to the relay) you

need to define up to six setup parameters: the setpoint trigger

parameter, operate and release limits, optional operate and

release delays, and the setpoint action. Tables 4-4, 4-5 and 4-6 list

the setpoint setup parameters, available triggers and setpoint

actions.

Example:

Trigger

parameter

Setpoint 1 is set to monitor the real-time

high current on phase 1 (the trigger

parameter).

Operate limit }

}

}

}

Release limit }

The operate (On) and release (OFF)

limits which determine setpoint

operation are defined as 1200A and

1100A respectively.

Operate delay }

}

}

Release delay

}

The delays before operation (On d)

and release (OFFd) are set at 5

seconds and 10 seconds respectively.

Setpoint action

The action to be triggered is relay

operation.

To select a setpoint:

Scroll to the desired setpoint using the up/down arrow keys.

To view the setup options for the setpoint:

Press to activate the middle window.

SP 1

RHi.C1

triG

SP 1

5

On d

SP 1

10

OFFd

SP 1

1200

On

SP 1

rEL

Act

SP 1

1100

OF

F

SELECT

SELECT

CH

G

SEtP

ENTER ENTER

Chapter 4 Setup Menus

24

Use the up/down arrow keys to scroll to the desired setup

option. The value associated with this option is displayed in the

lower window.

To change the selected setup option:

Press to activate the lower window.

Use the up/down arrow keys to scroll to the desired value.

Press to store the new value.

Press to leave the value unchanged.

To store your new setup for the setpoint:

From the middle window, press .

To quit the setpoint setup without changes:

From the middle window, press .

To quit the setpoints setup menu:

From the upper window, press or .

NOTES

1. If your instrument is not equipped with the optional relay, then these

setup parameters will not appear on the display.

2. When you enter the setpoints setup menu at the protected level,

monitoring setpoints is temporarily suspended until you return to the

main setup menu.

3. Each time you select a new trigger parameter, the operate and

release limits are set by default to zero.

4. You will not be able to store your setpoint setup to the instrument if a

setpoint action is directed to a relay allocated for pulsing.

5. The setpoint action directed to a relay output can be overridden using

commands sent via communications. A relay can be manually

operated or released. When the relay reverts to normal operation, it

is automatically returned under setpoint control.

Table 4-4 Setpoint Setup Options (middle window)

Code Option Description

triG

Trigger

parameter

The measurement parameter or signal to be

monitored by the setpoint.

On

Operate limit The threshold at which the setpoint becomes

operative.

OFF

Release limit The threshold at which the setpoint is released

(becomes inoperative).

On d

Operate delay Time delay (0.1 sec.resolution) before

operation.

OFF d

Release delay Time delay (0.1 sec. resolution) before release.

Act

Setpoint action The action performed when the setpoint is

operative.

SELECT

ENTER

ENTER

ENTER

ESC

ESC

ESC

Chapter 4 Setup Menus 25

Table 4-5 Setpoint Triggers

(lower window, when middle window is triG)

Code Parameter Unit Range

nonE Setpoint disabled

Phase Reversal

POS.ro.

Positive phase rotation reversal

NEG.ro.

