expertmeter™

High Performance Analyzer

PM180

SATEC PM180 PLC Configurator

Reference Guide

BG0611 REV.A1

2

Every effort has been made to ensure that the material herein is complete and accurate.

However, the manufacturer is not responsible for any mistakes in printing or faulty

instructions contained in this book. Notification of any errors or misprints will be received

with appreciation.

For further information regarding a particular installation, operation or maintenance of

equipment, contact the manufacturer or your local representative or distributor.

REVISION HISTORY

A1

Jan 2018

Initial release

All trademarks are property of their respective owners

February 2018

Copyright 2017-2018 SATEC Ltd.

3

Table of Contents

1 GENERAL........................................................................................................... 5

2 IEC61131 IMPLEMENTATION ........................................................................... 6

2.1 Limitations.............................................................................................................................. 6

2.2 Data types.............................................................................................................................. 6

2.3 Built-in functions .................................................................................................................... 7

2.3.1 AND ................................................................................................................... 7

2.3.2 OR ..................................................................................................................... 7

2.3.3 NOT ................................................................................................................... 7

2.3.4 GE...................................................................................................................... 8

2.3.5 EQ...................................................................................................................... 8

2.3.6 LE 8

2.3.7 GE_THRESHOLD .................................................................................................. 8

2.3.8 LE_THRESHOLD ................................................................................................... 8

2.3.9 TON ................................................................................................................... 9

2.3.10 TOF ............................................................................................................. 9

2.4 Function block ....................................................................................................................... 9

2.5 Implemented languages ........................................................................................................ 9

2.5.1 Functional block diagram .................................................................................... 10

2.5.2 Ladder diagram.................................................................................................. 10

3 PROGRAMMING GUIDE .................................................................................. 13

3.1 Getting started .....................................................................................................................13

3.2 Creating project ...................................................................................................................13

3.3 Adding devices ....................................................................................................................15

3.4 Device properties .................................................................................................................16

3.5 Main function block ..............................................................................................................17

3.6 Adding function blocks .........................................................................................................17

3.7 Setting function blocks .........................................................................................................18

3.7.1 Rename FB ........................................................................................................ 18

3.7.2 Add variables ..................................................................................................... 19

3.7.3 Variable properties ............................................................................................. 19

3.7.4 Add work area ................................................................................................... 23

3.7.5 Debug FB .......................................................................................................... 23

3.7.6 Delete FB .......................................................................................................... 24

3.8 Communication with the device ...........................................................................................24

3.8.1 Interfaces ......................................................................................................... 24

3.8.2 Upload configuration to the device ....................................................................... 26

3.8.3 Download configuration from the device ................................................................ 29

3.9 Functional block diagrams ...................................................................................................32

3.9.1 Open workspace ................................................................................................ 32

3.9.2 Add or delete variables ....................................................................................... 33

3.9.3 Variable properties ............................................................................................. 34

3.9.4 Add built-in components ..................................................................................... 34

3.9.5 Making connections ............................................................................................ 35

3.9.6 Making time delays ............................................................................................ 37

3.9.7 Programming limits for set point variables ............................................................. 38

3.10 Ladder diagrams ..................................................................................................................41

3.10.1 Add ladder diagram ..................................................................................... 41

3.10.2 Rails .......................................................................................................... 42

3.10.3 Contact ...................................................................................................... 42

3.10.4 Negated contact .......................................................................................... 42

3.10.5 Coil ............................................................................................................ 43

3.10.6 Negated coil................................................................................................ 43

4

3.10.7 Creating LD ................................................................................................ 43

3.10.8 Transformation LD into setpoints ................................................................... 47

3.11 Using PLC Configurator with PAS .......................................................................................47

4 TROUBLESHOOTING ...................................................................................... 49

4.1 Address in not set ................................................................................................................49

4.2 Connection error ..................................................................................................................49

4.3 No MAIN module .................................................................................................................50

4.4 Unconnected inputs .............................................................................................................51

5

1 General

This document specifies a subset of the IEC 61131 standard,

particularly part 3 that deals with the languages used to program

controllers. The document provides complete information necessary to

use SATEC PM180 PLC Configurator (hereinafter referred to as PLC

Configurator) in order to program the PM180 device using Functional

block diagrams (FBD) and Ladder diagrams (LD) and to communicate

with the device. Refer to the PM180 Installation Manual and PM180

Operation Manual for more information on communication connections

and configuring communication parameters in your device.

