SAS Opti-Fit 9800-25,Opti-Fit 9800-35,Opti-Fit 9800-45 Operation Manual

OPERATION MANUAL

DISTRIBUTED BY:

Pro Wood Finishes

14622 Southlawn Lane

Rockville MD 20850

Ph: (301) 424-3033

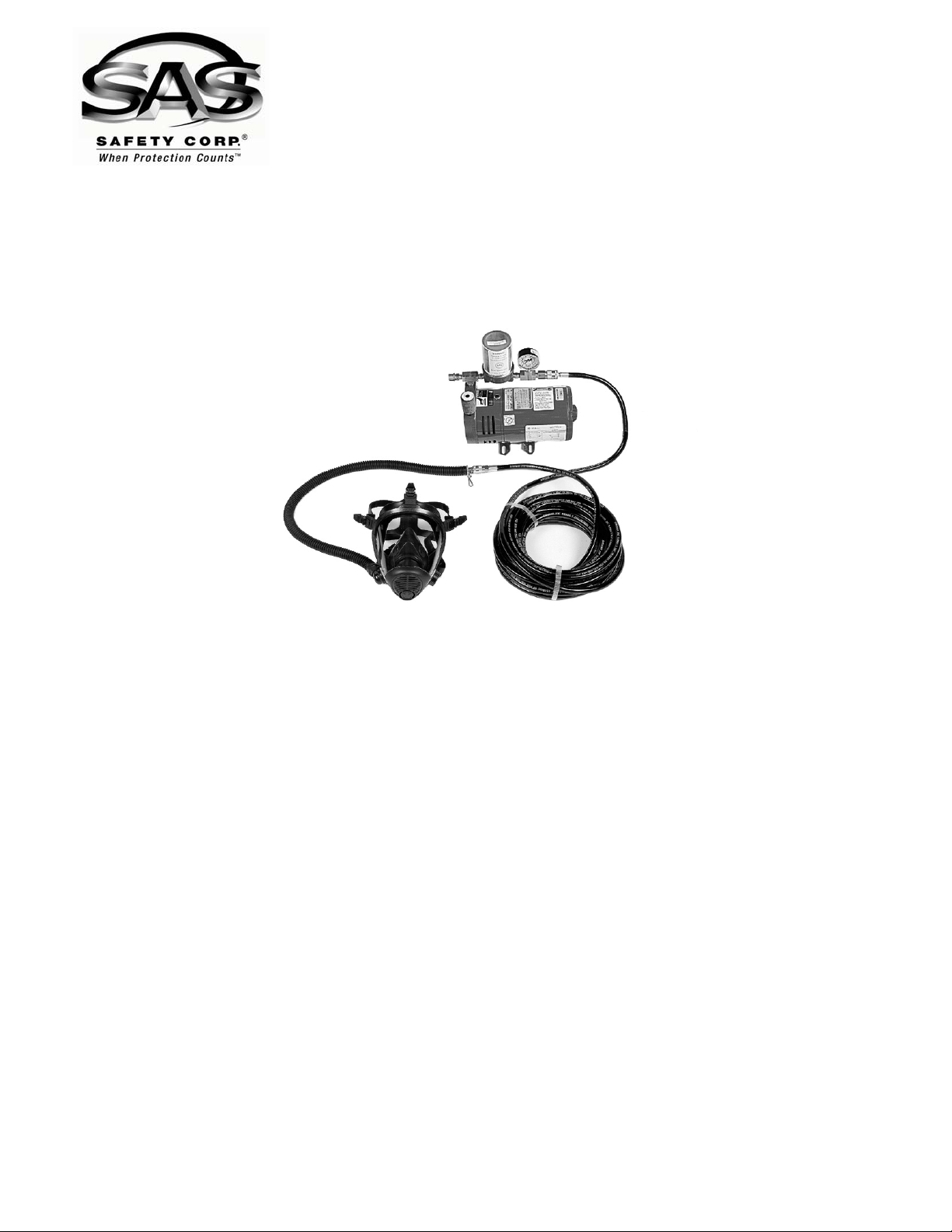

OPTI-FIT

SUPPLIED AIR SYSTEMS

9800-35

ONE-MAN FULLFACE SYSTEM - 1/4 HP

9800-25

TWO-MAN FULLFACE SYSTEM - 3/4 HP

9800-45

FOUR-MAN FULLFACE SYSTEM - 1 1/2 HP

READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE USING THESE PRODUCTS.

WORKERS WHO HAVE BECOME SENSITIZED TO ISOCYANATES SHOULD NOT WORK

WITH OR AROUND ISOCYANATES.

3031 GARDENIA AVE • LONG BEACH, CA 90807 • (800) 262-0200 • FAX (800) 244-1938

www.sassafety.com

CUSTOMER ACCEPTANCE

AND WARRANTY POLICY

I, the undersigned purchaser (may be signed by either owner or shop manager) of an SAS Safety

Corp Supplied-Air System or pump, agree that I have thoroughly read and understand the

Instruction Manual for the safe operation of the air-supply system. By signing and returning this

acceptance form, I acknowledge that I did not try and operate the system before studying the

manual, and further agree to continue to follow the recommended guidelines for safe operation per

OSHA 29CFR 1910.134. I also know that I can telephone SAS at any time, with any questions

concerning the Safe operation of the air supply system. I further agree that there will be no

warranty adjustments by SAS until I return this signed acceptance to them at:

3031 Gardenia Avenue, Long Beach CA 90807 (800) 262-0200 FAX (800) 244-1938.

________________________________________________________________________________

NAME and TITLE

________________________________________________________________________________

ACCOUNT NAME

________________________________________________________________________________

ADDRESS

________________________________________________________________________________

CITY STATE ZIP CODE

______________________________

TELEPHONE

_________________ _________________ ___________________

GAST MODEL # SAS SERIAL # DATE CODE

________________________________________________________________________________

SUPPLIER or SALESMAN

________________________________________________________________________________

DATE OF DELIVERY AND INVOICE #

________________________________________________________________________________

RECEIVED BY SAS

MUST BE RETURNED TO SAS SAFETY CORP. TO INITIATE WARRANTY!

