98647-002-37

Sartorius

YDK 01, YDK 01-0D, YDK 01LP

Density Determination Kit

User’s Manual

2

YDK 01, YDK 01-0D

9

8

7

2

1

3

4

56

3

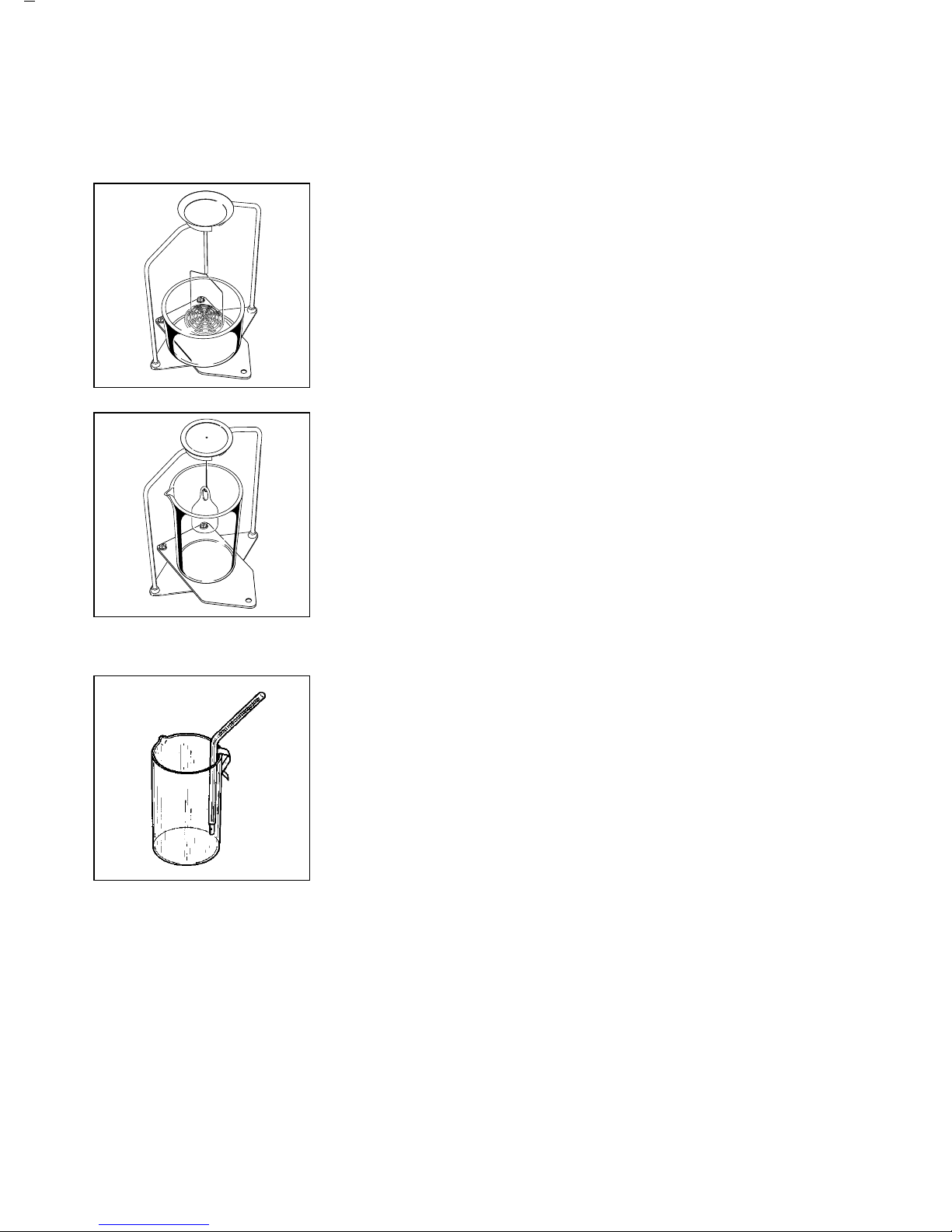

Kit Components

Die Bestandteile

Contenu de la livraison

1 Beakers (76 mm Ø and 55 mm Ø)

Bechergläser

(Ø 76 mm u. Ø 55 mm)