Negative phase rotation reversal

Real-time Values on any Phase

r. Hi. U

High voltage V 0 to Vmax

r. Lo. U

Low voltage V 0 to Vmax

r. Hi. C

High current A 0 to Imax

r. Lo. C

Low current A 0 to Imax

Real-time Auxiliary Measurements

r. Hi.Fr

High frequency Hz 0 to 100.00

r. Lo.Fr

Low frequency Hz 0 to 100.00

r. U.Unb

Voltage unbalance % 0 to 300

r. C.Unb

Current unbalance % 0 to 300

Average Values per Phase

A. Hi.C1

High current L1 A 0 to Imax

A. Hi.C2

High current L2 A 0 to Imax

A. Hi.C3

High current L3 A 0 to Imax

A. Lo.C1

Low current L1 A 0 to Imax

A. Lo.C2

Low current L2 A 0 to Imax

A. Lo.C3

Low current L3 A 0 to Imax

Average Values on any Phase

A. Hi. U

High voltage V 0 to Vmax

A. Lo. U

Low voltage V 0 to Vmax

A. Hi. C

High current A 0 to Imax

A. Lo. C

Low current A 0 to Imax

Average Total Values

A. Hi.P.i

High total kW import (positive) kW 0 to Pmax

A. Hi.P.E

High total kW export (negative) kW 0 to Pmax

A. Hi.q.i

High total kvar import (positive) kvar 0 to Pmax

A. Hi.q.E

High total kvar export (negative) kvar 0 to Pmax

A. Hi. S

High total kVA kVA 0 to Pmax

A. PF.LG

Low total PF Lag 0 to 1.000

A. PF.Ld

Low total PF Lead 0 to 1.000

Average Auxiliary Measurements

Ar neU.C

High neutral current A 0 to Imax

Ar Hi.Fr

High frequency Hz 0 to 100.00

Ar Lo.Fr

Low frequency Hz 0 to 100.00

Present Demands

Hi d.U1

High volt demand L1 V 0 to Vmax

Hi d.U2

High volt demand L2 V 0 to Vmax

Hi d.U3

High volt demand L3 V 0 to Vmax

Hi d.C1

High ampere demand L1 A 0 to Imax

Hi d.C2

High ampere demand L2 A 0 to Imax

Hi d.C3

High ampere demand L3 A 0 to Imax

P

E

P

E

P

E

P

E

P

E

P

E

Chapter 4 Setup Menus

26

Code Parameter Unit Range

Hi d.P

High block interval kW demand kW 0 to Pmax

Hi d.S

High block interval kVA demand kVA 0 to Pmax

Hi Sd.P

High sliding window kW demand kW 0 to Pmax

Hi Sd.S

High sliding window kVA demand kVA 0 to Pmax

Hi Ad.P

High accumulated kW demand kW 0 to Pmax

Hi Ad.S

High accumulated kVA demand kVA 0 to Pmax

Hi Pd.P

High predicted sliding window kW

demand

kW 0 to Pmax

Hi Pd.S

High predicted sliding window kVA

demand

kVA 0 to Pmax

The parameter limits are as follows:

Vmax (690 V input option) = 828 V @ PT Ratio = 1

Vmax (690 V input option) = 144 × PT Ratio [V] @ PT Ratio > 1

Vmax (120 V input option) = 144 × PT Ratio [V]

Imax (50% over-range) = 1.5 × CT primary current [A]

Pmax = (Imax × Vmax × 3)/1000 [kW] @ wiring mode 4Ln3 or 3Ln3

Pmax = (Imax × Vmax × 2)/1000 [kW] @ wiring mode 4LL3, 3OP2, 3dir2,

3OP3 or 3LL3

The setpoint is operated when the actual phase sequence does not match

the indicated normal phase rotation.

The actual frequency range is 45.00 - 65.00 Hz.

For 4LN3 or 3LN3 wiring modes, voltages will be line-to-neutral; for any

other wiring mode, they will be line-to-line.

Table 4-6 Setpoint Actions

(lower window, when middle window is Act)

Code Action

nonE No action

rEL Operate relay

In.Cn.1 Increment counter #1

In.Cn.2 Increment counter #2

In.Cn.3 Increment counter #3

In.Cn.4 Increment counter #4

ti.Cn.1 Count operating time using counter #1

ti.Cn.1 Count operating time using counter #2

ti.Cn.1 Count operating time using counter #3

ti.Cn.1 Count operating time using counter #4

When a setpoint is operated, its status is always stored to the alarm status

register even if no action is assigned to the setpoint. The alarm status can

be inspected and cleared from the front panel through the Status

Information Menu (see Section 6.2) or via communications.

This action converts a common event counter to the time counter which

measures time at 0.1 hour resolution while the setpoint is in the operated

state. Each time counter has a non-volatile shadow counter which counts

time at 1 second resolution before the corresponding time counter is

incremented. Time counters can be inspected via the Status Information

Menu. They are labeled by

an hour mark in the middle window.

E

E

E

E

E

E

E

E

available in the PM130E

E

available in the PM130P

P

Chapter 4 Setup Menus 27

4.5 Relay Operation Control Menu

This menu allows you to set the relay operation mode: non-failsafe

or failsafe. Failsafe relay operation is the opposite of normal

operation where relay contacts are closed when a relay is

operated (activated), and are open when a relay is released (deactivated). In failsafe mode, an alarm is activated by a nonenergized relay which will open in all cases when an alarm

condition is present or an alarm setpoint is not operational either

due to a loss of control power or due to corruption of the setpoint

setup configuration. A failsafe relay is closed only if it is under

setpoint control and no alarm conditions exist, or if it is manually

operated via communications.

To change the relay operation mode:

Press to activate the lower window.

Use the up/down arrow keys to set the desired

option. Select nor for normal (non-failsafe) relay

operation, or select FSAFE for failsafe relay

operation.

Press to store your new setting or press to

leave your previous setting unchanged.

To quit the setup menu:

From the middle window, press or .

NOTES

1. You will not be able to change the relay operation mode if a relay has

been allocated for pulsing.

2. When a failsafe relay is allocated for pulsing, it automatically reverts

to normal operation.

SELECT

CH

G

rELo

ENTER

ENTER

rELo

nor

rEL

ESC

ESC

SELECT

ENTER

ENTER

Chapter 4 Setup Menus

28

4.6 Display Setup Menu

This menu allows you to view and change display properties.

Table 4-7 lists available options with their code names and

applicable ranges.

Table 4-7 Display Options (∗ default setting)

Display Code Parameter Options Description

UPdt

Update

time

0.1 – 10.0 s

(0.5)*

defines interval

between display

updates

ScrL

Auto scroll

interval

nonE*

2-15 s

disables/enables auto

scroll on common

measurements

display; defines auto scroll interval

rEtn

Auto return

to the main

screen

diS*, En

Disables/enables

auto return to the

main screen after 30

seconds of

uninterrupted use

bAr

Nominal

load

current for

LED bar

graph

0-50000A

(0*)

defines the nominal

load (100%) level for

the bar graph display

(0 = CT primary

current)

Ph.P

Phase

powers

display

mode

diS*, En

disables/enables

display of phase

powers in common

measurements

To select a display option:

Press to activate the middle window, and then use the

up/down arrow keys to scroll to the desired option.