SUPPLIED-AIR RESPIRATOR

WARNING

• This respirator system reduces, but does not eliminate, exposure and inhalation of contaminants, it DOES NOT provide complete protection.

• If you are sensitized to paint, paint hardeners, isocyanates, epoxy, metal cutting fluid, latex, or

any other material, this respirator system WILL NOT protect you.

• If you have ever had breathing problems while or after using or being around paint or pain

hardeners, isocyanates, epoxy, metal cutting fluids, latex, or any other material. DO NOT

USE this respirator system. It WILL NOT protect you.

• Failure to read, understand, and follow ALL warnings and instructions provided here, in the

respirator user’s manual, and with the materials you are using (paint, epoxy, pesticides, etc.)

may cause INJURY, DISEASE, or DEATH.

• If you do not understand the instructions, and warning DO NOT USE this respirator system.

• If these instructions and warning indicate that you should not use this respirator system or that

it will not protect you. DO NO USE IT, even if conflicting instructions from somewhere else

(your boss or a paint store, for example) indicate you can.

• YOU assume responsibility for any damage, injury, disease, or death caused by YOUR failure

to follow instructions an d heed warnings.

3031 Gardenia Avenue ● Long Beach, CA 90807 ● (800) 262-0200 ● FAX (800) 244-1938

www.sassafety.com

INDEX

Page #

1 GENERAL SAFETY INSTRUCTION DO'S & DON'T

2 GENERAL DESCRIPTION

3 ASSEMBLY INSTRUCTIONS, OIL-LESS AIR PUMP

4 OPERATING INSTRUCTIONS, OIL-LESS AIR PUMP

5 PARTS DESCRIPTION, 9805-00

6 PARTS DESCRIPTION, 9810-00 & 9820-00

7 PARTS DESCRIPTION, 9840-00

8-9 MAINTENANCE, OIL-LESS AIR PUMP

10 TROUBLE SHOOTING

11 CONTROL OF AIR QUALITY

12 PARTS DESCRIPTION, 9814-05 FULLFACE

13-16 USER INSTRUCTIONS, SAR RESPIRATORS

16 SPECTACLE KIT, INSTALLATION INSTRUCTIONS

17-38 OSHA CODE OF FEDERAL REGULATIONS

39 RESPIRATORY PROTECTION PROGRAM

40 OPTI-FIT FULLFACE WARRANTY AND LIMITATION OF LIABILITY

41 GAST OIL-LESS AIR PUMP WARRANTY

IMPORTANT

GENERAL SAFETY INSTRUCTIONS

DO NOT use Supplied-Air System in any atmosphere immediately Dangerous to Life or Health

(IDLH) and/or from which the worker cannot escape without the use of a respirator.

OSHA 29CFR 1910.134.

DO NOT place oil-less air pump in an area that cannot guarantee clean, breathable air,

grade D per OSHA 29CFR 1910.134.

DO NOT place air pump where air intake could be contaminated by spray booth exhaust, other

spraying operations (i.e. primer application, etc.), mixing operations, auto exhausts,

etc.

DO NOT place oil-less air pump inside spray booth or in the same area in which you are

spraying.

DO NOT use 9805-00 (1/4 & 1/3hp) or 9810-00 (1/2hp) oil-less air pump for 2-man application.

DO NOT run oil-less air pump without breathing air-line and mask attached. This will cause

pump to over heat and shut off.

DO NOT use 9805-00 (1/4 & 1/3hp) oil-less pump for hood-type respirator.

DO NOT use ungrounded electrical receptacles.

DO NOT use ANY electrical extension cords.

DO NOT close off pressure relief value completely. This will cause pump to over heat and

shut off.

DO before start-up, unscrew aluminum cup on exhaust filter assembly and check that

exhaust filter in firmly seated in place. Replace aluminum cup and tighten firmly.

DO before start-up check intake filter to be sure it is secured to pump housing.

DO change intake filter and exhaust filer every 90 to 100 running hours or if pressure

drops below recommendations.

DO place air inlet pump in a clean air environment where breathable air can be assured

at all times.

DO check pressure gauge for a minimum 4.0 PSI while air is flowing into supplied-air

respirator. Pressure relief valve is factory set to deliver more than the minimum

OSHA required 4.0 CFM.

DO use grounded electrical connections.

1

GENERAL DESCRIPTION

SAS SUPPLIED AIR RESPIRATOR SYSTEMS

9800-35 ONE-MAN FULLFACE SYSTEM 1/4 HP

9814-05 Opti-Fit Full face Supplied Air Respirator - Medium

9852-42 Breathing Air Line Hose 50 ft.

9850-31 Nylon-Web Belt

7600-95 Peel-Off Lens Cover (1 Single)

9805-00 1/4 & 1/3 hp Oil-Less Carbon Vane Air Pump

9800-25 TWO-MAN FULLFACE SYSTEM 3/4 HP

9814-05 Opti-Fit Full face Supplied Air Respirator - Medium (Qty 2)

9852-42 Breathing Air Line Hose 50 ft. (Qty 2)

9850-31 Nylon-Web Belt (Qty 2)

7600-95 Peel-Off Lens Cover (2 Singles)

9810-00 3/4hp Oil-Less Carbon Vane Air Pump

9800-45 FOUR-MAN FULLFACE SYSTEM 1 1/2 HP

9814-05 Opti-Fit Full face Supplied Air Respirator - Medium (Qty 4)

9852-42 Breathing Air Line Hose 50 ft. (Qty 4)

9850-31 Nylon-Web Belt (Qty 4)

7600-95 Peel-Off Lens Cover (4 Singles)

Supplied Air Respirator - SAR

Optimum fit, comfort and superior optics in a full face respirator. Comfortable, durable silicone skirt

and five-strap suspension. The Opti-Fit™ features a distortion-free lens with exceptional view. The lens

is replaceable and treated with an anti-scratch coating. A nose cup is a standard feature to prevent

fogging. Lightweight construction reduces head and neck stress even during extended wear. Peel-Off

Lens covers available both in Clear and Tinted.