Béchers (Ø 76 mm et Ø 55 mm)

2 Bar frame

Gestell

Structure de suspension

3 Thermometer with retainer clip

Thermometer mit

Befestigungsklemme

Thermomètre avec clip de fixation

4 Glass plummet

Glassenkkörper

Plongeur calibré en verre

5 Sieve for immersing samples

(pan hanger assembly)

Tauchsieb

Panier pour échantillons «flottants»

(ensemble à suspendre)

6 Sample holder

(pan hanger assembly)

Tauchkorb

Panier pour échantillons

(ensemble à suspendre)

7 Metal platform

Brücke

Pont métallique

8 Gasket for ME models

Dichtring für ME-Modelle

Anneau d’étanchéité

pour modèles ME

9 Adapters (3)

Adapter (3 Stück)

Adaptateurs (3)

4

9

10

8

7

2

1

3

4

56

YDK 01LP

5

Kit Components

Die Bestandteile

Contenu de la livraison

1 Beakers (76 mm Ø and 55 mm Ø)

Bechergläser

(Ø 76 mm u. Ø 55 mm)

Béchers (Ø 76 mm et Ø 55 mm)

2 Bar frame

Gestell

Structure de suspension

3 Thermometer with retainer clip

Thermometer mit

Befestigungsklemme

Thermomètre avec clip de fixation

4 Glass plummet

Glassenkkörper

Plongeur calibré en verre

5 Sieve for immersing samples

(pan hanger assembly)

Tauchsieb

Panier pour échantillons «flottants»

(ensemble à suspendre)

6 Sample holder

(pan hanger assembly)

Tauchkorb

Panier pour échantillons

(ensemble à suspendre)

7 Metal platform

Brücke

Pont métallique

8 Adapter for LA/LP models

with an analytical draft shield

Adapter für LA/LP-Waagen

mit Analysenwindschutz

Adaptateur pour modèles LA/LP

avec chambre analytique

9 Adapter for LA/LP models

without an analytical draft shield

Adapter für LA/LP-Waagen

ohne Analysenwindschutz

Adaptateur pour modèles LA/LP

sans chambre analytique

10 Compensating disk

for LA/LP 3200 D models

Ausgleichsscheibe für LA/LP 3200 D

Disque de compensation

pour modèles LA/LP 3200 D

Contents

Page

Kit Components 2

Getting Started 8

Methods for Determining Specific Gravity/Density 13

Sources of Error and Possibilities for Correction 14

Determining the Specific Gravity/Density 17

– of Solids 17

– of Solids with a Density <1g/cm

3

18

– of Liquids 21

Application in Legal Metrology 22

Tables 23

Density Values of H2O23

Density Values of Ethanol 24

Supplement 25

6

With this Sartorius Density Determination Kit

you have acquired a high-quality accessory to your

electronic balance.

This accessory kit will ease your daily work load.

Please read the Installation and Operating Instructions

carefully before setting up your density determination

kit and working with it.

If your balance is equipped with a density

determination program, you can have the rho values

calculated by the program.

In this case, please follow the operating instructions

in “Getting Started.”

Perform density determination as described in the

density determination program.

Important Note:

The YDK 01-0D density determination kit can be

used for determining the density of liquid according

to weights and measures regulations.

7

Getting Started

YDK 01, YDK 01-0D

You can use the density determination kit, YDK 01or

YDK 01-0D, with the following balances:

– ME series balances (Genius series)

– BA balances with a readability ≤ 0.1mg

– BP/LA balances with a readability ≤ 0.1mg

– MC balances with a weighing range of 210 g

and up (Micro series)

– RC balances (Research series)

Preparing the Bar Frame

You must mount the adapter before the bar frame can

be placed on the balance.

Please use the adapter that is appropriate for the

balance you are using.