6

2 IEC61131 Implementation

IEC61131 is the standard relating to programmable controllers. Part 3

of this standard deals with the languages used for programming these

devices and is commonly referred as IEC61131-3. SATEC PM180 PLC

Configurator implements IEC61131-3 in order to create logic for PM180

devices.

IEC 61131-3 support is limited so that programmable controller system

configuration could be compiled to PM180 Setpoints.

2.1 Limitations

Limitations of IEC 61131-3 support are the following:

Programmable controller system configuration is limited to one task

executed at 20ms interval (PM180 hardware limitation). Any

program organization unit could be attached to this task.

Special (nonstandard) *_THRESHOLD functions are used to model

analogue values comparison functions of PM180 Setpoints.

2.2 Data types

Data types implemented in PLC Configurator are listed in the table

below.

Data type

Description

BOOL

Bit string of 1 bit. Logical state, values are FALSE and TRUE.

LREAL

Long real value (64 bit) ±10

±308

,

values are from +/-4.19E-307 to +/-1.67E+308.

TIME

Time duration in milliseconds,

values are from -T#24d20h31m23s648ms to

+T#24d20h31m23s647ms

DATE

Date format, values are from D#1-1-1 to D#65000-12-31,

Gregorian

For the PM180 device refers to the Packed date data type.

TOD

Time of Day format, values are from TOD#00:00:00.000 to

TOD#23:59:59.999

For the PM180 device refers to the Packed time data type.

DT

Date Time format combines DATE and TOD.

For the PM180 device refers to the Timestamp data type.

DP

Double point value. There are four possible values:

intermediate state (IS)

off state (OFF)

on state (ON)

bad state (BS)

7

2.3 Built-in functions

Functions are a type of Program Organization Unit. They are small

reusable units that form the fundamental building blocks of complex

industrial control programs. The implementation contains several builtin functions that are supported by PM180 devices. They are listed in the

table below.

Function

abbreviation

Function name

Inputs

data

type

Outputs

data type

Logical operations

AND

AND

ANY_BIT

ANY_BIT

OR

OR

ANY_BIT

ANY_BIT

NOT

NOT

ANY_BIT

ANY_BIT

GE_THRESHOLD

Greater or equal with threshold

LREAL

BOOL

LE_THRESHOLD

Less or equal with threshold

LREAL

BOOL

GE

Greater or equal

ANY

BOOL

EQ

Equal

ANY

BOOL

LE

Less or equal

ANY

BOOL

Time delays

TON

Timer ON

BOOL,

Time

BOOL

TOF

Timer OFF

BOOL,

Time

BOOL

2.3.1 AND

AND function returns result of all inputs using logical conjunction.

Number of inputs is not limited.

AND function is shown in the figure below.

Figure 1 - AND

2.3.2 OR

OR function returns result of all inputs using logical disjunction. Number

of inputs is not limited.

OR function is shown in the figure below.

Figure 2 - OR

2.3.3 NOT

NOT function returns result of one input using logical inversion.

NOT function is shown in the figure below.

8

Figure 3 - NOT

2.3.4 GE

GE function returns TRUE if input IN1 greater or equal to IN2.

GE function is shown in the figure below.

Figure 4 - GE

2.3.5 EQ

EQ function returns TRUE if input IN1 equal to IN2.

EQ function is shown in the figure below.

Figure 5 - EQ

2.3.6 LE

LE function returns TRUE if input IN1 less or equal to IN2.

LE function is shown in the figure below.

Figure 6 - LE

2.3.7 GE_THRESHOLD

GE_THRESHOLD function returns TRUE if input IN greater or equal to

OPERATE and returns FALSE if input IN less or equal to RELEASE.

In this function IN is a value input, OPERATE and RELEASE are inputs to

set threshold. Usually to set threshold locale variables are used.

GE_THRESHOLD function is shown in the figure below.

Figure 7 - GE_THRESHOLD

2.3.8 LE_THRESHOLD

LE_THRESHOLD function returns TRUE if input IN less or equal to

OPERATE and returns FALSE if input IN greater or equal to RELEASE.

In this function IN is a value input, OPERATE and RELEASE are inputs to

set threshold. Usually to set threshold locale variables are used.

9

LE_THRESHOLD function is shown in the figure below.

Figure 8 - LE_THRESHOLD

2.3.9 TON

TON function is used for making time delays.

TON function returns TRUE if input IN changes from FALSE to TRUE with

the delay set via input PT.