Oil-Less Carbon Vane Air Pump

The oil-less air pump produces completely oil-free air and does not generate carbon monoxide, oil

vapor or oil mists. The 115V pump comes with intake and exhaust filters, pressure-relief valve, pressure

gauge and airline couplings. CAUTION: PUMP MUST BE PLACE IN A "CLEAN-AIR" ENVIRONMENT

WHERE BREATHABLE AIR CAN BE ASSURED AT ALL TIMES! If "clean air" intake cannot be

guaranteed, a remote air intake may be used to assure safe breathable air for the user. Pump must not

be operated in potentially explosive atmosphere.

Respiratory Protection Program

OSHA requires a Respiratory Protection Program be implemented. The SAS Instruction Manual

outlines compliance requirements for employer and user.

NOT TO BE USED IN ATMOSPHERES IMMEDIATELY DANGEROUS TO LIFE OR HEALTH!

All products listed comply with the standards of the Occupational Safety and health Administration

(OSHA), assuming that the materials are used as designed and engineered in accordance with

instructions.

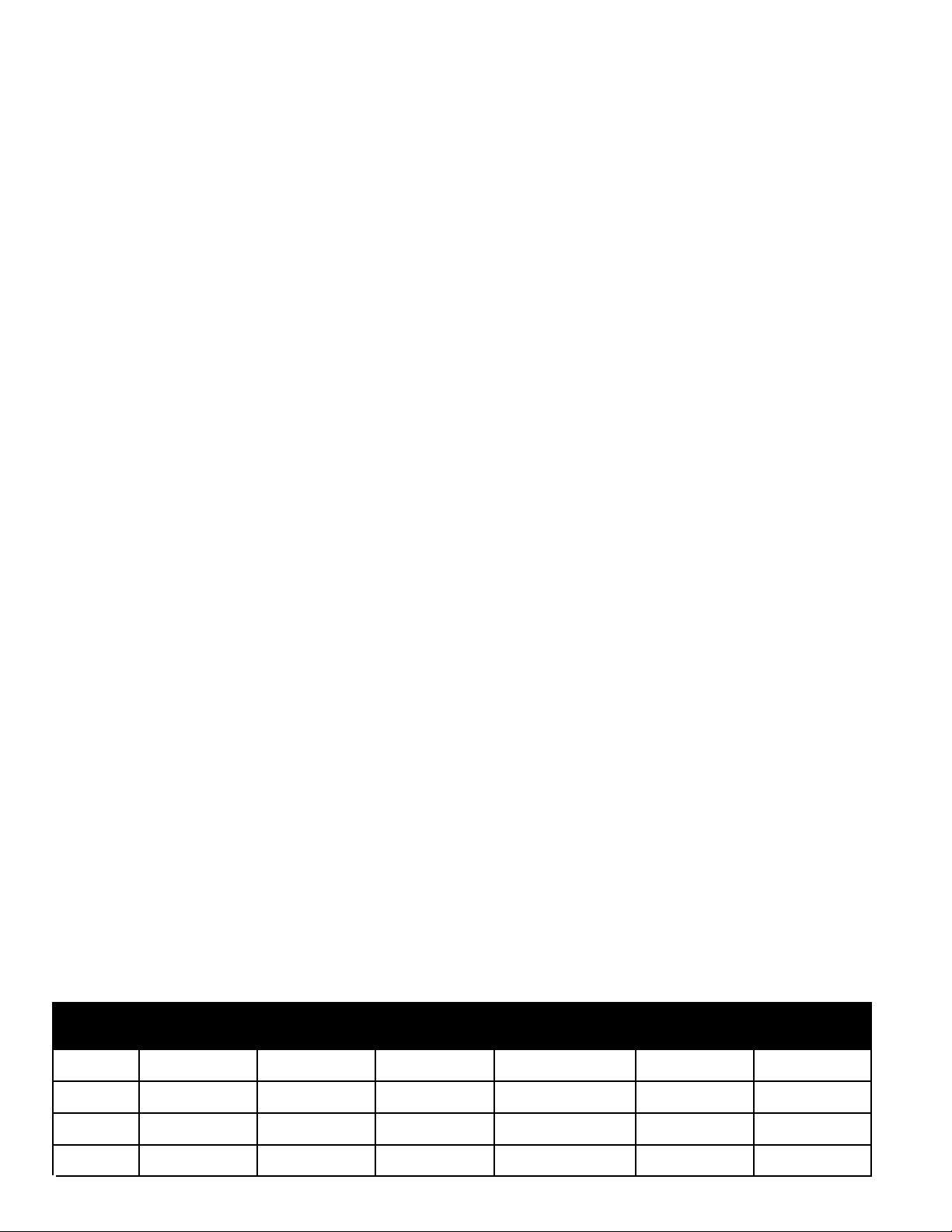

9840-00 1 1/2 hp Oil-Less Carbon Vane Air Pump

Item No. HP Max No. of

Respirators

9805-00 1/4 & 1/3 1 0 9A / 115V 0 to 10 0 to 4.5

9810-00 1/2 1 1 10.8A / 115V 0 to 10 0 to 8

9820-00 3/4 2 1 10.8A / 115/230V 0 to 10 0 to 10

9840-00 1 1/2 4 3 30A / 115/230V 0 to 10 0 to 22

Max No. of

Hoods

Amps / Volts PSI CFM

2

OIL-LESS AIR PUMP

ASSEMBLY INSTRUCTIONS

9805-00 OIL-LESS AIR PUMP

PUMP IS COMPLETELY ASSEMBLED AT FACTORY

-- RUBBER FEET (P/N 9700-06) AND HANDLE (P/N 9700-05) MAY BE

ORDERED IF DESIRED.