(approx. dimensions)

8 mm Ø, height 41.3 mm – ME balance

with gasket

7 mm Ø, height 16.5 mm – BA, BP*, MC and

RC balances

12 mm Ø, height 25.5 mm – BP**/LA balances

with a readability

≤ 0.1mg

** = BP 210 D, BP 300 S, BP 210 S, BP 160 P,

BP 110 S

** = BP 211 D, BP 301S, BP 221S, BP 161P,

BP 121S

8

Screw the appropriate adapter into the underside

of the bar frame base.

Now remove the following components from

the balance:

– weighing pan

– compensating ring for BA and BP balances

– pan support for BA and BP balances

Place the frame in the weighing chamber. The

wedge-shaped opening at the top of the frame must

face the direction from which the sample holder

(sieve/glass plummet) will be placed into the frame.

Always use the metal platform to hold a beaker.

Please position this platform through the frame so it

rests evenly on the base of the weighing chamber.

If you are using an BA, BP or ME balance, turn the

platform so it rests on the pins which are far apart. For

RC and MC balances, the platform should rest

on the pins which are closer together.

9

YDK 01LP

You can use the YDK 01 LP density determination kit

with LA/LP balances with a readability of 1mg.

Installing the Density Determination Kit

● Remove the draft shield cover, glass plate,

weighing pan and base from the balance

LA/LP Balances, Except Model LA/LP3200D

● Place the components on the balance

in the following order:

– Compensating ring

– Bar frame

k The wedge-shaped opening at the top of the bar

frame should face the direction from which

the sample holder (pan hanger assembly/glass

plummet) will be placed on the balance

LA3200D, LP3200D Balances

● Place the components on the balance

in the following order:

– Short adapter

– Compensating disk

– Bar frame

k The wedge-shaped opening at the top of the bar

frame should face the direction from which

the sample holder (pan hanger assembly/glass

plummet) will be placed on the balance

LA/LP Balances, Except Model LA/LP3200D

with the YDS01LP Draft Shield

● Place the components on the balance

in the following order:

– Longer adapter

– Bar frame

k The wedge-shaped opening at the top of the bar

frame should face the direction from which

the sample holder (pan hanger assembly/glass

plummet) will be placed on the balance

10

LA3200D, LP3200D Balances with the YDS01LP

Draft Shield

● Place the components on the balance

in the following order:

– Longer adapter

– Compensating ring

– Bar frame

k The wedge-shaped opening at the top of the bar

frame should face the direction from which

the sample holder (pan hanger assembly/glass

plummet) will be placed on the balance

Beaker/Immersion Device

● Use the metal plate to support the beaker.

Place it on the bar frame base and then set both

on the balance.

The choice of the beaker and the immersion device

depends on the sample to be determined (see below).

To determine the specific gravity of solids when

their density is greater than that of the liquid in which

the sample is immersed, use:

– 76 mm Ø beaker and sample holder

11

To determine the specific gravity of solids when

their density is less than that of the liquid in which the

sample is immersed, use:

– 76 mm Ø beaker and sieve for immersing

the sample

To determine the density of liquids:

– 55 mm Ø beaker and glass plummet

Thermometer

If necessary, attach the thermometer to the rim of the

beaker using the retainer clip.

12

Methods for Determining Specific Gravity/Density

The Archimedean principle is applied for determining the specific gravity of a solid

with this measuring device:

A solid immersed in a liquid is exposed to the force of buoyancy. The value of

this force is the same as that of the weight of the liquid displaced by the volume

of the solid.

With a hydrostatic balance which enables you to weigh a solid in air as well as

in water, it is possible to:

determine the specific gravity of a solid if the density of the liquid causing

buoyancy is known:

W (a) · ρ (fl)

ρ =

W (a) – W (fl)

or

determine the density of a liquid if the volume of the immersed solid is known:

G

ρ (fl) =

V

where:

ρ = specific gravity of the solid

ρ (fl) = density of the liquid

W (a) = weight of the solid in air

W (fl) = weight of the solid in liquid

G = buoyancy of the immersed solid

V = volume of the solid

13

Sources of Error and Possibilities for Correction

The formula on the previous page for determining the specific gravity of solids is

sufficient to obtain an accuracy of one to two decimal places.

Depending on the accuracy you require, consider the following error and

allowance factors.