In this function IN is control input (BOOL), input PT is used for setting

time delay in milliseconds.

TON function is shown in the figure below.

Figure 9 - TON

2.3.10 TOF

TOF function is used for making time delays.

TOF function returns FALSE if input IN changes from TRUE to FALSE

with the delay set via input PT.

In this function IN is control input (BOOL), input PT is used for setting

time delay in milliseconds.

TOF function is shown in the figure below.

Figure 10 - TOF

2.4 Function block

Function Block (FB) is a type of Program Organization Unit. It has set of

input variables and output variables. Each block has an algorithm,

which enables evaluation of all its inputs and produces set of output

values. Unlike functions, function blocks also have temporary variables,

which store intermediate values during its evaluation. The execution of

a function block can also depend on its own output in a previous

instance of execution.

Function block can include build-in functions.

2.5 Implemented languages

There are two graphical languages implemented in PLC Configurator:

Function Block Diagram (FBD).

Ladder Diagram (LD).

10

2.5.1 Functional block diagram

Function Block Diagram (FBD) is a programming language defined in

IEC61131-3. FBD is a graphical representation of an Industrial

programmed control system and adopts a set of symbols and

conventions defined in IEC-1131-3. It represents a control system in

terms of signal flow between processing elements similar to the

methodology adopted for signal flow in electronic circuits. By using

interconnected graphical blocks, it expresses the behavior of functions,

function blocks and a composite program.

An example of FBD is shown in the figure below.

Figure 11 – FBD

You can find detailed information about creating FBD in PLC

Configurator in chapter 3.9.

2.5.2 Ladder diagram

Ladder Diagram (LD) is a programming language defined in IEC61131-

3. Ladder diagrams are derived from electrical circuit diagrams, which

have been conventionally used to represent relay logic operations. Many

of the symbols and terminology have also been adopted from the circuit

diagrams. In other words, Ladder Diagrams are graphical

representations of Boolean expressions, but they can also include other

information normally not possible with Boolean expressions.

A ladder diagram has two vertical power rails, one on the left and

another on the right side of the diagram. The left vertical rail carries the

power to the coil (notionally) through the contacts. The contacts are

arranged along horizontal 'rungs' and the power flows through these

rungs to energize the coil, which is on the right hand side of the logic

diagram, when the logic condition represented by the contacts is TRUE

11

(AND logic). Alternative paths can be present with other contacts in

them (in parallel), which can be used to build OR logic.

An example of ladder diagram is shown in the figure below.

Figure 12 - LD

Basic concepts of LD implemented in PLC Configurator are the following:

There are two rails: left rail (so called “+” rail) and right rail (so

called “-” rail).

Between rails can be contacts and one coil. They are situated along

horizontal so called “rung”.

Contacts represent BOOL input variables, whereas coils represent

BOOL output variables.

There are two types of contacts and coils: normally closed and

normally opened.

Serial connection of contacts is used to create AND logic.

Parallel connection of contacts is used to create OR logic.

If all the contacts on the way from the left rail to a coil are closed,

the coil is energized and its state is TRUE.

Coils can have their own contacts like shown in the figure below.

12

Figure 13 – Coil’s contact

To create more complex logic it is possible to add built-in functions

and variables of other from BOOL data types.

Figure 14 - Using TON function in LD

You can find detailed information about creating LD in PLC Configurator

in chapter 3.10.

13

3 Programming guide

3.1 Getting started

Before starting PLC Configurator, be sure you have installed Java 8 64

bit on Windows 7 and above (64 bit versions only).

To start PLC Configurator:

1. Unzip the archive with the application in any folder.

2. Run file “bin/scadastudio.exe”.

3.2 Creating project

To create new project:

1. Start PLC Configurator application.

2. In the application, choose File -> New Project, like shown in the

figure below.

Figure 15 - File menu

3. In the New Project wizard, expand the SATEC category and select

SATEC PLC Project like shown in the figure below. Then click Next.

14

Figure 16 - Project choosing

4. In the Name and Location page of the wizard, do the following (like

shown in the figure below):

In the Project Name field type project name.

To setup project location click on Browse... button or type it in

the Project location field.

Figure 17 - Name and Location

5. Click Finish.

After that the project will be created and opened in PLC Configurator.

You should see the following components:

15

Figure 18 - Created project

3.3 Adding devices

To add new devices do following:

1. Click the right mouse button on the existing project.

Figure 19 - Add device menu

2. Select Device and Language in the “Add a new device” window and

click Ok.