9810-00 AND 9820-00 OIL-LESS AIR PUMP

-- INSTALL HANDLE TOWARD PUMP FRONT END WITH HANDLE

FLANGES ONTO OF MOTOR BASE. USE RUBBER FEET

INSTALLATION FOR HANDLE SUPPORT

-- INSTALL REMAINING RUBBER FEET WITH NUTS AND BOLTS

PROVIDED.

PARTIAL PUMP ASSEMBLY HAS BEEN COMPLETED AT FACTORY:

-- SCREW INLET FILTER ASSEMBLY INTO INLET PORT (MARKED "IN").

IF INLET HOSE KITS ARE TO BE USED FOR REMOTE LOCATION OF

INLET AIR

-- INSTALL EXHAUST FILTER HOUSING ASSEMBLY WITH PRESSURE

GAUGE AND HOSE COUPLING (PRE-ASSEMBLED AT FACTORY) TO

OUTLET "TEE" EXHAUST PORT.

9840-00 OIL-LESS AIR PUMP

PARTIAL PUMP ASSEMBLY HAS BEEN COMPLETED AT FACTORY:

-- SCREW INLET FILTER ASSEMBLY INTO INLET PORT (MARKED "IN").

IF INLET HOSE KITS ARE TO BE USED FOR REMOTE LOCATION OF

INLET AIR

-- INSTALL EXHAUST FILTER HOUSING ASSEMBLY WITH PRESSURE

GAUGE AND HOSE COUPLING (PRE-ASSEMBLED AT FACTORY) TO

OUTLET "TEE" EXHAUST PORT.

3

OIL-LESS AIR PUMP

OPERATING INSTRUCTIONS

MODEL # 9805-00, 9810-00, 9820-00 & 9840-00

-- FOR RESPIRATOR AND AIR-LINE ASSEMBLIES,

PRESSURE RELIEF VALVE IS FACTORY SET AT MINIMUM 4.0 PSI

FOR USE WITH 50 TO 100 FOOT AIR-SUPPLY LINE. DO NOT

CLOSE OFF PRESSURE RELIEF WHERE NO AIR CAN ESCAPE.

IMPORTANT -- FOR RESPIRATOR SYSTEMS OTHER THAN SAS SAFETY CORP.

-- FOR RESPIRATOR AIR-LINE SYSTEMS OTHER THAN SAS. ADJUST

PRESSURE RELIEF VALVE IF NECESSARY.

-- USE PRESSURE RELIEF VALVE AS A ADJUSTMENT DEVICE.

DELIBERATELY "BLEED OFF" AIR TO ACHIEVE DESIRED GAUGE

READING.

-- GAUGE READING SHOULD CONFORM TO MSHA/NIOSH APPROVED

MINIMUMS FOR EACH SPECIFIC RESPIRATOR MODE MANUFACTURER'S

OWNER'S MANUALS OR INSTRUCTIONS WILL SPECIFY THESE

PRESSURE RANGES.

-- COUPLING MAY NEED TO BE REPLACED ON PUMP IF AIR-LINE

CONNECTION IS OTHER THAN SAS SAFETY CORP. THIS DOES NOT

VIOLATE NIOSH APPROVAL (DO NOT CHANGE FITTINGS ON HOSE

AS THIS COULD NULLIFY RESPIRATOR NIOSH APPROVAL)