To change the display option:

Press to activate the lower window.

Use the up/down arrow keys to set the desired option.

Press to store your new setting or press to leave

your previous setting unchanged.

To quit the display setup menu:

From the middle window, press or .

SELECT

CH

G

diSP

ENTER

ENTER

SELECT

SELECT

ESC

ESC

ENTER

ENTER

available in the PM130E

E

available in the PM130P

P

diSP

5

ScrL

E

P

diSP

5000

bAr

diSP

5

rEtn

diSP

diS

Ph.P

diSP

0.5

UPdt

Chapter 4 Setup Menus 29

4.7 User Selectable Options Menu

This menu allows you to change options which relate to the

instrument features and functionality. Table 4-8 lists all available

options with their code names and applicable ranges.

To select an option:

Press to activate the middle window, and

then use the up/down arrow keys to scroll to the

desired option.

To change the selected option:

Press to activate the lower window.

Use the up/down arrow keys to set the desired value.

Press to store your new setting or to

leave the previous setting unchanged.

To quit the display setup menu:

From the middle window, press or .

Table 4-8 User Selectable Options (∗ default setting)

Code Parameter Options Description

P.cAL

Power calculation

mode

rEAc*

nAct

Using reactive power

Using non-active power

roLL

Energy roll value

10.E4

10.E5

10.E6

10.E7

10.E8*

10,000

100,000

1,000,000

10,000,000

100,000,000

Ph.En

Phase energy

measurements

diS*, En Enables/disables

measurements of energies

per phase

SELECT

SELECT

OPtS

rEAc

P.cAL

ENTER

ESC

ESC

ENTER

SELECT

CH

G

OPt

S

ENTER ENTER

E P

E

E

available in the PM130E

available in the PM130P

E

P

Chapter 4 Setup Menus

30

4.8 Access Control Menu

This menu can be only accessed via the Setup Change Menu

(CHG). It is used in order to:

• change the user password

• enable or disable password check

To view an option setting:

Press to activate the middle window.

Use the up/down arrow keys to scroll to the desired option (PASS

or CtrL).

Password Setting Password Protection Control

To change the password:

Press to activate the lower window.

Use the up/down arrow keys to modify the password. The password

can be up to four digits long.

Press to store your new password, or to leave the

password unchanged.

To enable/disable password checking:

Press to activate the middle window, and then use the

up/down arrow keys to move to the CtrL entry.

Press to activate the lower window.

Use the up/down arrow keys to change the password checking

status: select OFF to disable password protection, or select On to

enable password protection.

Press to store your new option, or to leave the

option unchanged.

To quit the setup menu:

From the middle window, press or .

Store your password in a safe place. If you do not provide the

correct password, you will need to contact your local

distributor for the super-user password to override password

protection.

SELECT

CH

G

AccS

ENTER ENTER

SELECT

SELECT

SELECT

SELECT

AccS

8780

PASS

AccS

OFF

CtrL

ENTER

ESC

SELECT

ESC

ESC

ENTER

Chapter 4 Setup Menus 31

4.9 Reset/Synchronization Menu

This menu allows you to reset to zero the accumulators and

Min/Max registers in your instrument, and also to synchronize the

power demand interval in the PM130E. The menu can be only

accessed via the Setup Change Menu (CHG). If the reset is

disabled from the Basic Setup Menu (see Section 4.1), you will not

be able to enter this menu.

The menu uses the following labels:

EnrG Resets total accumulated energies

dnd Resets all total maximum demands

P.dnd Resets total power maximum demands

A.dnd Resets volt/ampere maximum demands

Cnt Resets all event/time counters

Cnt.1 Resets counter # 1

Cnt.2 Resets counter # 2

Cnt.3 Resets counter # 3

Cnt.4 Resets counter # 4

Lo.Hi Resets Min/Max registers (does not affect maximum demands)

d.Snc Provides synchronization of the power demand interval (see

Notes below)

To reset the desired locations:

Press to activate the middle window; use the up/

down arrow keys to scroll to the desired data location entry.

Press to activate the lower window.

Press and hold for about 5 seconds until

the do label is replaced with done; release the key.

You will return to the middle window.

Press to quit the menu.

NOTES:

If you select the d.Snc entry, take into consideration the following:

1) If the power demand period is specified in minutes (see Section 4.1,

Basic Setup Options), this action provides synchronization of the

instrument’s internal timer. If the time expired from the beginning of the

current demand interval is more than 30 seconds, the new demand

interval starts immediately, otherwise synchronization is delayed until

the next demand interval.

2) The synchronization is made exactly 5 seconds after you first press

and hold .