Choose the type of diagram you want to use (Language):

16

FBD (Function Block Diagram).

LD (Ladder Diagram).

Figure 20 - Device properties

After that you will see a newly created device in the project tree.

Figure 21 - Created device in the project

3.4 Device properties

To open device properties double-click on a device in the project tree.

The properties will appear in the middle of the screen:

Figure 22 - Device properties

You can set the following settings:

1. “Release coefficient in comparison operations” – for details see

3.9.7.

17

2. “Settings range for the logic generator” – here you can set the

range of set points that will be used on the PM180 device, during

automatic logic generation. For detailed information see 3.11.

3.5 Main function block

A newly created device contains one function block named MAIN.

Figure 23 - Main function block

Main function block must be in every device. This block is sent to the

device when you use function “Send configuration to the device” (see

3.8.2). If you don’t have main function block in your device you will get

an error (see 4.3).

Note that if you add new function blocks to the device (see 3.6) you

have to use them in the Main function block otherwise that logic will be

ignored during uploading procedure.

3.6 Adding function blocks

To add additional function (FB) block do the following:

1. Click the right mouse button on the section “Programmable logic”

of the device and choose “New function block”.

Figure 24 - Add new function block

2. A new block named “POU” will appear in the project tree.

18

3.7 Setting function blocks

3.7.1 Rename FB

To rename FB click the right mouse button on FB in the project tree and

choose “Rename”.

Figure 25 - Rename FB

Type the new name in appeared window like shown in the figure below

and click OK.

Figure 26 - FB new name

In the following window confirm your action and click Ok.

The FB will be renamed.

19

3.7.2 Add variables

To add variables click the right mouse button on one of the following

sections depending on the type of variable you want to add:

1. Input variables.

2. Output variables.

3. Local variables.

Context menu will appear like shown in the figure below:

Figure 27 - Adding variables

In the menu choose the desired type of variable and click on it with the

left mouse button. A new variable will be added.

You can use the same input or local variable many times on the

same diagram. It can simplify visual perception of your project.

3.7.3 Variable properties

When you click on a variable in a FB tree its properties appear on the

right hand side of PLC Configurator (by default) like shown in the figure

below.

20

Figure 28 - Variable properties

You can set properties using Properties component.

There are following properties:

1. Name – name of a variable.

2. Type – type of a variable. Cannot be changed.

3. Initial value – a value that variable has before it is changed due to

signal flow.

4. Address – mapping variables to the PM180 internal variables such

as digital inputs, relay outputs, set points, etc. Local variables

don’t have such setting.

Please note that in order to operate on the PM180 device every

input and output variable of FB must be mapped to the device internal

variables otherwise you will get a message “Variable address is not set”

during uploading the configuration to the device.

Be advised that PLC Configurator automatically distributes set points

according to the device property “Settings range for the logic

generator”. To set this setting, see 3.4. We discourage you from

mapping output variables to set points, because PLC Configurator does

it automatically anyway. In case of manual mapping output variables to

set points you can get errors concerning execution sequence of function

blocks. In other words, logic that you made in PLC Configurator can be

executed in a different way on the device and the result that you get

will be different.

To set the address, click on icon in the Address setting. Depending

on the type of variable one of the following windows will appear:

21

Figure 29 - Input variables mapping

22

Figure 30 - Output variable mapping

For input variables set an internal device signal that will be a source of

input variable (digital input, relay output, event flag, etc.).

For output signal set an action that will be accomplish when the input

has the proper value.

In any case you should expand desired folder and choose variable you

want to map and then click on Ok.

Please note that you can choose addresses with corresponding type

only, other addresses in the «Setup variable address» are marked in

23

grey color and unavailable for choosing like shown in the figure below.

Variable’s type is shown in the Properties window.

Figure 31 - Variables with unsupported types

The chosen internal variable will appear in the Address setting.

You can rename or delete properties using its context menu.

Figure 32 - Variable context menu

3.7.4 Add work area

To add additional work area click on FB with the right mouse button and

choose one of the following options, depending on the diagram you are

using on the device:

1. Add work area (FBD).

2. Add work area (LD).

New work area will be added and will appear in the FB tree.

3.7.5 Debug FB

Debugger is used if you want to check the logic of FB that you created

or search for mistakes.

To debug FB choose Debug in the context menu of FB. Debugger will

appear like shown in the figure below:

24

Figure 33 - Debugger

You can set input or local variables by clicking on them with the left

mouse button.