4

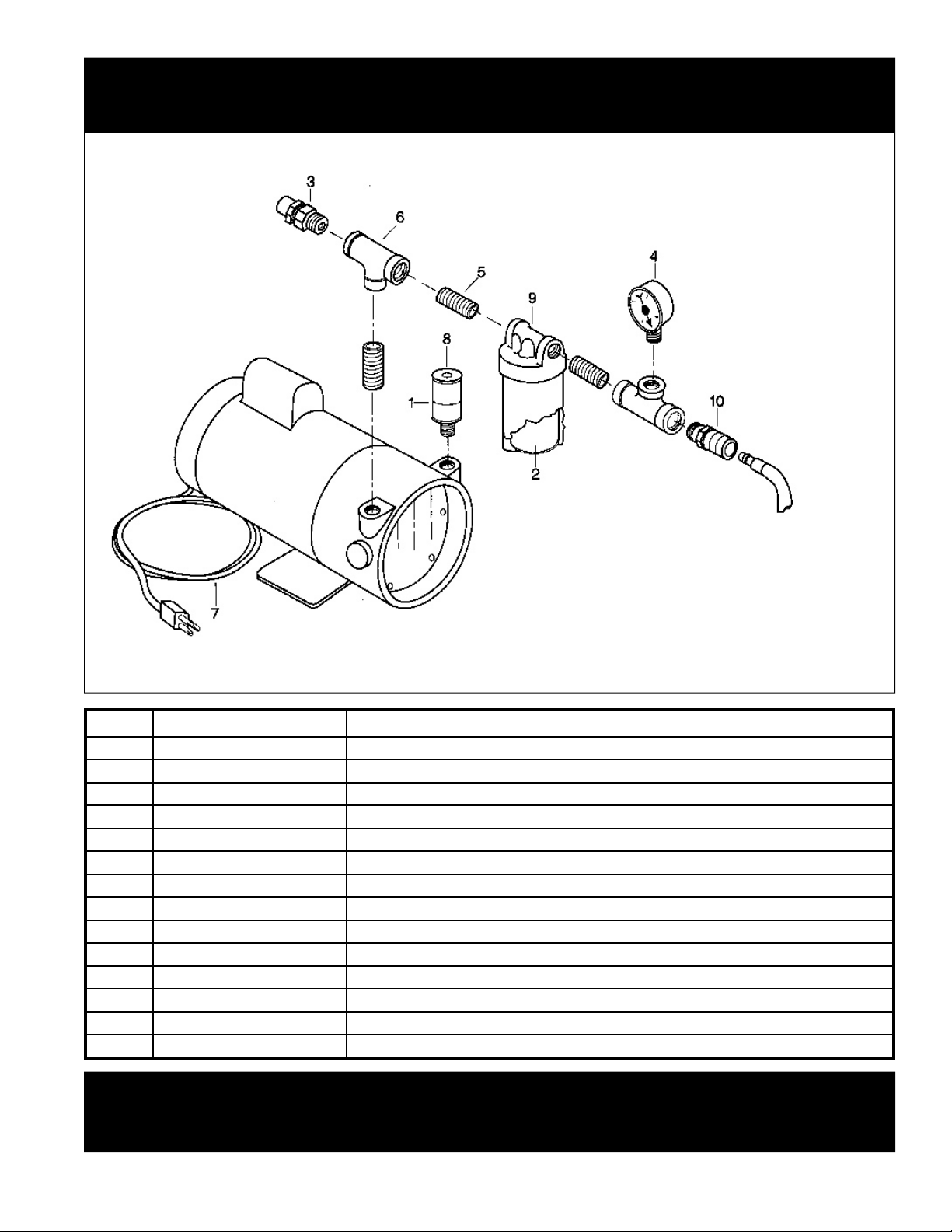

1/4 & 1/3 HP OIL-LESS AIR PUMP

MOTOR – OPEN TYPE (NOT EXPLOSIVE PROOF)

- 115V, SINGLE PHASE, 60HZ

ITEM PART NUMBER DESCRIPTION

1 9700-14 INTAKE FILTER ELEMENT

2 9700-02 EXHAUST FILTER ELEMENT

3 9700-19 PRESSURE RELIEF VALVE

4 9700-04 PRESSURE GAUGE

5 0200-002 1/4’ HEX NIPPLE

6 0200-021 1/4’ BRASS “T”

7 9700-07 ELECTRIC CORD, W/GROUND PLUG

8 9700-21 INTAKE FILTER ASSEMBLY

9 9700-22 EXHAUST FILTER ASSEMBLY

10 9700-10 1/4” NPT MALE COUPLER

9700-11 PUMP CLEANING SOLUTION (Not Shown)

9700-25 INLET HOSE KIT – 25 ft. (Not Shown)

9700-30 INLET HOSE KIT – 25 ft. (Not Shown)

9700-40 SERVICE KIT – VANES, FILTER & PUMP CLEANER (Not Shown)

Warning: Exhaust filter DOES NOT REMOVE dangerous organic vapors or gases. DO NOT USE this equipment if organic

vapors or gases are present. If this air pump is to be used as a breathing air source, the air inlet MUST be located

in a CLEAN AIR area where breathable air can be assured at all times

5

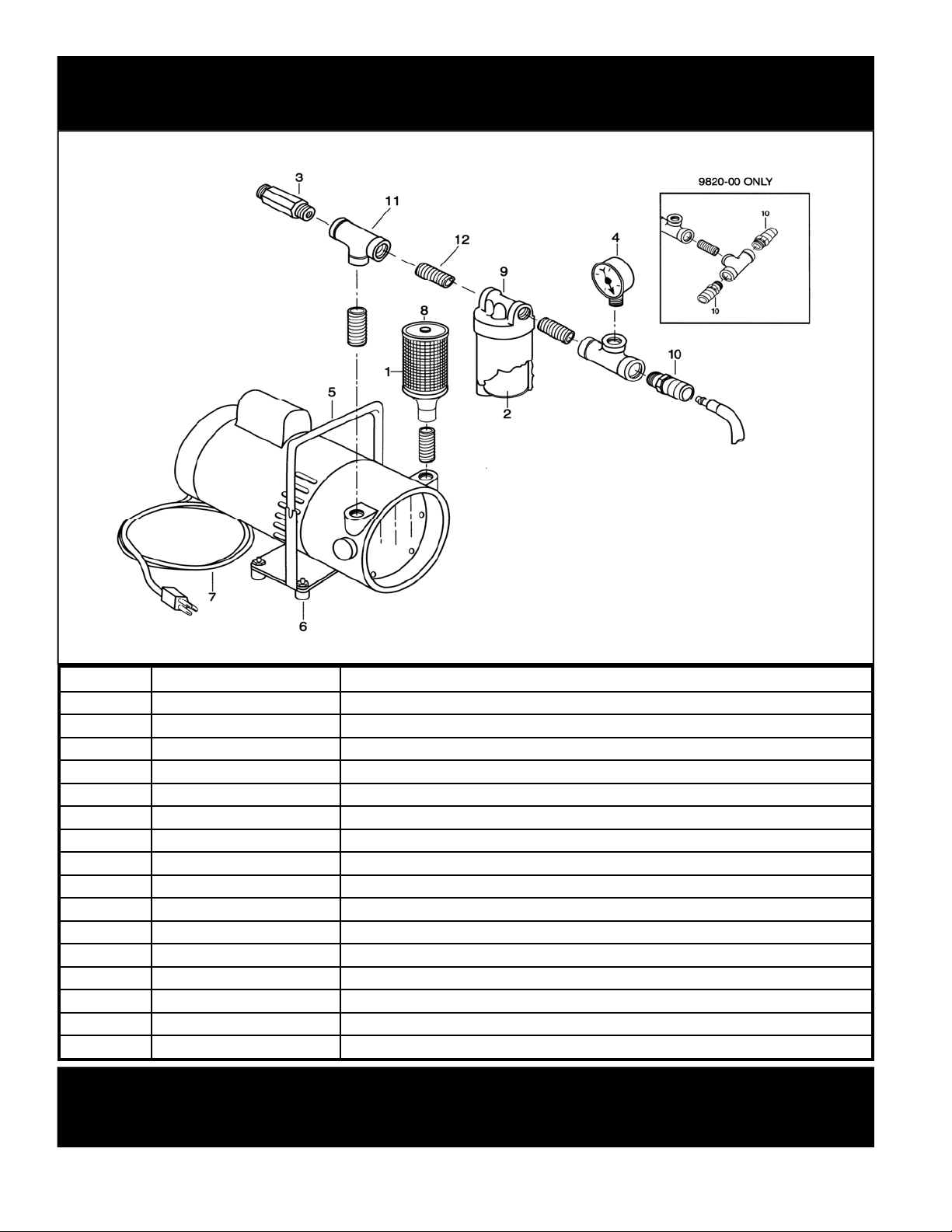

1/2 & 3/4 HP OIL-LESS AIR PUMP

MOTOR – OPEN TYPE (NOT EXPLOSIVE PROOF)