– The density of the liquid causing buoyancy depends on its temperature

– Air buoyancy during weighing in air

– The change in the immersion level of the pan hanger assembly when the sample

is immersed

– Adhesion of the liquid on the suspension wire of the pan hanger assembly

– Air bubbles on the sample

Some of these errors can be corrected by calculation. To do so, it is necessary to

proceed as follows:

– measure the temperature of the reference liquid and correct its density

accordingly

and

– define the inner diameter of the container which holds the reference liquid.

Dependence of the Liquid Density on Temperature

The density of the liquid causing buoyancy depends on the temperature.

The change in the density per °C change in temperature is in the range of

– 0.02% for distilled water

– 0.1% for alcohols and hydrocarbons.

In other words, this can show up in the third decimal place during specific

gravity/density determination.

14

To correct the liquid density for temperature, proceed as follows:

– measure the temperature of the liquid using the thermometer that comes

with the kit

– use the table at the back of this manual to find the density of the most commonly

used liquids, water and ethanol, at the temperature measured, and use this

density for the value ρ (fl).

Air Buoyancy

A volume of 1cm of air has a weight of approximately 1.2 mg, depending on

its temperature, humidity and air pressure. When weighed in air, a solid is

buoyed by a corresponding force per cm3of its volume. The error that results if the

air buoyancy is not allowed for shows up in the third decimal place and should

therefore be corrected.

The following formula allows for air buoyancy:

W (a) · [ρ (fl) – ρ (a)]

ρ =+ ρ (a).

W (a) – W (fl)

Where ρ (a) = 0.0012 g/cm3= Density of air under standard conditions

(temperature 20°C, pressure 101.325 kPa).

Depth of Immersion

The pan for holding and/or immersing the sample during weighing in liquid

is rigidly attached to two wires and is immersed approximately 30 mm below the

surface of the liquid. Since the balance is tared before each measurement, the

additional buoyancy caused by the immersed part of the measuring device is not

allowed for in the specific gravity determination.

When a solid sample is weighed in liquid, a volume of the liquid will be displaced

which corresponds to the volume of the solid sample. This causes the attachment

wires of the pan hanger assembly to be immersed deeper and generate additional

buoyancy which introduces an error in the specific gravity determination.

15

Use the following formula to correct this error:

W (a) · [ρ (fl) – ρ (a)]

ρ =+ ρ (a)

0.99983 [W (a) –W (fl)]

Since the correction factor is determined exclusively by the geometry of the

measuring device setup, be sure to only use the large diameter beaker (76 mm)

from the kit when determining the specific gravity of a solid. The “Supplement”

to this manual shows how this correction factor is derived.

Adhesion of Liquid to the Wire

When the sample holder (or sieve) is immersed in liquid causing buoyancy,

liquid travels up the wire because of adhesion forces and generates an additional

weight in the range of a few milligrams.

Since the sample holder (or sieve) is in the liquid causing buoyancy during both

weighing in air and weighing in liquid, and the balance is tared at the beginning

of each measuring procedure, the effect of the meniscus can be disregarded.

To reduce the surface tension and the friction of liquid on the wire, add three

drops of a tenside (Mirasol Antistatic or an ordinary dishwashing detergent) to the

distilled water in the beaker.

Because of the liquid travelling up the wire, the weight may slowly change even

after the stability symbol “g” appears. Therefore, read off the weight immediately

after the “g” is displayed.

Air Bubbles

The measuring error caused by air bubbles adhering to the sample can be

estimated in the following manner. An air bubble with a diameter of 0.5 mm

causes an additional buoyancy of less than 0.1mg when a sample is weighed in

water. An air bubble diameter of 1mm causes additional buoyancy of 0.5 mg

and an air bubble diameter of 2 mm causes approx. 4.2 mg additional buoyancy.

Larger air bubbles must be removed with a fine brush or other utensil.

You can also wet the sample in a separate container before you weigh it.