When you press button, output values will appear on the lines

corresponding to output variables like shown in the figure below.

Figure 34 - Debug result

3.7.6 Delete FB

To delete FB click on FB with the right mouse button and choose Delete

option. Confirm your action in the following window pressing “OK”. The

FB will be deleted.

3.8 Communication with the device

3.8.1 Interfaces

PCL Configurator supports communication with PM180 device via USB,

Serial port or Ethernet (TCP/IP).

1. To connect via USB you need to plug in USB cable to PM180 USB

port 1.1.

It uses PM180 MODBUS RTU protocol (12 Mb/s) for fast local

communications and data retrieving.

25

2. To connect via Serial port you need to use serial communication

port COM1 with cable suited for RS232/485.

3. Ethernet connection

26

Ethernet connection option is provided by one 10/100TX Ethernet

communication port on the CPU module. Use RJ45 Cable with "Straight

Through" wiring.

3.8.2 Upload configuration to the device

Before you start, need to create a new project or open the existing one.

In addition, your project must contain at least one device and you PC

must be connected to the PM180 device by any of interfaces.

Before uploading PLC Configurator reads current Ration settings from

the device and evaluates constants that are used in the logic you want

to upload.

Please note that you must set all analog values for variables in SI

units only (V, A, W, etc.), otherwise the logic you upload will be working

incorrectly.

To upload configuration from the device do the following:

1. Click the right mouse button on a device and select “Send

configuration to the device” from padding menu.

27

Figure 35 - Context menu

2. After that you will see the upload page.

Figure 36 – Internet site settings

There are 3 types of communication interfaces.

1. Internet site

To upload using TCP/IP you have to select Internet site radio

button and type in address like this:

IP address:Port

Also you have to know a Slave ID of your destination device.

28

2. Serial Port

To upload via Serial port you need to select Serial port radio button

and set properties to meet the serial port settings of the PM810

device.

Figure 37 – Serial port settings

3. USB port

To upload via USB port you need to select USB port radio button and

type in “Slave ID” of the PM180 device.

Figure 38 - USB port settings

After that, your project will be built and you will see the log page:

29

Figure 39 - Building log

In case of successful uploading you will see “Loading complete”

message in the right bottom corner of the application.

3.8.3 Download configuration from the device

Before you start, you need to create a new project or open the existing

one. In addition, your project must contain at least one device and you

must be connected to the PM180 device by any of interfaces.

To download configuration from a device do the following.

Click the right mouse button on a device and select “Import

configuration from the device” from padding menu.

Figure 40 - Import menu

After that you will see the download page.

30

Figure 41 - Internet page

There are three types of communication interfaces.

1. Internet site

To download via TCP/IP you need to select Internet site radio

button and type in address like this:

IP address:Port

Also you have to know a Slave ID of your destination device.

2. Serial port

To download via Serial port you need to select Serial port radio

button and configure properties to meet the settings.

31

Figure 42 - Serial port

3. USB port

To download via USB port you need to select USB port radio button

and type in “Slave ID” of the PM180 device.

Figure 43 - USB port

After that you will see the log page:

32

Figure 44 - Log page

In case of successful downloading you will see “Loading complete” in

the right bottom corner of the application.

Be advised that the graphical form of the algorithm reconstructed

from the device setpoints reflect the logic of the algorithm, however the

visual display representation may be different from the original one.

3.9 Functional block diagrams

See chapters 2.4 and 2.5.1 of this document to get information about

implementation of function blocks and functional block diagrams in PLC

Configurator.