- 115V, SINGLE PHASE, 60HZ

ITEM PART NUMBER DESCRIPTION

1 9700-01 INTAKE FILTER ELEMENT

2 9700-02 EXHAUST FILTER ELEMENT

3 9700-03 PRESSURE RELIEF VALVE

4 9700-04 PRESSURE GAUGE

5 9700-05 CARRYING HANDLE

6 9700-06 4 RUBBER FEET, W/NUTS & BOLTS

7 9700-07 ELECTRIC CORD, W/GROUND PLUG

8 9700-08 INTAKE FILTER ASSEMBLY

9 9700-09 EXHAUST FILTER ASSEMBLY

10 9700-10 1/4” NPT MALE COUPLER

0200-022 3/8”’ BRASS “T”

0200-03 3/8”’ HEX NIPPLE

9700-11 PUMP CLEANING SOLUTION (Not Shown)

9700-25 INLET HOSE KIT – 25 ft. (Not Shown)

9700-30 INLET HOSE KIT – 25 ft. (Not Shown)

9700-50 SERVICE KIT – VANES, FILTER & PUMP CLEANER (Not Shown)

Warning: Exhaust filter DOES NOT REMOVE dangerous organic vapors or gases. DO NOT USE this equipment if organic

vapors or gases are present. If this air pump is to be used as a breathing air source, the air inlet MUST be located

in a CLEAN AIR area where breathable air can be assured at all times.

6

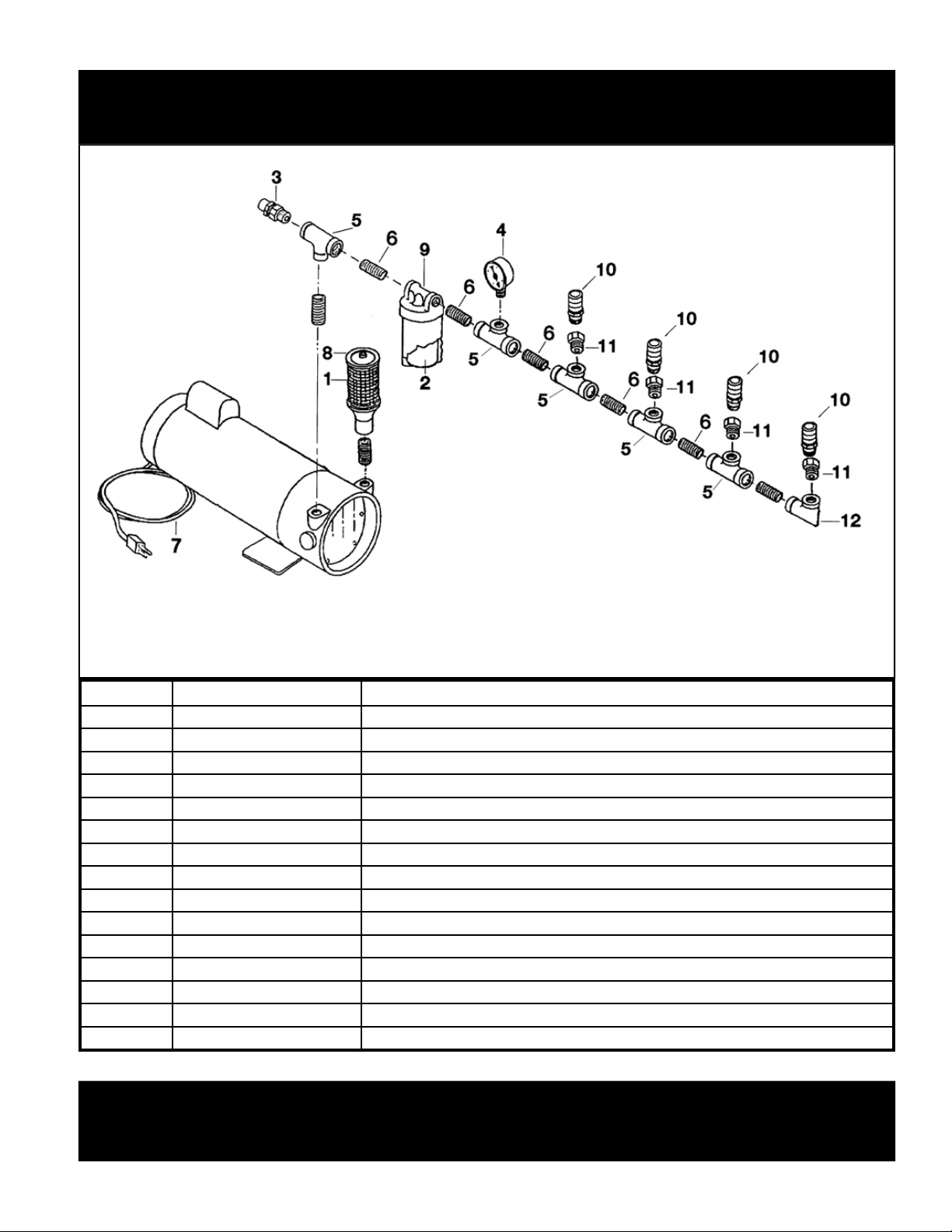

1 1/2 OIL-LESS AIR PUMP

MOTOR – OPEN TYPE (NOT EXPLOSIVE PROOF)