16

Determining the Specific Gravity/Density

Determining the Specific Gravity of Solids

Preparation

(Distilled water is used in the description)

– Center the large-diameter beaker (76 mm Ø) on the metal platform

– Fill it so that the distilled water is approximately 5 mm below the rim

– Add three drops of tenside to the distilled water

– Attach the thermometer to the rim of the beaker using the retainer clip

– Clean the sample holder with a solvent (especially the wires that will be

immersed) and hang it from the frame

Measuring Procedure

Determining the Weight of a Sample in Air

– Tare the balance

– Place the sample on the upper pan on the frame and weigh

– Record the weight W (a)

Determining the Buoyancy G = W (a) – W (fl)

– Tare the balance with the sample on the upper pan on the frame

– Place the sample in the sample holder1)

– Record the absolute readout of the buoyancy “G,” which is displayed with

a negative sign

1

) If you remove the pan hanger assembly from the measuring device to do this,

make sure that no additional air bubbles are on it when you re-immerse it; it

is better to place the sample directly on the pan using forceps or a similar utensil.

17

Calculating the Specific Gravity

– Read off the temperature of the liquid

– Using the tables at the back of this manual, find the density ρ (fl) which

corresponds to the temperature measured for the liquid you are using

– Calculate specific gravity using the following formula:

W (a) · [ρ (fl) – 0.0012 g/cm3]

ρ = + 0.0012 g/cm

3

0.99983 G

W (a) and G in g; ρ (fl) in g/cm

3

G = W (a) – W (fl)

Determining the Specific Gravity of Solids with a Density Less Than 1g/cm

3

There are two different methods for determining the specific gravity of solids with

a density less than1g/cm.

Method 1:

For this method, distilled water is still used as the liquid causing buoyancy, but the

pan hanger assembly is replaced by the sieve for immersing samples.

To determine the sample’s buoyancy, float it on the surface of the water and then

immerse it using the sieve.

It is also possible to use forceps or a similar tool to place the sample directly under

the sieve (without removing the sieve from the frame).

If the buoyancy of the substance to be measured is so high that the weight of

the sieve is not enough to immerse the sample, increase the weight of the sieve by

adding an additional weight to the upper pan on the frame.

18

Method 2:

(for this method, use the sample holder)

Here, use a liquid for causing buoyancy with lower density than that of the solid

for which the specific gravity is to be determined. We have had good results with

ethanol (up to a density of approx. 0.8 g/cm3).

The density ρ (fl) of ethanol (with regard to its temperature) can be found in the table

in the supplement.

The negative effect of the liquid’s surface tension on the results is less noticeable

when ethanol is used than when distilled water is employed. Therefore, it is not

necessary to add tensides.

When working with ethanol, you must observe the valid safety precautions.

Use method 2 if the density of the solid varies only slightly from that of distilled

water. Since the sample is suspended in water, measuring errors may occur if the

first method is used.

It also makes sense to use the second method when determining the specific

gravity of a granulated substance, since it would be difficult to get the entire sample

under the sieve as required when performing the first method.

Do not use ethanol if the sample could be attacked or dissolved by it.

Preparation (for Method 1 only)

(Distilled water is used in the description.)

– Center the large-diameter beaker (76 mm Ø) on the metal platform

– Fill it so that the distilled water is approximately 5 mm below the rim

– Add three drops of tenside to the distilled water

– Attach the thermometer to the rim of the beaker using the retainer clip

– Clean the sieve with a solvent (especially the wires that will be immersed) and

hang it from the frame

19

Measuring Procedure (for Method 1 only)

Determining the Weight of the Sample in Air

– Tare the balance

– Place the sample on the frame weighing pan and weigh

– Record the weight W (a)

Determining the Buoyancy G = W (a) – W (fl)

– Tare the balance again (with the sample on the frame weighing pan)

– Place the sample under the sieve or immerse it below the surface of the liquid

using the sieve1)

– Record the buoyancy “G,” which is displayed with a negative sign

Calculating the Specific Gravity

– Read off the temperature of the liquid

– Using the table at the back of this manual, find the density ρ (fl) which

corresponds to the temperature measured for distilled water

– Calculate the specific gravity using the following formula:

W (a) · ρ (fl)

ρ = + 0.0012 g/cm

3

0.99983 G

W (a) and G in g; ρ (fl) in g/cm

3

G = W (a) – W (fl)

1

) If you remove the pan hanger assembly from the measuring device to do this,

make sure that no additional air bubbles are on it when you re-immerse it in the

liquid; it is better to place the sample directly under the pan using forceps, etc.