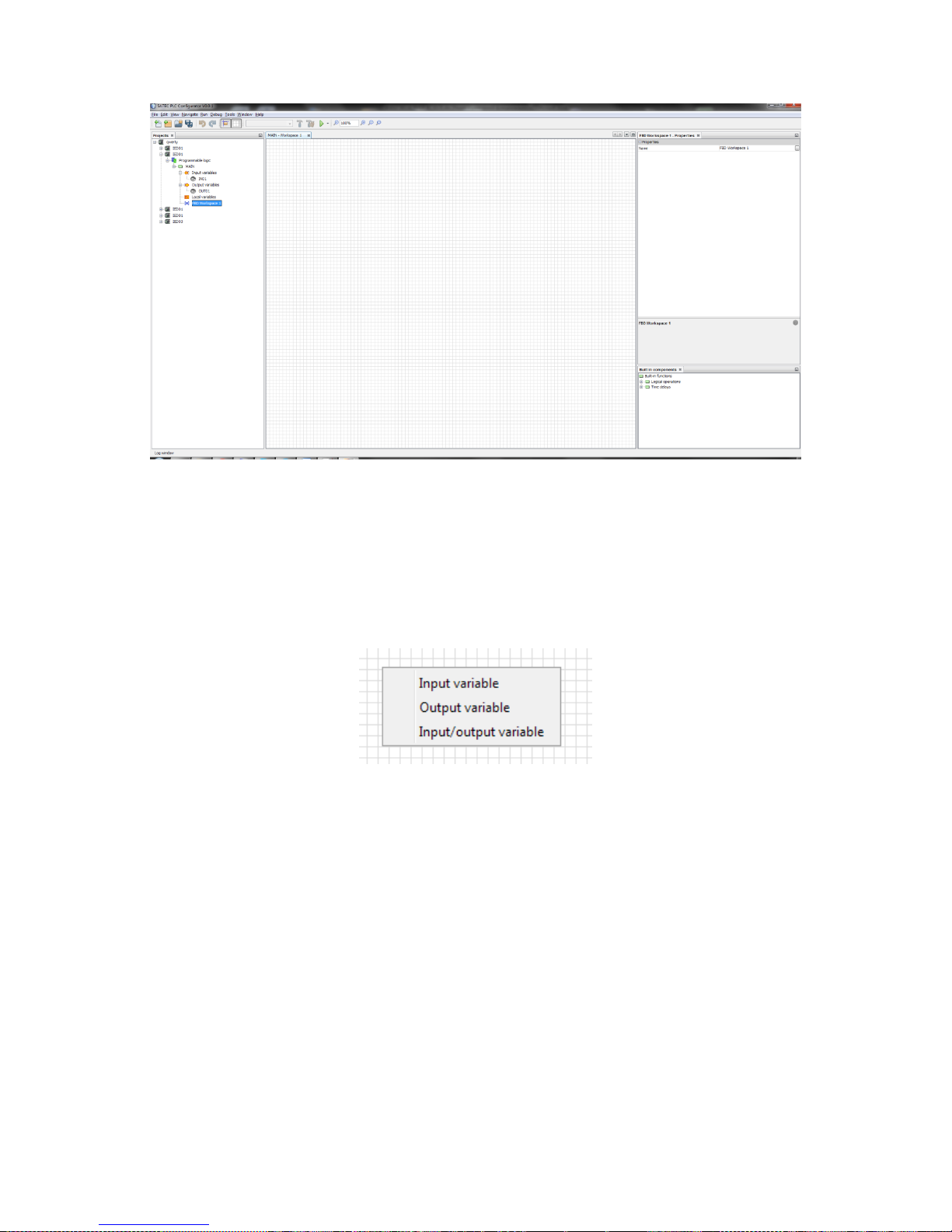

3.9.1 Open workspace

To start creation of FBD you need to open FBD workspace. To do that,

use double-click on workspace section of FB. Workspace will appear in

the middle of the screen like shown in the figure below.

33

Figure 45 - Workspace

3.9.2 Add or delete variables

Before you start to add variables on the workspace, you should add

them to the FB. To do that, see 3.7.2.

To add variable, just drag and drop it to the workspace.

In case of local variable you will get a menu where you need to choose

its type (input, output or input/output variable) like shown in the figure

below.

Figure 46 Type of a local variable

After adding, variables will appear on the workspace.

34

Figure 47 Workspace with variables

To delete variable click on it with the right mouse button and choose

“Delete”.

3.9.3 Variable properties

If you click on a variable that has been added to the workspace, its

properties will appear in the Properties window. They consist of two

parts, like shown in the figure below:

Main properties.

Interface variable properties.

Interface variable properties provide users with the information about

variable’s initial value and address.

3.9.4 Add built-in components

To add built-in functions you need to expand type of function and drag

and drop desired function to the workspace.

35

Figure 48 – Built-in components

After that, components will appear on the workspace.

Figure 49 - Workspace with functions

3.9.5 Making connections

Variables and functions have pins – circles that are used for making

connections. Red pins are not connected, green pins are connected.

Input pins are placed on the left side an element, output pins are placed

on the right side.

To make a connection between a variable and a function, click on an

output pin and drag and drop to the desired input pin.