If the CHG is not secured by a password, fast reset of the Min/Max

registers, maximum demands and energies can be done from the data

display mode (see Section 5.1) and counters from the status information

menu (see Section 6.1) without entering the reset menu.

SELECT

CH

G

rSt

ENTER

ENTER

SELECT

SELECT

ENTER

rSt

do

EnrG

E

E

E

E

available in the PM130E

E

ESC

ENTER

Chapter 5 Data Display

32

Chapter 5 Data Display

5.

5.1 Navigating in the Display Mode

The front panel has a simple interface that allows you to display

numerous measurement parameters in up to 38 display pages. For

easier reading, the parameters are divided into three groups, each

accessible by a designated key. These are:

Common measurements

- no selection key

Min/Max measurements

- selected by the key

Energy measurements

- selected by the key

The up/down arrow keys are used as follows in the Display Mode:

Scrolls through the pages downward (forward)

Scrolls through the pages upward (backward)

Returns to the first page within current measurement group

For each display page, up to three parameters can be displayed.

The Load bar graph displays the amount, in percent, of the current

load with respect to user-defined nominal load current. The highest

current measured by the PM130 is divided by the nominal load

current as defined in the Display Setup Menu (see Section 4.6)

and expressed as a percent by the LEDs (40% to 110%) which are

lit. For example, if all LEDs up to and including 90% are lit, this

means that the load is 90%-100% of the nominal load current. If

the nominal load current is set to 0, the CT primary current setup is

used.

MAX/MIN

ENERG

Y

small LEDs -

indicate measured

parameter

Load bar graph -

indicates %

nominal load

current

round LEDs -

indicate

measurement

group

Chapter 5 Data Display 33

In the Display Mode, the front panel display is updated

approximately twice per second; you can adjust the display update

rate via the Display Setup Menu (see Section 4.6).

Tables 5-1 and 5-2 list all displayed parameters and their LED

indicators.

NOTES

1. The common measurements group does not have a designated

indicator LED. If no indicator LED is lit up below the display, this means

that the common measurement parameters are being displayed at this

time. To return to the common measurements from another group, just

press the same key that you used to display this group (the key pointed

to by an illuminated LED).

2. When you move to another measurement group, the instrument stores

your last location; when you return to the previous group, the

instrument restores the last page. At power up, the instrument always

returns to the common measurements group and shows you the last

page that was displayed prior to loss of power.

Selecting a Display Page

Press the up/down arrow keys to scroll through display pages.

Selecting Common Measurements

Press the key pointed to by the illuminated round LED below the

front panel display. If no LED is lit up, this means that the front

panel displays the common measurements parameters.

When Display Auto Scroll is in effect (see Section 4.6), the

display will scroll automatically within 30 seconds after any of

the following:

• power up

• returning to the common measurements display

• pressing either arrow key

Press either arrow key to pause scrolling at the current page.

Selecting Min/Max Measurements

Press the key. Use the up/down arrow keys to scroll

through Min/Max measurements.

Selecting Energy Measurements

Press the key. Use the up/down arrow keys to scroll

through the different energy readings.

Auto Return to the Main Screen

If display Auto Return option is enabled (see Section 4.6), the

display will automatically return to the main screen from any other

measurement screen after 30 seconds of uninterrupted use.

MAX/MIN

ENERG

Y

Chapter 5 Data Display

34

Fast Reset of Accumulated Data

When changing data via the front panel is not secured by a

password, you can reset the Min/Max registers, maximum

demands and energies from the display mode without entering the

reset menu.

Select the display page of the data you want to reset. To reset:

• Min/Max log registers: select a Min/Max page from the

Min/Max measurements display (where a Max or Min round

LED is illuminated).

• Ampere and volt maximum demands: select the ampere or

volt maximum demand page from the Min/Max

measurements display (where a MAX DMD LED is

illuminated, and volts or amps LEDs at the right are lit).

• Power maximum demands: select the power maximum

demand page from the Min/Max measurements display

(where a MAX DMD LED is illuminated, and kVA/MVA and

kW/MW LEDs at the right are lit).

• Total and phase energies: select the energy measurements

display.

While holding the key, press and hold for

about 5 seconds. The displayed data is reset to zero.

5.2 Data Display Formats

The display windows are labeled in the table as follows: 1 = upper

window, 2 = middle window, 3 = lower window.

Table 5-1 Displayed Parameters for the PM130

Page Window Indicato

r

LED

Parameter

Digit

s

Unit

Common Measurements

1 1

V1/V1-2

Voltage L12 4 V/kV

1 2

V2/V2-3

Voltage L23 4 V/kV

1 3

V3/V3-1 L. Voltage L31

4 V/kV

2 1

V1/V1-2

Voltage L1 4 V/kV

2 2

V2/V2-3

Voltage L2 4 V/kV

2 3

V3/V3-1 P. Voltage L3

4 V/kV

3 1

A1

Current L1 4 A/kA

3 2

A2

Current L2 4 A/kA

3 3

A3

Current L3 4 A/kA

4 1

A Neut

Neutral current 4 A/kA

4 2

Hz

Frequency 4 Hz

4 3

Phase

Rot.