20

Determining the Density of Liquids

Preparation

– Center the small-diameter beaker (55 mm Ø) on the metal platform

– Attach the thermometer to the rim of the beaker using the retainer clip

Measuring Procedure

– Suspend the disk with the glass plummet (hanging on one wire) from the frame

– Tare the balance

– Fill the beaker with the liquid to be determined so that the liquid is10 mm above

the glass plummet

Determining the Buoyancy G = W (a) – W (fl)

The negative weight displayed by the balance corresponds to the buoyancy acting

on the glass plummet in the liquid.

– Record the buoyancy displayed with a negative sign

– Read off the temperature and record it also

Calculating the Density

– Calculate the density using the following formula:

G

ρ (fl) =

V

G in g; V in cm

3

The glass plummet included in the specific gravity/density determination kit has

a volume of 10 cm3.

It is easy to obtain the current density of the liquid (in g/cm3); you will not need

a calculator. Mentally shift the decimal point in the balance display one place to

the left.

21

Application in Legal Metrology

The density determination kit, YDK 01-0D, may only be used in legal metrology to

determine the density of liquids.

In addition to the bar frame, adapter and metal plate, the following components

provided with the YDK 01-0D will be needed:

– Beaker 55 mm Ø

– Glass plummet Material: AR glass

Volume: 10 cm

3

suspended on a constantan wire

– Verified thermometer: Designed in accordance with EO14.1

Scale of 15–25°C

Readability, 0.1°C

Accuracy, ± 0.1°C

22

Tables

Density of H2O at Temperature T (in °C)

T/°C 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

10. 0.99973 0.99972 0.99971 0.99970 0.99969 0.99968 0.99967 0.99966 0.99965 0.99964

11. 0.99963 0.99962 0.99961 0.99960 0.99959 0.99958 0.99957 0.99956 0.99955 0.99954

12. 0.99953 0.99951 0.99950 0.99949 0.99948 0.99947 0.99946 0.99944 0.99943 0.99942

13. 0.99941 0.99939 0.99938 0.99937 0.99935 0.99934 0.99933 0.99931 0.99930 0.99929

14. 0.99927 0.99926 0.99924 0.99923 0.99922 0.99920 0.99919 0.99917 0.99916 0.99914

15. 0.99913 0.99911 0.99910 0.99908 0.99907 0.99905 0.99904 0.99902 0.99900 0.99899

16. 0.99897 0.99896 0.99894 0.99892 0.99891 0.99889 0.99887 0.99885 0.99884 0.99882

17. 0.99880 0.99879 0.99877 0.99875 0.99873 0.99871 0.99870 0.99868 0.99866 0.99864

18. 0.99862 0.99860 0.99859 0.99857 0.99855 0.99853 0.99851 0.99849 0.99847 0.99845

19. 0.99843 0.99841 0.99839 0.99837 0.99835 0.99833 0.99831 0.99829 0.99827 0.99825

20. 0.99823 0.99821 0.99819 0.99817 0.99815 0.99813 0.99811 0.99808 0.99806 0.99804

21. 0.99802 0.99800 0.99798 0.99795 0.99793 0.99791 0.99789 0.99786 0.99784 0.99782

22. 0.99780 0.99777 0.99775 0.99773 0.99771 0.99768 0.99766 0.99764 0.99761 0.99759

23. 0.99756 0.99754 0.99752 0.99749 0.99747 0.99744 0.99742 0.99740 0.99737 0.99735

24. 0.99732 0.99730 0.99727 0.99725 0.99722 0.99720 0.99717 0.99715 0.99712 0.99710

25. 0.99707 0.99704 0.99702 0.99699 0.99697 0.99694 0.99691 0.99689 0.99686 0.99684

26. 0.99681 0.99678 0.99676 0.99673 0.99670 0.99668 0.99665 0.99662 0.99659 0.99657