36

Figure 50 - Connections

If a connection is made the pin will change its color to green and pins

will be linked with an arrow.

Please note that some inputs can be multiple (for example in AND,

OR functions). You can connect unlimited number of inputs there.

Please note that the type of a variable and an input you want to

connect with must be compatible. If they are not, you will not be able to

make a connection between them. You can check type of a pin by

pointing on it with a mouse cursor.

Figure 51 - Pin data type

To disconnect variable click on it with the right mouse button and

choose “Disconnect”.

37

Figure 52 - Disconnect link

After making connections FBD is ready to be uploaded to the device.

Just check that you have set addresses for all variables (see 3.7.3) and

you can proceed to uploading the configuration to the PM180 device

(see 3.8.2).

3.9.6 Making time delays

To make time delays use functions TON and TOF. For detailed

information see 2.3.9 and 2.3.10. Time values are set via local variables

with TIME data type.

Time delay example is shown in the figure below.

Figure 53 - Time delay

Time delay is set in Initial value property in one of these formats (in

accordance with IEC 61131): “T#100ms”, “T#200ms” or “T#1s0ms” (if

a value is more than 1 second).

In the figure below you can see the result of this logic in PAS (after

uploading to the device).

38

Figure 54 - Time delays in PAS

3.9.7 Programming limits for set point variables

There are two standard functions in IEC 61131 that are used for analog

values comparisons: GE and LE. For detailed information about them

see 2.3.4 and 2.3.6.

Be advised that when you use comparison functions you are able to

compare only variables with the same data type (see the figure below).

39

Figure 55 - Comparisons

Limits (particularly release coefficients) aren’t supposed to be used with

these functions. However the PM180 device claims setting these

parameters. To do that, there is a “Release coefficient in comparison

operations” property that you can set via Device properties (see 3.4).

This coefficient has the value range from 0 (exclusively) to 1 (0,95 by

default). When PLC Configurator compiles logic with GE or LE functions,

it multiplies or divides to this coefficient to get operate or release limits.

To set exact (not evaluated) operate or release limits for variables use

functions GE_THRESHOLD and LE_THRESHOLD. For detailed

information about these functions see 2.3.7 and 2.3.8. In this case

limits that are set for these functions compile to operate and release

limits directly.

In the figure below you can see an example of programming limits

using threshold functions.

40

Figure 56 – Using GE_THRESHOLD

In this case limits are set using local variables L01 and L02, IN05 is a

value input.

In the figure below you can see the result setpoint in PAS.

Figure 57 - Setpoint with limits

41

3.10 Ladder diagrams

See chapter 2.5.2 of this document to get basic information about

implementation of ladder diagrams in PLC Configurator.

Basic concepts are similar to creating FBD. We suggest you to read

chapter 3.9 first, then proceed to this chapter.

3.10.1 Add ladder diagram

To create a ladder diagram you need to add a device in your project

and choose LD language in the window shown in the figure below.

Figure 58 - Add new device with LD

If you want to add a ladder diagram to existing function block, just click

with the right mouse button on the function block and choose “Add

work area (LD)”.

Figure 59 - Add work area (LD)

You can use FBD and LD workspaces together in one function block

and divide information between them if it is necessary.

After creating a workspace use double-click on it to open.

A ladder diagram consists of elements such as rails, contacts, coils. Also

it can contain built-in functions (see 2.3).

All elements have pins. Pins can be attached or unattached. Attached

pin are marked as green circle, unattached is marked as red circle.

To add any element to a ladder diagram (excluding rails) you need to

drag-and-drop variable from variables list. Input, output and local

variables are allowed.

42

3.10.2 Rails

There are two power rails: left rail and right rail. Left rail can be

attached to any of variables excluding output variables and to any kind

of coils. Right rail can be attached only to any kind of coils.

Multiple connections are allowed.

You cannot delete rails.

Figure 60 - Rails

3.10.3 Contact

Contact represents a normally open contact. It is closed whenever its

coil or an input which controls it is energized. (Open contact at rest).

It has 2 pins:

Input pin (left pin), that can be attached to left rail output, output

variable, input-output variable, built-in function block contact or

negated contact.

Output pin (right pin) - can be attached to coil, built-in functions,

contact, negated contact or right rail.

Multiple connections are allowed.

Contact can be created from any BOOL variable.

Figure 61 - Contact

3.10.4 Negated contact

Negated contact represents a normally closed ("not") contact. It is

closed whenever its coil or an input which controls it is not energized.