Phase rotation sequence

(POS/NEG/ERR)

4

SELECT

ENTER

Chapter 5 Data Display 35

Page Window Indicato

r

LED

Parameter

Digit

s

Unit

Min/Max Measurements

MIN

1 1

V1/V1-2

Min. real-time voltage

L1/L12

4 V/kV

1 2

V2/V2-3

Min. real-time voltage

L2/L23

4 V/kV

1 3

V3/V3-1

Min. real-time voltage

L3/L31

4 V/kV

MAX

2 1

V1/V1-2

Max. real-time voltage L1/L12 4 V/kV

2 2

V2/V2-3

Max. real-time voltage L2/L23 4 V/kV

2 3

V3/V3-1

Max. real-time voltage L3/L31 4 V/kV

MAX DMD

3 1

A1

Max. ampere demand L1 4 A/kA

3 2

A2

Max. ampere demand L2 4 A/kA

3 3

A3

Max. ampere demand L3 4 A/kA

Displayed readings for all electrical quantities except Min/Max log are sliding

average values.

Voltage and current readings with a decimal point are displayed in kV and

kA. When the value width exceeds the window resolution, the right-most

digits are truncated.

When the 4LN3 or 3LN3 wiring mode is selected, the voltages will be line-to-

neutral; for any other wiring mode, they will be line-to-line voltages.

Displayed only in the 4LN3 or 3LN3 wiring mode.

' L' and ' P' indicators appear only in the case of 4LN3 or 3LN3 wiring

modes where both line-to-line and line-to-neutral voltages are present.