- 115V, SINGLE PHASE, 60HZ

ITEM PART NUMBER DESCRIPTION

1 9700-01 INTAKE FILTER ELEMENT

2 9700-02 EXHAUST FILTER ELEMENT

3 9700-03 PRESSURE RELIEF VALVE

4 9700-04 PRESSURE GAUGE

5 9700-05 3/4”’ BRASS “T”

6 9700-06 3/4”’ HEX NIPPLE

7 9700-07 ELECTRIC CORD, W/GROUND PLUG

8 9700-08 INTAKE FILTER ASSEMBLY

9 9700-09 EXHAUST FILTER ASSEMBLY

10 9700-10 1/4” NPT MALE COUPLER

11 0200-054 3/4” TO 1/4” REDUCER

12 0200-074 3/4” BRASS ELBOW

9700-11 PUMP CLEANING SOLUTION (Not Shown)

9840-25 INLET HOSE KIT – 25 ft. (Not Shown)

9840-30 INLET HOSE KIT – 25 ft. (Not Shown)

Warning: Exhaust filter DOES NOT REMOVE dangerous organic vapors or gases. DO NOT USE this equipment if organic

vapors or gases are present. If this air pump is to be used as a breathing air source, the air inlet MUST be located

in a CLEAN AIR area where breathable air can be assured at all times.

7

HOW TO GET TOP PERFORMANCE AND

LONG LIFE FROM SAS PUMPS

GENERAL INFORMATION:

This pump is only to be used for the purpose of pumping air and under NO circumstances be

used with any other gases. The pump must not be used for the pumping of fluids, particles,

solids or any substance mixed with air, particularly combustible substances likely to cause

explosions. Your rotary pump is a precision product with a clearance of Top . 0015” End .0015”

for model 0523 (1/4 HP & 1/3HP) and Top .003” End .002” for models 0823 and 1023 (1/2HP

and 3/4HP). Foreign particles or excessive dirt and/or dust could cause eventual “jamming” of

the pump. The unit is built of steel and cast iron and is designed for pumping dry air.

Consequently, any moisture (especially when pump stands idle) will tend to corrode interior. The

Carbon Vanes life is between 5,000 - 15,000 hours depending upon application.

NEVER lubricate this oil-less rotary vane pump. The sealed bearing are grease-packed. The

service life of the carbon vanes will be reduced by petroleum or hydrocarbon products. Precision

ground vanes take up their own wear and will last thousands of hours depending upon speed

and degree of pressure. Excessive dirt, foreign particles, or moisture could cause the vanes to

stick in the rotor slots and even break.. Periodic “Flushing” could prevent this see page 10.

PRODUCT USE CRITERIA:

Pump only clean, dry air and operate at 32°F - 104°F (0° C - 40°C). Protect unit from dirt and

moisture. Do not pump flamable or explsive gases or use in an atmosphere that contains such

gases.

INSTALLATION:

WARNING ELECTRICAL SHOCK HAZARD:

Disconnect electrical power at the circuit breaker or fuse box before installing this product. Install

this product where it will not come into contact with water or other liquids. Install this product

where it will be weather protected. Electrically ground this product. Failure to follow these

instructions can result in death, fire or electrical shock.

CAUTION: Blocking air flow around the product in any way can cause the product to over heat

and shut off.

MOUNTING:

This product may be installed in any orientation. Mounting the product to a stable, rigid operating

surface and using shock mounts will reduce noise and vibration.

INSPECTION:

Regular inspection, cleaning filters, and "flushing" (see page 10) may prevent extensive repairs.

Dirty or clogged intake filter felt can be responsible for failure of the pump to build up pressure

and eventual pump overheating. Replace exhaust filter element every 90 to 100 running hours.

Do not be alarmed if temperature of exhaust air reaches 225°F when running continuously. If

there is evidence of overheating or excessive noise, stop immediately for repairs. Keep external

surfaces clean for proper heat dissipation. Most failures to build up pressure are due to leaks in

connecting lines, damaged filter jar threads, collapsed air lines, dirty filtering elements or sluggish

vanes in the pump. The latter is generally caused from the pump being operated above its

recommended duty and getting too hot.

8

START UP:

If the motor fails to start or slows down significantly under load, shut off and disconnect from

power supply. Check that the voltage is correct for motor and the motor is turning in the proper

direction. Vane life will be drastically reduced if motor is not operating properly. Vanes can

break or be damaged it motor/pump runs in the wrong direction. Motors are equipped with

thermal protector that turns current of automatically when to mechanical or electrical overloads.

Also check the wiring instructions on motor case or on thermal plate cover.

LUBRICATION:

CAUTION: NEVER LUBRICATE DRY "OIL-LESS" AIR PUMPS. The carbon vanes and

grease packed bearing s require NO oil.

FLUSHING:

Flushing this product to remove excessive dirt, foreign particles, moisture or oil that occurs in the

operating environment will help to maintain proper vane performance. Most pump troubles can

be corrected by flushing solvent rather than by taking apart. A noisy or inefficient pump is

frequently nothing more serious than vanes stuck in a rotor slot due to foreign material (dust)

and / or dirty filters.

CAUTION -- Recommended commercial solvents for SAS pumps are Loctite Safety Solvent,

Inhibisol Safety Solvent, and Dow Chemical Chlorothane. In the event one of the above are not

available, use any NON-FLAMMABLE, NON-TOXIC, NON-PETROLEUM BASE, INDUSTRIAL

CLEANING SOLVENT. (SAS PUMP FLUSHING LIQUID --- P/N 9700-11).