(Closed contact at rest)

It has 2 pins:

Input pin (left pin) - can be attached to left rail output, output

variable, input-output variable, built-in function block contact or

negated contact.

Output pin (right pin) - can be attached to coil, built-in functions,

contact, negated contact or right rail.

Multiple connections are allowed.

Negated contact can be created from any BOOL variable

43

Figure 62 - Negated contact

3.10.5 Coil

Coil represents a normally inactive coil, energized whenever its rung is

closed. (Inactive at rest)

It has 2 pins:

Input pin (left pin) - can be attached to contact, negated contact,

built-in function block, input variable, input-output variable.

Output pin (right pin) – can be attached only to right rail.

Multiple connections are allowed.

Coil can be created only from an output variable or a local variable.

Figure 63 - Coil

3.10.6 Negated coil

Negated coil represents a normally active ("not") coil, energized

whenever its rung is open. (Active at rest)

It has 2 pins:

Input pin (left pin) - can be attached to contact, negated contact,

built-in function block, input variable, input-output variable.

Output pin (right pin) – can be attached only to right rail.

Multiple connections are allowed.

Negated coil can be created only from an output variable or a local

variable.

Figure 64 - Negated coil

3.10.7 Creating LD

Let’s create a simple ladder diagram that contains several contacts and

coils.

To create a contact you need to drag-and-drop a variable to the

workspace.

44

Figure 65 - Add contact

On the appeared menu choose type of the contact, for example

“Normally opened contact”.

Figure 66 – A contact on LD

A contact will be added to a ladder diagram and it will be assigned to

the variable you chose.

Similarly you can add a coil. Just drag and drop an output variable to

the workspace and choose type of the coil you want to add. A coil will

be added to your ladder diagram.

45

Figure 67 - A contact and a coil on LD

Now let’s connect the elements.

To do that, you need to click on the right pin of any element and drag

an arrow from the pin.

Figure 68 - Making connections

Then, drag the arrow to any valid pin, for example, left coil pin.

Now the elements are connected.

46

Figure 69 - Connection made

Let’s finish our rung by connecting other elements.

Figure 70 - A complete rung

Now you can see that when you add more links between rails, the

quantity of pins is being incremented. You are able to make as many

rungs as you like.

Please note that before uploading the configuration to the PM180

device you need to set addresses for all input and output variables. To

do that, see 3.7.3.

47

After that your ladder diagram is ready to be uploaded to the device. To

do that, see 3.8.2.

3.10.8 Transformation LD into setpoints

After uploading you can check the uploaded setpoints in PAS. In the

figure below you can see how a ladder diagram transforms in setpoints

that the PM180 device can use.

Figure 71 - LD logic in PAS

3.11 Using PLC Configurator with PAS

PLC Configurator is only used for setpoints configuration and PAS

should be used for other configuration needs.

48

To create logic on the PM180 devices you can you use PLC Configurator

together with PAS. Some set points can be set via PLC Configurator and

some of them can be set via PAS.

PLC Configurator has a special logic generator which automatically

distributes logic among set points in accordance with a special property

“Settings range for the logic generator” (see 3.4). To set which set

points will be used in this distribution you need to set this property. By

default PLC Configurator uses all set points (1-64). You can set this

range using “-” and “,” symbols like shown in the figure below.

Figure 72 - Settings range

In this case PLC Configurator will be using the first, second set point

and set points between 10 and 16 and between 20 and 30. Other set

points can be programmed via PAS application.

49

4 Troubleshooting

4.1 Address in not set

If you linked a variable on a diagram but didn’t set its address you will

get a message like in the figure below.

Figure 73 - Unknown address

In this case you need to set variables address. To do that, see 3.7.3.

4.2 Connection error

If you have a connection error during uploading or downloading a

configuration you will get a message like shown in the figure below.

50

Figure 74 - Connection error

To fix this you need to press Return and check the communication

interface and connection settings.

You can get proper settings by connecting to the device using PAS

software.

4.3 No MAIN module

“No MAIN module” error appears during building project before

uploading configuration to the device (when you use function “Send

configuration to the device”).

51

In this case you should rename one of the function blocks that are in

the device project or add new function block and set name “MAIN” to it.

4.4 Unconnected inputs

If you get a message like in the figure below, you should check your

FBD for unconnected pins (they are marked as red circles).

Figure 75 – Unconnected inputs error

Figure 76 - Unconnected input

Loading...

Loading...