Chapter 5 Data Display

36

Table 5-2 Displayed Parameters for the PM130P/PM130E

Page Window Indicator

LED

Parameter

Digits Unit

Common Measurements

1 1

V1/V1-2

Voltage L12 4 V/kV

1 2

V2/V2-3

Voltage L23 4 V/kV

1 3

V3/V3-1 L. Voltage L31

4 V/kV

2 1

V1/V1-2

Voltage L1 4 V/kV

2 2

V2/V2-3

Voltage L2 4 V/kV

2 3

V3/V3-1 P. Voltage L3

4 V/kV

3 1

A1

Current L1 4 A/kA

3 2

A2

Current L2 4 A/kA

3 3

A3

Current L3 4 A/kA

4 1

kVA

Total kVA 4 kVA/MVA

4 2

PF

Total power factor 4

4 3

kW

Total kW 4 kW/MW

5 1

A NEUT

Neutral current 4 A/kA

5 2

Hz

Frequency 4 Hz

5 3

kvar

Total kvar 4 kvar/Mvar

6 1

Ph.L1

Label

6 2

PF

Power factor L1 4

6 3

kW

kW L1 4 kW/MW

7 1

kVA

kVA L1 4 kVA/MVA

7 2

Ph.L1

Label

7 3

kvar

kvar L1 4 kvar/Mvar

8 1

Ph.L2

Label

8 2

PF

Power factor L2 4

8 3

kW

kW L2 4 kW/MW

9 1

kVA

kVA L2 4 kVA/MVA

9 2

Ph.L2

Label

9 3

kvar

kvar L2 4 kvar/Mvar

10 1

Ph.L3

Label

10 2

PF

Power factor L3 4

10 3

kW

kW L3 4 kW/MW

11 1

kVA

kVA L3 4 kVA/MVA

11 2

Ph.L3

Label

11 3

kvar

kvar L3 4 kvar/Mvar

12 1

U.Unb

Label

12 3

Voltage unbalance 4 %

13 1

C.Unb

Label

13 3

Current unbalance

4 %

Chapter 5 Data Display 37

Page Window Indicator

LED

Parameter

Digits Unit

Min/Max Measurements

MIN

1 1

V1/V1-2

Min. real-time voltage

L1/L12

4 V/kV

1 2

V2/V2-3

Min. real-time voltage

L2/L23

4 V/kV

1 3

V3/V3-1

Min. real-time voltage

L3/L31

4 V/kV

2 1

A1

Min. real-time current L1 4 A/kA

2 2

A2

Min. real-time current L2 4 A/kA

2 3

A3

Min. real-time current L3 4 A/kA

3 1

kVA

Min. real-time total kVA 4 kVA/MVA

3 2

PF

Min. real-time total power

factor

4

3 3

kW

Min. real-time total kW 4 kW/MW

4 1

A NEUT

Min. real-time neutral

current

4 A/kA

4 2

Hz

Min. real-time frequency 4 Hz

4 3

kvar

Min. real-time total kvar 4 kvar/Mvar

MAX

5 1

V1/V1-2

Max. real-time voltage

L1/L12

4 V/kV

5 2

V2/V2-3

Max. real-time voltage

L2/L23

4 V/kV

5 3

V3/V3-1

Max. real-time voltage

L3/L31

4 V/kV

6 1

A1

Max. real-time current L1 4 A/kA

6 2

A2

Max. real-time current L2 4 A/kA

6 3

A3

Max. real-time current L3 4 A/kA

7 1

kVA

Max. real-time total kVA 4 kVA/MVA

7 2

PF

Max. real-time total power

factor

4

7 3

kW

Max. real-time total kW 4 kW/MW

8 1

A NEUT

Max. real-time neutral

current

4 A/kA

8 2

Hz

Max. real-time frequency 4 Hz

8 3

kvar

Max. real-time total kvar 4 kvar/Mvar

MAX DMD

9 1

V1

Max. volt demand L1/L12 4 V/kV

9 2

V2

Max. volt demand L2/L23 4 V/kV

9 3

V3

Max. volt demand L3/L31 4 V/kV

Chapter 5 Data Display

38

Page Window Indicator

LED

Parameter

Digits Unit

10 1

A1

Max. ampere demand L1 4 A/kA

10 2

A2

Max. ampere demand L2 4 A/kA

10 3

A3

Max. ampere demand L3 4 A/kA

11 1

kVA

Max. sliding window kVA

demand

4 kVA/MVA

11 2

PF

Power factor at max. kVA

demand

4

11 3

kW

Max. sliding window kW

demand

4 kW/MW

Total Energies

1 1

MWh Ac.En.

Label

1 2

IP.

Label

1 3

MWh import 5 MWh

2 1

Mvarh rE.En.

Label

2 2

IP.

Label

2 3

Mvarh import 5 Mvarh

3 1

MVAh AP.En.

Label

3 3

MVAh 5 MVAh

4 1

MWh Ac.En.

Label

4 2

EP.

Label

4 3

MWh export 5 MWh

5 1

Mvarh rE.En.

Label

5 2

EP.

Label

5 3

Mvarh export 5 Mvarh

Phase Energies

6 1

MWh Ac.En.

Label

6 2

IP.L1

Label

6 3 MWh import L1 5 MWh

7 1

Mvarh rE.En.

Label

7 2

IP.L1

Label

7 3 Mvarh import L1 5 Mvarh

8 1

MVAh AP.En.

Label

8 2

L1

Label

8 3 MVAh L1 5 MVAh

9 1

MWh Ac.En.

Label

9 2

IP.L2

Label

9 3 MWh import L2 5 MWh

10 1

Mvarh rE.En.

Label

10 2

IP.L2

Label

10 3 Mvarh import L2

5 Mvarh

E

E

E

E

Chapter 5 Data Display 39

Page Window Indicator

LED

Parameter

Digits Unit

11 1

MVAh AP.En.

Label

11 2

L2

Label

11 3 MVAh L2 5 MVAh

12 1

MWh Ac.En.

Label

12 2

IP.L3

Label

12 3 MWh import L3 5 MWh

13 1

Mvarh rE.En.

Label

13 2

IP.L3

Label

13 3 Mvarh import L3 5 Mvarh

14 1

MVAh AP.En.

Label

14 2

L3

Label

14 3 MVAh L3 5 MVAh

Display readings for all electrical quantities except Min/Max log and

energies are sliding average values.

Voltage and current readings with a decimal point are displayed in kV and

kA. Power readings with a decimal point are displayed in MW, Mvar, and

MVA. When the value width is over the window resolution, the right most

digits are truncated.

By default, the maximum range for energy readings is 99,999,999

MWh/Mvarh/MVAh. Beyond this value, the reading will roll over to zero.

When the energy reading exceeds the window resolution, the right-most

digits are truncated. To avoid truncation, you can change the energy roll

value to lower limit via the User Selectable Options menu (see Section

4.7). Negative (exported) energy readings are displayed without a sign.

Per phase power and power factor readings are displayed only in

4LN3/4LL3 and 3LN3/3LL3 wiring modes (see Section 4.1) if the phase

powers display is enabled in the Display Setup menu (see Section 4.6).

Phase energy readings are displayed only in 4LN3/4LL3 and 3LN3/3LL3

wiring modes if they are enabled in the User Selectable Options menu (see

Section 4.7).

When the 4LN3 or 3LN3 wiring mode is selected, the voltages will be line-

to-neutral; for any other wiring mode, they will be line-to-line voltages.

Displayed only in the 4LN3 or 3LN3 wiring mode.

5.3 Self-Test Diagnostics Display

The PM130 periodically performs self-test diagnostics during

operation. If the instrument fails the test, it discards the last

measurement results, and an error code is displayed for one

second on all LEDs. Error codes are listed in Table 5-3. Code ‘8’

indicates normal operation.

available in the PM130E

E

Chapter 5 Data Display

40

Frequent failures may be the result of excessive electrical noise in

the region of the instrument. If the instrument continuously resets

itself, contact your local distributor.

Table 5-3 Self-Test Diagnostic Codes

Code Meaning

1 ROM error

2 RAM error

3 Watch dog timer reset

4 Sampling failure

5 Out of control trap

7 Timing failure

8 Normal power up

9 External reset (warm restart)

NOTE

The PM130 provides a self-check alarm register accessible through

communications that indicates possible problems with instrument

hardware or setup configuration. The hardware problems are indicated

by the appropriate bits which are set whenever the instrument fails selftest diagnostics or in the event of loss of power. The setup

problems are

indicated by the dedicated bit which is set when either configuration

register is corrupted. In this event, your instrument will use the default

configuration. For more information on the self-check alarm register, refer

to the communications reference guides provided with your instrument.