FLUSHING PROCEDURES:

Remove Intake Filter Assembly and Exhaust Port Assembly. Flushing should be done while the

unit is running and in a well ventilated area. Then while wearing proper protection have a clean

cloth over the exhaust port marked "OUT". Spray or pour a small amount of flushing solution in

the intake port marked "IN". Continue flushing until solution coming out exhaust port appears to

be clear. After all solvent has passed through the pump continue to let the pump run while

unseen solution can dissipate into the air, then re-attach the Intake Filter Assembly to the port

marked “IN” and Exhaust Port Assembly to the port marked “OUT”. Frequent flushing is

recommended to help maintain proper vane performance.

FILTER ELEMENTS:

Replace Intake and Exhaust Filter every 90 to 100 running hours.

DISASSEMBLY:

If foreign matter has entered pump, try flushing. If this does not eliminate the foreign matter,

unplug pump, remove only the dead end plate and the four vanes (DO NOT at any time remove

the rotor). Wash vanes, end plate, and pump chamber with solvent (see above for correct type of

solvents to be used). Dry and reassemble.

DANGER: TO PREVENT EXPLOSIVE HAZARD, DO NOT PUMP COMBUSTIBLE LIQUIDS

OR VAPORS WITH ANY SAS UNIT.

FOR MAXIMUM PUMP LIFE USE MINIMUM PRESSURE NEEDED TO DO THE JOB.

9

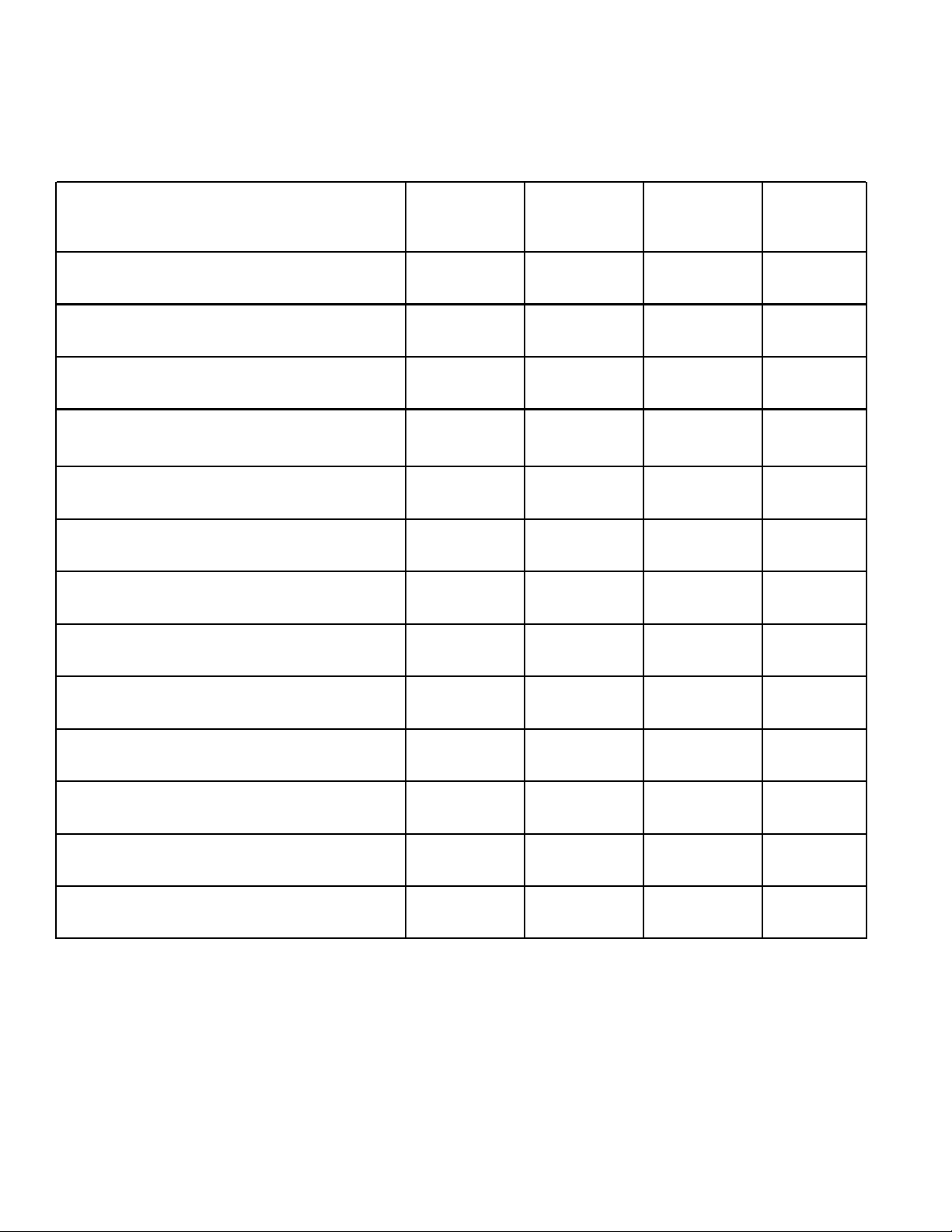

TROUBLE SHOOTING CHART

Reason and remedy for Problem Low

Pressure

Filter(s) dirty

Clean or replace

Relief valve set to high

Inspect and adjust

Relief valve set to low.

Inspect and adjust

Plugged vacuum / pressure line.

Inspect and adjust

Vanes sticking.

Clean or replace

Vanes worn.

Replace

Shaft seal worn.

Replace

Dust or offset powder in pump.

Inspect and clean

X

X

X

X At Pump X X

X

X

X

X X X

High

Pressure

Pump

Overheat

Motor

Overheat

Motor not wired correctly.

Check wiring diagram and line voltage.

Damaged jar thread.

Replace

Damaged jar gasket.

Replace

Plugged pressure line.

Inspect and/or replace

Running to high RPM.

Inspect and adjust

X X X

X X X

X

X At Pump X X

X X X

10

Loading...

Loading...