27. 0.99654 0.99651 0.99648 0.99646 0.99643 0.99640 0.99637 0.99634 0.99632 0.99629

28. 0.99626 0.99623 0.99620 0.99617 0.99614 0.99612 0.99609 0.99606 0.99603 0.99600

29. 0.99597 0.99594 0.99591 0.99588 0.99585 0.99582 0.99579 0.99576 0.99573 0.99570

30. 0.99567 0.99564 0.99561 0.99558 0.99555 0.99552 0.99549 0.99546 0.99543 0.99540

23

Density of Ethanol at Temperature T (in °C)

T/°C 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

10. 0.79784 0.79775 0.79767 0.79758 0.79750 0.79741 0.79733 0.79725 0.79716 0.79708

11. 0.79699 0.79691 0.79682 0.79674 0.79665 0.79657 0.79648 0.79640 0.79631 0.79623

12. 0.79614 0.79606 0.79598 0.79589 0.79581 0.79572 0.79564 0.79555 0.79547 0.79538

13. 0.79530 0.79521 0.79513 0.79504 0.79496 0.79487 0.79479 0.79470 0.79462 0.79453

14. 0.79445 0.79436 0.79428 0.79419 0.79411 0.79402 0.79394 0.79385 0.79377 0.79368

15. 0.79360 0.79352 0.79343 0.79335 0.79326 0.79318 0.79309 0.79301 0.79292 0.79284

16. 0.79275 0.79267 0.79258 0.79250 0.79241 0.79232 0.79224 0.79215 0.79207 0.79198

17. 0.79190 0.79181 0.79173 0.79164 0.79156 0.79147 0.79139 0.79130 0.79122 0.79113

18. 0.79105 0.79096 0.79088 0.79079 0.79071 0.79062 0.79054 0.79045 0.79037 0.79028

19. 0.79020 0.79011 0.79002 0.78994 0.78985 0.78977 0.78968 0.78960 0.78951 0.78943

20. 0.78934 0.78926 0.78917 0.78909 0.78900 0.78892 0.78883 0.78874 0.78866 0.78857

21. 0.78849 0.78840 0.78832 0.78823 0.78815 0.78806 0.78797 0.78789 0.78780 0.78772

22. 0.78763 0.78755 0.78746 0.78738 0.78729 0.78720 0.78712 0.78703 0.78695 0.78686

23. 0.78678 0.78669 0.78660 0.78652 0.78643 0.78635 0.78626 0.78618 0.78609 0.78600

24. 0.78592 0.78583 0.78575 0.78566 0.78558 0.78549 0.78540 0.78532 0.78523 0.78515

25. 0.78506 0.78497 0.78489 0.78480 0.78472 0.78463 0.78454 0.78446 0.78437 0.78429

26. 0.78420 0.78411 0.78403 0.78394 0.78386 0.78377 0.78368 0.78360 0.78351 0.78343

27. 0.78334 0.78325 0.78317 0.78308 0.78299 0.78291 0.78282 0.78274 0.78265 0.78256

28. 0.78248 0.78239 0.78230 0.78222 0.78213 0.78205 0.78196 0.78187 0.78179 0.78170

29. 0.78161 0.78153 0.78144 0.78136 0.78127 0.78118 0.78110 0.78101 0.78092 0.78084

30. 0.78075 0.78066 0.78058 0.78049 0.78040 0.78032 0.78023 0.78014 0.78006 0.77997

24

Supplement

This supplement should help you to better understand how the formulas and

allowance factors used have been derived.

Fundamental Principles

Mass (g)

Density =

Volume (cm3)

The Archimedean Principle:

A solid immersed in a liquid is exposed to the force of buoyancy (G). This value

is the same as that of the weight of the liquid displaced by the volume of the solid.

The volume of an immersed solid V (s) equals the volume of the displaced

liquid V (fl).