Chapter 6 Viewing Status Information 41

Chapter 6 Viewing Status

Information

6.

Through the Status Information Menu (STA), it is possible to view the

status of various instrument features.

6.1 The Status Information Menu

To enter the Status Information Menu:

From the display mode, press to enter the Primary

Selection Menu.

Press to activate the StA window.

Press .

To select a display page:

Press the up/down arrow keys to scroll through the display

pages.

To quit the menu and return to the display mode:

Press or .

Front Panel Display

When you are in the Status Information Menu, the front panel

display is updated approximately four times per second and shows

you a wide variety of status information that you can review by

scrolling through display pages.

The status parameters are designated by the abbreviated labels in

the upper and/or middle window. The upper window flashes,

indicating that you are in the menu display.

Viewing and Clearing Alarms

Whenever a setpoint signals an alarm, it is latched to non-volatile

memory and remains when the alarm condition disappears.

Alarms which have occurred can be inspected and cleared all

together through the Status Information Menu. When a number of

alarms are present, use the up and down keys to scroll through all

alarms.

To clear alarms:

From the Status Information Menu, select either display page

where an alarm is displayed.

SELECT

StA

ENTER

SELECT

SELECT

ENTER

ENTERESC

Chapter 6 Viewing Status Information

42

While holding the key, press and hold for

about 5 seconds until the alarm trigger code displayed in the

lower window changes to "none".

Fast Reset of Counters

When changing data via the front panel is not secured by a

password, you can reset the counters from the Status Information

Menu display without entering the reset menu:

Select the page where the counter you want to reset is displayed.

While holding the key, press and hold for

about 5 seconds. The displayed data is reset to zero.

6.2 Status Display Formats

Table 6-1 lists all the displays available from the Status

Information Menu. The display windows are labeled in the table as

follows: 1 = upper window, 2 = middle window, 3 = lower window.

Table 6-1 Status Information

Page Window Parameter Digits Unit

1 1

PHAS

Label

1 2

rOt

Label

1 3 Phase rotation sequence

(POS/NEG/ERR)

4

2 1

rEL

Label

2 3 Relay status 1

3 1

Cnt.1

Label

3 3 Counter #1 5

4 1

Cnt.2

Label

4 3 Counter #2 5

5 1

Cnt.3

Label

5 3 Counter #3 5

6 1

Cnt.4

Label

6 3 Counter #4 5

7 1

Port

Label

7 2

rd. Receiver status (flashing r

while receiving data)

1

7 3

td. Transmitter status (flashing t

while transmitting data)

1

8 1

Alar

Label

8 2

SP. Alarm setpoint number

4

8 3 Alarm trigger code (see Table 4-5) 5

P E

SELECT

ENTER

SELECT

ENTER

available in the PM130P

P

available in the PM130E

E

Appendix: Technical Specifications 43

Appendix: Technical Specifications

7. ions

Input and Output Ratings

3 voltage

inputs

690 V:

(standard)

DIRECT INPUT - Nominal: 690V line-to-line

voltage, 790V maximum; 400V line-to-neutral,

460V maximum - Burden: <0.5 VA

INPUT USING PT - Burden: <0.15 VA

120 V:

(optional)

INPUT USING PT - Nominal: 120V line-to-line

voltage, 144V maximum - Burden: <0.1 VA

3 current

inputs

5A:

(standard)

(galvanically

INPUT VIA CT with 5A secondary output

Burden: 2.5 to 4 mm

2

(13-11 AWG) wire from CT

Overload withstand: 15A RMS continuous, 250A

RMS for 1 second

isolated)

1A:

(optional)

INPUT VIA CT with 1A secondary output

Burden: 2.5 to 4 mm

2

(13-11 AWG) wire from CT

Overload withstand: 3A RMS continuous, 50A

RMS for 1 second

Voltage input terminals

UL recognized E129258

Maximum wire section: 4 mm

2

(10 AWG)

Optically isolated

communication port

EIA RS-485 standard

Maximum wire section: 2.5 mm

2

(12 AWG)

Relay output

Relay rated at 3A, 250 V AC / 3A, 30 V DC /

0.5A, 110 V DC

Maximum wire section: 1.5 mm

2

(14 AWG)

2 contacts (SPST Form A)

Display

3 windows high-brightness 7-segment digit LEDs

3 color LED bar graph 40-110%

Power Supply

Galvanically isolated

power supply (factory

set) 120 or 230 V AC

Maximum wire section: 1.5 mm

2

(14 AWG)

88-138V AC or 176-265V AC; 50/60 Hz;

Burden: 5 VA

Environmental Conditions

Operating temperature

-20°C to +60°C (-4°F to +140°F)

Storage temperature

-25°C to +80°C (-13°F to +176°F)

Humidity

0 to 95% non-condensing

Appendix: Technical Specifications

44

Construction

Instrument

body

Case enclosure: flame resistant ABS & Polycarbonate

blend

Dimensions: 114.3

x 114.3 x 109 mm ( 4.5 x 4.5 x 4.29 “)

Mounting: 4-inch round or 92x92mm square cut-out

Instrument

weight

0.70 kg (1.54 lb.)

Standards Compliance

UL File # E129258

CE-EMC: 89/336/EEC as amended by 92/31/EEC and 93/68/EEC

CE-LVD: 72/23/EEC as amended by 93/68/EEC and 93/465/EEC

Harmonized standards to which conformity is declared:

EN55011:1991; EN50082-1:1992; EN61010-1:1993; A2/1995

EN50081-2:1994 EMC Generic Emission Standard - Industrial

Environment

EN50082-2:1995 EMC Generic Immunity Standard - Industrial

Environment

EN55022: 1994 Class A

EN61000-4-2: 1995 Electrostatic Discharge

EN61000-4-4: 1995 Electrical Fast Transient

EN61000-4-8: 1993 Power Frequency Magnetic Field

ENV50140: 1993 Radio Frequency Electromagnetic Field, Amplitude

Modulated

ENV50204: 1995 (200Hz) Radio Frequency Electromagnetic Field, Pulse

Modulated

ENV50141: 1993 Radio Frequency Common Mode, Amplitude Modulated

ANSI C37.90.1: 1989 Surge Withstand Capability

ANSI C62.41 - 1991 Standard Surge

Appendix: Technical Specifications 45

Measurement Specifications

Accuracy, % Range Display resolution (%Rdg)

Parameter Full scale Rdg FS Conditions

@

range

Voltage

120V

×PT

@ 120V

400V×PT

@ 690V

208V

×PT

@ 120V

690V

×PT

@ 690V

0.3 10% to 120% FS 0 to 999,000 V

1 V @ 1V to 9,999 V

≤0.1%

@

10,000 V to 999,000 V

Starting voltage 1.5% FS

Line current

CT PRIMARY CURRENT 0.3 2% to 150% FS 0 to 60,000 A

1 A @ 1A to 9,999 A

≤0.1%

@

10,000 A to 60,000 A

Starting current 0.75% FS

Active power

0.36

×PT×CT @ 120V input

1.2

×PT×CT @ 690V input

0.5

|PF| ≥ 0.5

-2,000,000 to

+2,000,000 kW

1 kW @ 1kW to 9,999 kW

≤0.1%

@

10 MW to 2,000 MW

Reactive power

0. 36

×PT×CT @ 120V input

1.2

×PT×CT @ 690V input

0.5

|PF| ≤ 0.9

-2,000,000 to

+2,000,000 kvar

1 kvar @ 1kvar to 9,999 kvar

≤0.1%

@

10 Mvar to 2,000 Mvar

Apparent power

0. 36

×PT×CT @ 120V input

1.2

×PT×CT @ 690V input

0.5

|PF| ≥ 0.5

0 to

2,000,000 kVA

1 kVA @ 1kVA to 9,999 kVA

≤0.1%

@

10 MVA to 2,000 MVA

Power factor

1 1

|PF| ≥ 0.5,

U ≥ 10% FSU

I ≥ 10% FSI

-0.999 to +1.000 0.001

Frequency

0.1 45.00 to 65.00 Hz 0.01 Hz

For Ln reading

and for

3OP2/3OP3

wiring

modes

For LL

reading except

3OP2/3OP3

wiring modes

Appendix: Technical Specifications

46

Accuracy, % Range Display resolution (%Rdg)

Parameter Full scale Rdg FS Conditions

@

range

Neutral

(unbalanced)

current

CT PRIMARY CURRENT 0.6 2% to 150% FS 0 to 60,000 A

1 A @ 1A to 9,999 A

≤0.1%

@

10,000 A to 60,000 A

Ampere demand same as for current

kW demand (block & sliding) same as for kW

kVA demand (block & sliding ) same as for kVA

Active energy

Import & Export

according to power accuracy

0 to 99,999 MWh

1 kWh @ 1 to 99,999 kWh

10 kWh

@

100.00 to 999.99

MWh

100 kWh

@

1000.0 to 9999.9

MWh

1MWh @ 10.0 to 99.99 GWh

Reactive energy

Import & Export

according to power accuracy

0 to 99,999 Mvarh

1 kvarh @ 1 to 99,999 kvarh

10 kvarh

@

100.00 to 999.99

Mvarh

100 kvarh

@

1000.0 to 9999.9

Mvarh

1Mvarh @ 10.000 to 99.999

Gvarh

Apparent energy

according to power accuracy

0 to 99,999 MVAh

1 kVAh @ 1 to 99,999 kVAh

10 kVAh

@

100.00 to 999.99

MVAh

100 kVAh

@

1000.0 to 9999.9

MVAh

1MVAh @ 10.000 to 99.999

GVAh