The following are determined:

1. The weight of the sample in air: W (a)

2. The buoyancy of the solid in liquid: G

The specific gravity of a solid is:

sample mass

ρ ===

sample volume

If the density ρ (fl) of the displaced liquid is known, then

Mass (fl)

V (fl) = =

ρ (fl)

Therefore:

W (a) · ρ (fl)

ρ =

G

Calculation

The specific gravity of a solid is calculated from the ratio

ρ : W (a) = ρ (fl) : W (a) – W (fl),

where:

W (a) · ρ (fl)

ρ =

W (a) – W (fl)

W (a) – W (fl) = G = buoyancy of the sample

G

ρ (fl)

W (a)

V (fl)

W (a)

V (s)

25

The density of a liquid is determined from the buoyancy of the plummet, which has

a defined volume

G

ρ (fl) =

V

where:

ρ = specific gravity of a solid

ρ (fl) = density of the liquid

W (a) = weight of the solid in air

W (fl) = weight of the solid in liquid

G = buoyancy of the plummet

V = volume of the solid

Allowance Factors

You must allow for the following when determining the specific gravity of solids:

– the air buoyancy that affects the sample weighed in air

where ρ (a) = 0.0012 g/cm3= density of air under standard conditions

(temperature 20°C, pressure 101.325 kPa);

which results in the following:

W (a) · [ρ (fl) – ρ (a)]

ρ =+ ρ (a)

W (a) – W (fl)

– the immersion of the wires of the sample holder or sieve

When using this specific gravity determination kit, you must multiply the buoyancy

G = [W (a) – W (fl)] by the factor 0.99983 (Corr).

Therefore:

W (a) · [ρ (fl) – ρ (a)]

ρ =+ ρ (a)

[W (a)– W(fl)] · Korr

This factor allows for the buoyancy of the wires which are submerged deeper

when the sample is in the sample holder.

How this allowance factor is derived:

The buoyancy caused by the submerged wires depends on the height “h” by which

the liquid rises when the sample is immersed.

26

Here, the sample volume V (pr) corresponds to the liquid volume V (fl). The sample

volume is determined by measuring the buoyancy. Hence, it is:

V (pr) = V (fl)

or

W (a) – W (fl) π · h · D

2

=

ρ (fl) 4

4 · [W (a) – W (fl)]

Therefore, h =

ρ (fl) · π · D

2

The buoyancy “A” caused by the immersed wires is:

π – d

2

A = 2 · · h · ρ (fl)

4

When “h” is used:

2 · π · d2· 4 · [W (a) – W (fl)] · ρ (fl)

A =

4 · ρ (fl) · π · D

2

d

2

A = 2 · · [W (a) – W (fl)]

D

2

To allow for the buoyancy of the wires, subtract the buoyancy “A” caused by the

immersed wires from the buoyancy determined for the sample: G = W (a) – W (fl).

The corrected buoyancy “A (corr)” to use in this calculation is then: G – “A.”

d

2

A (corr) = [W (a) – W (fl)] – 2 · · [W (a) – W (fl)]

D

2

d

2

A (corr) =[1–2·

]

· [W (a) – W (fl)]

D

2

The specific gravity determination kit uses the large-volume beaker (76 mm Ø)

and an immersing device with 2 wires (0.7 mm diameter) for the determination of

the specific gravity of solids.

When the values d = 0.7 mm and D = 76 mm are plugged in the equation, the

correction factor is:

0.7

2

1 – 2 · = 0.99983

76

2

When using devices with other dimensions, the correction factor must

be recalculated.

27

Sartorius AG

b 37070 Goettingen, Germany

p Weender Landstrasse 94–108, 37075 Goettingen, Germany

t (+49/551) 308-0, f (+49/551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Goettingen, Germany.

All rights reserved. No part of this publication

may be reprinted or translated in any form or by any means

without the prior written permission of Sartorius AG.

The status of the information, specifications and

illustrations in this manual is indicated by the date

given below. Sartorius AG reserves the right to

make changes to the technology, features,

specifications and design of the equipment

without notice.

Status: June 2001, Sartorius AG, Goettingen, Germany

Printed in Germany on paper that has been bleached without any use of chlorine · W399-A00.YDK01LP_ME · KT

Publication No.: WYD6093-t01062

Loading...

Loading...